Patents

Literature

658 results about "Dioctyl sebacate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dioctyl sebacate (di(2-ethylhexyl) sebacate) is an organic compound which is the diester of sebacic acid and 2-ethylhexanol. It is an oily colorless liquid and is used as a plasticizer, including in the explosive C4. It has also found use in Dot 5 brake fluid. Furthermore, the substance is also commonly used as seed particle for PIV.

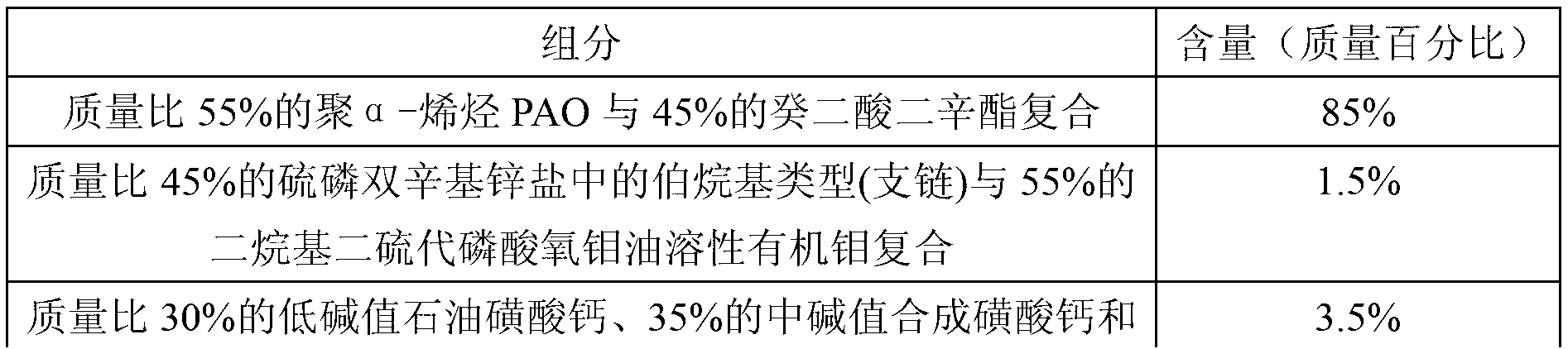

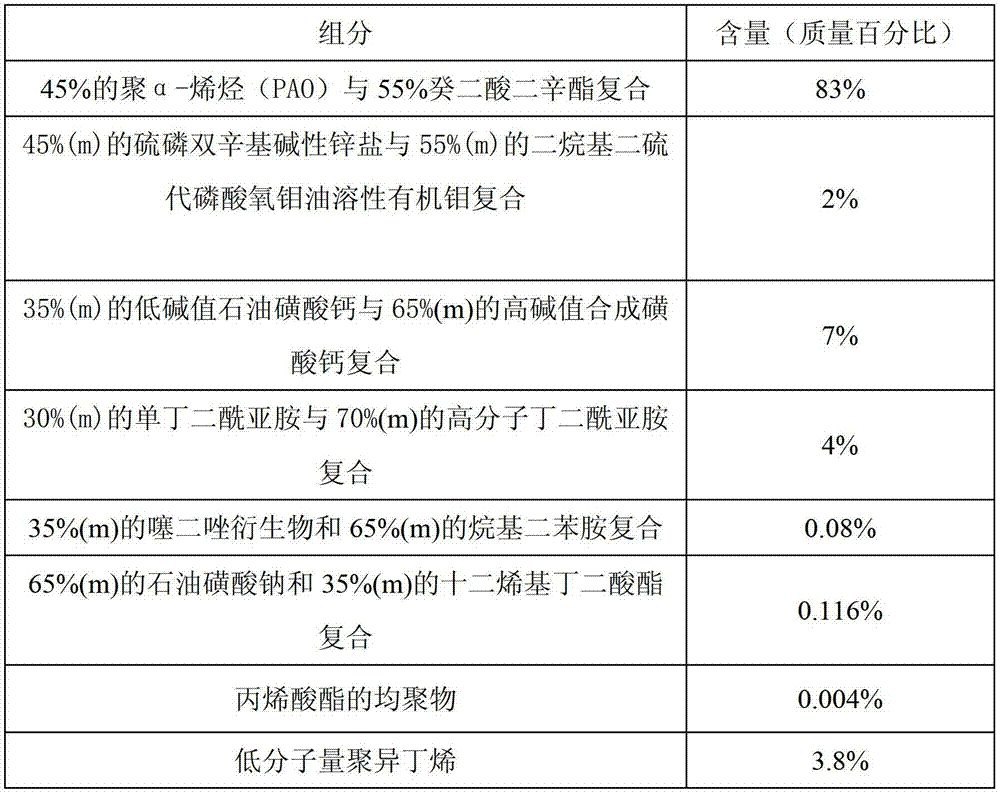

Universal oil composition for environment-friendly energy-saving engineering machinery

The invention discloses a universal oil composition for environment-friendly energy-saving engineering machinery. The universal oil composition comprises the following components according to mass percent: 85%-90% of composite base oil and 15%-10% of other additives. The universal oil composition for the environment-friendly energy-saving engineering machinery adopts a poly-alpha-olefin (PAO) and dioctyl sebacate composition as the base oil, is good in comprehensive performance, can replace diesel engine oil, hydraulic oil, gear oil, hydraulic transmission fluid and other various unit oil used in the engineering machinery, achieves multiple purposes, increases the power of a diesel engine, improves the reliability, the fuel economy and the low-temperature start performance of the diesel engine and the working efficiency and the precision of a hydraulic system, and effectively prolongs the service life and the oil draining period of the hydraulic system, the diesel engine, a gear system, a hydraulic transmission system and other various units.

Owner:GUANGXI UNIV

High cold resistance polyvinyl chloride cable material and preparation method thereof

InactiveCN101260214AEasy to useExpand the usable rangeInsulated cablesInsulated conductorsPolyvinyl chlorideEngineering

The invention provides a polyvinyl chloride (PVC) cable material used in gelid state (minus 50 DEG C to minus 70 DEG C) and a preparation method of the cable material. During use, the cable material does not split and can be bent normally, thereby greatly increasing the application range of products. Moreover, the cable material is made from the following raw materials in portions by weight: PVC of 80 to 100 portions, dioctyl phthalate of 20 to 40 portions, dioctyl sebacate of 60 to 80 portions, dioctyl butane dicarboxylic acid of 4 to 8 portions, light activated calcium carbonate of 20 to 40 portions, lubricant of 1 to 3 portions , Ca-Zn composite stabilizer of 4 to 8 portions, antioxidant 1010 of 1 to 4 portions, frost resisting agent K175C of 0.5 to 5 portions and nitrile butadiene rubber of 20 to 50 portions.

Owner:WUXI DONGTIAN CABLE

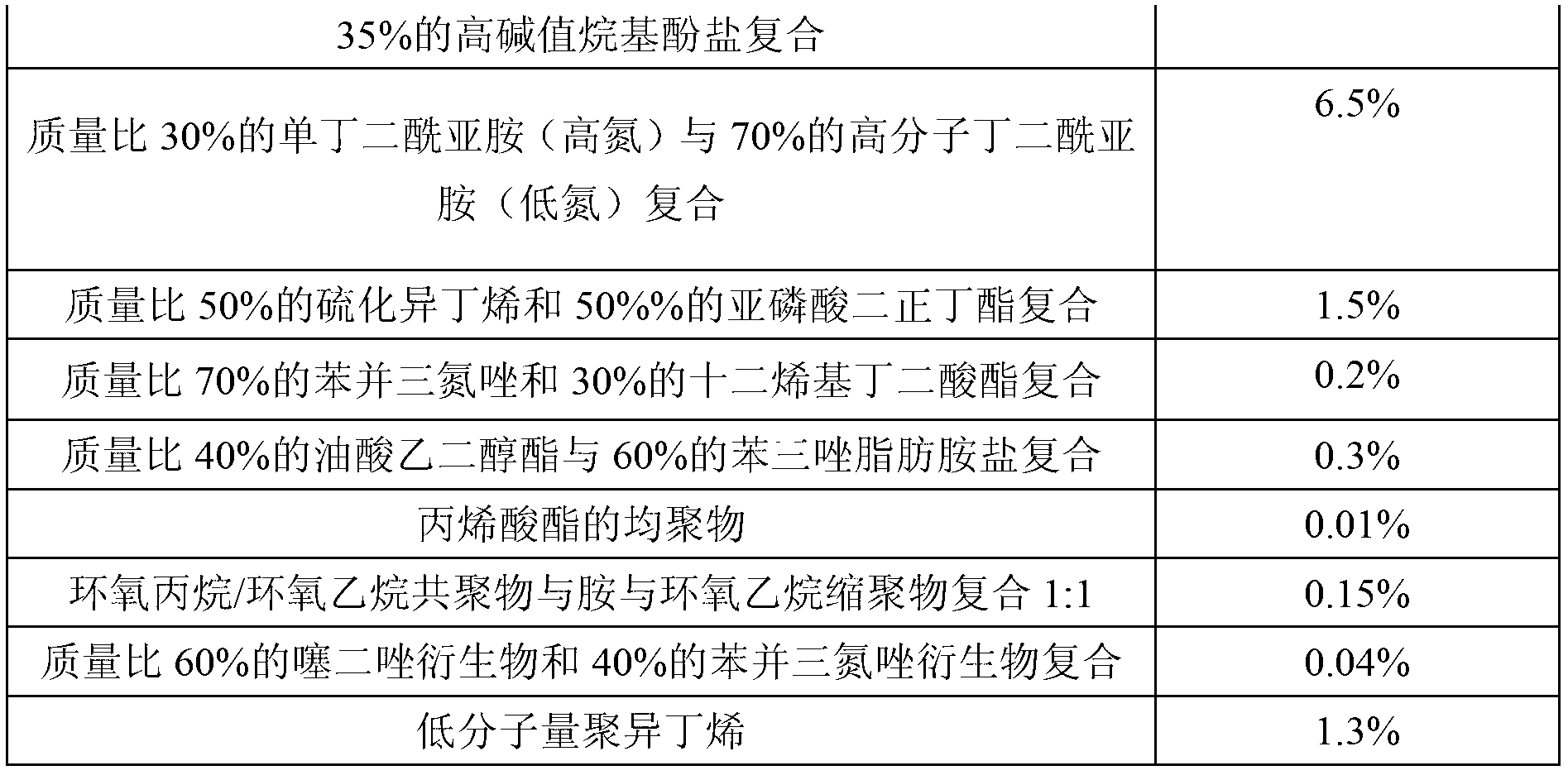

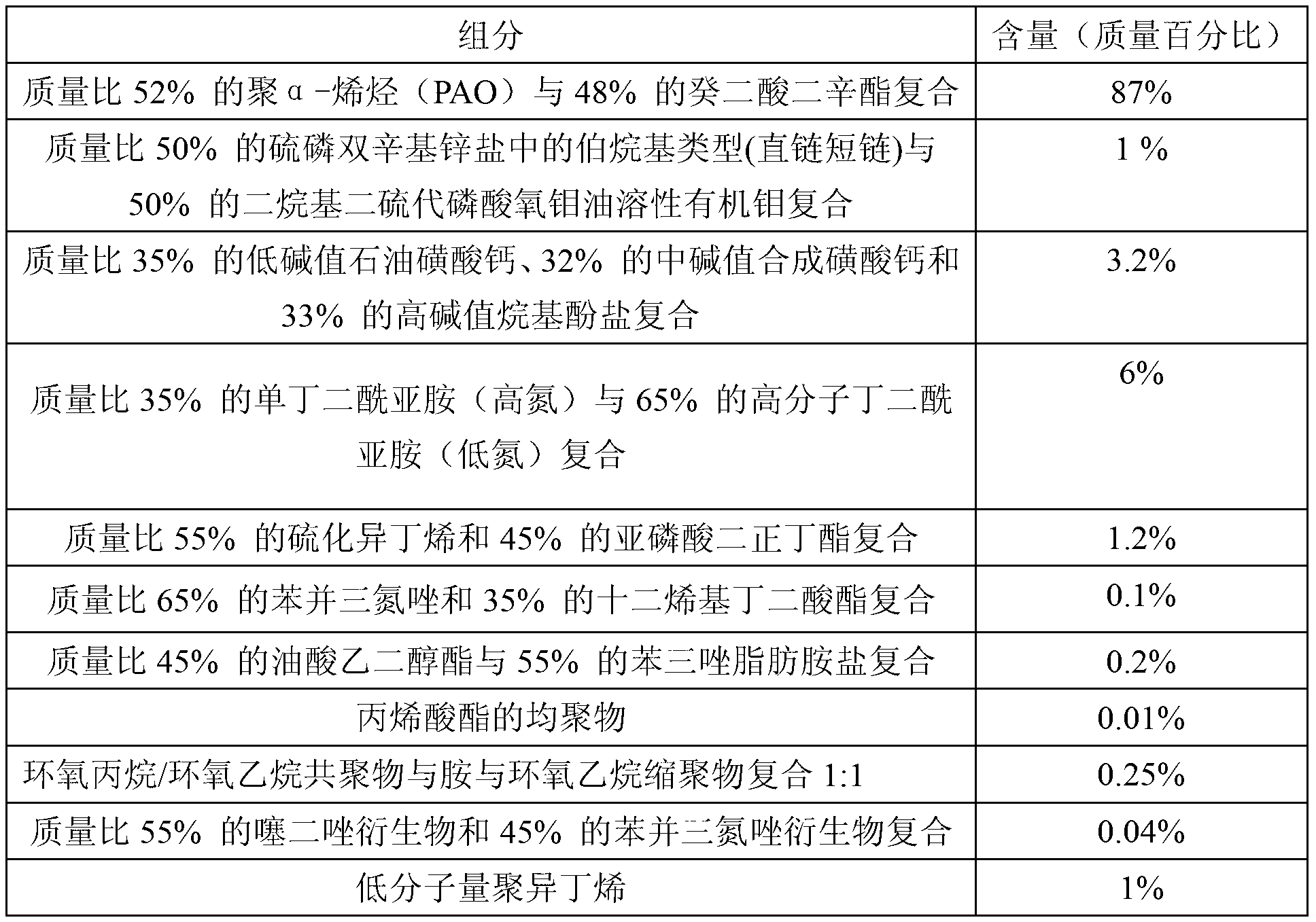

Environment-friendly and energy-saving gasoline engine lubricating oil

The invention discloses environment-friendly and energy-saving gasoline engine lubricating oil, which is composed of composite base oil, a composite oxidation and a corrosion inhibitor, a composite metal detergent, a composite ashless dispersant, a metal passivator, an antirusting agent, an antifoaming agent and a viscosity index improver, wherein the base oil is compounded from poly-alpha-olefin (PAO) and dioctyl sebacate. With the adoption of the gasoline engine lubricating oil, energy conservation, long oil change period, and reduction for waste oil, waste gas and particulate matters are realized, biodegradability is high compared with the traditional lubricating oil, the fuel economy of an engine is improved, the service life of the engine is prolonged, and the generation of oil sludge and carbon deposition in the engine can be inhibited; and the base oil technical requirements of quality grade specifications SG, SH, SJ, SL, SM and SN of gasoline engine lubricating oil, and the performance requirements of multi-grade oil with viscosity grades 0W, 5W, 10W, 15W, 20W and the like can be met.

