Patents

Literature

59results about How to "Solve the softness problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of continuous filament of asphalt-based carbon fiber

InactiveCN103046165ASmall diameterIncrease the number of filamentsNew-spun product collectionArtificial thread manufacturing machinesFiber bundleCarbonization

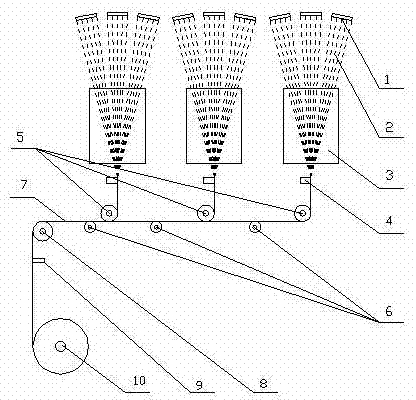

The invention discloses a preparation method of a continuous filament of an asphalt-based carbon fiber, and belongs to the field of carbon fiber production. The preparation method solves the problems that the existing spinning speed is lower, the fiber bundle damage is large, the infusibility efficiency is low, and doubling and embrittlement are easy. The preparation method comprises the specific process steps that a, spinning asphalt is extruded into fines by spinning position fusion, humidified, oiled and bundled to form a protogenic asphalt fiber bundle; b, double roller stranding and tensioning are conducted; c, the asphalt fiber bundle is wound on a spinning roller sleeve; d, an asphalt fiber reel is immersed in an oxidability liquid phase, and a liquid-phase oxidized fiber bundle reel is obtained; e, the reel is immersed in a high-temperature-resistant oil solution; the filament is unreeled and rollers are removed at a low speed; the oxidized fiber bundle continuously enters a continuous infusible furnace and a continuous low-temperature pre-carbonization furnace to form a pre-carbonization fiber bundle reel; and f, drawing heat treatment is conducted through a continuous carbon-fiber high-temperature carbonization furnace and a graphitization furnace, and then the continuous filament of the asphalt-based carbon fiber is obtained.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Radiation-proof polyester fiber for emitting negative ions and far infrared rays and preparation method thereof

InactiveCN102220655AComfortable to takeWith Guard BandwidthFilament/thread formingConjugated synthetic polymer artificial filamentsFiberActivated carbon

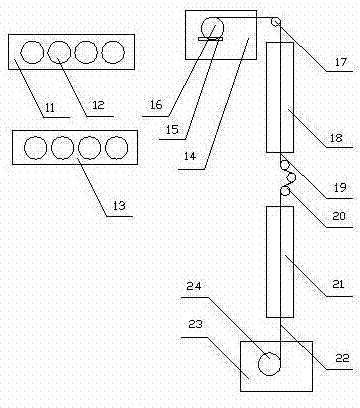

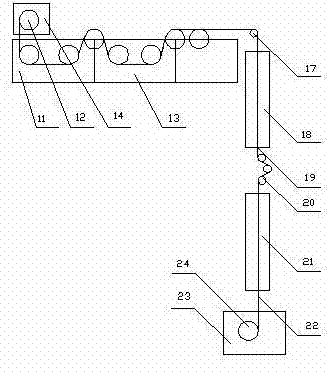

The invention relates to a radiation-proof polyester fiber for emitting negative ions and far infrared rays and a preparation method thereof. The polyester fiber has the following raw materials according to weight percentages: 0.1-10% of active carbon loaded with BaSO4, 0.1-3% of nanometer silver anti-bacterial agent, 0.1-3% of far infrared-emitting agent, and the balance of fiber slice. The polyester fiber is soft, light and radiation-proof, and has the health functions of emitting the negative ions, the far infrared rays, and the like; the polyester fiber has wide application prospect; and the preparation method of the polyester fiber is simple in operation, has lower cost and low equipment requirement, and is suitable for large-scale production.

Owner:DONGHUA UNIV

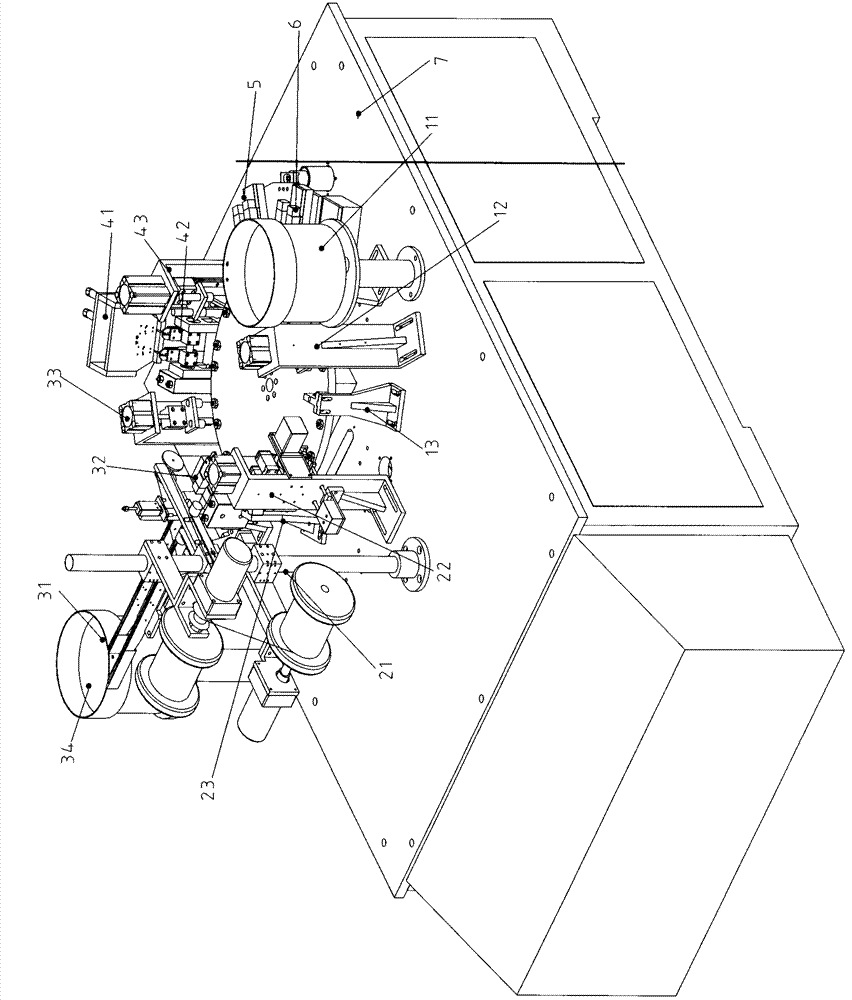

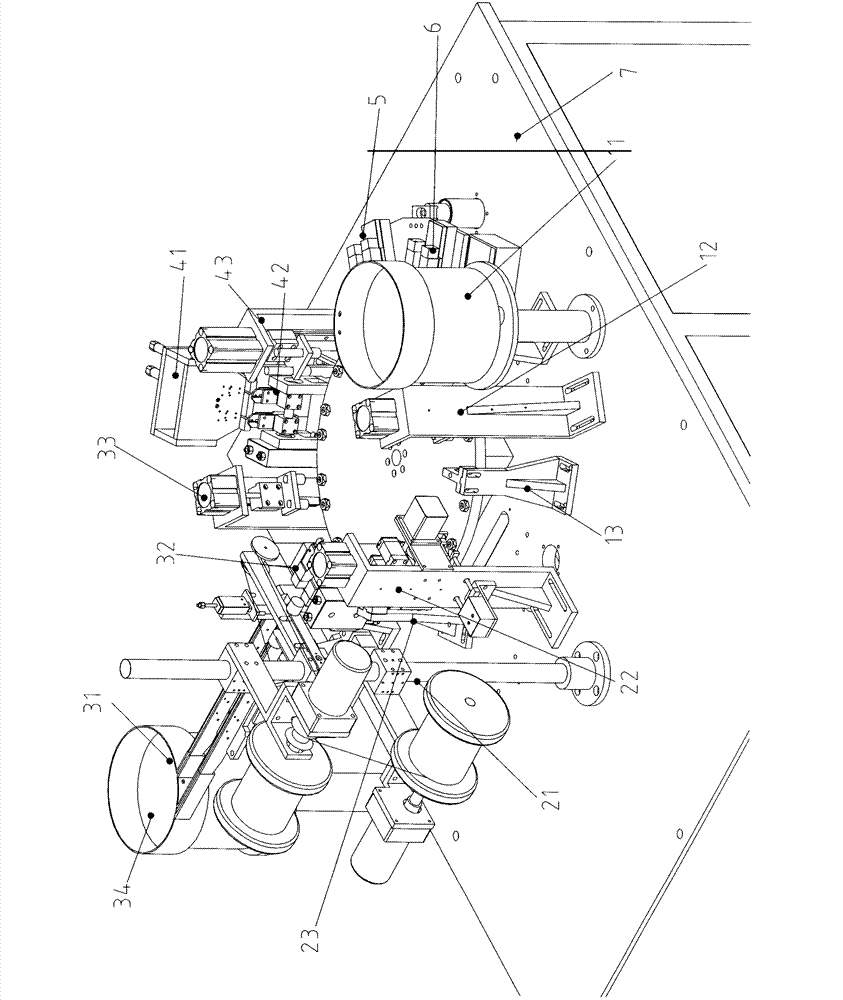

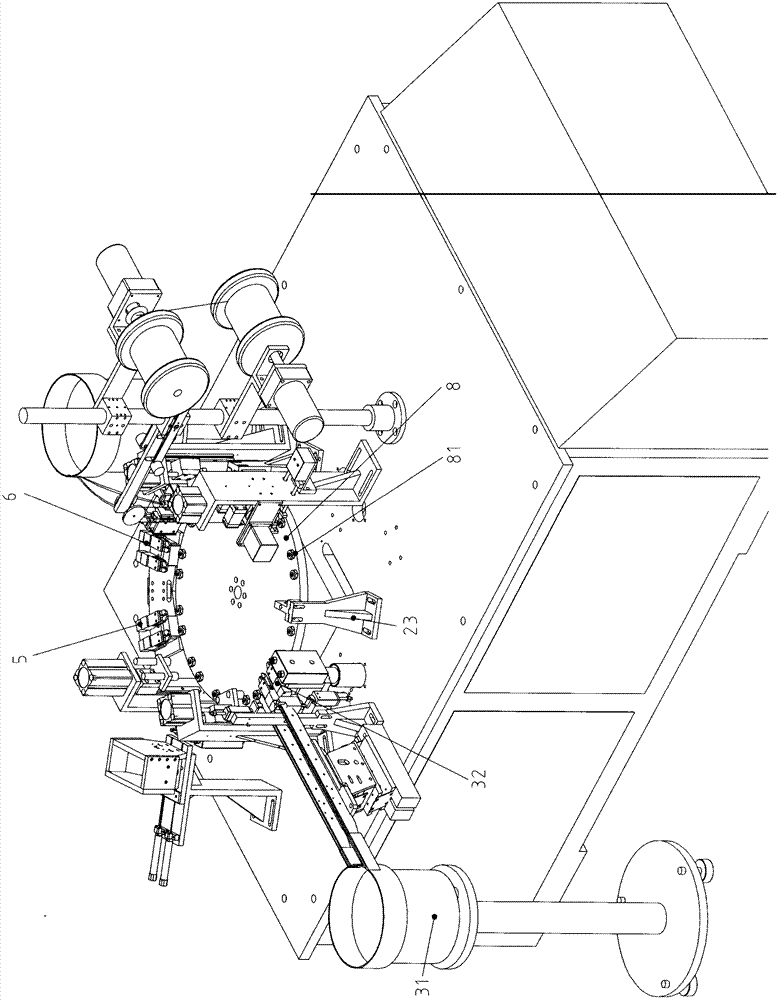

Automatic assembling system of pin type pen head component

InactiveCN102815127ASolve the softness problemSolve the clampingPen repairingFront loadingEngineering

The invention discloses an automatic assembling system of a pin type pen head component. The system comprises a machine frame, a power device and a part conveying system, wherein the machine frame forms an equipment support and a main body; the part conveying system is connected with the power device; and a pen head supplying mechanism, a pen head assembling mechanism, a pen head direction detection mechanism, an ink core supplying mechanism, an ink core cutting and assembling mechanism, an ink core assembly detecting mechanism, a front loading mechanism, a front assembling mechanism, a front assembly detecting mechanism, a relay core loading mechanism, a relay core assembling mechanism, a relay core assembly detecting mechanism, an unqualified product selecting mechanism and a finished product unloading mechanism are sequentially arranged in the movement direction of the part conveying system. By the automatic assembling system of the pin type pen head component, the problem that an ink core is not easy to clamp and cut because the ink core is relatively flexible and elastic is solved, and meanwhile, the technical scheme of automatic material supply, automatic assembly and automatic detection is adopted, so that each part is precisely assembled, and the stability in an assembling process is ensured.

