Patents

Literature

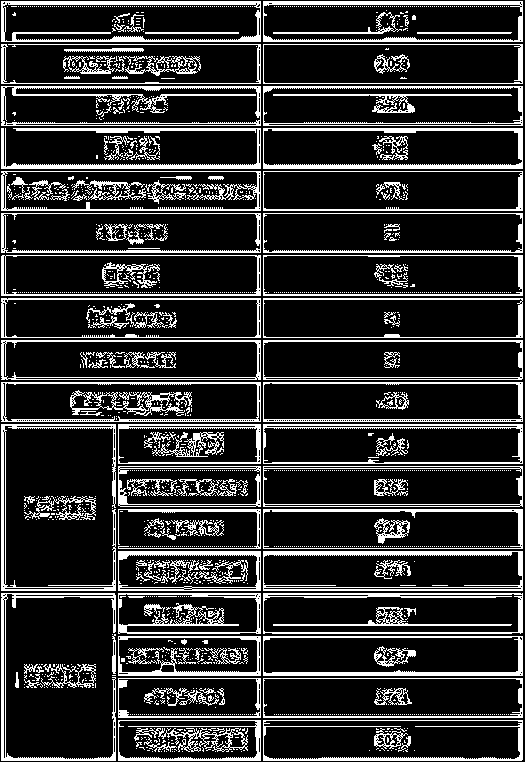

110 results about "Viscosity grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description. The viscosity grade of a lube oil is determined by the Society of Automotive Engineers (SAE). Oils can be separated into multigrade oils and monograde oils. Multigrade oils must fulfill two viscosity specifications, their viscosity grade consists of two numbers, e.g. 10W-40: 10W refers to the low-temperature viscosity ("Winter"),...

Physically stable aqueous suspensions of active pharmaceuticals

The present invention concerns methods of making physically stable aqueous suspensions of sparingly soluble to insoluble in water, active pharmaceuticals. More particularly, the invention provides an aqueous pharmaceutical suspension composition comprising an active pharmaceutical component which is sparingly soluble to insoluble in water; a water soluble, low viscosity grade cellulose polymer with a viscosity range of 3 mPa·s to 50 mPa·s as a surfactant; a suspending agent; and water.

Owner:TRIAD GRP

Reinforced wallboard

InactiveUS6841232B2Well mixedHigh viscosity gradeConstruction materialOther chemical processesCelluloseViscosity grade

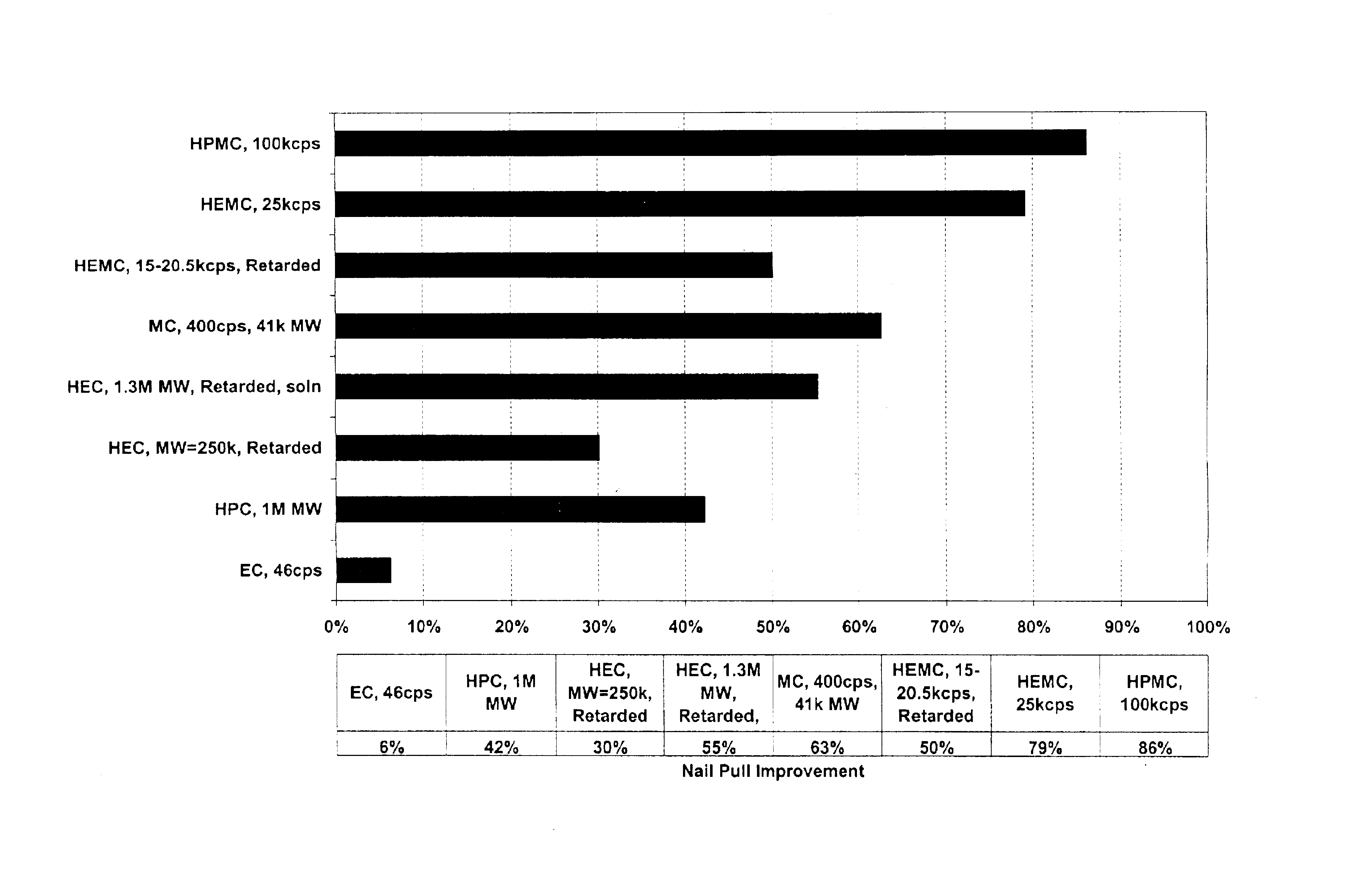

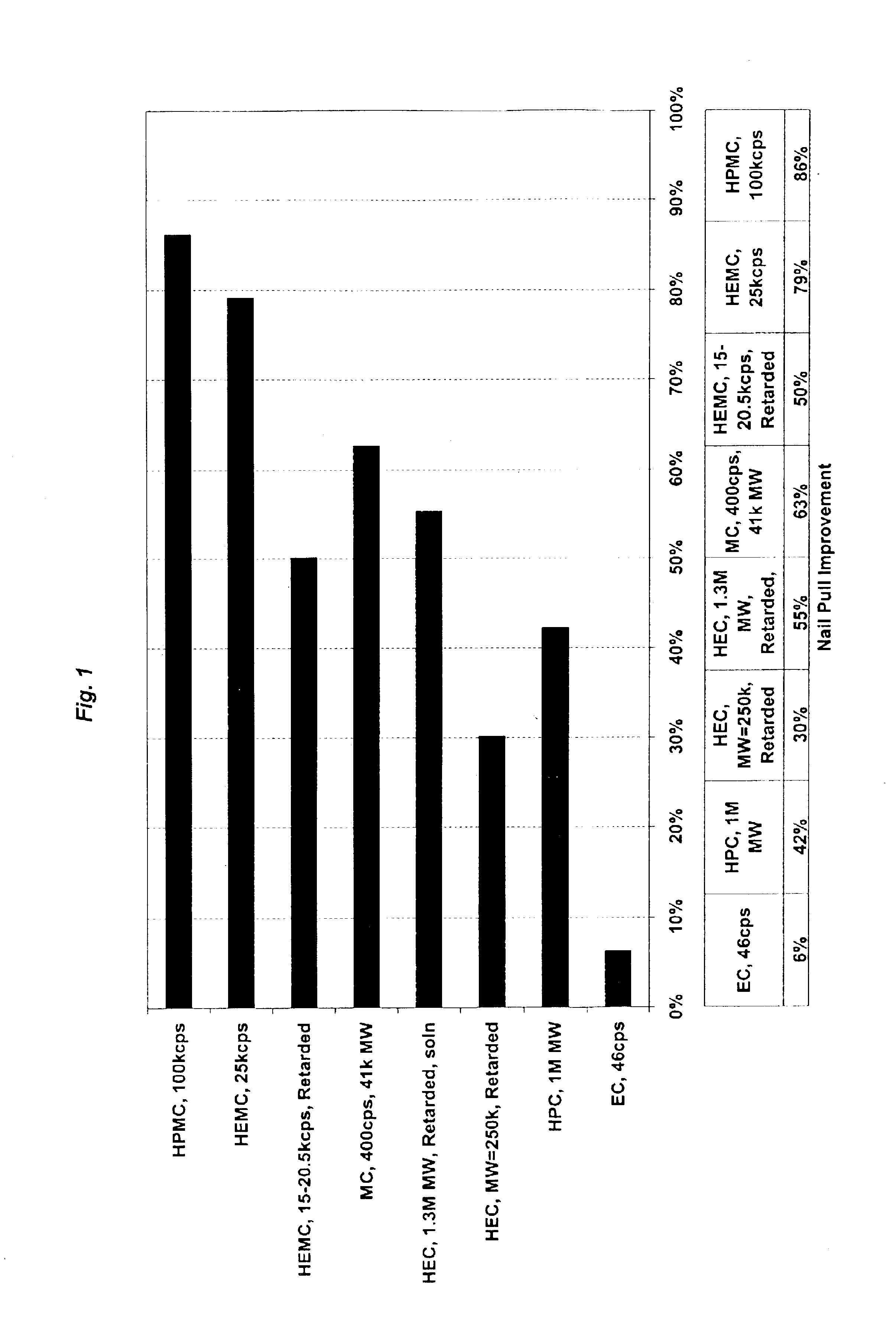

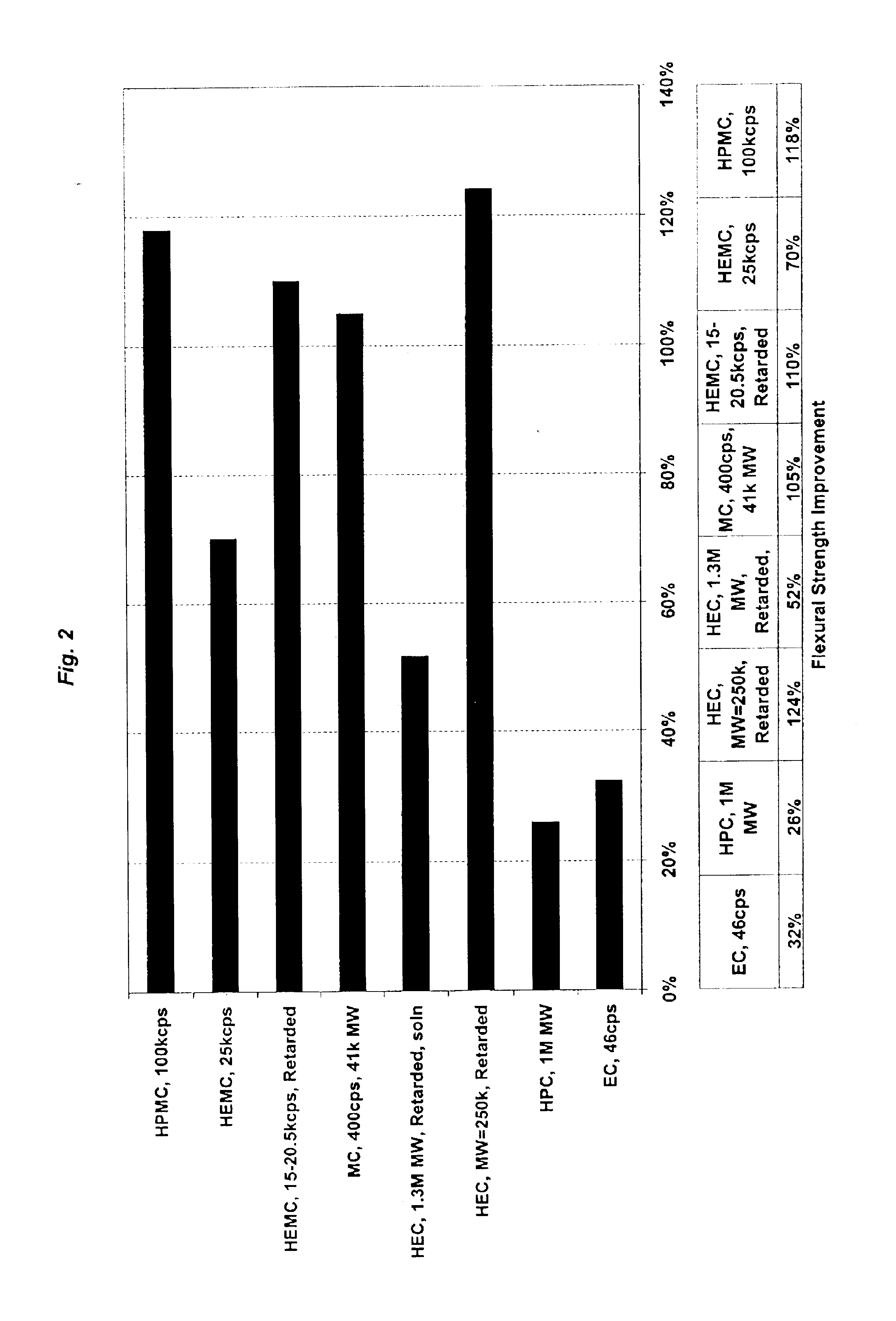

A reinforced wallboard core is prepared from a slurry comprising a mixture of β-calcium sulfate hemihydrate, a cellulose ether additive other than CMC and an amount of water that is sufficient to form a slurry and resulting in a wallboard density of less than 0.8 g / cc. The β-calcium sulfate hemihydrate is hydrated by the water forming a wallboard core reinforced by the cellulose ether additive. The cellulose ether, having a molecular weight of at least about 20,000 and a viscosity grade of at least about 100 cps, is selected to give the reinforced wallboard core improved nail pull resistance and greater flexural strength than unreinforced wallboard of the same density. The reinforced wallboard core may be used for reduced-paper wallboard and / or for lightweight wallboard, for example.

Owner:SAINT GOBAIN PLACO SAS

Lubricating oil composition

InactiveUS20100093578A1Improve fuel saving effectReduce resistanceAdditivesViscosity gradeViscosity index

The present invention provides a lubricating oil composition improved in fuel-saving properties by reducing lubrication resistance within the same viscosity grade oils. The lubricating oil composition comprises a lubricating base oil and a viscosity index improver with a PSSI of 30 or lower blended such that the viscosity index of the composition is 160 or greater and the 100° C. kinematic viscosity loss after shearing is 15 percent or less.

