Measuring and checking method based on segmental box girder stub matching prefabricated pedestal foundation

A short-line matching and prefabricated platform technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the inability to accurately and reliably detect and check the maximum uniform settlement difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

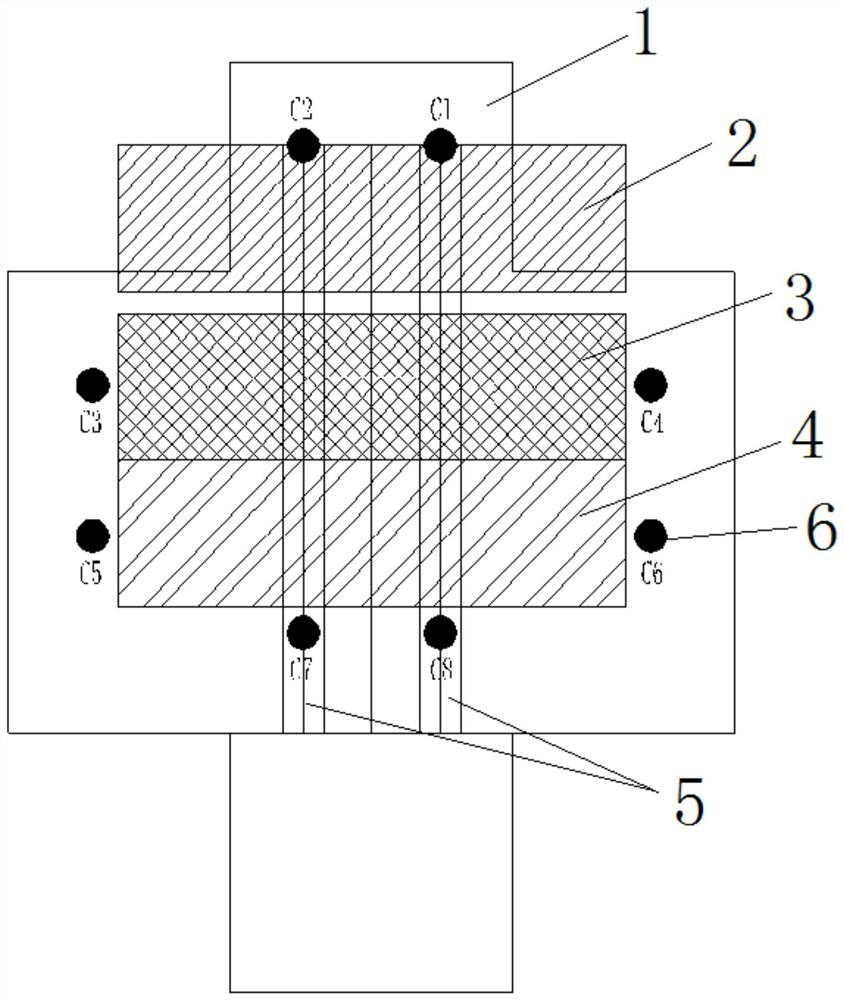

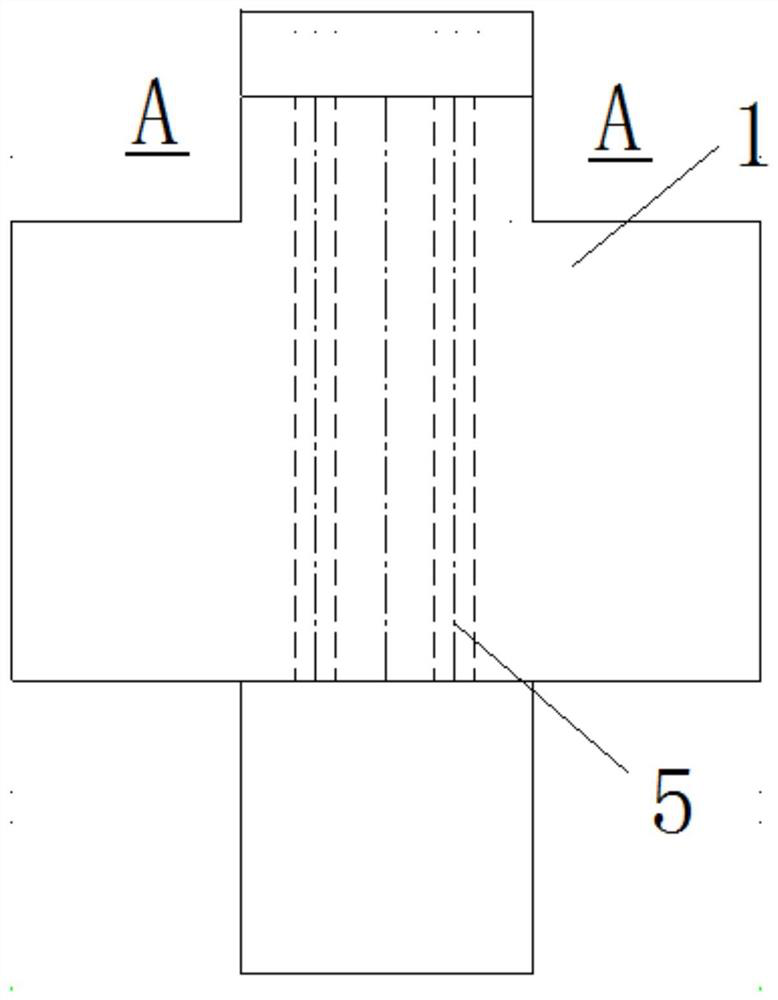

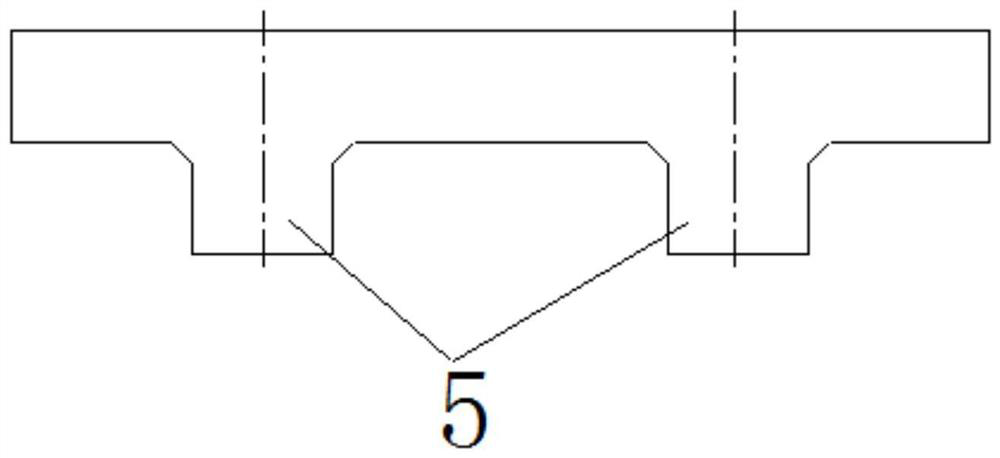

[0035] like Figure 1-3 As shown, the prefabricated pedestal 1 used for carrying box girders in the background technology has a pair of longitudinal track beams 5 symmetrical to the center line of the prefabricated pedestal in the middle of the bottom for support and guidance, and improves the prefabricated pedestal 1. part of the structural strength. The prefabricated pedestal 1 is sequentially provided with area 1 2 , area 2 3 and area 3 4 for carrying equal strength beams, matching beams and beams to be poured respectively from front to back. The maximum load analysis of each area is as follows:

[0036] The maximum load in area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com