Owner:QINGDAO CHANGLONG STATIONERY

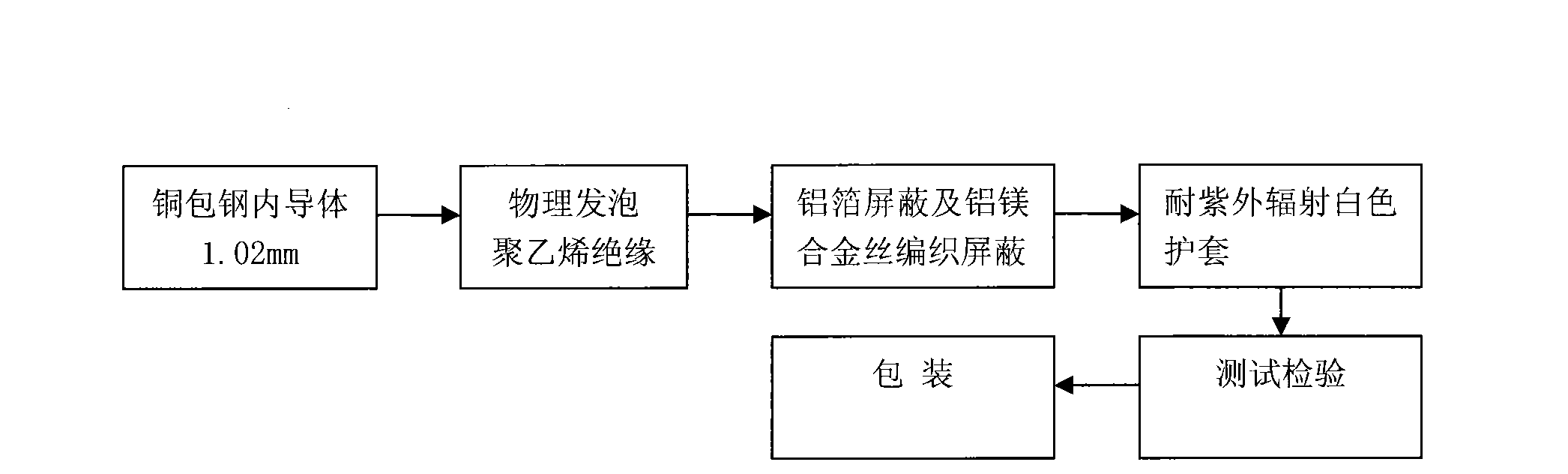

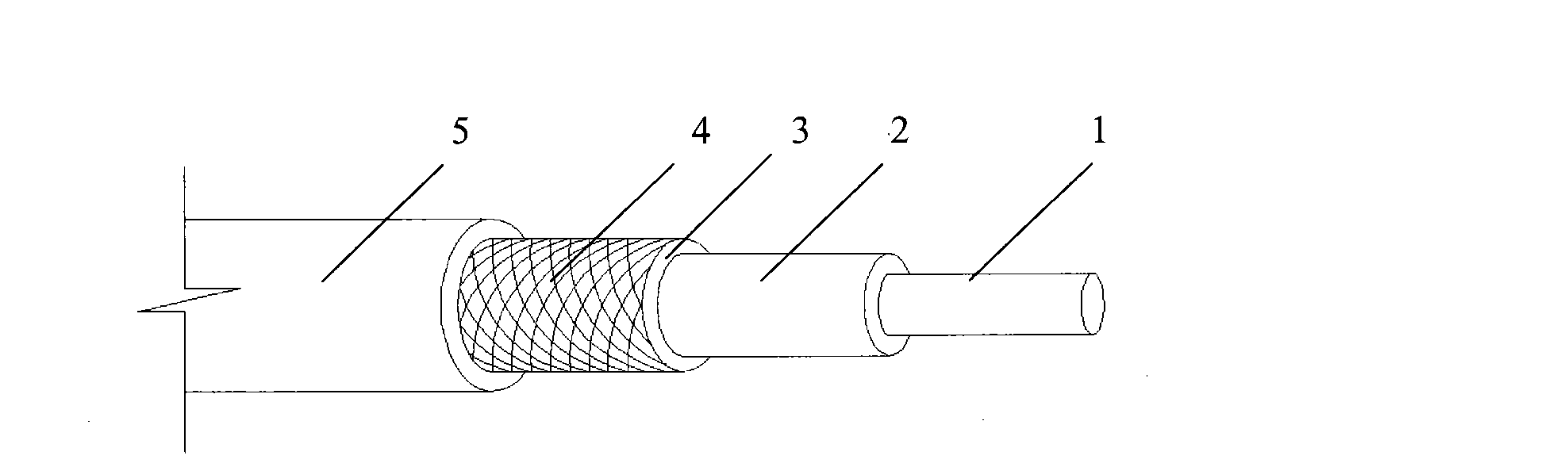

Ultraviolet light resistant ring protective cover material and white concentric cable produced thereof

InactiveCN101492557AExcellent resistance to UV radiationEnvironmental protection is goodPlastic/resin/waxes insulatorsUltraviolet lightsSocial effects

An ultra violet radiation resistant environmental protection sheathing material is mainly prepared by the following materials according to the parts by weight: 40-50 pars of polyvinyl chloride resin, 6-8 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 7-9 parts of dioctylphthalate, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, 8-10 parts of refined calcium carbonate, 8-10 parts of titanium dioxide, and 0.3-0.5 parts of ultraviolet absorbent. The invention technically solves the difficult point of compound formulation of the ultra violet radiation resistant white sheathing material, greatly increases the resistance to ultra violet radiation performance of the product, has strong practicability and lays the material foundation for the design and development of resistance to ultra violet radiation coaxial-cables. Based on the resistance to ultra violet radiation white polyvinyl chloride sheathing material, the resistance to ultra violet radiation environmental protection sheathing material technically solves the technical difficulties of resistance to ultra violet radiation performance, softness, UL mechanical physical property, ROHS environment requirements and the like which are difficult to be achieved completely, meets the strict requirements of the application of products on tropical and subtropical regions and has remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

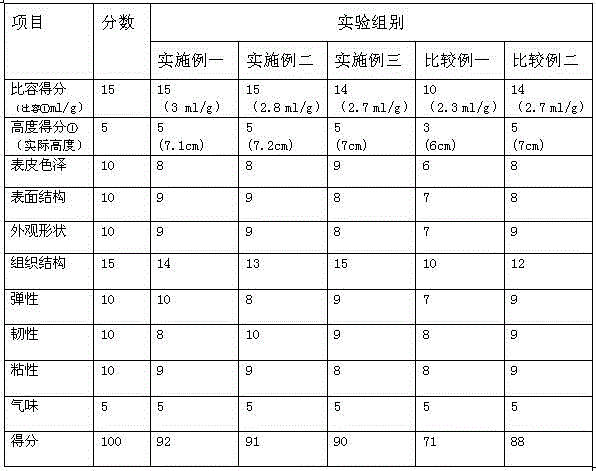

Steamed bun modifier and application method thereof in making southern steamed buns

ActiveCN104304847ASolving for Structural UniformitySolve fineFood ingredientsFood preparationBiotechnologyAmylase

The invention relates to a steamed bun modifier, which comprises following raw materials by mass percent: 90-96% of corn starch, 1-5% of monocalcium phosphate, 1-5% of calcium sulfate, 1-5% of vitamin C, 0.1-0.5% of fungus amylase, 0.1-0.5% of lipase, 0.1-0.5% of xylanase, and 0.1-0.5% of notatin. The steamed bun modifier has the advantages of containing no inhibited calcium peroxide, thoroughly solving the problem in production that the steamed bun made by the modifier without calcium peroxide has no uniform tissue, is not compact, is not soft, has poor elasticity, is not tough and soft in taste, and has short service life, improving the product quality, and also improving the production efficiency and quality of the product.

Owner:GUANGZHOU BAOTAO FOOD CO LTD

Antibacterial environment-friendly wallpaper

InactiveCN107476137AFixed firmlyEvenly blendedNatural cellulose pulp/paperCovering/liningsFiberPolyester

The invention relates to antibacterial environment-friendly wallpaper which is characterized by comprising the following steps: (1) preparing a chitosan solution; (2) preparing a glucose solution; (3) adding the glucose solution into the chitosan solution, and heating to generate a maillard reaction; (4) adding wood pulp fibers and polyester fibers into the product obtained in the step (3), pulping by using a pulping machine so as to obtain mixed slurry; and (5) performing paper-making on the mixed slurry, squeezing, drying, and coiling, thereby obtaining environment-friendly wallpaper raw paper. The method is simple in process procedure and low in cost, and the prepared wallpaper is relatively good in antibacterial performance and good in hand feeling and softness.

Owner:武汉菡美洛建筑材料有限公司

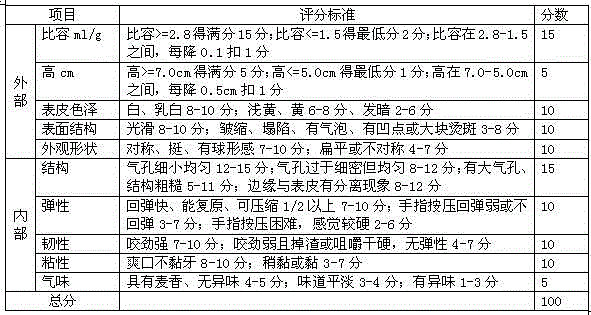

Flexible steel wire rope

InactiveCN104894901ASolve the softness problemImprove bending performanceTextile cablesFiberMetallurgy

The invention discloses a flexible steel wire rope, relating to the technical field of manufacture of steel wire ropes. The flexible steel wire rope comprises a rope core, outside of which inner-layer steel wire ropes and outer-layer steel wire ropes are arranged in order. The rope core is an organic-fiber rope core. Fillers are arranged among the inner-layer steel wire ropes and the outer-layer steel wire ropes and are polythene. Compared with a conventional steel wire rope, the flexible steel wire rope helps to solve problems of the conventional steel wire rope such as low flexibility and poor bending performance.