Owner:NIPPON OIL CORP

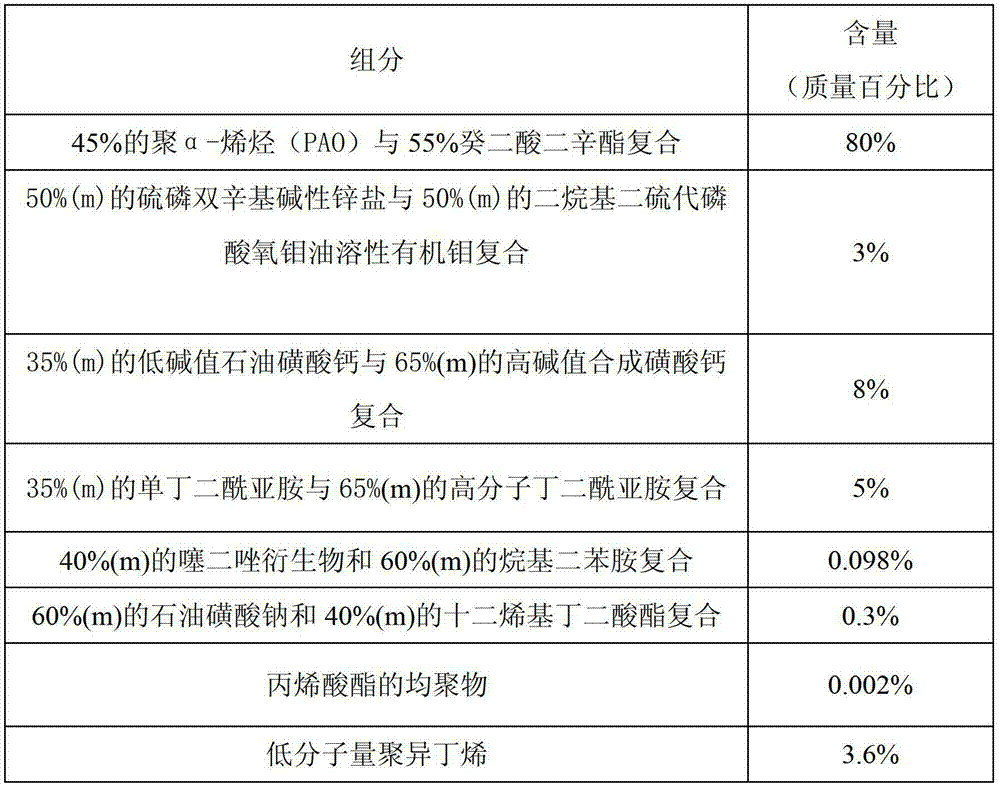

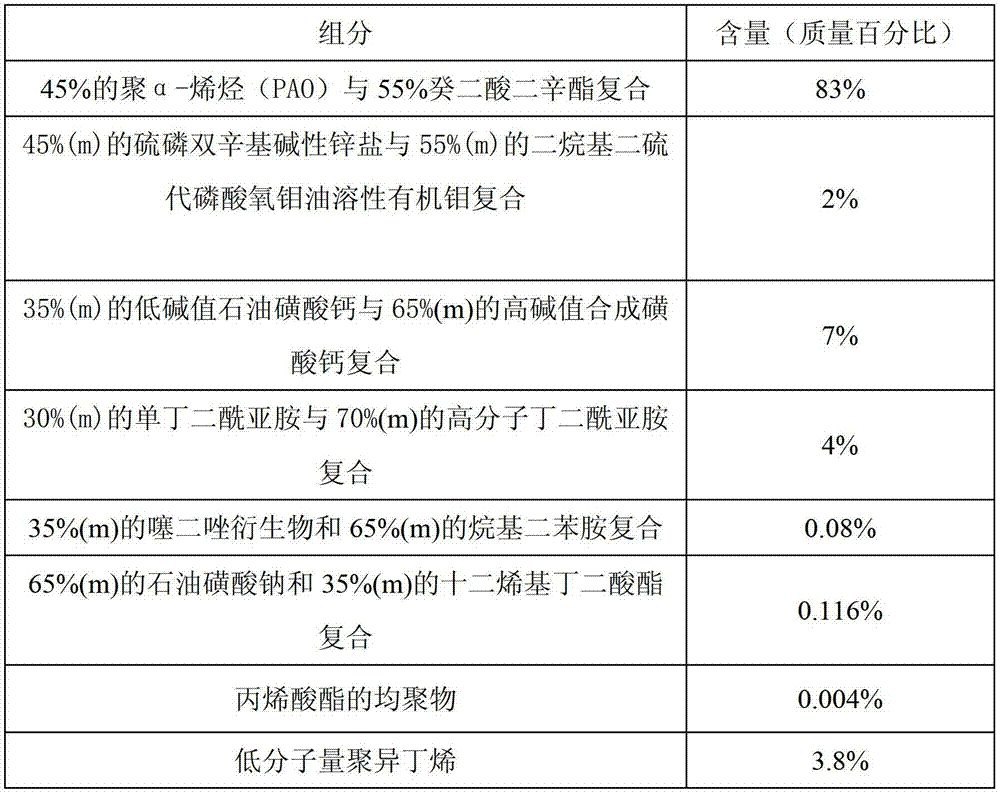

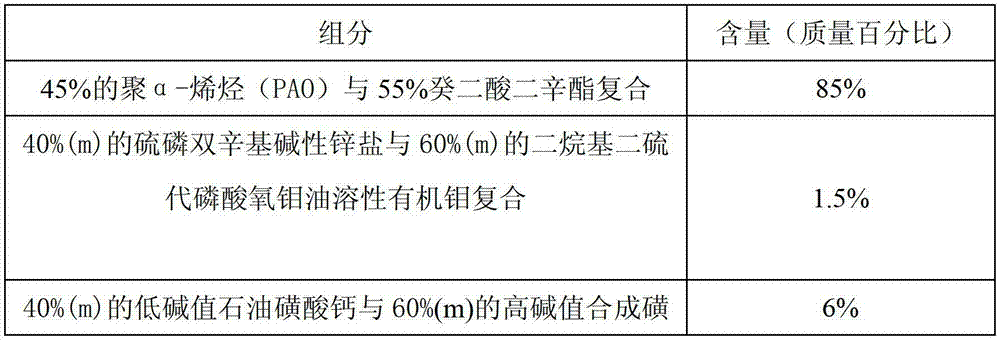

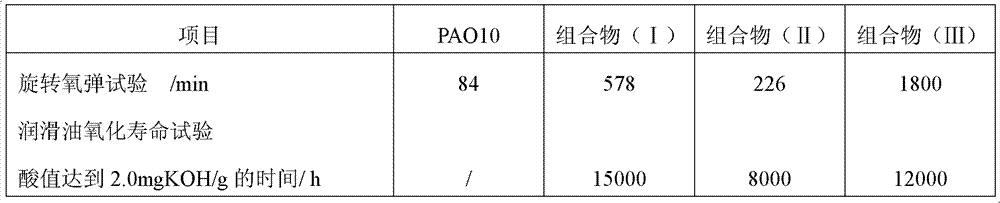

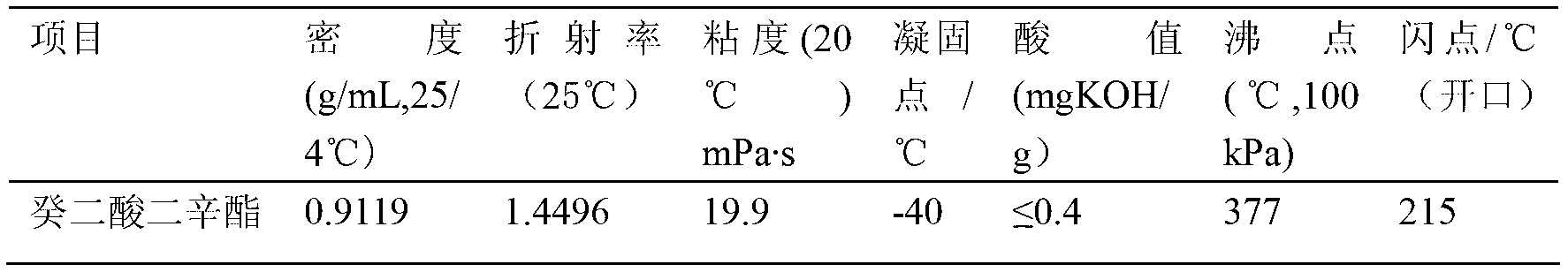

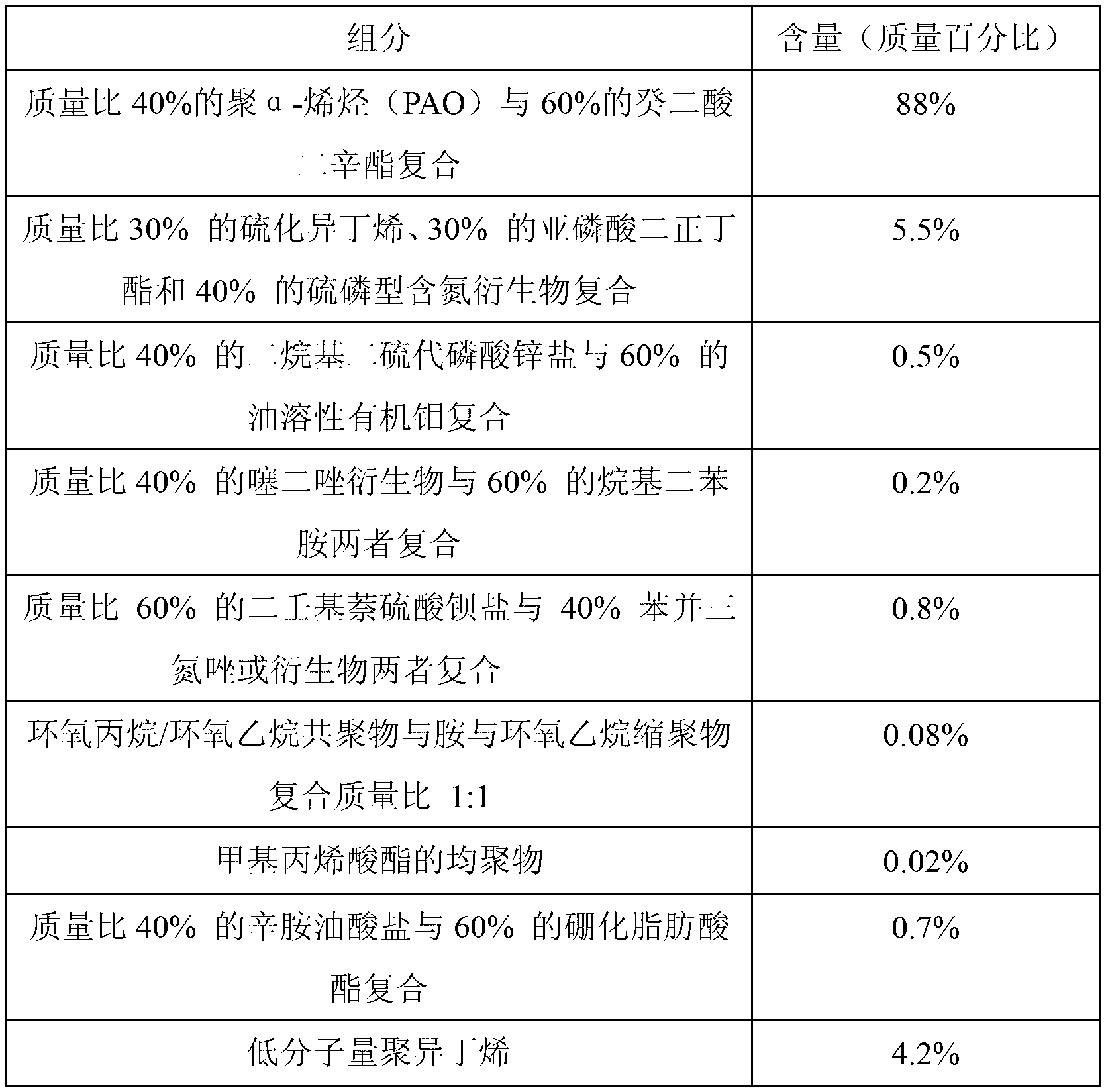

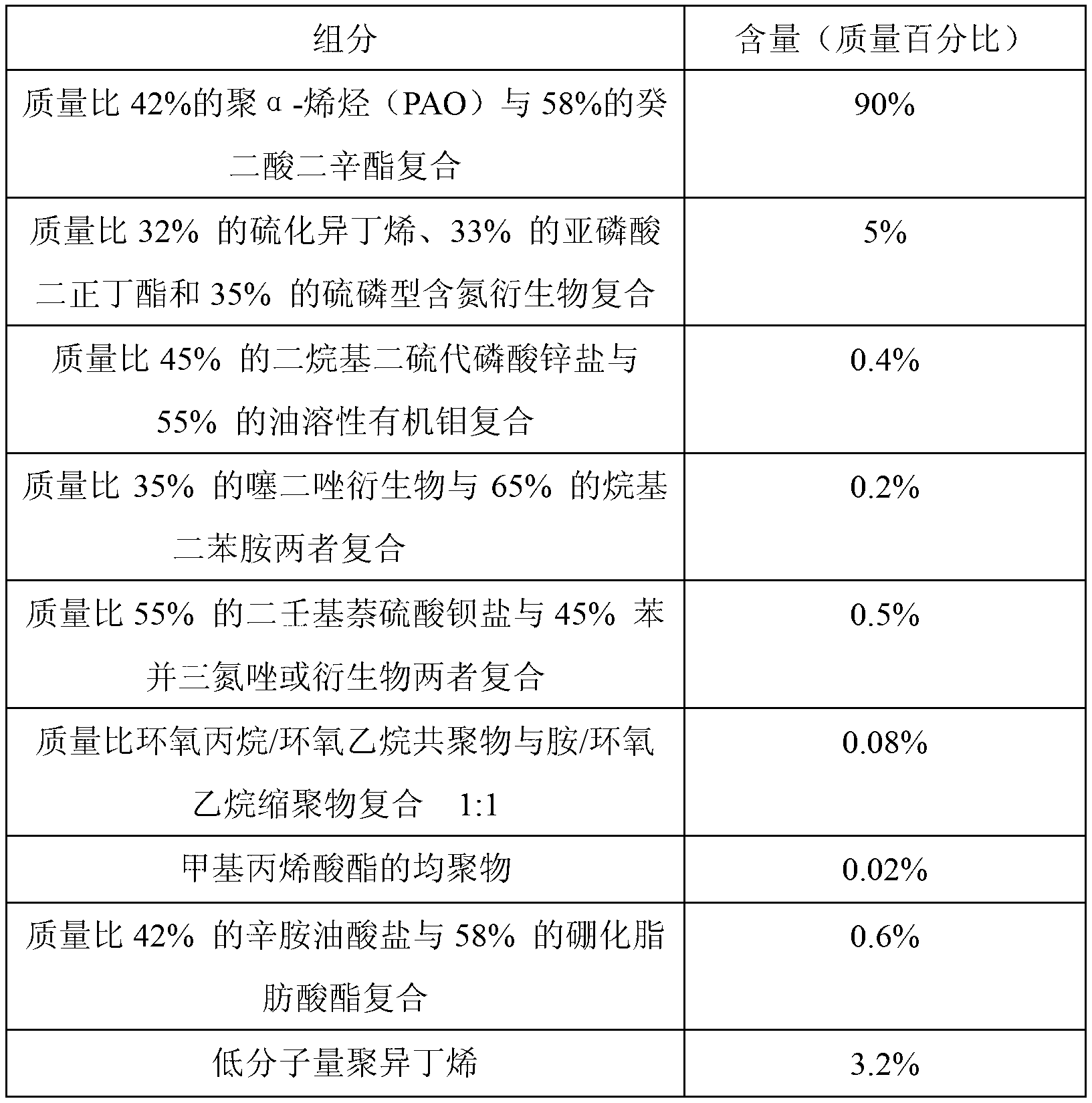

Environment-friendly and energy-saving gasoline engine lubricating oil

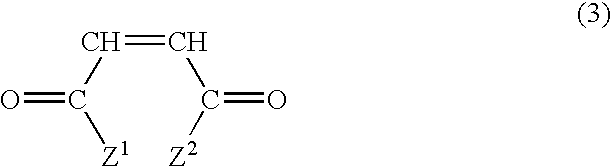

The invention discloses environment-friendly and energy-saving gasoline engine lubricating oil, which is composed of composite base oil, a composite oxidation and a corrosion inhibitor, a composite metal detergent, a composite ashless dispersant, a metal passivator, an antirusting agent, an antifoaming agent and a viscosity index improver, wherein the base oil is compounded from poly-alpha-olefin (PAO) and dioctyl sebacate. With the adoption of the gasoline engine lubricating oil, energy conservation, long oil change period, and reduction for waste oil, waste gas and particulate matters are realized, biodegradability is high compared with the traditional lubricating oil, the fuel economy of an engine is improved, the service life of the engine is prolonged, and the generation of oil sludge and carbon deposition in the engine can be inhibited; and the base oil technical requirements of quality grade specifications SG, SH, SJ, SL, SM and SN of gasoline engine lubricating oil, and the performance requirements of multi-grade oil with viscosity grades 0W, 5W, 10W, 15W, 20W and the like can be met.

