Patents

Literature

69results about How to "Reliable deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

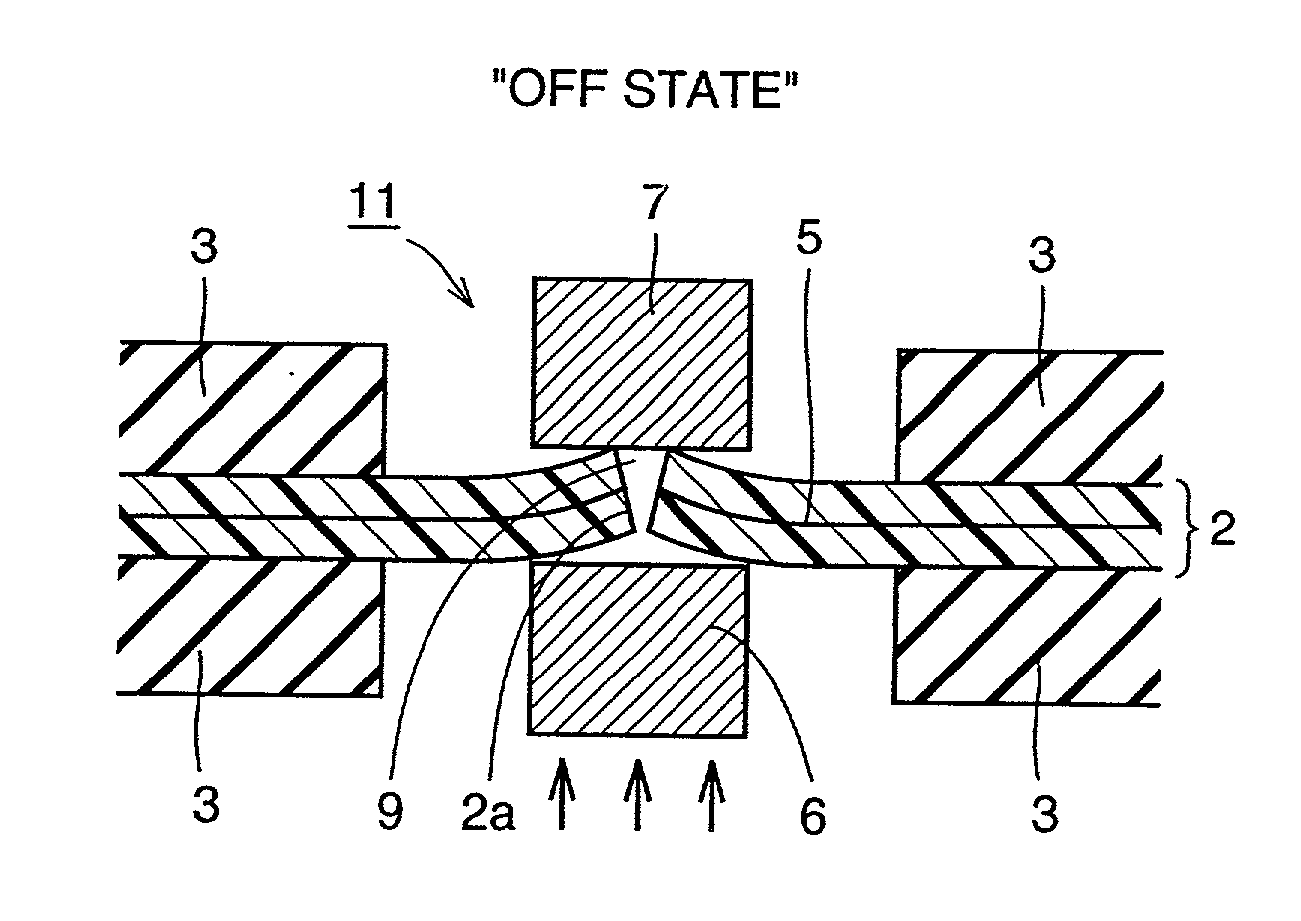

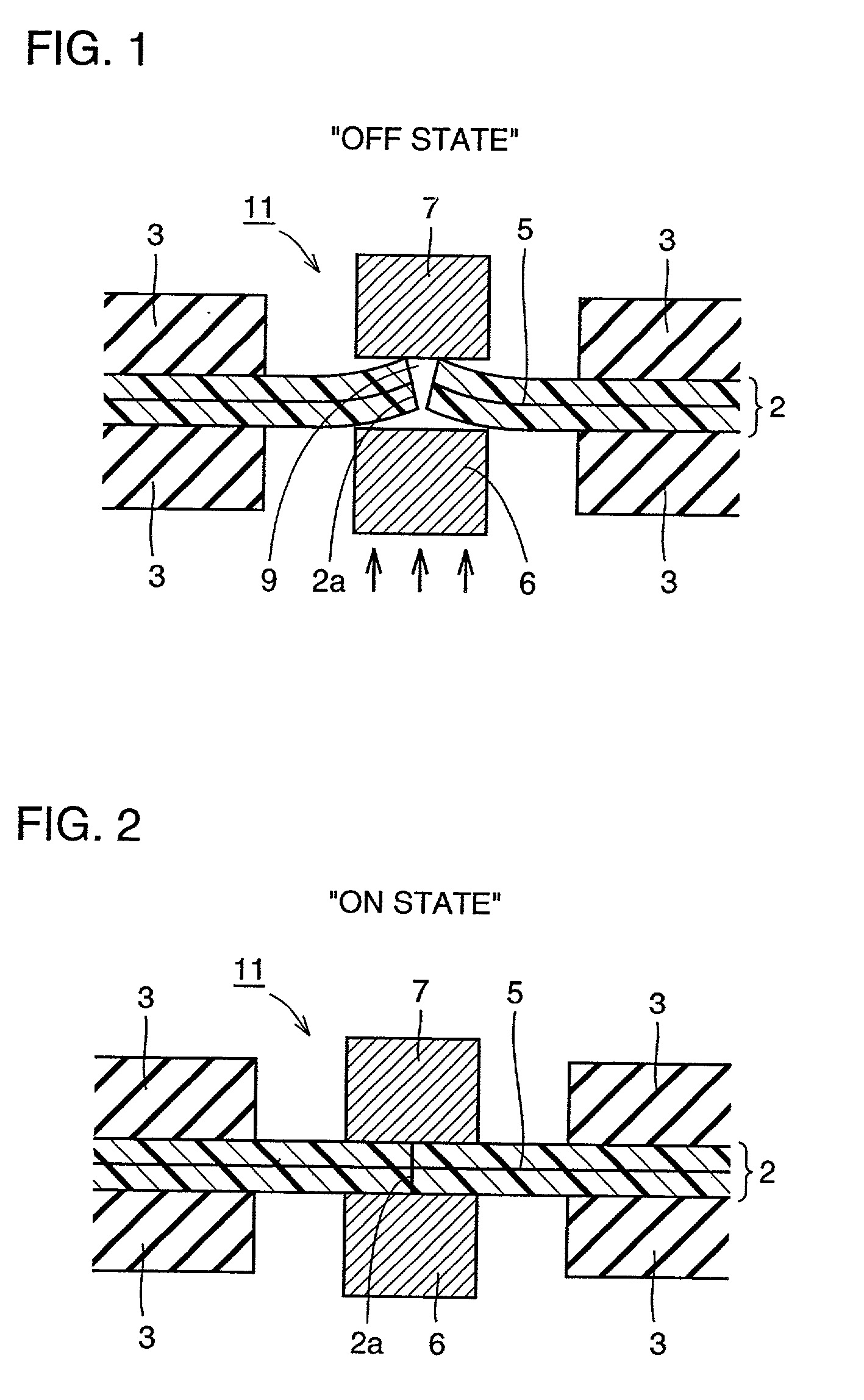

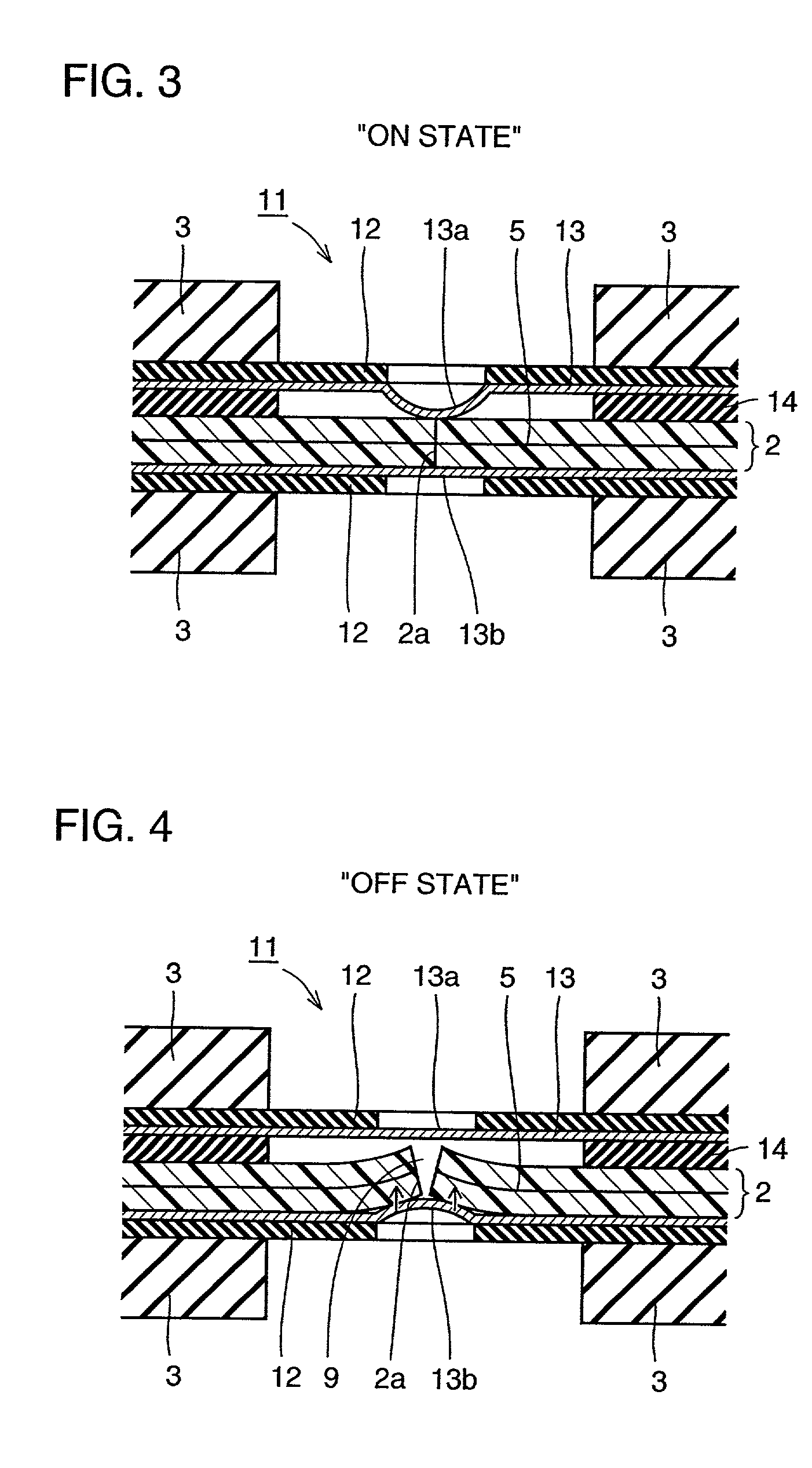

Optical switch and optical waveguide apparatus

InactiveUS20020168133A1Firmly connectedGuaranteed uptimeCoupling light guidesDriver/operatorWaveguide

Highly reliable optical switch and optical waveguide apparatus are obtained, which can perform stable and reliable ON / OFF operations for optical connection at a waveguide crossing portion. The optical switch is provided in an optical waveguide apparatus including a waveguide propagating light and a waveguide housing sheet enclosing the waveguide, and includes a slit portion slitting to traverse the waveguide; a driver performing driving action onto the slit portion; and a driver assistant member interposing the slit portion between the driver assistant member and the driver to assist the driver, the driver and driver assistant member pushing open the slit portion to provide a gap, and bring the slit portion into contact to connect waveguides.

Owner:MITSUBISHI ELECTRIC CORP

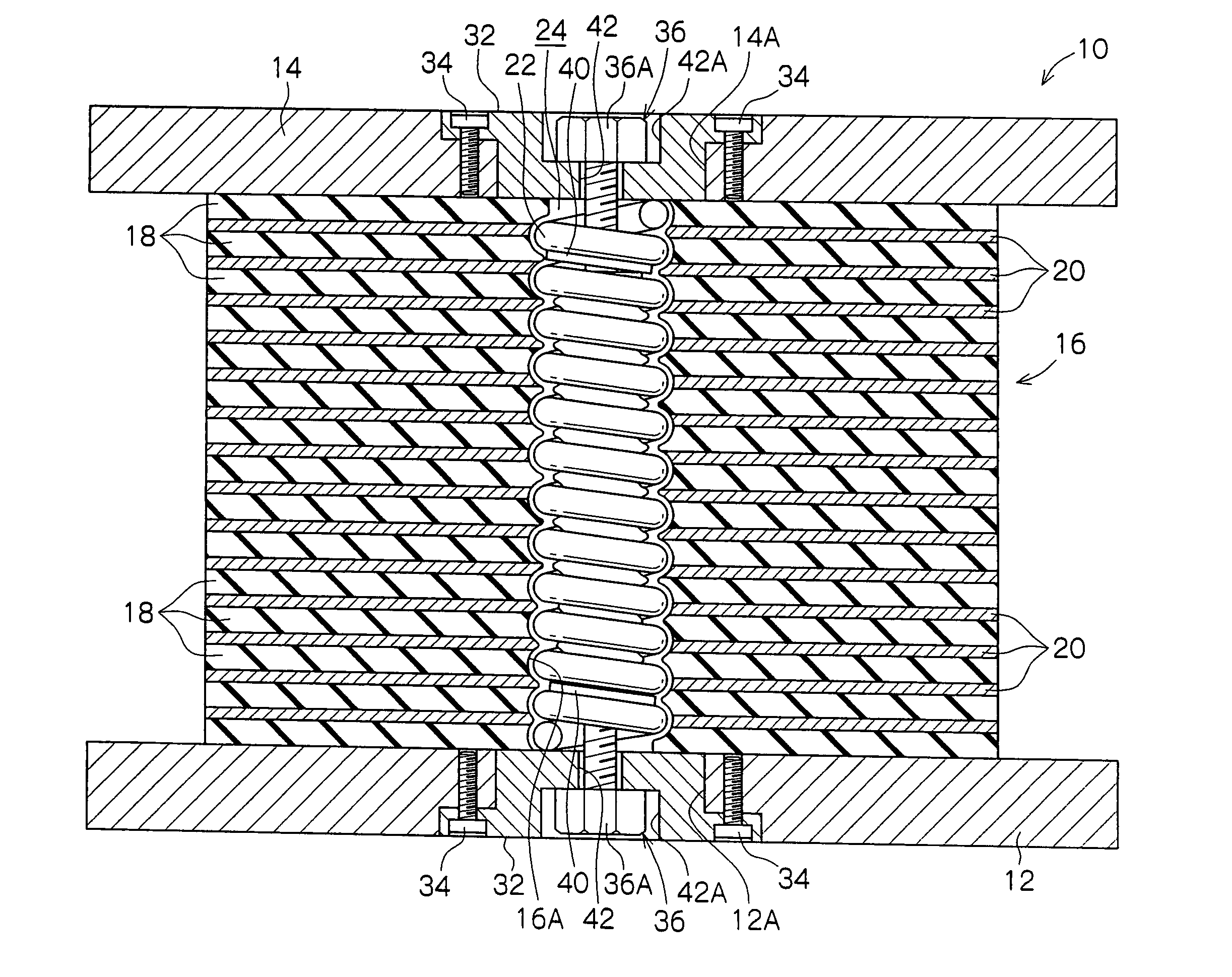

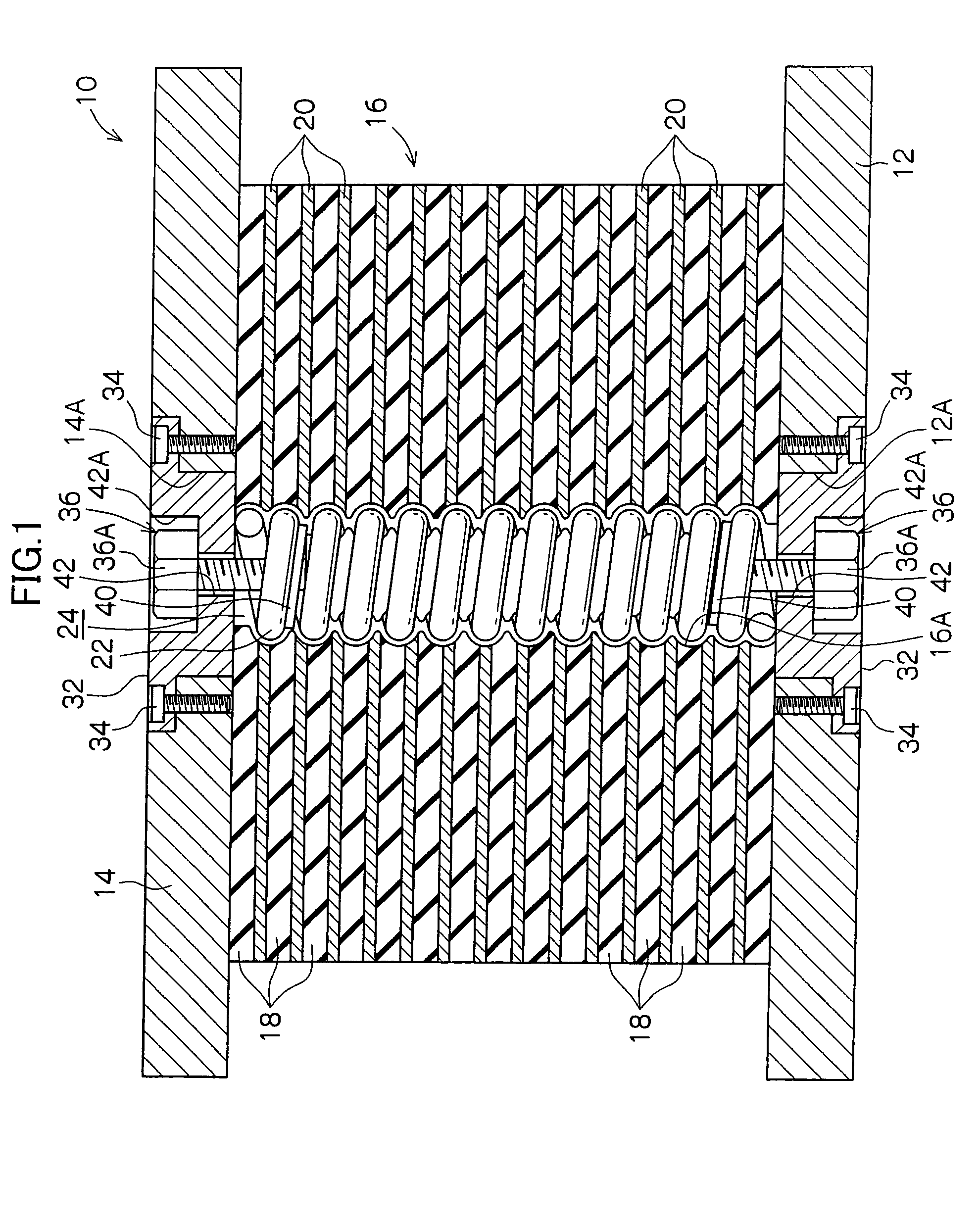

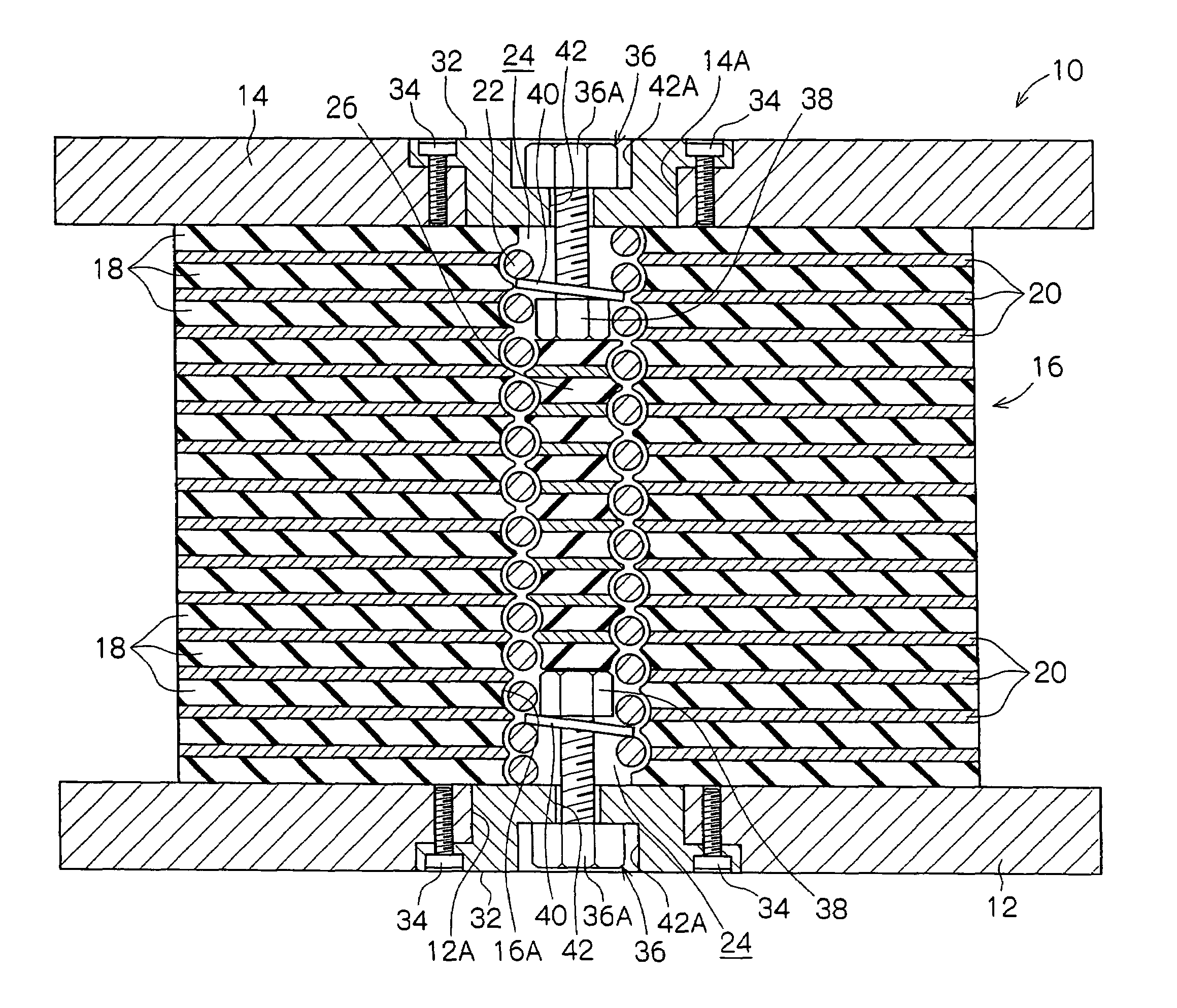

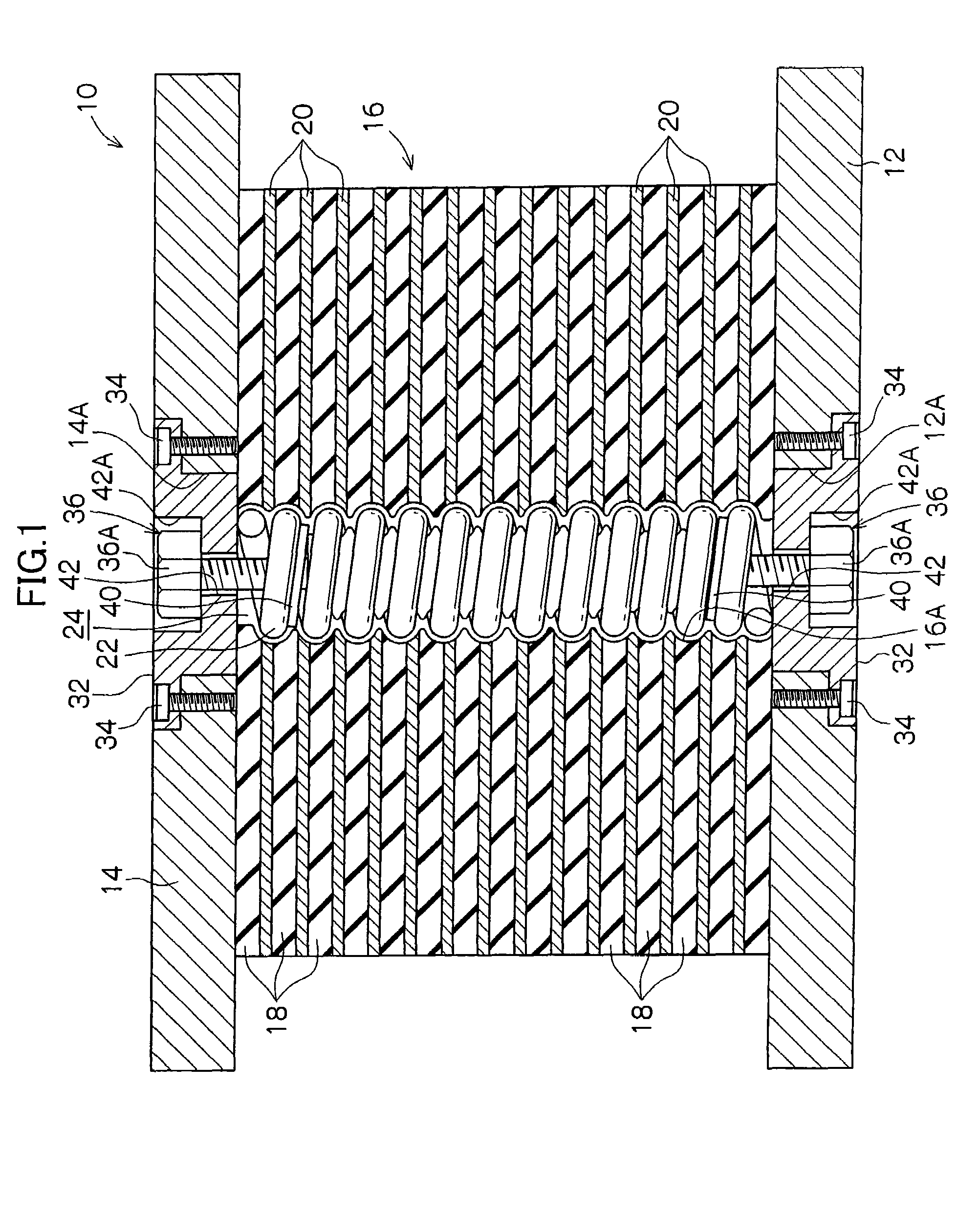

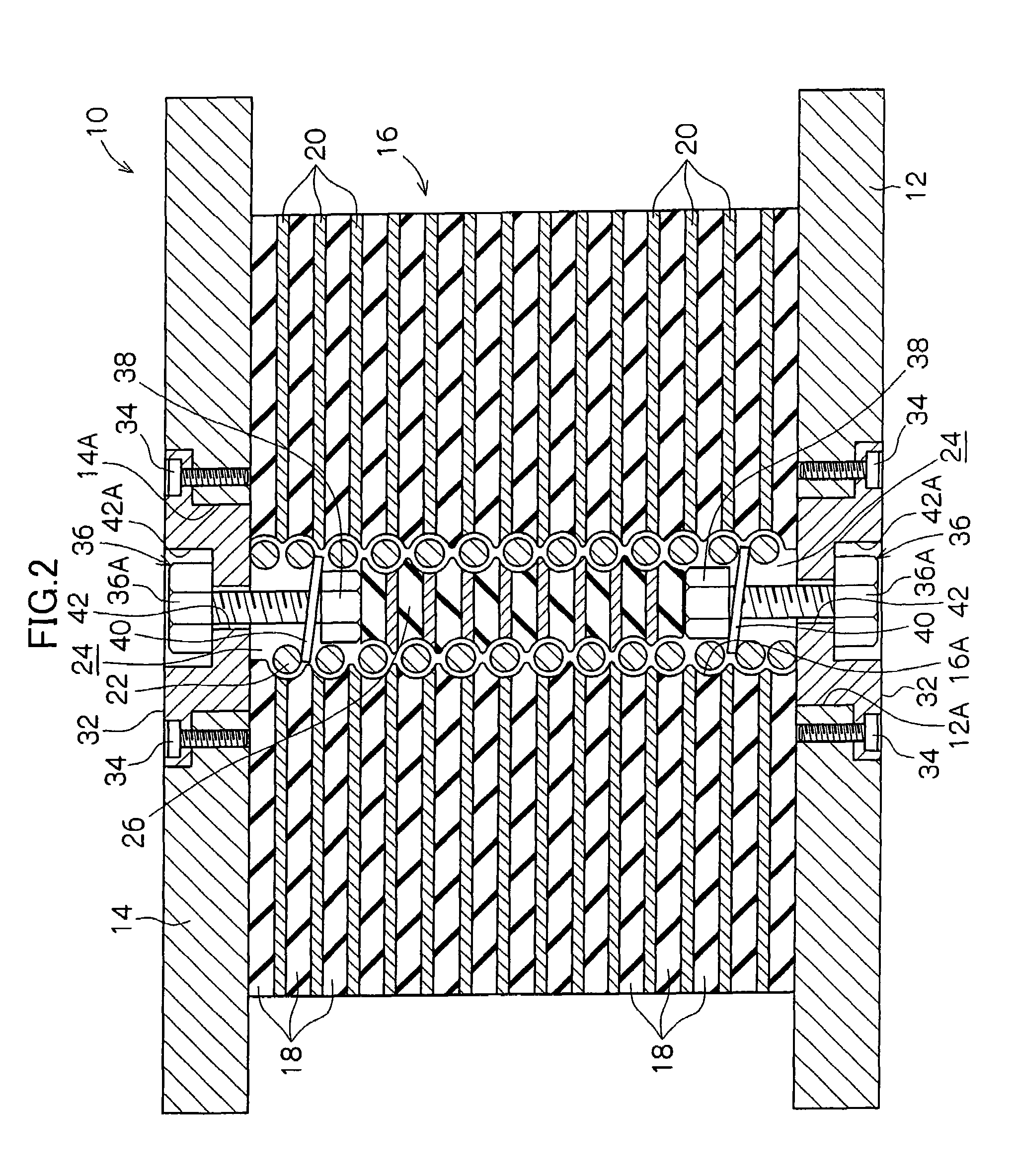

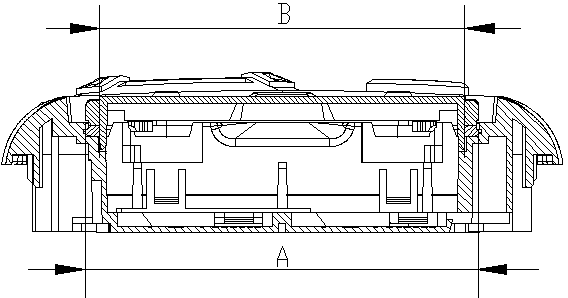

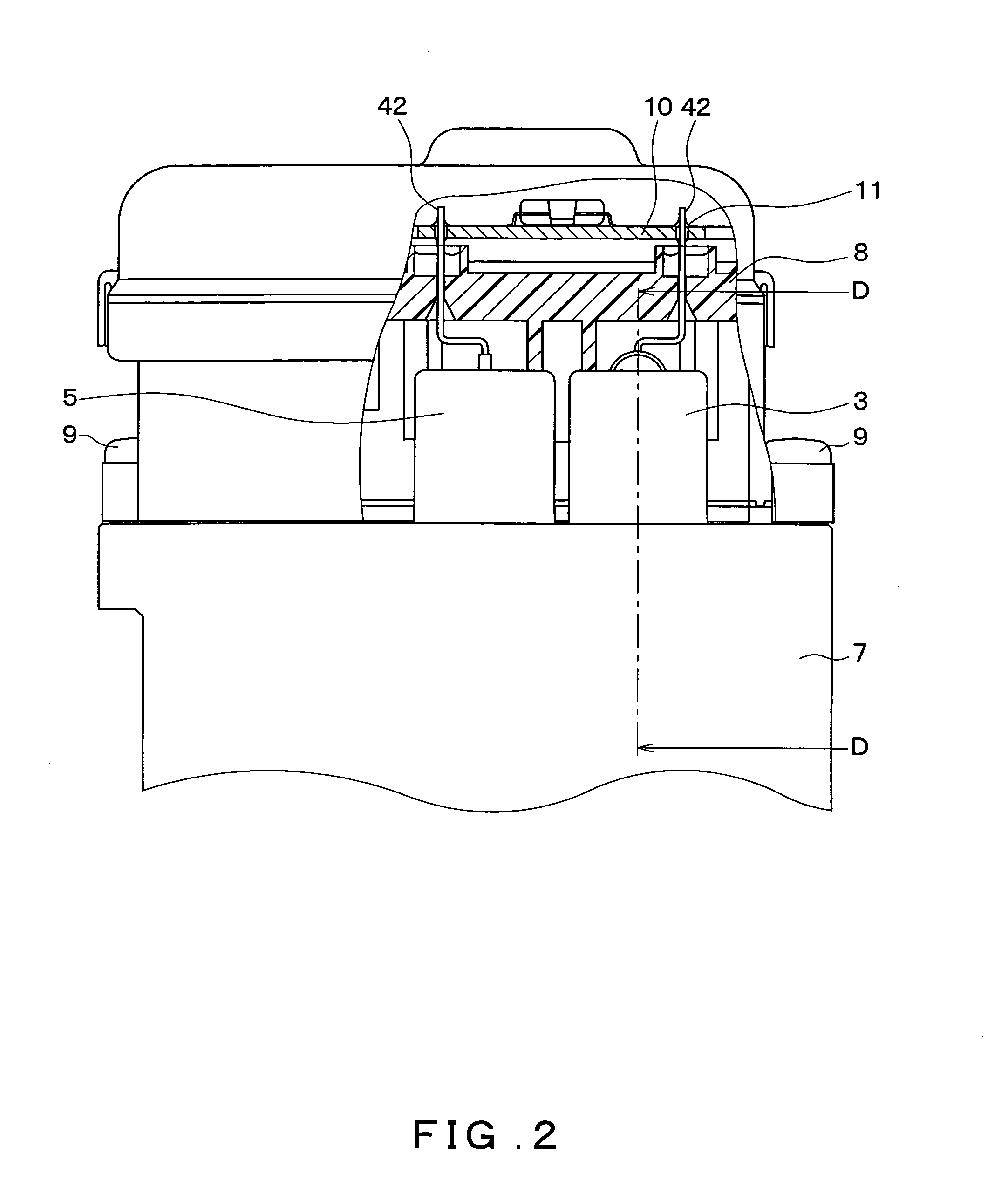

Seismic isolation apparatus

InactiveUS20060137264A1Prevent collapseStable damping capabilityStands/trestlesKitchen equipmentRubber ringEngineering

A seismic isolation apparatus features damping characteristics equivalent to or better than prior art, without burdening the environment. In this seismic isolation apparatus, a cylindrical cavity portion is formed at the middle of an outer side laminated body, which has a form in which respective pluralities of resiliently deformable rubber rings and metal rings for maintaining rigidity are alternately laminated. A helically formed coil spring is disposed in this cavity portion so as to be snugly fitted. An inner side laminated body, which has a form in which respective pluralities of resiliently deformable rubber plates and metal plates for maintaining rigidity are alternately laminated, is disposed at an inner peripheral side of the coil spring.