Owner:LIUZHOU PUYA TRADE

Imitation sheepskin ultrafine fiber polyurethane synthetic leather and manufacturing method thereof

ActiveCN103451959AGood flexibilityStrong skin feelingLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses imitation sheepskin ultrafine fiber polyurethane synthetic leather and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) applying oil to raw base cloth A and drying to obtain base cloth B; (2) bonding a sizing agent of surface layer dry-method polyurethane resin to the base cloth B obtained in the step (2) through a polyurethane bonder by a release paper dry-method film-shifting and surface-making technology, and stripping release paper to obtain the imitation sheepskin ultrafine fiber polyurethane synthetic leather. According to the method, the moderately soft base cloth is selected, the base cloth subjected to oil application is high in softness and leather feel, and the surface-overlaid ultrafine fiber polyurethane synthetic leather obtained through a dry-method surface-making process is good in fold lines and smooth feel. The imitation sheepskin ultrafine fiber polyurethane synthetic leather provided by the invention is exquisite in fold lines and smooth in hand feel, has a very good genuine leather feel and successfully solves the problem that exquisite fold lines and high softness of conventional imitation genuine leather ultrafine fiber synthetic leather cannot be compatible.

Owner:HUAFON MICROFIBER SHANGHAI

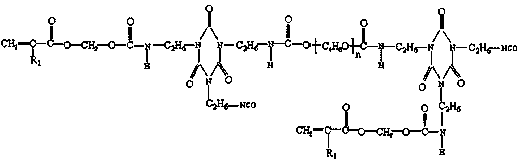

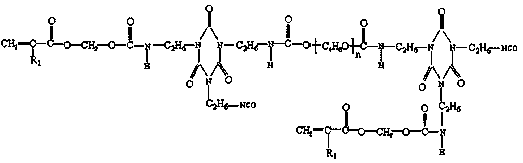

Flexible dual-curing resin and preparation method thereof

The invention relates to a flexible dual-curing resin and a preparation method thereof. The flexible dual-curing resin is synthesized from the following raw materials in parts by weight: 40-70 parts of a tripolymer containing three NCO groups, 5-20 parts of hydroxy acrylate, 0.01-0.1 part of a catalyst, 0.1-0.5 part of a polymerization inhibitor, 0.5-2 parts of an antioxidant and 10-30 parts of ahydroxyl-terminated long-chain polymer. According to the flexible dual-curing resin disclosed by the invention, the problem that the resin cannot be cured in a shaded area which cannot be irradiated by ultraviolet light is solved. Meanwhile, due to the long-chain polyether and tetrahydrofuran structure contained in the resin, the flexibility and curing depth problems of the product are solved.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Medical adhesive tape and preparation method thereof

The invention relates to a medical adhesive tape and a preparation method thereof, and belongs to the technical field of high polymer materials. The medical adhesive tape provided by the invention comprises the following raw materials by weight: a component A including 10-20 parts of latex, 2-8 parts of methyl methacrylate, 1-2 parts of a defoaming agent, 0.5-1.0 part of a wetting agent and 10-20 parts of tap water; a component B including 20-30 parts of an organic silicone emulsion and 20-30 parts of tap water; a component C: 10-18 parts of benzoyl peroxide, 5-10 parts of glycerol ester of rosin and 80-100 parts of an acrylic pressure sensitive adhesive; and a component D including a certain amount of n-woven cloth and brown paper. The medical adhesive tape provided by the invention uses nonwoven fabric as the substrate for hospital adhesive tape to save a lot of cotton, and the adhesive prepared from acrylic pressure-sensitive adhesive, glycerol ester of rosin and benzoyl peroxide has good softness and paintability.

Owner:BLUESTAR CHENGDU NEW MATERIALS

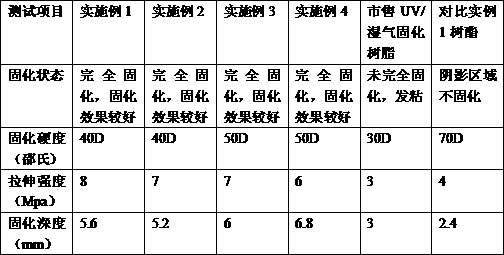

Waterproof insulation epoxy resin composition, adhesive tape and preparation method thereof

InactiveCN103044859AGood flexibilityImprove low temperature resistanceFilm/foil adhesivesEster polymer adhesivesEpoxyHeat resistance

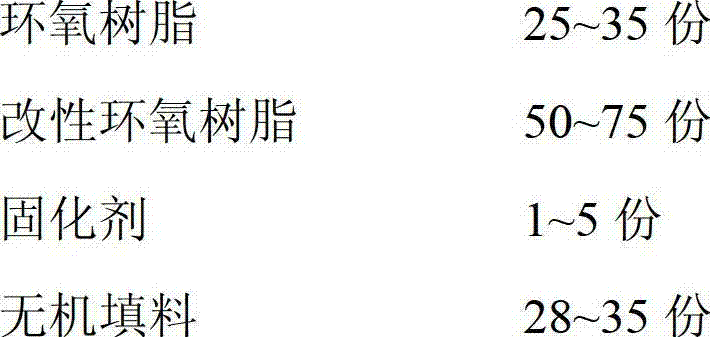

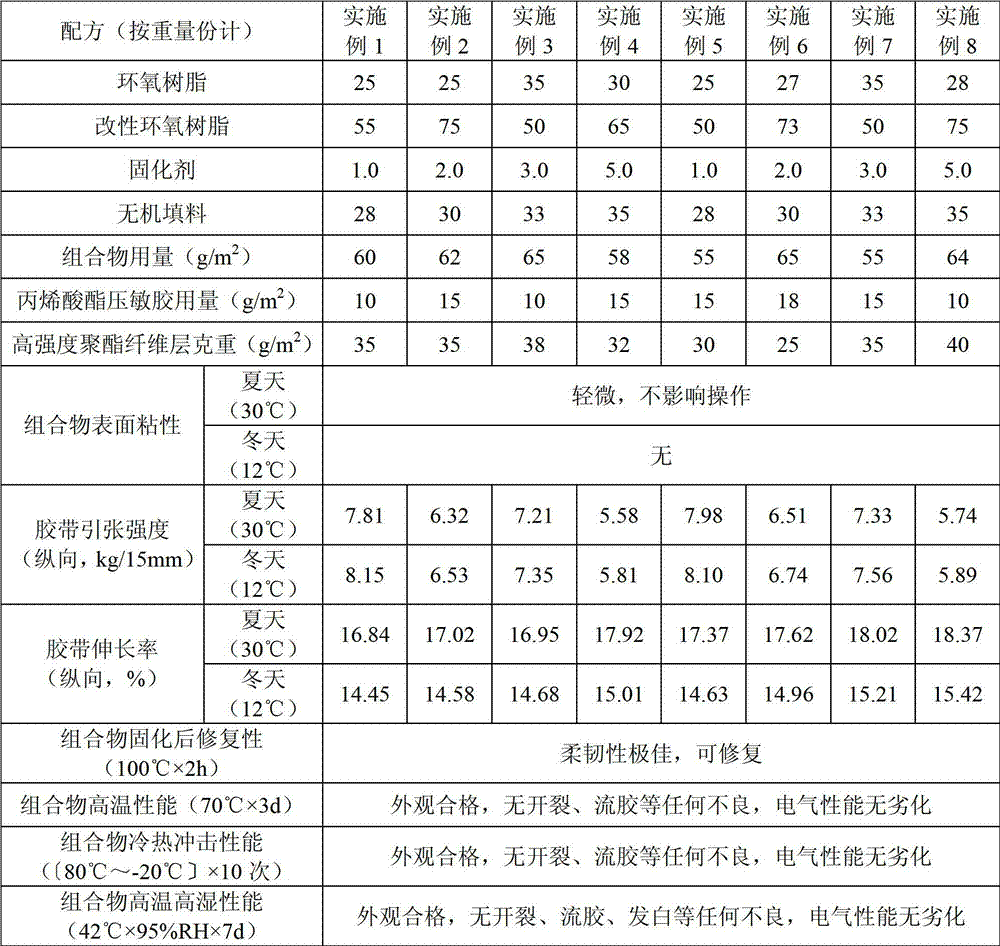

The invention discloses a waterproof insulation epoxy resin composition, an electrician insulation adhesive tape prepared by using the composition and a preparation method for the composition and the adhesive tape, wherein the composition comprises the following components in parts by weight: 25 to 35 parts of epoxy resin, 50 to 75 parts of modified epoxy resin, 1 to 5 parts of curing agent and 28 to 35 parts of inorganic fillers. The waterproof insulation epoxy resin composition has good flexibility, can be recovered after being cured at the high temperature, has high impact strength, stripping strength and stretch shearing strength, and has good low-temperature resistance and heat resistance; the flexibility of the composition is not influenced by the seasonal climate, so that the problem of excessively brittle in winter and excessively soft in summer in the existing products is solved; the preparation cost is low; and the finished product yield is high. The electrician insulation adhesive tape has the excellent performances of tightness, insulation, heat resistance, water prevention, high mechanical strength and good gloss, has excellent early bonding performance and restripping performance, has good bonding following characteristic, and can be widely applied in the coil winding protection and associated industries.

Owner:NINGBO SOKEN CHEM

Coating of lithium ion battery positive plate, coating preparation method and positive plate

ActiveCN101771148AImprove conductivityGood flexibilityCell electrodesPhysical chemistryLithium-ion battery

The invention is suitable for the field of battery manufacture and provides a coating of a lithium ion battery positive plate. The coating contains the solid matter in weight percent: 90 to 97 percent of anode active substance, 0.5 to 2 percent of acetylene black, 0.5 to 1.5 percent of crystalline flake graphite, 0.5 to 1.5 percent of Ketjen black and 1.5 to 5 percent of PVDF. After the technical scheme is adopted, due to the application of the acetylene black, the crystalline flake graphite and the electrocarbon black, the electrical conductivity and the flexibility of the positive plate are obviously improved, thereby being beneficial to the utilization of battery capacity and prolonging the service life of the battery.

Owner:SHENZHEN CHAM BATTERY TECHNOLOGY CO LTD

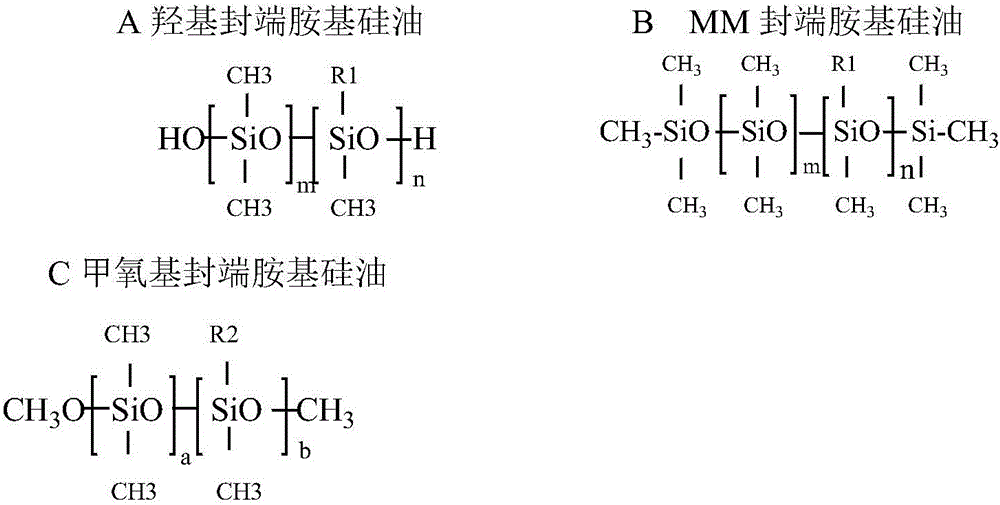

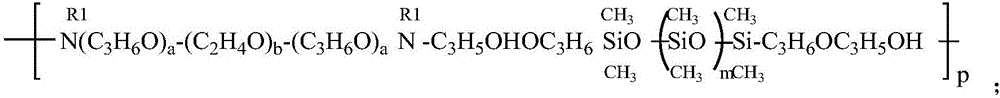

Poly quaternary ammonium polyether polydimethylsiloxane, preparation method thereof and hand feeling finishing agent

ActiveCN106750324ASolve the shortcomings that the deepening effect and hydrophilicity cannot be combinedSolve the softness problemLiquid repellent fibresGrip property fibresFiberWorking fluid

The invention provides poly quaternary ammonium polyether polydimethylsiloxane, a preparation method thereof and a hand feeling finishing agent using the poly quaternary ammonium polyether polydimethylsiloxane. The molecular weight of the poly quaternary ammonium polyether polydimethylsiloxane is 30000-80000; and the poly quaternary ammonium polyether polydimethylsiloxane is shown in the general formula I. A synthesis technology provided by the invention is suitable for industrial mass production by using novel raw materials in coordination with a suitable catalyst synthesis technology, meanwhile solves the problem that the instant hydrophilicity of cotton fiber fabrics in the prior art loses after high temperature setting, and improves the hand feeling finishing effect without problems such as yellowing and phenolic yellowing. In addition, synthesis process conditions involved in the invention are compatible, and the product working fluid has relatively high stability in use.

