Patents

Literature

188results about How to "Not easy to break and damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molded object having nonwoven fibrous structure

ActiveUS20090130939A1Increased bending stressImprove toughnessErasing devicesConstruction materialPolyesterApparent density

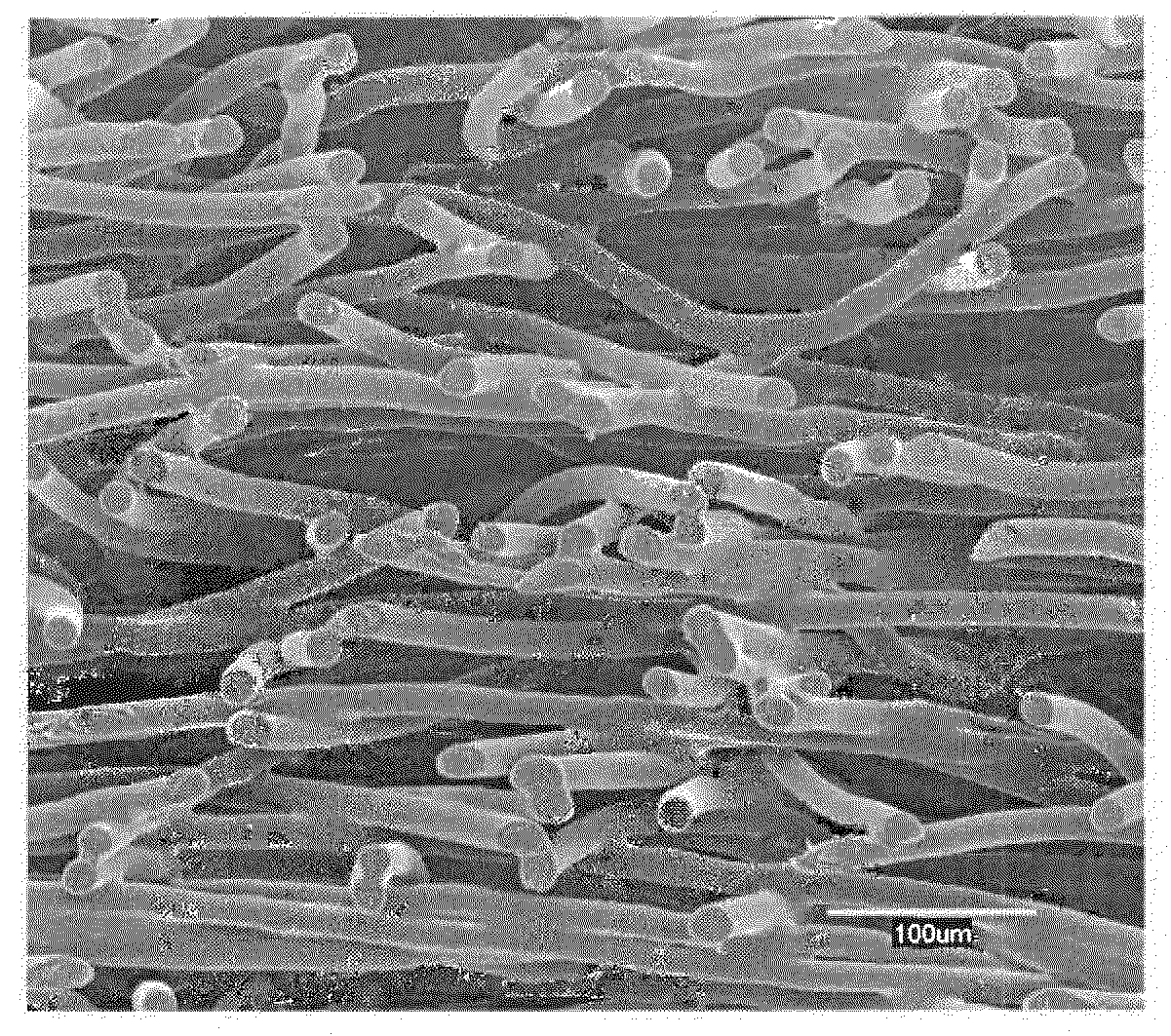

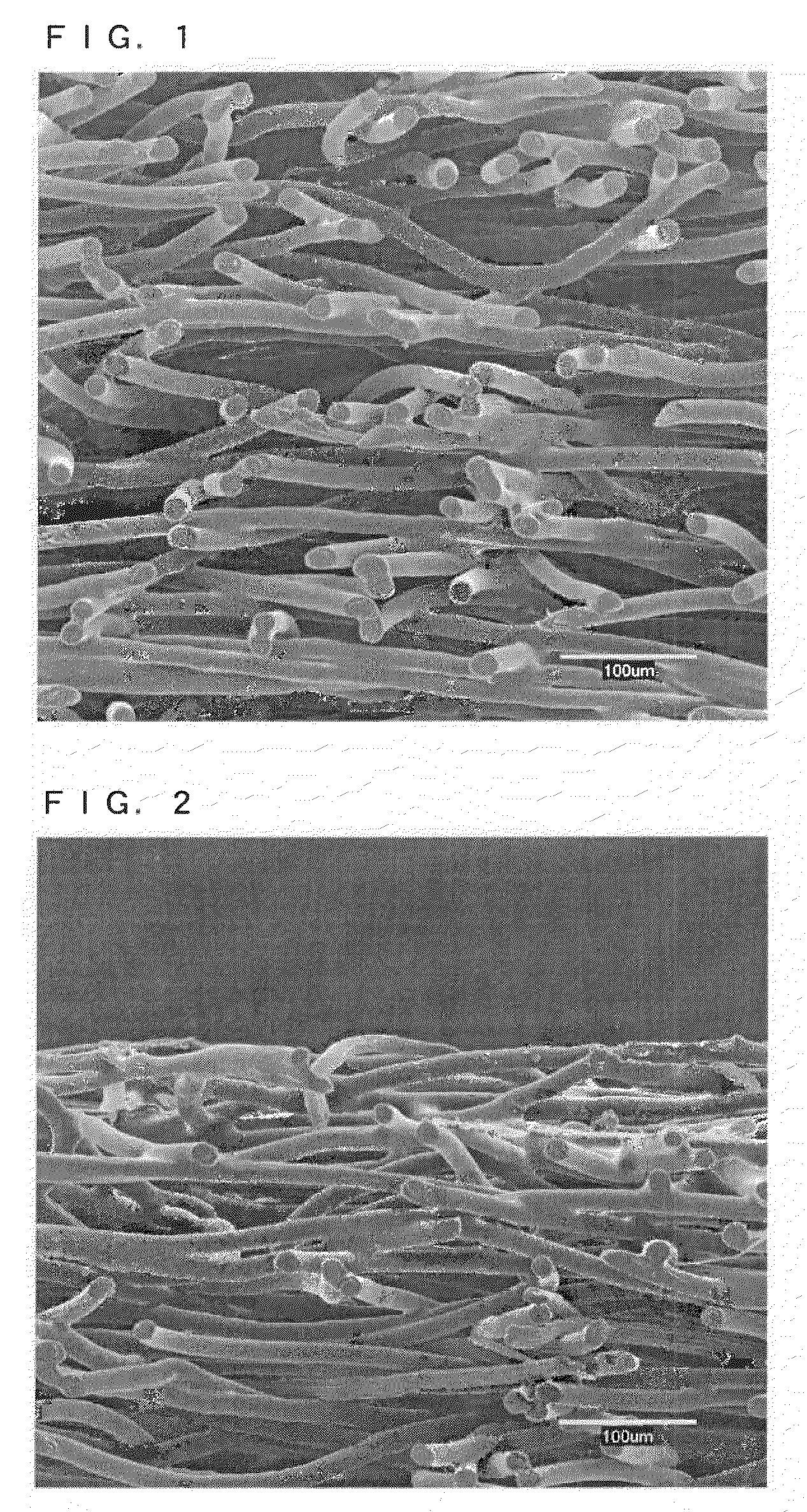

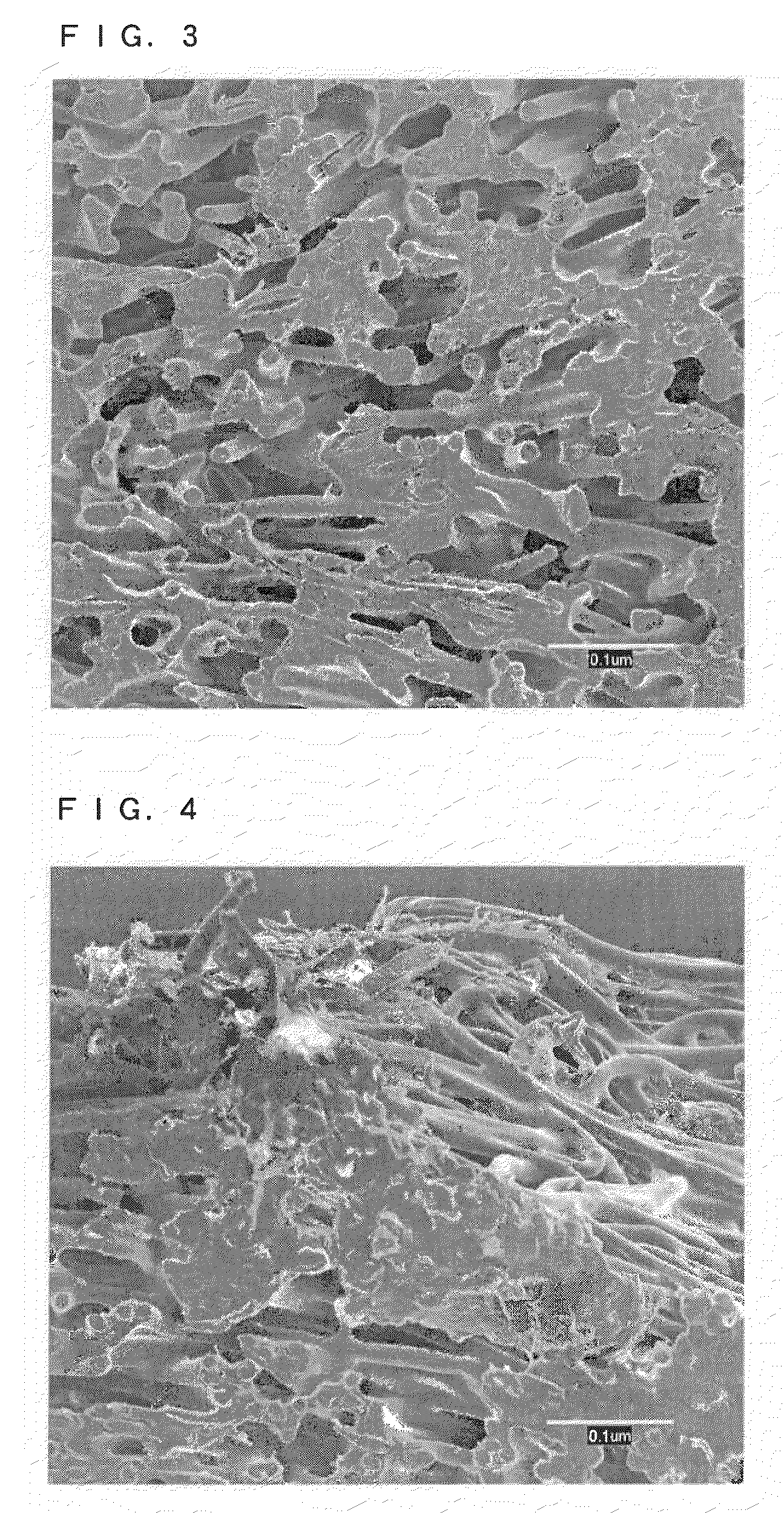

To prepare a shaped product comprising a thermal adhesive fiber under moisture and having a fiber aggregate nonwoven structure. In the shaped product, the thermal adhesive fibers under moisture are melted to bond to fibers constituting the fiber aggregate nonwoven structure and the bonded fiber ratio is not more than 85%. The shaped product has an apparent density of 0.05 to 0.7 g / cm3, a maximum bending stress of not less than 0.05 MPa in at least one direction, and a bending stress of not less than ⅕ of the maximum bending stress at 1.5 times as large as the bending deflection at the maximum bending stress. The moistenable-thermal adhesive fiber may be a sheath-core form conjugated fiber comprising a sheath part comprising an ethylene-vinyl alcohol-series copolymer and a core part comprising a polyester-series resin. Such a shaped product can be used for a building board or the like since the shaped product has a high bending stress although the product is light and has a low density.