Owner:广西谛恒生物能源投资有限公司

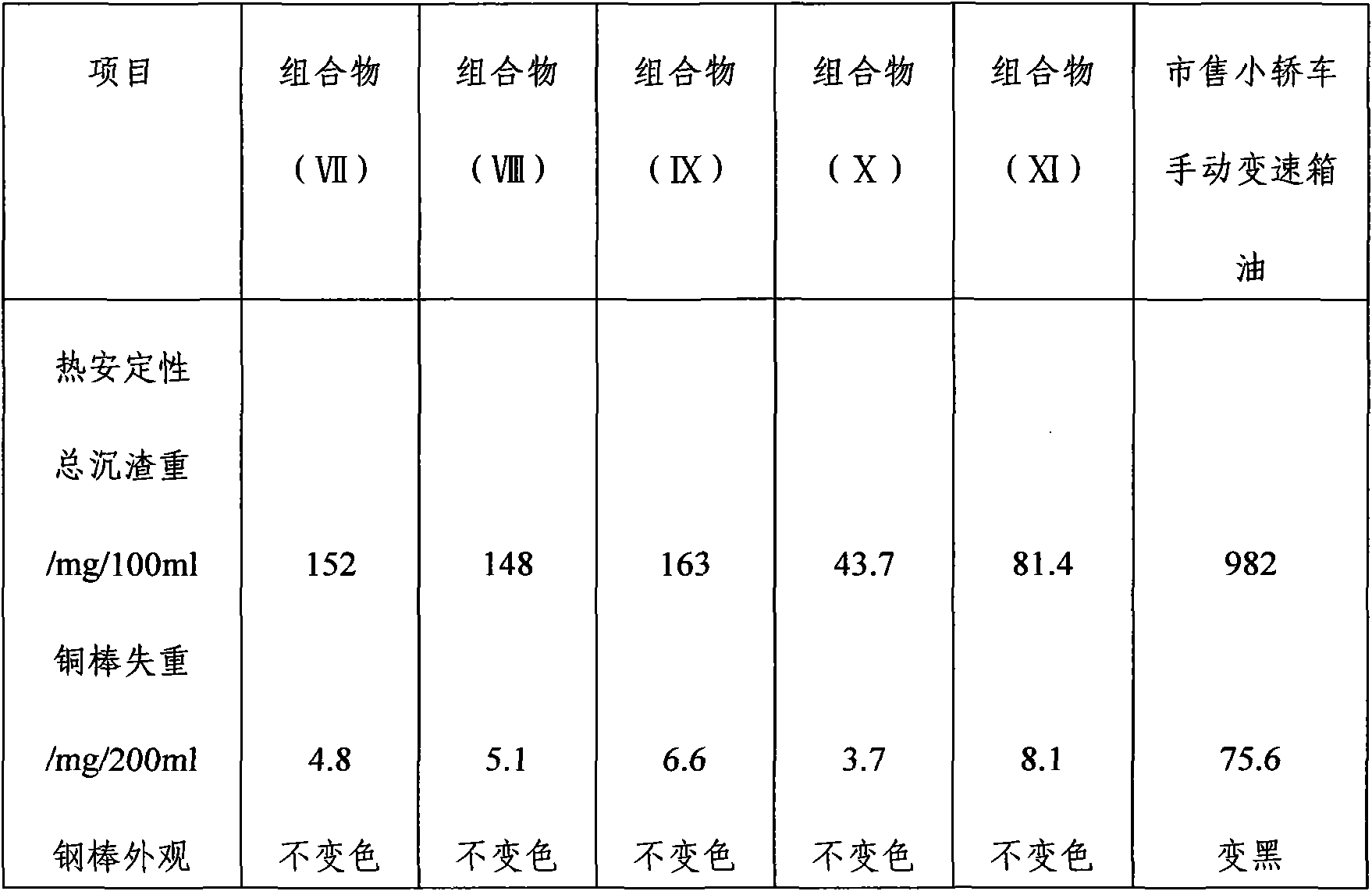

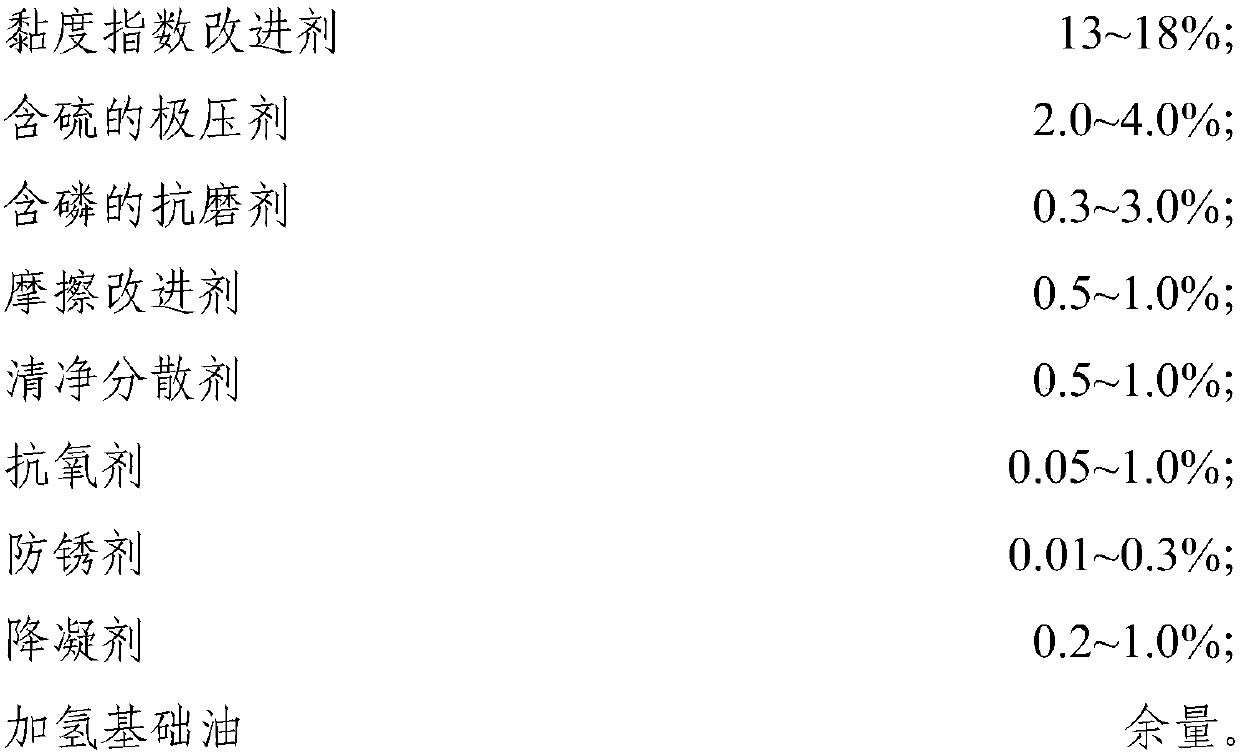

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

Gasoline engine oil composition

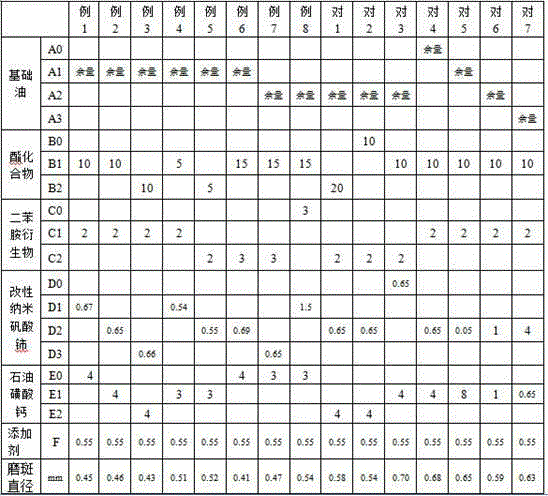

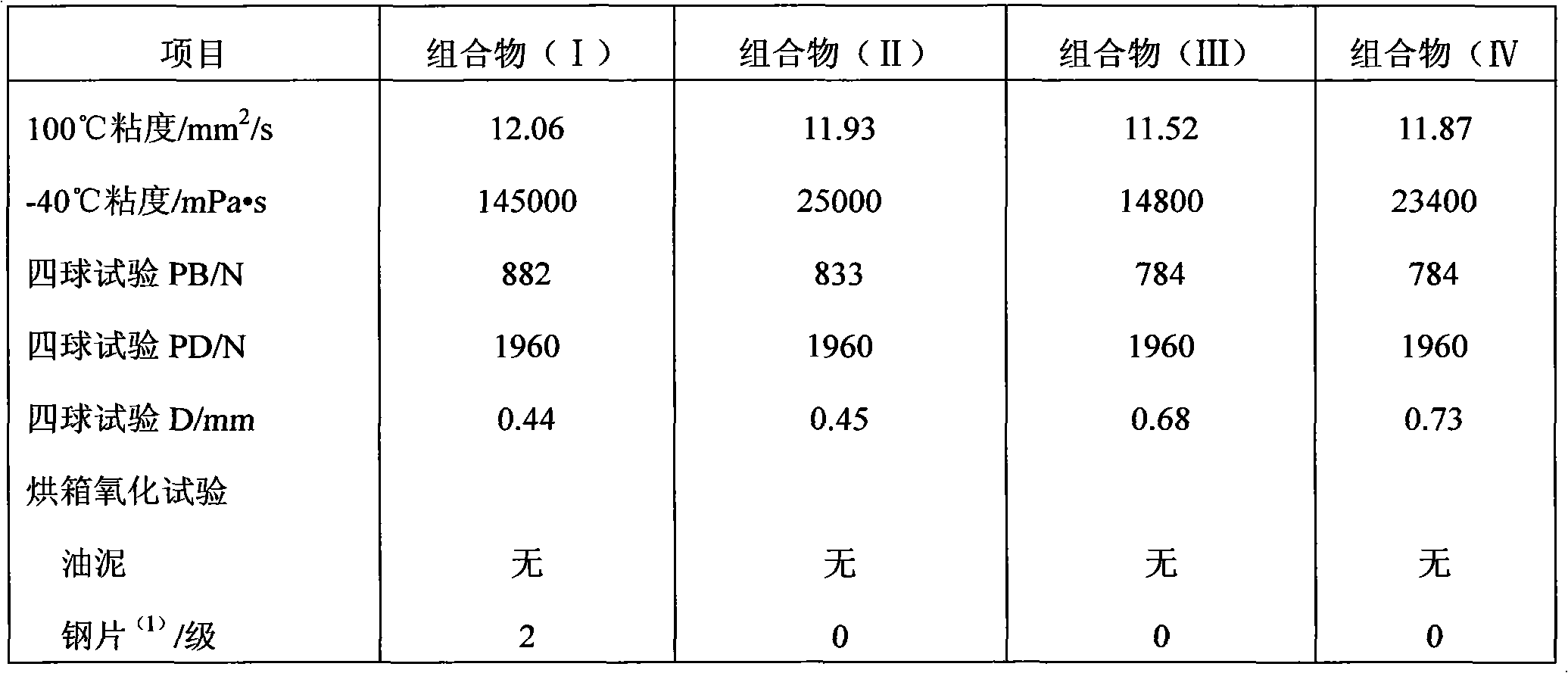

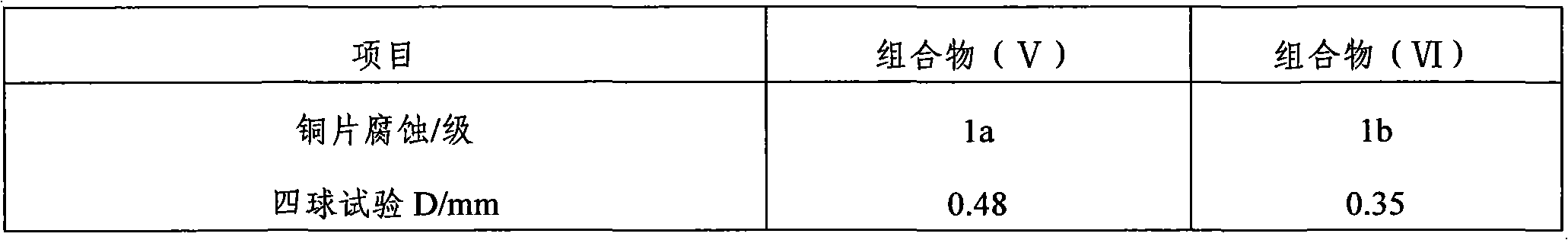

The invention provides a gasoline engine oil composition. The gasoline engine oil composition has the SAE viscosity grade of 0W-40 and is prepared from, by weight, 5.0% to 20.0% of ester compounds, 0.1% to 5.0% of diphenylamine derivatives, 0.01% to 2.0% of modified nanometer cerium vanadium acid, 1.0% to 8.0% of petroleum calcium sulfonate, 0.001% to 1.0% of common gasoline engine oil additives and the balance base oil. The API quality of the gasoline engine oil composition reaches the SN grade, abrasion resistance is good, friction between engine parts can be effectively reduced, the mileage of gasoline can be increased, the durability of gasoline can be improved, and it is guaranteed that the acme performance of an engine is achieved.

Owner:邵宏良 +1

Lubricating Oil Composition For Lubricating Automotive Engines

ActiveUS20120132166A1High HTHS viscosityImprove fuel economyNon-fuel substance addition to fuelCombustion enginesAlkaline earth metalViscosity grade

A lubricating oil composition of SAE viscosity grade 0W20 which comprises a base oil and additive components comprising a nitrogen-containing ashless dispersant, an alkaline earth metal-containing detergent, a phosphorus-containing wear inhibitor, an oxidation inhibitor and a viscosity index improver and which shows a viscosity index of 200-240, a HTHS viscosity of not less than 2.9 mPa·s s at 150° C. and a Noack evaporation loss of not more than 13% favorably gives a high fuel economy and high wear inhibition to a four cycle gasoline engine of motorcycles and a diesel engine mounted on motor cars equipped with an exhaust gas post-processing apparatus.

Owner:CHEVRON JAPAN

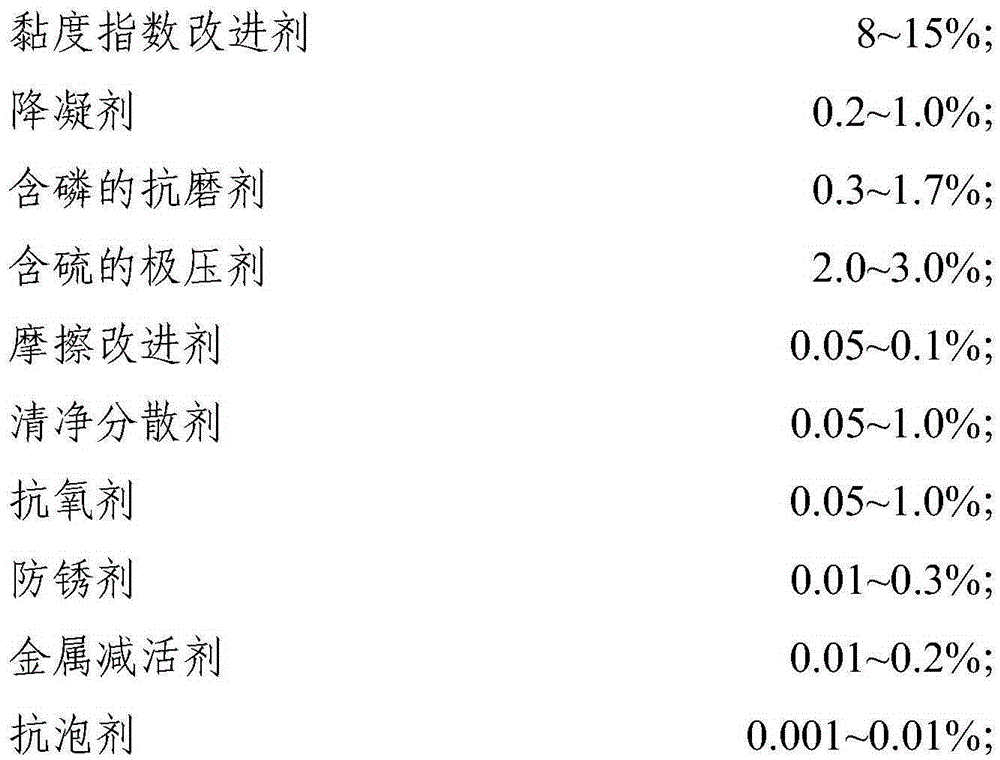

Clean-type universal gear lubricating oil composition

The invention provides clean-type universal gear lubricating oil composition which comprises (A) at least one of high-viscosity index deeply-refined mineral oil, or synthetic oil, or any composition of the above components; (B) at least one viscosity index improver; (C) at least one pour point depressant; (D) at least one phosphorus-containing antiwear additive; (E) at least one metal detergent; (F) at least one ashless dispersant; (G) at least one high temperature anti-oxidant; (H) at least one friction reducer. The lubricating oil composition has excellent high and low temperature performance, and can meet the requirements for gear oil with a 75W / 85 viscosity grade; the lubricating oil composition has excellent high temperature detergency and antiwear durability, passes gearbox cycle bench tests and rear axle gear bench tests, is applicable to vehicle transmission systems, and is especially applicable to transmission systems of passenger cars.

