A spiral net tensioner

A helical and helical technology, applied in the field of helical net tensioners, can solve the problems of easily damaged camouflage nets, easy to break, and high rigidity of the net tensioner, and achieves the prevention of hanging nets, not easy to break and damage, reliable deformation and reset. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

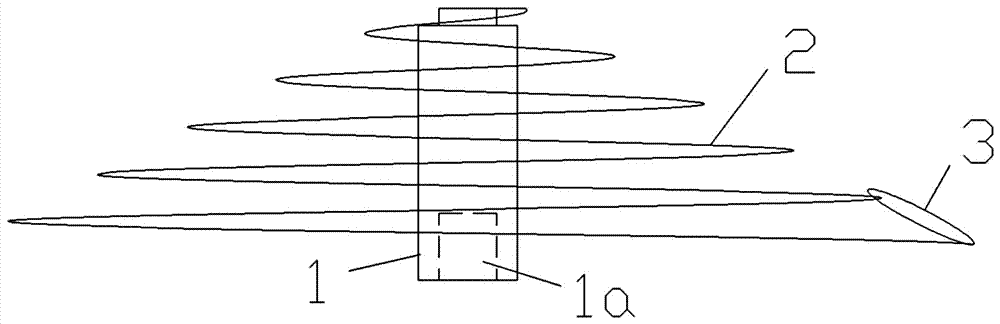

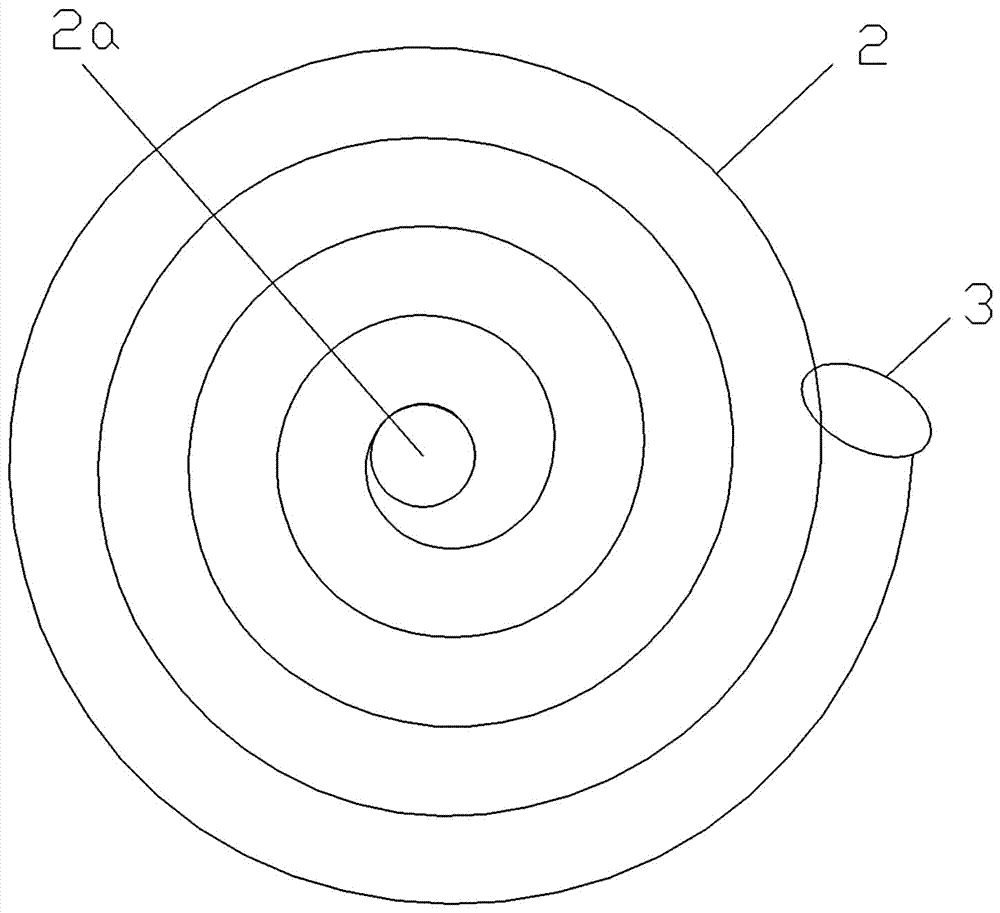

[0010] combine figure 1 and figure 2 As shown, the present invention provides a spiral net tensioner, including a fixed column 1 and a support bar 2, the support bar 2 is in the shape of a spiral line, the center of the bottom of the support bar 2 is provided with an installation hole 2a, and the support bar 2 passes through the installation hole 2a Connected with the top of the fixed column 1, the outer end of the support bar 2 is provided with a ring 3, and the second circle of the support bar 2 from the outside to the inside is formed to cooperate with the ring 3; Mating socket 1a.

[0011] The support bar 2 in the shape of a spiral is used as the main body of the camouflage net. Under the pressure of the camouflage net, the support bar 2 deforms downward, which can support the camouflage net and is not easy to break and damage; the ring 3 On the one hand, it plays the role of closing the support bar 2 to prevent the net from hanging; on the other hand, the ring 3 can sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com