Owner:广西谛恒生物能源投资有限公司

High-performance complex calcium sulfonate grease and preparation method thereof

InactiveCN101824357AImprove high temperature resistanceGood mechanical stabilityLubricant compositionAntioxidantDioctyl sebacate

The invention discloses high-performance complex calcium sulfonate grease and a preparation method thereof. The complex calcium sulfonate grease comprises the following components: 35 to 80 percent of base oil, 10 to 40 percent of ultrahigh-base-number synthetic calcium sulfonate, 0.5 to 2 percent of antioxidant and 0.5 to 20 percent of transforming agent, wherein the base oil is dicarboxylic acid diester, dioctyl sebacate, dioctyl adipate and the like; the ultrahigh base number of the ultrahigh-base-number synthetic calcium sulfonate is between 380 and 420mgKOH / g; and the synthetic calcium sulfonate comprises the following complex components: 0.5 to 8 percent of C12 to C24 hydroxy fatty acid, 0.5 to 4 percent of boric acid and 0.5 to 2 percent of calcium hydroxide. The complex calcium sulfonate based grease has high-temperature resistance, high mechanical stability and high extreme-pressure abrasion resistance, reduces the using amount of the transforming agent such as alcohol, ether and the like and environmental pollution in the production process, and improves the efficiency of transforming Newtonian high-base-number calcium sulfonate into non-Newtonian high-base-number calcium sulfonate completely, so that the production technology is simpler.

Owner:李墨菊

High-cold-resistant insulated cable material and preparation method thereof

ActiveCN103351520AImprove cold resistanceImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesMorpholineTriethoxysilane

The invention provides a high-cold-resistant insulated cable material and a preparation method thereof. The materials is characterized by comprising the following raw materials by weight parts: 14-19 parts of ethylene propylene diene monomer (German Lanxess 9650), 68-70 parts of ethane-vinyl acetate copolymer, 15-20 parts of wollastonite powder, 2-3 parts of zinc oxide, 1-2 parts of magnesium oxide, 1-2 parts of an accelerator DTDM, 1-2 parts of an accelerator TMTM, 1-2 parts of an antioxidant ODA, 4-6 parts of dioctyl sebacate, 2-3 parts of amino propyl triethoxysilane, 1-2 parts of methyl triethoxysilane, 10-20 parts of carbon black N 339, 5-15 parts of carbon black N 660, 3-4 parts of zinc stearate, 1-2 parts of morpholine, and 6-8 parts of modified diatomite. According to the invention, the dioctyl sebacate is used as a plasticizer to improve cold-resistant performance of the cable material; and the cable material is relatively good in insulating property and high-temperature-resistant performance.

Owner:ANHUI CABLE

No-cleaning leadless solder and preparation method thereof

InactiveCN101391350AAffect physical propertiesImprove liquidityWelding/cutting media/materialsSoldering mediaBenzyl benzoatActive agent

The invention relates to a no-clean lead-free tin welding wire and a preparation method thereof, wherein the lead-free welding wire is composed of 2 to 3 percent of flux and 97 to 98 percent of lead-free solder. The lead-free solder is composed of 0.5 to 0.7 percent of Cu, 0.03 to 0.05 percent of Ni, 0.01 to 0.02 percent of P, 0.005 to 0.01 percent of Ga and the remnant amount of Sn. The No-clean flux is composed of 1.0 to 4.0 percent of organic acid active agent, 0.5 to 5.0 percent of halogenated derivative active solvent, 2.0 to 5.0 percent of heat-resistant resin , 1.0 to 4.0 percent of cosolvent, 2.0 to 5.0 percent of high boiling point solvent and the remnant amount of modified rosin. The cosolvent belongs to ester compound and the high boiling point solvent is the mixed solvent of one or more of the SAF-25, dioctyl sebacate, benzyl benzoate, dioctyl adipate. In the preparation of the welding wire, the key point is first to form the alloys of Sn with other metals, and then the alloys can be added to the tin for melting. The lead-free welding wire of the invention has good heat resistance without halogen, low flux spattering, low odor, non-corrosive flux residue, strong practical feature, good electrical insulation after being welded, crack-free flux residue and high reliability.

Owner:太仓市首创锡业有限公司

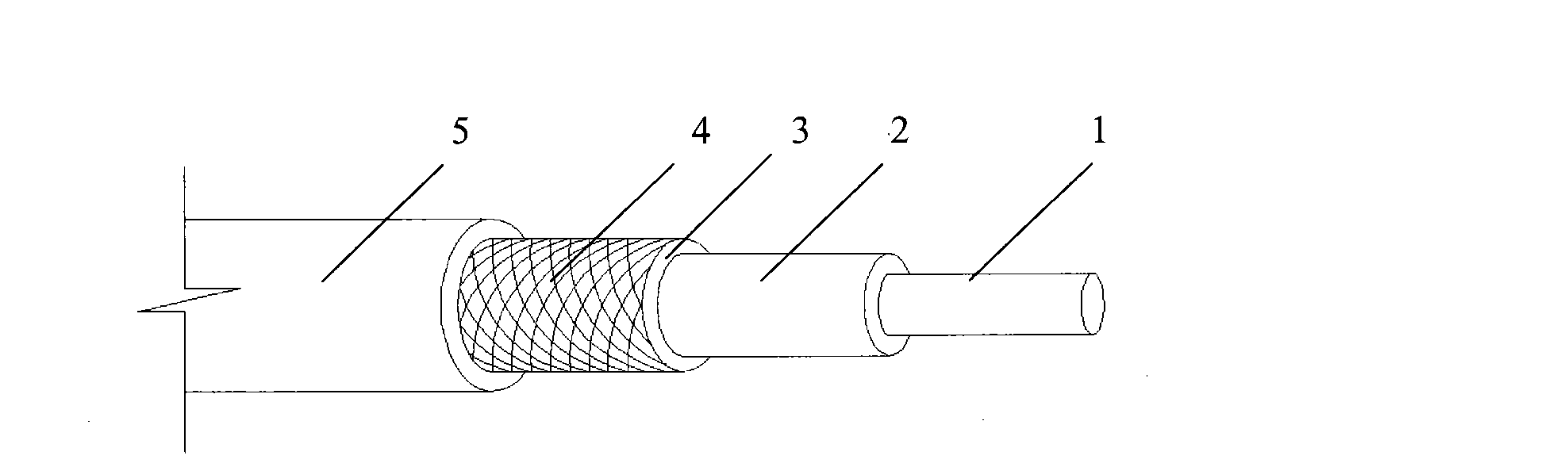

Ultra-high-pressure steel wire winding composite hose

ActiveCN104100783AImprove stress resistanceImprove pulse lifeFlexible pipesPolymer scienceMicrocrystalline wax

The invention discloses an ultra-high-pressure steel wire winding composite hose, which comprises an inner rubber pipe, a framework layer, a middle rubber layer and an outer rubber layer, wherein the framework layer is arranged outside the inner rubber pipe, the middle rubber layer and the framework layer are made into a whole, the outer rubber layer is arranged outside the middle rubber layer, inner rubber of the inner rubber pipe is prepared from the following ingredients including nitrile rubber, high styrene rubber, solution polymerized styrene-butadiene rubber, sulphur S, vulcanizing agents DTDM, vulcanization accelerators CZ, accelerators D, nanometer zinc oxides, stearic acid, scorch retarders CTP, flowing exhaust agents SC617, integral anti-aging agents 4020, anti-aging agents BLE, microcrystalline wax, carbon black, nanometer silicon dioxide, bonding agents RC, bonding agents RC-23, tackifying resin SP1068, dioctyl sebacate and polyolefin, and the middle rubber layer and the outer rubber layer are respectively made of different materials. The rubber pipe belongs to the ultra-high-pressure steel wire winding composite hose capable of bearing the pressure as high as 50 to 300 Mpa, and belongs to an ultra-high-pressure hydraulic rubber pipe meeting the requirements of engineering machinery and oil drilling.

Owner:河南亿博科技股份有限公司

Modified EPT rubber packing material and preparation method thereof

The modified ethylene propylene terpolymer sealing material and its preparation process belong to the field of rubber polymer material technology. The modified ethylene propylene terpolymer sealing material is prepared with ethylene propylene terpolymer, carbon black, zinc oxide, stearic acid, antiager 2, 2, 4-trimethyl-1, 2-dihydro quinoline, dioctyl sebacate, sulfur and promoter paraffin in certain weight proportion, and through compounding material, banburying, roll mixing, vulcanizing and other technological steps. It is applied in making rubber parts in apparatus for storing, transporting, loading and unloading methane, liquefied gas and other fuel, and automobile engine. It has high elasticity, high heat stability, high oil resistance and other advantages.

Owner:安阳市鑫河科技研究院有限责任公司

Butyronitrile-PVC (polyvinyl chloride) compound elastomer flame-retardant sheath material for wires and cables and manufacturing method of butyronitrile-PVC compound elastomer flame-retardant sheath

InactiveCN103205033AImprove air tightnessDelay agingInsulated cablesInsulated conductorsElastomerPolyvinyl chloride

The invention discloses a butyronitrile-PVC (polyvinyl chloride) compound elastomer flame-retardant sheath material for wires and cables and a manufacturing method of the butyronitrile-PVC compound elastomer flame-retardant sheath material. The butyronitrile-PVC (polyvinyl chloride) compound elastomer flame-retardant sheath material is composed of, by weight, 100-120 parts of butyronitrile rubber, 40-45 parts of PVC resin, 1-2 parts of sulfur, 0.1-0.2 part of accelerant TMTD, 1-1.5 parts of accelerant CZ, 2-3 parts of antiager, 15-20 parts of antimonous oxide, 5-7 parts of zinc oxides, 1-2 parts of stearic acid, 12-14 parts of DOP (dioctyl-phthalate), 6-8 parts of DOS (dioctyl sebacate), 15-18 parts of TCP (tertiary calcium phosphate), 0.5-0.8 part of zinc stearate, 1-1.5 parts of barium stearate, 0.1-0.2 part of bisphenol A, 2-2.5 parts of butyl ester, 2.5-3 parts of carbon black master batch, 15-20 parts of modified diopside and 25-30 parts of semi-reinforced carbon black. The flame-retardant sheath material has the advantages of good mechanical and physical performance, good high and low temperature resistance, oil resistance, solvent resistance, wear resistance, ozone resistance, ageing resistance, flame retardancy, low smoke and the like and is long-lasting, durable, environment-friendly and pollution-free.

Owner:ANHUI HUAJIN CABLE GROUP

Rubber composite containing graphene oxide

The invention relates to a rubber composite containing graphene oxide. The rubber composite is characterized by comprising the following raw materials in parts by weight: 100 parts of chlorosulfonated polyethylene, 10-15 parts of ethylene-vinyl acetate rubber (EVM), 20-25 parts of hydrogenated butadiene-acrylonitrile rubber (HNBR), 0.5-5 parts of graphene oxide, 30-70 parts of hard carbon black with mean grain size of 15-25nm, 1-10 parts of dioctyl sebacate (DOS), 3-6 parts of zinc oxide, 3-6 parts of stearic acid, 0.5-4 parts of N,N-nickel dibutyl dithiocarbamate, 1-4 parts of dipentamethylenethiuram hexasulfide, 0.5-4 parts of PbO and 1-6 parts of insoluble sulfur. The rubber composite has the beneficial effects that by using the chlorosulfonated polyethylene, EVM and HNBR with low acrylonitrile content simultaneously, the rubber composite perfectly balances fuel oil resistance and low temperature resistance, distorts 2000 cycles under the low temperature condition of minus 55 DEG C, is free of cracks and distortion on the surface, and is suitable for alpine and low-temperature regions.