Owner:PETROCHINA CO LTD

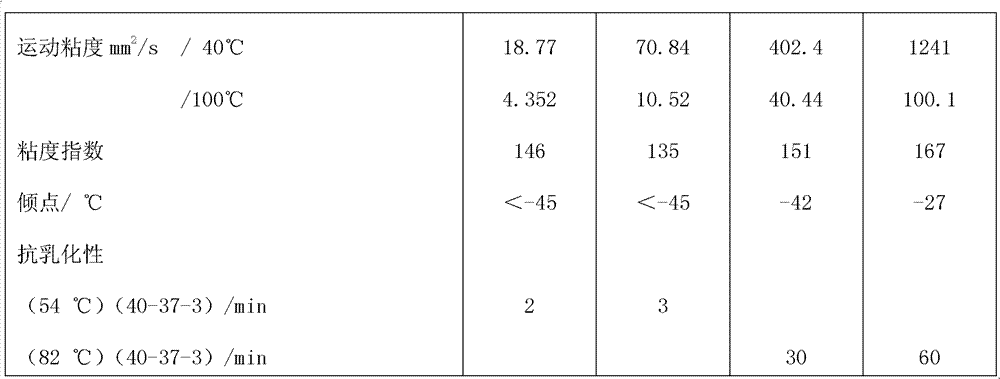

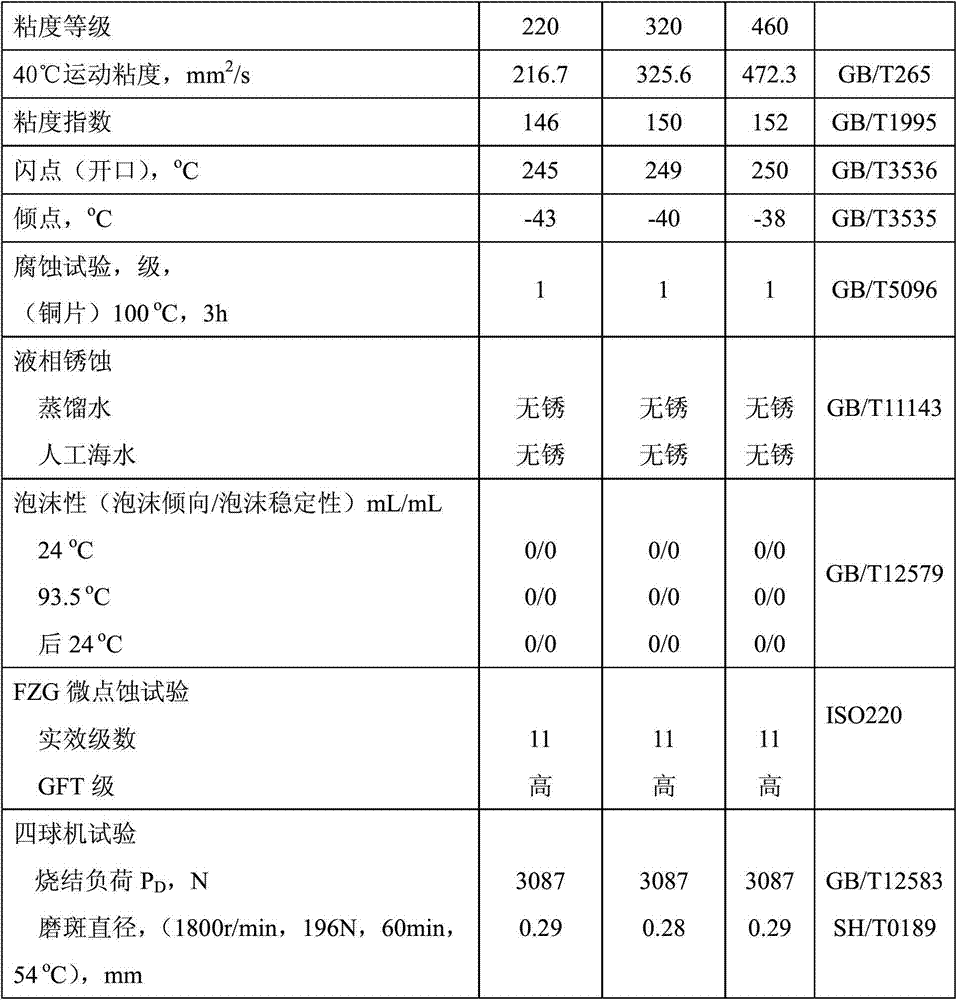

Long-life fully synthetic industrial gear lubricant composition

ActiveCN102766508AGood high and low temperature performanceImprove Oxidation StabilityLubricant compositionViscosity gradeOxidation resistant

The invention provides a long-life fully synthetic industrial gear lubricant composition, which comprises (A) at least one synthetic base oil; (B) at least one anti-oxidant; (C) at least one metal passivator; (D) at least one metal detergent; (E) at least one antiwear agent; (F) at least one antirust agent; and (G) at least one friction modifier. The above lubricant composition has characteristics of high viscosity index and low pour point and can satisfy needs of industrial gear oil of 68-680 viscosity grade. The above lubricant composition has excellent anticorrosive and antirust properties, anti-foaming property, demulsibility, oxidation resistance and abrasion resistance. The antioxidation performance of the lubricant composition is particularly prominent. In addition, the lubricant composition is applicable to industrial gear and bearing lubrication system under harsh conditions of high temperature, high pressure, heavy duty and the like, and especially has outstanding performance in equipment protection, oil life and failure-free operation.

Owner:PETROCHINA CO LTD

Wind-turbine gear oil composition

ActiveCN103113968ASuitable lubrication requirementsGuaranteed uptimeLubricant compositionPhenolHeavy load

The invention discloses a wind-turbine gear oil composition. The wind-turbine gear oil composition is characterized by comprising the following components: (1), full-synthetic base oil, (2), at least one phenol-type antioxidant or amine-type antioxidant, (3), at least one sulphur-containing or phosphor-containing anti-wear reagent at extreme pressure, (4), at least one antirust agent, (5), at least one metal passivator and (6), at least one demulsifying agent. The needed full-synthetic base oil is added to a blending kettle with a stirrer in proportion according to the viscosity grade of the wind-turbine gear oil composition; and other components are added to the blending kettle in proportion for being blended to obtain the wind-turbine gear oil composition disclosed by the invention after the full-synthetic base oil is blended. According to the wind-turbine gear oil composition disclosed by the invention, the full-synthetic base oil is adopted, so that the wind-turbine gear oil composition has long service life even under the harsh working conditions and is suitable for the lubricating requirements of a gearbox which is used within the wide range; and meanwhile, the pole tension anti-wear additive with micropitting performance is added, so that the formation of point erosion is effectively avoided or restrained, and the normal operation of a large heavy-load mechanical gear transmission device is ensured.

Owner:苏州惠丰润滑材料有限公司

Stress absorption structured llayer of discontinuous ajar particle distribution limit mixture for asphaltum with high viscosity

InactiveCN101092808AImprove shear resistanceImprove fatigue resistanceIn situ pavingsBuilding insulationsFiberViscosity grade

This invention relates to a stress absorption structure layer of asphalt intermittent high viscosity grade semi mixture laid between a cement concrete road surface and asphalt mixture worn layer taking Embedded crowded Mineral coarse aggregate as the frame to fill mastic fat composed of high viscosity asphalt combined material, mineral powder filling material, lignin fiber stabilizer and mineral fine material among the framework, the mass percentage includes: high viscosity asphalt combined material 5-6.50, mineral powder filling material 4-6.00, lignin fiber stabilizer .020-0.40 and the rest is the intermittent semi mixture.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR

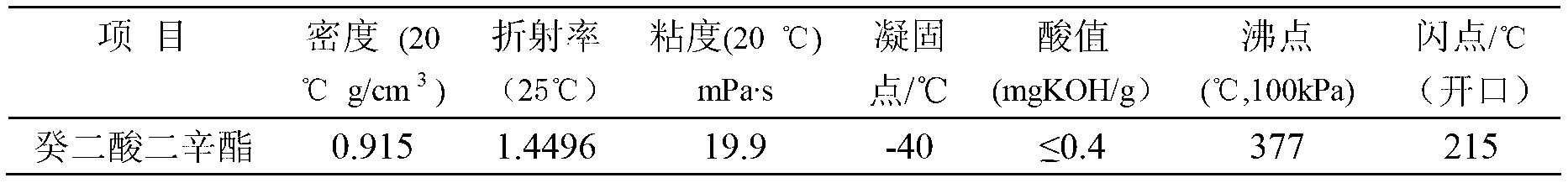

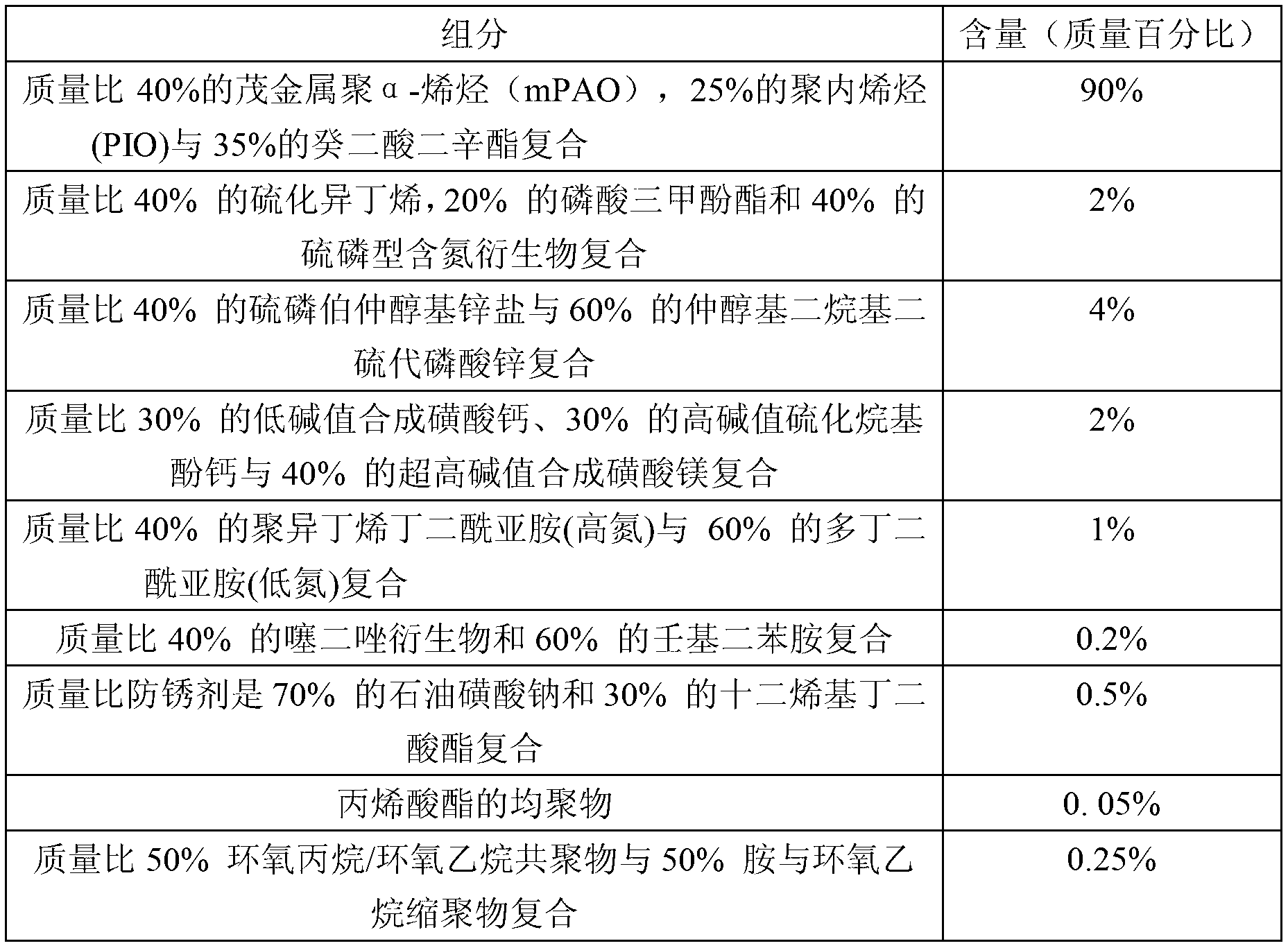

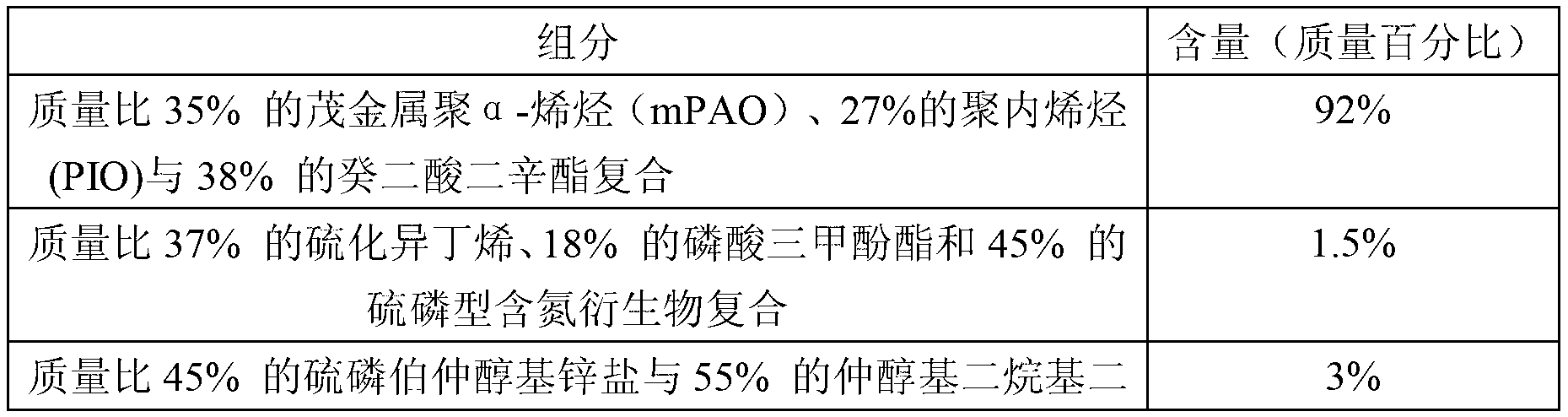

Environment friendly energy-efficient heavy-load compression machine oil

ActiveCN103232880AMeet the requirements of different working conditionsAchieve qualityBase-materialsEngineeringCrankcase

The invention provides environment friendly energy-efficient heavy-load compression machine oil, which comprises the following components by mass percentage: 90-95% of base oil and 10-5% of other additives. Metallocene poly alpha-olefins (mPAO), poly internal olefin (PIO) and dioctyl sebacate are composited as base oil of heavy-load compressor oil. One main component of the base oil of the compressor oil is dioctyl sebacate which has a sufficient raw material source, and the product is a reproducible resource with high economic benefit and social benefit, and the preparation technology is simple. Each physical and chemical index of the heavy-load compressor oil reaches the usage requirement, and the polyisobutylene can be blended with the product for producing a product which meets the performance requirements of L-DAC heavy-load compressor oil with viscosity grades as follows: N32, N46, N68, N100 and N150. The product is suitable for lubricating, cooling and sealing the cylinder and the crankcase of the middle and heavy-load piston compressor and the large-scale rotary compressor.

