Environment friendly cold-resistant flexible sheath material and coaxial cable produced thereof

A sheathing material and soft technology, applied in plastic/resin/wax insulators, organic insulators and other directions, can solve the problems of inability to meet physical performance indicators, increase costs, increase the difficulty of development, etc., to achieve effective cost control and improve cold resistance. , the effect of significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

[0057] An environment-friendly and cold-resistant soft sheathing material, said sheathing material is mainly prepared from the following substances by weight:

[0058] (1) 420 kg of polyvinyl chloride resin

[0059] (2) Trioctyl trimellitate (TOTM) 70 kg

[0060] (3) Dioctyl sebacate (DOS) 60 kg

[0061] (4) Dioctyl phthalate (DOP) 90 kg

[0062] (5) Di(2-propylheptyl) phthalate (DPHP) 60 kg

[0063] (6) Calcium zinc composite stabilizer 50 kg

[0064](7) epoxidized soybean oil (ESO) 15 kg

[0065] (8) Antimony trioxide 15 kg

[0066] (9) 120 kg of magnesium hydroxide

[0067] (10) 100 kg of fine calcium carbonate.

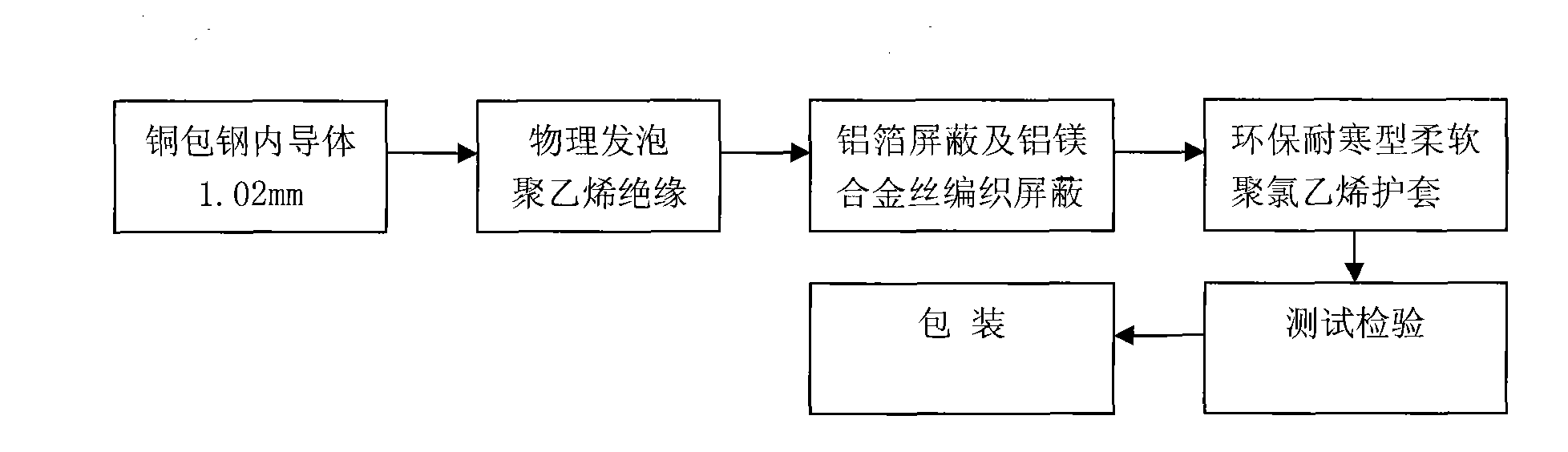

[0068] The production process of the above-mentioned sheath material consists of three major processes: batching, mixing and extrusion. Batching is to mix various raw materials according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com