Owner:滁州旭中化工有限公司

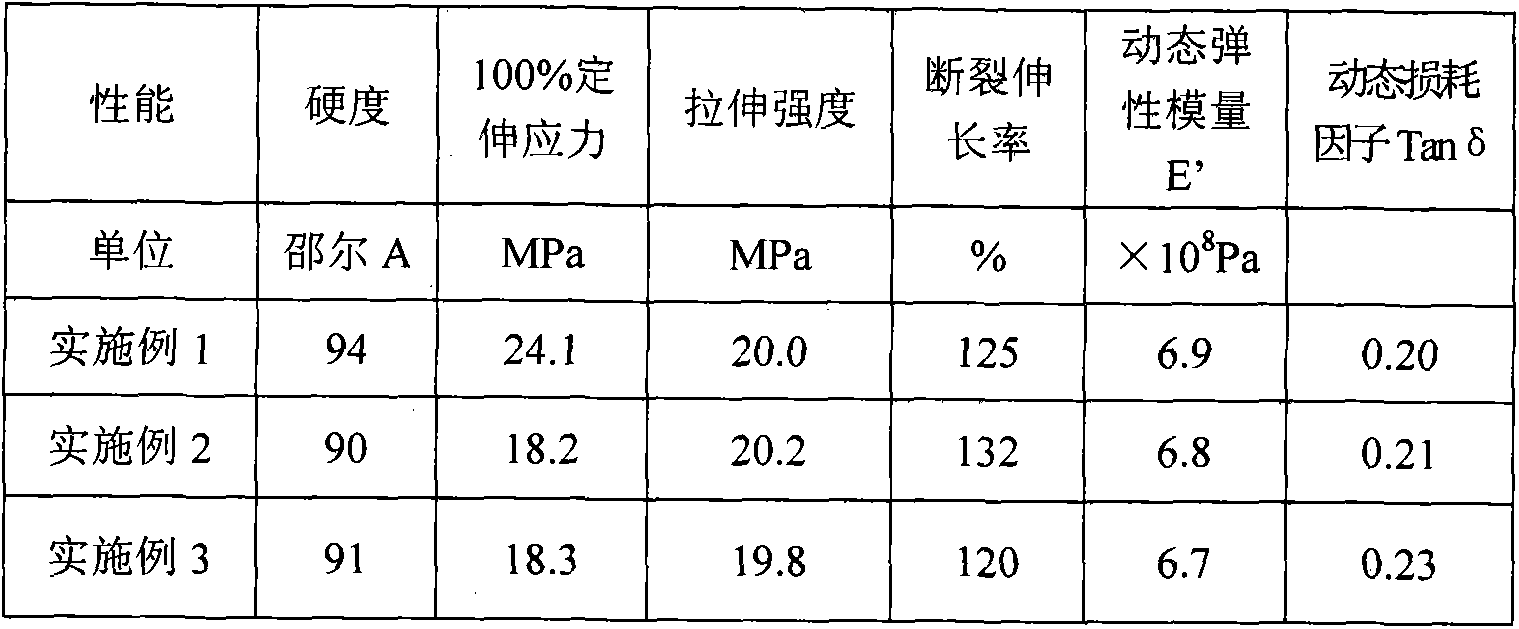

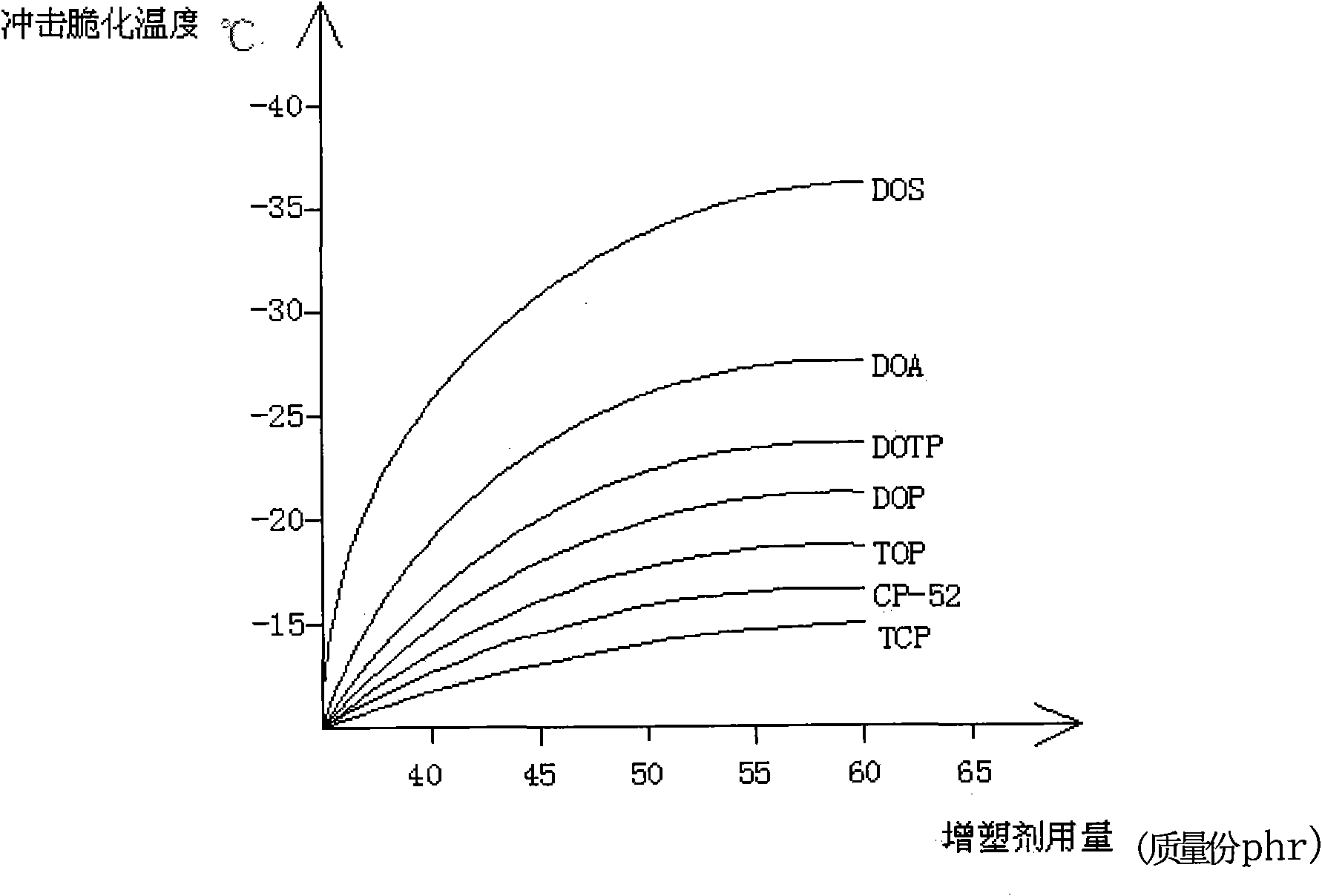

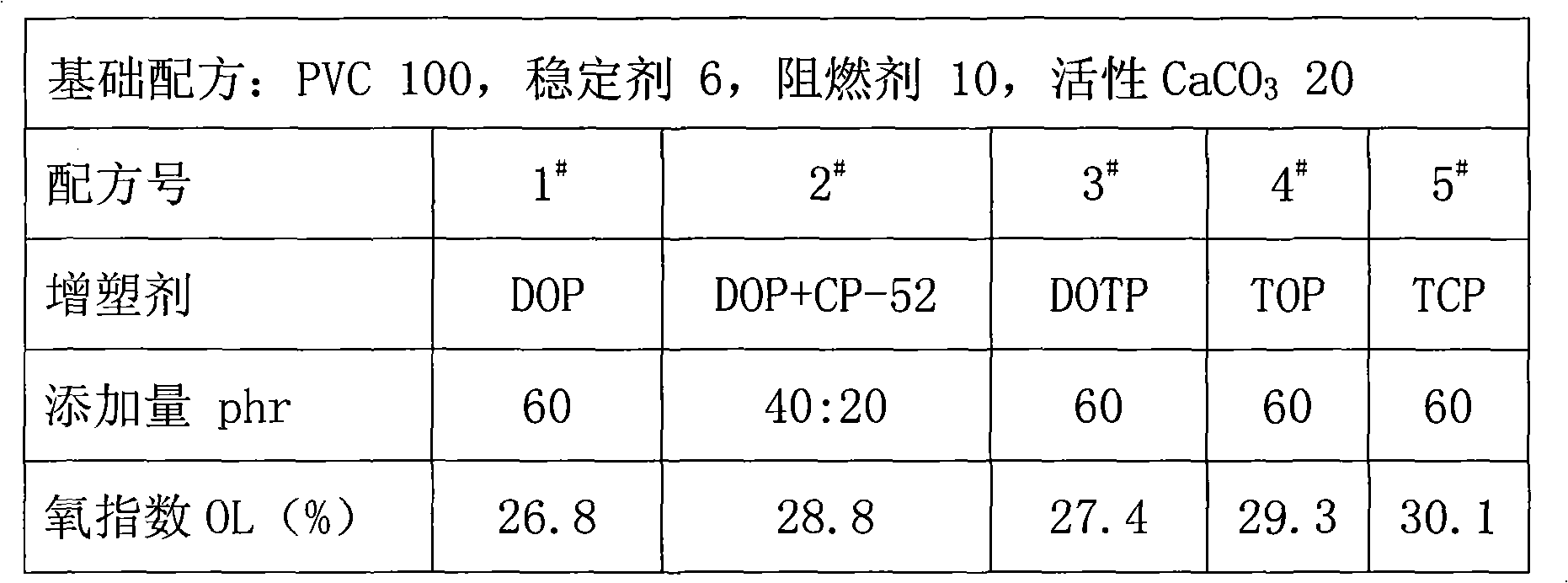

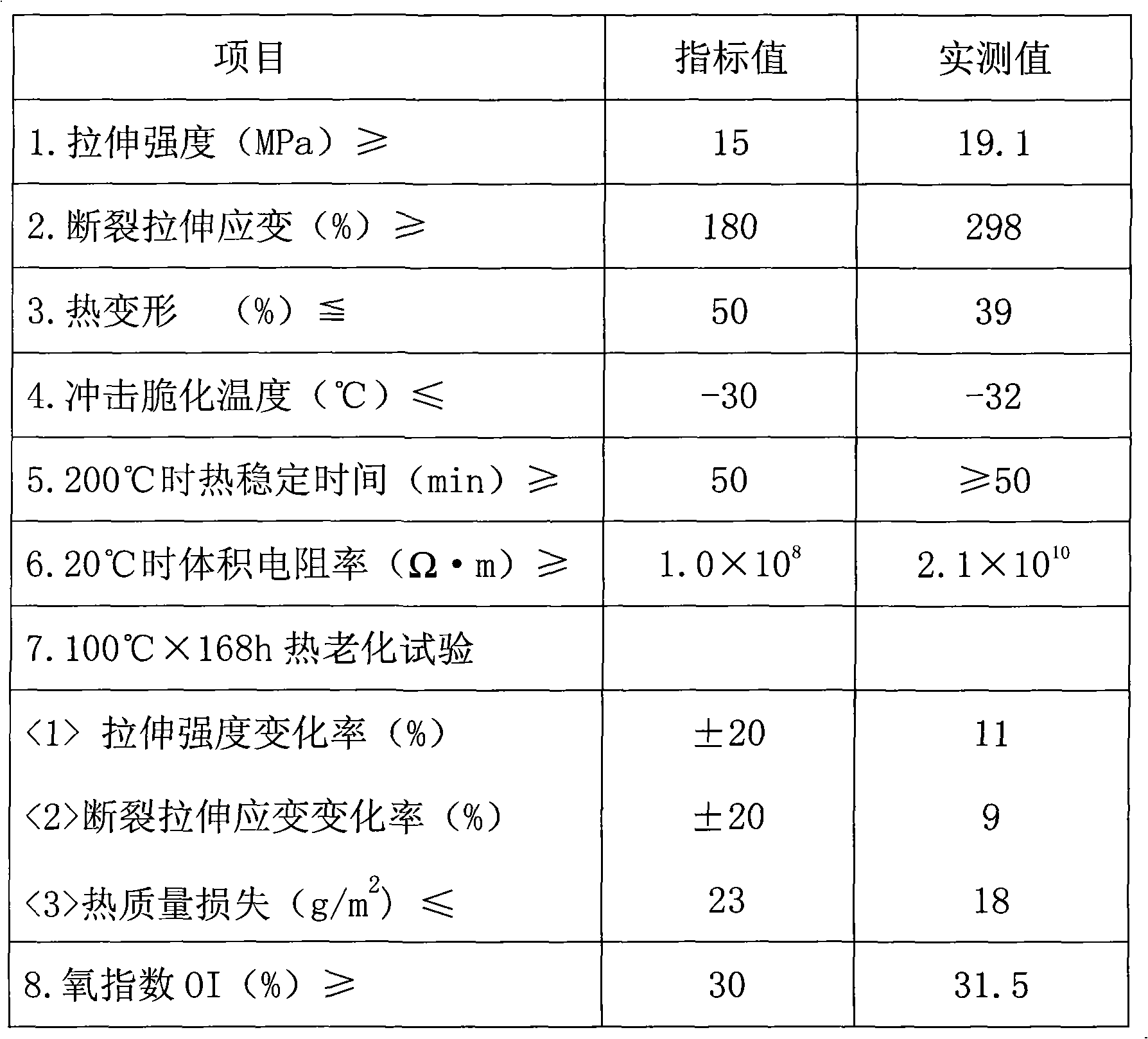

Cold-resistance and flame-retardant level PVC (polyvinyl chloride) cable material

The invention mainly discloses a cold-resistance and flame-retardant level PVC (polyvinyl chloride) cable material. The cold-resistance and flame-retardant level PVC cable material is characterized by adopting 100 parts by weight of PVC as the standard and comprising the other following components in parts by weight: 20-22 parts of dioctyl phthalate, 16-18 parts of dioctyl terephthalate,4-6 parts of trioctyl phosphate, 4-8 parts of dioctyl sebacate, 12 parts of 52 chlorcosane, 6-7 parts of heat stabilizer, 8-10 parts of antimonous oxide, 6-8 parts of CP-70, and 16-20 parts of active CaCO3. The cold-resistance and flame-retardant level PVC cable material has the advantages that different from the common-level cable material, firstly, the mechanical performance and the ageing performance meet the requirements of GB / T8S15-2008; secondly, the low-temperature impact embrittlement performance is less than 50% in fracture at the temperature of below minus 36 DEG C; and thirdly the requirement for the oxygen index (OI) in the flame-retardant performance is more than 30%.