Owner:GUANGXI UNIV

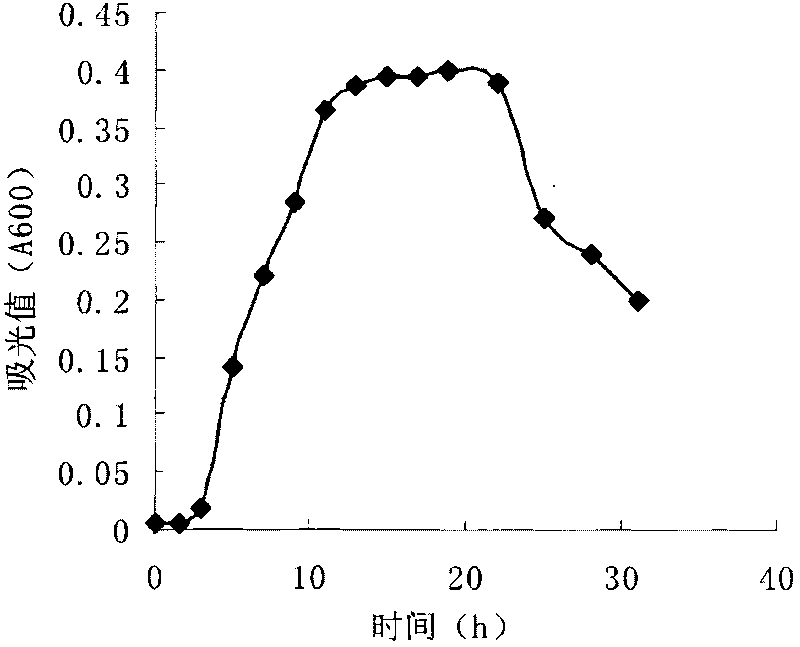

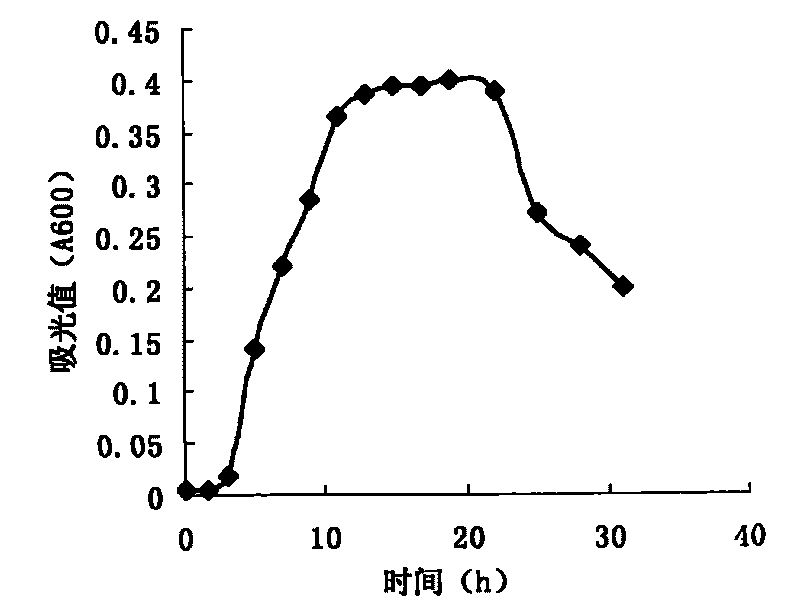

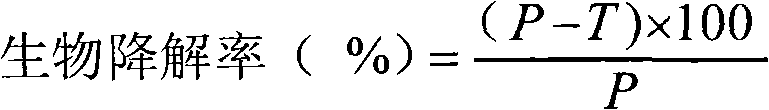

Biodegradation test method of synthetic oil and vegetable oil-based lubricating oil product

InactiveCN101748184ASimple and fast operationStable Data ReproducibilityMicrobiological testing/measurementWater/sewage treatmentActivated sludgeVegetable oil

The invention relates to a biodegradation test method of a synthetic oil and vegetable oil-based lubricating oil product. The collected activated sludge is accessed to a synthetic oil and vegetable oil-based lubricating oil degradation culture medium after acclimatization and the tested microorganism bacteria solution biomass in the degradation culture medium and the lubricating oil organic matter residue in a liquid phase culture medium are served as an evaluation method and standard for evaluating the biodegradation rate of the synthetic oil and vegetable oil-based lubricating oil after seven days of continuous shaking culture under constant temperature. The biodegradation test method is a biodegradation evaluation method of the synthetic oil and vegetable oil-based lubricating oil, which has simple and convenient operation, good data reproducibility and stable repeatability and is applicable to biodegradable lubricating oil with different specifications and viscosity grades. The method is applied in the biodegradation tests of castor-based fully-synthetic high-performance lubricating oil products and uses the castor oil which has the degradation rate of about 96% in the literature reports as the reference oil, the tested degradation rate of the castor oil is 97%, and the degradation rate of the castor-based fully-synthetic high-performance lubricating oil reaches up to 85%.

Owner:TIANJIN NANKAI UNIV CASTOR ENG SCI & TECH

Environment-friendly type oil for heavy-duty industrial gear

ActiveCN103215114AImprove the lubrication effectEmission reductionBase-materialsFriction reductionHigh torque

The invention discloses environment-friendly type oil for a heavy-duty industrial gear. The oil comprises base oil, an anti-wear reagent at extreme pressure, an antioxidant corrosion-resistant agent, a metal passivator, an antirust agent, a demulsifier, an antifoaming agent, an oiliness agent, and a viscosity index improver. The oil for the heavy-duty industrial gear is good in comprehensive property, not only has good antioxidant and corrosion-resistant properties, antirust property, anti-wear and corrosion-resistant properties, friction reduction, bearing, high torque, high-temperature stability, demulsibility, antifoaming property and the like, and is capable of reducing emission, good in biodegradability, and lower in cost, but also can be used for enabling an industrial gear to form an anti-wear, high temperature-resistant and extrusion-resistant boundary lubricating oil film under the high torque or impact load, so as to ensure that the gear is well lubricated. Additives are selected by adopting an artificial neural network algorithm, the optimal formula can be selected by a genetic algorithm, and the environment-friendly type oil for the heavy-duty industrial gear can meet the performance requirements of the GB5903-1995 heavy-duty industrial gear on the oil with the viscosity grades of 100, 150, 220, 320, 460 and 680.

Owner:GUANGXI UNIV

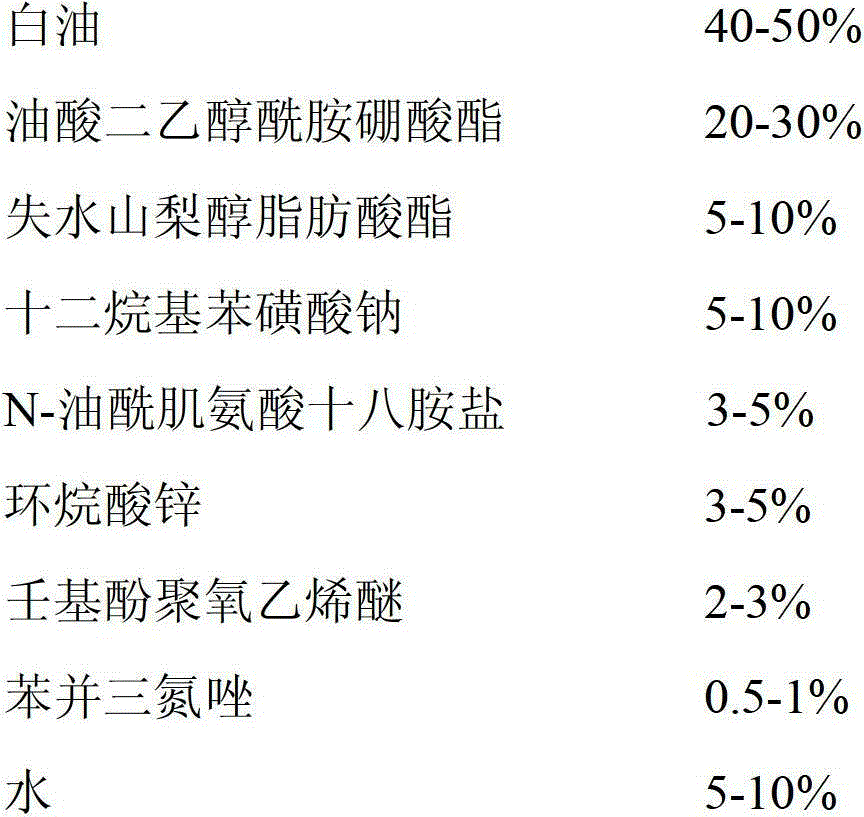

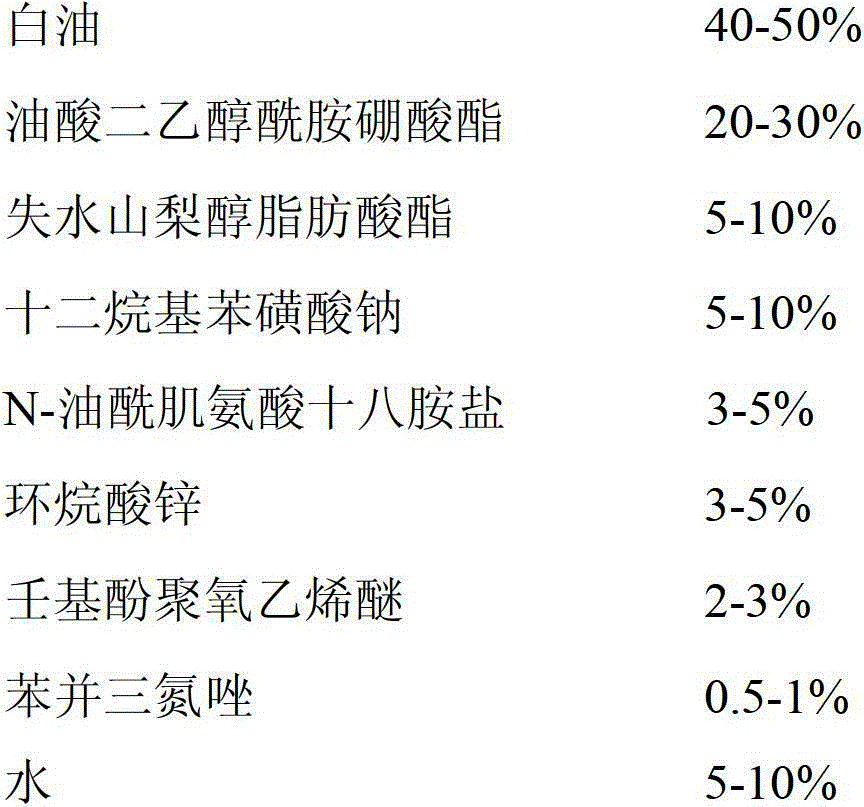

Environment-friendly long-life emulsified antirust agent and preparation method thereof

The invention discloses an environment-friendly long-life emulsified antirust agent and a preparation method of the environment-friendly long-life emulsified antirust agent. The antirust agent is prepared from the following components: 40-50% of white oil with the ISO viscosity grade lower than 46#, 20-30% of diglycolamide oleate borate, 5-10% of sorbitan fatty acid ester, 5-10% of sodium dodecyl benzene sulfonate, 3-5% of N-oleoylsarcosine octadecylamine, 3-5% of zinc naphthenate, 2-3% of nonylphenol polyoxyethylene ether, 0.5-1% of benzotriazole, and 5-10% of water. The preparation method is as follows: the benzotriazole and the sorbitan fatty acid ester are weighed and fully stirred to be transparent, then, the white oil, the diglycolamide oleate borate, the N-oleoylsarcosine octadecylamine, the zinc naphthenate, the nonylphenol polyoxyethylene ether and the sodium dodecyl benzene sulfonate premixed with water are added sequentially, and the mixture is fully stirred at the temperature of 25-40 DEG C for 30-60 minutes to complete transparency. The antirust agent provided by the invention has a good antirust property, and still has an excellent antirust property after being added with water with the weight of 4-20 times that of the antirust agent, meanwhile, the antirust agent is convenient to clean, the energy is saved and the consumption is reduced, and the damage to the environment and workers is reduced.

Owner:山东科瑞沃新材料科技有限公司

Full-synthetic gear/bearing oil for four seasons and preparation method thereof

ActiveCN101531947ASignificant positive effectWide temperature rangeBase-materialsViscosity gradeOil additive

The invention discloses full-synthetic gear / bearing oil for four seasons and a preparation method thereof. The full-synthetic gear / bearing oil for four seasons is prepared by blending synthetic oil taken as base oil and an additive; the selected base oil is one of ester oil, synthetic hydrocarbon-type oil and a mixture of the ester oil and the synthetic hydrocarbon-type oil; the selected additive is a high-performance complexing agent, which is one of gear oil compound additive, wind turbine oil additive, industrial lubricant friction modifier, general gear oil complexing agent and multifunction gear oil additive; and the blending ratio of the base oil to the additive is 1.0 to 5.0 weight percent of the high-performance complexing agent and the balance of the base oil. According to viscosity grades of the gear oil, the synthetic oil with one or more compositions is added to a blending kettle with a stirrer in required proportion, is stirred for 0.5 to 1.5 hours at a temperature of between 30 and 60 DEG C, and is blended into the base oil of the gear oil; and the base oil is added with the high-performance complexing agent in a certain proportion and stirred for 1 to 3 hours at a temperature of between 30 and 60 DEG C to form the gear lubricant of the invention.

Owner:精锐化学(上海)有限公司

Synthetic ester refrigerator oil composition

InactiveCN105132088AGood extreme pressure and anti-wear propertiesGood anti-oxidation and anti-corrosion propertiesLubricant compositionViscosity gradeOrganic chemistry

The invention provides a synthetic ester refrigerator oil composition. The synthetic ester refrigerator oil composition comprises, by weight, 100.0 parts of synthetic ester base oil, 0.01-50.0 parts of other base oil, 0.5-10.0 parts of an anti-wear agent, 0.5-3.0 parts of an oxidation and corrosion inhibitor, 0.2-1.0 part of a multifunctional anti-wear, antifriction and energy saving additive, 0.1-0.5 parts of a metal deactivator, and 0.0001-0.01 parts of an antifoaming agent. The synthetic ester refrigerator oil composition can meet performance requirements of the viscosity grades of GB / T16630-2012 refrigerator oil of 7, 10, 15, 22, 32, 46, 68 and 100.

Owner:XINJIANG FUKE OIL PROD CO LTD

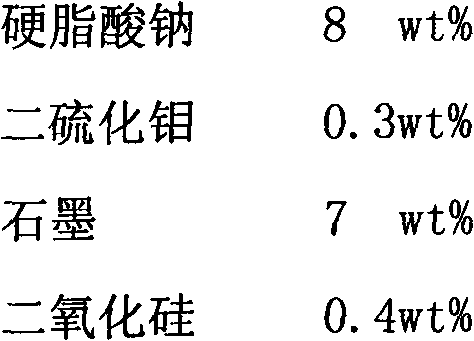

High temperature resistance lubrication mold release agent for glassware molding

The invention relates to a high temperature resistance mold release agent composition for glassware molding. The composition comprises: (a) a refined plant lubrication oil or a refined mineral lubrication oil, (b) at least a viscosity index improver selected from a styrene-isoprene copolymer or a polyisoprene copolymer, (c) at least a thickener selected from zinc stearate, sodium stearate or magnesium stearate, (d) at least an anti-wear agent selected from molybdenum disulfide or silica, and (e) at least an inorganic lubricant selected from graphite, boron nitride or talc powder. The composition has multiple effects of excellent oxidation stability, excellent lubricity, high temperature resistance and the like, and can meet requirements of high temperature resistance mold release agents for molding of glassware with different viscosity grades.

