Ultra-high performance drying and softening combination machine

A softener and dryer technology, applied in dryers, drying, progressive dryers, etc., can solve the problems of insufficient softening, incomplete drying, and discontinuous drying and softening processes, saving time , good texture, reducing the effect of trivial procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

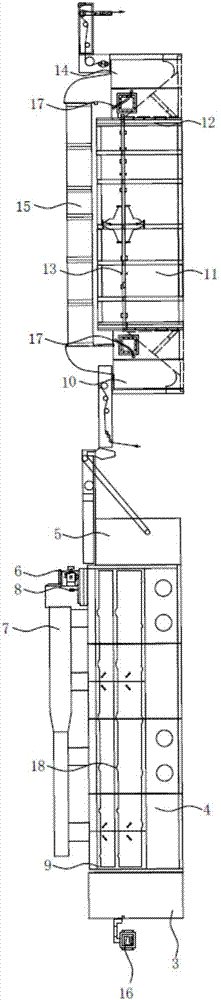

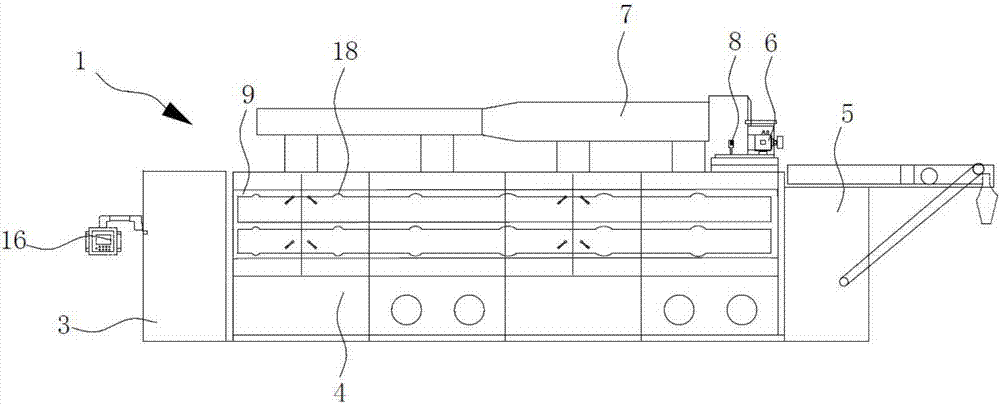

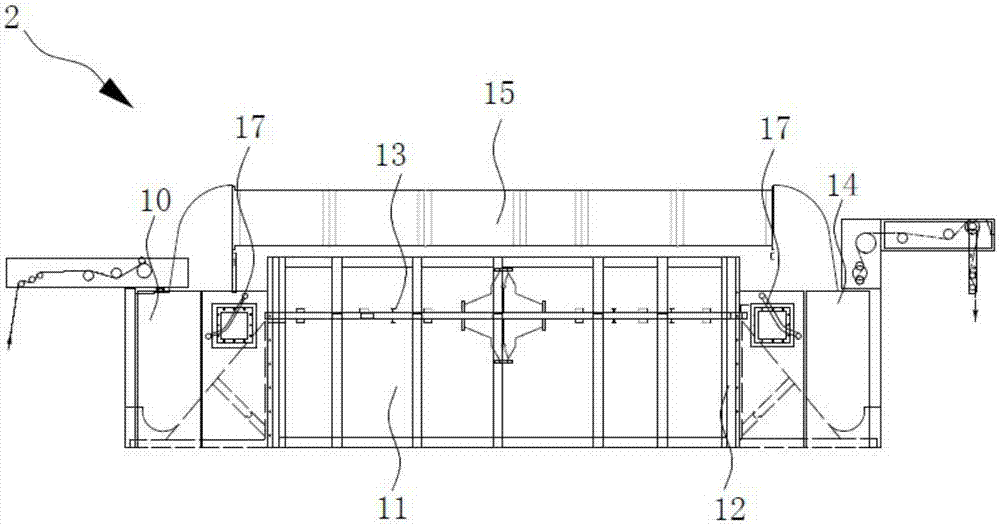

[0020] Such as Figure 1-Figure 3 As shown, this embodiment provides an ultra-efficient drying and softening combined machine, including a pre-dryer 1 and a post-softening machine 2, and the pre-dryer 1 includes a dryer cloth feeding area 3, a drying Machine body 4 and dryer cloth outlet area 5, dryer body 4 is provided with blower fan 6, air inlet passage 7, heater 8 and a plurality of spray pipes 9 and drying cabinet, heater 8 is located in air inlet passage 7 The head end of the fan 6 is fixed at the air inlet of the air inlet passage 7, and the air inlet passage 7 is connected to a plurality of nozzle pipes 9. When drying, the heater 8 starts to heat, and the blower fan 6 starts to blow air into the air inlet channel 7, and the air is heated when passing through the heater 8, and then the fabric is dried by the nozzle 9, preferably, the The air inlet channel 7 is arranged above the drying box, and a plurality of nozzles 9 are all arranged inside the drying box. The plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com