Owner:RUGAO ZHONGRU CHEM

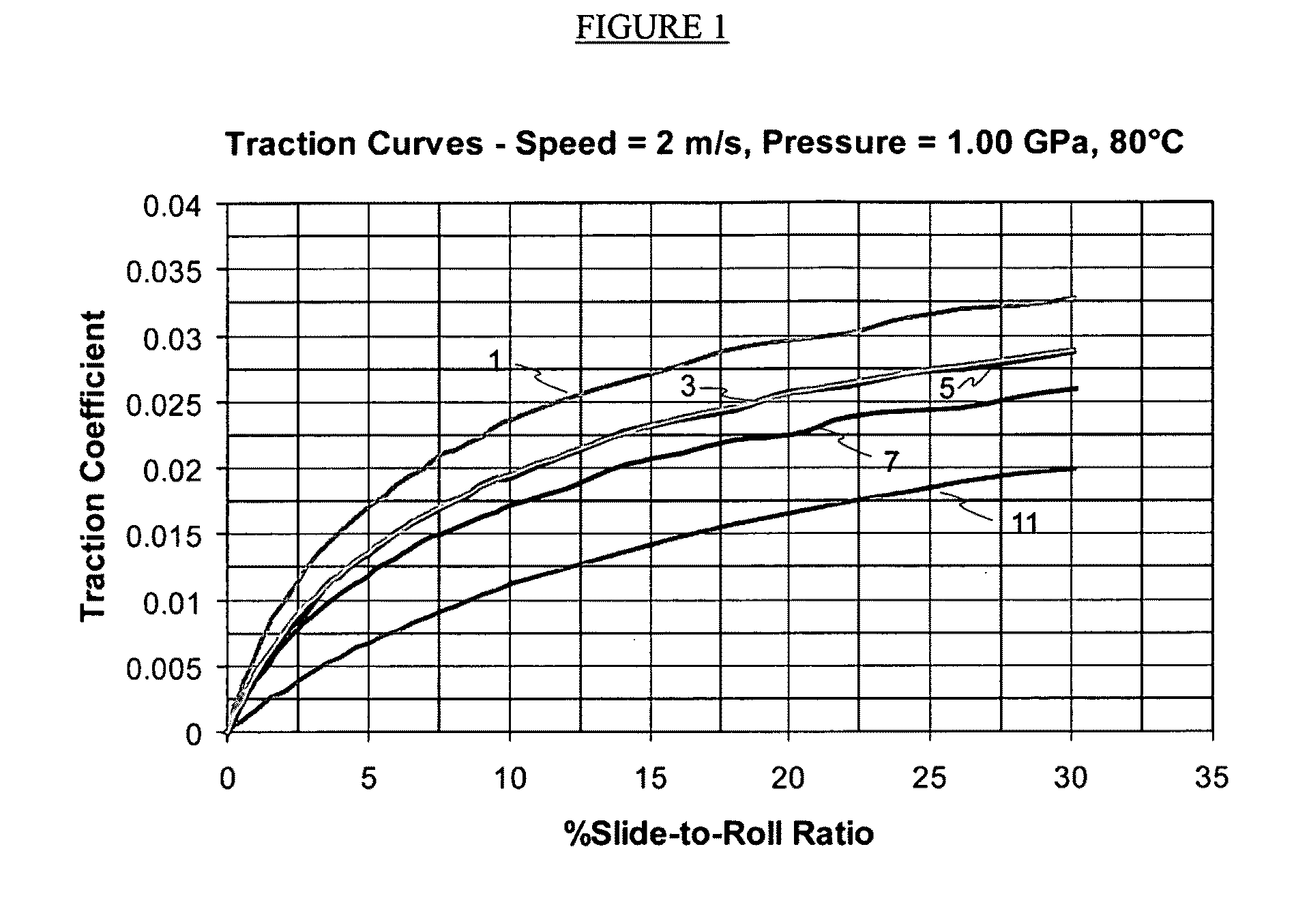

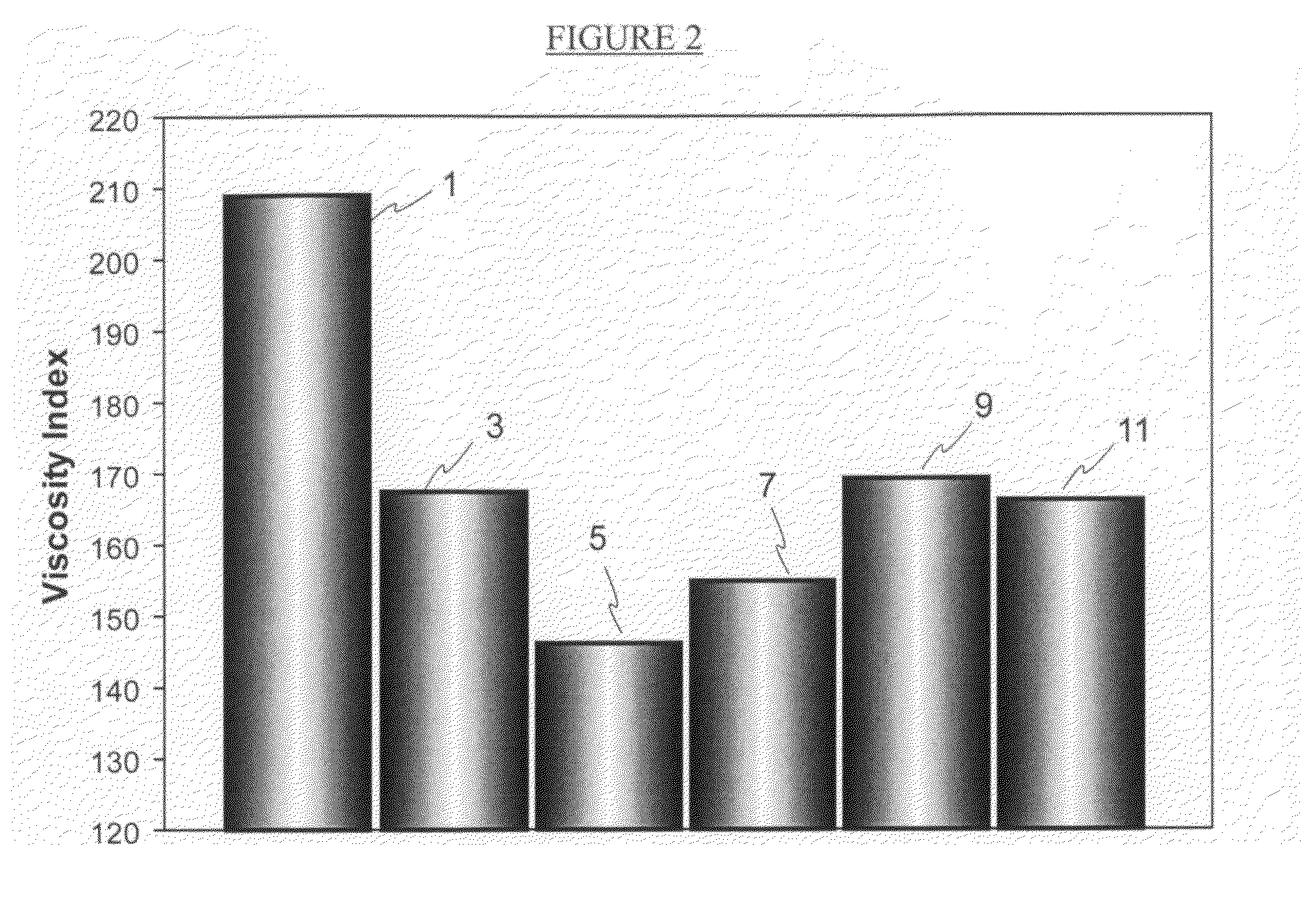

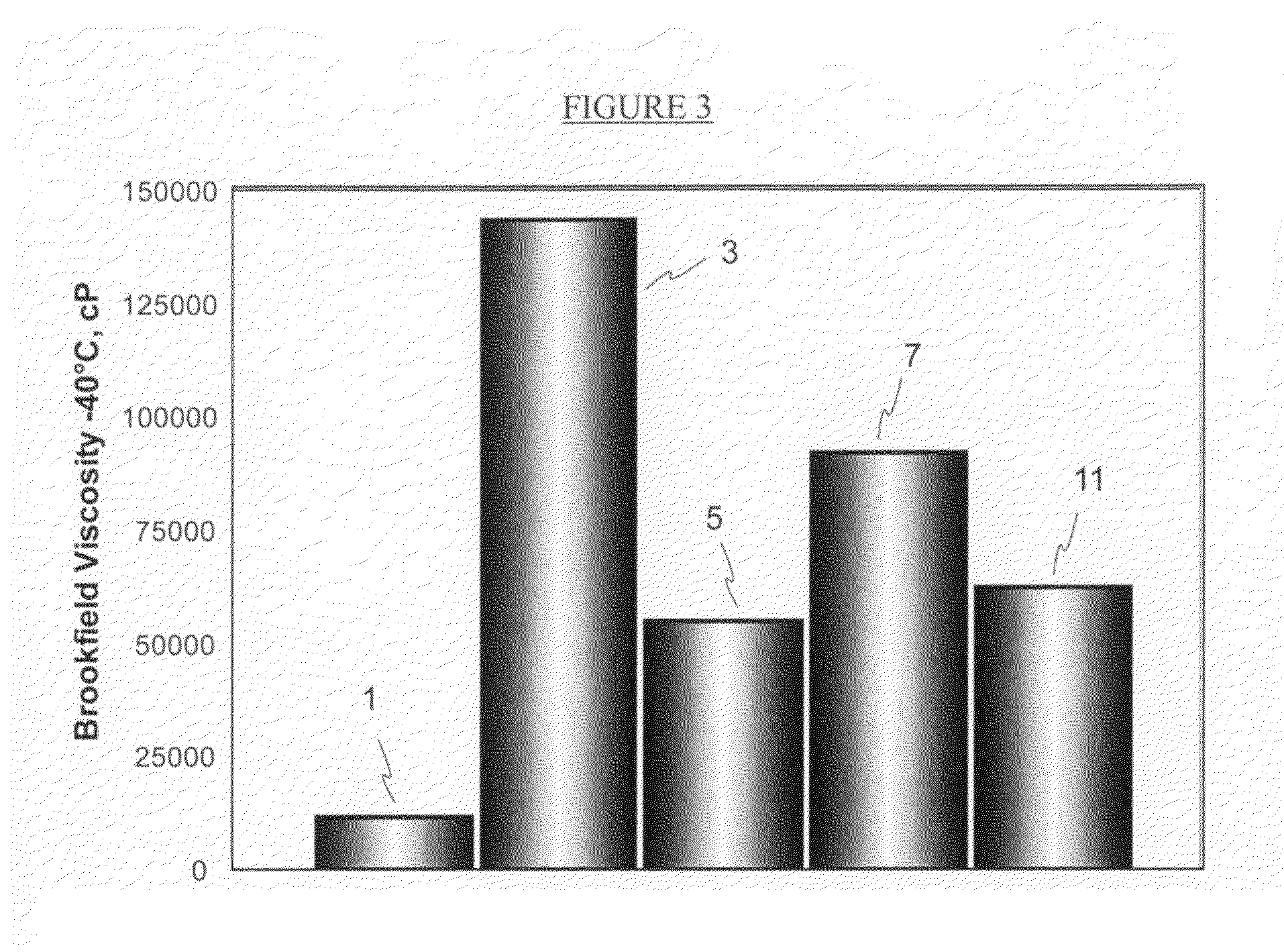

Chromium HVI-PAO bi-modal lubricant compositions

ActiveUS20100105589A1High viscosityBig advantageOrganic chemistryBase-materialsBi modalViscosity index

Owner:EXXON RES & ENG CO

Solid gas generator and preparation method thereof

The invention provides a solid gas generator and a preparation method thereof. The solid gas generator comprises 12 to 23% of a polyether adhesive, 1.2 to 3.6% of a curing agent, 50 to 80% of an oxidizing agent, 0 to 5% of a plasticizer, 0 to 30% of a cooling agent, 0 to 5% of a combustion conditioning agent and 0 to 2% of other additives, wherein the polyether adhesive is one or a composition of more than one selected from the group consisting of ethylene oxide tetrahydrofuran copolyether and propylene oxide tetrahydrofuran copolyether, the curing agent is one or a composition of more than one selected from the group consisting of toluene diisocyanate, isophorone diisocyanate and multifunctional aliphatic diisocyanate, and the plasticizer is one or a composition of more than one selected from the group consisting of dioctyl sebacate, acetyl triethyl citrate and triethyl glycerin tricarbonate. The solid gas generator provided by the invention has a negative pressure exponent of 0 to - 0.30 and provides a power source for attitude control and orbit control power systems of light-weight kinetic kill vehicles (KKV).

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

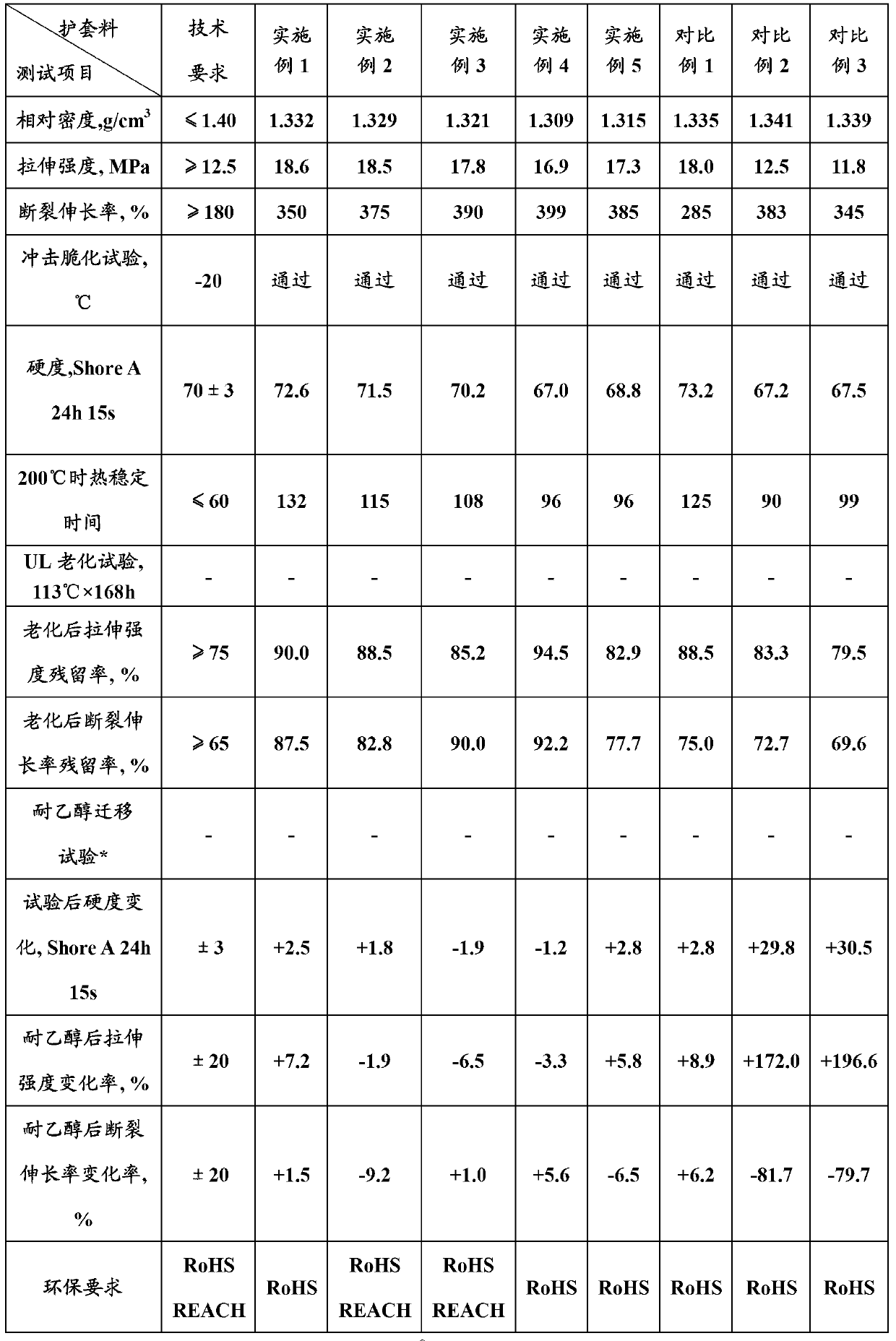

Environment-friendly ethanol migration resistance elastomer sheathing compound and preparation method thereof

InactiveCN103342868AGood mechanical propertiesExcellent resistance to ethanol migrationPlastic/resin/waxes insulatorsInsulated cablesPolyesterElastomer

The invention relates to an environment-friendly ethanol migration resistance elastomer sheathing compound and a preparation method thereof. The environment-friendly ethanol migration resistance elastomer sheathing compound comprises polyvinyl chloride resin, a plasticizer, a stabilizer, a lubricating agent and packing which serve as raw materials, wherein the polyvinyl chloride resin comprises low-polymerization-degree polyvinyl chloride resin powder with the polymerization degree of 1200-1400 and high-polymerization-degree polyvinyl chloride resin powder with the polymerization degree of 2500-3000 according to a weight ratio of 1: (0.8-1.2), and the plasticizer comprises a polyester plasticizer and one or several of trimellitic acid phosphate ester, epoxy soybean oil, dioctyl sebacate, dioctyl phthalate and di-isodecyl phthalate according to a weight ratio of (1.5-15): 1; and the preparation method of the sheathing compound comprises the following steps of: firstly carrying out low-speed kneading, then carrying out high-speed kneading and finally mixing and pelleting. The preparation method can be used for ensuring that the sheathing compound has excellent ethanol migration resistance under the condition of ensuring that the sheathing compound has good mechanical and physical properties and good machining property.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