Owner:BRIDGESTONE CORP

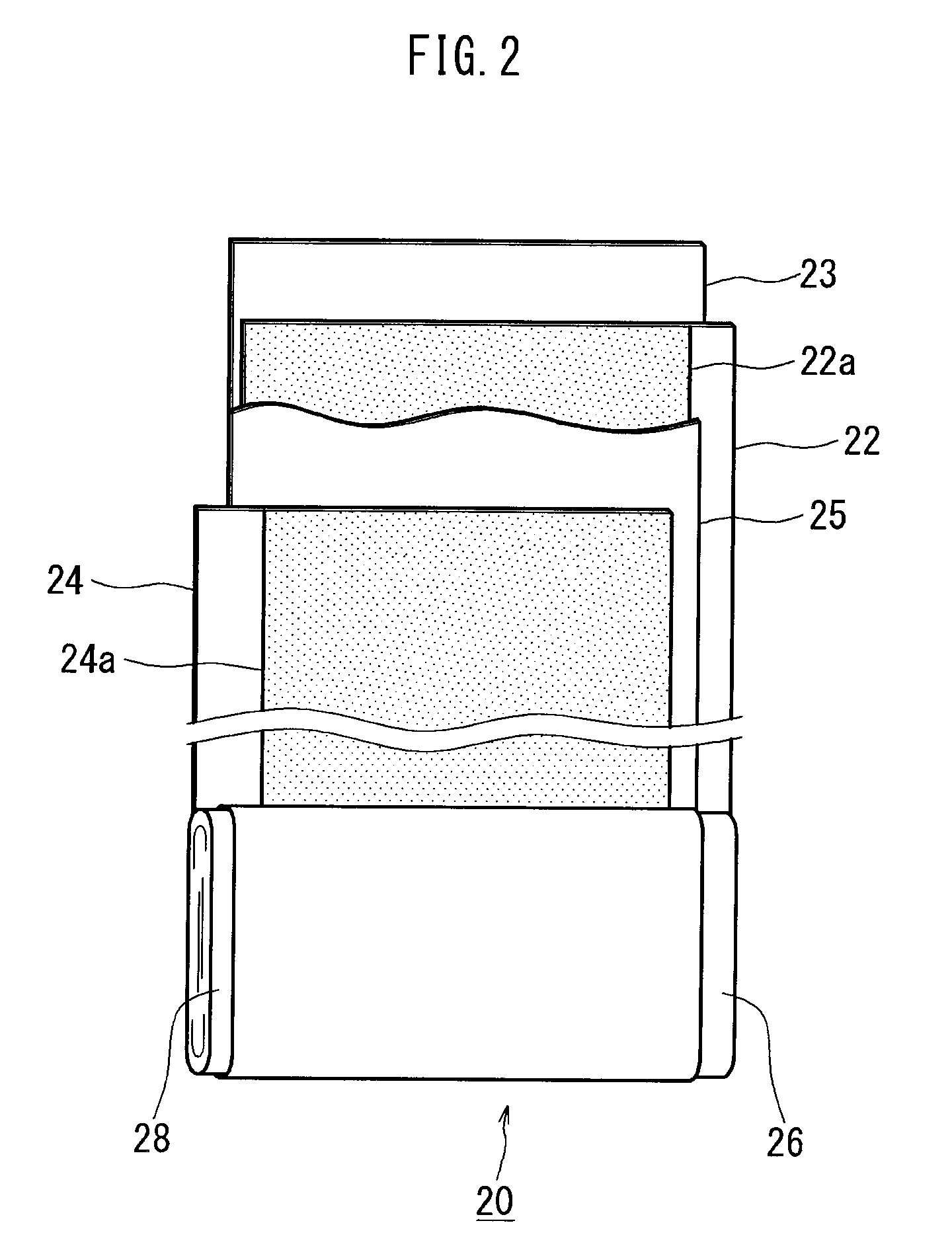

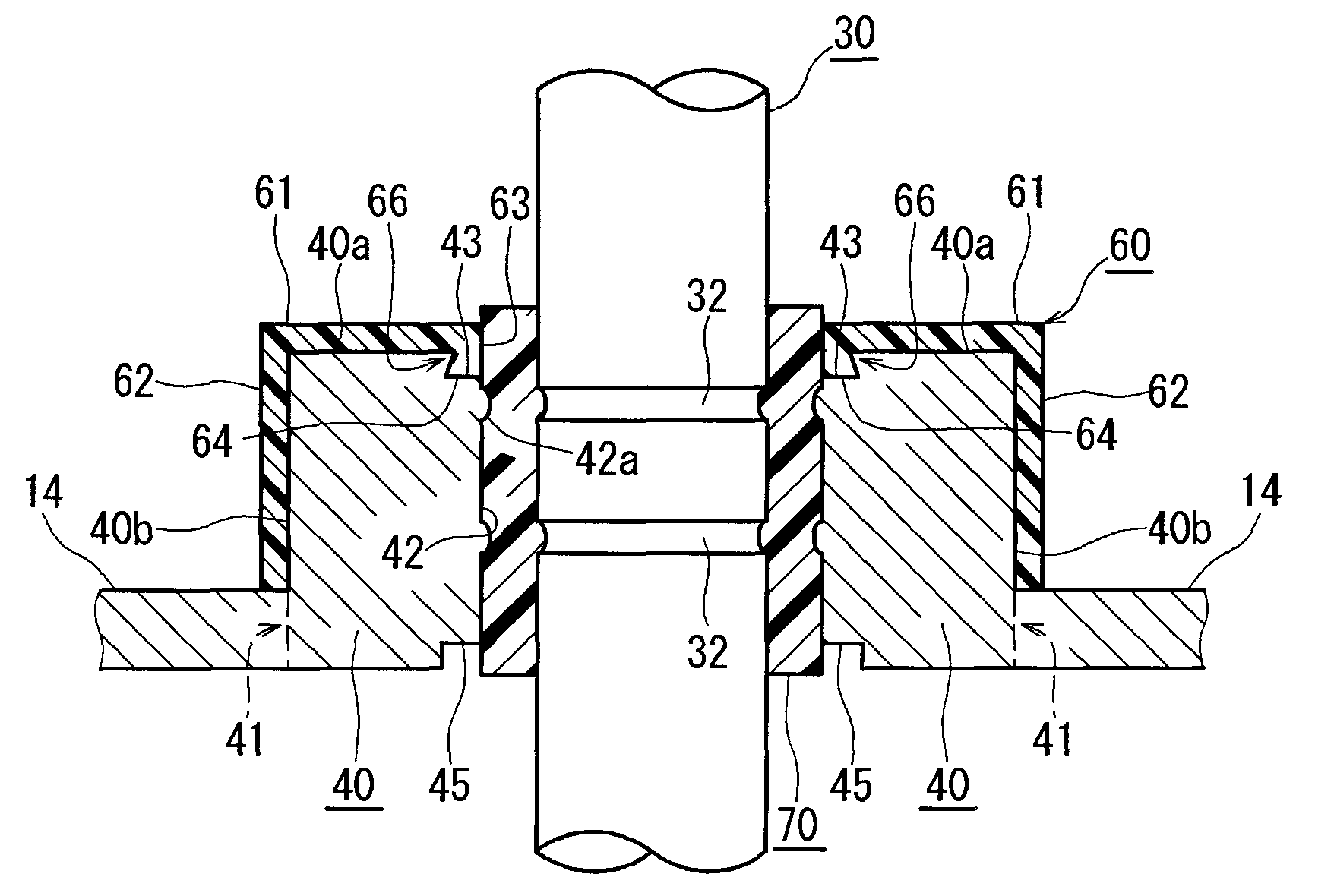

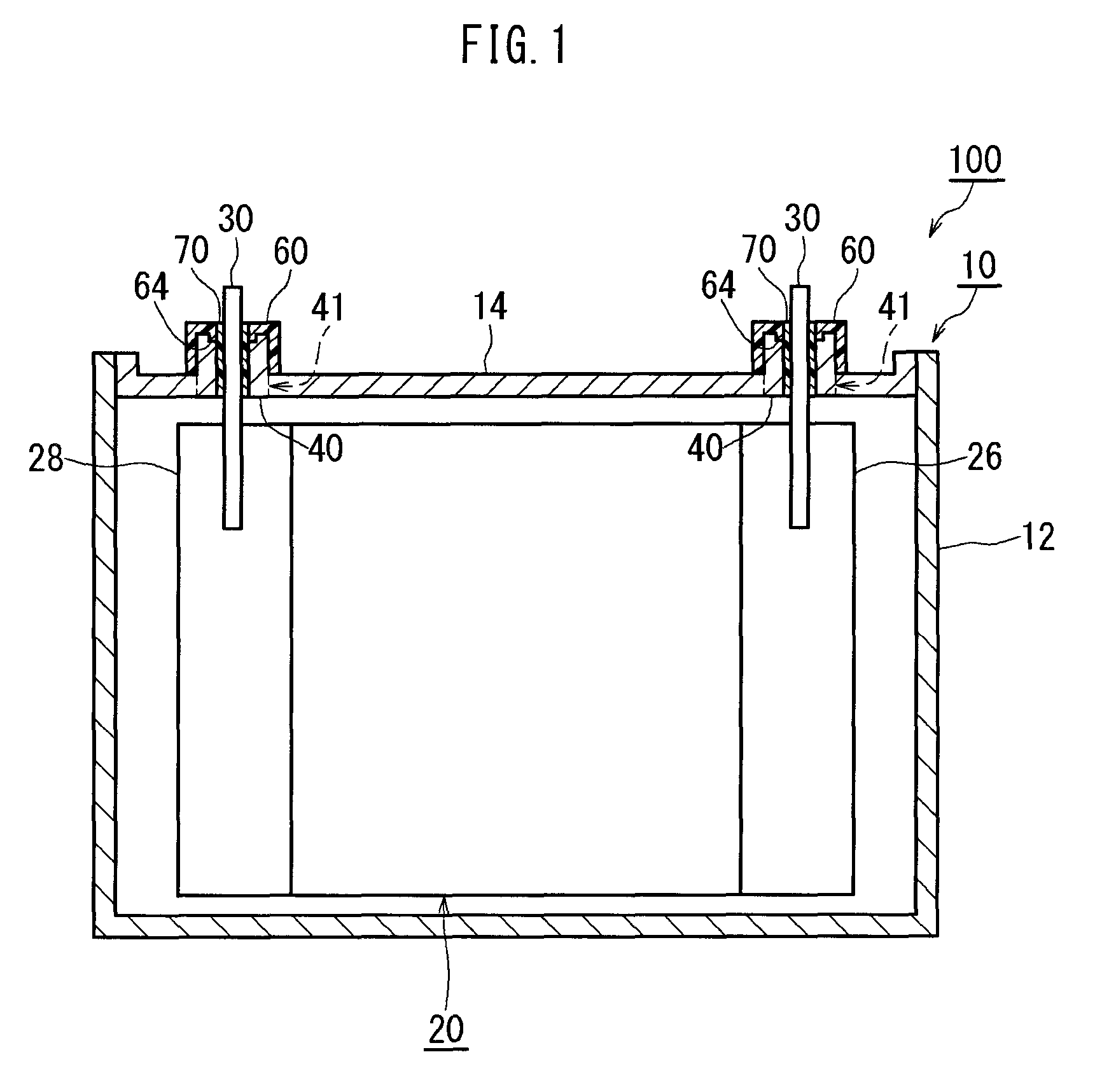

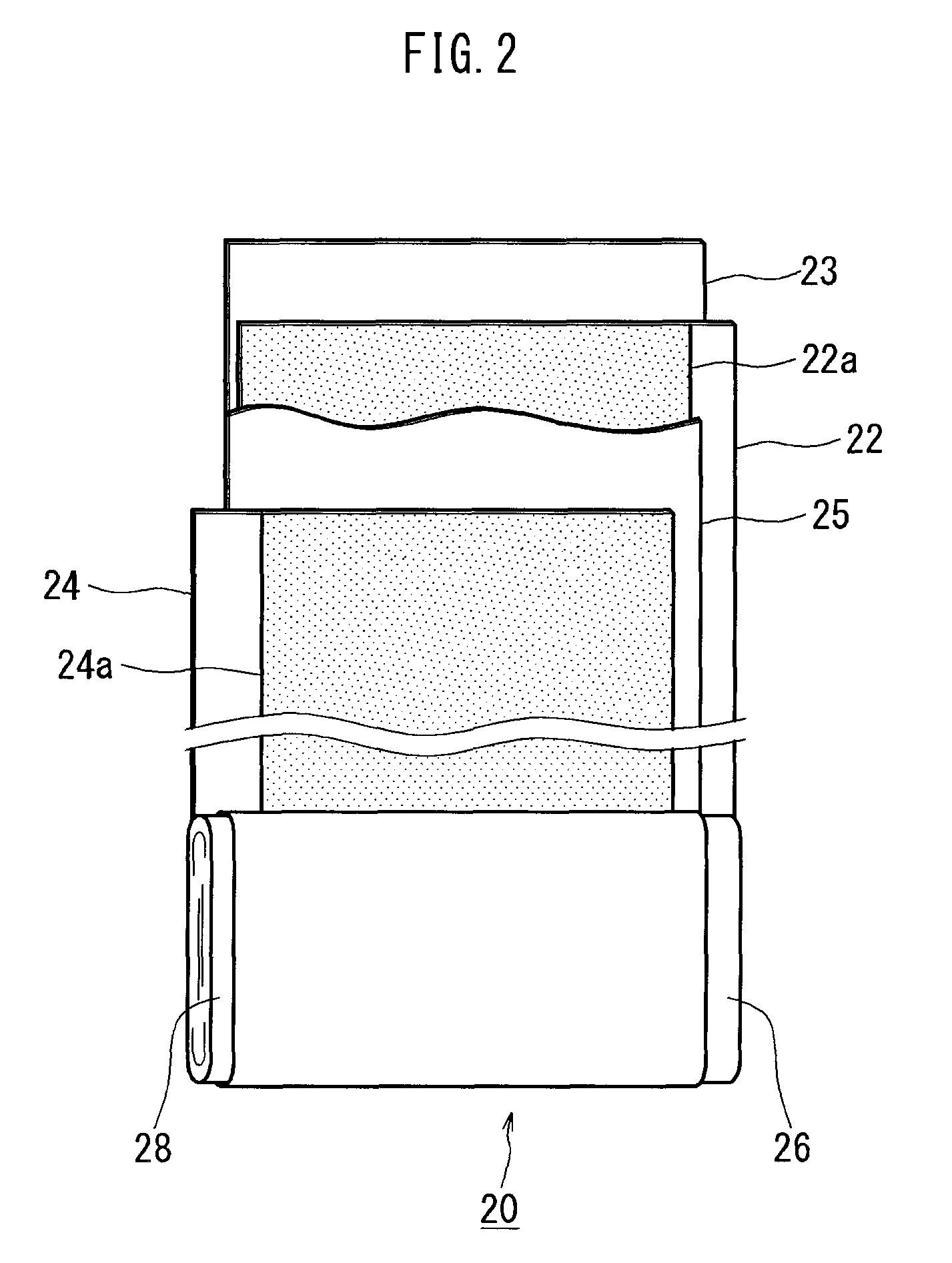

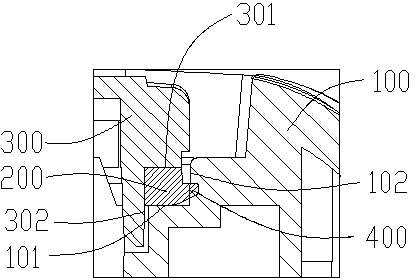

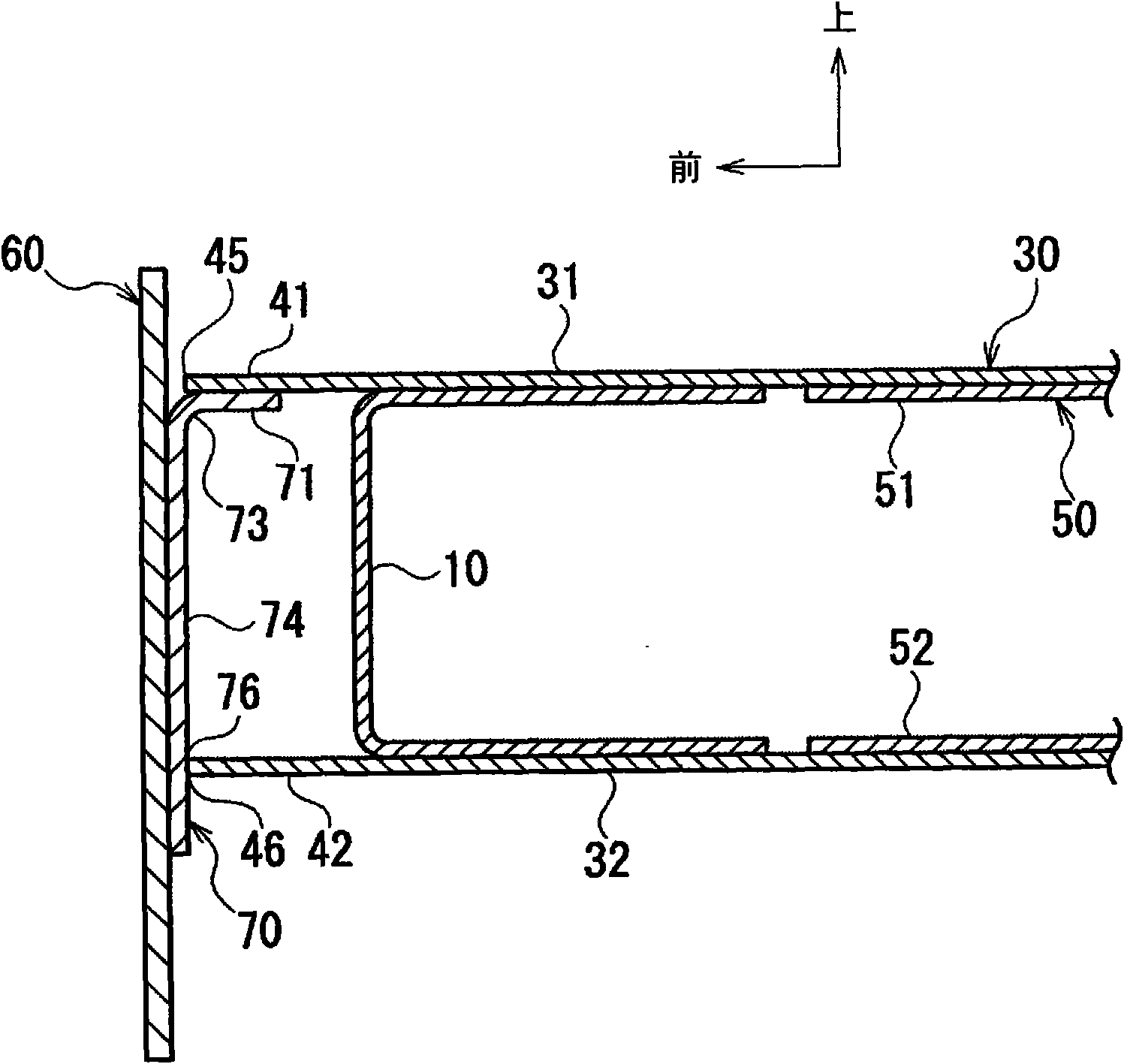

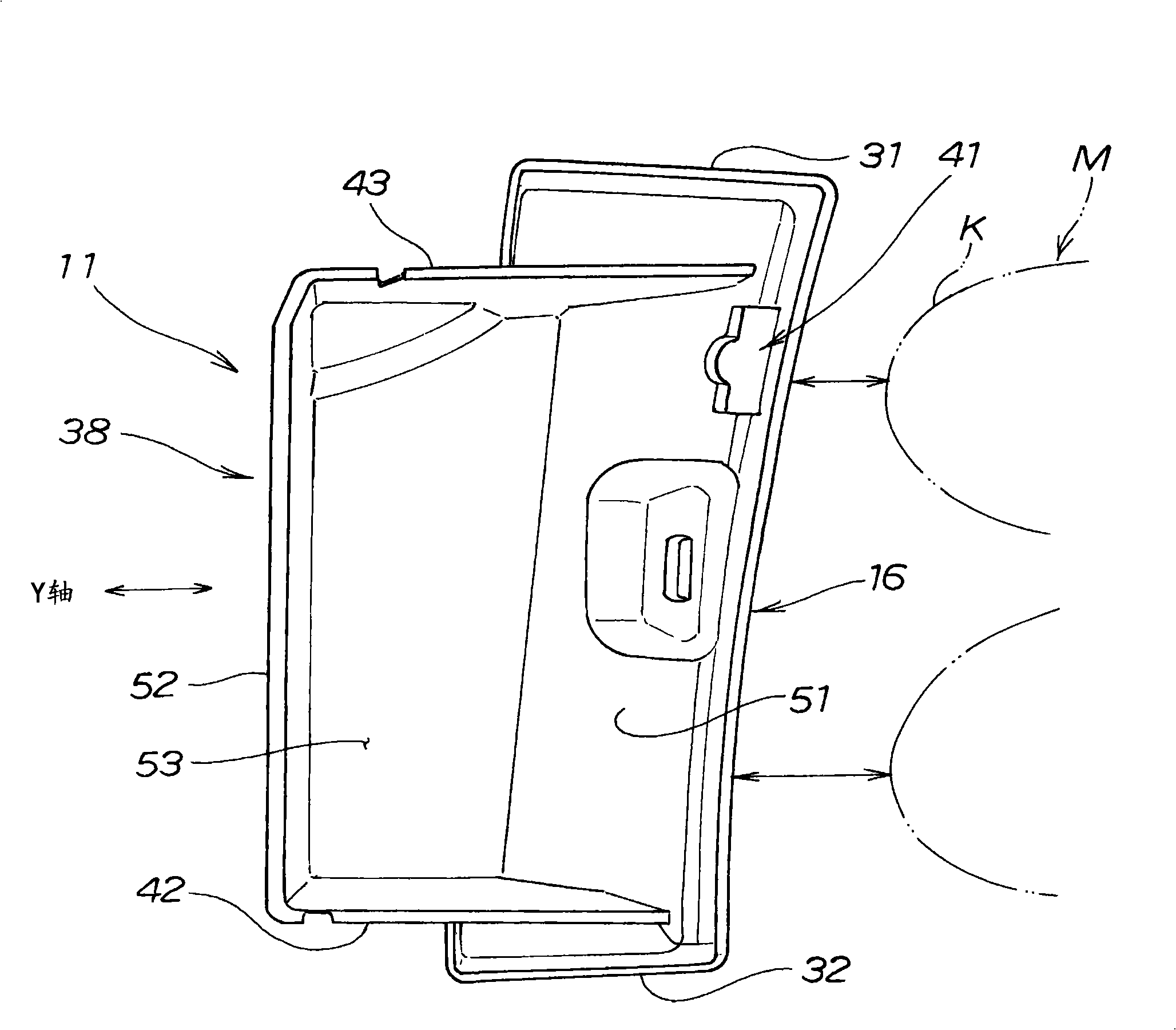

Battery

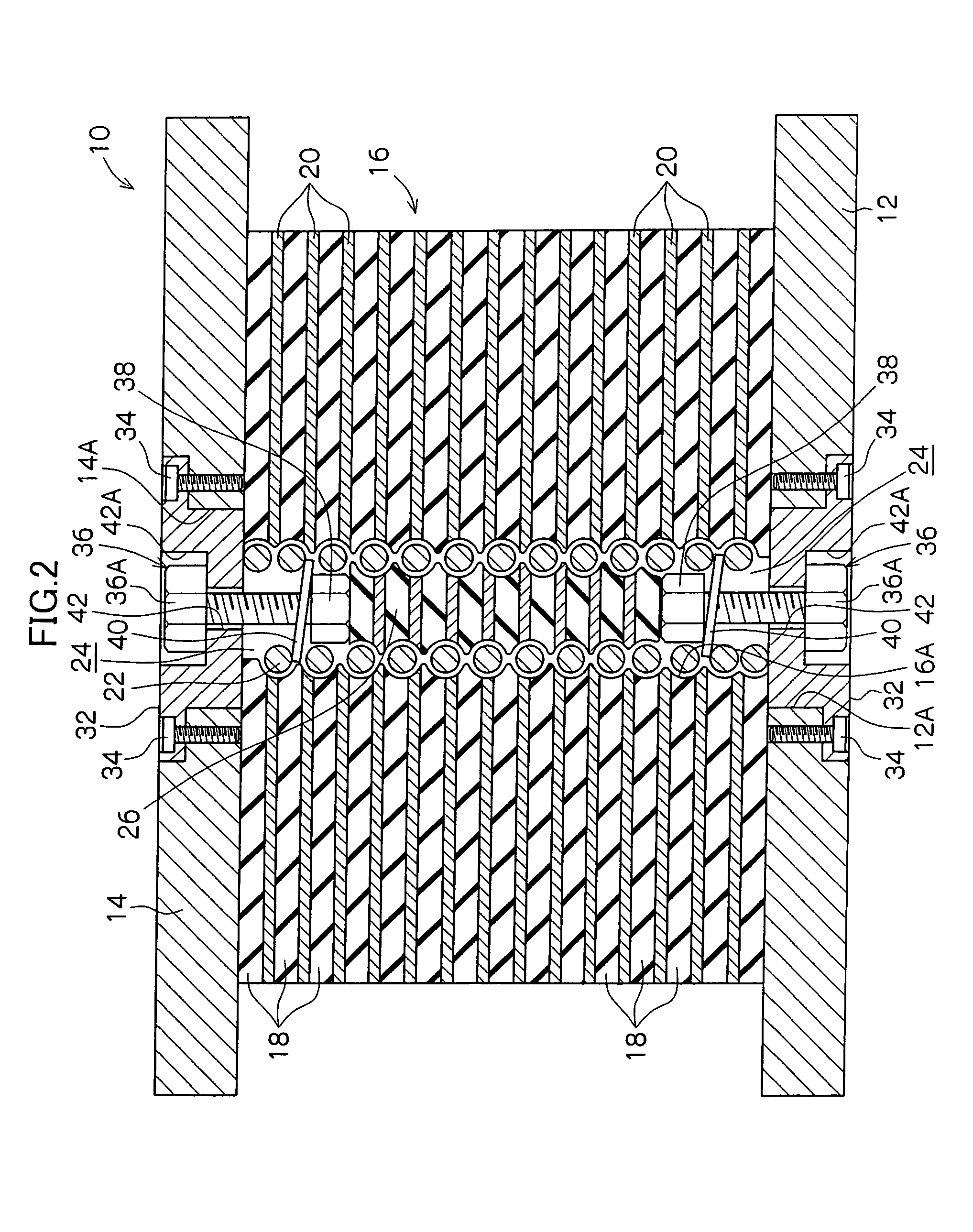

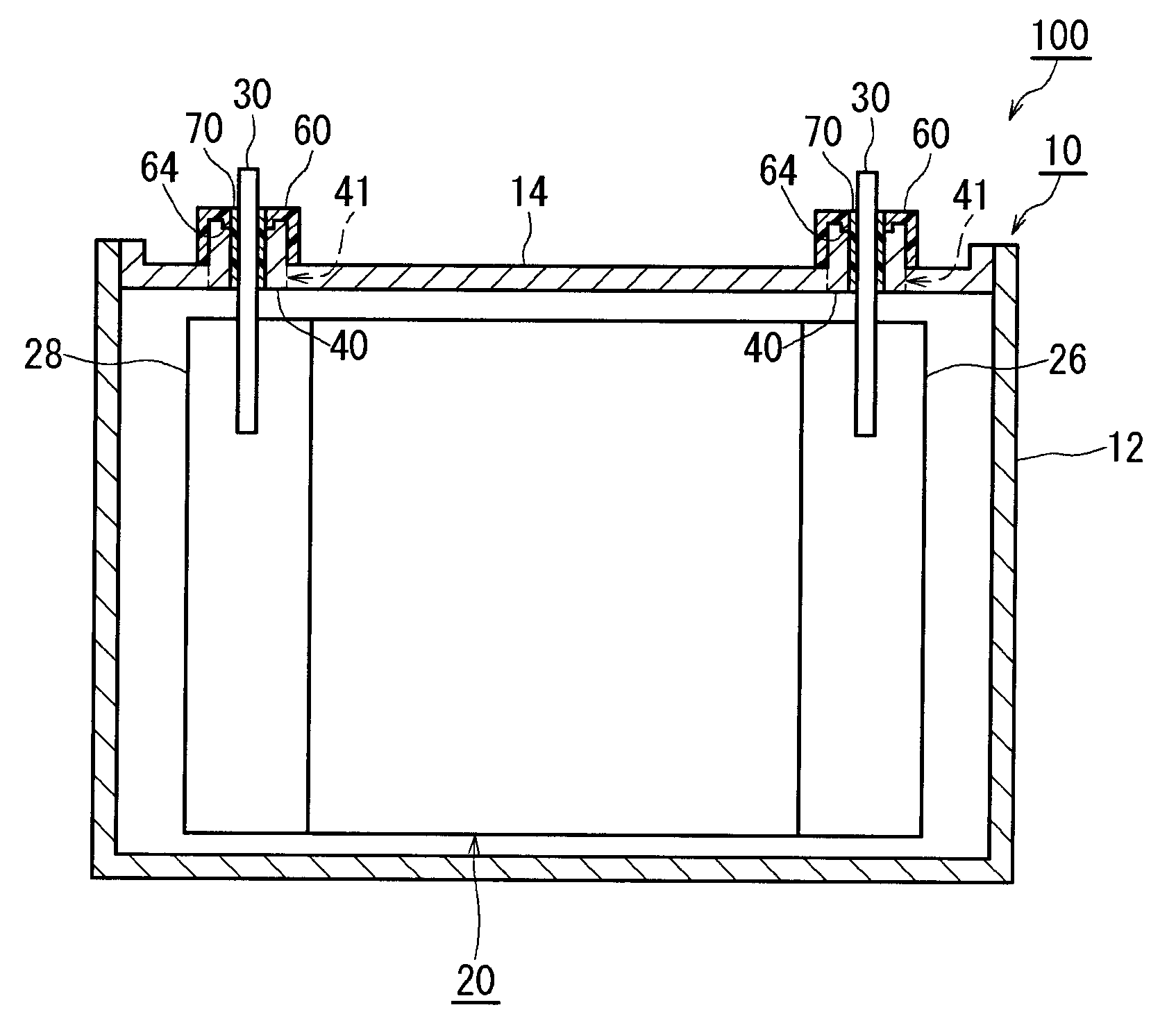

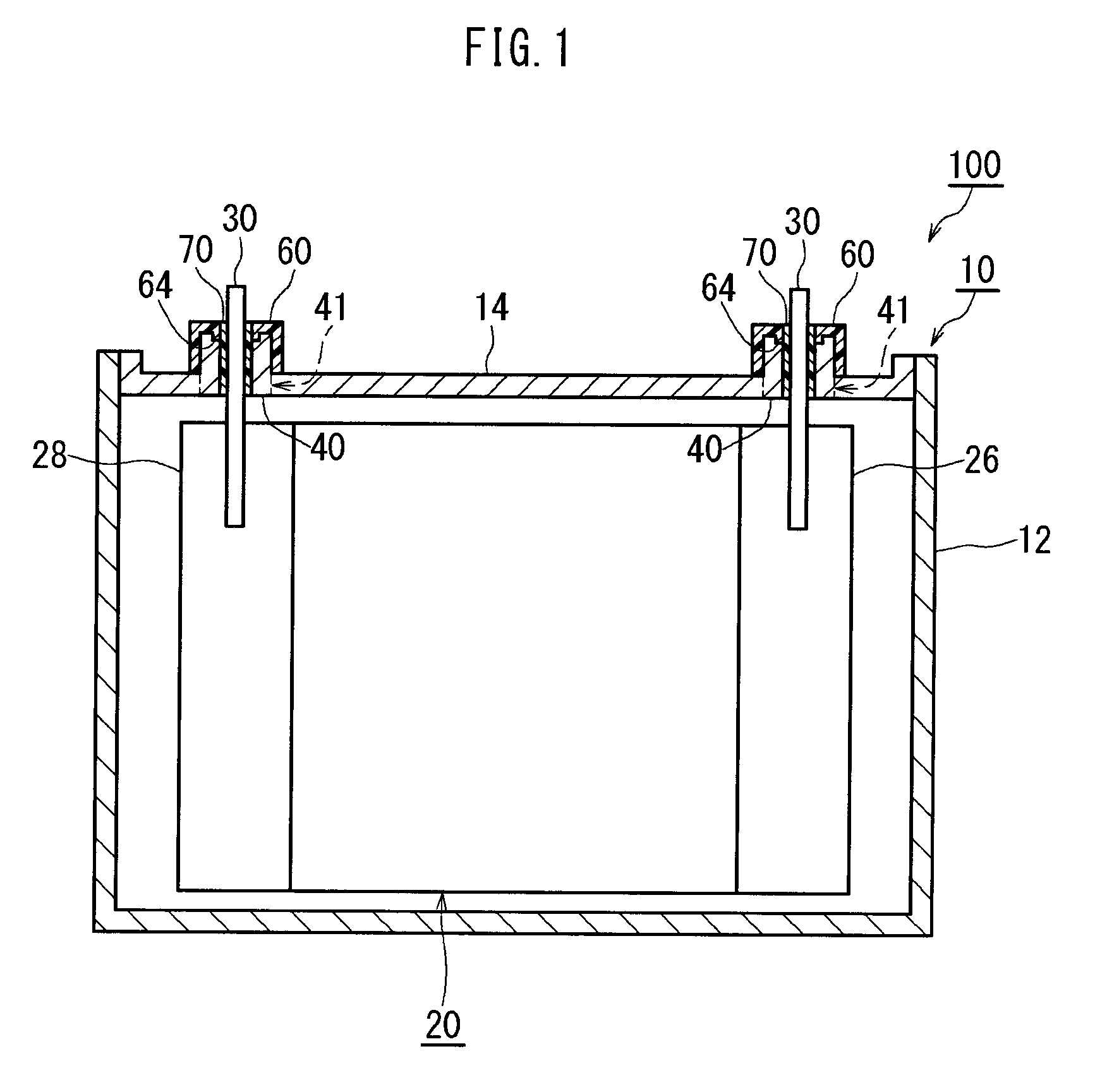

ActiveUS20100129709A1More sealReliable deformationSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringElectrical and Electronics engineering

A battery (100) includes a terminal fixing portion (40) projecting outwardly from a lid body (14), and an outer cover member (60) covering the terminal fixing portion (40). The terminal fixing portion (40) includes a hole (42) into which an electrode terminal (30) is inserted. The outer cover member (60) includes a cylindrical portion (62) (deformation restricting portion) covering an outer peripheral surface (40b) of the terminal fixing portion (40) and restrict deformation of the outer peripheral surface (40b) of the terminal fixing portion (40), and a pressure application portion (64) that compresses against a top end portion (40a) of the terminal fixing portion (40) and causes the terminal fixing portion (40) to deform.