Owner:天津市硅酸盐研究所有限公司

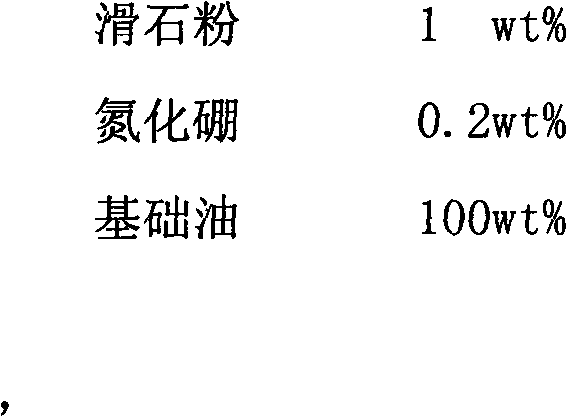

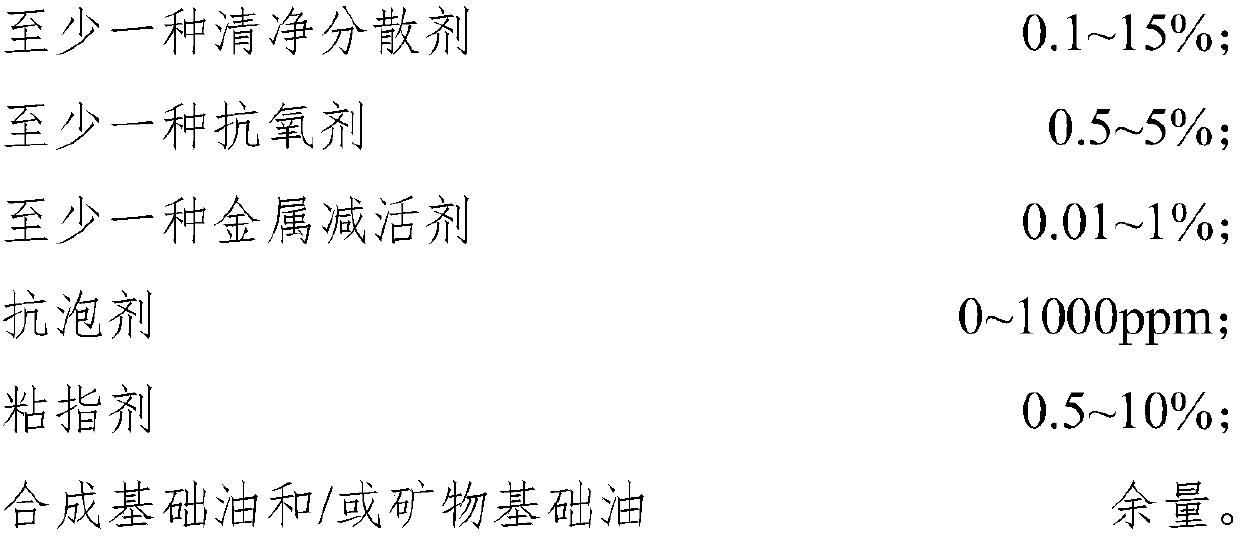

Oil composition special for low-viscosity manual transmission

InactiveCN109679742AGood synergyGood extreme pressure and anti-wear propertiesLubricant compositionViscosity gradeAntioxidant

The invention relates to an oil composition special for a low-viscosity manual transmission. The viscosity grade of the composition is not higher than 75 W, and the oil composition is prepared from the following components in percentage by mass: 0.05-2% of at least one friction modifier, 1-10% of at least one extreme-pressure antiwear agent, 0.1-15% of at least one purification dispersant, 0.5-5%of at least one antioxidant, 0.01-1% of at least one metal deactivator, 0-1000 ppm of an antifoaming agent, 0.5-10% of viscosity index improver, and the balance of synthetic base oil and / or mineral base oil. The oil composition special for the low-viscosity manual transmission is specially developed for the manual transmission with the high fuel economy requirement, obtained lubricating oil has excellent extreme-pressure antiwear performance, shear stability performance, oxidation stability performance and shows up excellent fuel economy on the basis of meeting the low-viscosity requirement, and the oil composition is suitable for lubricating the manual transmission with the high fuel economy requirement or a new energy vehicle reduction box.

Owner:CHINA PETROLEUM & CHEM CORP

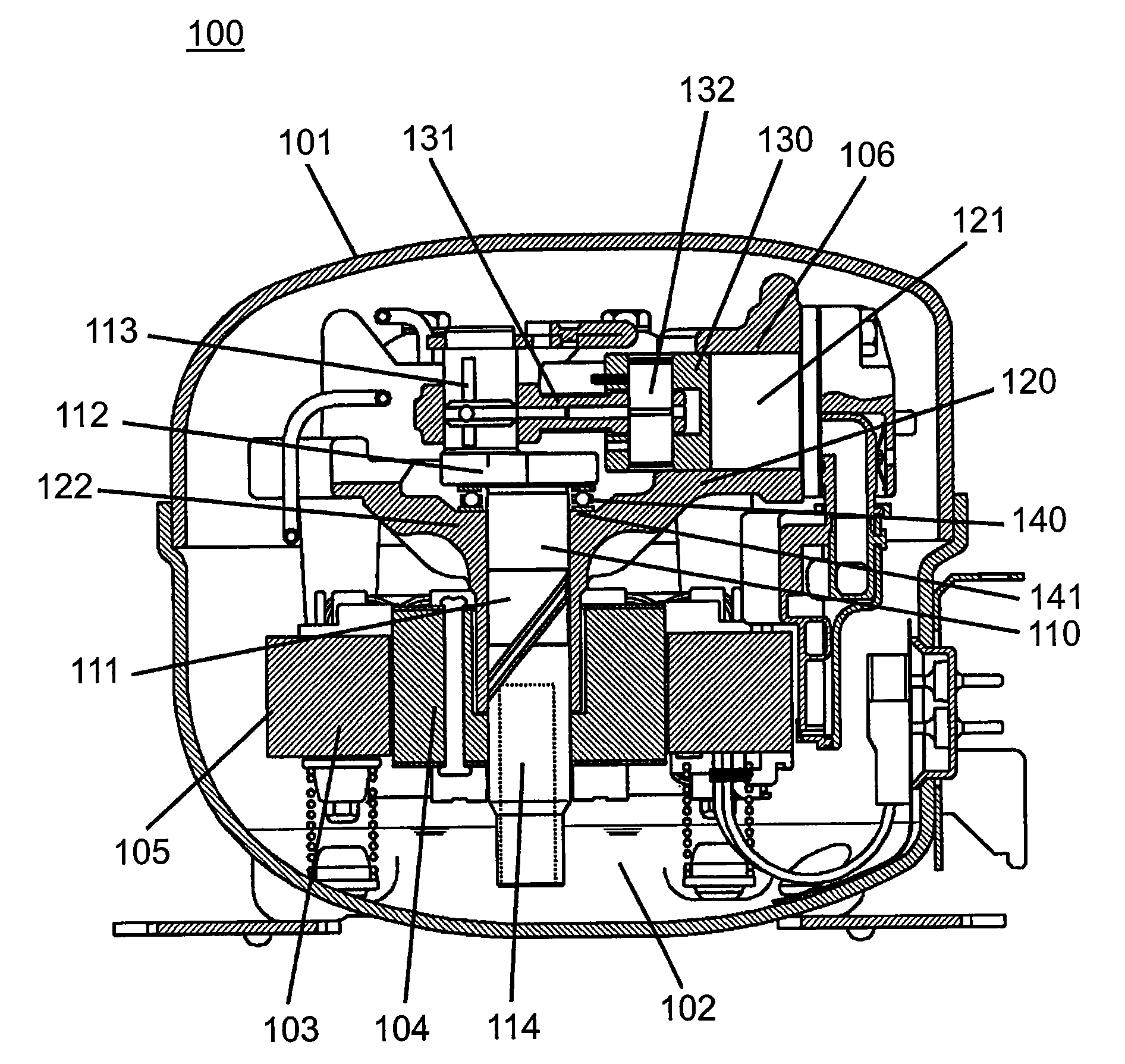

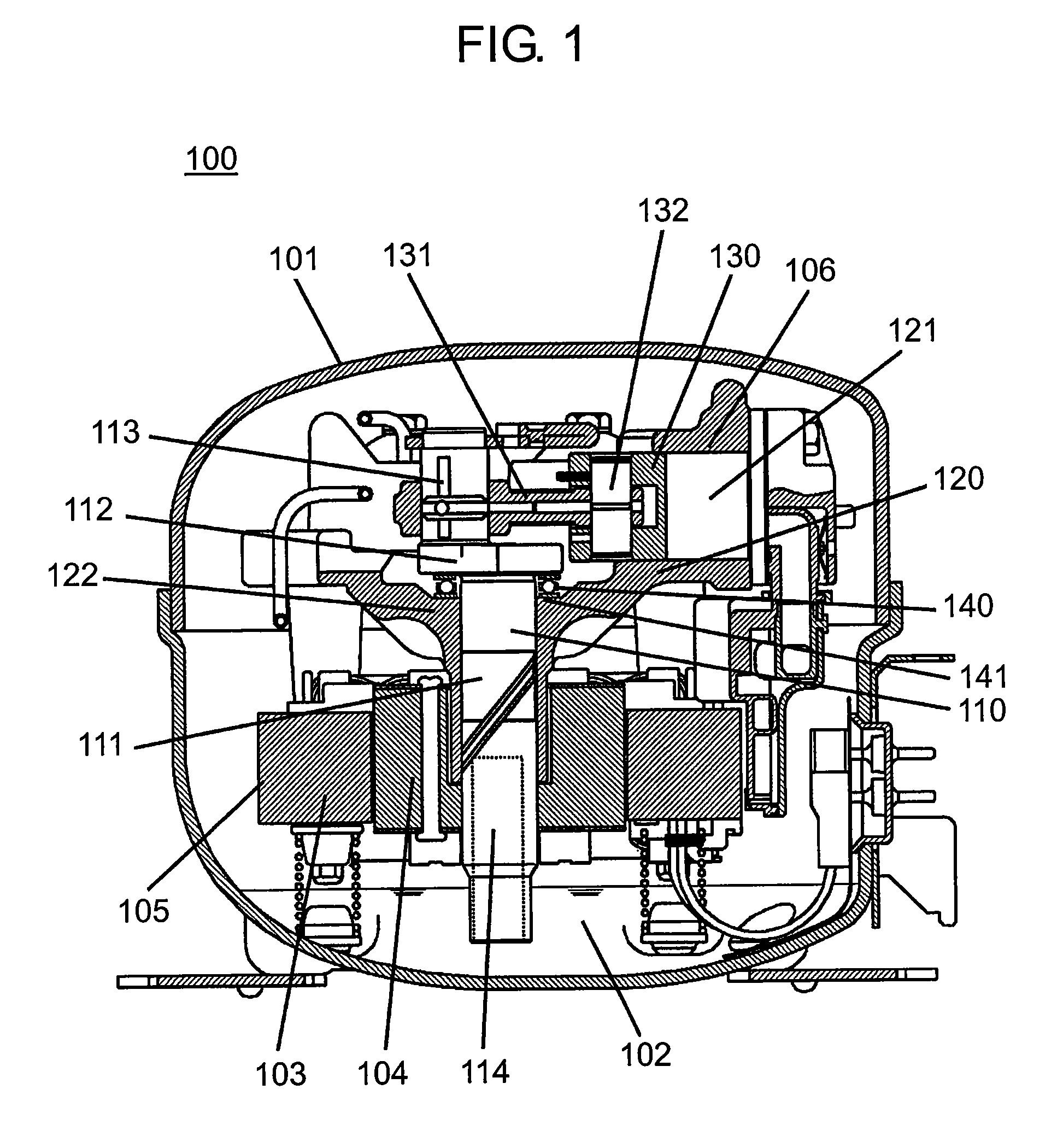

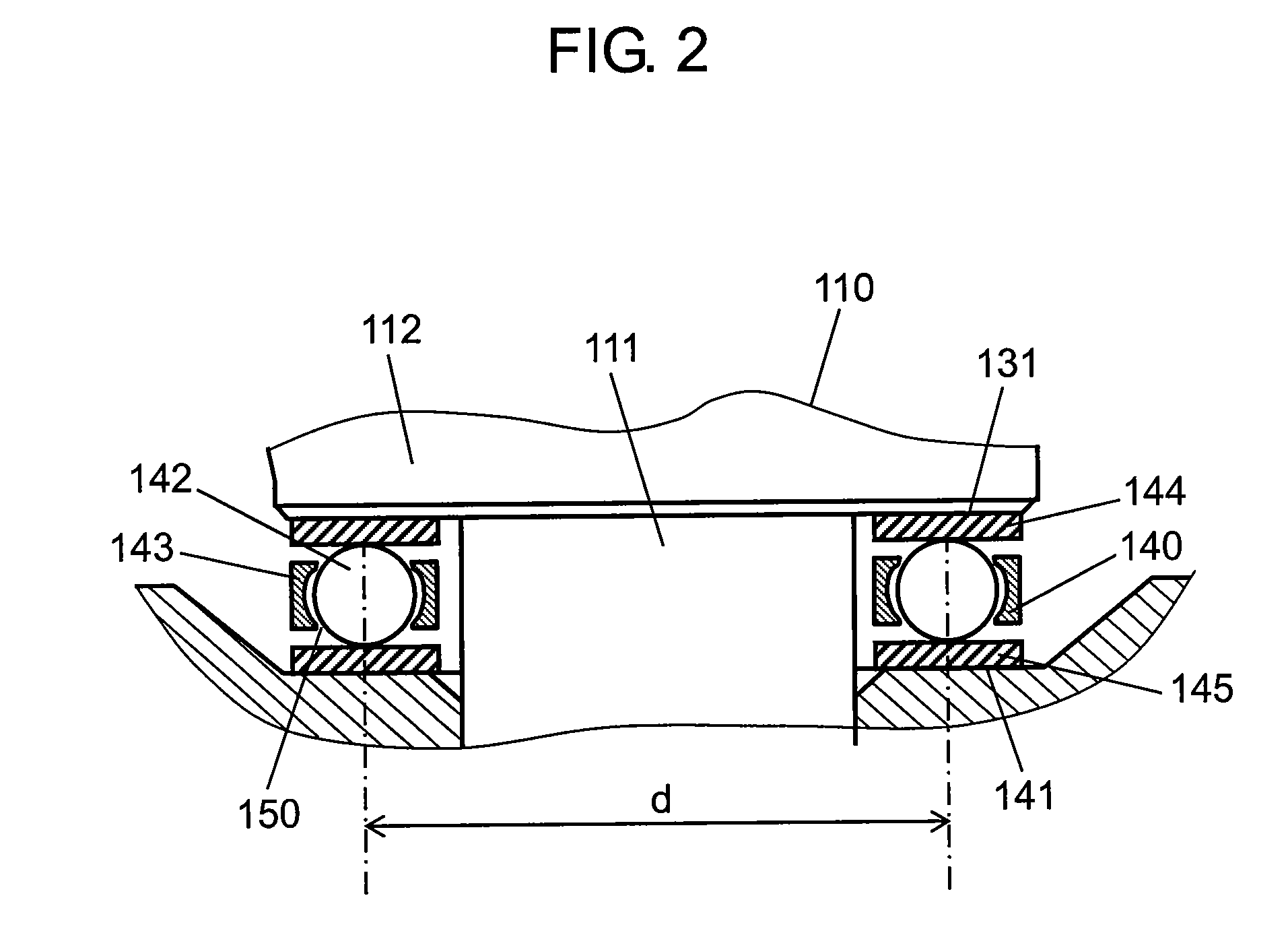

Hermetic reciprocating compressor with thrust ball bearing

InactiveUS20090116982A1Reduce centrifugal forceReduce surface pressurePositive displacement pump componentsBall bearingsBall bearingViscosity grade

A hermetic compressor includes a hermetic container that stores lubricating oil, an electrically-driven element having a stator and a rotor, a shaft having a compressing element driven by the electrically-driven element, and including an eccentric shaft portion, a cylinder block, a piston, a coupling device that connects the piston and the eccentric shaft portion, a main bearing, and a thrust ball bearing that supports a vertical load by the self weight of the rotor and the shaft. The thrust ball bearing includes a plurality of balls having a diameter of 3 mm or less, a holder portion holding the balls and formed of a polymeric material, and an upper washer and a lower washer disposed above and below the balls, respectively, and the viscosity grade of the lubricating oil is from ISO VG3 to ISO VG10.