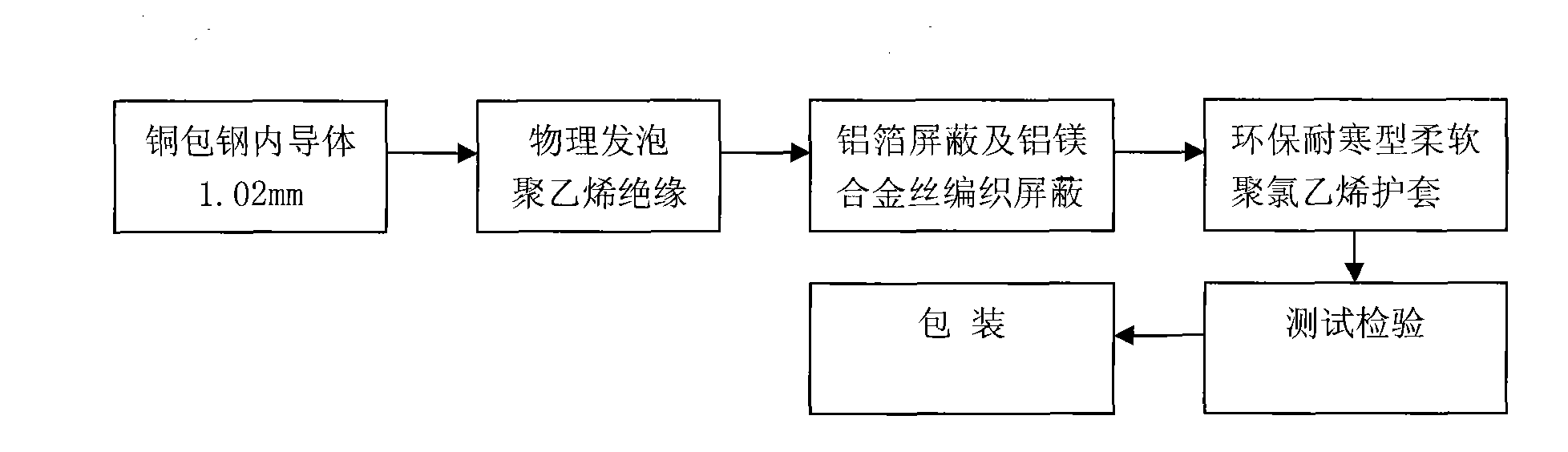

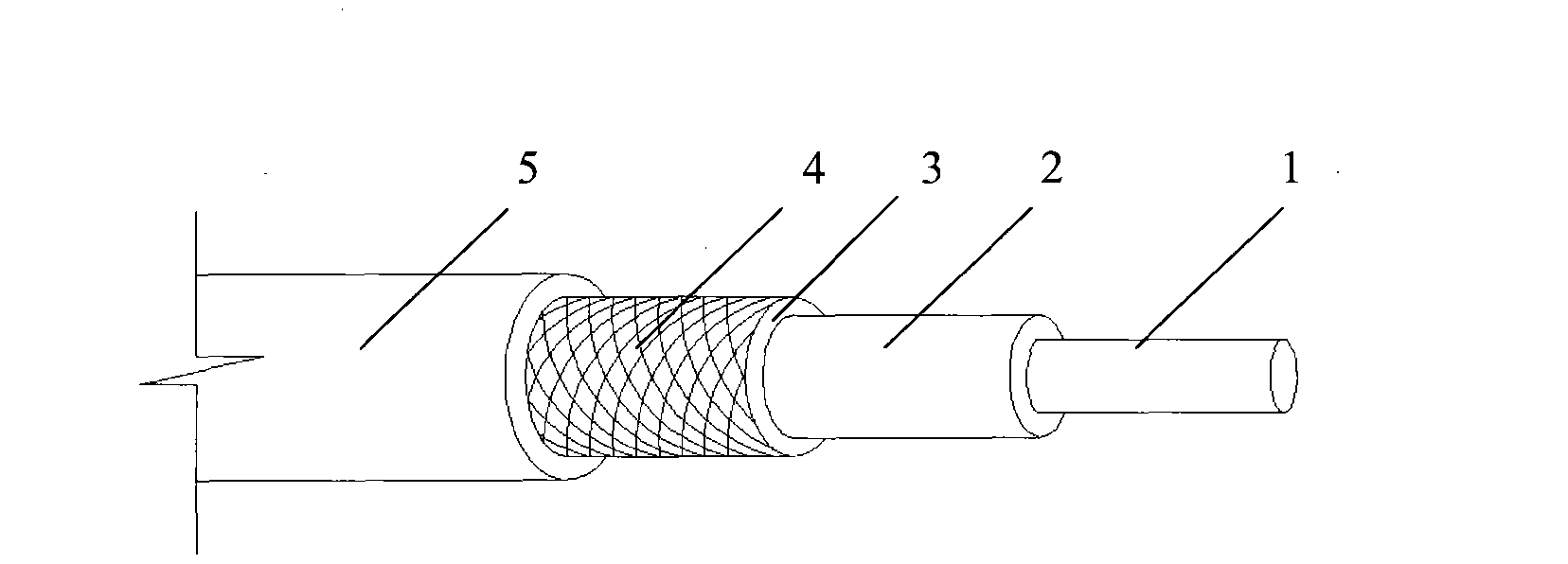

Environment friendly cold-resistant flexible sheath material and coaxial cable produced thereof

InactiveCN101492558AImprove cold resistanceGood flexibilityPlastic/resin/waxes insulatorsCoaxial cableSocial effects

An environmental protection cold resistance soft sheathing material is mainly prepared by the following materials according to the parts by weight: 40-45 pars of polyvinyl chloride, 5-7 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 8-10 parts of dioctylphthalate, 5-7 parts of phthalandione (2- propyl heptylasetate) diester, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, and 10-13 parts of refined calcium carbonate. The sheathing material has excellent cold resistance and environmental protection performance, low cost and high softness, and simultaneously the physical property of the sheathing material meets the European Union electronic apparatus ROHS commands and UL requirements. Based on the environmental protection cold resistance soft sheathing material, environmental protection cold resistance soft coaxial-cables which meet the UL requirements are successfully developed, thus technically solving the technical difficulties of softness, cold resistance, UL mechanical physical property and the like which are difficult to be achieved completely, meeting the strict requirements of the application of products on cold regions and having remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

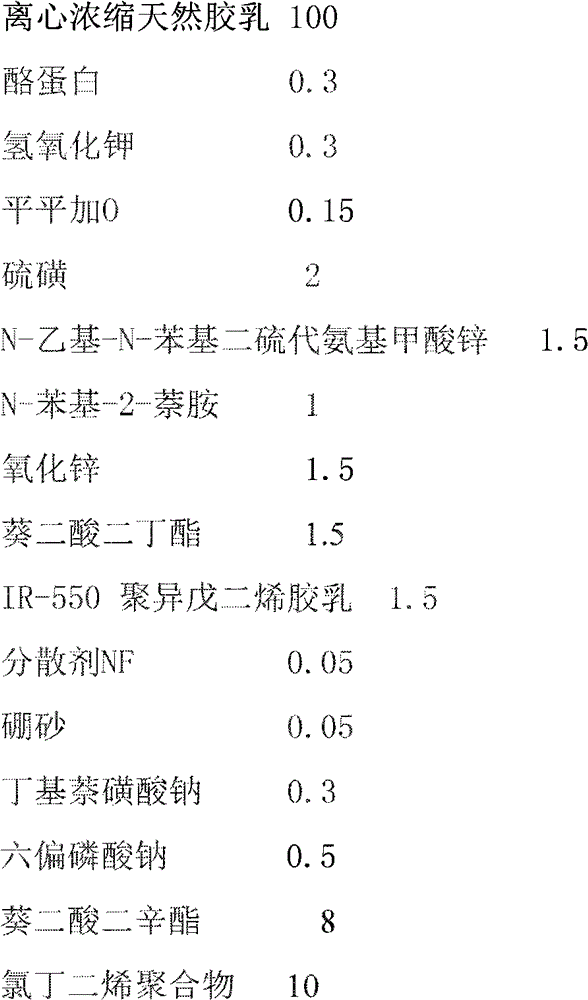

Meteorologic balloon and production method thereof

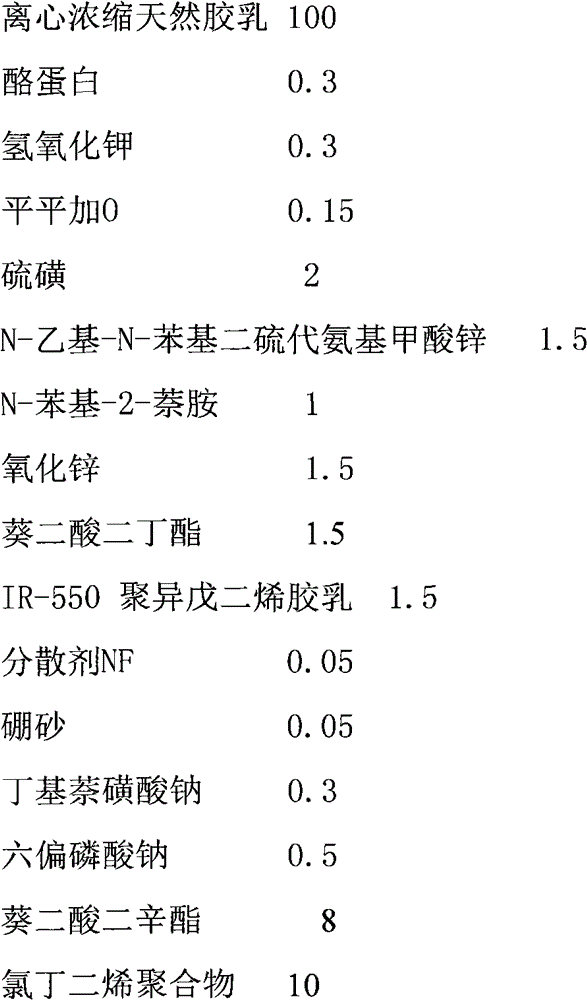

ActiveCN101592742AThere will be no problem of uneven distributionAgainst destructive powerInstrumentsPotassium hydroxideDioctyl sebacate

The invention discloses a meteorologic balloon and a production method thereof. The raw materials consist of a solid raw material, an oily raw material and a gluey raw material; the solid raw material comprises the following components by weight: 0 to 0.30 portion of potassium hydroxide, 0 to 0.15 portion of casein, 0 to 0.10 portion of peregal O, 1.00 to 3 portions of sulfur, 1.00 to 2 portions of N-phenyl-2-naphthylamine, 1.00 to 2 portions of N-phenyl-N'-isopropyl-ursol, 1.50 to 3 portions of ethyl-phenyl-zinc dithiocarbamate, 0.20 to 5 portions of zinc oxide, and 5 to 30 portions of chloroprene polymer; the oily raw material is dioctyl sebacate, and the weight rate of the dioctyl sebacate is 5.00 to 10.0 portions; and the gluey raw material is centrifugally-concentrated natural latex, and the adding amount of the centrifugal concentrated natural latex is 100 portions. The weight of the meteorologic balloon is 1,600 to 1,700 grams, the length of the balloon body is 3.05 to 3.55 meters, the width of the ball handle is 10 to 11 centimeters, and the length of the ball handle is 12 to 16 centimeters. The meteorologic balloon can adapt to the requirement of probing high-altitude meteorological elements of more than 35,000 meters, has the advantages of good aging resistance, high blastoff height, long balloon service time and the like, and can effectively overcome the morning-evening difference.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

