Hydraulic oil stability determinator

A hydraulic oil stability technology, which is applied in the field of hydraulic oil stability testers, can solve problems such as low pump efficiency, long test cycle, and complex test bench structure, and achieve reduced test costs, simple structure, and great promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

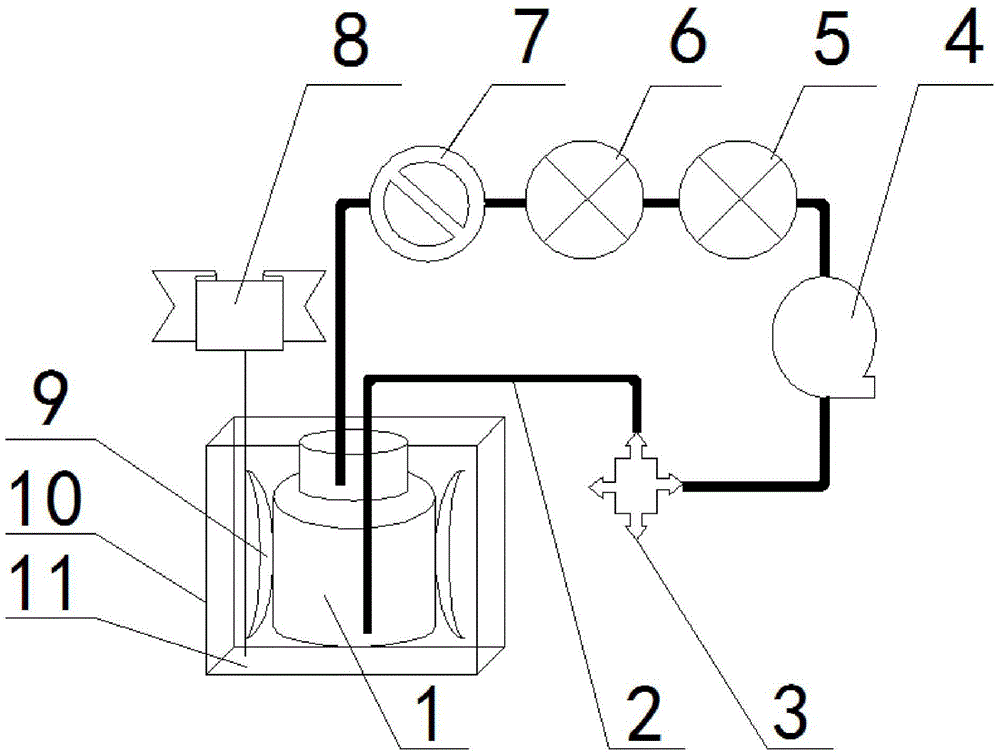

Embodiment 1

[0034] The principle of the test is: when the hydraulic pump 4 continuously circulates and shears different hydraulic oils, due to the different shear resistance of the hydraulic oils, when the system runs for a certain period of time, the viscosity change rate is also different. Therefore, under fixed test conditions, the viscosity change rate of different hydraulic oils is tested to determine its stability performance, that is, the smaller the viscosity change rate of the oil, the more stable it is.

[0035] The steps of the test are: open each equipment and pass through the constant temperature oil bath 11, heat the hydraulic oil sample to 95°C and keep the temperature constant, then turn on the hydraulic pump 4, the equipment starts to run, set the pump speed to 1500r / min, and the hydraulic oil flow rate in the system is 10L / min min; start timing after the system runs stably (within 30 minutes), and take samples after 168 hours to measure the viscosity, acid value, and colo...

Embodiment 2

[0038] The principle of the test is: during the use of the hydraulic equipment, the maximum input power of the system, the parameters of the hydraulic pump 4 and the pressure output of the hydraulic cylinder are fixed, and the viscosity of the hydraulic oil is different, so the internal leakage of the hydraulic pump is also different. The output flow of the pump 4 is different, resulting in a different time for a cycle of reciprocating movement of the hydraulic cylinder. In the actual working process, the smaller the change in the time used for the reciprocating movement of the hydraulic cylinder for one cycle, the better, that is, the smaller the change in the viscosity of the hydraulic oil during use, the better. After setting the input power of the fixed hydraulic pump 4, the output pressure of the system and the oil temperature of the hydraulic system through the hydraulic oil stability tester, the hydraulic oil stability is evaluated by judging the change of the flow rate ...

Embodiment 3

[0045] The principle of the test is: when the hydraulic pump 4 leaves the factory, the displacement parameter of the hydraulic pump 4 is fixed, and the displacement is different with different output pressures. When the output pressure parameters of the hydraulic system, the displacement of the hydraulic pump 4 and the input power of the hydraulic pump 4 are fixed, the smaller the internal leakage of the hydraulic pump 4, the larger the output flow, that is, the shorter the time it takes for the hydraulic cylinder to reciprocate one cycle. During use, the greater the viscosity, the smaller the leakage in the system, but the greater the energy loss caused by the internal friction of the hydraulic oil. Through the hydraulic oil stability tester, find the balance point in terms of internal leakage and energy loss, and choose the hydraulic oil with the most suitable viscosity grade.

[0046] The steps of the test are as follows: open each device and pass through the constant tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com