Lubricating oil composition for lubricating automotive engines

A technology for lubricating oil composition and engine, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve the problems of inability to provide high temperature-high shear viscosity, etc., and achieve the effects of good fuel economy and good wear inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

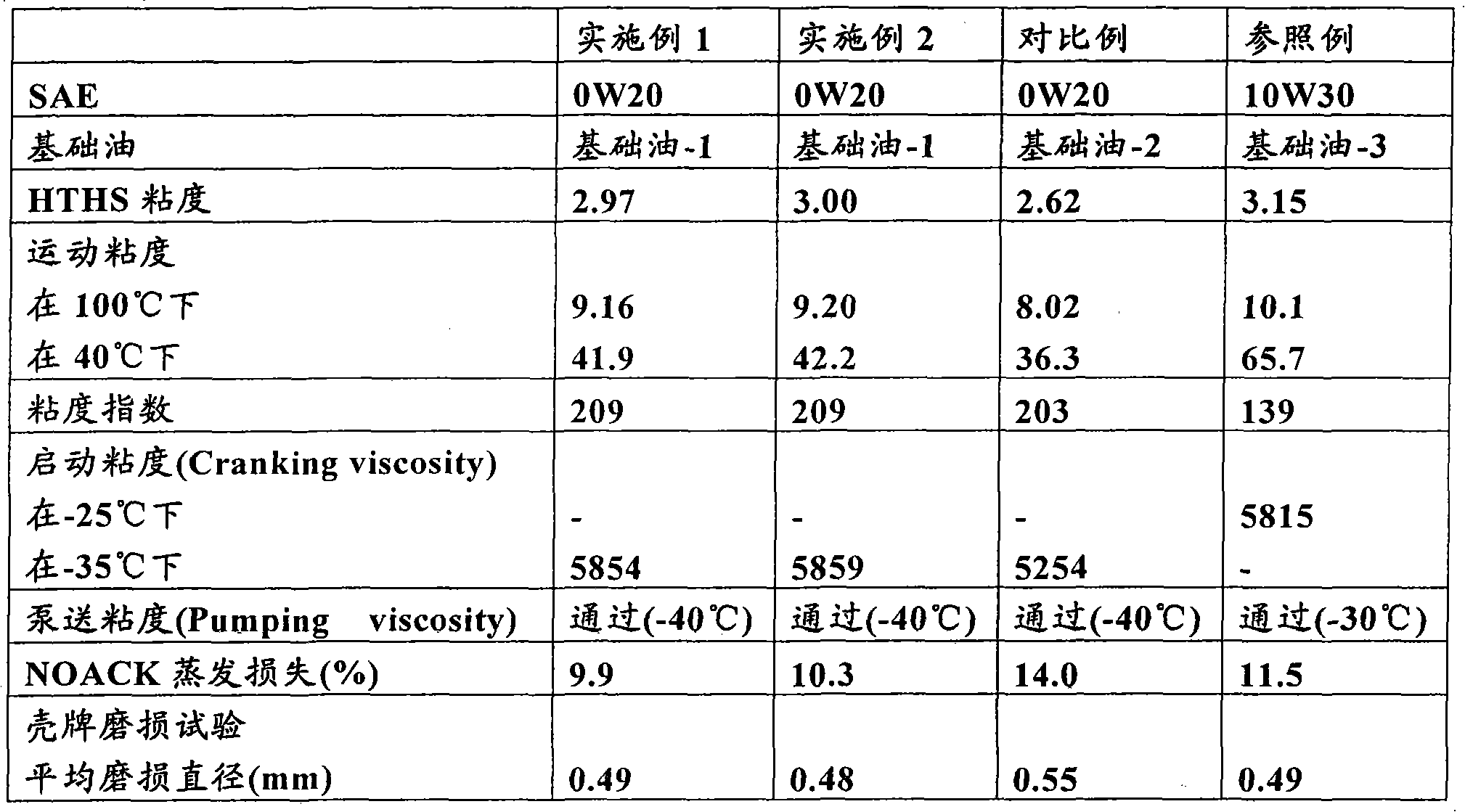

[0080] [embodiment 1, 2, comparative example & reference example]

[0081] (1) Preparation of lubricating oil composition

[0082] The lubricating oil composition of the present invention (SAE viscosity grade: 0W20, high temperature high shear viscosity: 2.9 mPa·s or higher) was prepared using the following additives and base oil in Examples 1 and 2. In a comparative example, a lubricating oil composition (SAE viscosity grade: 0W20, high-temperature high-shear viscosity: 2.6 mPa·s) was prepared. In the reference example, a lubricating oil composition (SAE viscosity grade: 10W30, high-temperature high-shear viscosity: 2.9 mPa·s or higher) was prepared.

[0083] (2) Base oil

[0084] Base oil-1: a mixture of base oil (a) and base oil (b) in a weight ratio of 60:40 (base oil (a): base oil (b), viscosity index: 142; kinematic viscosity at 100°C : 4.9mm 2 / s; NOACK evaporation loss: 10.1%), wherein the base oil (a) is a mineral oil-derived base oil prepared by subjecting slack ...

Embodiment 1

[0104] Example 1 (amount: 5.4wt.%), embodiment 2 (amount: 5.5wt.%) and the polymethacrylate viscosity index improver (SSI=23 ).

[0105] The ethylene-propylene copolymer viscosity index improver (SSI=24) used in the reference example (amount: 4.5 wt.%).

[0106] [Pour point depressant]

[0107] Polymethacrylate pour point depressant: 0.3 wt.%.

[0108] [auxiliary additive]

[0109] For all examples, the sum of small amounts of friction modifiers, rust inhibitors, defoamers, etc.: 0.6 wt.%

[0110] Evaluation of Lubricating Oil Compositions

[0111] Each lubricating oil composition was subjected to a Shell Four Ball Test under conditions of an oil temperature of 75° C., a load of 40 kgf, and rotation at 1,200 rpm for 60 minutes to evaluate its wear inhibiting performance. Wear inhibition performance was evaluated by measuring the wear scars formed on the surface of the tested balls.

[0112] Table 1 shows the physical properties of the lubricating oil compositions of Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com