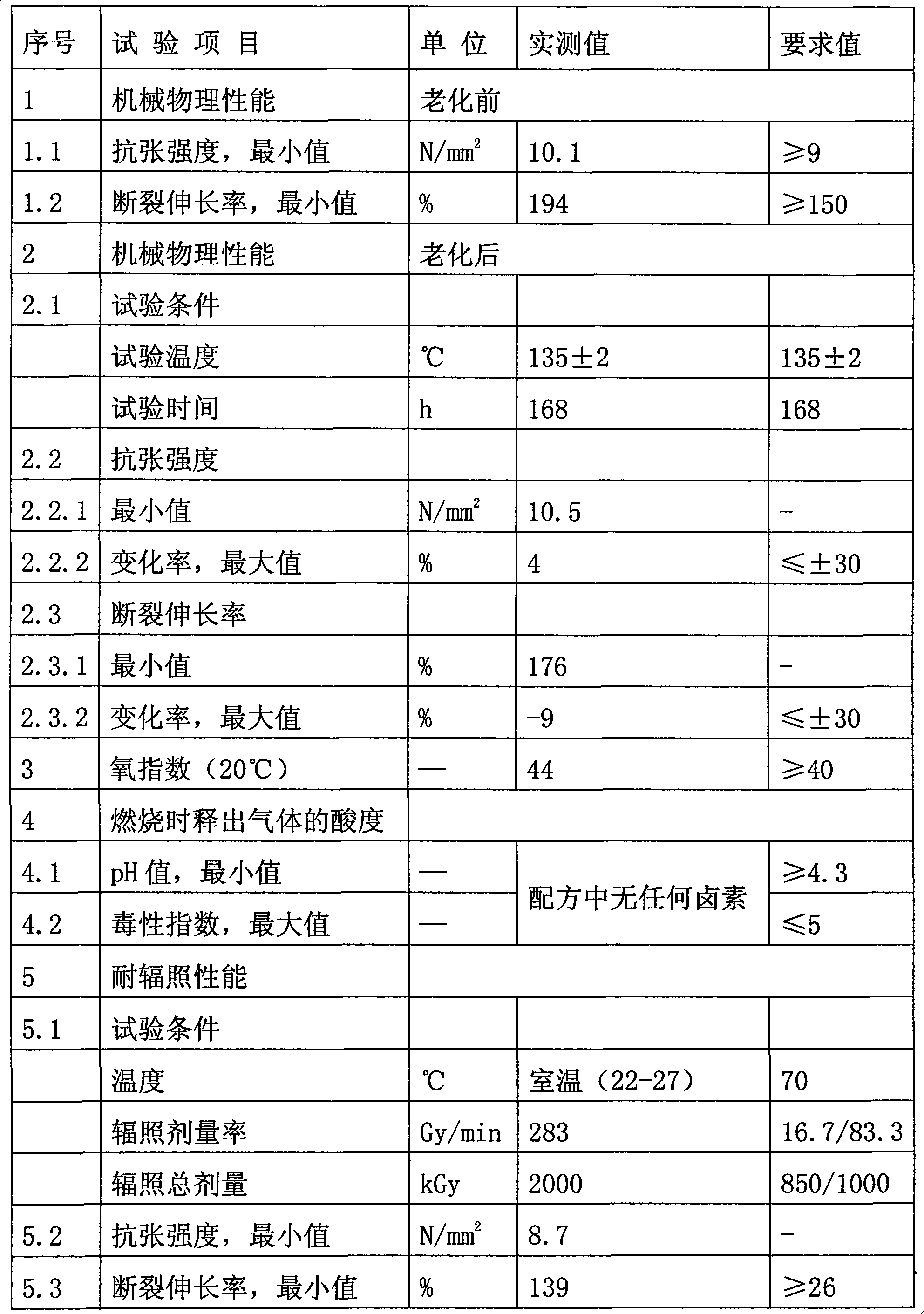

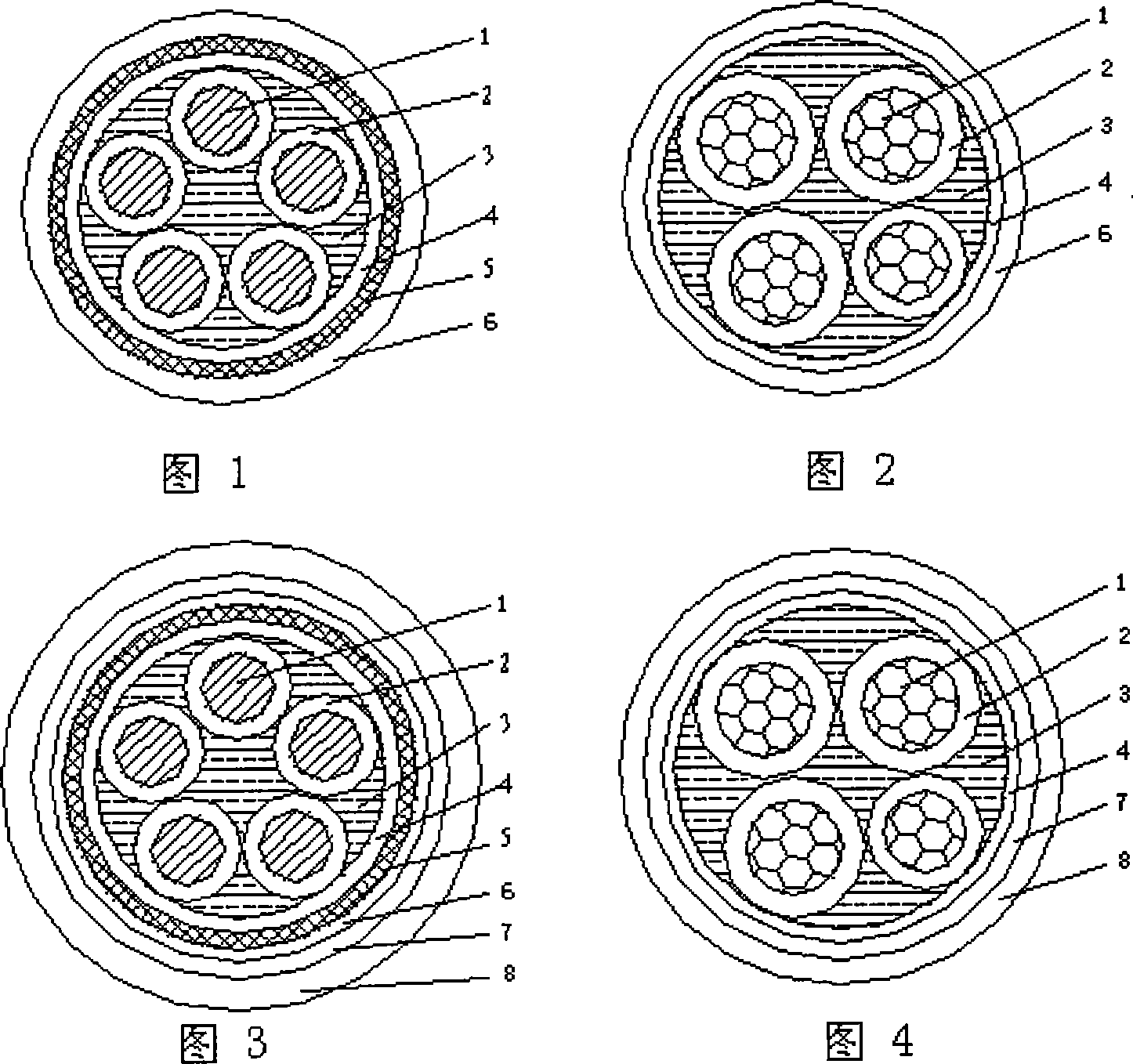

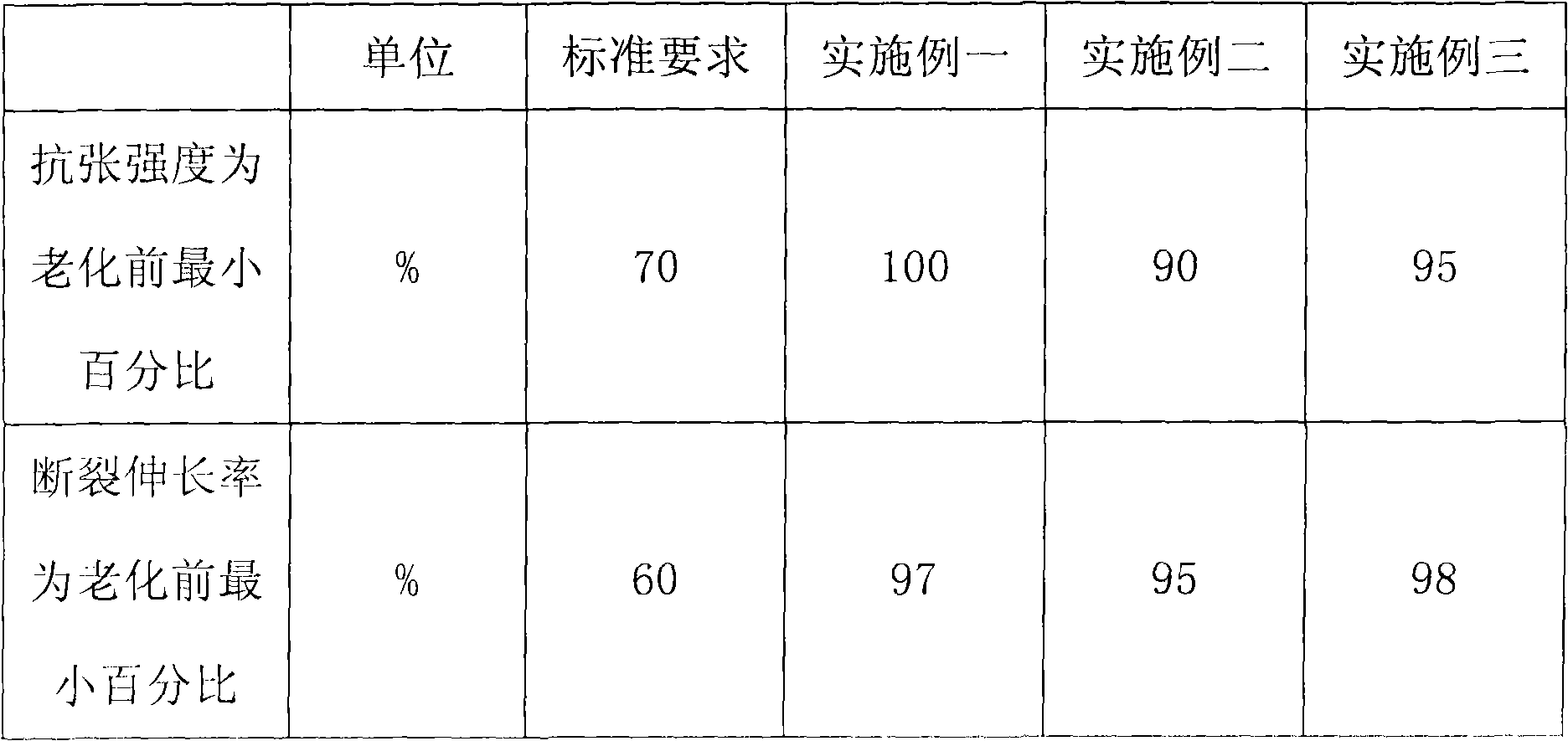

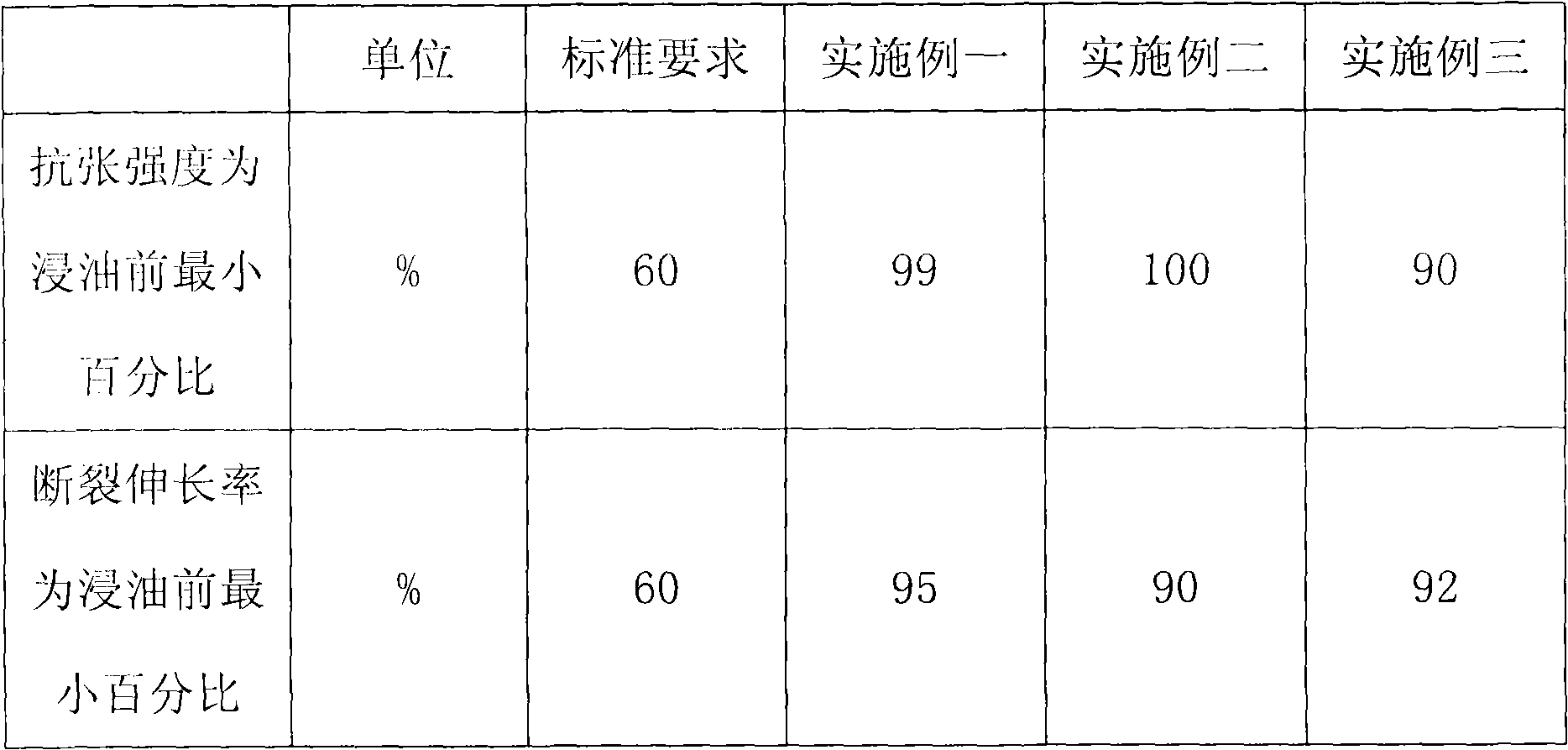

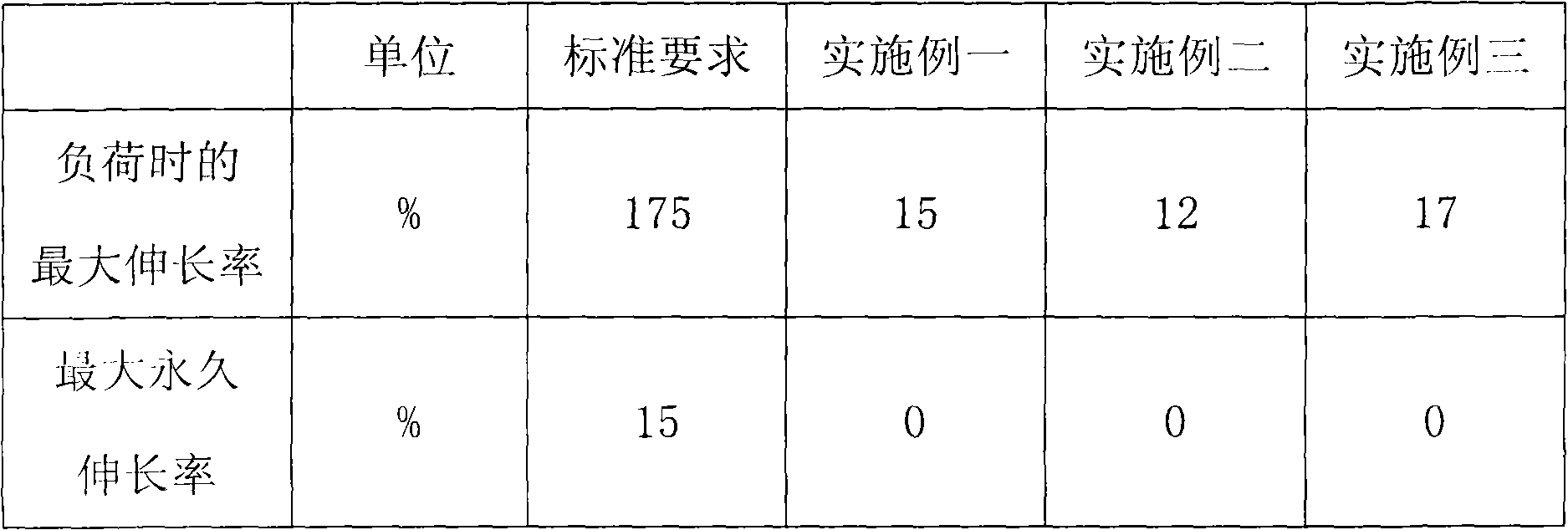

Irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and preparation method

ActiveCN101597397AImprove radiation resistanceThe ratio is scientific and reasonableInsulated cablesInsulated conductorsDi-tert-butyl peroxideNuclear power

The invention discloses an irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and a preparation method. The raw materials comprises ethane-vinyl acetate rubber, maleic anhydride stem grafting ethane-vinyl acetate rubber, magnesium hydroxide fire retardant, organic silicon fire retardant, nano cerium oxide, FEF, zinc stearate, stearic acid, vinyl trisilane, Aflux A-16, Aflux A-25, polycarbonate diimine(PCD-50), 2, 2, 4-trimethyl-1, 2-dihydride quinoline, antiager DDA, di-tert-butyl peroxide cumene, triene propylcyanide uric acid ester and decanedioic acid dioctyl, which are heated and mixed to obtain the materials of the invention. The invention features scientific and reasonable formula and proportion, and the process is advanced. The sheathing material features fine irradiation resistance, excellent mechanical properties and long service life, thus being a good irradiation resistant non-halogen low smoke and flame-retardant sheathing material applied to nuclear power stations.