Owner:TOYOTA JIDOSHA KK

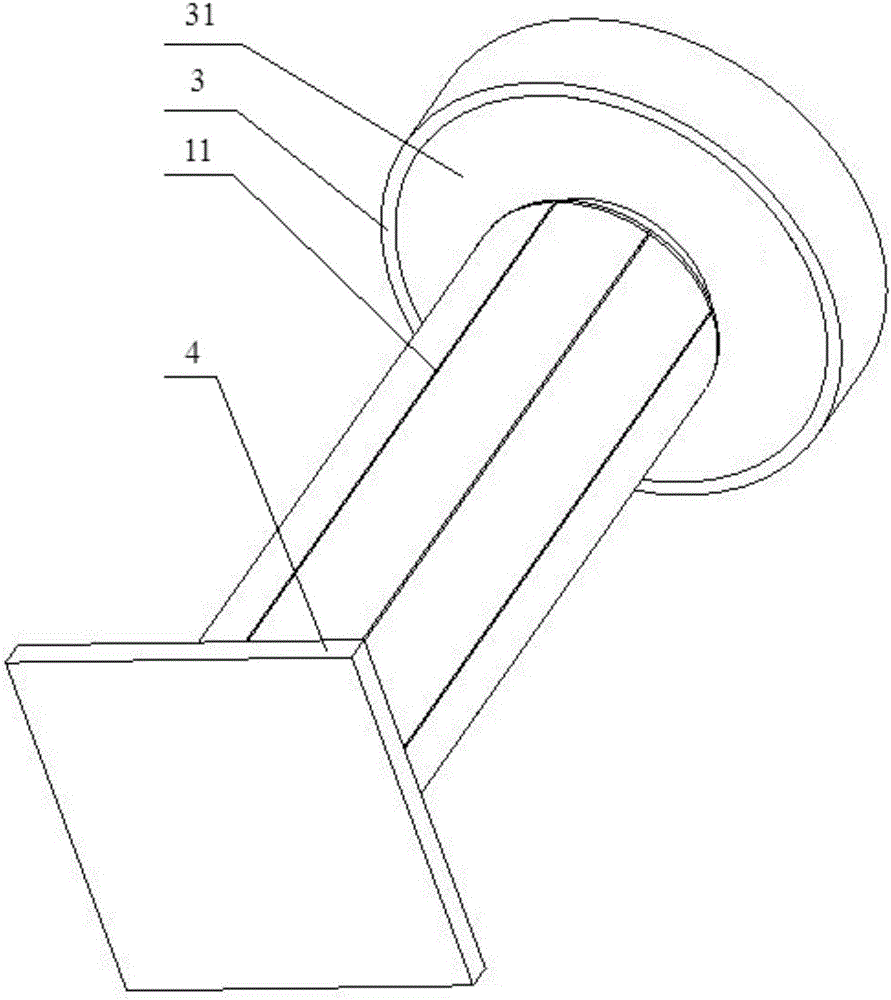

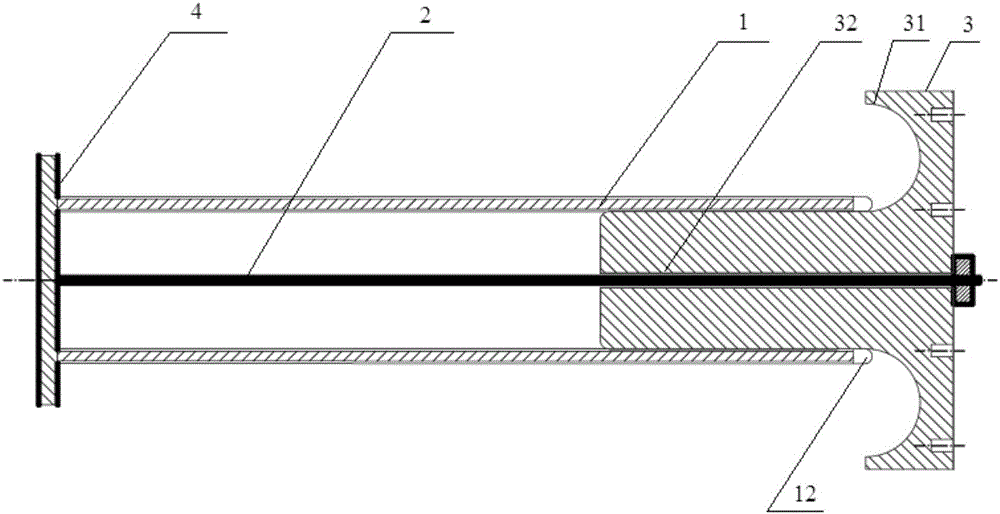

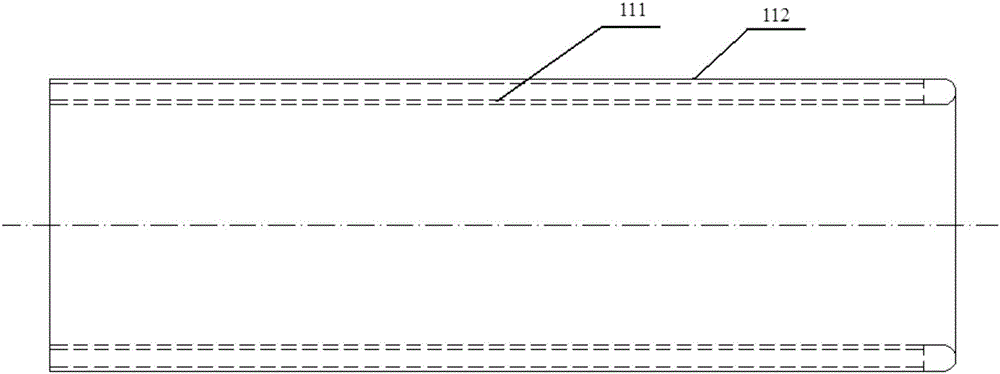

Collision energy absorption device for railway vehicle

ActiveCN105644579AGood energy absorptionSmall footprintRailway wheel guards/bumpersBufferRadial positionEnergy absorption

The present invention provides a collision energy absorption device for a railway vehicle. The collision energy absorption device for the railway vehicle comprises a connector, a base and an energy absorption tearing pipe arranged on the outer side of the connector in the radial direction, a pair or multiple pairs of kerfs corresponding in the radial position are formed in the inner and outer walls of the energy absorption tearing pipe, each pair of the kerfs comprises an inner kerf and an outer kerf, each kerf is an unclosed linear kerf, the width of each kerf is 0.05-0.8 mm, and the sum of the width of each pair of kerfs is less than the wall thickness of the energy absorption tearing pipe. By applying the collision energy absorption device for the railway vehicle, the peak of the initial collision force of the device can be obviously reduced, and the effective stroke can reach 100% theoretically. The device can be conveniently installed at the end of the railway vehicle, so that in the collision process of the vehicle, an effect of dissipating the collision kinetic energy is achieved.

Owner:CENT SOUTH UNIV

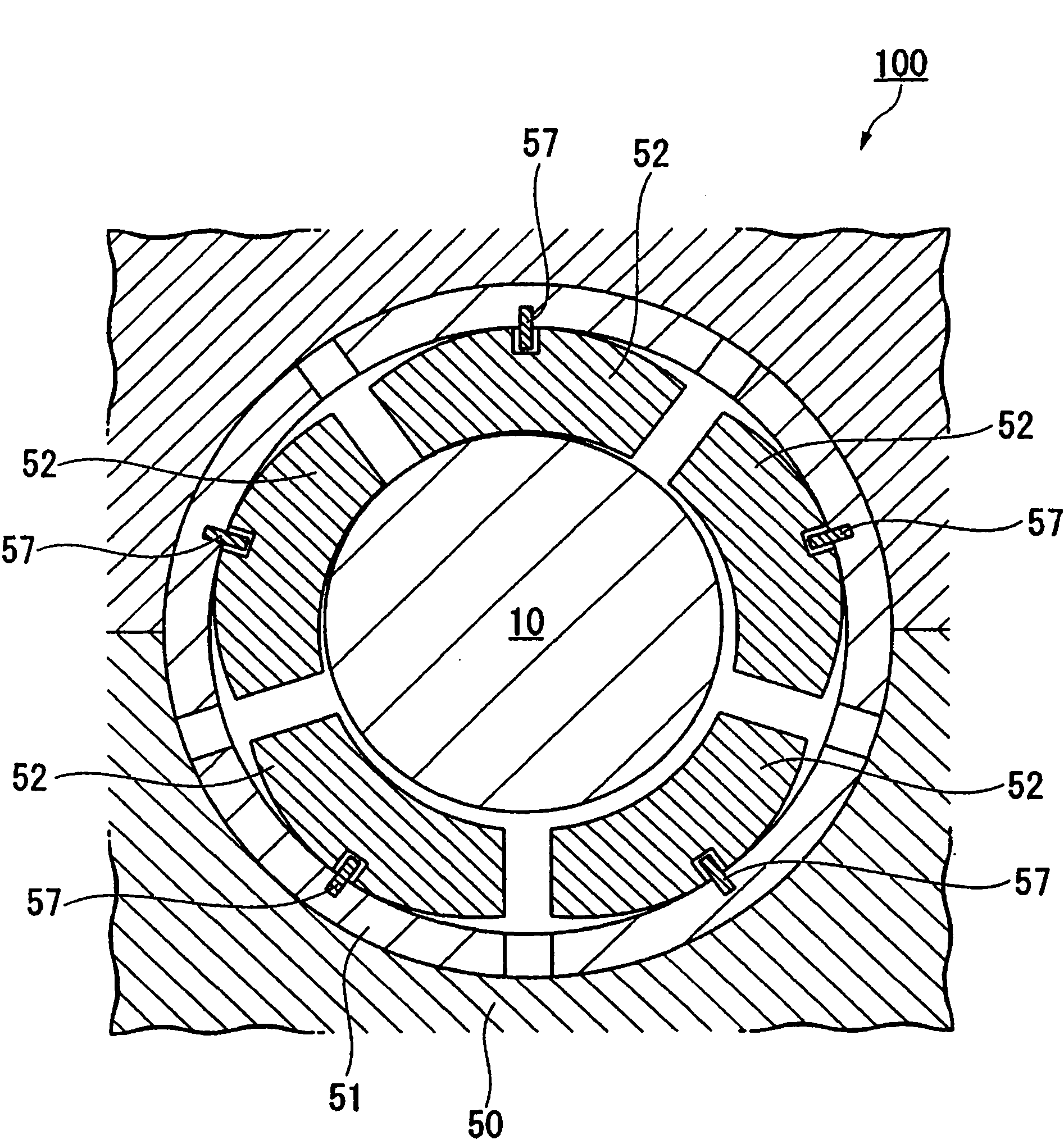

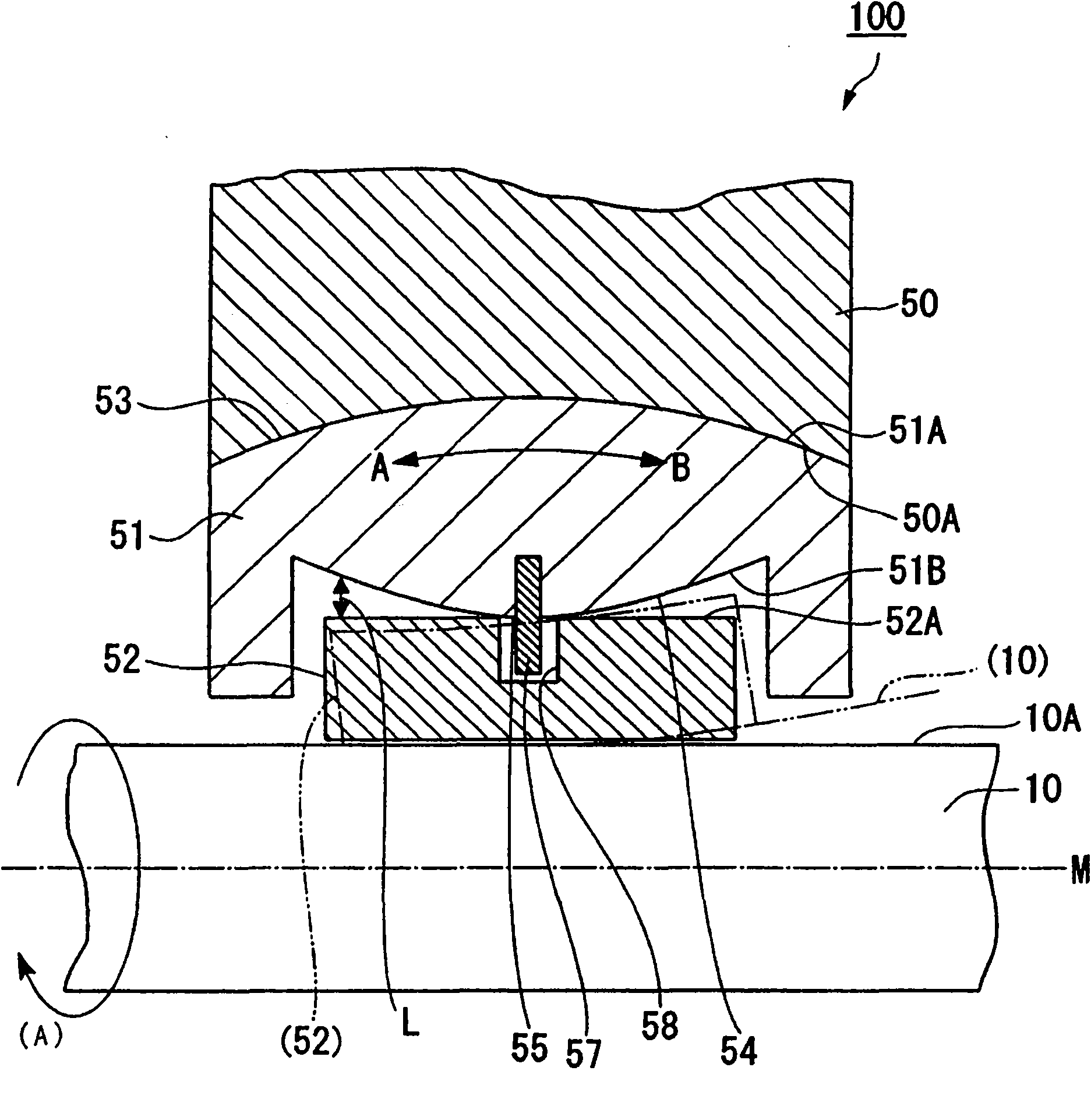

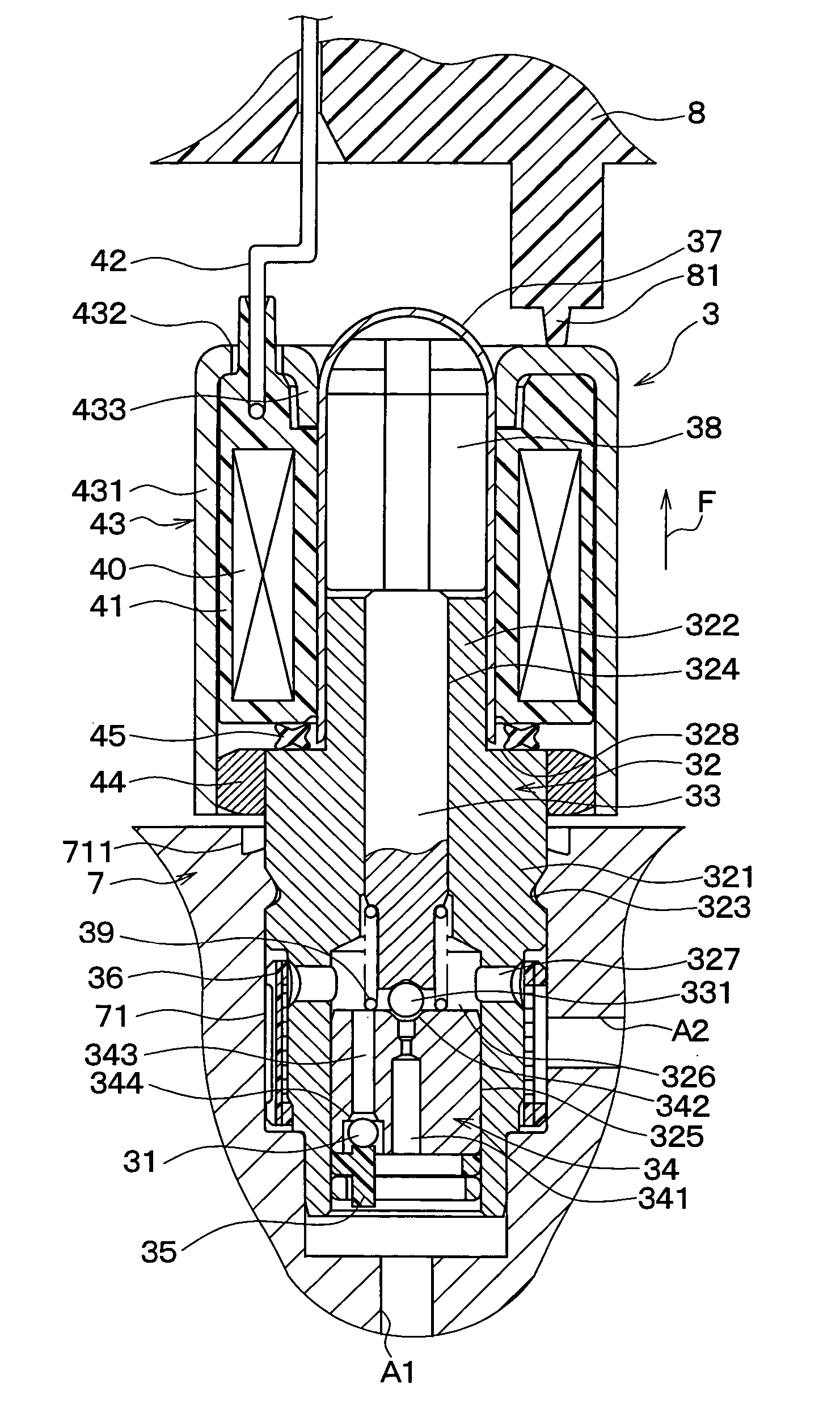

Bearing device and rotary machine

InactiveCN101932839ADeformation stableReliable deformationShaftsMachines/enginesEngineeringMechanical engineering

A bearing device has a bearing housing which is supported by a bearing base mounted to a body of a rotary machine having a rotating shaft and through which the rotating shaft penetrates, and also has pads arranged in the bearing housing so as to circumferentially surround the rotating shaft and rotatably supporting the rotating shaft. The contact surfaces between the outer peripheral surface of the bearing housing and the inner peripheral surface of the bearing base are convex curved surfaces protruding outward along the axis direction of the rotating shaft. The bearing housing is rockably supported by the bearing base via the contact surfaces, or the convex curved surfaces. At least either the inner peripheral surface of the bearing housing or the outer peripheral surface of the pads is a curved surface extending along the axis direction. The distance between the inner peripheral surface of the bearing housing and the outer peripheral surface of the pads gradually increases from the center toward the ends in the axis direction of the bearing housing.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

Seismic isolation apparatus

InactiveUS7565774B2Improve damping performanceDamping characteristics can be stably preservedStands/trestlesKitchen equipmentRubber ringCoil spring

A seismic isolation apparatus features damping characteristics equivalent to or better than prior art, without burdening the environment. In this seismic isolation apparatus, a cylindrical cavity portion is formed at the middle of an outer side laminated body, which has a form in which respective pluralities of resiliently deformable rubber rings and metal rings for maintaining rigidity are alternately laminated. A helically formed coil spring is disposed in this cavity portion so as to be snugly fitted. An inner side laminated body, which has a form in which respective pluralities of resiliently deformable rubber plates and metal plates for maintaining rigidity are alternately laminated, is disposed at an inner peripheral side of the coil spring.

Owner:BRIDGESTONE CORP

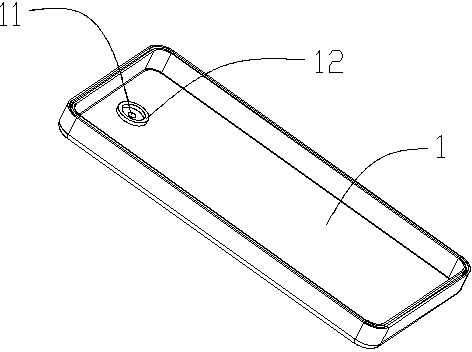

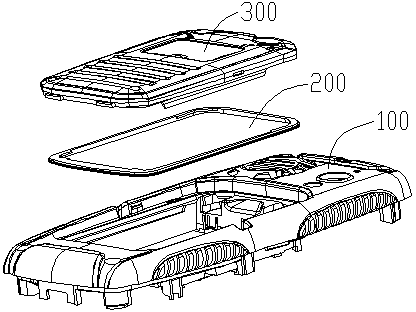

Electronic device with pressure relief structure

InactiveCN103974604AGuaranteed waterproof performanceGuaranteed functionCasings/cabinets/drawers detailsTelephone set constructionsEngineeringAtmospheric pressure

The invention relates to an electronic device with a pressure relief structure. The device comprises a first shell, a sealing part and a second shell, the sealing part is arranged between the first shell and the second shell, the first shell and the second shell are arranged on the sealing part in a press fitting mode until the first shell and the second shell are deformed to be assembled together, a sealing space is formed between the first shell and the second shell, the pressure relief structure comprises at least one ventilation waterproof film and at least one pressure relief hole, the pressure relief hole is formed in at least one of the first shell or the second shell, and the ventilation waterproof film is arranged on the pressure relief hole and is sealed with the edge of the pressure relief hole. Therefore, when the device is used for the different environments with the large temperature or pressure changes, the pressure relief structure can keep connectedness and consistency of the shell sealing space and the external temperature and pressure all the time, so that the electronic device can be normally used in the different environments with the rapid changes of temperature and pressure.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

Battery having an electrode terminal fixed to a battery case

ActiveUS8795880B2More sealReliable deformationSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical and Electronics engineeringElectrode

A battery (100) includes a terminal fixing portion (40) projecting outwardly from a lid body (14), and an outer cover member (60) covering the terminal fixing portion (40). The terminal fixing portion (40) includes a hole (42) into which an electrode terminal (30) is inserted. The outer cover member (60) includes a cylindrical portion (62) (deformation restricting portion) covering an outer peripheral surface (40b) of the terminal fixing portion (40) and restrict deformation of the outer peripheral surface (40b) of the terminal fixing portion (40), and a pressure application portion (64) that compresses against a top end portion (40a) of the terminal fixing portion (40) and causes the terminal fixing portion (40) to deform.

Owner:TOYOTA JIDOSHA KK

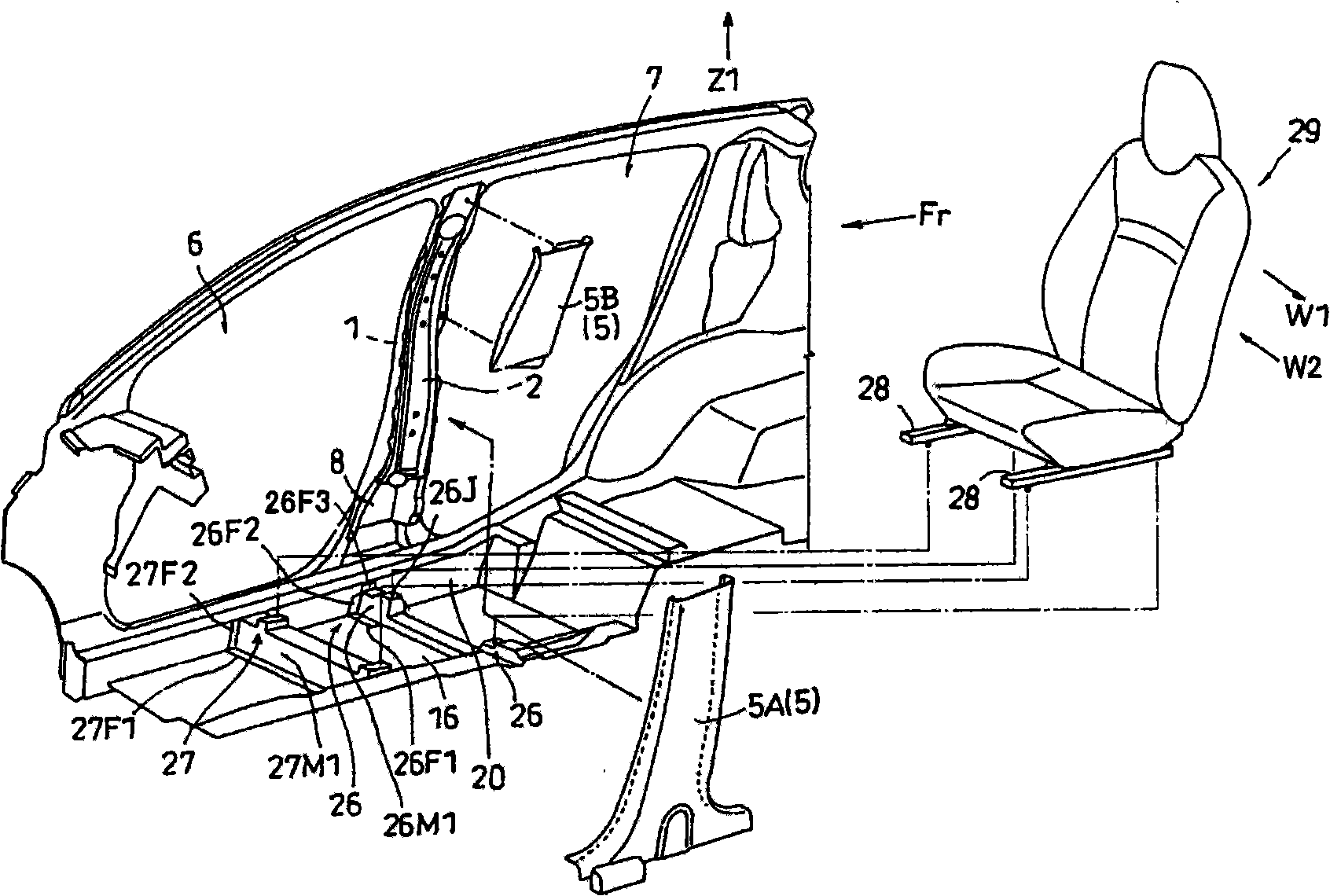

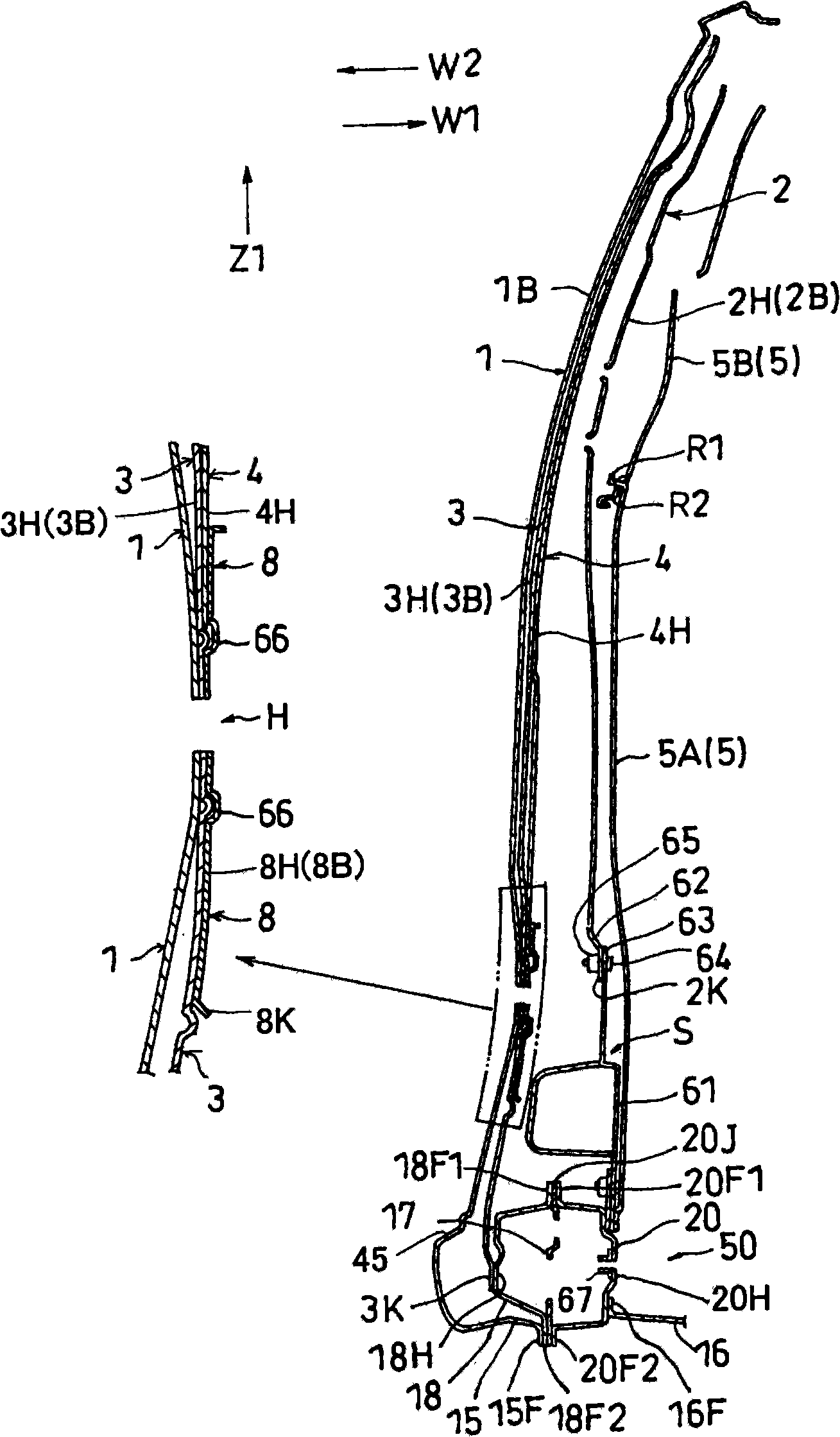

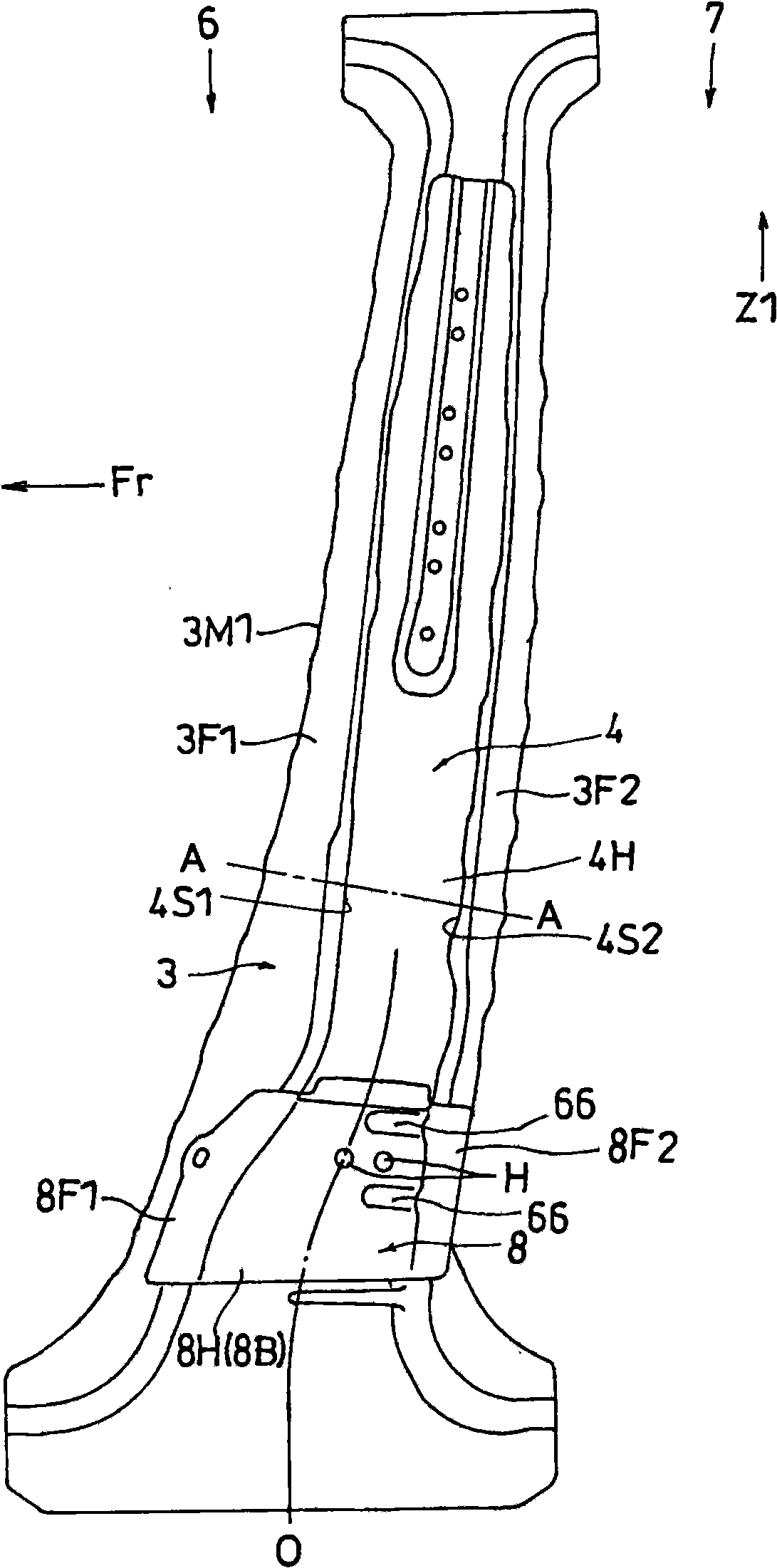

Vehicle middle pillar structure

InactiveCN101565059AImprove rigidityLarge closed sectionPedestrian/occupant safety arrangementSuperstructure subunitsCouplingEngineering

The invention provides a vehicle middle pillar structure which has an outer plate, an inner plate and a first reinforcement member. The first reinforcement member has a protuberance part, a front flange and a rear flange; the front flange is welded onto the front edge of the inner plate to form a first coupling part; the rear flange is welded onto the rear edge of the inner plate to form a second coupling part; The front flange is provided with a front extension part which extends from the first coupling part to the front side of the vehicle; The rear flange is provided with a rear extension part which extends from the second coupling part to the back side of the vehicle; and both the front and the rear extension part are welded onto the outer plate.