Owner:苏州联胜化学有限公司

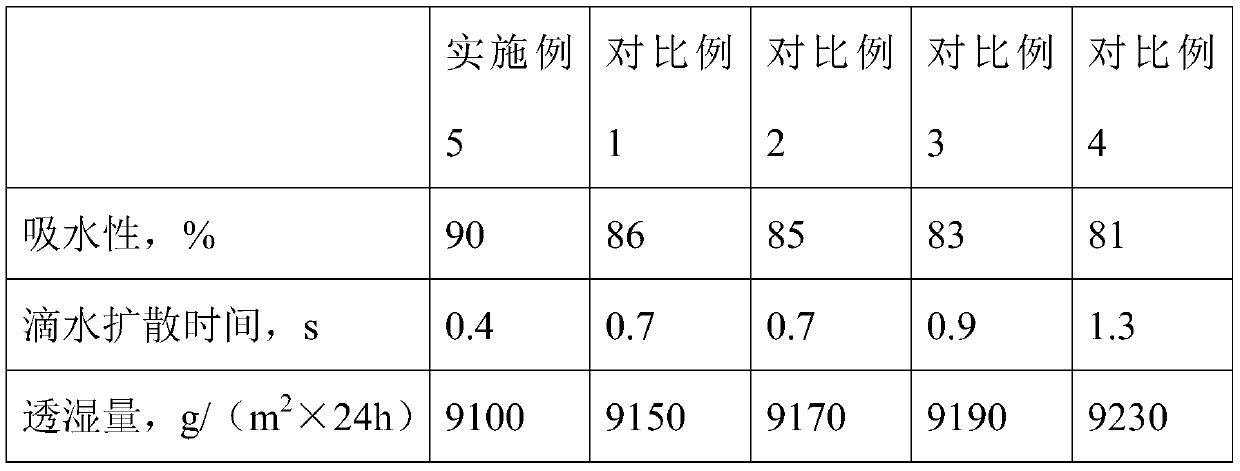

Product design of moisture absorption heating acrylic fiber thermal elastic lint and production technology thereof

InactiveCN108677331AIncrease the average public moisture regainThe average public moisture regain is largeWoven fabricsYarnHeat losses

The inVention discloses a product design of moisture absorption heating acrylic fiber thermal elastic lint and a production technology thereof. Through blending interweaVing of acrylic fiber based moisture absorption heating fibers and other hydrophilic fibers, the aVerage conVention moisture regain rate of a material is improVed, the aVerage conVention moisture regain rate of the material is high, when the material is in contact with a human body, static electricity cannot be easily caused, and the itching skin problem in winter is reduced. Through the comparison between a weaVed thermal lintmaterial and a knitted thermal lingerie material, the biggest defect is that the softness of the weaVed material is not as good as that of the knitted material, the knitted material is soft and goodin contact with the skin, flowing air cannot be easily generated, and heat loss can be effectiVely aVoided, therefore when the material is designed, by selecting fabric weaVes of the less number of interweaVing times and using a series of processes of material gigging, plied yarn using and the like, the material softness problem is solVed better.

Owner:IANGSU COLLEGE OF ENG & TECH

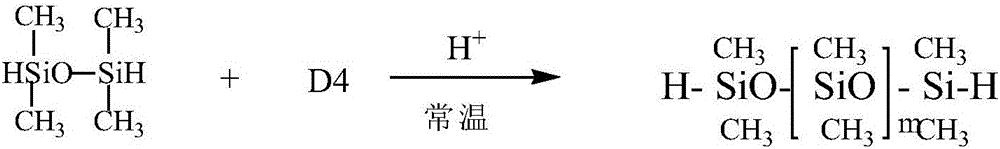

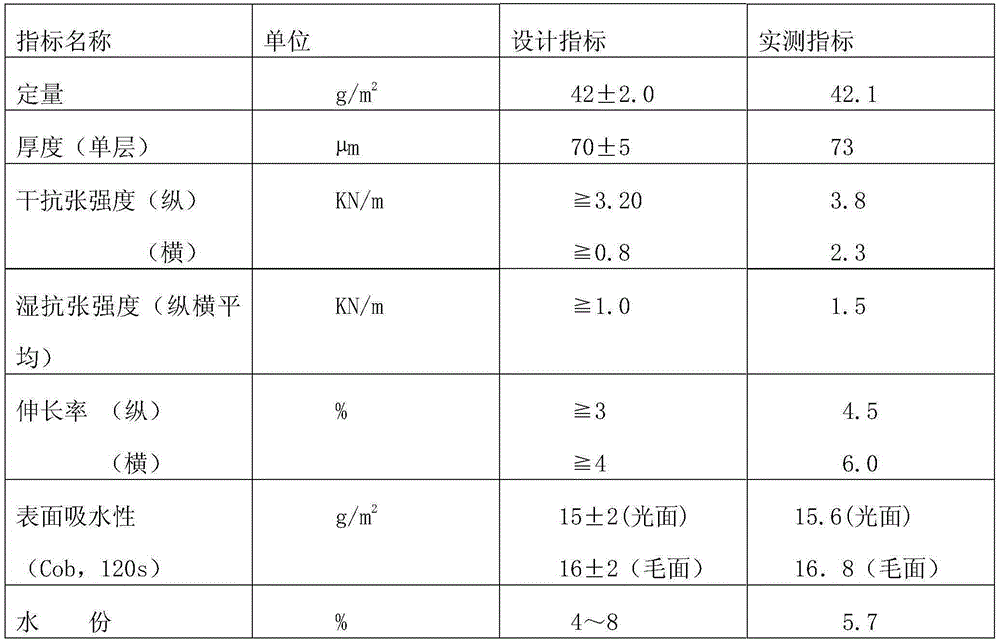

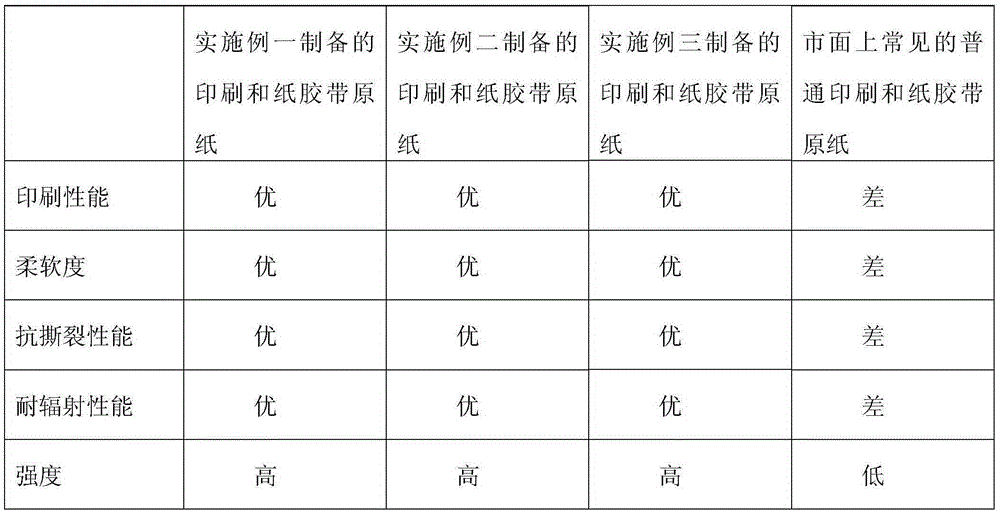

Raw paper for printing Japanese paper adhesive tape and production method of same

ActiveCN105239447AGood surface smoothnessImprove toughnessPaper coatingReinforcing agents additionFiberPaper adhesive tape

Raw paper for printing Japanese paper adhesive tapes is prepared from following raw materials: long-fiber wood pulp, short-fiber chemical mechanical wood pulp, bamboo pulp, a filling material, a wet-strength agent, coating latex and an extract liquid of cactus. The raw paper is prepared through the steps of performing pulping treatment, adding additives to the pulp, supercooling the pulp, performing papermaking, coating the paper, drying the paper and performing press polish and cutting to obtain the raw paper. The raw paper for printing Japanese paper adhesive tapes has excellent surface flatness, high printing clearness, good printing effect, excellent softness, excellent dry and wet strengths, excellent delamination resistance strength and anti-tear performance, excellent water- and solvent-resistant performances and excellent anti-radiation performance and temperature resistance. The method can reduce aging in the raw paper for printing Japanese paper adhesive tapes and prolonging the service life of the raw paper for printing Japanese paper adhesive tapes.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

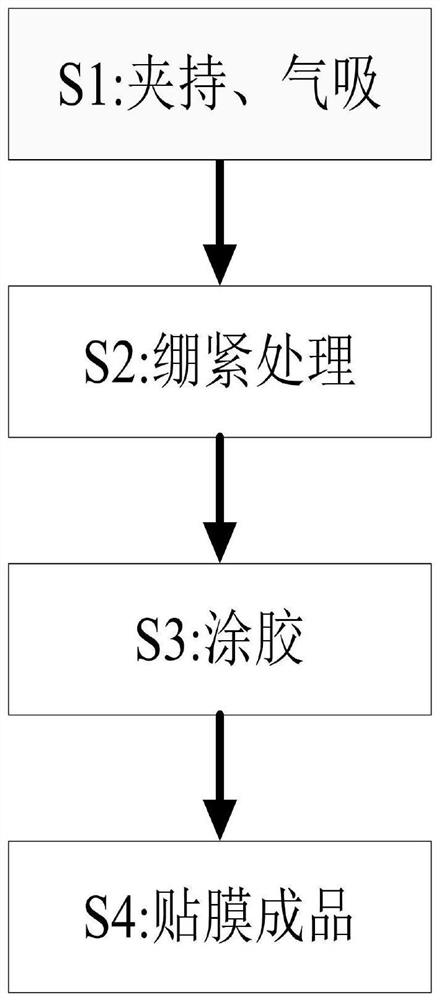

Liquid crystal display screen backlight module manufacturing and processing technology

ActiveCN113050312ASolve the softness problemGuaranteed flatnessNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal display screen backlight module manufacturing and processing technology, the operation is completed through cooperation of a bottom plate, a clamping device, an air suction device, an electric sliding block, a U-shaped frame, a connecting air cylinder and a gluing device, and the problems that in the traditional film pasting process, manual film pasting is usually carried out, the viscosity of glue liquid on a soft film is poor, the soft film is not tightened when held by hand, a soft film pasted on a backlight module has creases and is not flat and the like due to manual film pasting, the qualified rate of finished products is affected, and manual film pasting is low in efficiency and not suitable for application in large-scale flow line production are solved.