Owner:BAOSHENG SCI & TECH INNOVATION

PVC (Polyvinyl Chloride) stone-bumping resistant paint and preparation method thereof

The invention relates to PVC (Polyvinyl Chloride) stone-bumping resistant paint and a preparation method thereof. The PVC stone-bumping resistant paint is formed by mediating, reacting and finely rolling dioctyl phthalate, dibutyl phthalate, dioctyl sebacate, light calcium carbonate, heavy calcium carbonate, nano active calcium carbonate, zinc stearate, barium stearate, organic bentonite, polyamide resin, carbon black, titanium pigment and PVC resin. The low-temperature flexibility of the PVC stone-bumping resistant paint can be improved by compounding three plasticizers of the dioctyl phthalate, the dibutyl phthalate and the dioctyl sebacate; the thixotropic performance of the paint can be improved by combining the organic bentonite with the nano active calcium carbonate; the adhesive force and the high-temperature yellowing resistance of the paint can be enhanced by combining the polyamide resin with heat stabilizers of the zinc stearate and the barium stearate and the paint has no foaming, crack and falling after baked at 210DEG C, so that the coating effect of the automobile body can be improved and the service life of the automobile body can be prolonged. The PVC stone-bumping resistant paint has no lead salt heat stabilizers and avoids the damage to the environment and human body; and the produced PVC stone-bumping resistant paint has excellent performance and can carry out the multilayer anticorrosion protection of the body and the bottom of the automobile.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

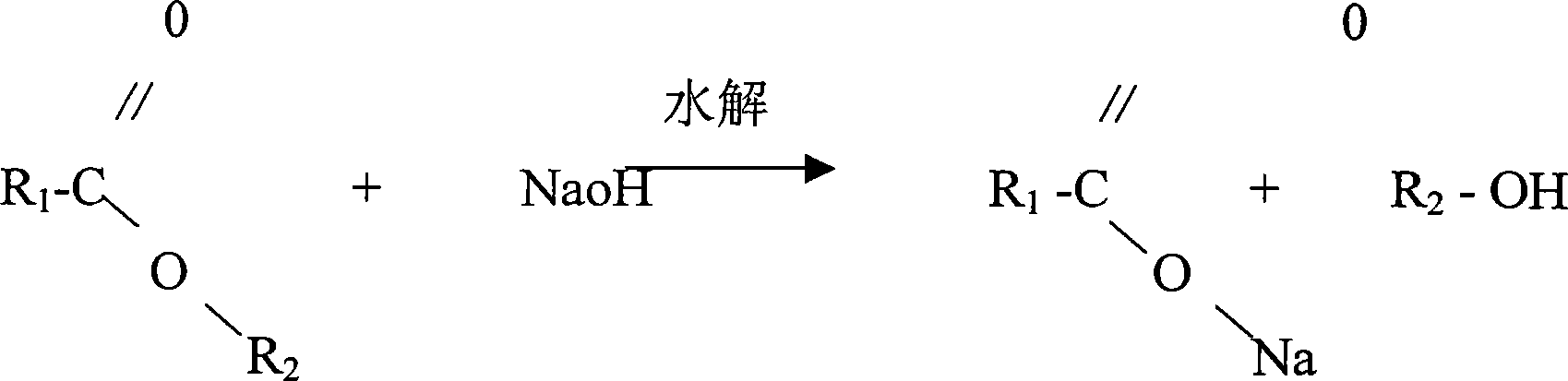

Acid, alkali, and salt corrosion resistant soft polychloroethylene cable sheath material and corrosion-resistant cable

InactiveCN101205341ALess intrusiveAvoid hydrolysisPlastic/resin/waxes insulatorsInsulated cablesPolyethylene vinyl acetatePolyvinyl chloride

The invention relates to a flexible polyvinyl chloride granula for cable with resistance to highly corrosive mediums comprised of acids, alkaline, saline, etc. The components of the invention: 100 shares of polyvinyl chloride resin, 10-30 shares of Polyethylene vinyl acetate or Di-octyl terephthalate and / or Dinonyl phthalate, 6-20 shares of dioctyl sebacate, 5-20 shares of dioctyl phthalate, 8-20 shares of chlorcosane with 52 percent chloride content, 0.3-1.5 shares of paraffin, 4-10 shares of stabilizing agent. Owing to the adapting of the insoluble or slightly dissolving in water, acid or alkali alkaline hydrolysis mixing plasticiser, the hydrolysis and extraction of the plasticiser are effectively prevented; the moisture content is decreased without adding hygroscopicity plugging compound; adding paraffin, the paraffin is dissolved out after the cooling, and then the waterproof membrane is formed at the surface of the plastic and the immergence of the moisture is prevented. The suction of the outside aqueous solution is decreased or avioded, the hydrolysis and extraction with plasticiser are decreased and avioded, and the acid resistance, the alkali resistance and the salt resistance are acheived, the service life in the saline and alkaline areas and coastal areas is prolonged. The invention can be led underground in saline and alkaline areas (inland) and coastal areas (tideland) and the safe service life can be prolonged one time to six times.

Owner:WUXI HUANCABLE +1

Sealing gasket for hydraulic cylinder and preparation method thereof

InactiveCN103408810AGood oil resistanceImprove temperature resistanceMicrocrystalline waxPolymer science

The invention discloses a sealing gasket for a hydraulic cylinder and a preparation method thereof. The sealing gasket is prepared from the raw materials including nitrile rubber, epichlorohydrin rubber, polyformaldehyde (POM), polyisobutene, 2,4-dichlorobenzoyl peroxide, 2,2'-disulfide dibenzo thiazine, dioctyl sebacate, n-butyl methacrylate, microcrystalline wax, modified wollastonite, nano sepiolite, calcium sulfate whiskers and the like. On the basis of blending of the nitrile rubber and the epichlorohydrin rubber, POM and polyisobutene are also added, so that the performances such as the oil resistance, the temperature tolerance, the abrasive resistance, the compressive strength and the like of the rubber can be improved; and the modified wollastonite is also added, so that the dispersibility of the wollastonite in the rubber can be obviously improved; and the performances such as the mechanical strength, the oil resistance, the abrasive resistance, the high thermal resistance and the like of a seal material are improved.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Polyvinyl chloride hot-dipping plastic compounded product, and its production and use

The present invention relates to a kind of PVC heat soaking plastic product and its producing method and application. It's produced by the technics steps of preparing coal paste, preparing materials, adjusting viscosity, pumping into vacuum and placed according to proportions of these materials: PVC resin powder, DOP, epoxy soybean oil, DOS, DIDG, fire retarder, stabilizing agent, meteorological method hydration silicon dioxide, carbon black and viscosity reducing agent; and its products are used in cable golden implement accessories as cable preventing tube. The compound layer has such performances as combining firmly with substrate surface, anti-corrosive, anti-aging, good insulating property, fire retarding, waterproofing and antimagnetic. It's surface compound layer material preferred by metal products.

Owner:BAOYUAN ELECTRIC ENG GEZHOU CITY

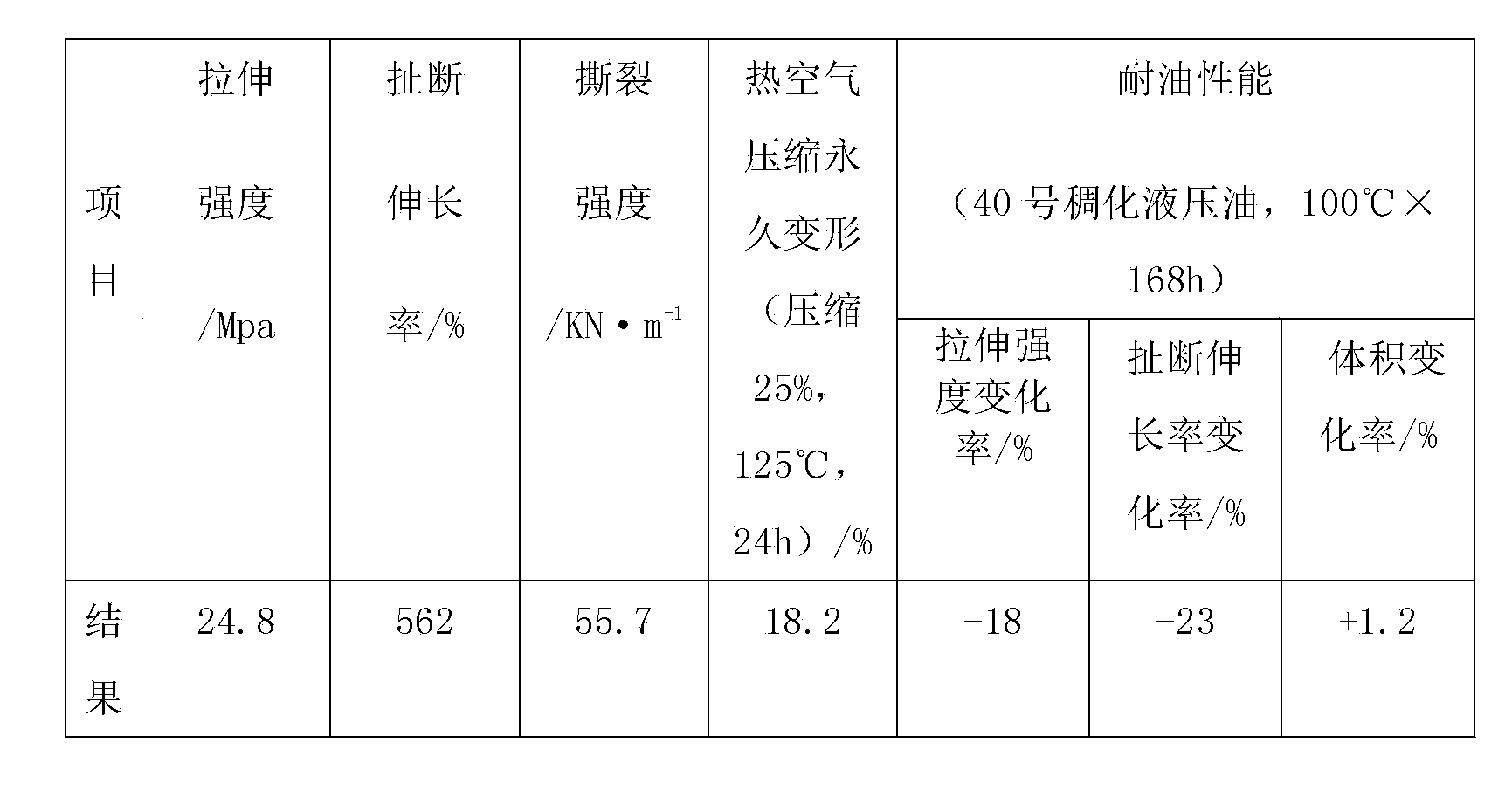

Modified acrylonitrile butadiene packing material and preparation method thereof

The modified nitrile butadiene rubber sealing material and its preparation process belong to the field of rubber polymer material technology. The modified nitrile butadiene sealing material is prepared with nitrile butadiene rubber, carbon black, zinc oxide, stearic acid, antiager 2, 2, 4-trimethyl-1, 2-dihydro quinoline, dioctyl sebacate, sulfur and promoter paraffin in certain weight proportion, and through compounding material, banburying, roll mixing, vulcanizing and other technological steps. It is applied in making rubber parts in apparatus for storing, transporting, loading and unloading methane, liquefied gas and other fuel, and automobile engine. It has high elasticity, high heat stability, high oil resistance and other advantages.

Owner:安阳市鑫河科技研究院有限责任公司

Slag pot carrier cable sheath material and manufacturing method thereof

InactiveCN102344590AImprove mechanical propertiesHigh tensile strengthInsulated cablesInsulated conductorsHigh fractureSlag

The invention discloses a slag pot carrier cable sheath material and a manufacturing method thereof. The slag pot carrier cable sheath material comprises 23 parts of chloroprene rubber CR3221, 1.2 to 1.5 parts of zinc oxide, 1 to 1.5 parts of magnesium oxide, 0.1 to 0.3 parts of tetramethylthiuram disulfide (TMTD), 0.2 to 0.3 parts of ethylene thiourea (ETU), 1.0 to 1.3 parts of dioctyl sebacate (DOS), 0.45 to 0.6 parts of dioctyl phthalate (DOP), 0.1 to 0.15 parts of stearic acid (SA), 1.2 to 1.4 parts of microcrystalline paraffin, 0.9 to 1.2 parts of iso-octyl decyl adipate (ODA), 0.1 to 0.15 parts of N-(p-toluene-sulphonylamido-N'-phenylene diamine) (TPPD), 0.2 to 0.4 parts of 4,4-bis(alpha,alpha-dimethylbenzyl)diphenylamine (HS)-911, 5 to 8 parts of carbon black, 4.5 to 6 parts of semi-reinforced carbon black, 0.5 to 0.7 parts of vaseline, 8 to 10 parts of calcining potter's clay and 3 to 4 parts of calcium carbonate. The manufacturing method comprises the following steps of 1, mixing the chloroprene rubber CR3221 for 5 to 7 minutes, 2, adding the magnesium oxide as an active agent, the zinc oxide as an active agent, the microcrystalline paraffin, the SA, the calcium carbonate, the DOP, the carbon black, the DOS, the semi-reinforced carbon black and the vaseline into the mixture obtained by the step 1 to carry out mix for 9 to 11 minutes, 3, adding the calcining potter's clay, the ODA, the TPPD, the HS-911, the TMTD and the ETU into the mixture obtained by the step 2 to carry out mixing, wherein the TMTD and the ETU are added at the last 90 seconds, and 4, moving the mixture obtained by the step 3 to an open mill to carry out tabletting, turning eight triangular cornerites, and cutting into tablets. A cable sheath prepared from the slag pot carrier cable sheath material has the advantages of excellent mechanical properties, high tensile strength, high fracture elongation, aging resistance and oil resistance.

Owner:JIANGSU YUANYANG DONGZE CABLE

Weather monitoring device and application thereof

ActiveCN102718994AGood dispersionSame plasticizing effectBalloon aircraftsInstrumentsDibutyl sebacateDIETHYL SEBACATE

The invention relates to a weather monitoring device, in particular to a new weather balloon, which comprises the following components by weight percent: 100 of centrifugal concentrated natural latex, 0.3 of casein, 0.3 of potassium hydroxide, 0.15 of peregal 0, 2 of sulphur, 1.5 of N-ethyl-N-phenyl dithiocarbamate zinc, 1 of N-phenyl-2-naphthylamine, 1.5 of zinc oxide, 1.5 of dibutyl sebacate, 1.5 of IR-550 polyisoprene latex, 0.05 of dispersing agent NF, 0.05 of borax, 0.3 of sodium butylnaphthalenesulfonate, 0.5 of sodium hexametaphosphate, 8 of dioctyl sebacate and 10 of chloroprene polymer. The new weather balloon provided by the invention has the advantages of high sounding altitude, long sounding time and wide application prospect.