Owner:SUZUKI MOTOR CORP

Waterproof structure and electronic device with same

InactiveCN103732026AReliable deformationLow structural strength requirementHermetically-sealed casingsInterference fitSoft materials

The invention relates to a waterproof structure which comprises a shell and a cover, wherein the cover is assembled on the shell. The shell is provided with a groove. The cover comprises a protruding rib and a soft material structure, wherein the protruding rib is coated with the soft material structure, and the protruding rib and the soft material structure are integrally formed. The soft material structure is in interference fit with the groove. Due to the arrangement of the protruding rib, when the soft material structure is in interference fit with the groove, a support of the protruding rib can make the deformation of the soft material be reliable and achieve a good waterproof effect. Meanwhile, due to the fact that the soft material structure and the cover are integrally formed, additional assembly waterproof soft rubber is not needed, the assembly deviation of the waterproof soft rubber does not need to be taken into consideration for the arrangement of magnitude of interference, and therefore the good waterproof effect is achieved through a small amount of interference, and the requirement for the structure strength of a battery cover is lowered. The invention further relates to an electronic device with the waterproof structure, for example, a mobile phone. The waterproof structure has the good waterproof effect, assembly processes are reduced, and production efficiency is improved.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

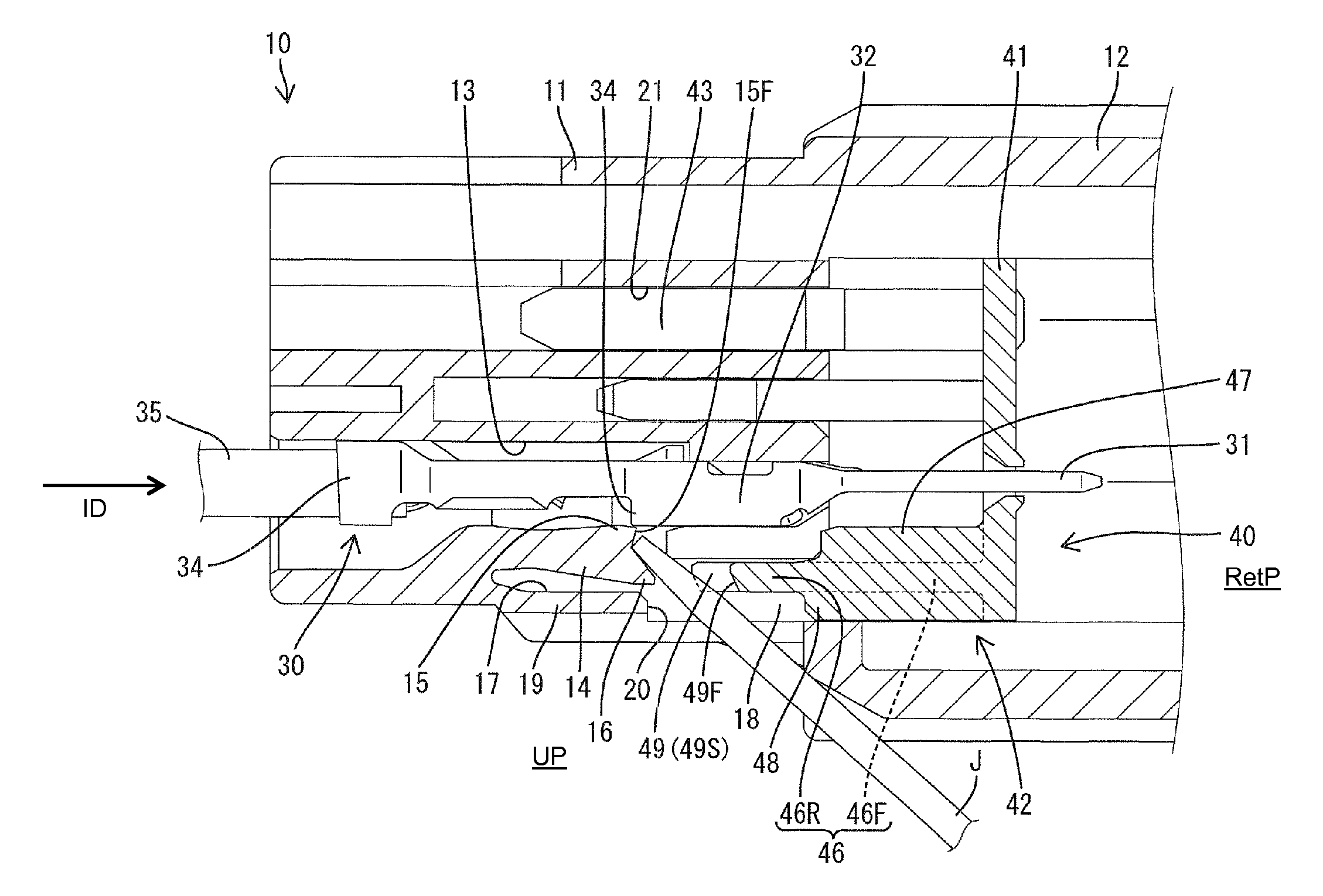

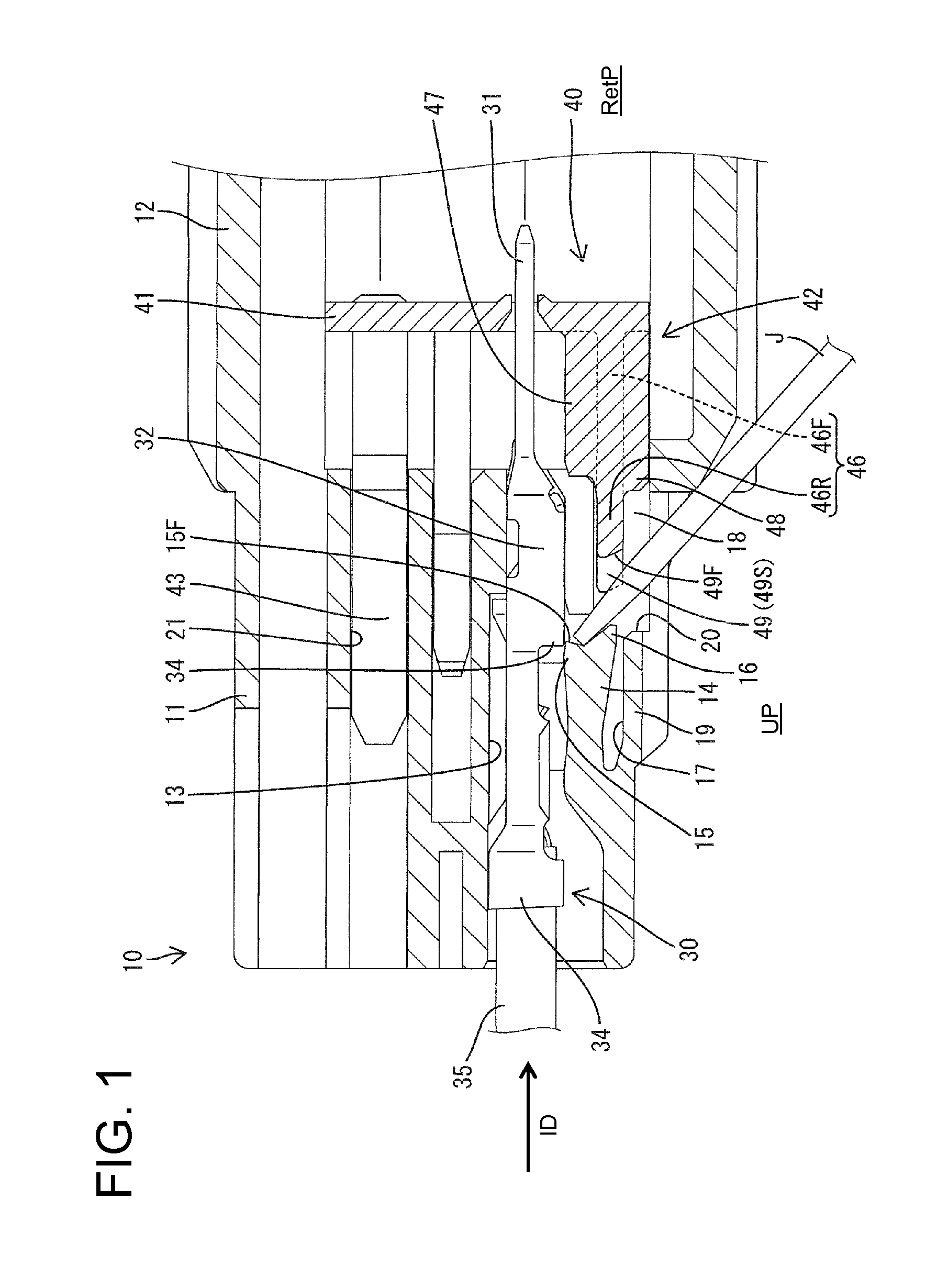

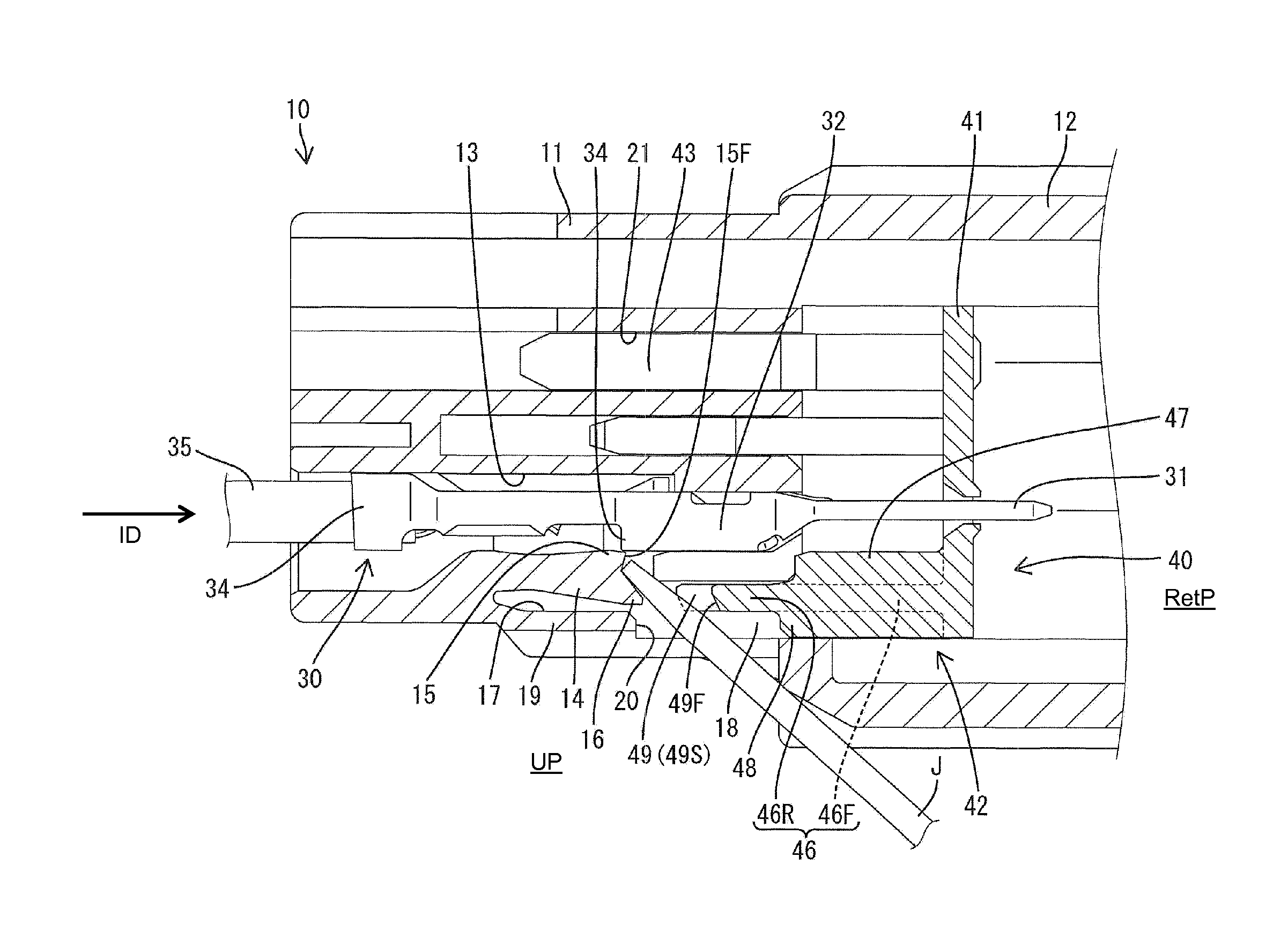

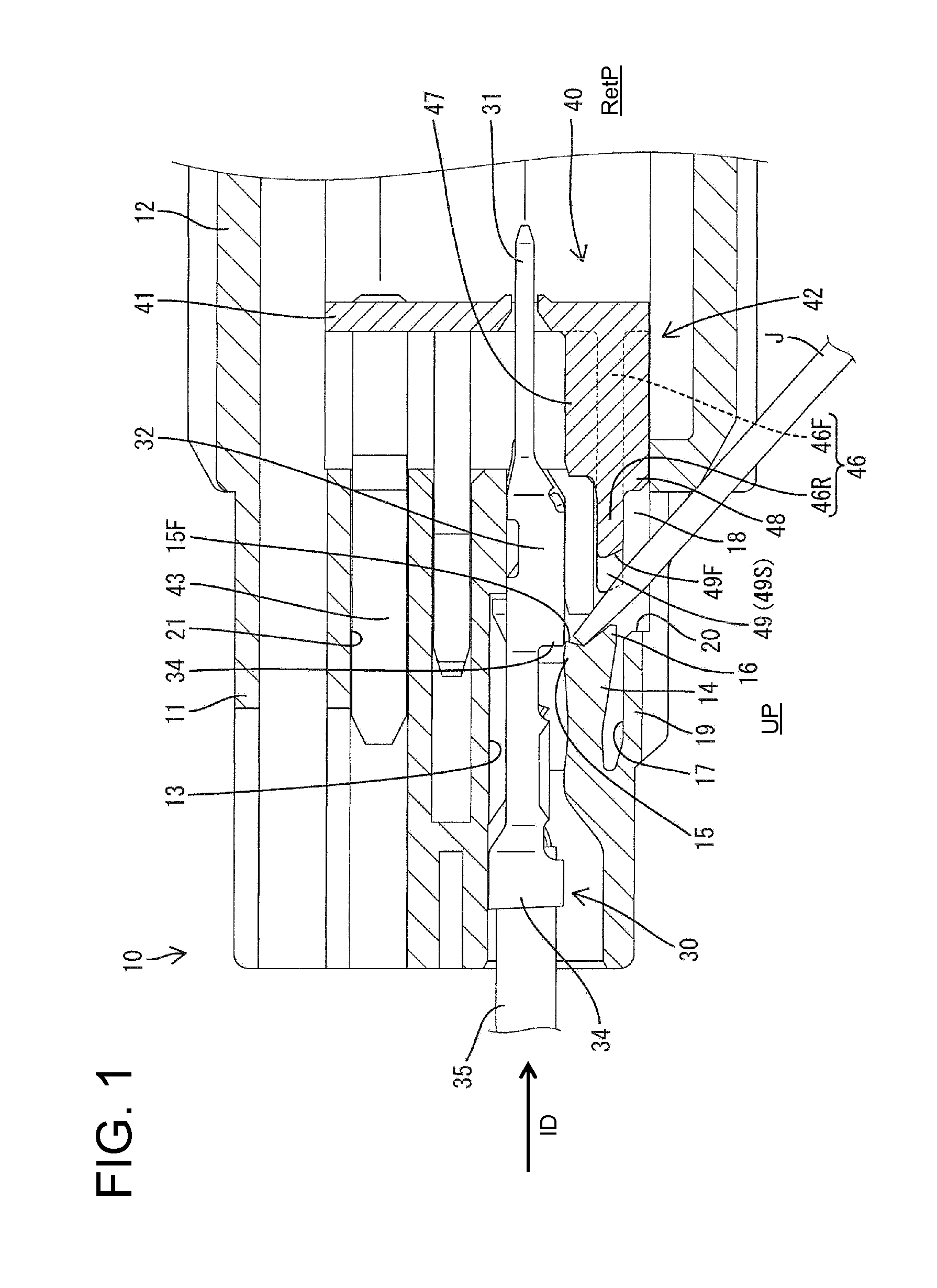

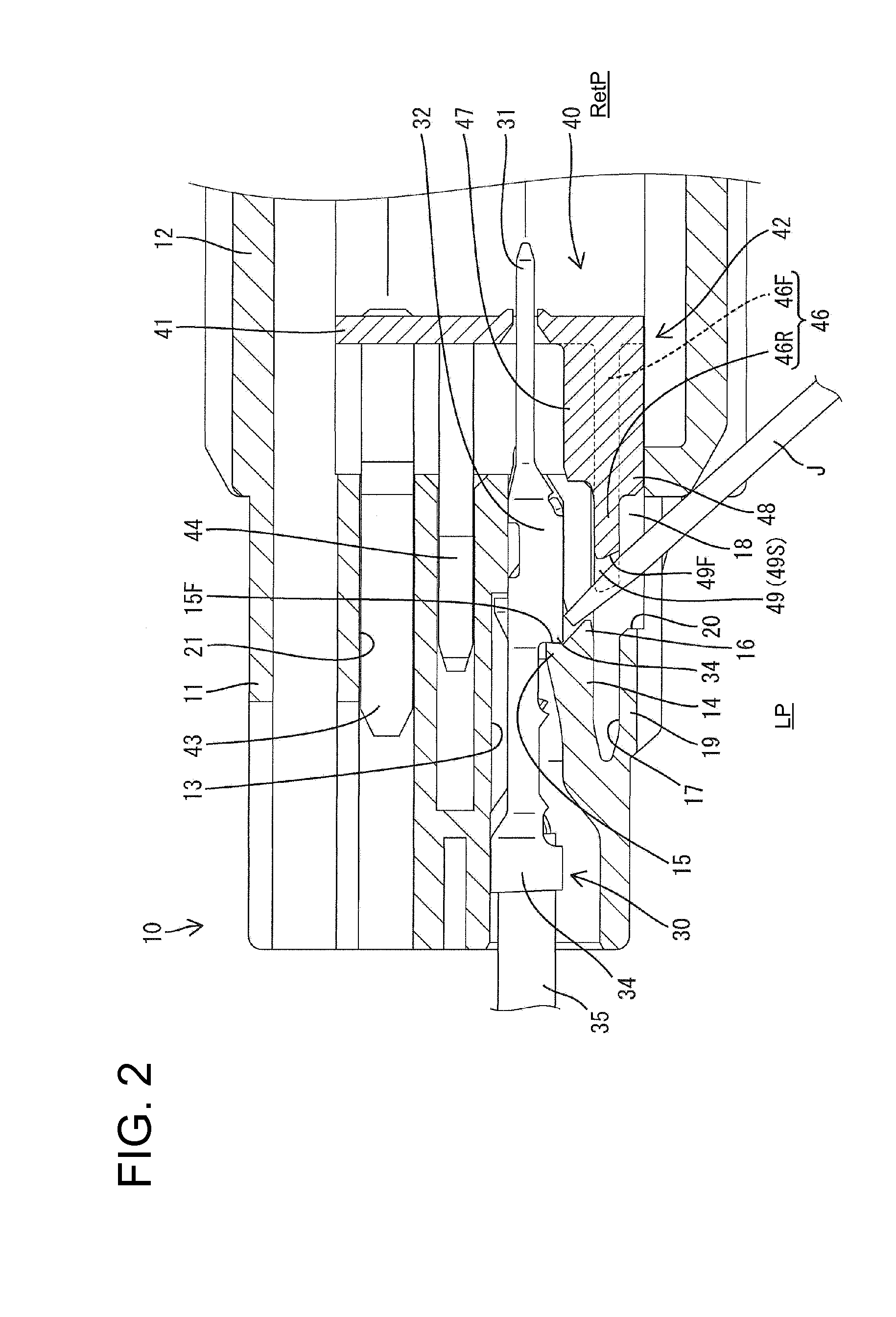

Connector

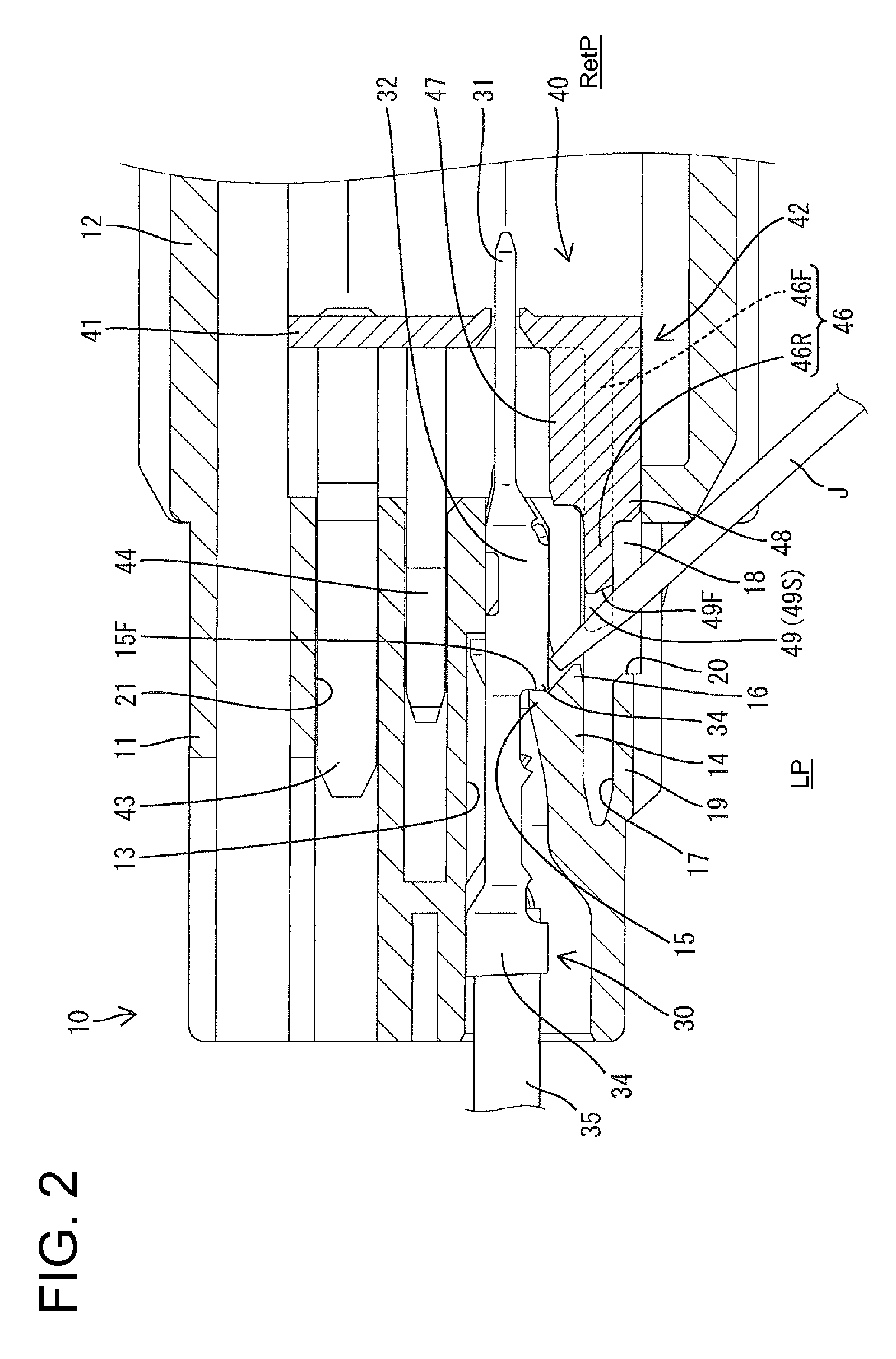

ActiveUS8523594B2Easy to operateNot to damageContact member assembly/disassemblySecuring/insulating coupling contact membersEngineeringMechanical engineering

A housing (10) is formed with jig insertion holes (20) penetrating through an outer wall (19) located at a side of deformation spaces (17) opposite to locking lances (14). Deformation restrictions (42) of a front retainer (40) are formed with guides (49) that are cut out to allow an unlocking jig inserted through the jig insertion hole (20) to reach the locking lance (14) when the front retainer (40) is at a retracted position and to position the unlocking jig in a width direction crossing both a resiliently deforming direction of the locking lances (14) and an inserting direction of terminal fittings (30) into cavities (13).

Owner:SUMITOMO WIRING SYST LTD

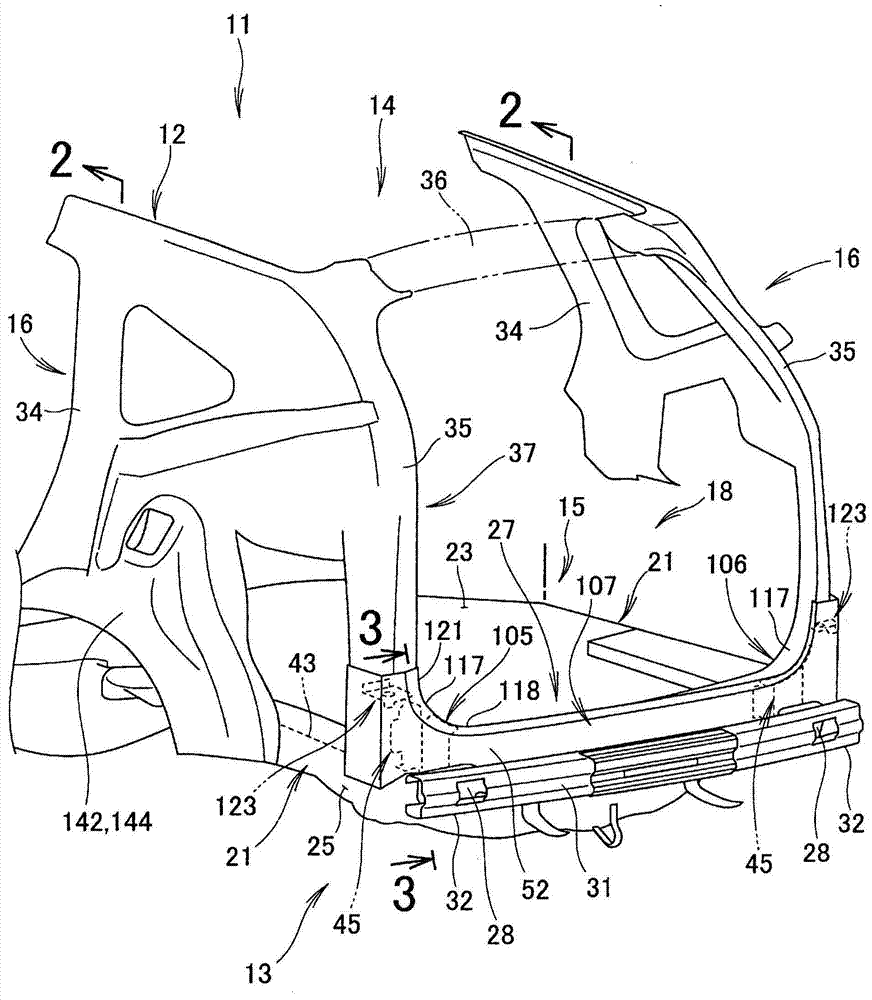

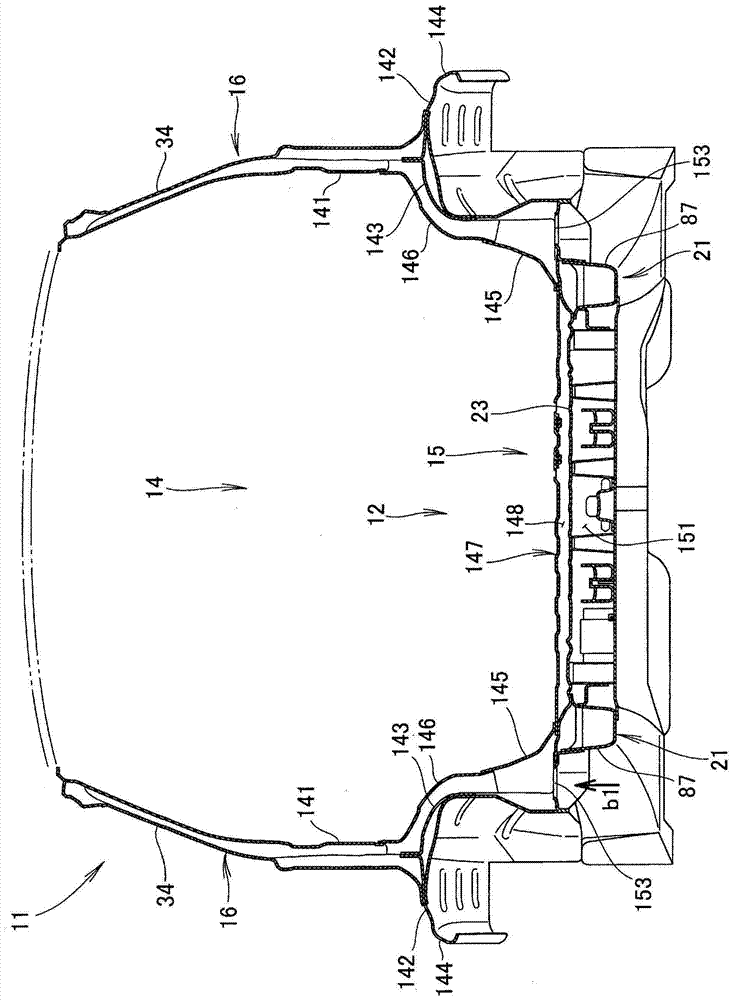

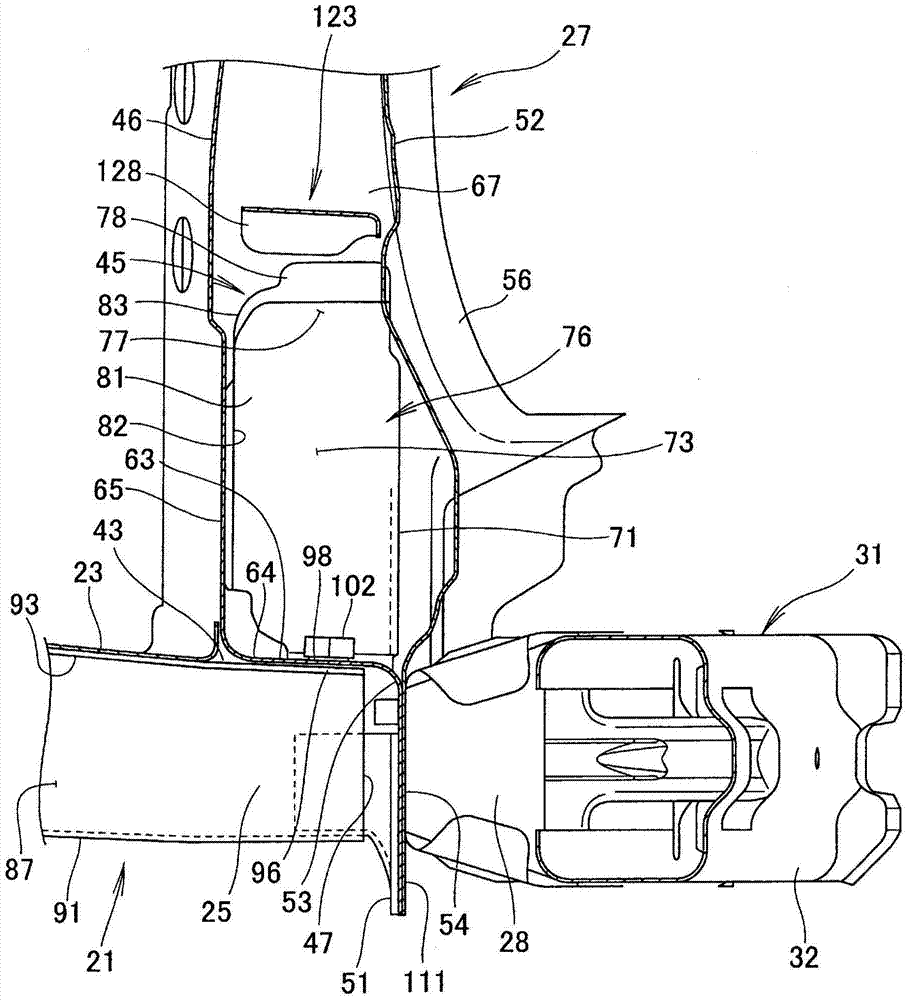

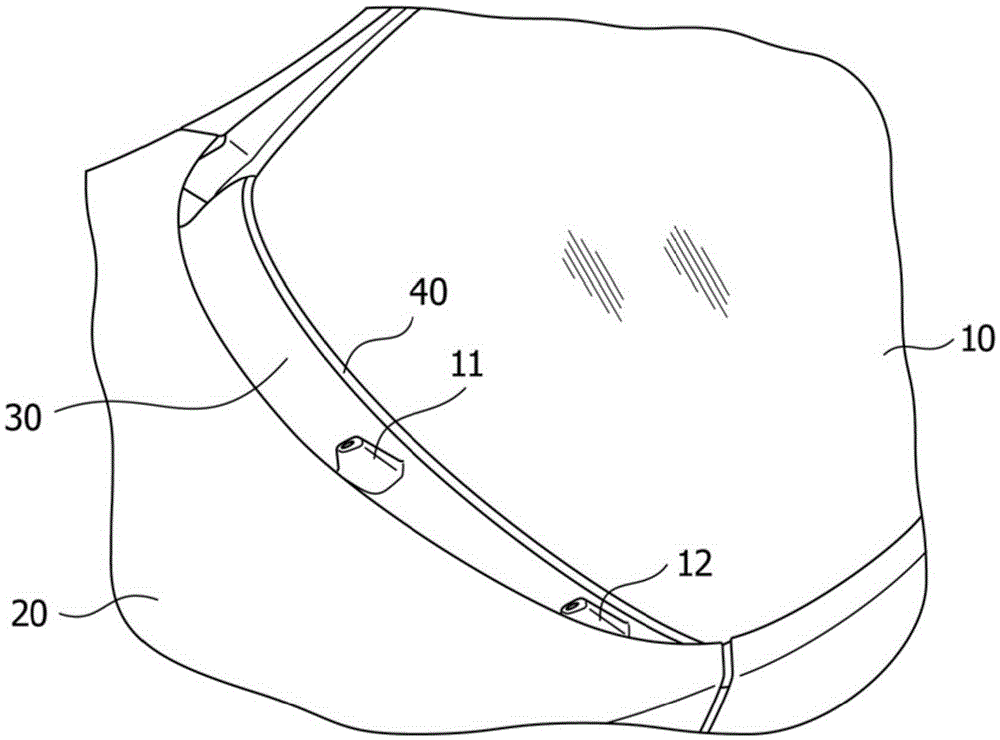

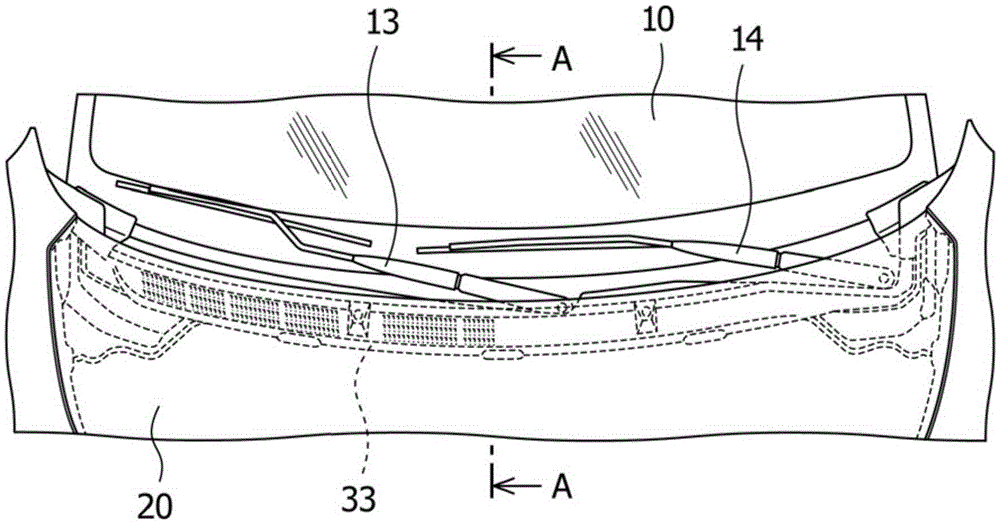

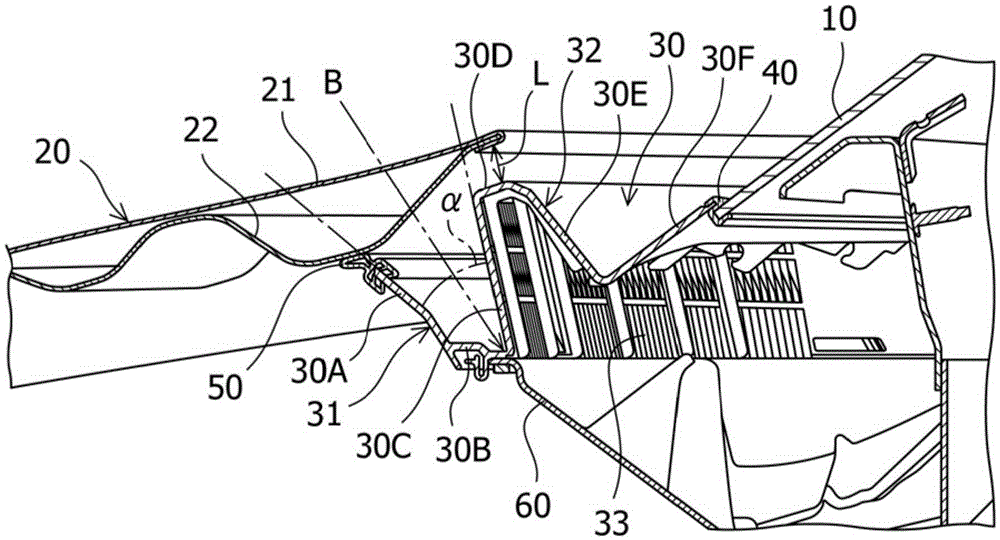

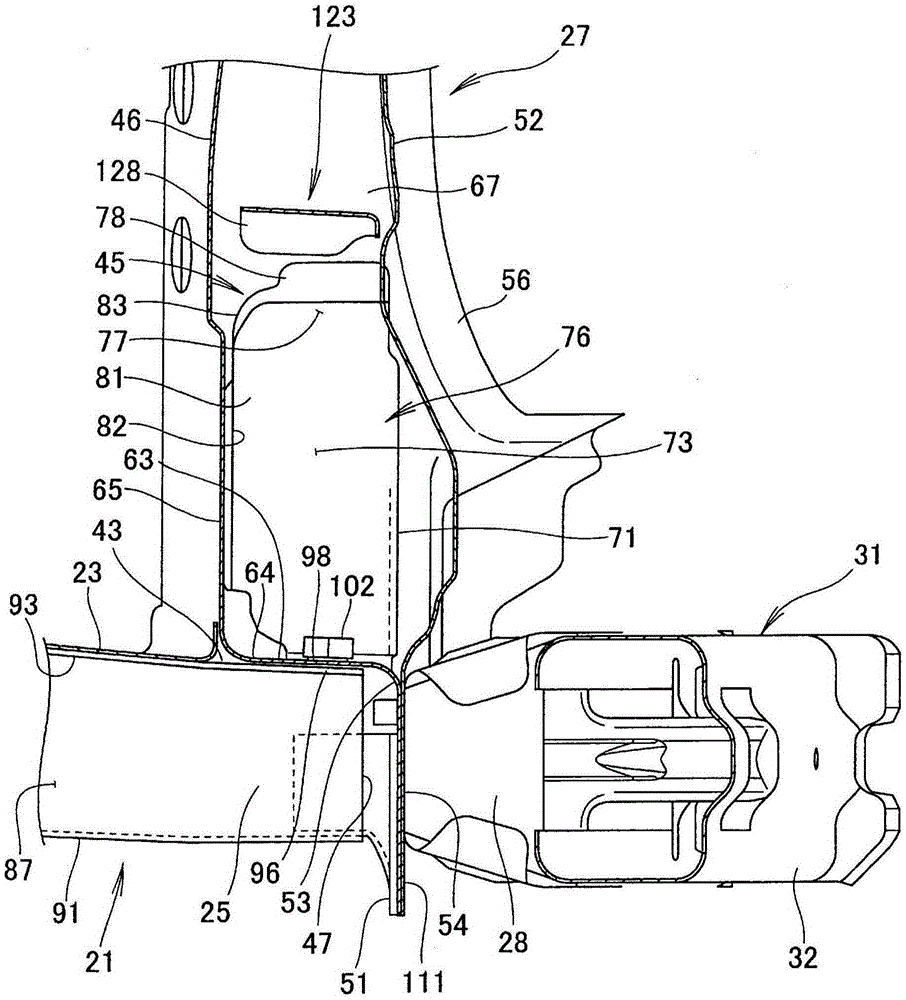

Vehicle body rear structure

This vehicle body rear structure is provided with: a left and right rear-side frame (21) that extend in the front-back direction of the vehicle body (12); and a rear panel assembly (27) that forms a closed-cross-section section (41) extending in the direction of vehicle width intersecting the rear-side frames (21), is provided to the back end (25) of the rear-side frames (21), and configures the bottom of a vehicle body rear opening (37). The rear panel assembly (27) is provided with a bulkhead (45) that is disposed in the closed-cross-section section (41) at the upper surface (43) of the rear-side frames (21), and that partitions the interior of the closed-cross-section section (41) with surfaces oriented in the direction of vehicle width.