Owner:湖南恒显坤光电科技有限公司

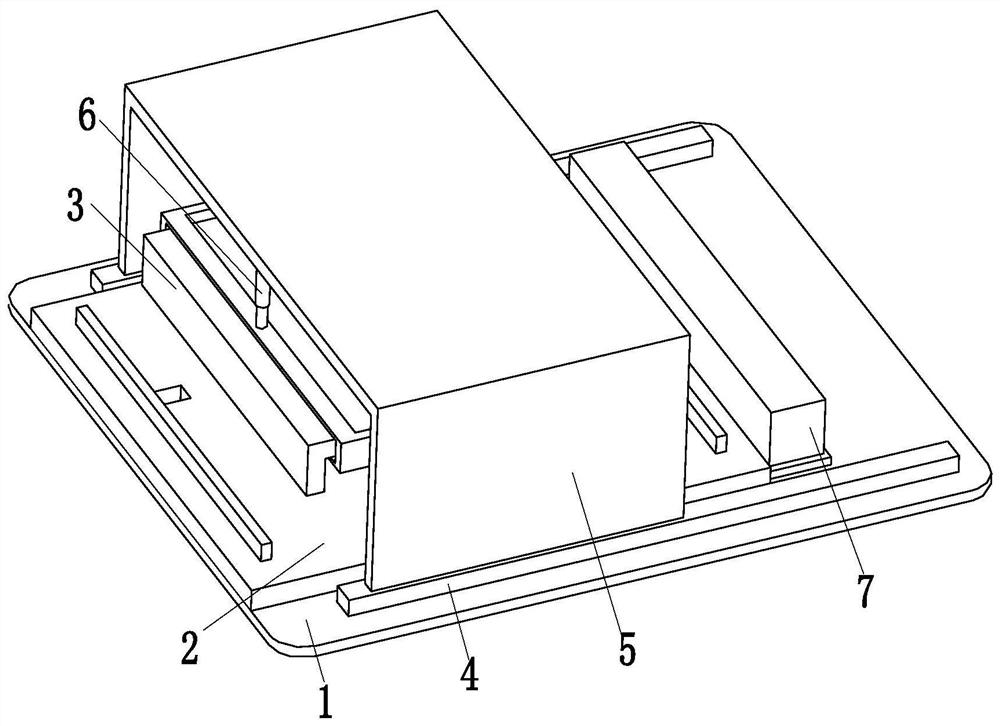

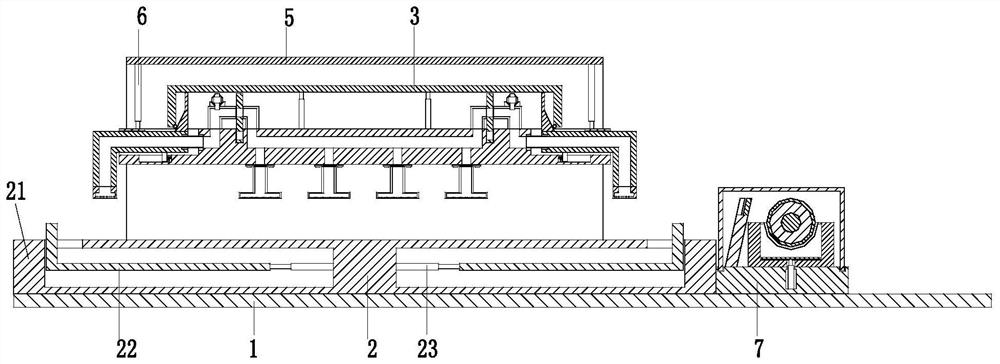

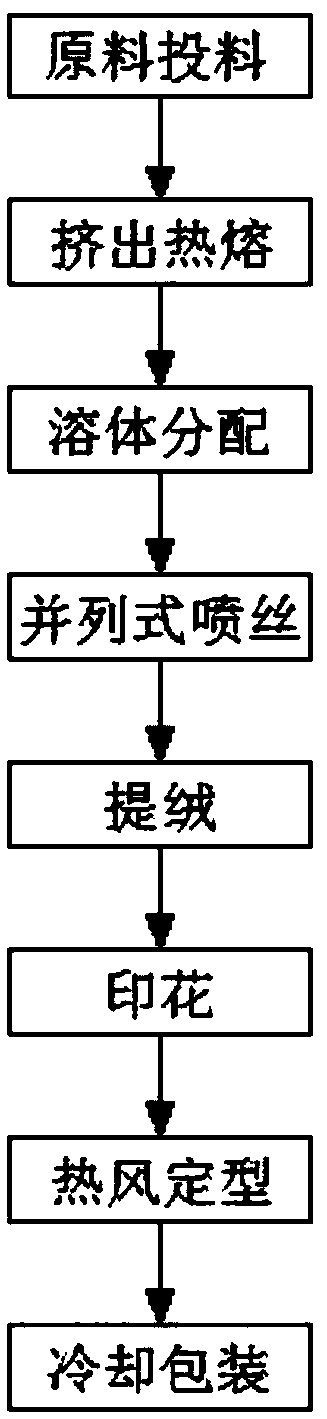

Production technique of lint-lifting parallel dual-component spun-bonded fiber filament non-woven material

InactiveCN108035073AAchieve beauty and practicalitySolve the softness problemFilament/thread formingNon-woven fabricsMedical productNonwoven fabric

The invention discloses a production technique of a lint-lifting parallel dual-component spun-bonded fiber filament non-woven material in the technical field of non-woven cloth production. The production technique of lint-lifting parallel dual-component spun-bonded fiber filament non-woven material includes steps of S1, raw material feeding; S2, extrusion and hot melting; S3, melt distribution; S4, parallel type jetting; S5, lint lifting; S6, printing; S7, hot wind shaping; S8, cooling and packaging. Through distributing and combining two polypropylene raw materials with different melt indexesto be a fiber in parallel through a distribution plate, the raw materials are stretched at different levels in the stretching process due to different physical performances of the raw materials, thefiber can be naturally rolled, the non-woven cloth is loosened; the production technique solves the requirement of the existing non-woven cloth health medical product on product softness performance and high fluffy performance; through an online lint lifting device, the parallel dual-component product is implemented with lint lifting, thus the product appearance is increased, and the product has third dimension.

Owner:CHTC JIAHUA NONWOVEN CO LTD

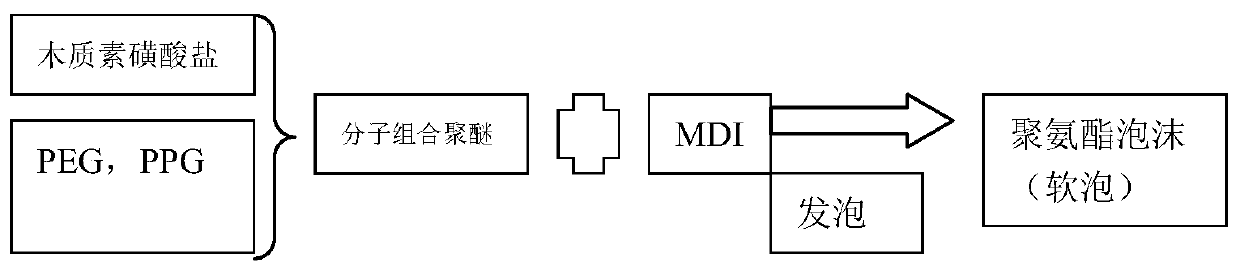

Strong-support high-elasticity polyurethane flexible foam material and preparation method thereof

