Silk fiber used for non-woven fabric and preparation method of silk fiber

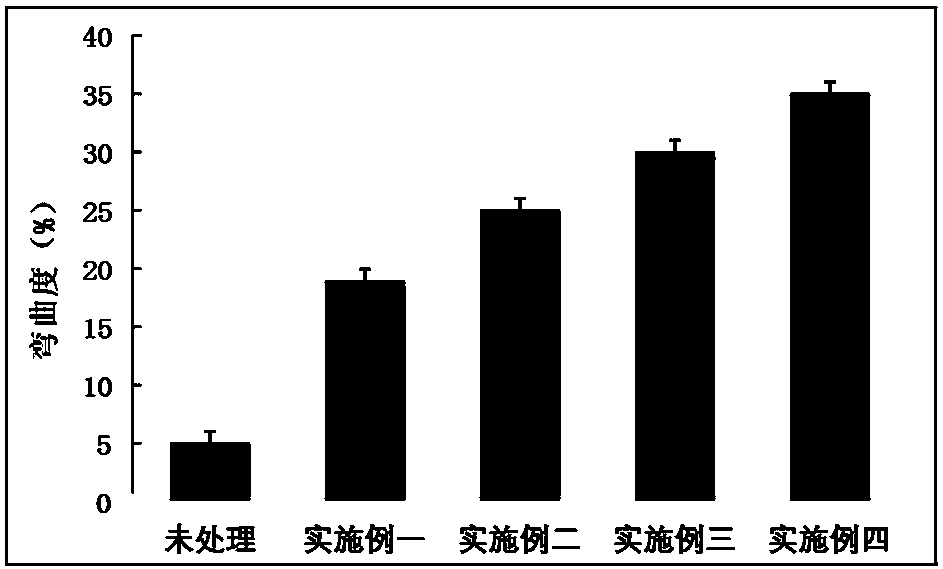

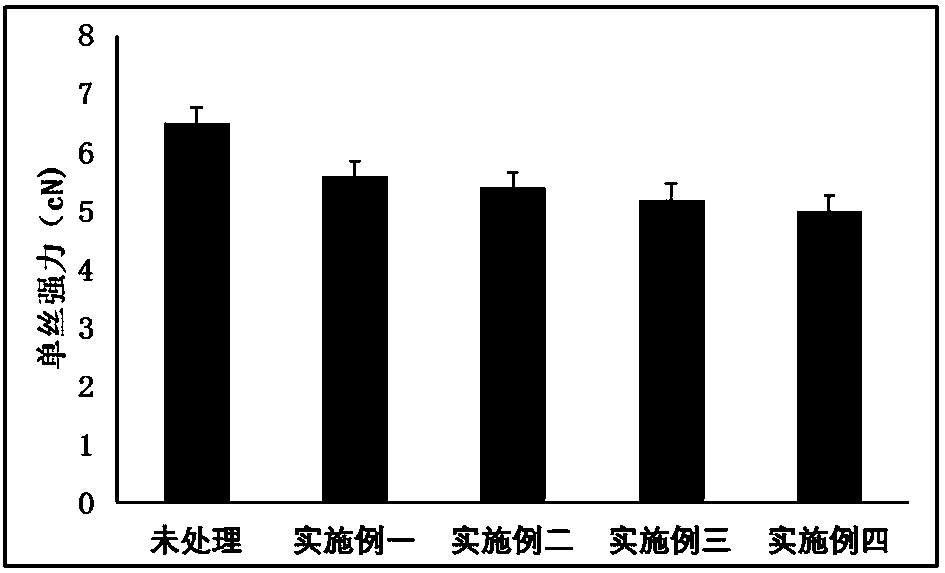

A technology of silk fibers and non-woven fabrics, applied in fiber processing, animal fibers, non-woven fabrics, etc., can solve problems such as stimulating biocompatibility, limiting fabric strength, stripping and stimulating skin, etc., to maintain biocompatibility, The effect of increasing the bending degree and improving the tear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Take 1 kg of degummed and dried silkworm silk, soak it in 5000 ml of 3.5 mol / L lithium bromide solution containing 20 grams of silk protective agent for 30 minutes, and absorb the solution at 25°C to obtain swollen silk; the silk protective agent contains 58 % mass of sodium sulfate, containing 35% mass of sucrose, containing 6% mass of glycerin, containing 1% mass of saccharin.

[0024] 2. Pass the swollen silk through a pressing roller to remove excess solution, and the pressure of the pressing roller is 0.2 MPa;

[0025] 3. Take out the pressed silk and wash it fully with water until the bromide ion in the eluate is detected by 0.01mol / l silver nitrate solution and there is no precipitation;

[0026] 4. Put the washed silk into an oven at 100°C and quickly dry it to constant weight to obtain silk with a certain degree of curvature, which can be used in the manufacture of silk non-woven fabrics.

[0027] Detection of bending degree: put the treated silk on the bla...

Embodiment 2

[0029] 1. Take 2 kg of degummed and dried silkworm silk, soak it in 10 liters of 5mol / L lithium bromide solution containing 40 grams of silk protective agent for 20 minutes, and absorb the solution to obtain swollen silk; the silk protective agent contains 45% Sodium sulfate by mass, containing 45% by mass of sucrose, containing 8% by mass of glycerin, containing 2% by mass of saccharin.

[0030] 2. Pass the swollen silk through a pressing roller to remove excess solution, and the pressure of the pressing roller is 0.25 MPa;

[0031] 3. Take out the pressed silk and wash it fully with water until the bromide ion in the eluate is detected by 0.01mol / l silver nitrate solution and there is no precipitation;

[0032] 4. Put the washed silk into an oven at 101°C and quickly dry it to constant weight to obtain silk with a certain degree of curvature, which can be used in the manufacture of silk non-woven fabrics.

[0033] Detection of bending degree: put the treated silk on the bla...

Embodiment 3

[0035] 1. Take 2 kg of degummed and dried silkworm silk, soak it in 10 liters of 6 mol / L lithium bromide solution containing 40 grams of silk protective agent for 10 minutes, and absorb the solution at 35°C to obtain swollen silk; the silk protective agent contains 42 % mass of sodium sulfate, containing 50% mass of sucrose, containing 7% mass of glycerin, containing 1% mass of saccharin.

[0036] 2. Pass the swollen silk through a pressing roller to remove excess solution, and the pressure of the pressing roller is 0.25 MPa;

[0037] 3. Take out the pressed silk and wash it fully with water until the bromide ion in the eluate is detected by 0.01mol / l silver nitrate solution and there is no precipitation;

[0038] 4. Put the washed silk into an oven at 101°C and quickly dry it to constant weight to obtain silk with a certain degree of curvature, which can be used in the manufacture of silk non-woven fabrics.

[0039] Detection of bending degree: put the treated silk on the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com