High-bending silk as well as preparation method and application thereof

A silk and bending technology, applied in textiles and papermaking, fiber treatment, animal fibers, etc., can solve problems such as stimulating biocompatibility, limiting fabric strength, dissolution and stimulating skin, etc., to maintain biocompatibility and improve bending degree , Improve the effect of tearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present embodiment modifies silk, and its specific steps are:

[0025] 1. Take 100 grams of degummed and dried silkworm silk, soak it in 400 ml of 76 v / v% formic acid aqueous solution containing 2 grams of silk protective agent for 70 seconds at a temperature of 35°C, and absorb the solution to obtain swollen silk; the silk protective agent contains 58% by mass of sodium sulfate, contains 35% by mass of sucrose, contains 6% by mass of glycerin, contains 1% by mass of saccharin.

[0026] 2. Immediately press the swollen silk through a roller to remove excess formic acid aqueous solution, and the pressure of the roller is 0.2 MPa;

[0027] 3. Take out the pressed silk and wash it with water immediately until the pH value of the eluate rises above 6.5;

[0028] 4. Put the washed silk in an oven at 100°C and quickly dry it to constant weight to obtain silk with a certain degree of curvature, which can be used in the manufacture of silk non-woven fabrics.

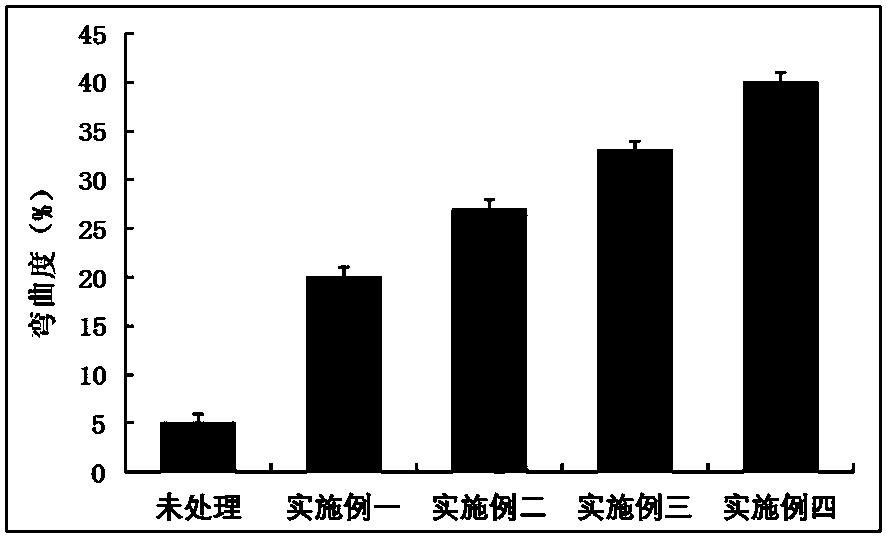

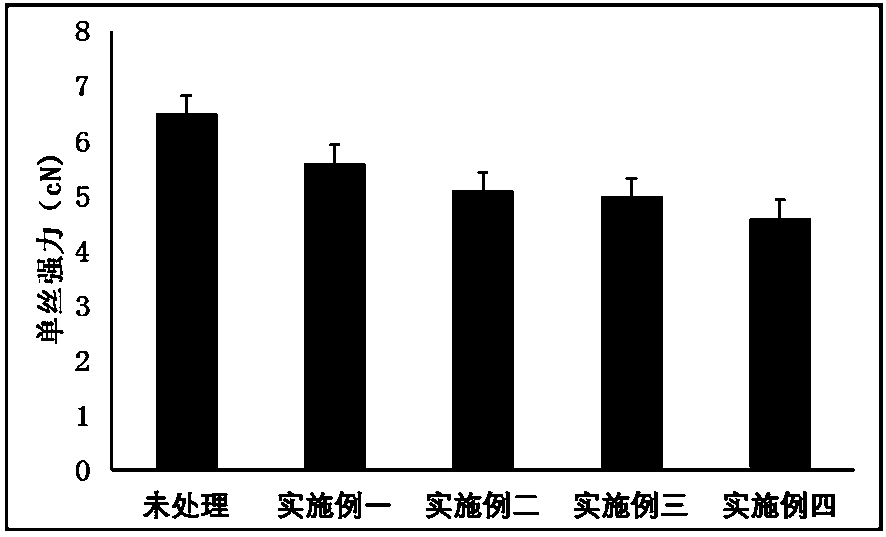

[0029] Dete...

Embodiment 2

[0031] 1. Take 100 grams of degummed and dried silkworm silk, soak it in 400 ml of 83 v / v% formic acid aqueous solution containing 2 grams of silk protective agent for 30 seconds, and absorb the solution to obtain swollen silk; the silk protective agent contains 45% by mass of sodium sulfate, containing 45% by mass of sucrose, containing 8% by mass of glycerin, containing 2% by mass of saccharin.

[0032] 2. Rapidly pass the swollen silk through the pressing roller to remove excess formic acid aqueous solution, and the pressure of the pressing roller is 0.25 MPa;

[0033] 3. The silk that has been pressed by the pressure roller is quickly and fully washed with water until the pH value of the eluate rises above 6.2;

[0034] 4. Put the washed silk into an oven at 101°C and quickly dry it to constant weight to obtain silk with a certain degree of curvature, which can be used in the manufacture of silk non-woven fabrics.

[0035] Detection of bending degree: put the treated silk...

Embodiment 3

[0037] 1. Take 200 grams of degummed and dried silkworm silk, soak it in 800 ml of 86 v / v% formic acid aqueous solution containing 4 grams of silk protective agent for 20 seconds, and absorb the solution at 28°C to obtain swollen silk; the silk protective agent is Contains 42% by mass of sodium sulfate, contains 50% by mass of sucrose, contains 7% by mass of glycerin, and contains 1% by mass of saccharin.

[0038] 2. Rapidly pass the swollen silk through the pressing roller to remove excess formic acid aqueous solution, and the pressure of the pressing roller is 0.25 MPa;

[0039] 3. The silk that has been pressed by the pressure roller is quickly and fully washed with water until the pH value of the eluate rises above 6.1;

[0040] 4. Put the washed silk into an oven at 101°C and quickly dry it to constant weight to obtain silk with a certain degree of curvature, which can be used in the manufacture of silk non-woven fabrics.

[0041] Detection of bending degree: put the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com