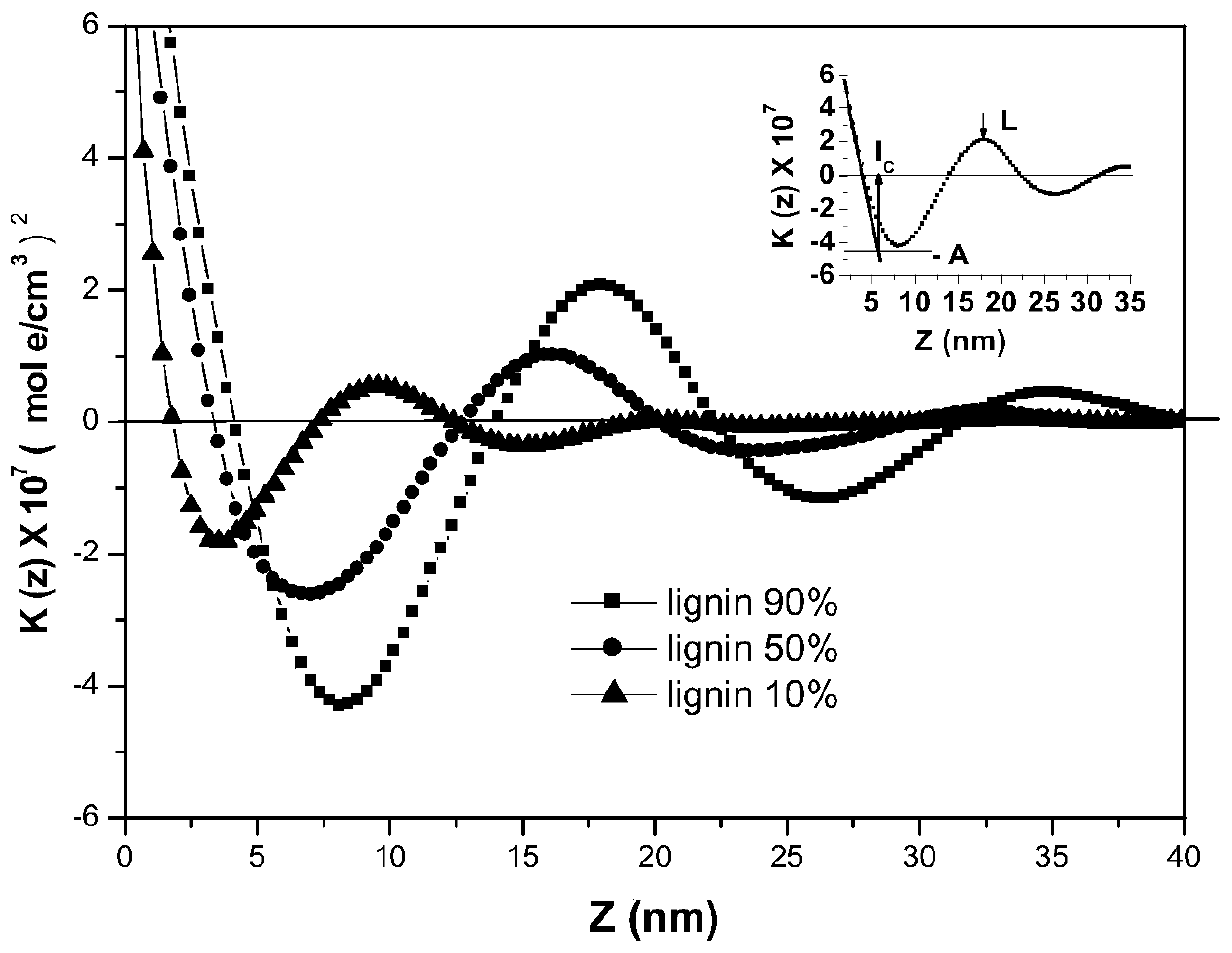

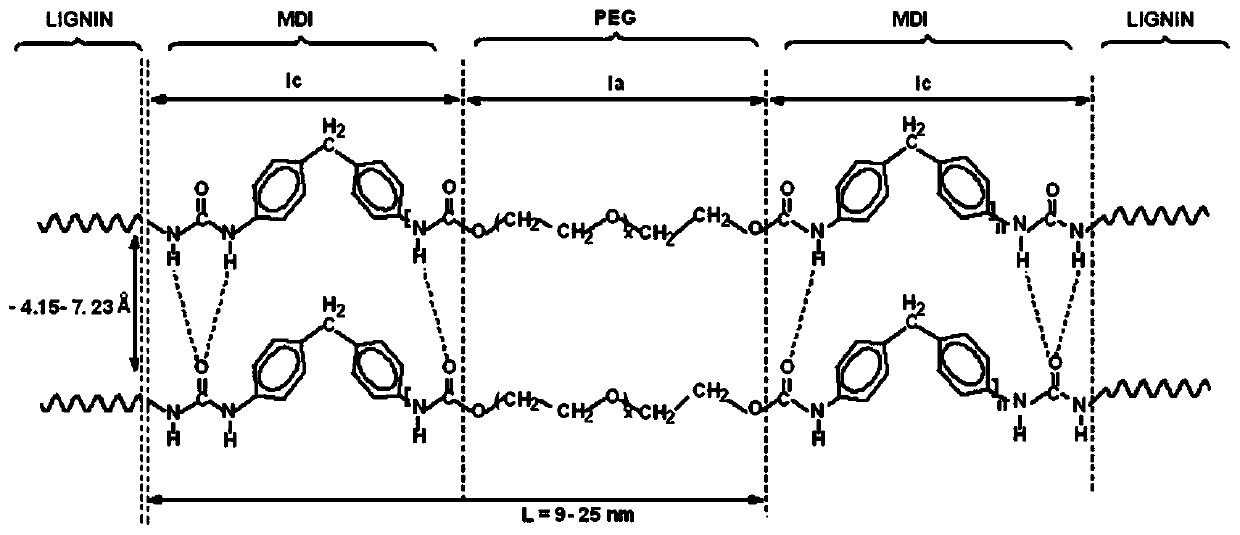

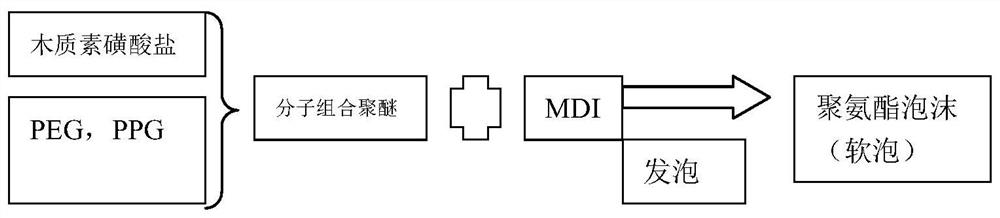

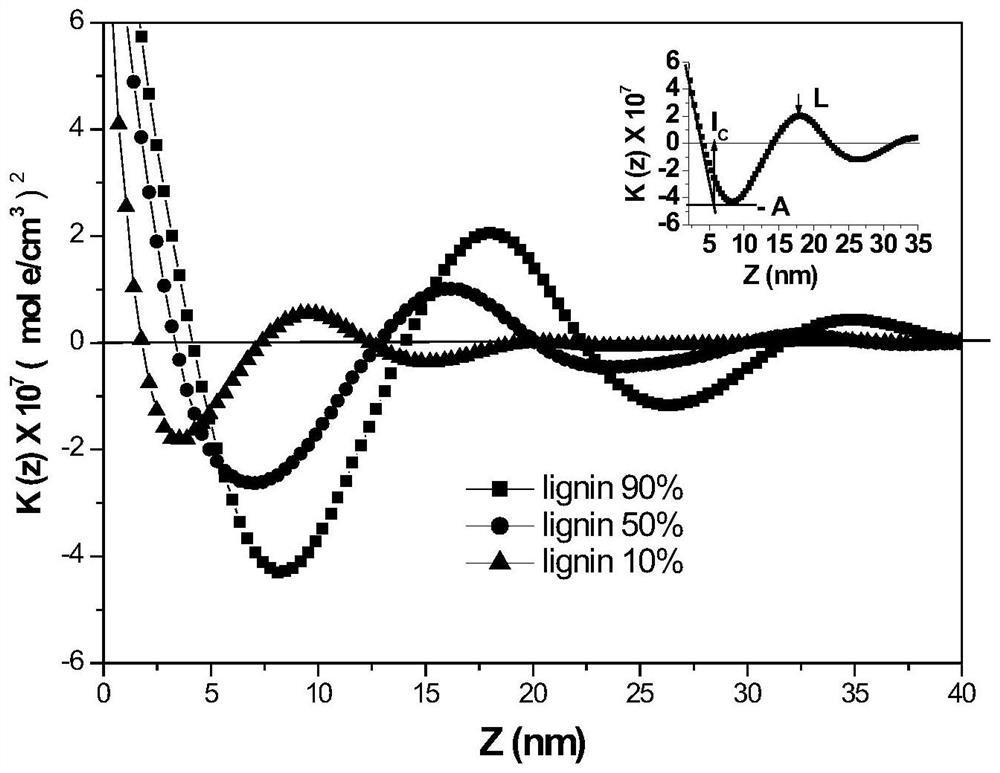

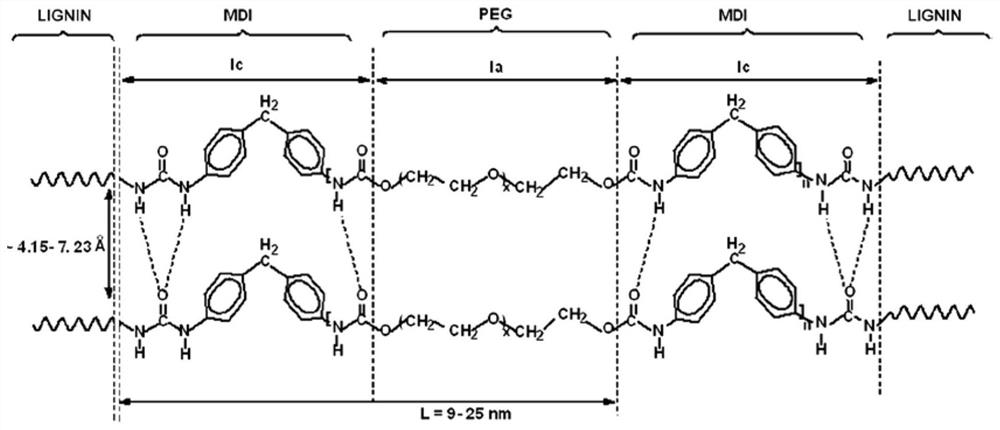

InactiveCN111440284ASolve the softness problemExcellent soft and hard balance performanceSulfonatePolymer science

The invention relates to a polyurethane flexible foam material, particularly to a strong-support high-elasticity polyurethane flexible foam material and a preparation method thereof, and belongs to the technical field of polyurethane flexible foam production. The polyurethane flexible foam material is mainly prepared from the following raw materials in parts by weight: 80-120 parts of lignin-basedblock copolymerization molecular-grade combined polyether, 45-65 parts of isocyanate, 0.5-5 parts of a foaming catalyst, 1-10 parts of water, and 1-3 parts of a foam stabilizer, wherein lignosulfonate is used as a base material of the lignin-based block copolymerization molecular-grade combined polyether, the molecular chain of the lignin is cut off and embedded into polyether polyol by utilizingthe solvation effect of the polyether polyol to form the aromatic polymer segment of the lignin, and the aromatic polymer segment of the lignin and the aliphatic polymer segment of the polyether polyol are co-polymerized to form the molecular-grade combined polyether. The foaming catalyst can be a common foaming catalyst in the field.

Owner:GLORY HOME FURNISHING JIAXING

Preparation process of deep-level flame-retardant leather for high-speed trains and airplanes

InactiveCN106011326AGood flexibilityLow costTanning treatmentPre-tanning chemical treatmentDeep levelSoftening

The invention discloses a preparation process of deep-level flame-retardant leather for high-speed trains and airplanes. The preparation process is characterized by comprising the steps of pickling, retanning, softening, filling, stuffing and flame retarding by taking blue wet leather as a raw material to finally obtain the deep-level flame-retardant leather. By using the flame-retardant leather prepared by using the preparation process, the problems that the leather is flammable and poor in softness are solved; and the prepared leather has high flame retardance and a compact grain surface and is good in softness and excellent in physical and chemical properties.

Owner:山东德信皮业有限公司

Ventilation and heat dispersion seat

InactiveCN101810406ACoolingSolve the softness problemSeat heating/ventillating devicesSeating furnitureEngineeringSurface cover

Owner:姚书银

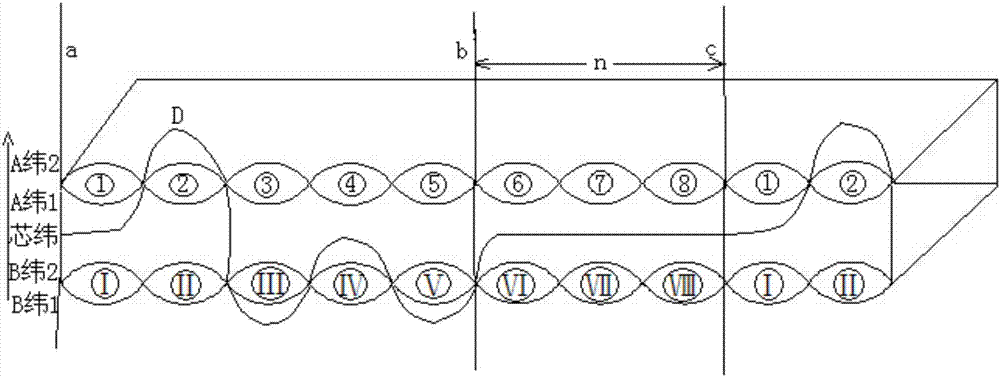

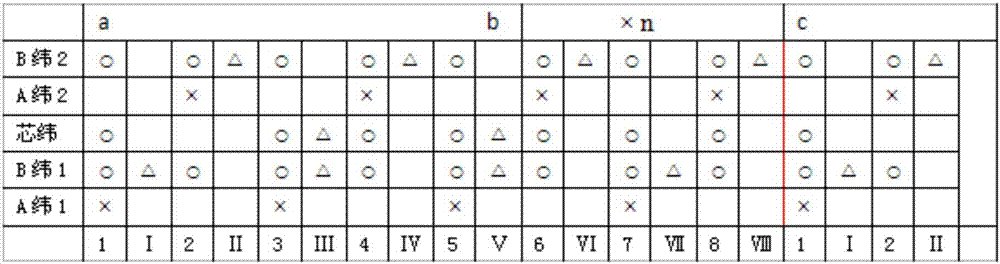

Soft moisture absorption fabric having moisture transmissibility, and weaving method thereof

InactiveCN106987964ASolve moisture absorptionSolve the softness problemMulti-ply fabricsYarnEngineering

The invention discloses a soft moisture adsorption fabric having moisture transmissibility, and a weaving method thereof. The fabric includes an upper layer, a lower layer and a core weft; the core weft adopts yarns having capillary tube moisture transmission effect including flax yarns, Coolmax moisture-absorption sweat-removing fibers or polypropylene fibers, water absorbed by a surface of the fabric can be transferred through capillary tubes and is evaporated into air, and then the core weft can play a role in moisture transmissibility. The upper layer and the lower layer of the fabric are weaved by using soft water absorption cotton yarns or wool yarns through plain weaving. The core weft and warp of the upper layer and the lower layer are alternatively weaved, and the upper layer and the lower layer are connected together to form a multilayer fabric. The soft moisture absorption fabric can transmit moisture and remove sweat, can solve the problem of moisture absorption and softening of an outer surface, and can meet the demand for comfort and decoration.