Owner:PANASONIC CORP

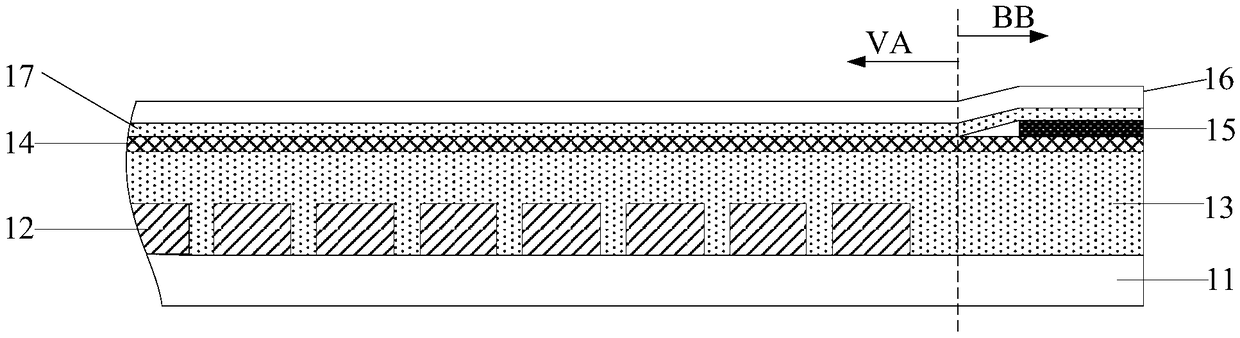

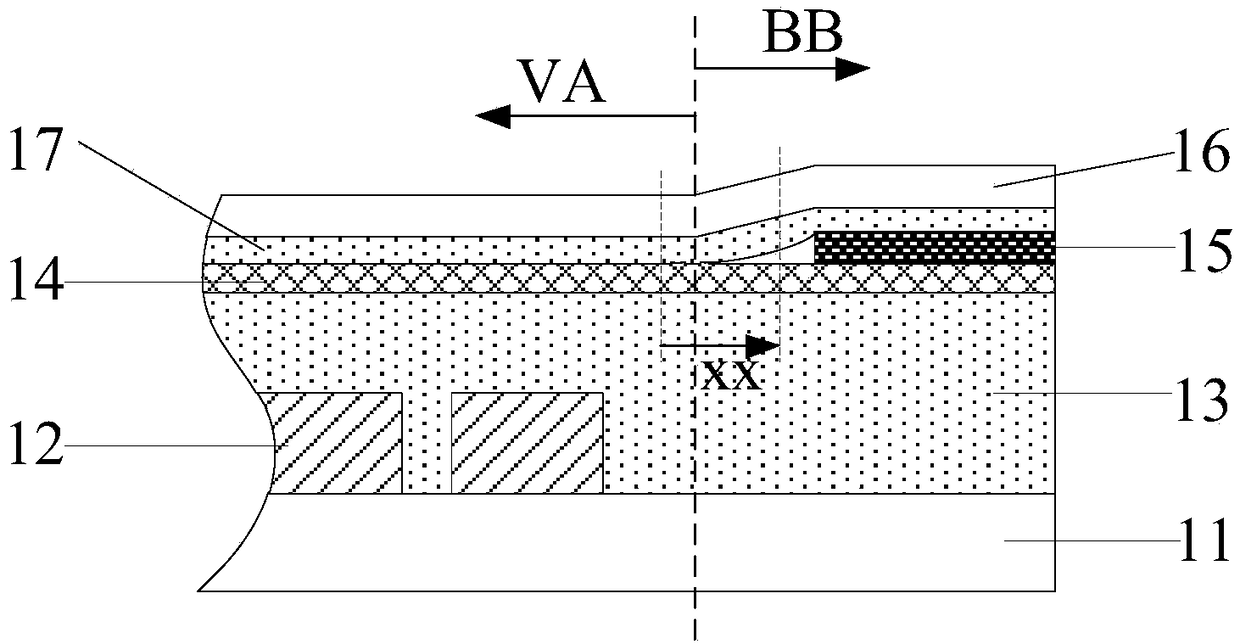

Organic light-emitting display panel, manufacturing method thereof and display device

ActiveCN109148722AAvoid light leakageTightly bondedSolid-state devicesSemiconductor/solid-state device manufacturingViscosity gradeDisplay device

The invention discloses an organic light emitting display panel, a manufacturing method thereof and a display device, the organic light-emitting display panel includes a substrate, a plurality of organic light emitting diode devices located on the substrate, an encapsulation layer located on one side of the organic light emitting diode devices deviating from the substrate, a touch electrode layeron one side of the encapsulation layer deviating from the organic light emitting diode devices, a peripheral circuit on the side of the touch electrode layer facing away from the encapsulation layer,a circular polarizer on the side of the touch electrode layer and the peripheral circuit facing away from the encapsulation layer, and an adhesive layer between the touch electrode layer and the circular polarizer; The touch electrode layer is tightly bonded to the circular polarizer through the adhesive layer in the visible region. The adhesive layer can be a glue material with high viscosity grade, so that the circular polarizer and the touch electrode layer can be tightly bonded in a large range, and there is no gap or bubble in the visible region and the edge position of the visible region, thereby avoiding the light leakage phenomenon of the display panel and improving the display quality.

Owner:BOE TECH GRP CO LTD +1

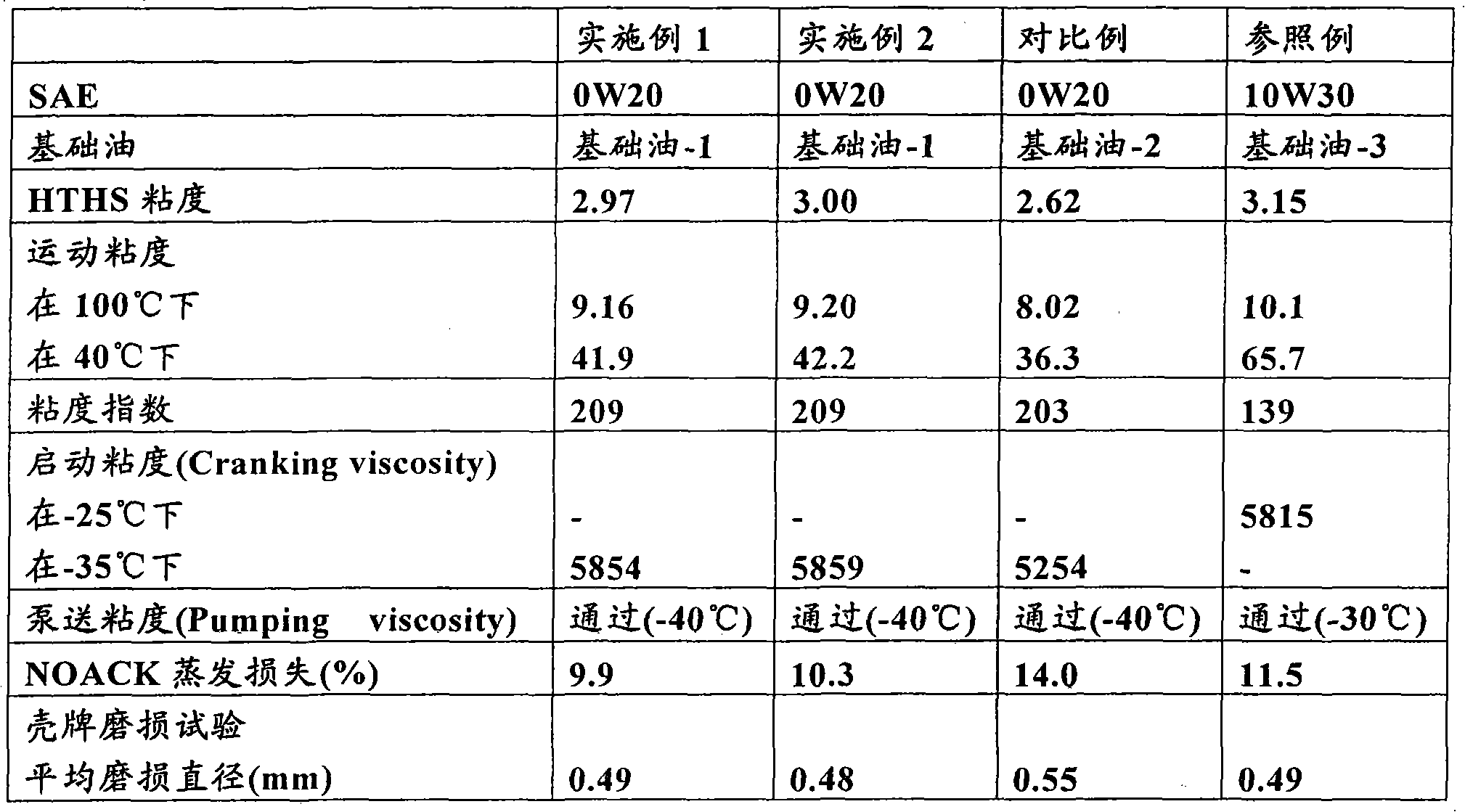

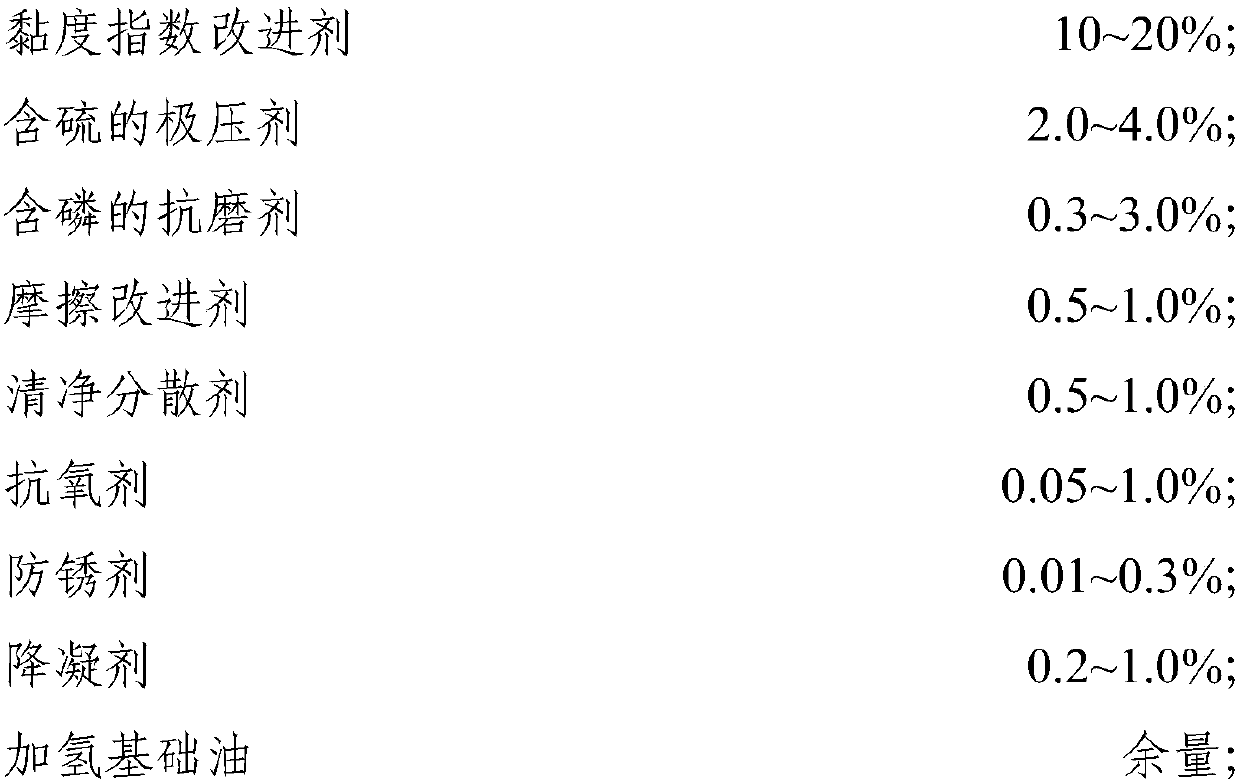

Lubricating oil composition for lubricating automotive engines

ActiveCN102618355AGood wear inhibitionSAE high viscosityAdditivesAlkaline earth metalViscosity grade

A lubricating oil composition of SAE viscosity grade 0W20 which comprises a base oil and additive components comprising a nitrogen-containing ashless dispersant, an alkaline earth metal-containing detergent, a phosphorus-containing wear inhibitor, an oxidation inhibitor and a viscosity index improver and which shows a viscosity index of 200-240, a HTHS viscosity of not less than 2.9 mPas s at 150 DEG C. and a Noack evaporation loss of not more than 13% favorably gives a high fuel economy and high wear inhibition to a four cycle gasoline engine of motorcycles and a diesel engine mounted on motor cars equipped with an exhaust gas post-processing apparatus.