Owner:HONDA MOTOR CO LTD

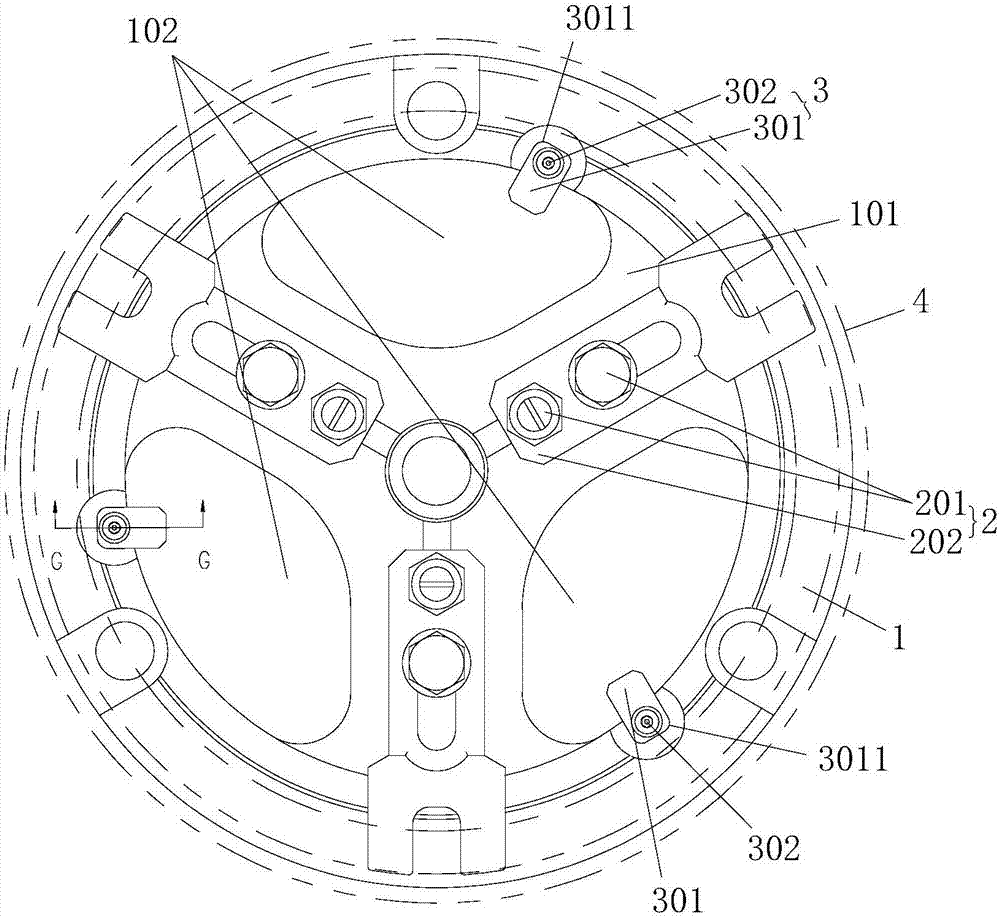

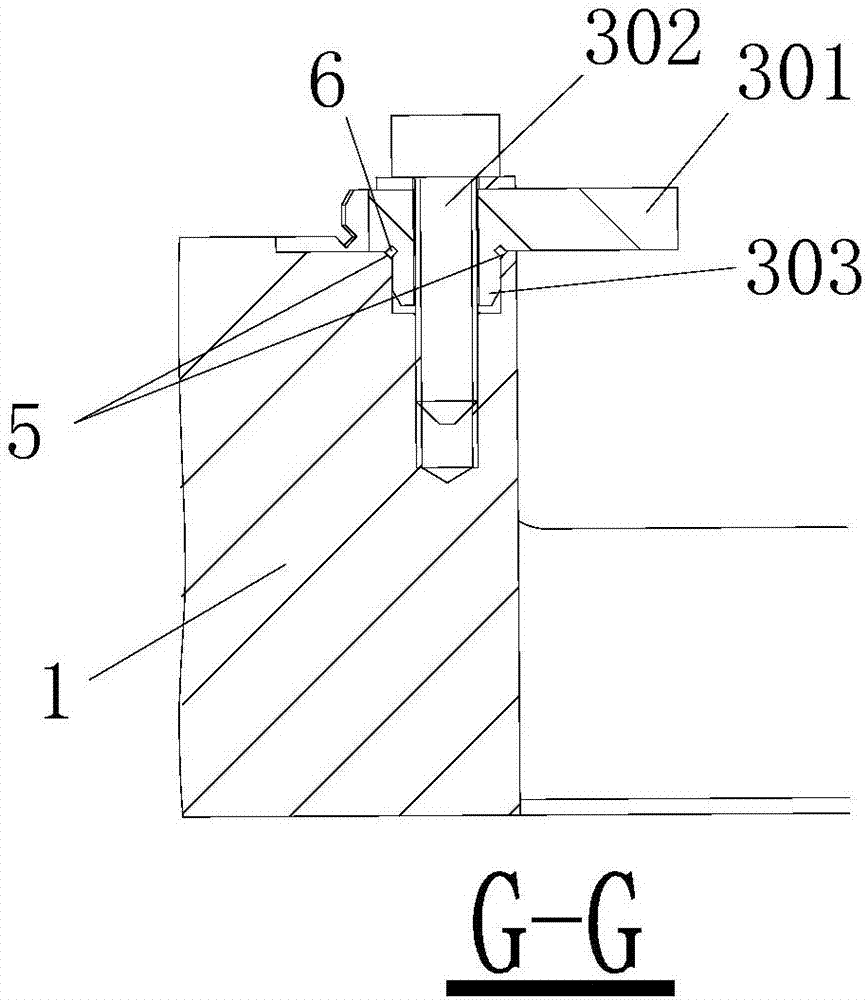

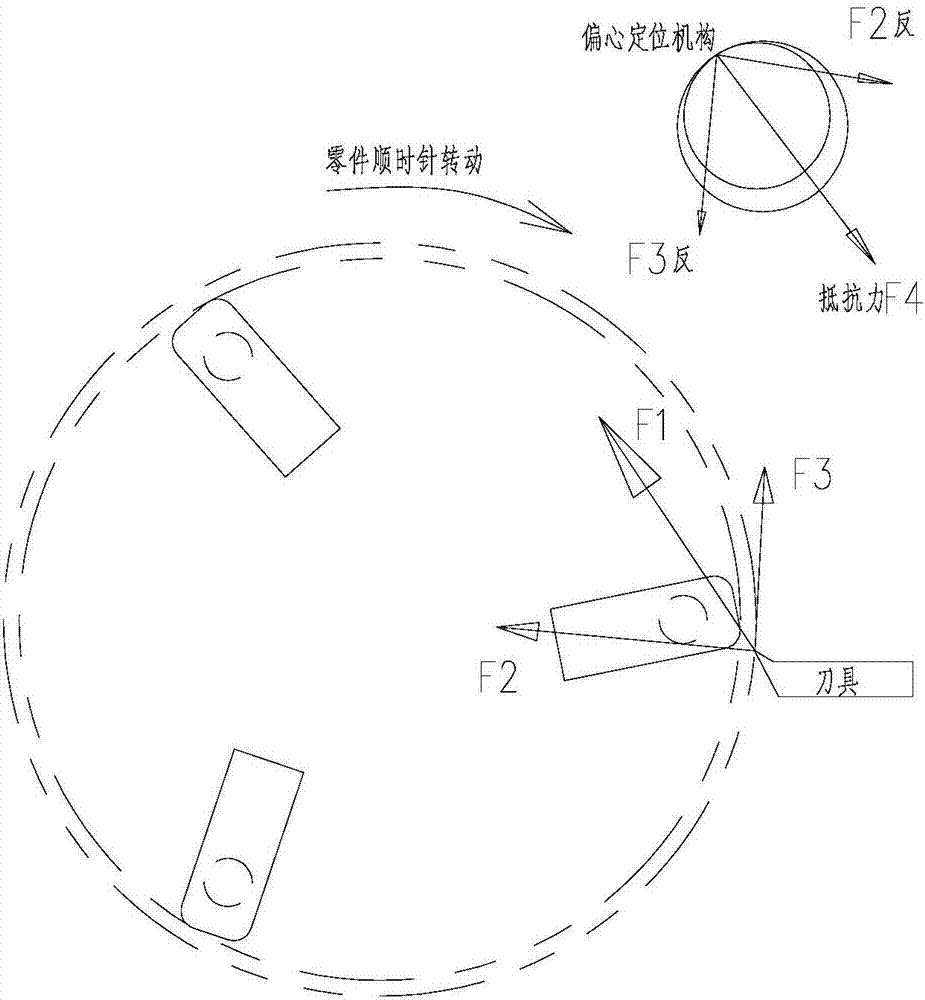

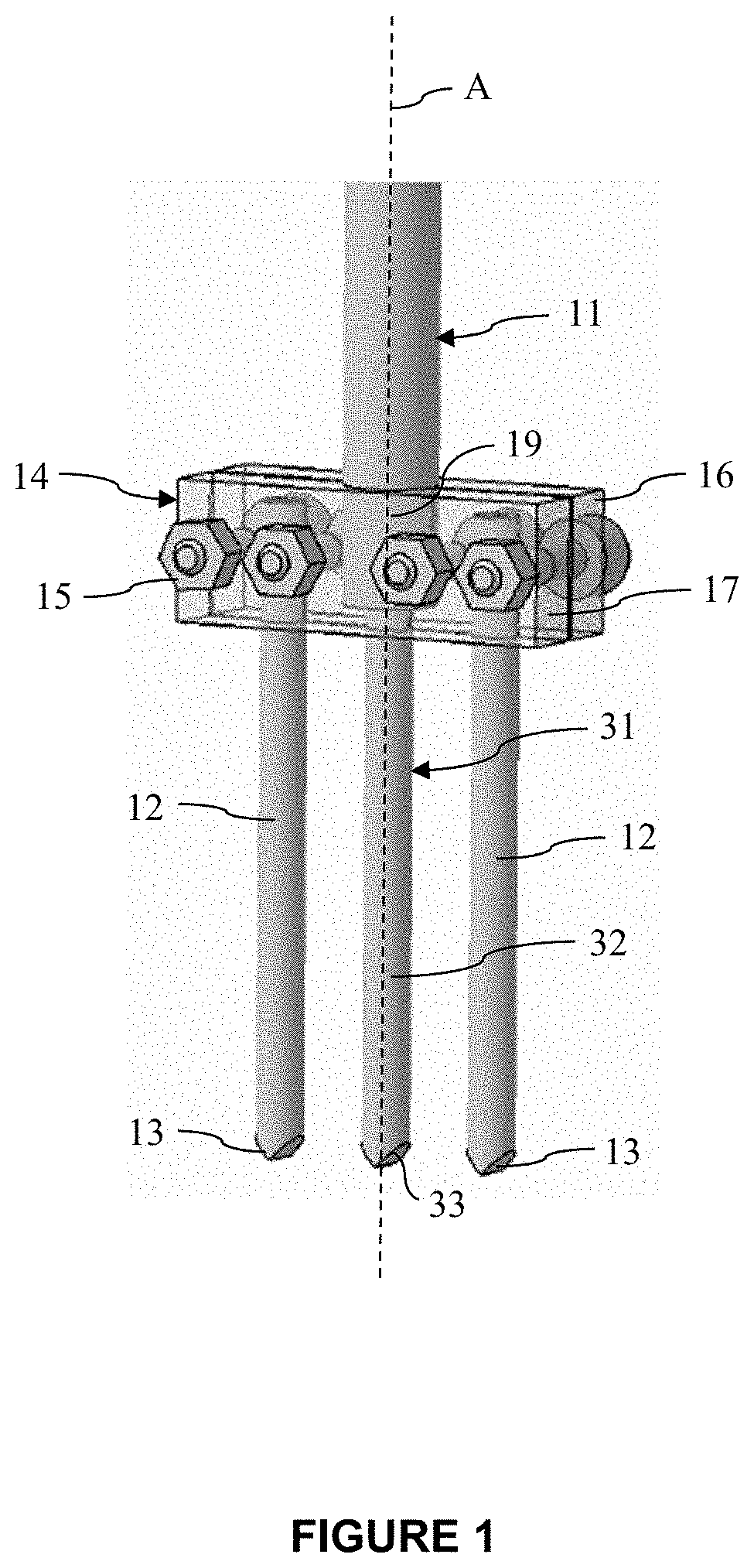

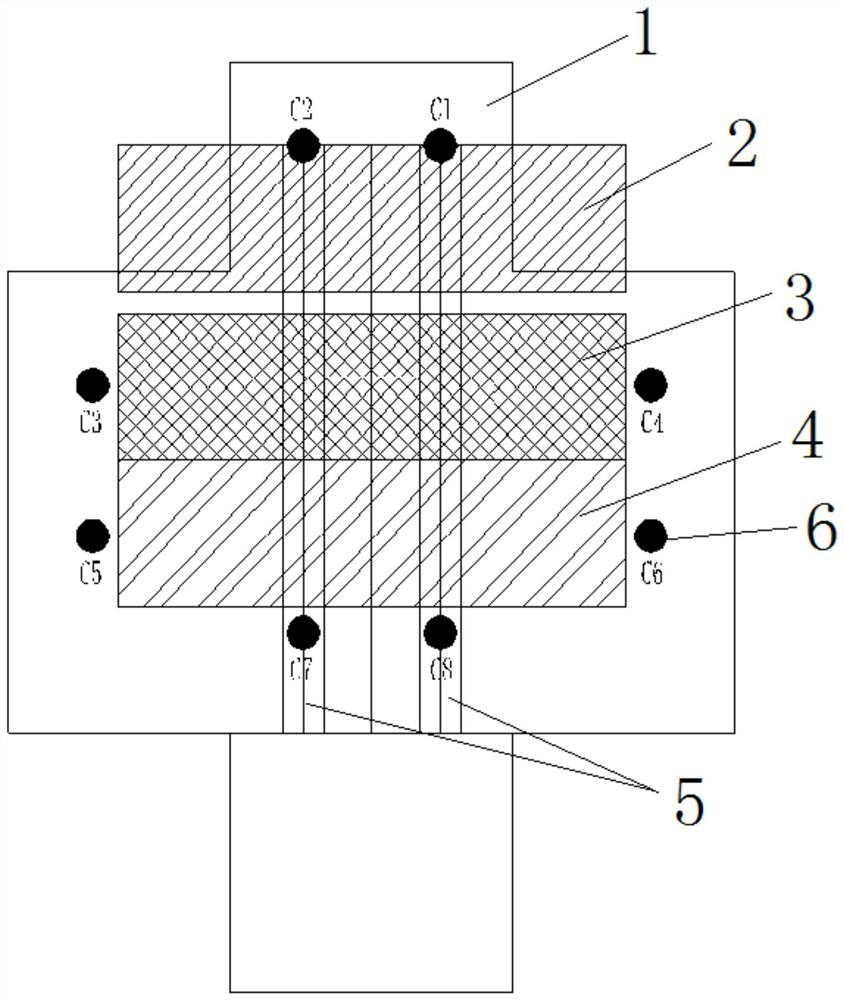

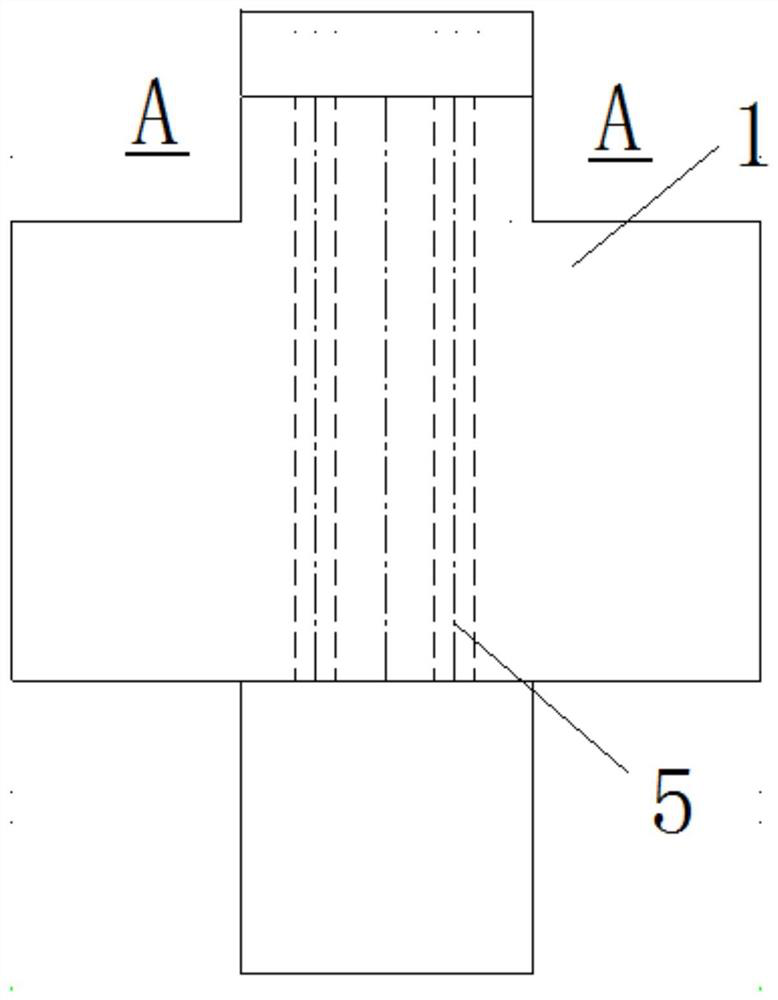

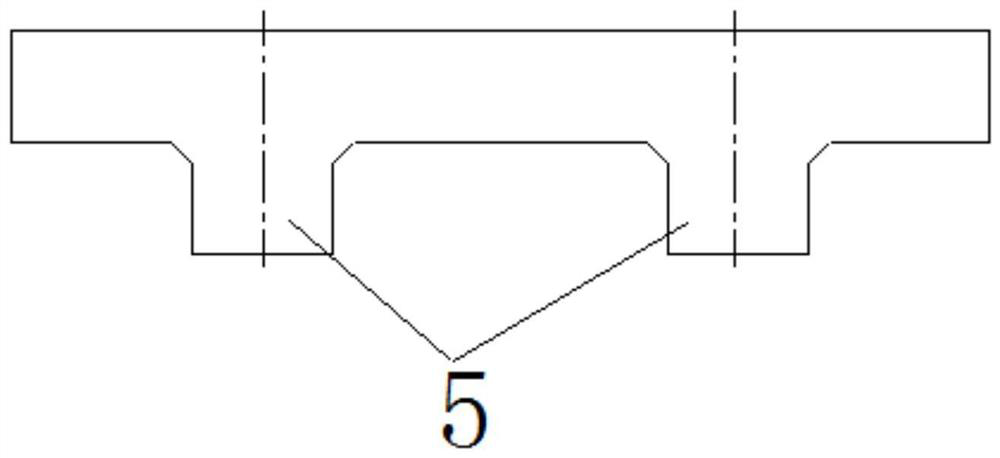

Turning clamp and turning fixing method for thin-wall deforming part

ActiveCN107297635AReliable deformationPrecise lock positionPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a turning clamp and turning fixing method for a thin-wall deforming part. The turning clamp for the thin-wall deforming part comprises a base and a compression mechanism, wherein the base is used for bearing a to-be-processed part and installed on a machine tool spindle and rotates along with the rotation of the machine tool spindle; and the compression mechanism is used for compressing the to-be-processed part on the base. The base is provided with multiple groups of eccentric locating mechanisms, wherein the eccentric locating mechanisms are eccentrically installed on the base and used for making tight contact with the locating face of the to-be-processed part obtained after generating stress deformation through the rotation in the radial direction of the to-be-processed part and radially limiting the to-be-processed part through locking; rotational adjusting contact and locking fixing are conducted by the eccentric locating mechanisms on the to-be-processed part in at least three directions. By means of the turning clamp and the turning fixing method, the elastic deformation of the to-be-processed part after being disassembled from the turning clamp is reduced, the precision of the size, circularity, flatness and the like of the processed to-be-processed part is ensured, and the out-of-tolerance problems are avoided.

Owner:CHINA HANGFA SOUTH IND CO LTD

Connector

ActiveUS20120034805A1Easy to operateNot to damageContact member assembly/disassemblySecuring/insulating coupling contact membersEngineeringMechanical engineering

A housing (10) is formed with jig insertion holes (20) penetrating through an outer wall (19) located at a side of deformation spaces (17) opposite to locking lances (14). Deformation restrictions (42) of a front retainer (40) are formed with guides (49) that are cut out to allow an unlocking jig inserted through the jig insertion hole (20) to reach the locking lance (14) when the front retainer (40) is at a retracted position and to position the unlocking jig in a width direction crossing both a resiliently deforming direction of the locking lances (14) and an inserting direction of terminal fittings (30) into cavities (13).

Owner:SUMITOMO WIRING SYST LTD

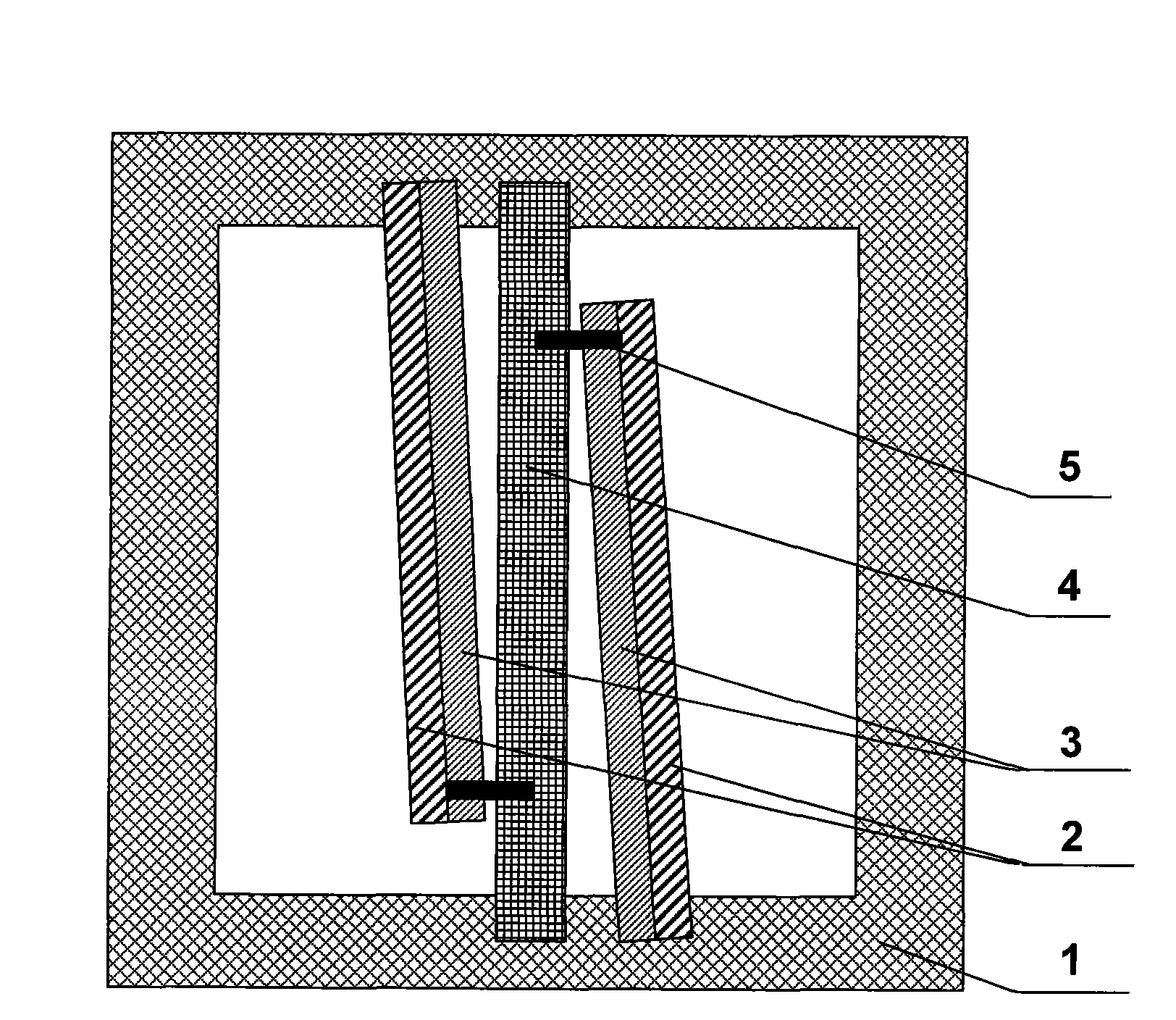

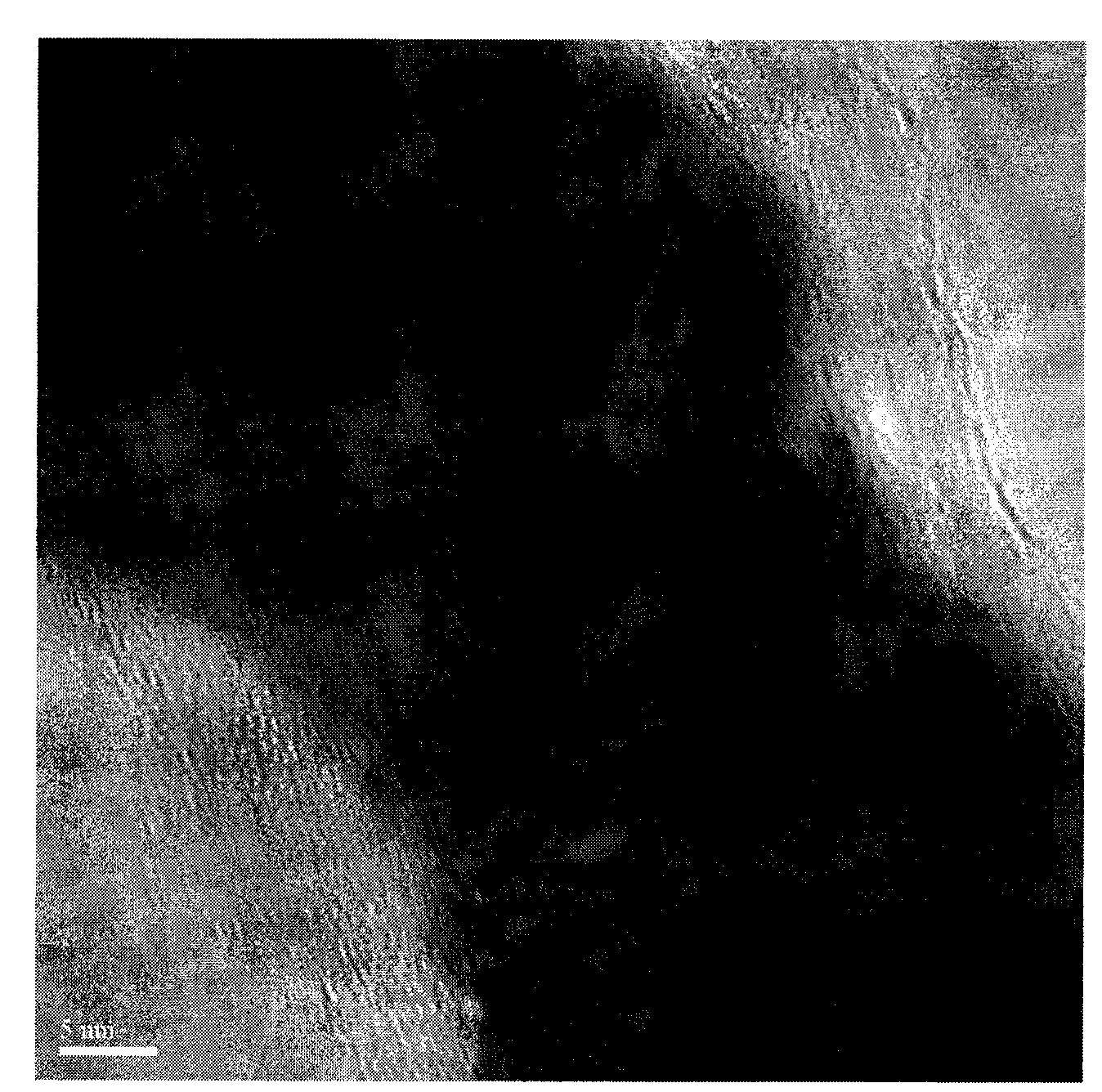

Nonmagnetic bimetallic strip driver used in transmission electron microscope

ActiveCN101582366AWide range of applicationsRich research objectsPiezoelectric/electrostriction/magnetostriction machinesElectric discharge tubesTransmission electron microscopyLinear expansion coefficient

The invention relates to a nonmagnetic bimetallic strip driver used in a transmission electron microscope, which comprises a nonmagnetic signal metallic strip, a nonmagnetic bimetallic strip and a heat conducting metal frame and is characterized in that the nonmagnetic bimetallic strip formed by a nonmagnetic metallic strip with small linear expansion coefficients and a nonmagnetic metallic strip with big linear expansion coefficients is fixed above the heat conducting metal frame; the nonmagnetic signal metallic strip is positioned between the two nonmagnetic metallic strips; nanophase materials are positioned above the nonmagnetic bimetallic strip and placed into the transmission electron microscope to be heated, and then the nonmagnetic bimetallic strip deforms to drive the nanophase materials to deform. The driver excludes the influence of the magnetism of the bimetallic strip on the nanophase materials in the transmission electron microscope and can conveniently and fast obtain the atomic size information of the nanophase materials.

