Thread dismounting device applicable to oil pressure vibration reducer

A technology for hydraulic shock absorbers and dismantling devices, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as the inability to meet batch inspections of hydraulic shock absorbers, heavy maintenance tasks, and high work intensity. Achieve the effect of convenient disassembly, improving work quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

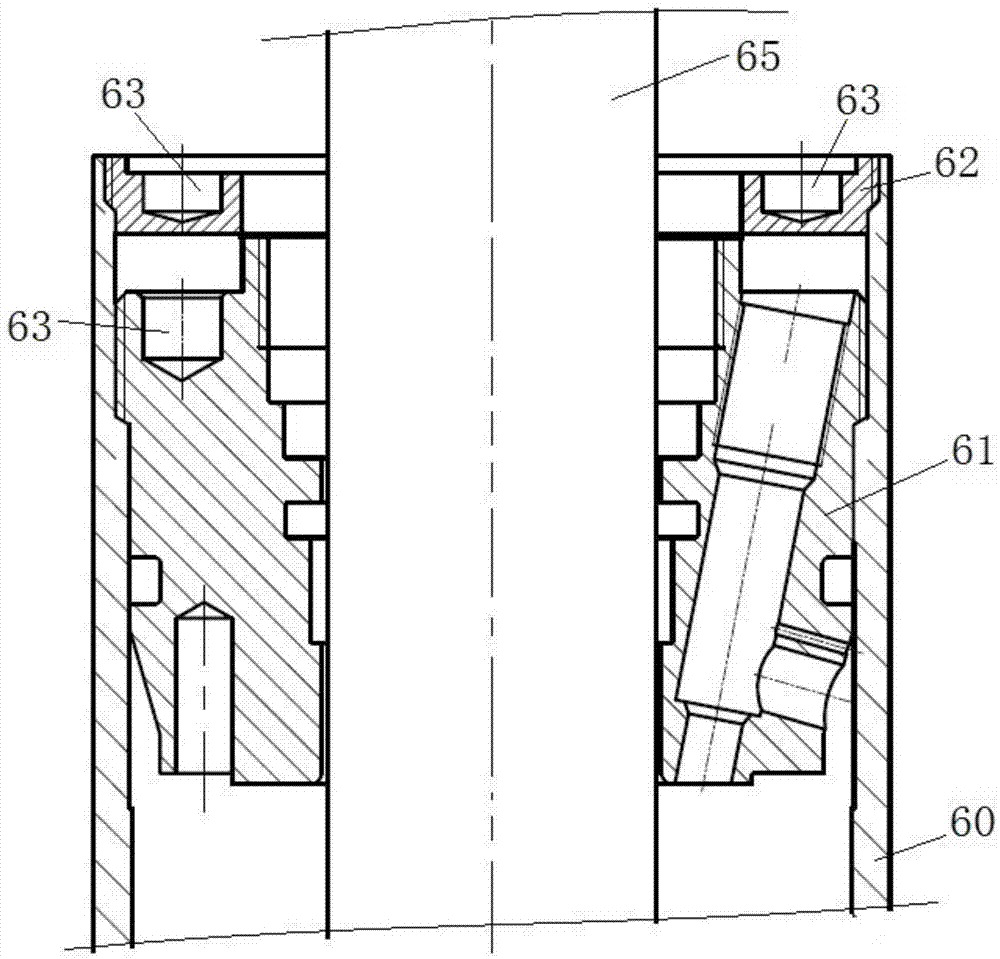

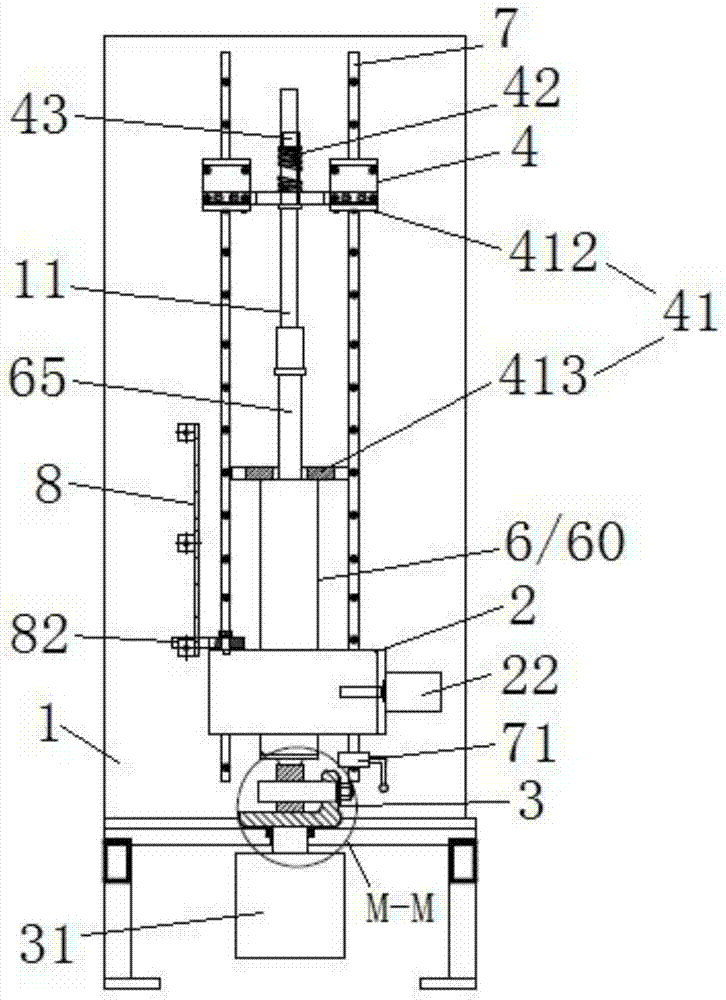

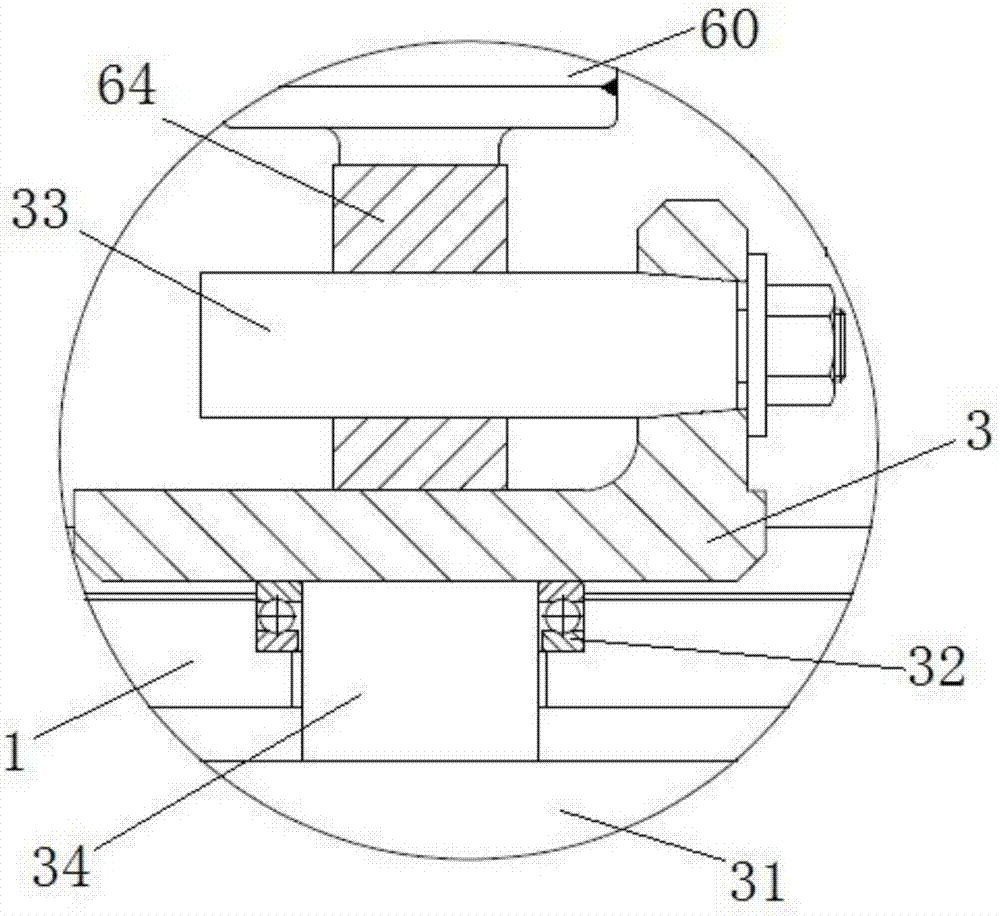

[0036] See Figure 2 (including Figure 2a and Figure 2b )~ Figure 12 The hydraulic shock absorber thread removal device includes a frame 1 and a centering clamping mechanism 2, a turret 3 and a wrench assembly 4 respectively arranged on the frame, and the centering clamping mechanism is arranged between the turret and the wrench assembly. In this embodiment, the wrench assembly is arranged above the centering clamping mechanism, and the turret is arranged below the centering clamping mechanism, and the centering clamping mechanism is used for positioning and clamping the cylinder body 60 of the hydraulic shock absorber to be disassembled. And make the axis line of the cylinder body coincide with the positioning center line of the centering clamping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com