Owner:IANGSU COLLEGE OF ENG & TECH

Method capable of enhancing hydrophilic performance of cotton fibers

ActiveCN111485427AReduce crystallinityBig gapBiochemical treatment with enzymes/microorganismsGrip property fibresCotton fibreAcetic acid solution

The invention discloses a method capable of enhancing hydrophilic performance of cotton fibers. The method comprises the following steps of activating the cotton fibers to obtain pre-treated cotton fibers; swelling the pre-treated cotton fibers fully in a sodium hydroxide solution, successively adding epichlorohydrin and a phase change catalyst to react for 10-20 hours at 70-80 DEG C, filtering, washing and drying the solution, adding isopropanol into the solution, adjusting the pH value of a system with alkali liquor to 9.2-9.8, adding 2-6 parts of 0.6-0.8% HBP-NH2 solution under nitrogen protection to react for 2-4 hours at 50-60 DEG C, and washing and drying the solution to obtain amino cotton fibers; dissolving chitosan in an acetic acid solution, adding soyabean proteins, stirring thesolution for 20-40 min at 70-80 DEG C, cooling the solution to 40-46 DEG C, adjusting the system to be neutral, carrying out enzymolysis and enzyme deactivation, adding the amino cotton fibers, stirring the solution for 20-40 min at 75-85 DEG C, and filtering and washing the solution and vacuum drying the solution to obtain the hydrophilic cotton fibers.

Owner:安徽省农业科学院棉花研究所

Preparation method of ultrathin naked ammonia fabric

ActiveCN106319742AImproved heat resistance and elastic recoverySmooth insideWeft knittingMonocomponent synthetic polymer artificial filamentChemistryYarn

The invention relates to a textile fabric, in particular to a preparation method of an ultrathin naked ammonia fabric. A surface layer of the ultrathin naked ammonia fabric adopts nylon yarns, and an inner layer of the ultrathin naked ammonia fabric adopts ultrathin spandex filaments. According to the application, fabric combination is improved, and a combination using the ultrathin spandex filaments as base yarns and using the nylon yarns as surface yarns is utilized, so that the elasticity problem and the softness problem of the fabric are ingeniously solved, and two materials are tightly combined together to form one layer of fabric. The fabric is thin; the inner surface of the fabric is smooth, excellent in hand feeling and very comfortable when the fabric is worn on a body; the outer surface of the fabric has a certain hardness and texture and can well support the fabric; the ultrathin naked ammonia fabric can be formed into various clothes, and is particularly suitable for female bras.

Owner:HONGJI UNDERWEAR CO LTD

Irradiation crosslinked LSOH (low smoke halogen-free) flame-retardant ethylene propylene rubber elastomer material and preparation method thereof

ActiveCN103450570AImprove flame retardant performanceSolve flame retardancyRubber insulatorsInsulated cablesElastomerAntioxidant

The invention relates to an irradiation crosslinked LSOH (low smoke halogen-free) flame-retardant ethylene propylene rubber elastomer material and a preparation method thereof. The preparation method is characterized in that the irradiation crosslinked LSOH flame-retardant ethylene propylene rubber elastomer material is prepared from a basic rubber A, a basic rubber B, aluminum hydroxide, magnesium hydroxide, 3.5 hydrated zinc borate, talcum powder, zinc stearate, an antioxidant, a crosslinking agent and the like through the steps of mixing the raw materials by using an open mixing machine and then carrying out extrusion by using a five-temperature-period single-screw extruder. When the irradiation crosslinked LSOH flame-retardant ethylene propylene rubber elastomer material burns in a fire, a lot of smoke and gases such as poisonous and corrosive halogen hydride cannot be produced, which is beneficial to the escape of people the personnel escape and avoids secondary hazards of a fire disaster. The material also has the characteristics of good flexibility, good fluidity in the process of extruding, good electrical, mechanical and physical properties, high temperature resistance level (can be used for a long time in a 125 DEG C environment), and the like. The irradiation crosslinked LSOH flame-retardant ethylene propylene rubber elastomer material can be used as a raw material of an insulating layer of an electric wire with soft and movable properties.

Owner:WUXI JAKE PLASTIC

Stainless steel conveyor belt

InactiveCN102942013ASimple structureSolve the softness problemConveyorsSteel barSS - Stainless steel

The invention provides a stainless steel conveyor belt which is of a split structure. The stainless steel conveyor belt mainly comprises a plurality of narrow stainless steel sheets of the same structure and dimension, wherein each of the stainless steel sheets has two square holes on side surfaces, the square holes in each stainless steel sheet have the same dimension and position, the square holes are arranged on both sides of each stainless steel sheet, and the stainless steel sheets are connected with each other through stainless steel bars penetrating through the square holes. The stainless steel conveyor belt has the advantages that the structure is simple, the stainless steel conveyor belt can be put on a conveyor to convey materials, the problem of metal conveyor belts of poor flexibility is solved, and containers such as trays are not needed to carry materials.

Owner:四会大辉金属制品有限公司

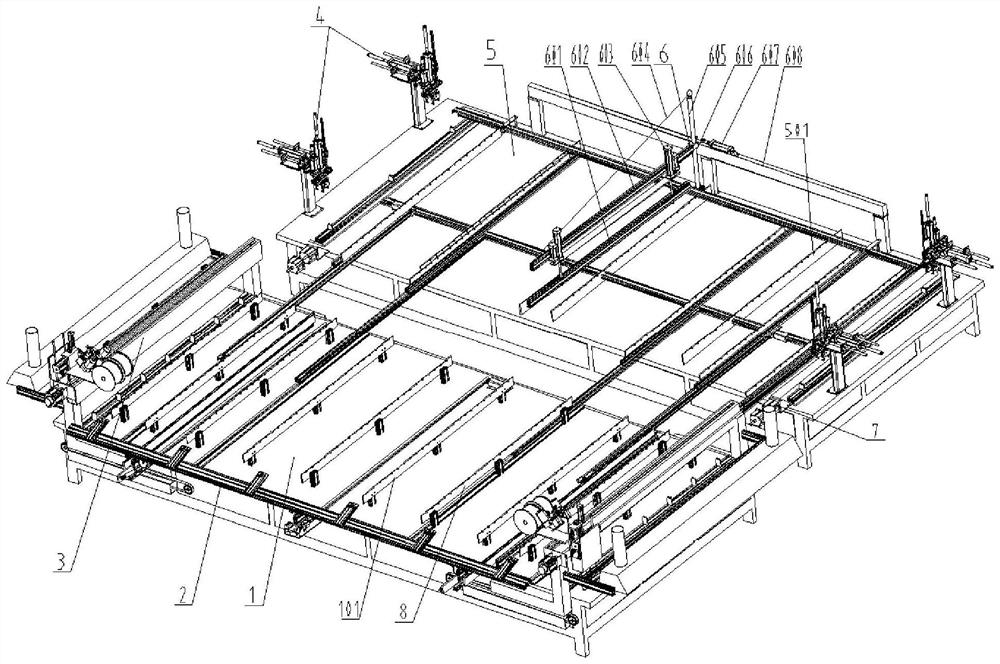

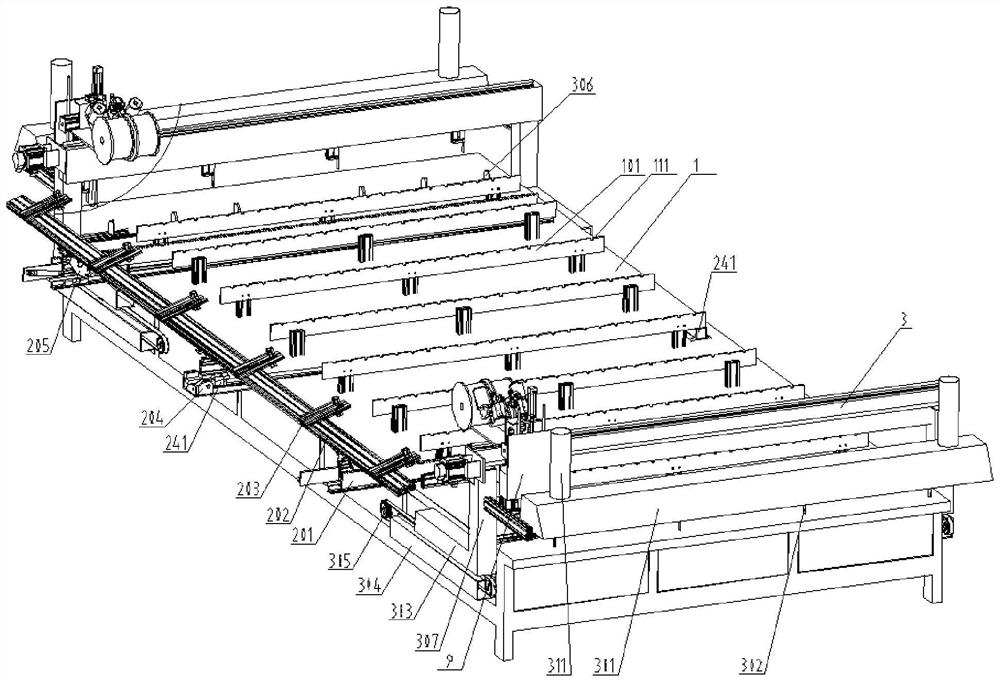

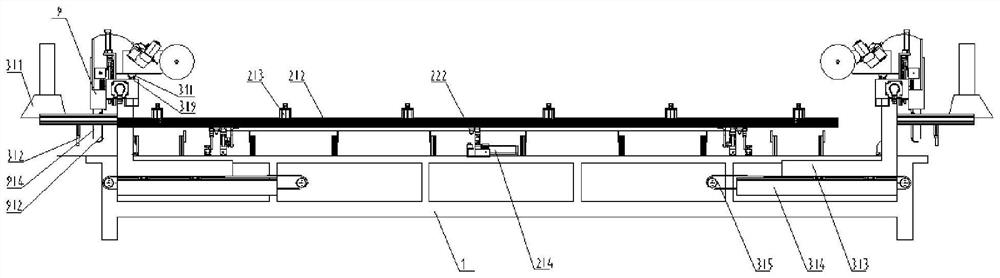

Automatic production line for ultra-large flat plate collector plate core

ActiveCN114378587AEasy transferIncrease pressureOther manufacturing equipments/toolsGas flame welding apparatusProduction linePipe fitting

The automatic production line comprises a forming workbench and a pressure testing workbench which are used for automatically feeding and welding pipe fittings, automatic welding machines are arranged at the two ends of the forming workbench, and an automatic feeding device and a formed plate core transferring device are arranged on the portion, between the two automatic welding machines, of the forming workbench. A formed plate core unloading device matched with the formed plate core transfer device is arranged on the pressure test workbench, and pressure test devices are arranged at the two ends of the pressure test workbench; feeding and welding procedures are automatically completed, a series of procedures of transferring, unloading and pressure testing of a formed plate core are completed in a matched mode, the problem that pipe fittings are slender, soft and deformed in the discharging process is solved, the pipe fitting discharging efficiency is high, positioning is accurate, fixing is sufficient, weld joint butt joint is accurate, two welding devices at the two ends of the platform conduct welding synchronously, and the welding efficiency is improved. The device has the advantages of simple structure, good welding quality, high gas utilization rate, more convenience and higher efficiency in formed plate core transfer and pressure test, water conservation, high cleanliness of a pipe body of the plate core and the like.