Owner:BEIJING UNIV OF TECH

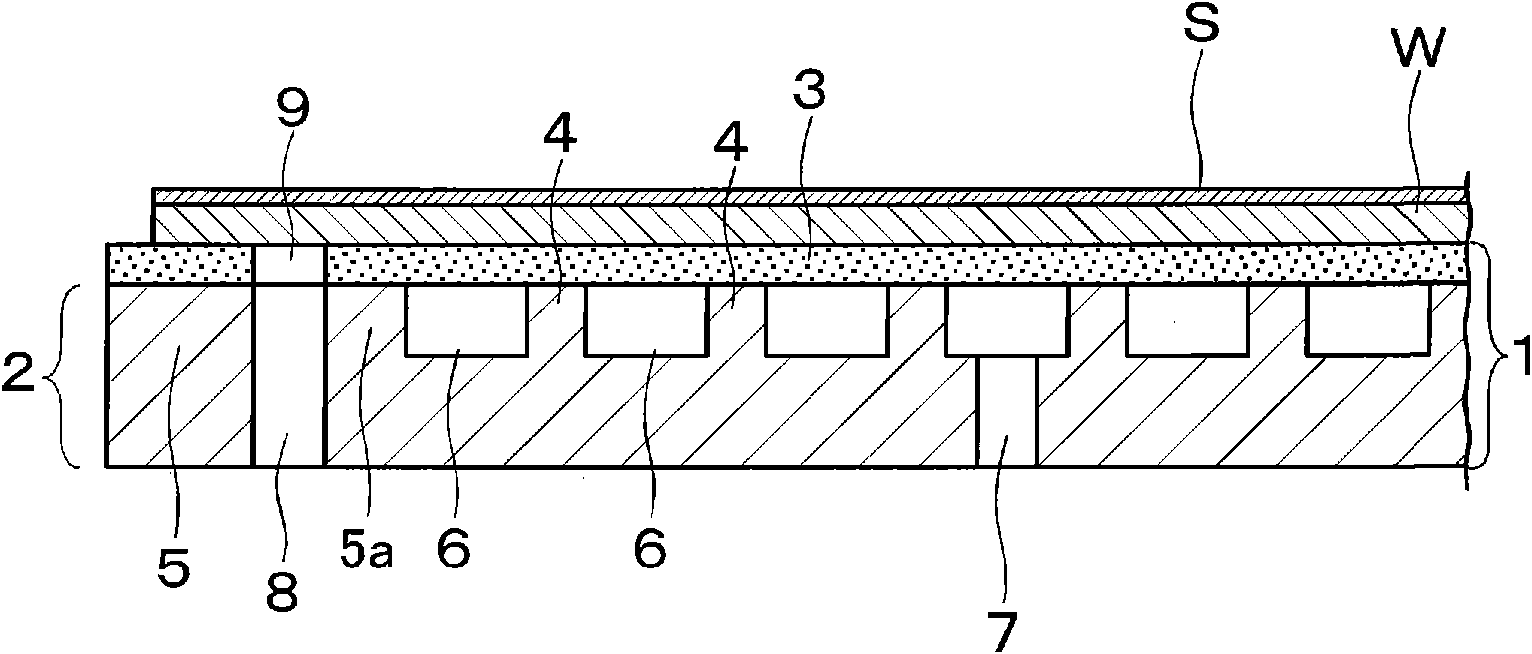

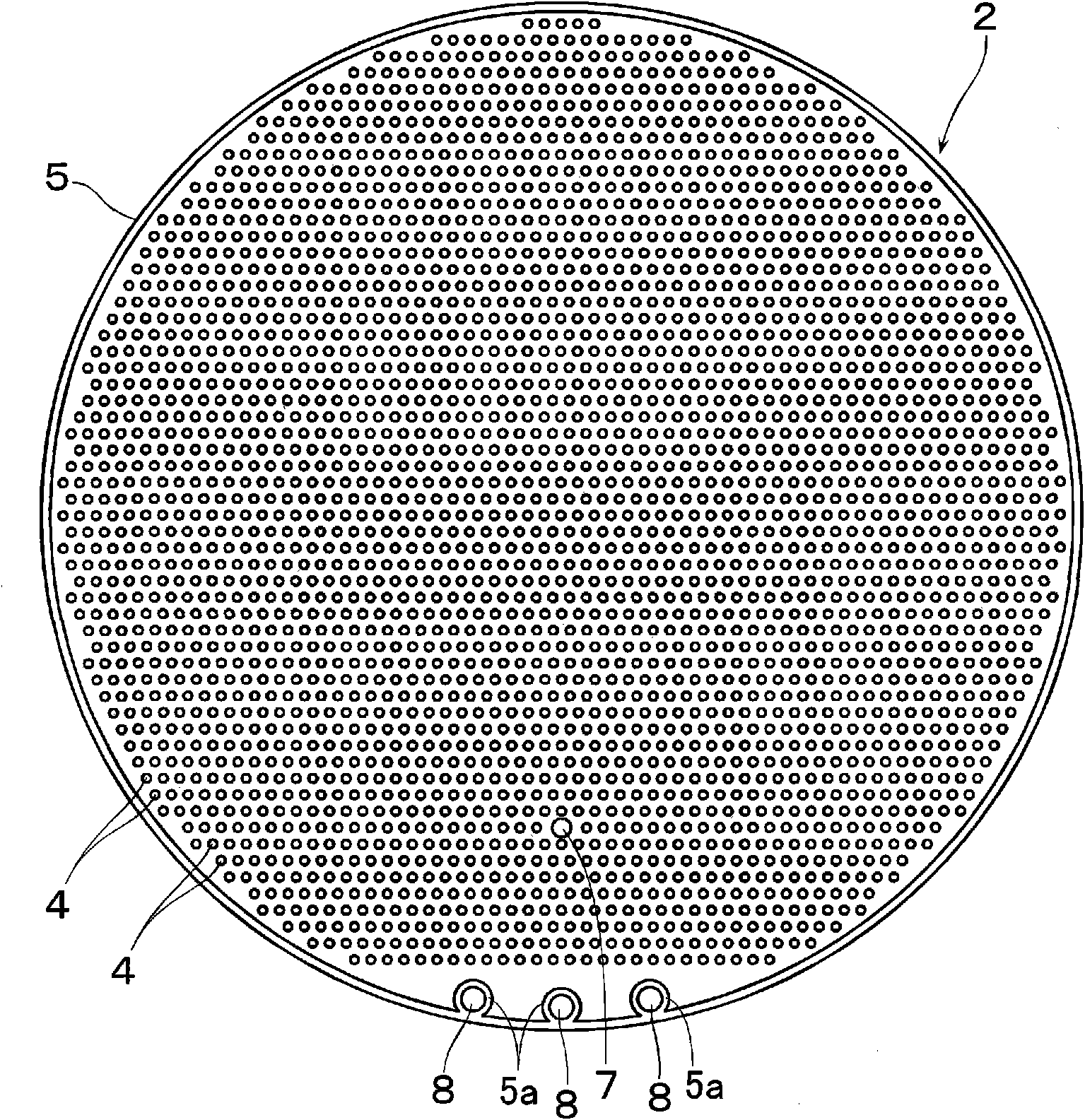

Securing tool and work processing method

InactiveCN101802999AReliable deformationAvoid breakingSemiconductor/solid-state device manufacturingAdhesivesSuction forceEngineering

Owner:LINTEC CORP +1

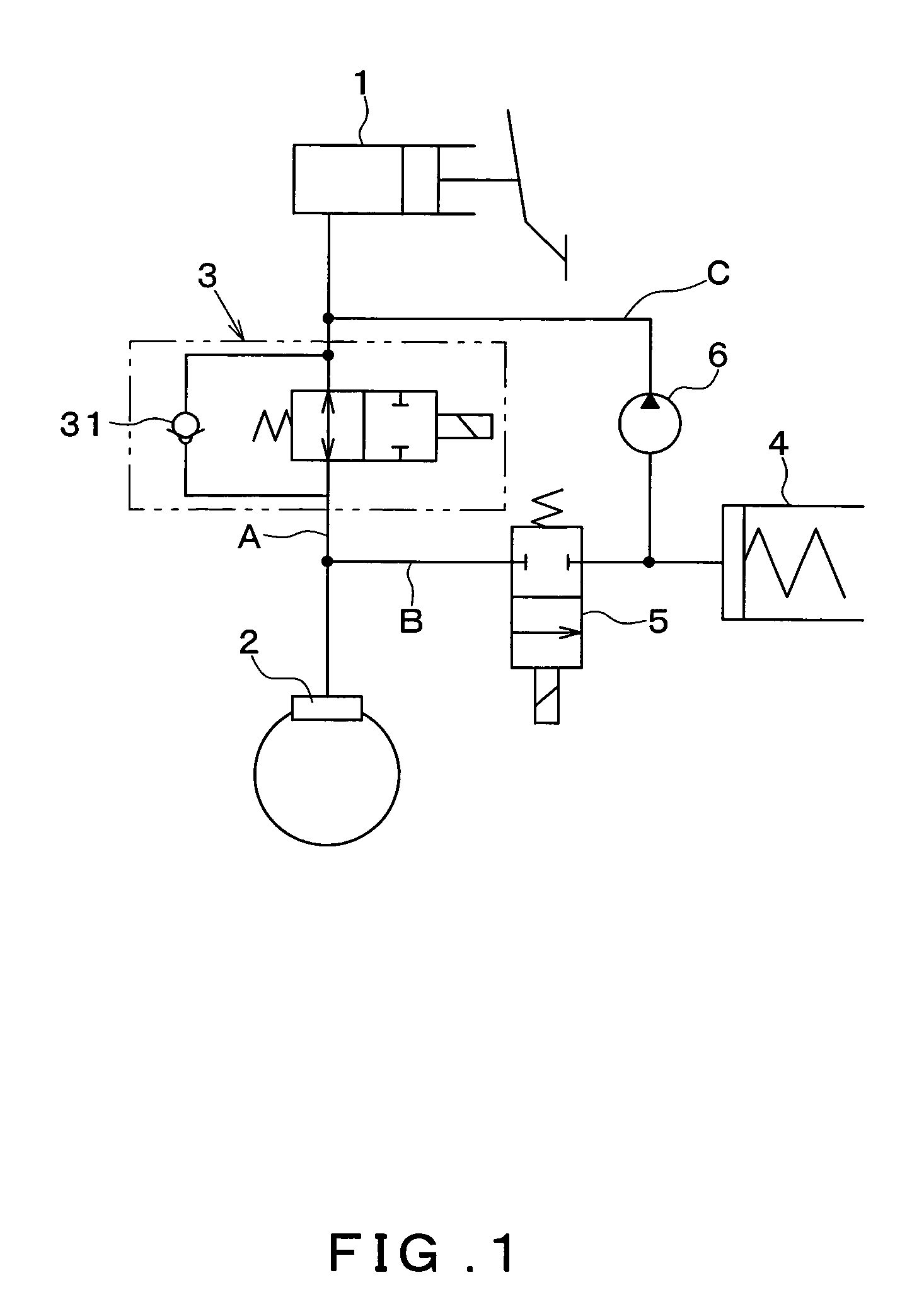

Fluid control apparatus

InactiveUS7048252B2Low costSmall sizeOperating means/releasing devices for valvesApplication and release valvesFluid controlEngineering

An elastic member made of rubber which urges a coil portion toward a cover is formed into a shape such that the elastic member can be deformed by bending. A rate of change in reaction force of the elastic member with respect to an amount of deformation in a bending deformation region is less than a case where the elastic member is subject to compressive deformation. Therefore, even in the case where the amount of deformation of the elastic member increases due to dimensional variation of a component part, the reaction force of the elastic member does not become excessively large.

Owner:ADVICS CO LTD

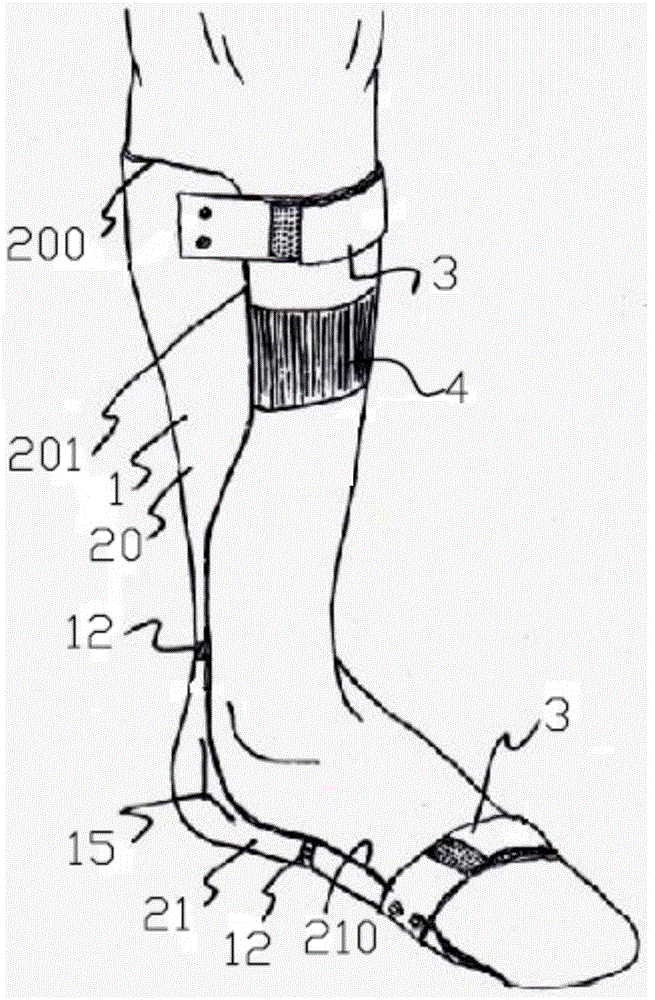

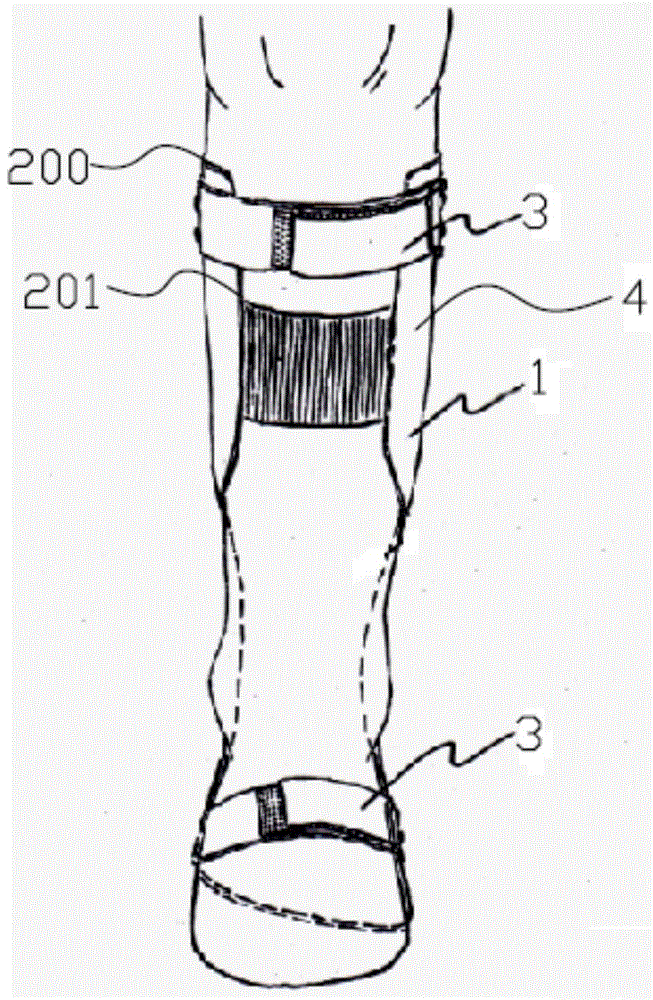

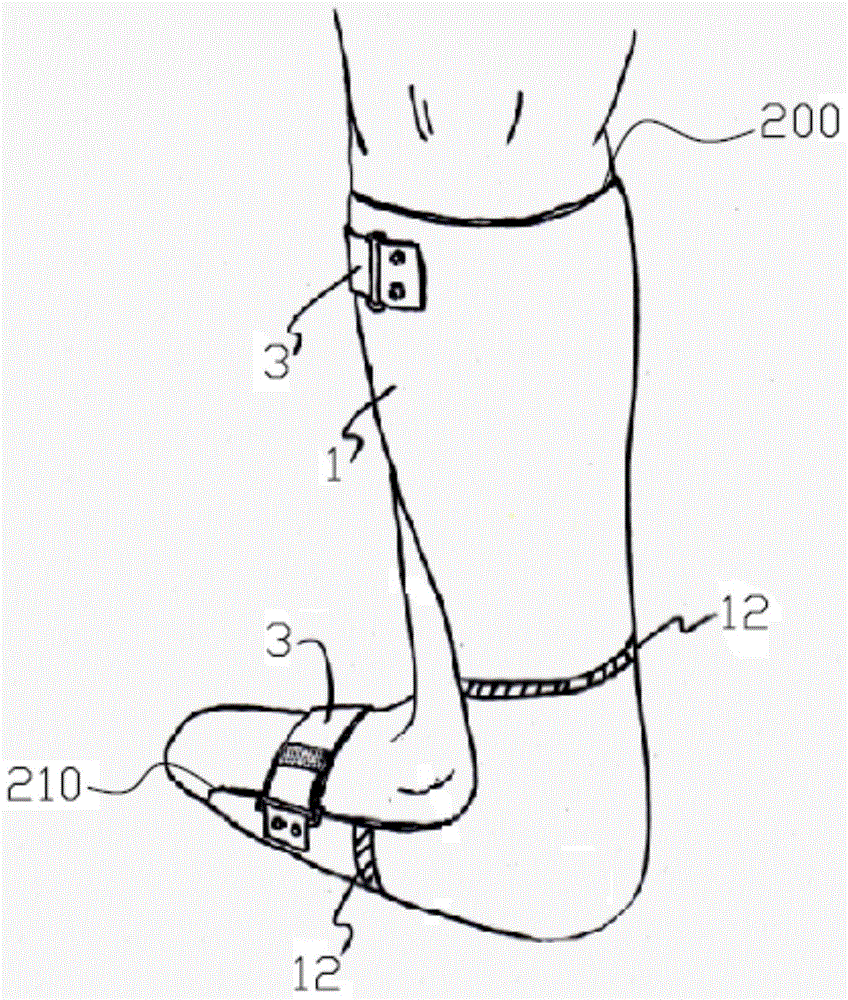

Orthotics and orthopedic system

The invention relates to an orthotics. The orthotics comprises a foot support in the shape matched with the shape of the portion, needing orthopedic treatment, of a patient. The foot support comprises a function layer and a resistance layer. The function layer is made of shape memory polymer, can be softened and deforms under the preset high temperature, is hardened again under the preset low temperature with the fixed shape, and then recovers the original shape at the preset high temperature. The resistance layer is used for generating heat under the current effect so as to change the temperature of the function layer. The invention further relates to an orthopedic system. The orthopedic system comprises the orthotics and a computer system connected with the orthotics. The computer system adjusts the temperature of the orthotics by adjusting the voltage applied on the resistance layer. The orthotics has the advantages that the requirements of a patient are met by adjusting the shape of the orthotics safely and conveniently, and the service life of the orthotics is prolonged.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

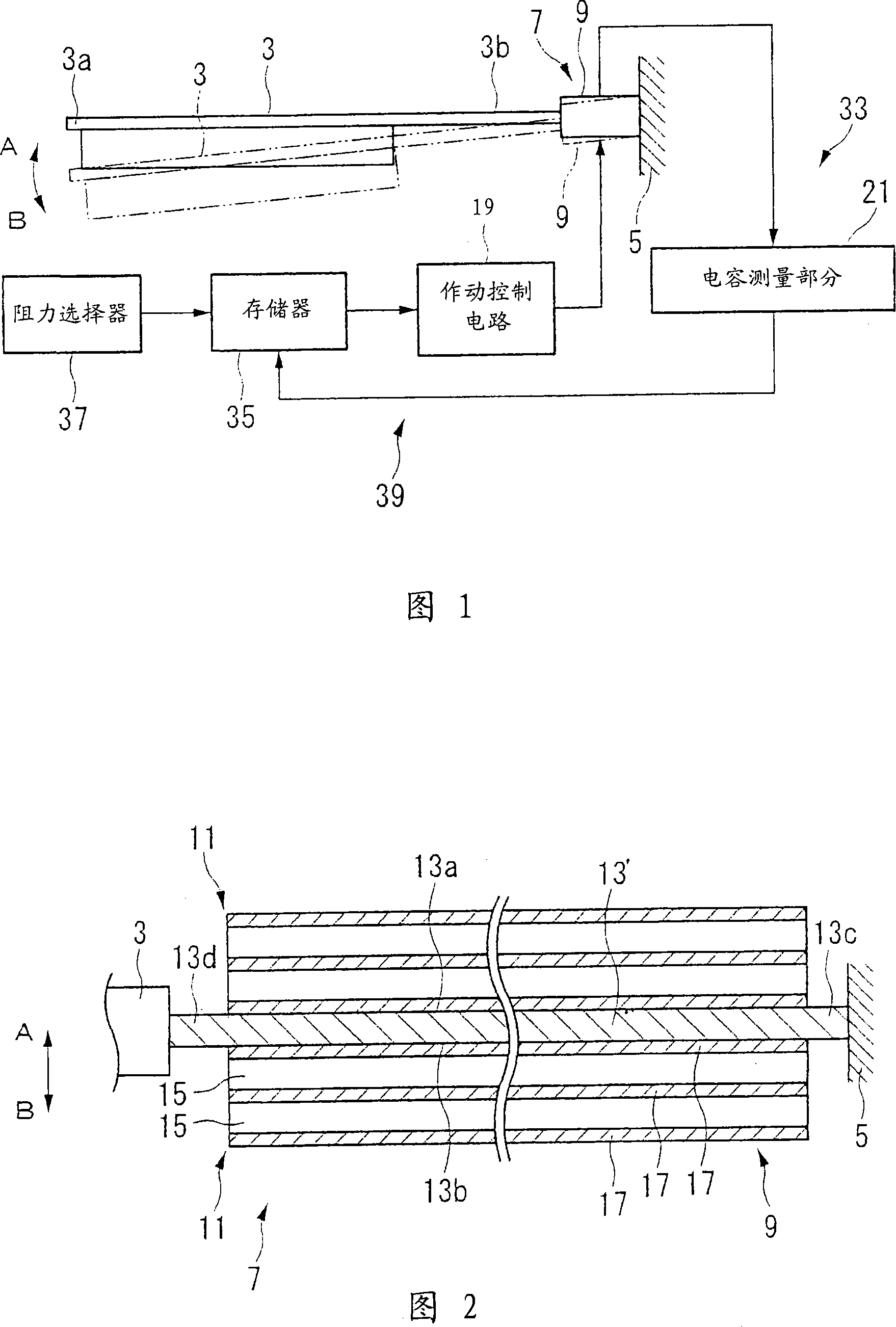

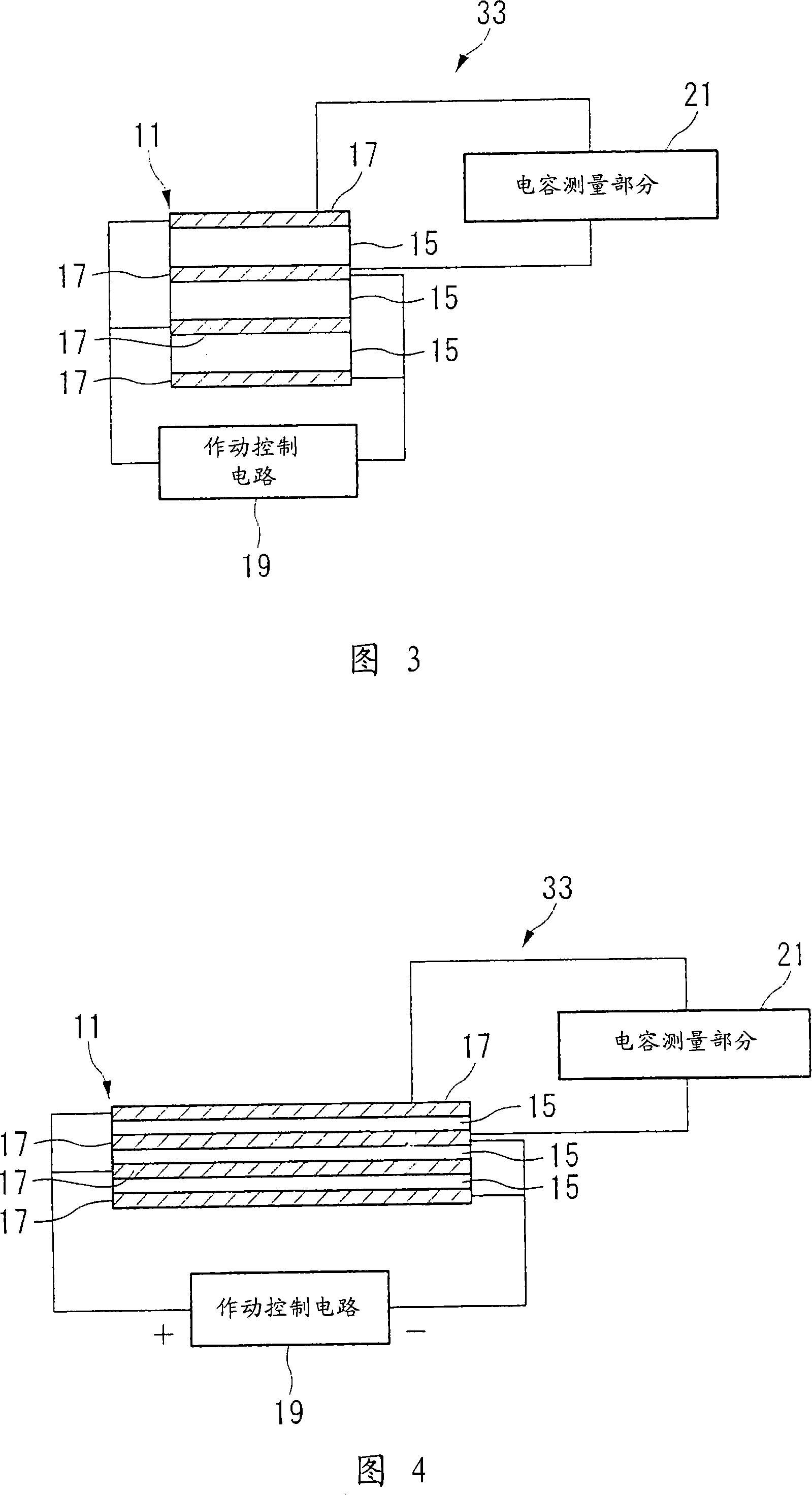

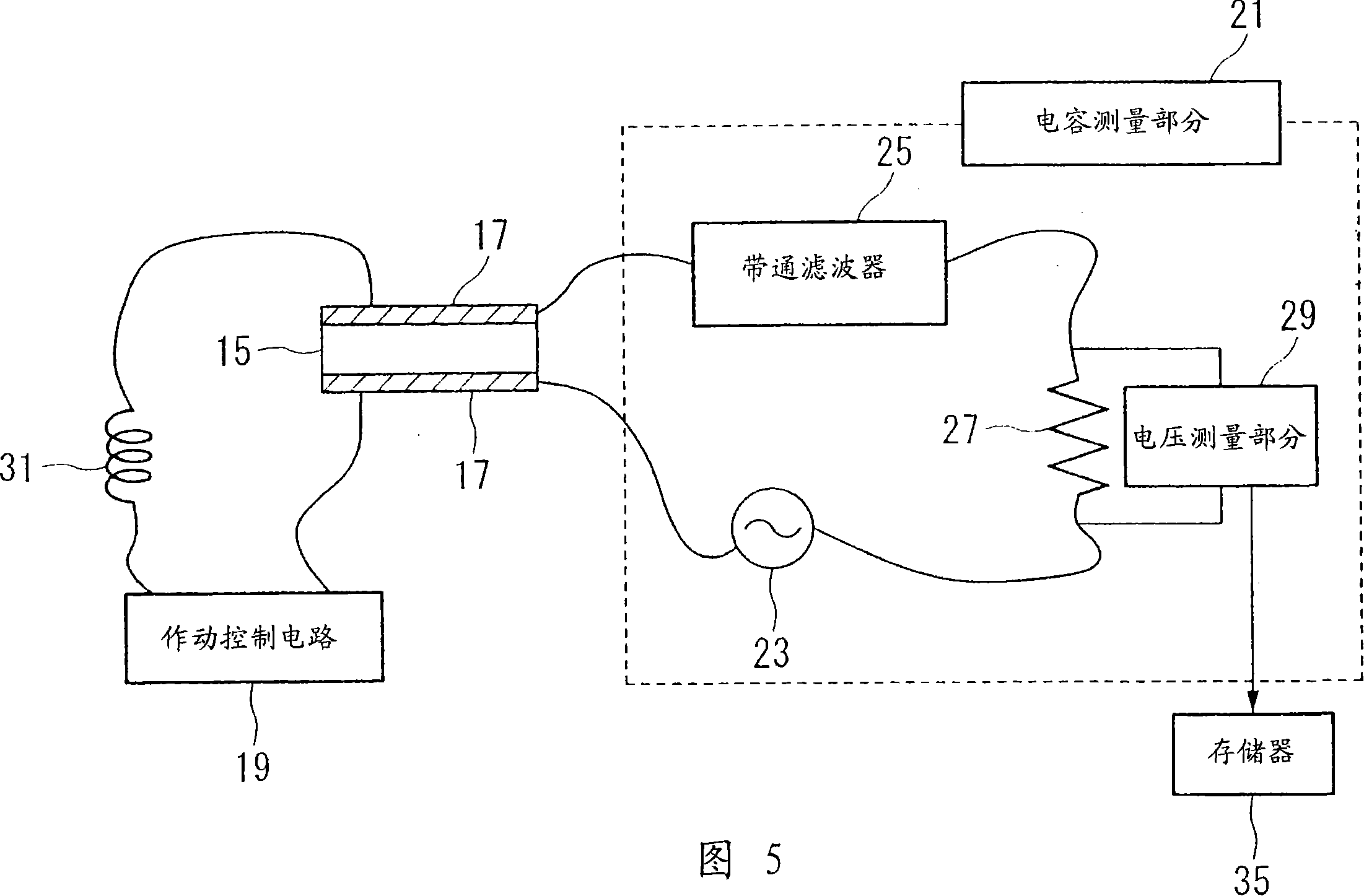

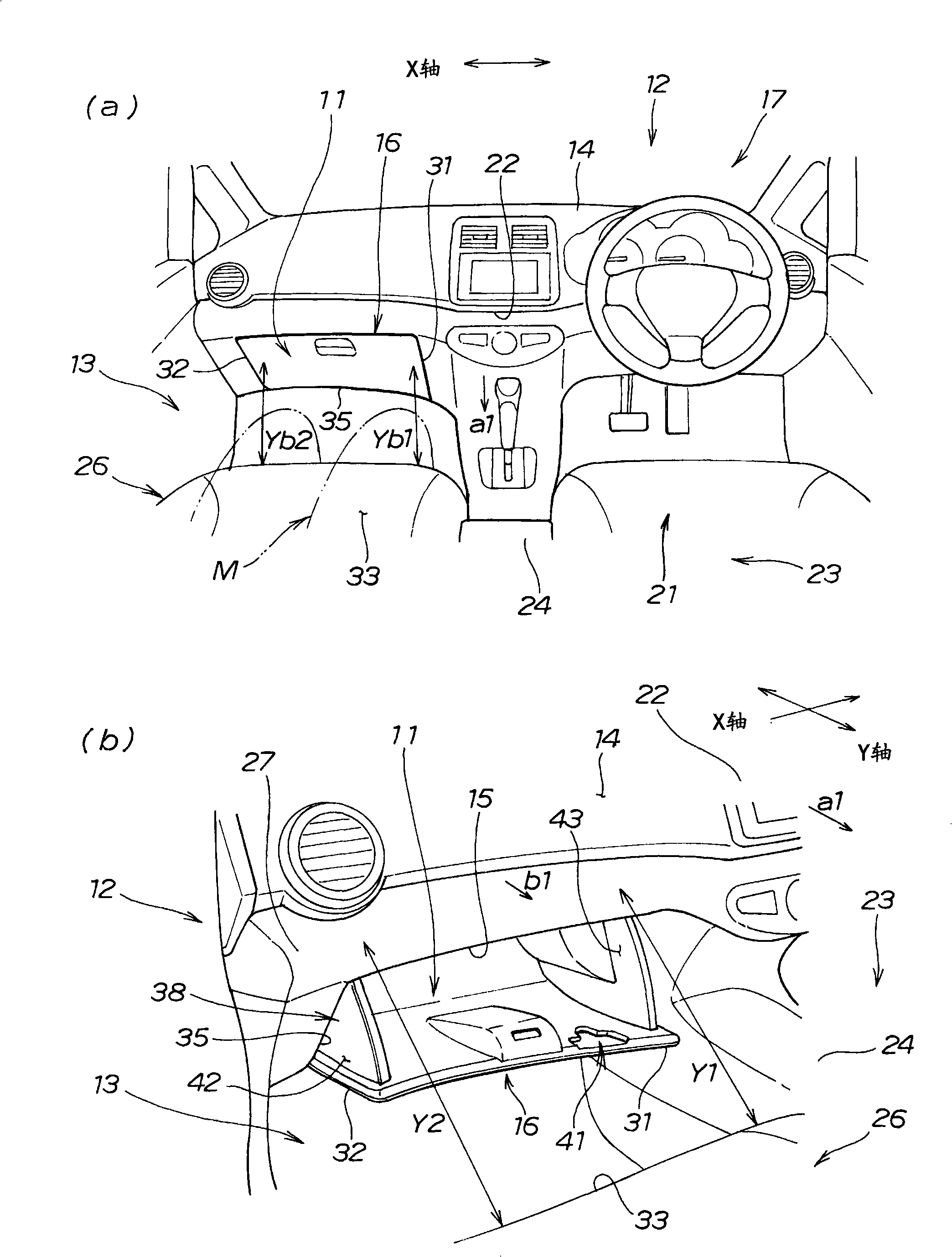

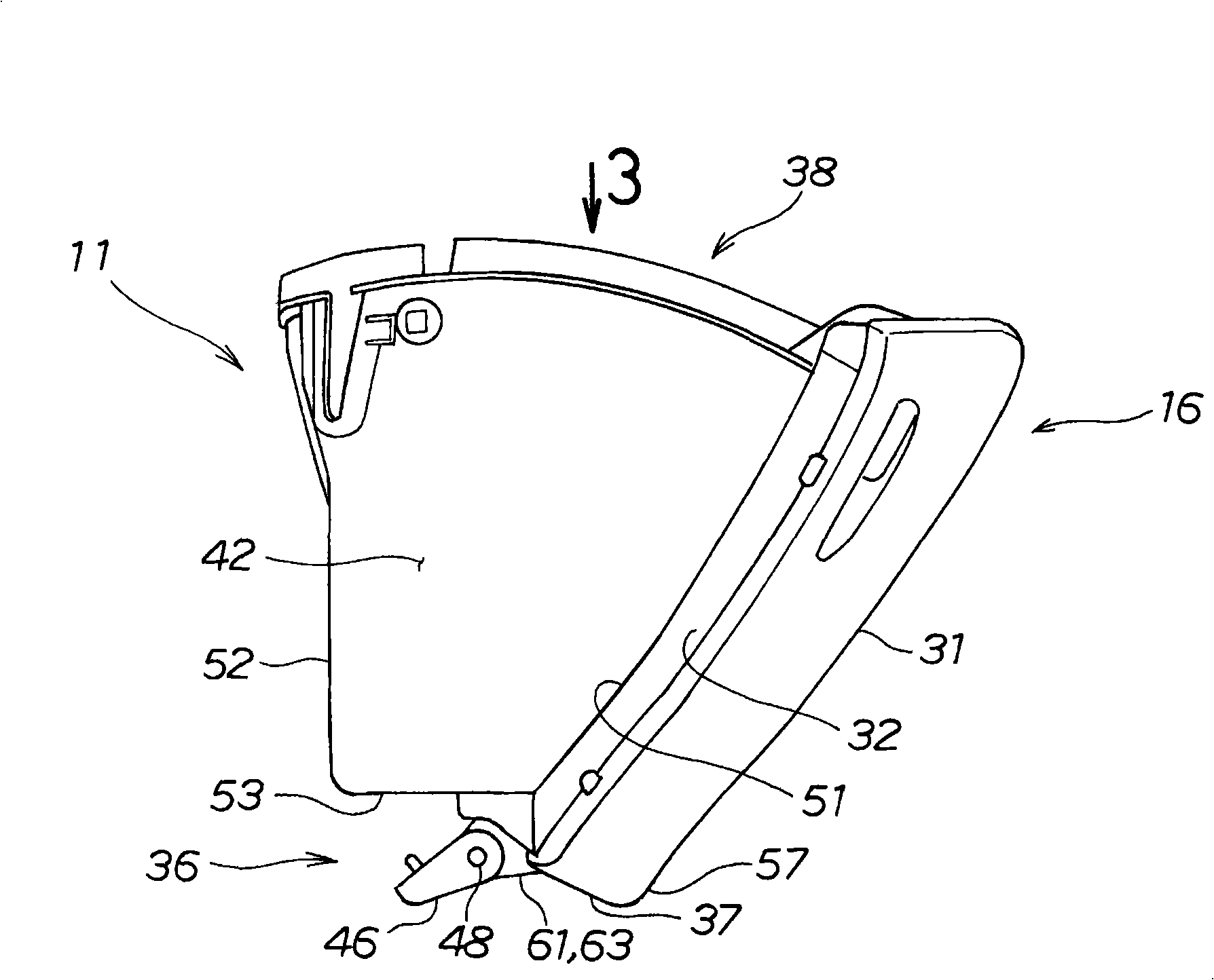

Key actuating apparatus and key actuation control system

InactiveCN101140755ASimple structureLow costElectrophonic musical instrumentsStringed musical instrumentsControl systemTransducer

In order to realize a small and light key actuating apparatus for actuating a key which is rotatably supported with respect to a frame, a key actuating apparatus (7) is provided which includes a polymer transducer (9) for rotatably moving the key (3) by using a deformation of the transducer, wherein the transducer which is substantially formed in a plate shape includes: a polymer film (15) which is dielectric and made from an elastically deformable polymer material; and a pair of electrodes (17) arranged at both sides of surfaces of the polymer film, and the transducer is deformed corresponding to switching between an application of voltage and a lack of voltage between the electrodes.

