Securing tool and work processing method

A technology for fixing fixtures and workpieces, which is applied in semiconductor/solid-state device manufacturing, electrical components, adhesives, etc. It can solve problems such as excessive wafer action and damage, and achieve the effect of enhanced fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

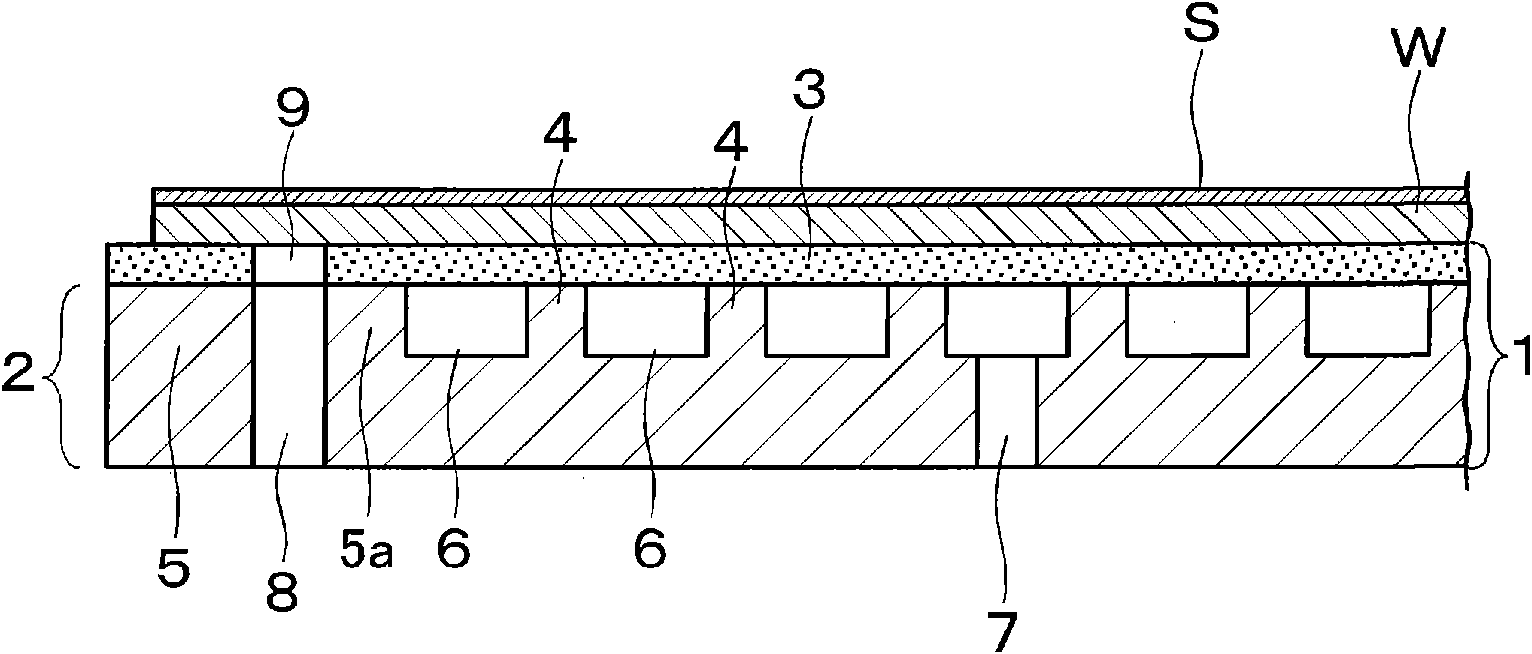

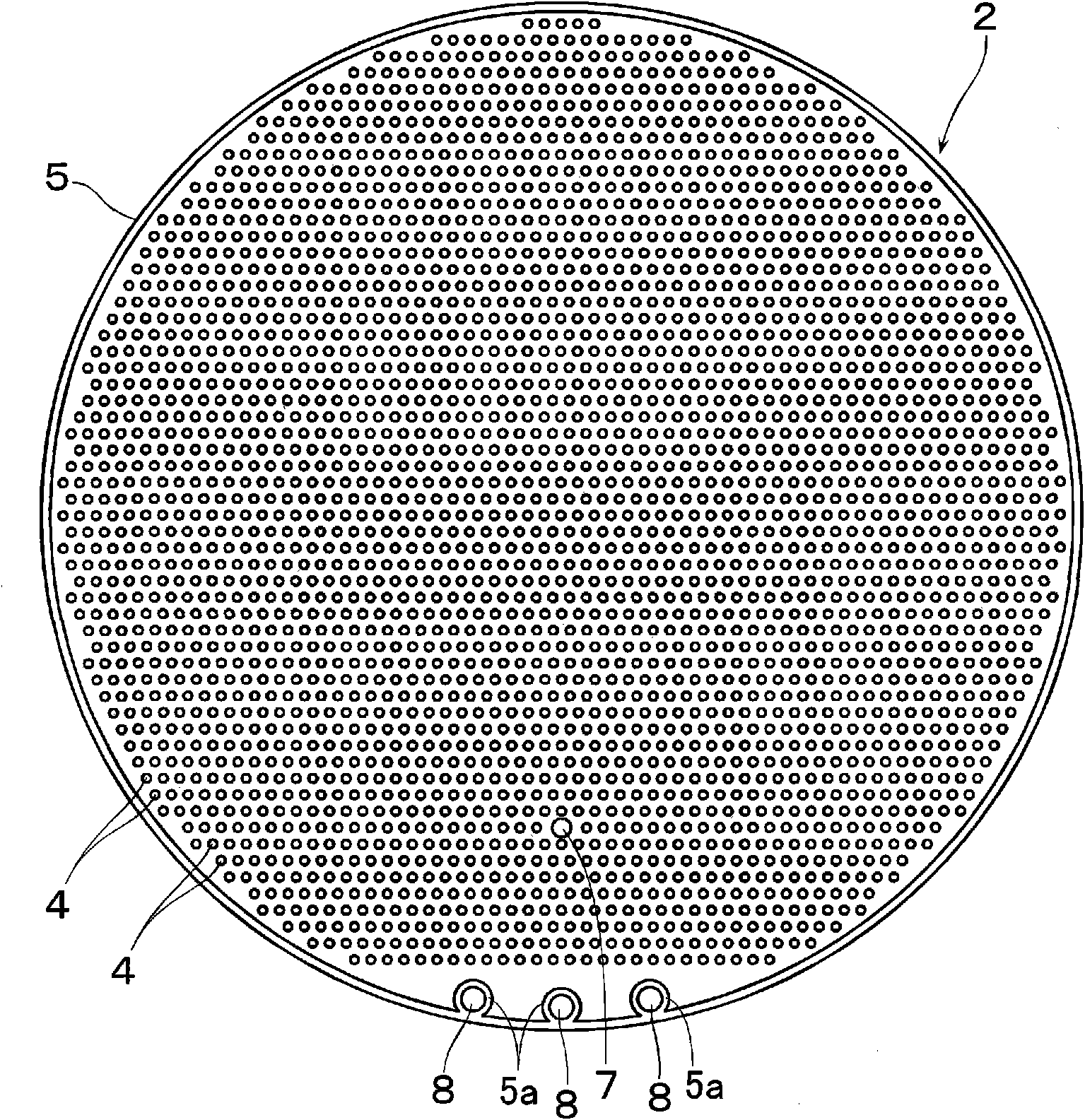

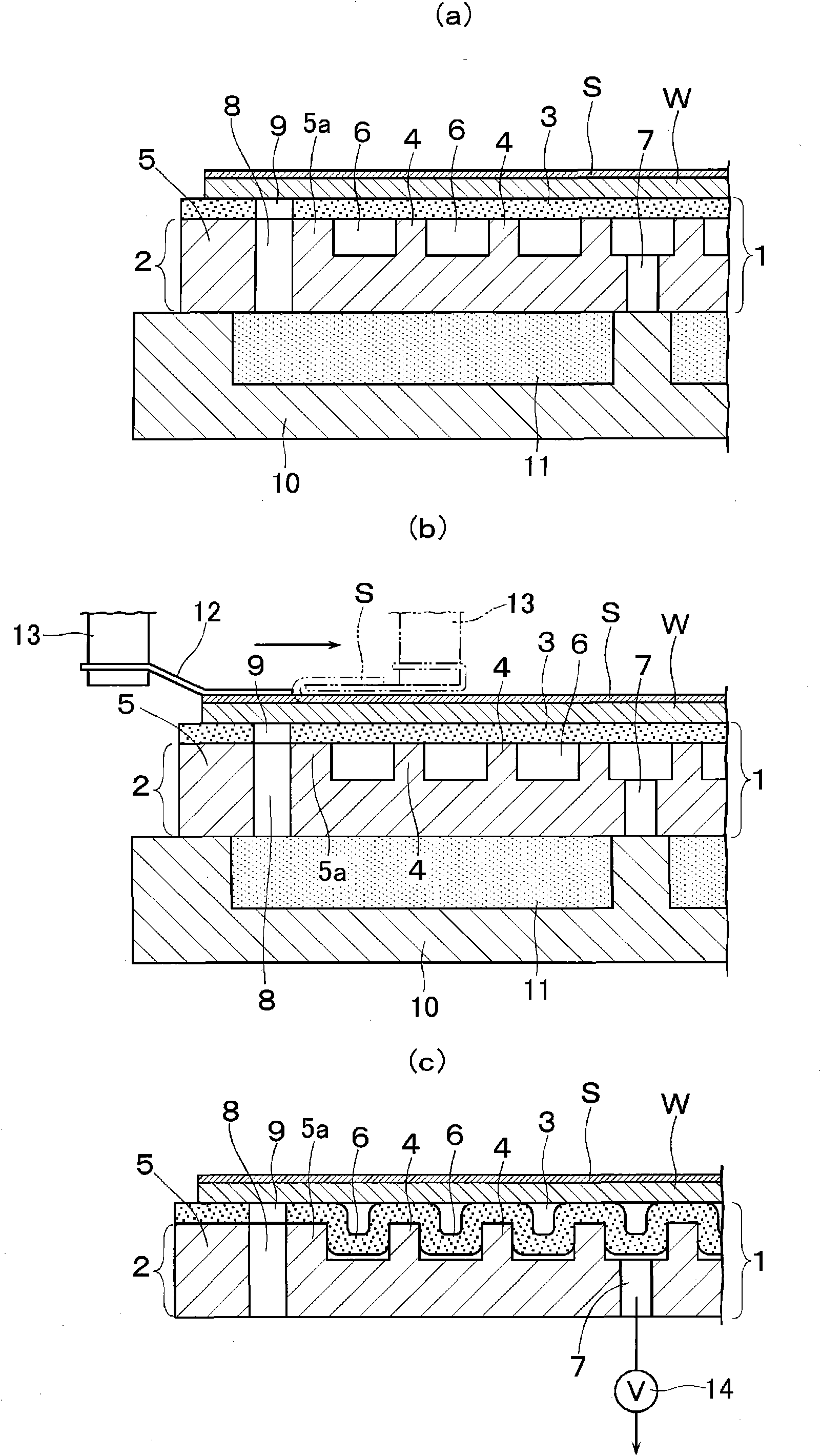

[0017] refer to figure 1 , figure 2 , 1 denotes a fixing jig for fixing a wafer W which is a thin-plate-shaped workpiece. The fixing jig 1 is composed of a plate-shaped jig body 2 and an adhesive layer 3 provided on one side of the jig body 2 .

[0018] The jig main body 2 is formed in a disc shape with a diameter slightly larger than that of the wafer W. As shown in FIG. The material of the jig body 2 is not particularly limited as long as it is a material with excellent mechanical strength, for example, metal materials such as aluminum alloy, magnesium alloy, stainless steel, polyamide, polycarbonate, polypropylene, propylene, polyvinyl chloride, etc. Resin molding materials such as glass, inorganic materials such as glass, and organic-inorganic composite materials such as glass fiber reinforced epoxy resin, etc.

[0019] On one surface of the jig main body 2, a plurality of cylindrical support protrusions 4 having a height of about 0.05 to 0.5 mm and a diameter of about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com