Owner:南通市通州区新志浩实业有限公司

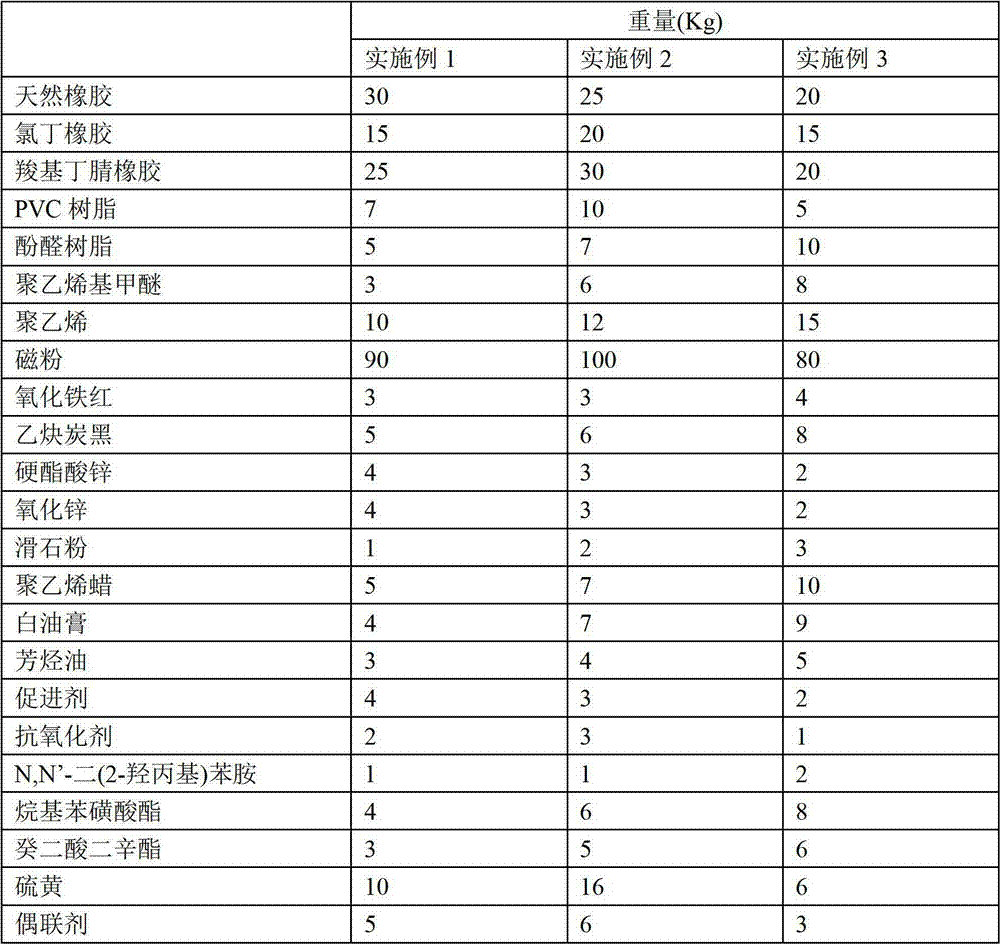

High-intensity magnetic rubber

InactiveCN102875854AImprove mechanical propertiesImprove magnetic propertiesPolymer sciencePolyvinyl chloride

The invention discloses a high-intensity magnetic rubber, belonging to the technical field of macromolecular materials. The magnetic rubber is made from the following raw materials by weight: 20-30 parts of natural rubber, 10-20 parts of chloroprene rubber, 20-30 parts of carboxylated nitrile rubber, 5-10 parts of PVC (Polyvinyl Chloride) resin, 5-10 parts of phenolic resin, 3-8 parts of polyvinyl methyl ether, 10-15 parts of polyethylene, 80-100 parts of magnetic powder, 3-4 parts of iron oxide red, 5-8 parts of acetylene black, 2-4 parts of zinc stearate, 2-4 parts of zinc oxide, 1-3 parts of French chalk, 5-10 parts of polyethylene wax, 4-9 parts of white factice, 3-5 parts of aromatic hydrocarbon oil, 2-4 parts of accelerant, 1-3 parts of antioxidant, 1-2 parts of N,N'-di(2-hydroxypropyl)aniline, 4-8 parts of alkyl besilate, 3-6 parts of dioctyl sebacate, 6-16 parts of sulphur and 3-6 parts of coupling agent. The tensile strength of the magnetic rubber can reach more than 5.5MPa, the elongation at break of the magnetic rubber can reach more than 400%, the Shore hardness of the magnetic rubber can reach more than 60%, and the magnetic induction intensity of the magnetic rubber can reach more than 720Gs.

Owner:昆明云垦橡胶有限公司

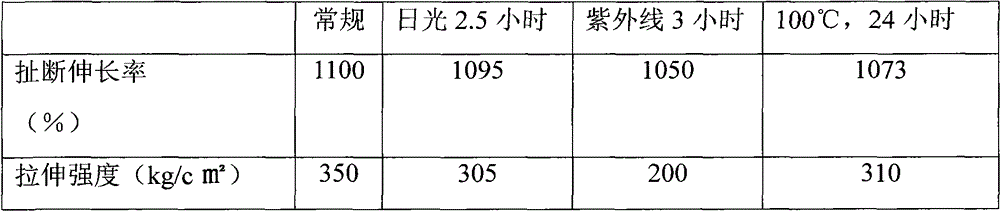

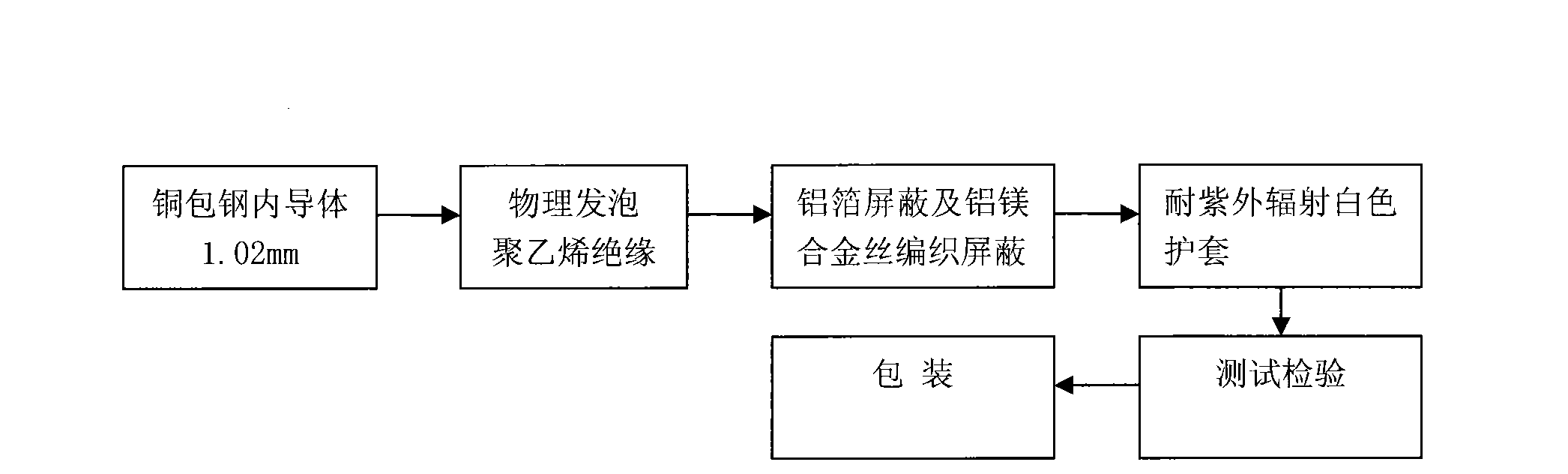

Ultraviolet light resistant ring protective cover material and white concentric cable produced thereof

InactiveCN101492557AExcellent resistance to UV radiationEnvironmental protection is goodPlastic/resin/waxes insulatorsUltraviolet lightsSocial effects

An ultra violet radiation resistant environmental protection sheathing material is mainly prepared by the following materials according to the parts by weight: 40-50 pars of polyvinyl chloride resin, 6-8 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 7-9 parts of dioctylphthalate, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, 8-10 parts of refined calcium carbonate, 8-10 parts of titanium dioxide, and 0.3-0.5 parts of ultraviolet absorbent. The invention technically solves the difficult point of compound formulation of the ultra violet radiation resistant white sheathing material, greatly increases the resistance to ultra violet radiation performance of the product, has strong practicability and lays the material foundation for the design and development of resistance to ultra violet radiation coaxial-cables. Based on the resistance to ultra violet radiation white polyvinyl chloride sheathing material, the resistance to ultra violet radiation environmental protection sheathing material technically solves the technical difficulties of resistance to ultra violet radiation performance, softness, UL mechanical physical property, ROHS environment requirements and the like which are difficult to be achieved completely, meets the strict requirements of the application of products on tropical and subtropical regions and has remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

Port machine cable storage basket sling cable sheath rubber and preparation method thereof

InactiveCN102093645AImprove mechanical propertiesImprove anti-agingPlastic/resin/waxes insulatorsParaffin waxEngineering

The invention discloses a port machine cable storage basket sling cable sheath rubber and a preparation method thereof, belonging to the field of cables. The sheath rubber comprises the following components: 26.5 parts of chlorinated polyethylene 352, 2.5-3 parts of magnesium oxide, 0.3-0.5 part of antioxidant RD, 0.25-0.5 part of paraffin wax, 3.5-4.0 parts of DOS (Dioctyl Sebacate), 2.0-2.5 parts of TOTM (Trioctyl Trimellitate), 1.5-2.0 parts of white carbon black, 1.2-1.5 parts of diantimony trioxide, 1.2-1.5 parts of chlorinated paraffin 70, 0.3-0.5 part of lead stearate, 0.2-0.4 part of three salts, 6-8 parts of calcined clay, 0.2-0.3 part of A-172, 3-4 parts of high-abrasion carbon black, 3-4 parts of semi-reinforcing carbon black, 0.85-1 part of DCP (Dibasic Calcium Phosphate) and 1-1.5 parts of triallyl cyanurate (TAC). The preparation method of the port machine cable storage basket sling cable sheath rubber comprises the following steps of: firstly, blending the chlorinated polyethylene 352, adding the magnesium oxide and the like, blending and stirring uniformly; pouring filtered rubber into an internal mixer, adding the DCP and the TAC, blending uniformly, and blanking; and making the mixture into five triangular packages in an open mill, rolling for five times and delivering out sheets. The sheath rubber has excellent mechanical properties and good corrosion resistance and aging resistance.

Owner:JIANGSU YUANYANG DONGZE CABLE

Environment-friendly polyvinyl chloride cable sheathing compound

InactiveCN101638499AEnvironmental protection is goodExcellent resistance to moisture absorptionPlastic/resin/waxes insulatorsMoisture absorptionAntimony trioxide

The invention relates to an environment-friendly polyvinyl chloride cable sheathing compound mainly comprising the following materials in parts by weight: 40-45parts of polyvinyl chloride resin, 5-7parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 8-10parts of acetyl tributyl citrate, 5-7 parts of DX-360, 4-6parts of Ca-Zn composite stabilizing agent, 1-1.5 parts of epoxidized soybeanoil, 1-1.5 pats of diantimony trioxide, 10-30 parts of magnesium hydroxide and 10-13parts of fine calcium carbonate. The environment-friendly polyvinyl chloride cable sheathing compound technically satisfies European Union ROHS and REACH index requirements, resists ultraviolet irradiation, and the like, increases stability and anti-moisture absorption, prolongs a storage period and has high practicability, wide development prospect and large market potential. The environment-friendly polyvinyl chloride cable sheathing compound is successfully developed to supply raw material guarantee for designing and selecting an environment-friendly cable product which can simultaneously satisfy the European Union ROHS and REACH requirements, promotes the stable sustainable development of linked industries and conforms the development direction of products of new and high technologies of China.

Owner:王一群

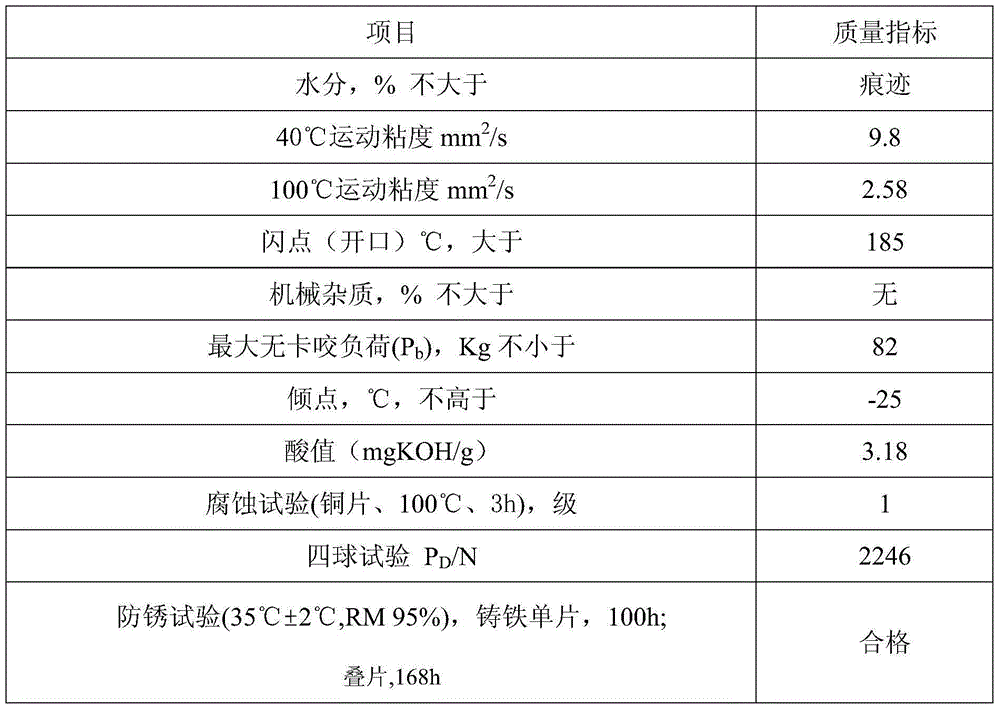

Composition of castor-based EC-2 hardened gear face cutting oil

The invention discloses a composition of castor-based EC-2 hardened gear face cutting oil. The composition of the castor-based EC-2 hardened gear face cutting oil is prepared by compounding isomerised polyolefin and castor-based dioctyl sebacate as a base oil and matching with a variety of composite additives, and comprises an oily agent, an anti-wear agent, an anti-foaming agent, a catalytic refrigerant, a demulsifier, a penetrating agent, a friction modifier, a reinforcing agent, an antioxidant and a rust inhibitor. The composition of the castor-based EC-2 hardened gear face cutting oil has good flowability, permeability, cooling performance, lubricity, wear resistance, rust resistance, anti-foaming performance and emulsification resistance, can form a good lubricant film on the surface of a workpiece in a gear machining process to play a boundary lubricating role, can reduce friction in the machining process to reduce wear, can weaken a crumb sticking phenomenon, can take away cutting heat in time, can reduce thermal shock of cutter teeth and collapse of a cutter, and can prolong the service life of the cutter.

Owner:GUANGXI UNIV

Preparation of magnetic fluid for ultra-high vacuum sealing device

ActiveCN101388270AHigh strengthImprove stabilityMagnetic liquidsIron compoundsWater bathsUltra-high vacuum

The invention relates to a method for preparing magnetic fluid for a ultrahigh vacuum sealing device, which uses the following steps: A) Fe2+ soluble salt and aqueous solution of Fe3+ soluble salt are mixed according to the molar ratio of Fe2+ and Fe3+, which is 1:2. B) obtained mixed solution is placed in 80 DEG C constant temperature water bath, excessive ammonia is added to generate Fe3O4 particles, oleic acid is added, thereby obtaining magnetic nano Fe3O4 particles which are coated with the oleic acid. C) the magnetic nano Fe3O4 particles which are coated with the oleic acid are dispersed in dioctyl sebacate and is placed in 100 DEG C constant temperature water bath, modified polyoxyethylene ether is added after being stirred for 30min, the temperature is increased to 150 DEG C, emulsification pretreatment is done for 60min, the temperature is reduced below 60 DEG C, thereby obtaining the magnetic fluid for the ultrahigh vacuum sealing device. The method for preparing the magnetic fluid for the ultrahigh vacuum sealing device has lower requirements for experiment instruments and operation conditions, the prepared magnetic fluid is very steady, the saturated vapor pressure is very low, and the startup torque is also low.

Owner:浙江微磁精密技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com