Owner:YAMAHA CORP

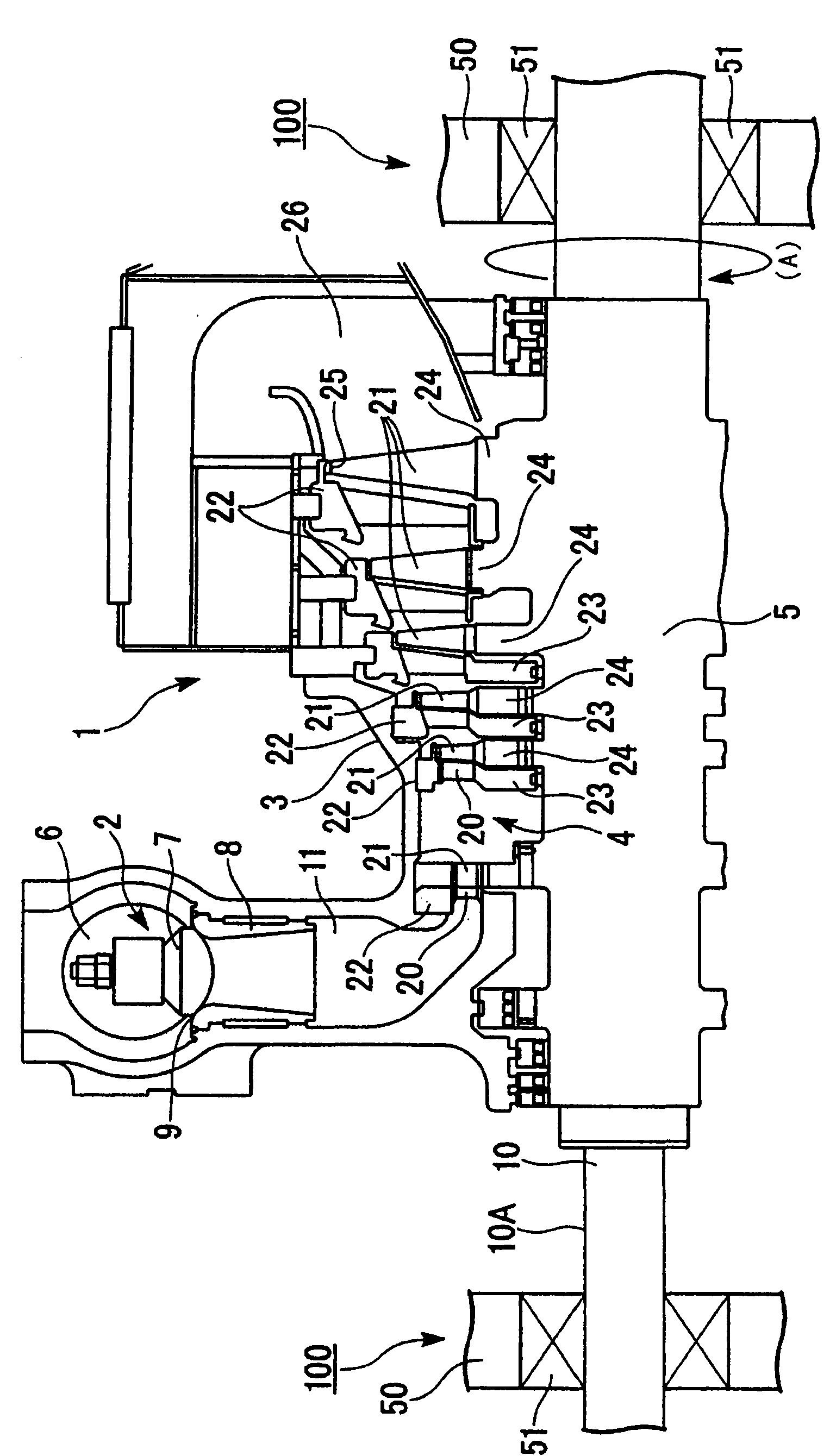

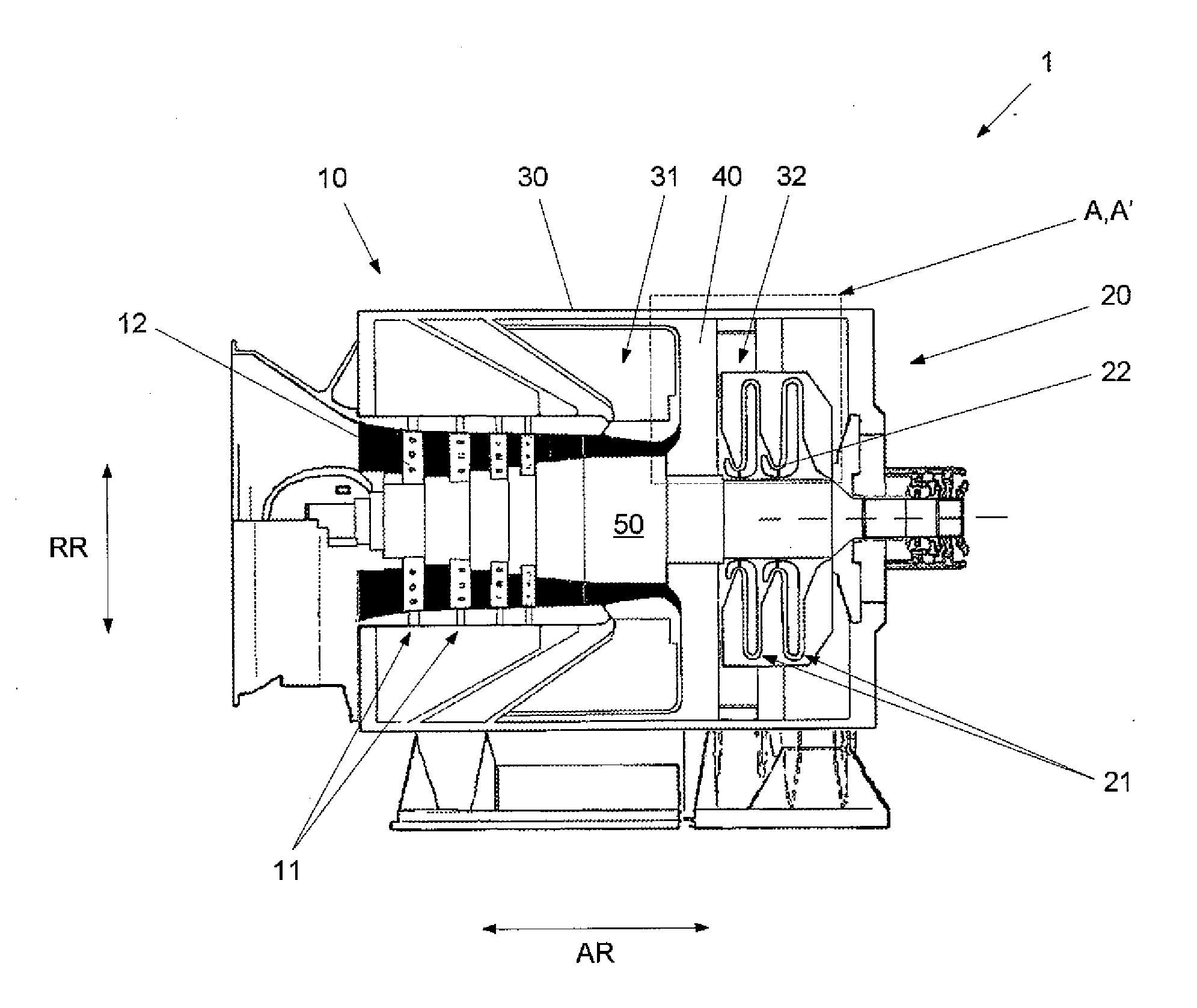

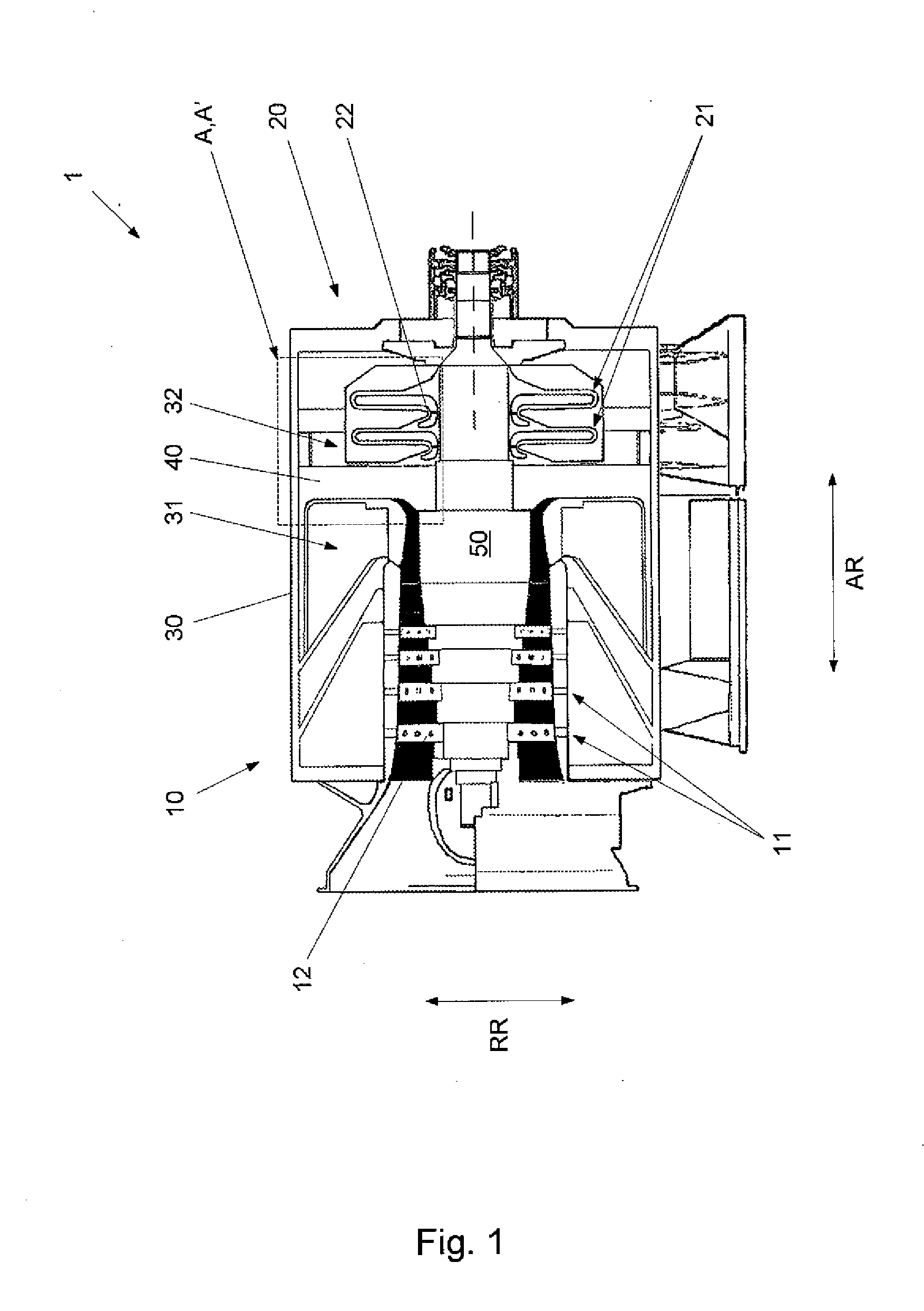

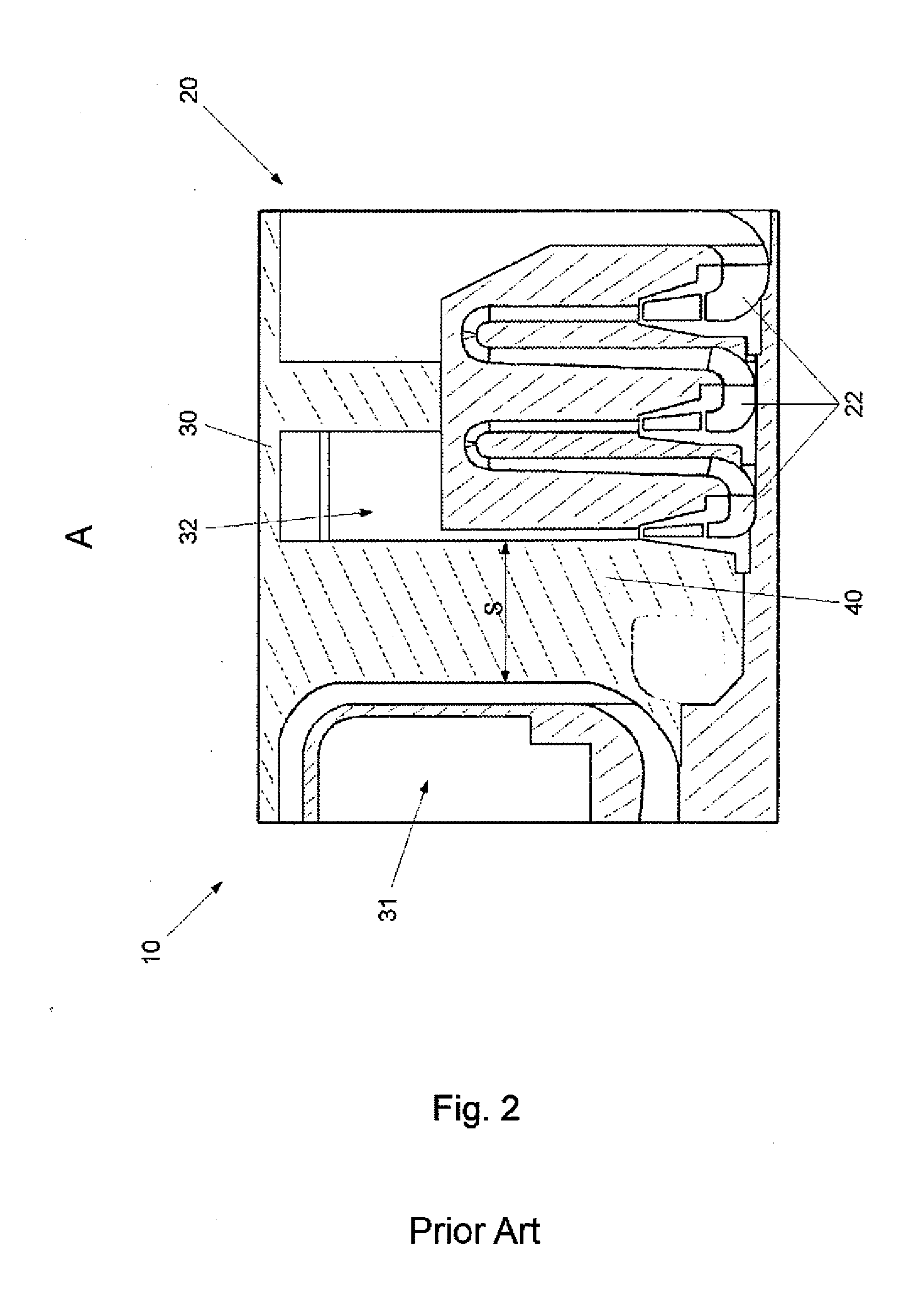

Axial-radial turbomachine

InactiveUS20130028724A1Small wall thicknessReliable deformationPump componentsStatorsInterior spaceImpeller

Axial-radial flow machine having an axial portion with at least one axial stage, a radial portion with at least one radial stage, a housing having an interior space with a dividing wall extending in a radial direction dividing the housing in an axial direction into a first partial space in which the axial portion is received and a second partial space in which the radial portion is received, and a shaft that extends in axial direction through the interior space and through the dividing wall and on which impellers of the axial portion and of the radial portion are received. A radial gap is formed between the dividing wall and a fluid guiding element of the radial portion. The fluid guiding element is axially fixed to the housing so as to be adjacent to the dividing wall. A plurality of fixing units which are distributed in circumferential direction are arranged in the radial gap, each of which fixing units axially fixes the dividing wall to the fluid guiding element.

Owner:MAN ENERGY SOLUTIONS SA

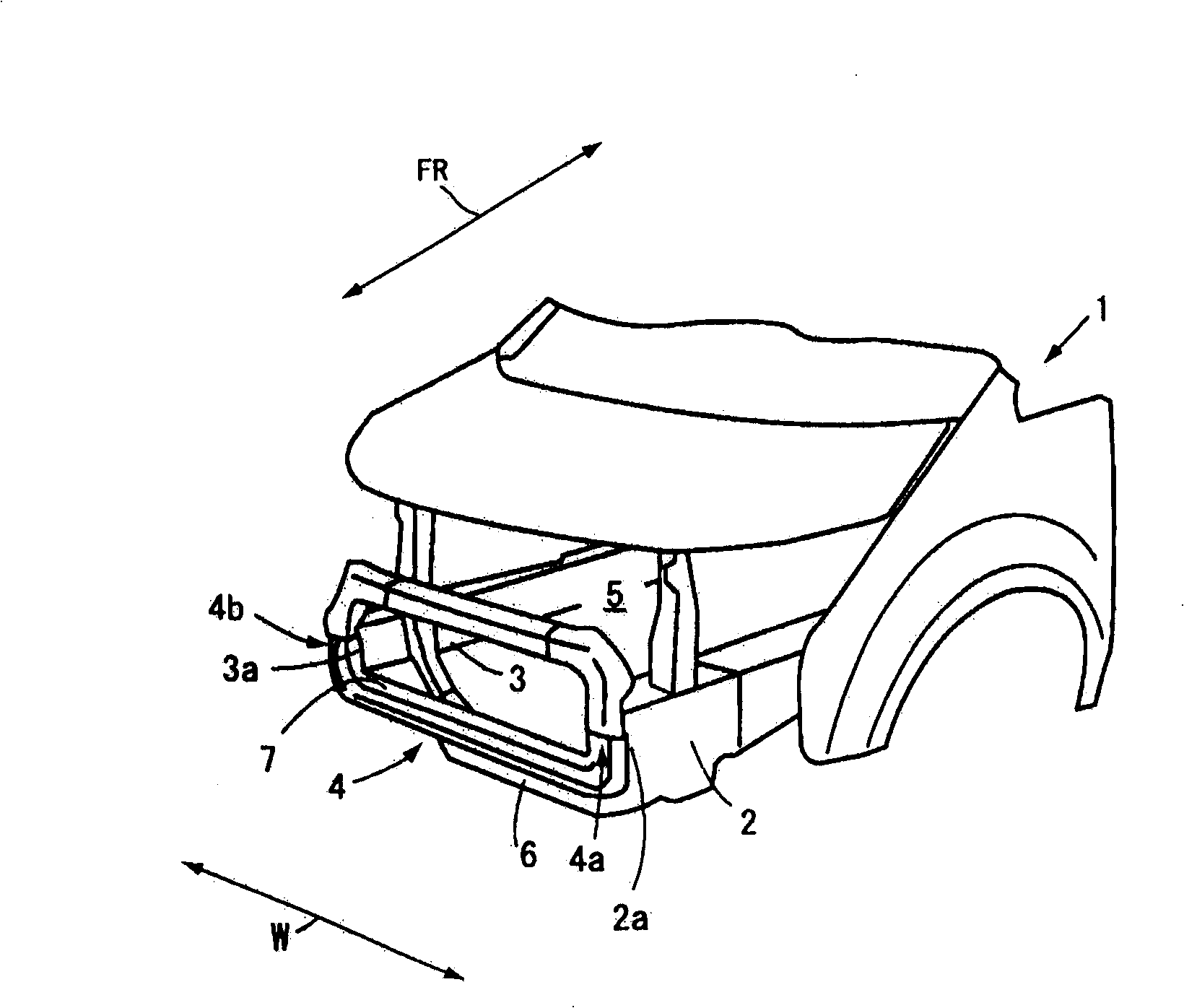

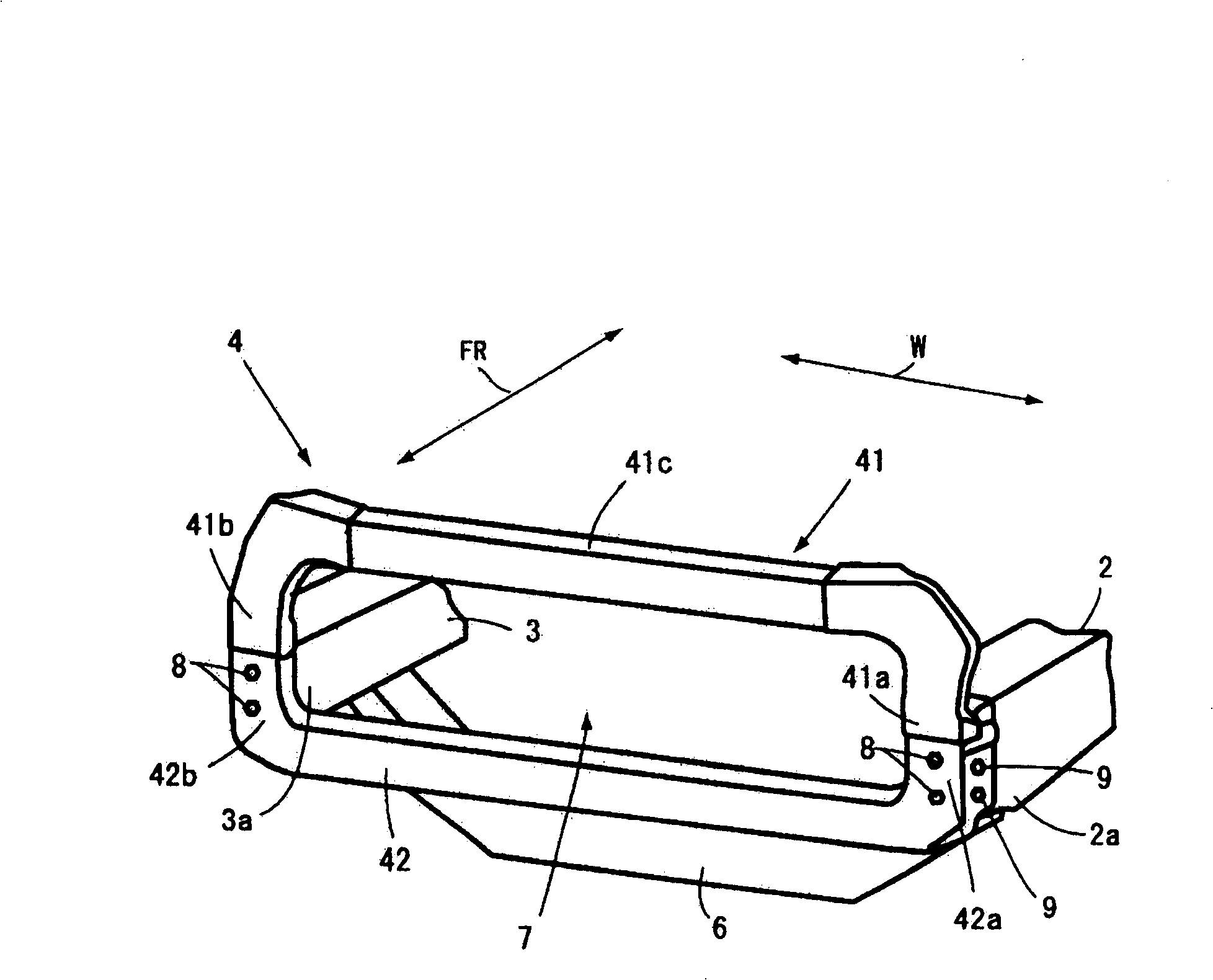

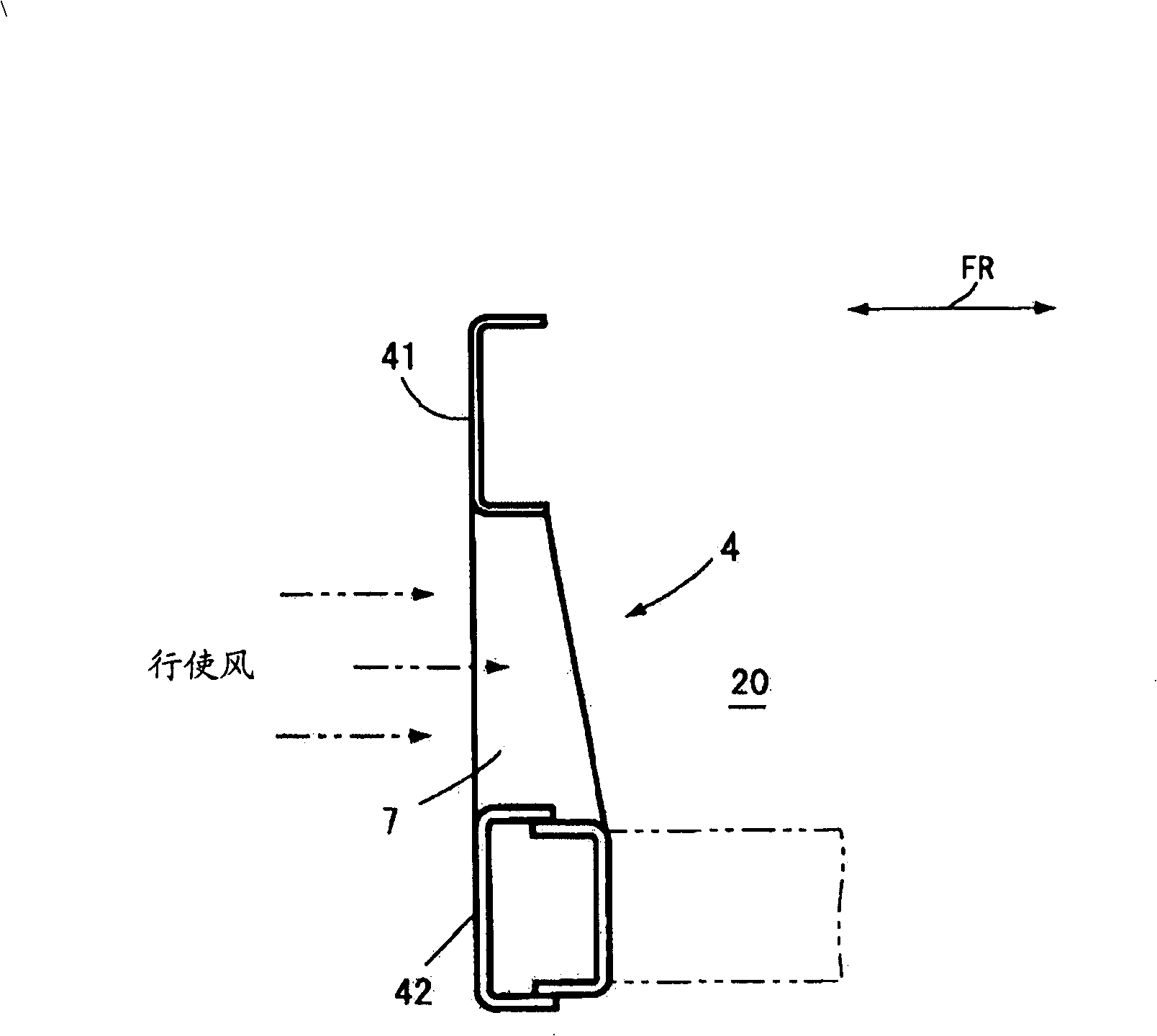

Vehicle body structure

InactiveCN101254768AGuaranteed Cooling PerformanceNot easily deformedSuperstructure subunitsBumpersEngineeringPedestrian

The invention provides a vehicle body structure effective for protection of a pedestrian and absorption of the collision load while ensuring the cooling performance. The vehicle body structure comprises a lower member (42) connected to fore ends (2a, 3a) of a pair of front side members (2, 3) extending in the back and forth direction FR of a vehicle body and arranged in the vehicle width direction W, and a bumper beam (4) located above the lower member (42) and forming an opening part (7) by an upper member (41) connected to the fore ends (2a, 3a). The strength of the upper member 41 is set to be lower than that of the lower member (42).

Owner:MITSUBISHI MOTORS CORP

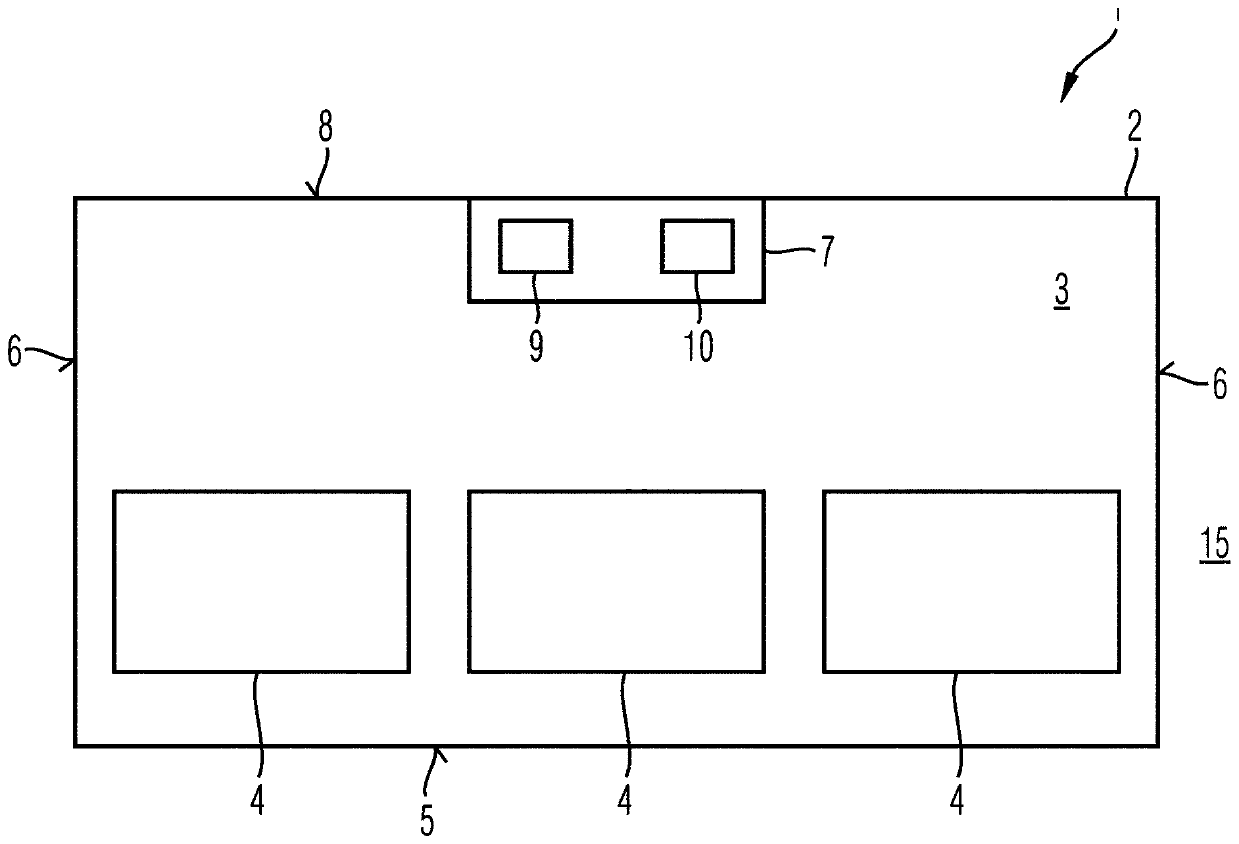

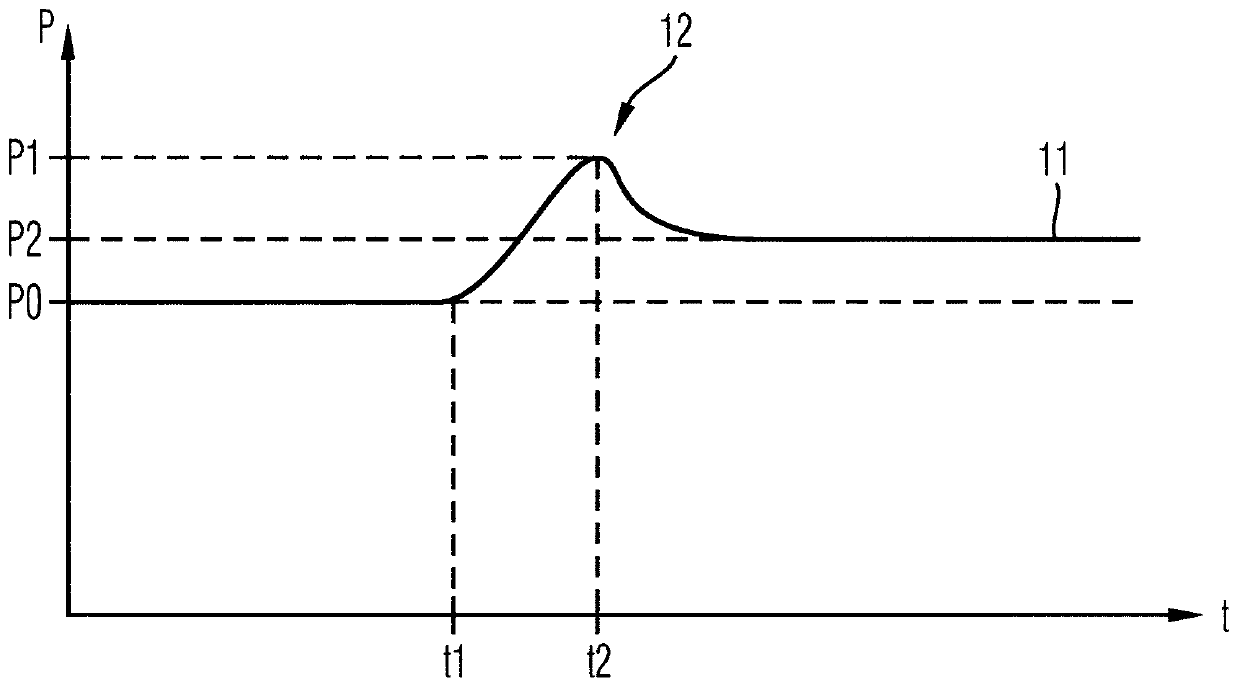

High-voltage battery for motor vehicle having detection device for detecting damage to the high-voltage battery, method for detecting damage to the high-voltage battery, and motor vehicle

ActiveCN111602263ANot airtightReliable deformationRegistering/indicating working of vehiclesCell/batteries leak testingInterior spaceElectrical battery

The invention relates to a high-voltage battery (1) for a motor vehicle, comprising a battery housing (2) for receiving a plurality of battery modules (4) in an interior space (3) of the battery housing (2), and a detection device (7) for detecting damage to the battery housing (2). The detection device (7) comprises at least one pressure sensor (9) arranged in the interior space (3) of the battery housing (2), which is configured to detect a pressure signal (11, 13) in the interior space (3) of the battery housing (2), and an evaluation unit (10), which is configured to identify the damage tothe battery housing (2) on the basis of the pressure signal (11, 13) detected by the pressure sensor (9). The invention further relates to a method and to a motor vehicle.