Owner:CHEVRON JAPAN

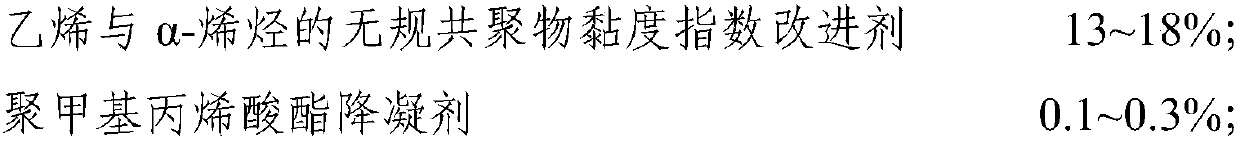

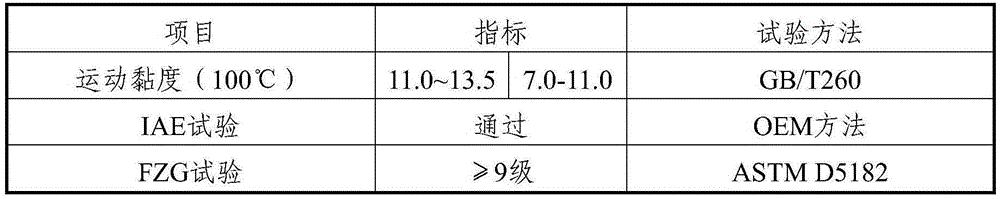

Heavy-duty vehicle gear oil composition with viscosity grade of 75W-90 and application thereof

InactiveCN107868691ASimple ingredientsRaw materials are easy to getLubricant compositionAntioxidantSimple component

The invention relates to a heavy-duty vehicle gear oil composition with a viscosity grade of 75W-90. The composition is composed of the following components in parts by weight: 70-80 parts of hydrogenated base oil, 10-20 parts of a viscosity index improver and 1-20 parts of a complexing agent, wherein the viscosity index improver is a random copolymer of ethylene and alpha-olefin, and the complexing agent comprises one or more selected from a sulfur-containing extreme pressure agent, a phosphorus-containing anti-wear agent, a friction modifier, a detergent dispersant, an antioxidant, an antirust agent and a pour point depressant. The heavy-duty vehicle gear oil composition provided by the invention has excellent performance and a wide application range; the shearing stability performance of heavy-duty vehicle gear oil can be improved to a large extent; and special requirements of clients to the heavy-duty vehicle gear oil with a viscosity grade of 75W-90 can be met. The composition isgood in stability and excellent in low-temperature performance. In addition, the heavy-duty vehicle gear oil composition with a viscosity grade of 75W-90 provided by the invention has simple components, easily acquired raw materials, and a simple and easy preparation method, and has a wide large-scale application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

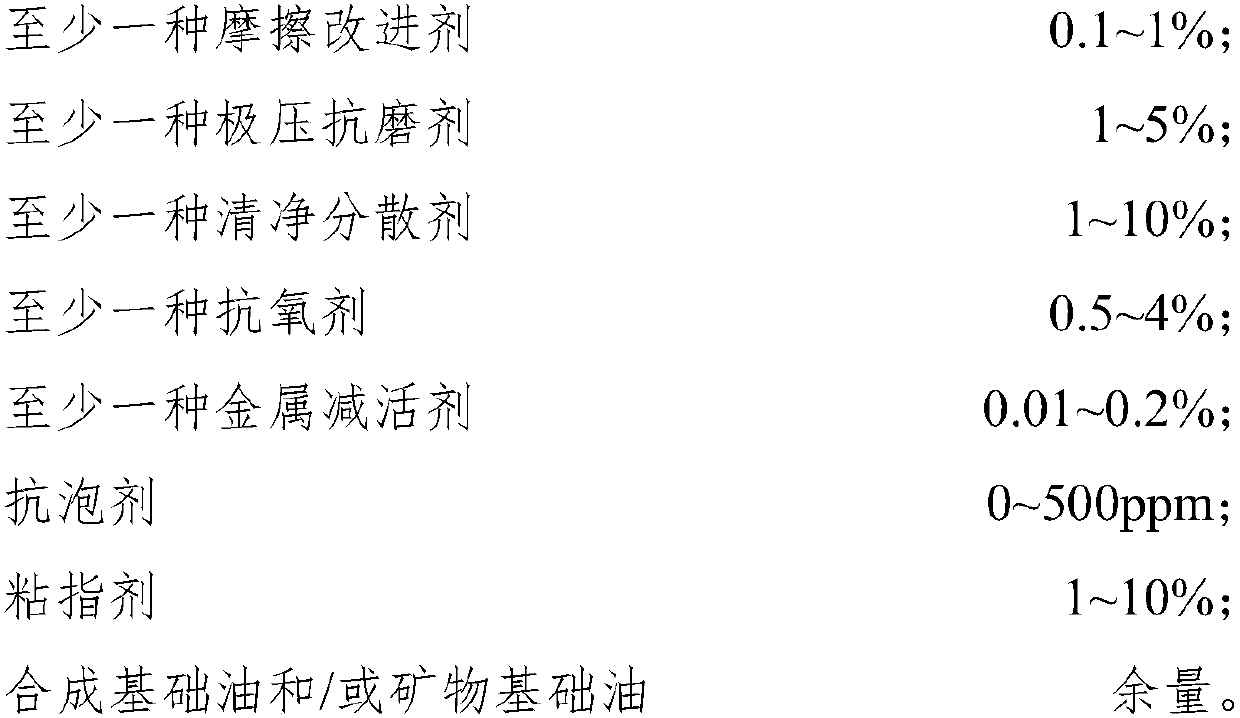

Low-viscosity manual transmission oil composition with extreme pressure and anti-wear behaviors, and application thereof

InactiveCN106609170AImprove performanceSimple ingredientsAdditivesBase-materialsViscosity gradeMetal

The invention relates to a low-viscosity manual transmission oil composition with extreme pressure and anti-wear behaviors. The composition comprises, by weight, 100 parts of manual transmission oil with a viscosity grade of 75 W / 80 or 75 W / 85 and 2 to 5 parts of sulfurized olefin. The manual transmission oil composition provided by the invention has excellent performance and a wide application scope, can greatly improve the extreme pressure and anti-wear behaviors of low-viscosity manual transmission oil for passenger cars, meets the special requirement of clients for the extreme pressure and anti-wear behaviors of low-viscosity manual transmission oil, and is good in stability and low in metal corrosivity. Moreover, the manual transmission oil composition provided by the invention is simple in composition, uses easily available raw materials, is easy to prepare and has good large-scale application prospects.

Owner:CHINA PETROLEUM & CHEM CORP

Special lubricating oil composition for circulatory system of paper machine

ActiveCN103965997AMeet lubrication requirementsMeet lubricationLubricant compositionAntioxidantLubrication

The invention provides a special lubricating oil composition for a circulatory system of a paper machine. The composition comprises: (A) at least one deeply refined mineral oil with high viscosity index or synthetic oil, or arbitrary composition of the above components; (B) at least one sulfurous extreme pressure additive; (C) at least one phosphorus anti-wear additive; (D) at least one emulsifying additive; (E) at least one antifoam additive; (F) at least one metal passivator; (G) at least one antioxidant; and (H) at least one metal detergent. The above lubricating oil composition can meet the requirements of N100, 150, 220 and 320 viscosity grades, has excellent extreme pressure abrasion resistance, filterability, emulsification resistance, foaming resistance, air release property, thermal oxidation stability, rust and corrosion resistance and high temperature detergency, and is applicable to lubrication of the circulatory system of the paper machine.

Owner:PETROCHINA CO LTD

Production method for high-viscosity index lubricant base oil

InactiveCN103102954AReduce in quantitySolve viscosityTreatment with hydrotreatment processesLubricant compositionWaxViscosity grade

The invention relates to a production method for high-viscosity index lubricant base oil. According to the method, wax-bearing oil needing no pre-fractionation is used as a feed for hydrogenation isodewaxing, a viscosity index of the feed is increased by adding wax substance into the feed, so the purpose of producing APIIII lubricant base oil with a viscosity index of more than 120 and of a variety of viscosity grades is achieved. Compared with the prior art, the method provided by the invention has the following advantages: lubricant base oil with a high viscosity index and of a variety of viscosity grades can be obtained, and the method is simple and easily practicable.

Owner:CHINA PETROLEUM & CHEM CORP +1

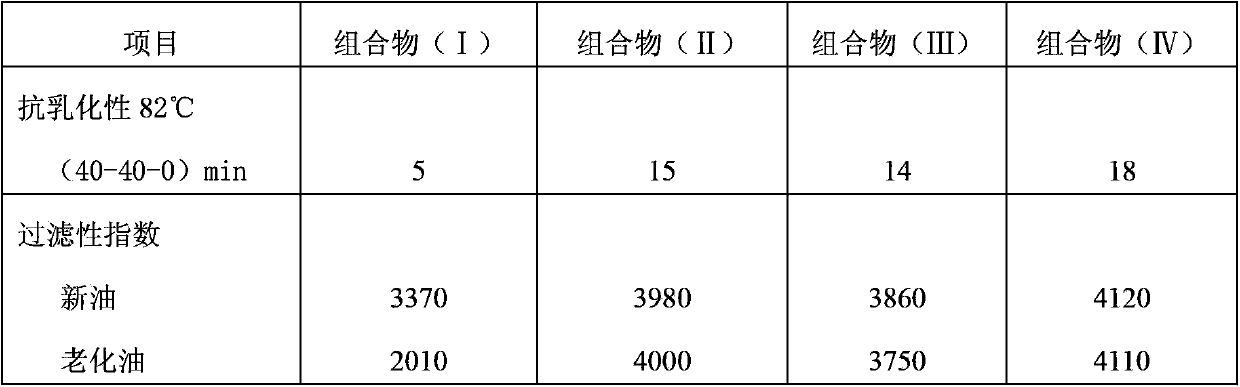

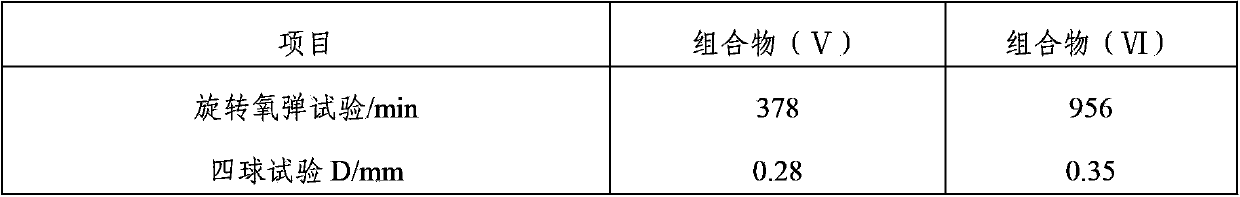

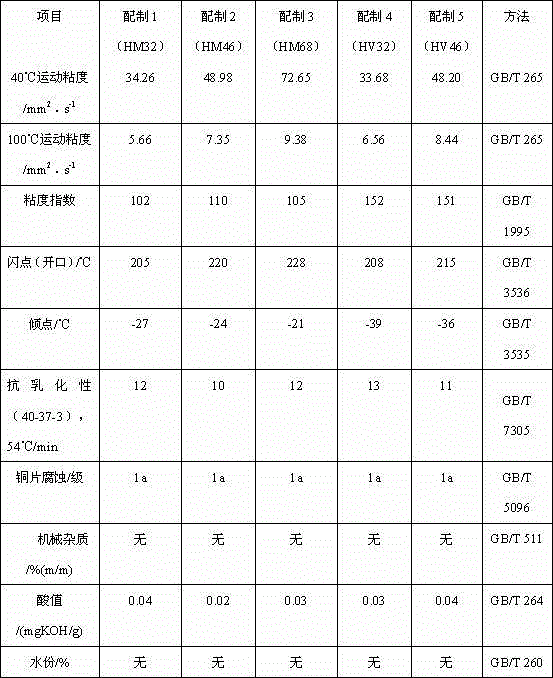

Antiwear hydraulic oil composition produced from reclaimed oil

ActiveCN104694233AHigh viscosity indexModerate viscosityLubricant compositionViscosity gradeEmulsion

The invention provides an antiwear hydraulic oil composition produced from reclaimed oil. The lubricating oil comprises the following materials in parts by weight: 100.0 parts of reclaimed base oil, 0.01-99.0 parts of other base oil, 0.01-10.0 parts of viscosity modifier, 3-10.0 parts of detergent, 1.0-5.0 parts of dispersing agent, 0.5-3.0 parts of antioxidant and corrosion inhibitor, 0.5-3.0 parts of pour point depressant, 0.5-3.0 parts of extreme pressure agent, 1.0-5.0 parts of antirust, 0.0001-0.3 part of emulsion inhibitor and 0.0001-0.01 part of defoaming agent. The antiwear hydraulic oil composition disclosed by the invention meets the property requirements of the viscosity grades 32, 46, 68 and 100 of GB 11118.1-2011 antiwear hydraulic oil.

Owner:XINJIANG FUKE OIL PROD CO LTD

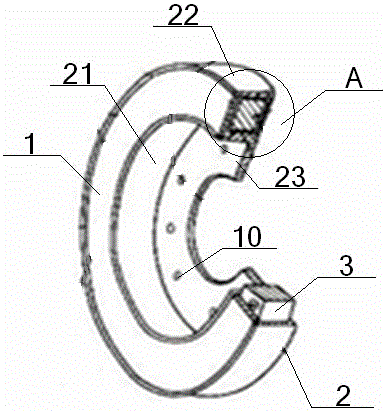

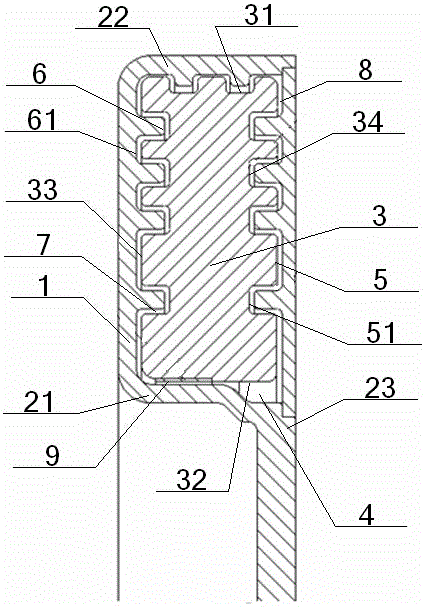

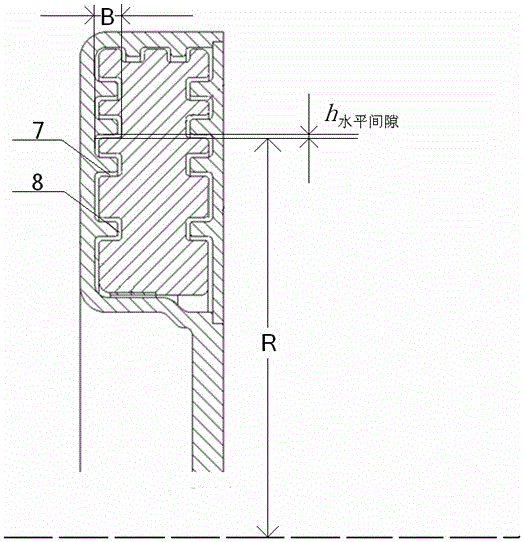

Silicone-oil torsional vibration damper with high rigidity and high damping

InactiveCN105156543AIncrease stiffnessIncrease powerSpringsLiquid based dampersViscosity gradeEngineering

The invention discloses a silicone-oil torsional vibration damper with high rigidity and high damping. The silicone-oil torsional vibration damper comprises a shell, an inertia ring and a side cover which are concentrically arranged, wherein the shell comprises an inner shell wall, an outer shell wall and a side shell wall which are concentrically arranged; two sides of the outer shell wall are respectively connected with two sides of the inner shell wall through the side shell wall and the side cover; silicone oil is injected in a gap between the inertia ring which is arranged in an inner cavity defined by the side cover, the outer shell wall, the side shell wall and the inner shell wall in a sleeving and sliding manner, and the inner cavity; a plurality of tooth slot matches are arranged between a side cover ring surface and the inner wall of the side cover, between a top ring surface and the inner wall of the outer shell wall, and between the side shell ring surface and the inner wall of the side shell wall, in the inertia ring, so that the fluid area between the inertia ring and the inner cavity which relatively move, is enlarged; therefore, the rigidity of the silicone oil and the damping of the silicone oil are improved. Through the adoption of the design of the silicone-oil torsional vibration damper disclosed by the invention, the rigidity of the silicone oil and the damping of the silicone oil can be improved by 1.5-2 times under the premise that the external structure of a conventional vibration damper and the viscosity grade of silicone oil are not changed, so that the vibration damper meets higher requirements for the torsional vibration of shaft systems, and therefore, the torsional vibration damper meets higher requirements for power per liter and detonation pressure.

Owner:DONGFENG COMML VEHICLE CO LTD

Production process of food-grade white oil

InactiveCN111518589AWide variety of sourcesWide application range of processTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystViscosity grade

The invention provides a production process of food-grade white oil. Lubricating oil base oil, industrial white oil, hydrocracked tail oil, hydroisomerized and dewaxed tail oil and the like are used as raw oil, a noble metal catalyst is adopted, a reaction product is obtained through one-stage series hydrogenation, the reaction product is subjected to high-pressure and low-pressure gas-liquid separation and then subjected to vacuum fractionation and side steam stripping, and food-grade white oil products with different viscosity marks are obtained. Compared with the prior art, the method has the advantages that the process flow is simple, the separation precision is high, a reaction system and a fractionation system are reasonably designed and optimally adjusted, the same set of device canbe used, the raw materials with various viscosity grades are fed and produced in a switching manner, and food-grade white oil products with different grades can be obtained according to market requirements.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Automobile transmission oil composition with improved low-temperature transmission performance

InactiveUS20120028857A1Low viscosityReduce rattling noiseOrganic chemistryLubricant compositionViscosity gradeViscosity index

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com