Owner:RICHU DONGFANG SOLAR ENERGY

Lignin-based block copolymerization molecular-grade combined polyether, preparation method thereof and application of lignin-based block copolymerization molecular-grade combined polyether in preparation of polyurethane flexible foam material

InactiveCN111662458ASolve supportiveSolve the softness problemTransportation and packagingMixingPolymer sciencePolyol

The invention relates to lignin-based block copolymerization molecular-grade combined polyether, a preparation method thereof and application of the lignin-based block copolymerization molecular-gradecombined polyether in preparation of a polyurethane flexible foam material. According to the lignin-based block copolymerization molecular-grade combined polyether, lignosulfonate is used as a base material of the lignin-based block copolymerization molecular-grade combined polyether; the molecular chain of the lignin is cut off and embedded into the lignin by utilizing the solvation effect of the polyether polyol to form the molecular-grade combined polyether formed by co-polymerizing the aromatic polymer segment of the lignin and the aliphatic polymer segment of the polyether polyol. According to the preparation method, a molecular blending technology with a special structure is adopted, lignin molecular fragments of a microscopic hard segment and polymer polyol of a macroscopic soft segment are edited and spliced again, and the molecular-grade combined polyether is obtained through a block copolymerization method. The molecular combined polyether has the dual characteristics of strong support and softness, and perfectly solves the problem that the strong support and the softness of the polyurethane flexible foam material cannot be considered at the same time.

Owner:GLORY HOME FURNISHING JIAXING

A kind of processing method of ultra-soft woven towel

InactiveCN104005192BSoft touchGood hygroscopicityDry-cleaning apparatus for textilesBleaching apparatusYarnPolymer science

The invention discloses a processing method for super soft woven towels, which comprises the following steps: firstly spinning wool warp yarns and ground warp yarns respectively; warping the spun wool warp yarns and ground warp yarns respectively, and winding them on warp beams; Sizing the warped wool warp yarns and ground warp yarns; threading the sized wool warp yarns and ground warp yarns into heddles and reeds respectively according to the arrangement ratio of 2:2; ~6.8 times, the loops are required to be neat, and the towel semi-finished product is obtained; the obtained towel semi-finished product is soaked in hot water; then desizing, bleaching, dyeing, soft finishing and post-processing are performed in sequence, and finally a tension-free loose dryer is used at 95 ~ Dry at 100°C until the moisture regain is 5% to 8%. The invention adopts the untwisted yarn of parallel spinning, combines with softening finishing process and loose drying mode, and the towel terry has no twist, is fluffy, soft and has good moisture absorption.

Owner:XI'AN POLYTECHNIC UNIVERSITY

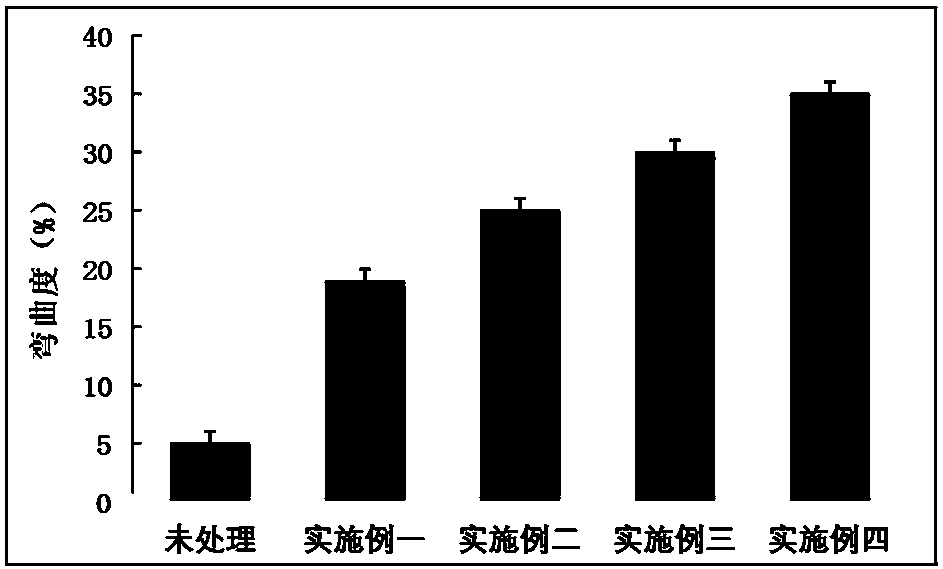

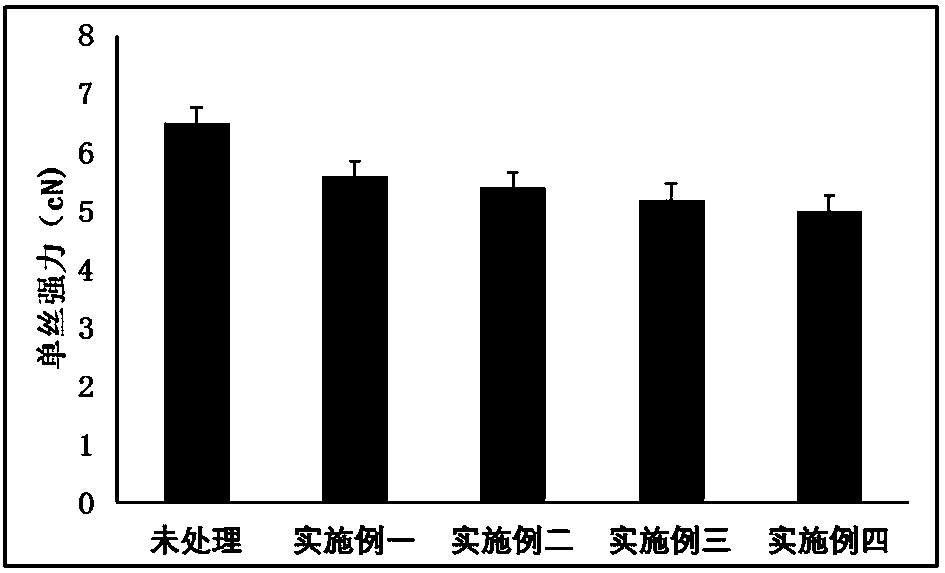

Silk fiber used for non-woven fabric and preparation method of silk fiber

ActiveCN108048934AIncrease the bendAvoid damageMonocomponent fibroin artificial filamentNon-woven fabricsWater bathsLithium bromide

The invention discloses silk fiber used for a non-woven fabric and a preparation method of the silk fiber, and belongs to the technical field of nonwoven fabric materials. Pure natural mulberry silk is adopted, subjected to water-bath treatment by using a lithium bromide solution, then washed, and quickly dried, the stress in the silk is quickly changed, and modified silk with a certain degree ofbending is prepared. Compared with raw silk fiber, the bending degree of the modified silk fiber is greatly improved, strength is not significantly reduced, and the problems that through coating, blending, sericin bonding and other methods, the strength of cloth is improved unilaterally and the cloth is air permeable, moisture permeable and poor in softness can be solved. The modified silk fiber is excellent in performance, mild and free of stimulation, no other materials are introduced, the good performance of fibroin fiber can be give full play to and can serve as raw materials of a pure silk nonwoven fabric, the entanglement rate of silk in a spunlace silk nonwoven fabric is improved, the friction force in unit area is improved, and thus the strength of pure silk nonwoven fabric products is effectively improved.

Owner:SUZHOU UNIV +1

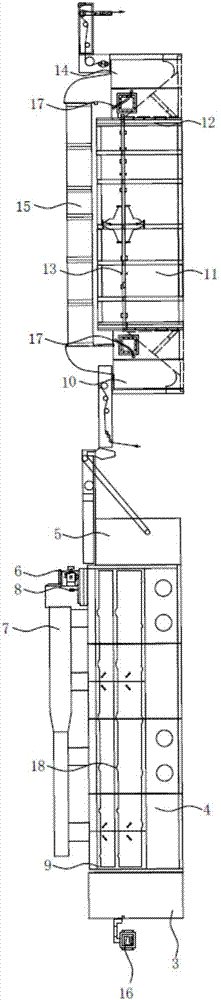

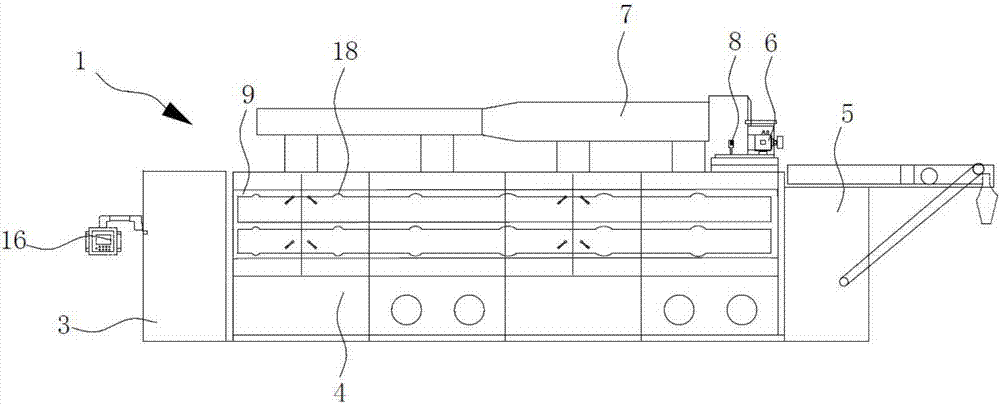

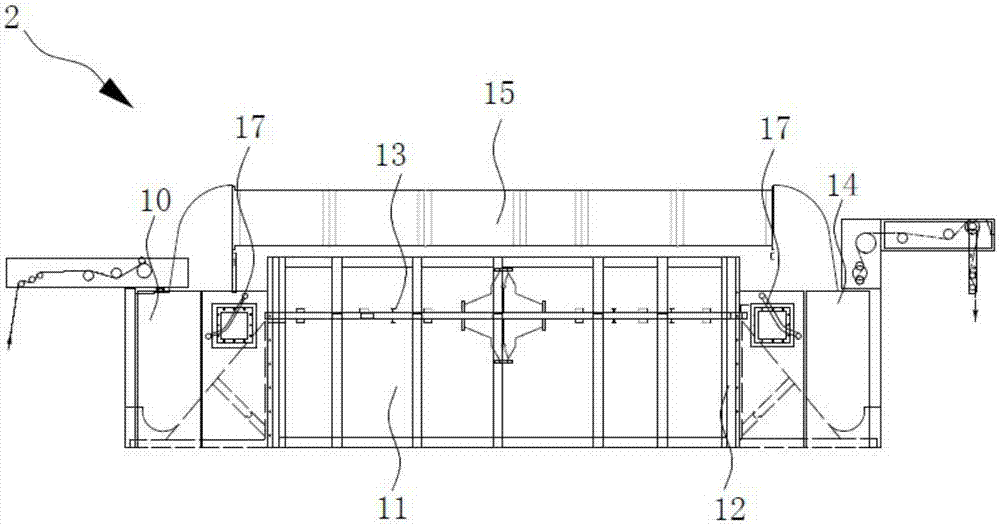

Ultra-high performance drying and softening combination machine

PendingCN107419469ASolve the softness problemSolve the problem of incomplete dryingFabric breaking/softeningDrying gas arrangementsIndustrial engineeringElectric wire

The invention discloses an ultra-high performance drying and softening combination machine. The combination machine comprises a front drier, a rear softener and a control cabinet, wherein the front drier and the rear drier are connected with the control cabinet through electric wires; the front drier comprises a drier cloth feeding area, a drier body and a drier cloth discharging area; the rear softener comprises a softener cloth feeding area, a softener body and a softener cloth discharging area; and the drier cloth discharging area is connected with the softener cloth feeding area. According to the ultra-high performance drying and softening combination machine, a drying process and a softening process for cloths are integrated, complicated procedures between two processes are reduced to save time, the drying area is increased for the front drier, an optimized drying effect is achieved with minimized energy consumption, and cloths are continuously and constantly treated with the rear softener, so that cloths can be sufficiently softened, excellent texture of the cloths can be guaranteed, and requirement of enterprises can be met.

Owner:无锡市信文机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com