Owner:BAYERISCHE MOTOREN WERKE AG

Front structure for vehicle

ActiveCN101541622AIncrease the number ofWeight increaseUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

Owner:ISUZU MOTORS LTD

Structure for front part of vehicle

InactiveCN105358411AAvoid direct intrusionAvoid direct exposurePedestrian/occupant safety arrangementSuperstructure subunitsEngineeringMechanical engineering

Owner:SUZUKI MOTOR CORP

System for measuring a bending deformation of a surface of a material

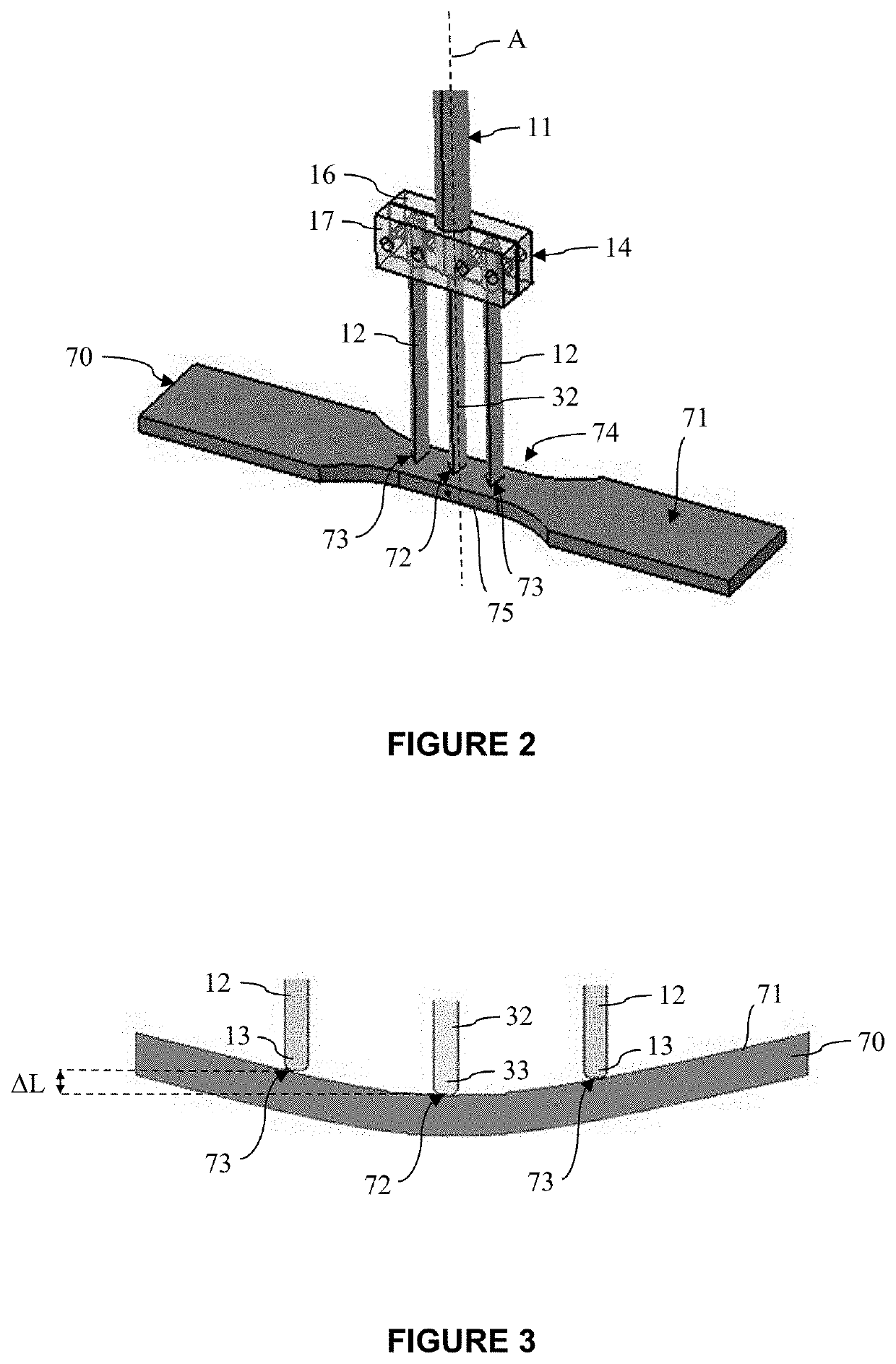

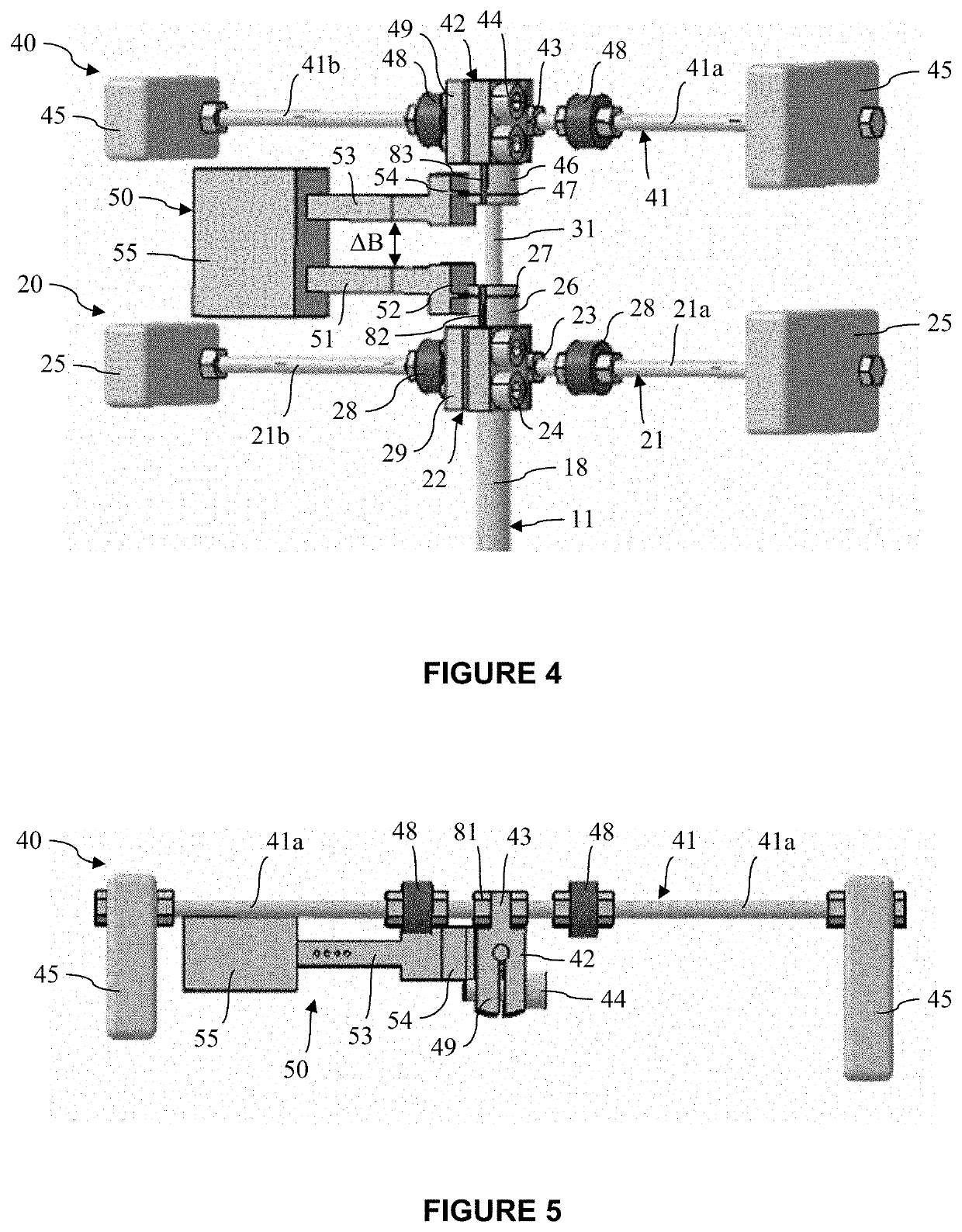

ActiveUS20200271433A1Reliable and repeatable deformation measurementWithout riskMechanical counters/curvatures measurementsMechanical clearance measurementsConstant forceClassical mechanics

A system for measuring a bending deformation of a surface of a material which cooperates with a bending test machine to deform a test piece. The system includes a first portion with lateral teeth which bear against an upper surface of the test piece. A first load support connected to the lateral teeth applies a constant force towards the test piece. A second portion with a central tooth bears against the upper surface. A second load support connected to the central tooth applies a constant force oriented towards the test piece. A measuring device includes a deformation sensor having a first arm connected to the first portion, and a second arm connected to the second portion. The first arm and the second arm are separated from each other by a variable distance (AB) measured by the measuring device.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Storage device for vehicle

ActiveCN101402335AReliable deformationEffective absorptionPassenger spacePedestrian/occupant safety arrangementEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

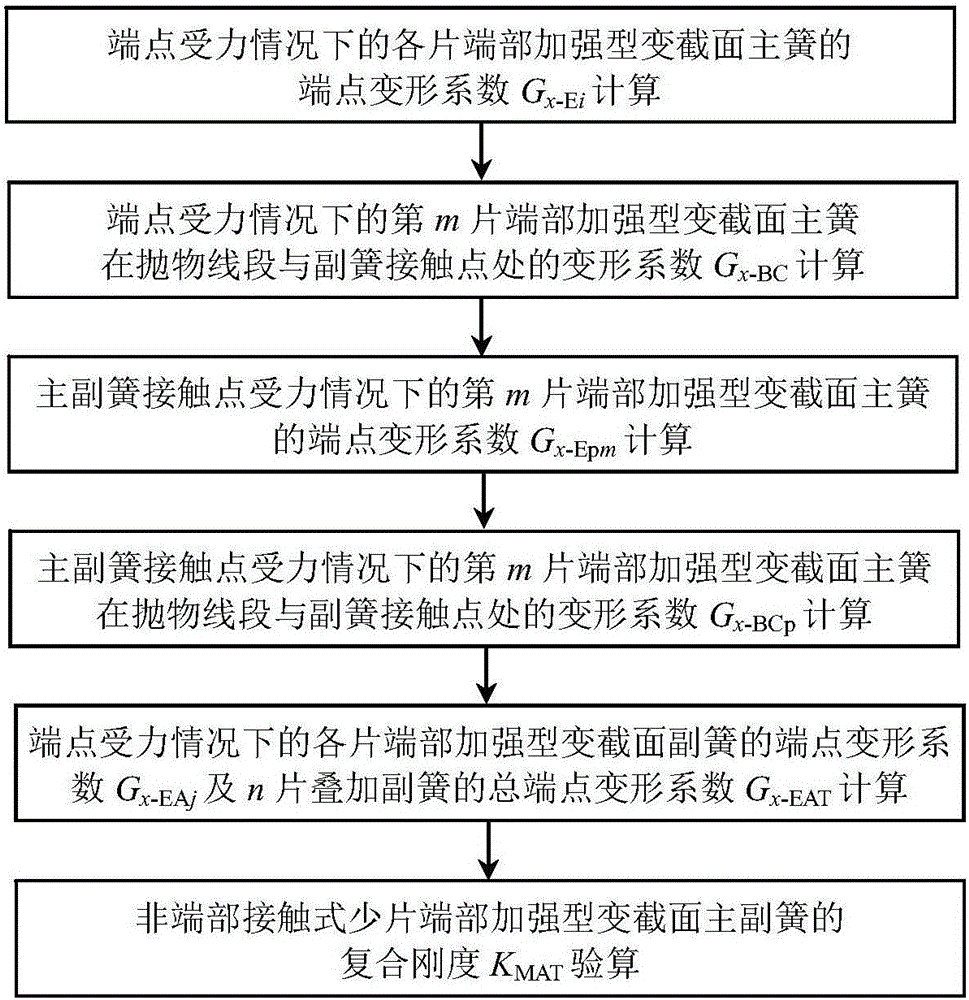

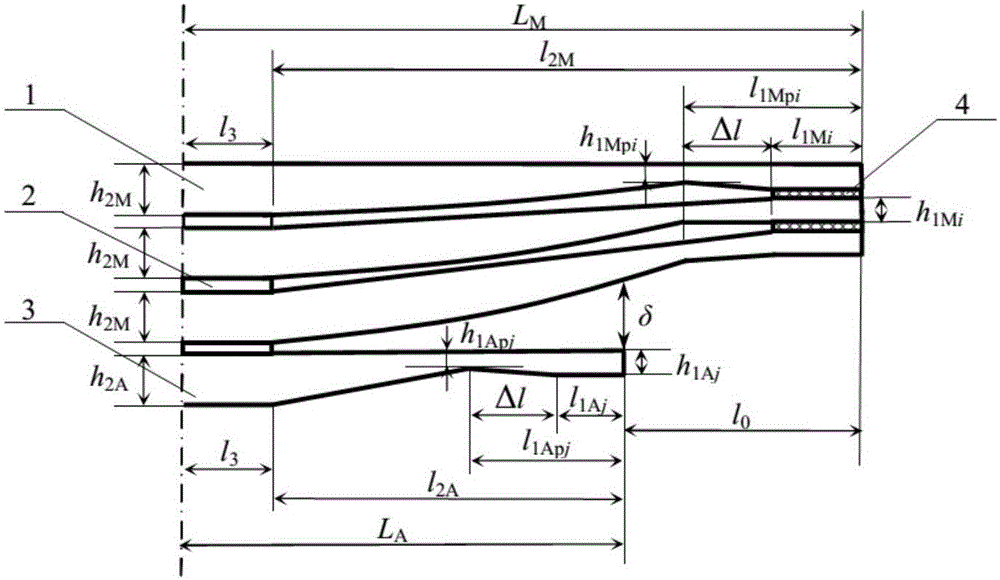

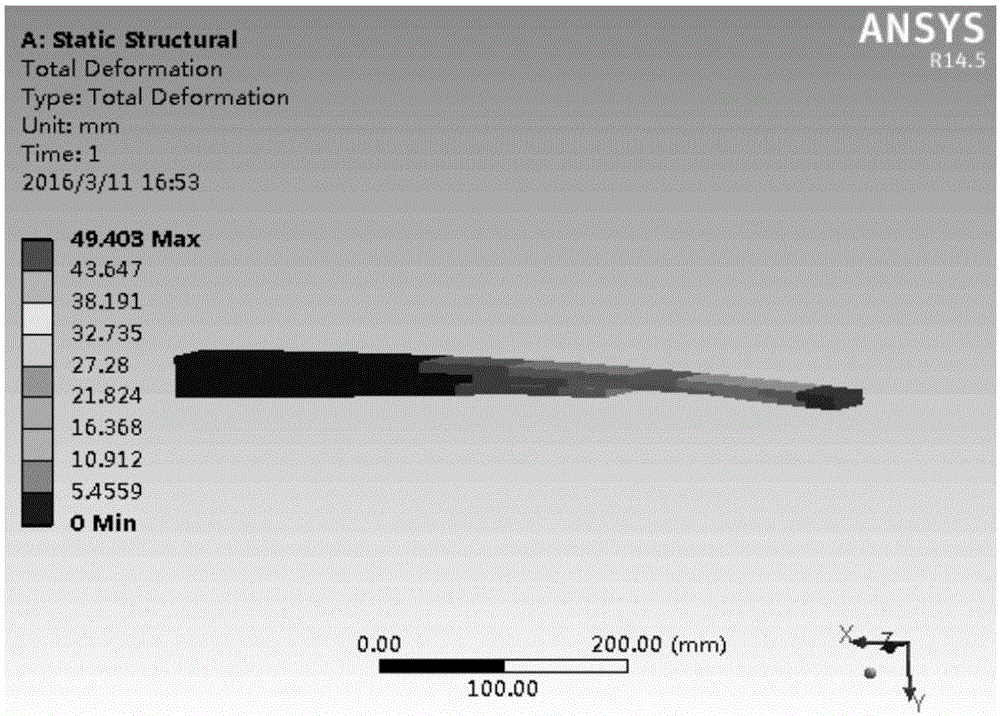

Method for checking composite stiffness of non-end contact type taper leaf root enhanced main and auxiliary leaf springs

InactiveCN105956308AReliable Composite Stiffness Check ValueExact Composite Stiffness Check ValueGeometric CADMachine part testingComputer Aided DesignContact type

The invention provides a method for checking the composite stiffness of non-end contact type taper leaf root enhanced main and auxiliary leaf springs, and belongs to the technical field of suspension leaf springs. The composite stiffness of the main and auxiliary leaf springs can be checked according to the structural parameter and elastic modulus of each main leaf spring and auxiliary leaf spring of the non-end contact type taper leaf root enhanced variable cross-section main and auxiliary leaf springs. An example and ANSYS simulation verification show that, the method can obtain an accurate and reliable composite stiffness checking value of the non-end contact type taper leaf root enhanced main and auxiliary leaf springs, provide a reliable checking method for checking the composite stiffness of the non-end contact type taper leaf root enhanced variable cross-section main and auxiliary leaf springs, and lay a technical foundation for the analytical design and CAD (Computer Aided Design) software development of the main and auxiliary leaf springs of this structure. By using the method for checking the composite stiffness of the non-end contact type taper leaf root enhanced main and auxiliary leaf springs provided by the invention, the design level, the product quality and performance and the vehicle ride comfort of a vehicle suspension variable cross-section main and auxiliary leaf springs can be improved; and meanwhile, the weight and cost of the suspension springs can be reduced, the product design and testing expenses can be reduced, and the product development speed can be accelerated.

Owner:SHANDONG UNIV OF TECH

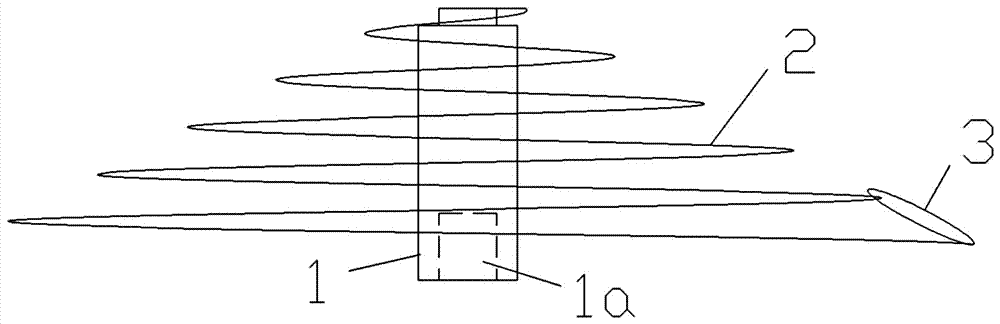

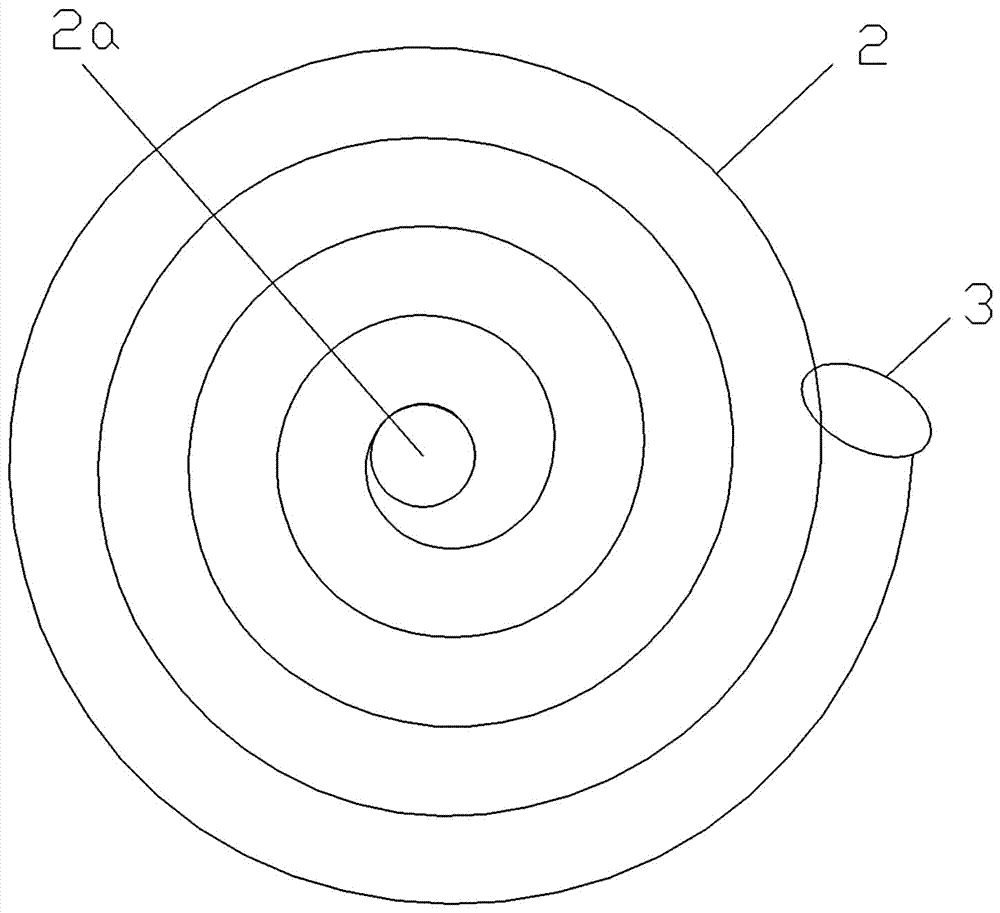

A spiral net tensioner

ActiveCN106123693BPlay a supporting roleReliable deformationCamouflage devicesProtective buildings/sheltersEngineeringMechanical engineering

Owner:SHANGHAI JUTONG IND

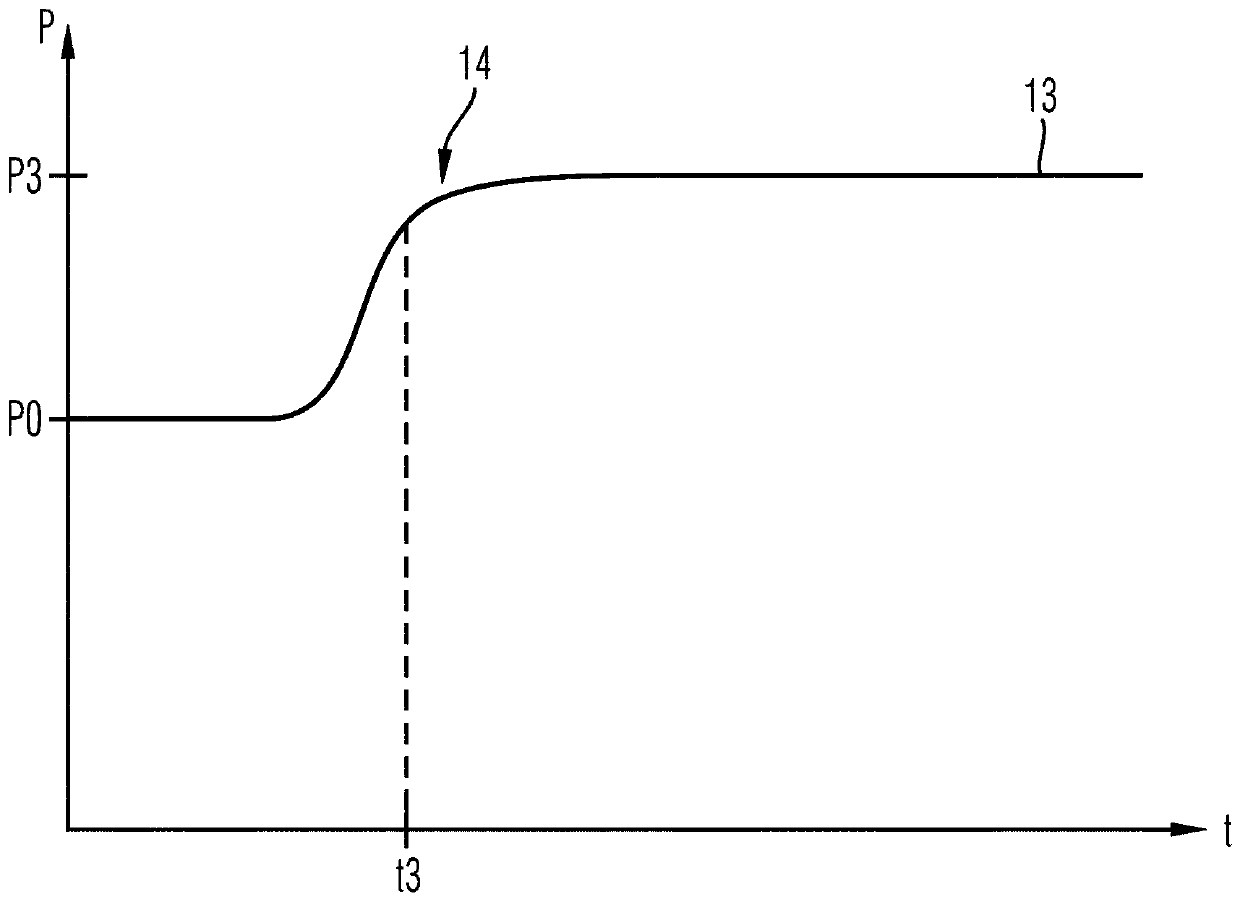

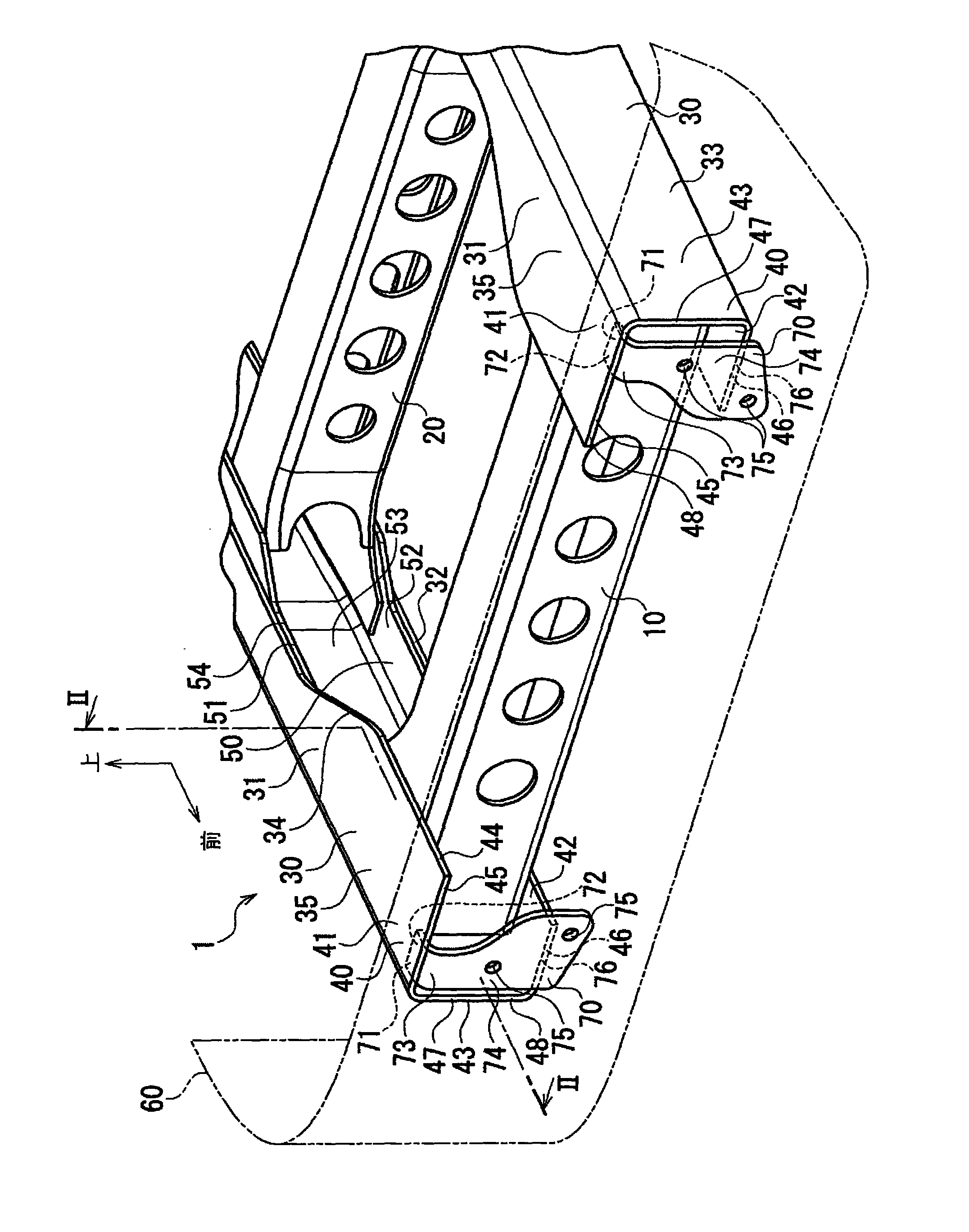

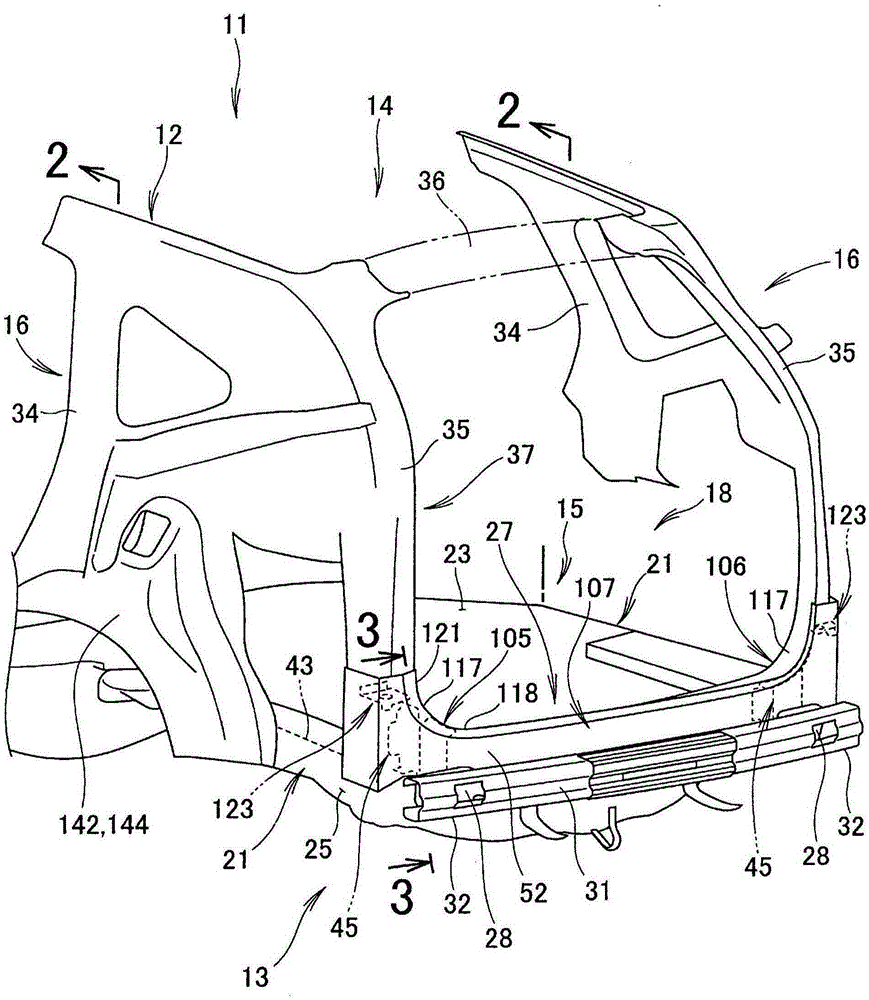

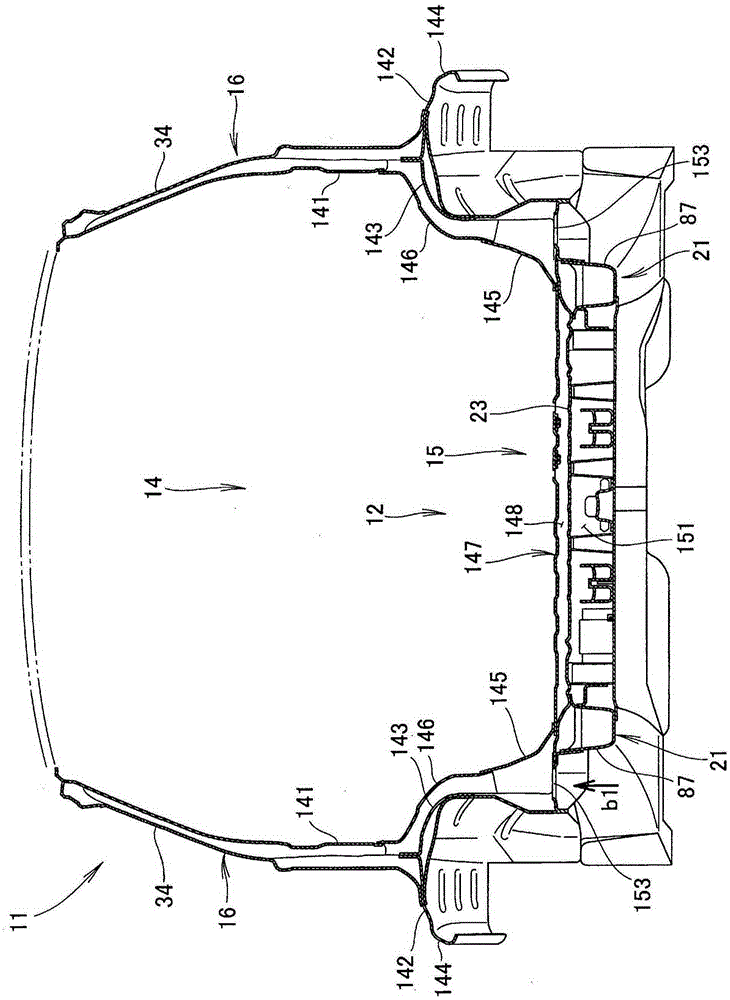

rear body structure

ActiveCN103717482BImprove rigidityHigh strengthSuperstructure subunitsEngineeringMechanical engineering

The rear structure of the vehicle body includes: left and right rear side frames (21) extending in the front-rear direction of the vehicle body (12); and a rear panel assembly (27) formed with The closed cross section (41) extending in the vehicle width direction is provided at the rear end (25) of the rear side frame (21) and constitutes the lower part of the rear opening (37) of the vehicle body. The rear panel assembly (27) is equipped with a partition (45), and the partition (45) is arranged in the upper surface (43) of the rear side frame (21) and the closed section (41), and faces the vehicle width direction to partition the closed section. Inside the section (41).

Owner:HONDA MOTOR CO LTD

Measuring and checking method based on segmental box girder stub matching prefabricated pedestal foundation

ActiveCN111809523AReduce adverse effectsReliable deformationBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a measuring and checking method based on a segmental box girder stub matching prefabricated pedestal foundation. The method comprises the steps of 1, burying measuring points in a prefabricated pedestal, 2, setting an electronic level, 3, carrying out a first loading test, and carrying out an overall uniform loading test on each region on each prefabricated pedestal to eliminate non-elastic deformation, 4, carrying out a second loading test, carrying out full loading on the region I and the region II, respectively loading the region III according to the two conditions of the total weight of the template and the full loading weight after pouring, and simulating the load condition of a prefabricated construction process to measure the settlement amount before and after pouring of the to-be-poured beam, and 5, calculating the maximum differential settlement difference of the prefabricated pedestal through data analysis, and judging whether the maximum differentialsettlement difference meets the construction requirement or not. According to the method, the maximum differential settlement difference is difficult to detect and check, the reliability is insufficient, and the interference of non-elasticity on a measurement result can be avoided.

Owner:CCCC SHEC FOURTH ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com