rear body structure

A rear and car body technology, applied in the field of car body rear structure, can solve problems such as increased cost and rear beam deformation, and achieve the effect of increasing strength, rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

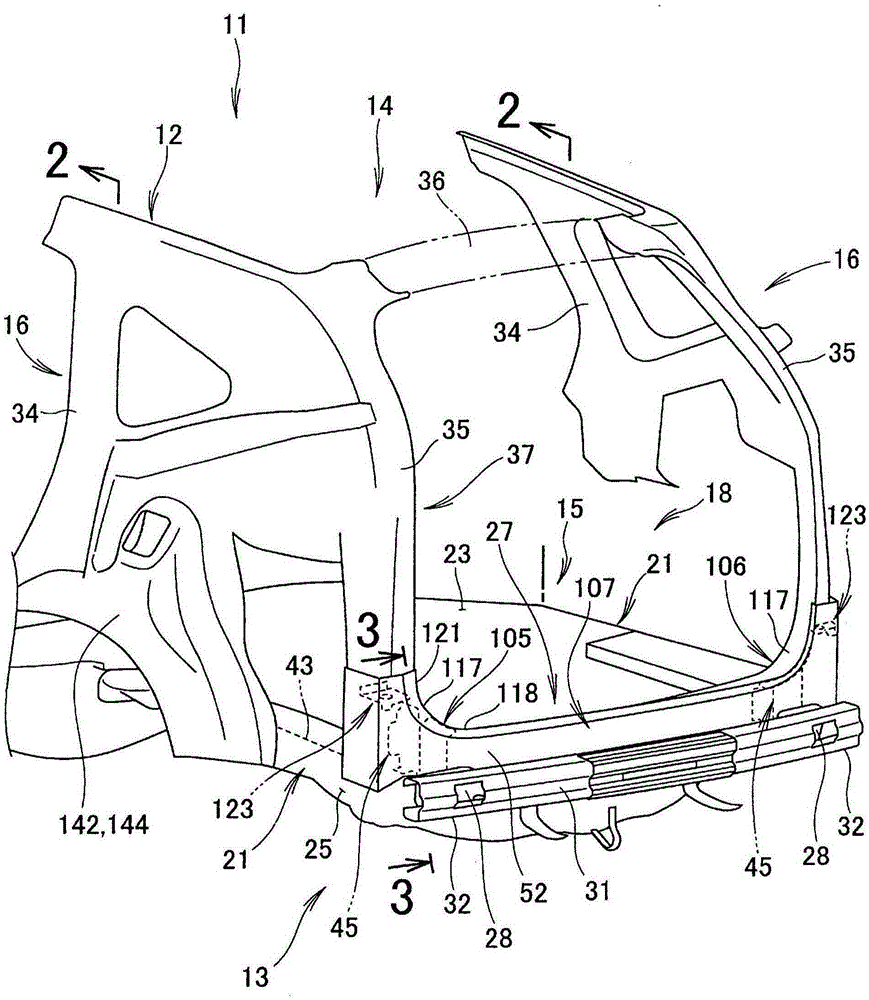

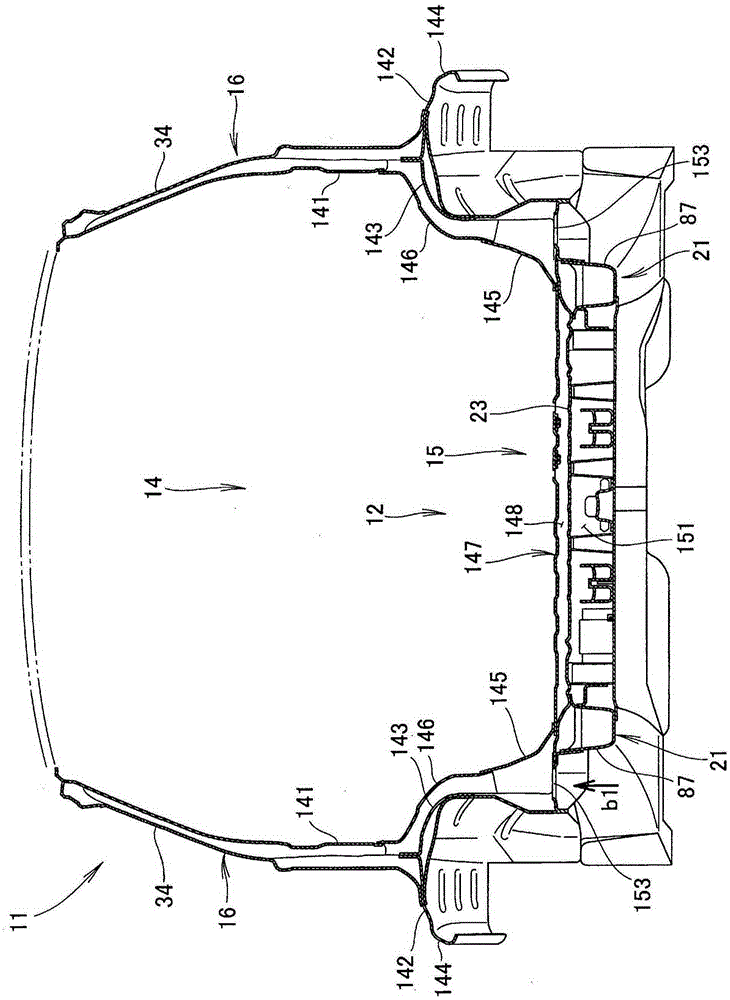

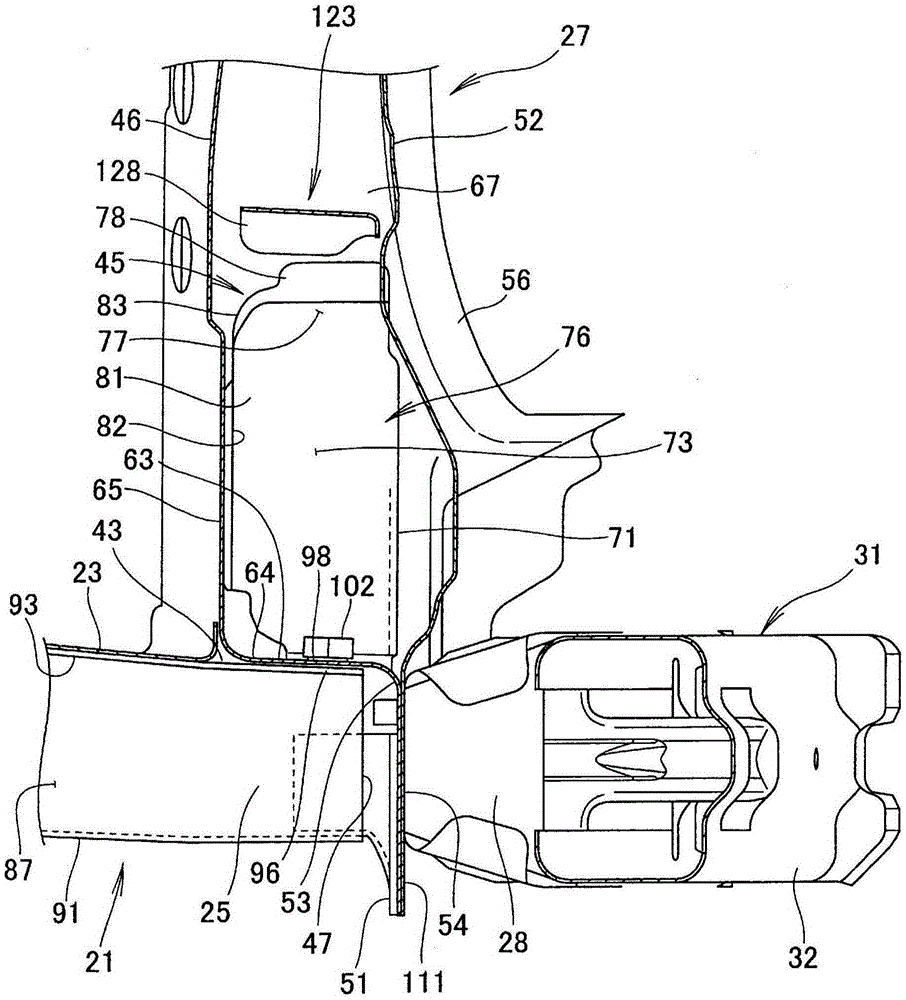

[0038] refer to figure 1 and figure 2 , in the vehicle 11, the vehicle body rear portion 13 of the present embodiment is mounted on the vehicle body. The vehicle body 12 includes: an underbody 15 constituting the bottom surface of the vehicle compartment 14 ; and left and right vehicle body side portions 16 constituting side walls of the vehicle compartment 14 . The storage room 18 is formed by the lower body 15 and the body side 16 .

[0039] Such as Figure 1 to Figure 7 As shown, the lower vehicle body 15 includes a rear floor panel 23 and rear side frames 21 extending in the front-rear direction of the vehicle body and disposed on the left and right sides of the vehicle body. The lower body 15 further includes a rear panel assembly 27 of the rear body. The rear panel assembly 27 is joined to the rear end portions 25 of the left and right rear side frames 21 , extends in the vehicle width direction, and extends upward of the vehicle.

[0040] Rear end portions 25 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com