Owner:KURARAY CO LTD

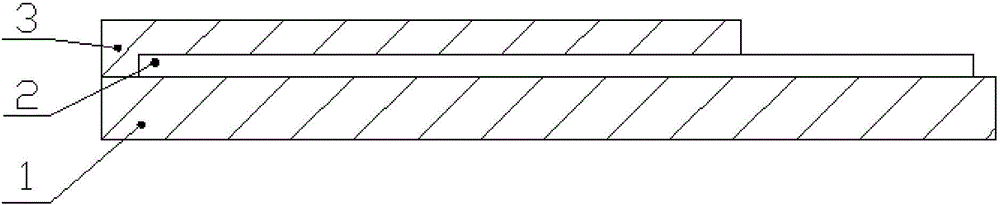

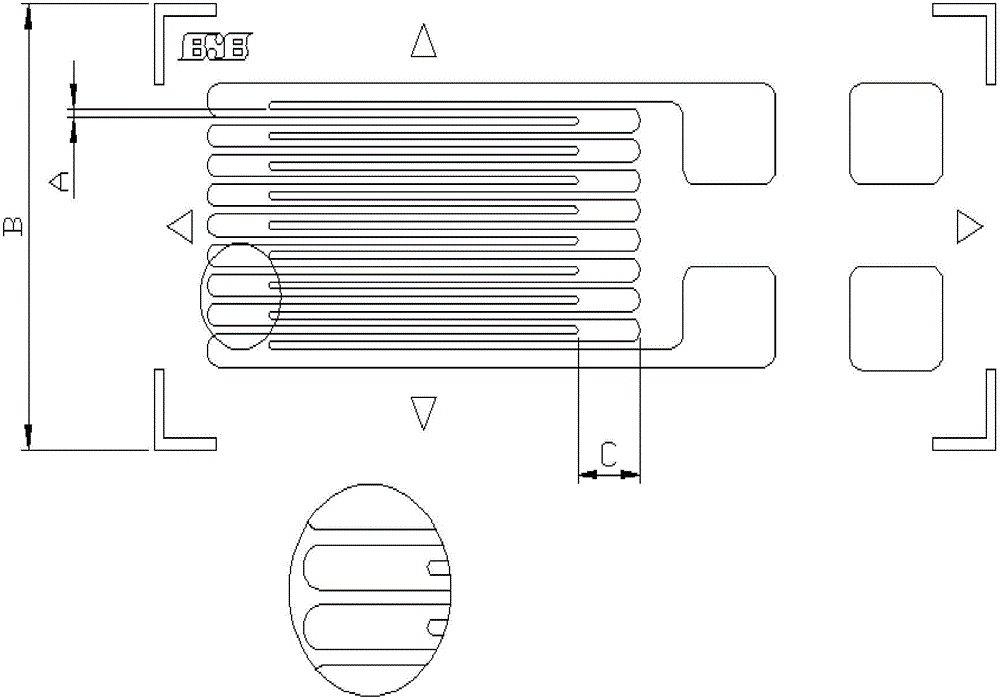

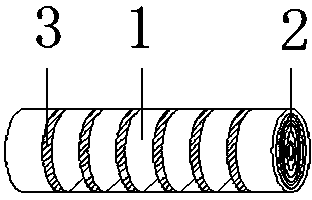

Strain meter for plastic deformation test and manufacturing and calibration method thereof

ActiveCN103604363ANot easy to break and damageImprove ductilityElectrical/magnetic solid deformation measurementAlloyVacuum annealing

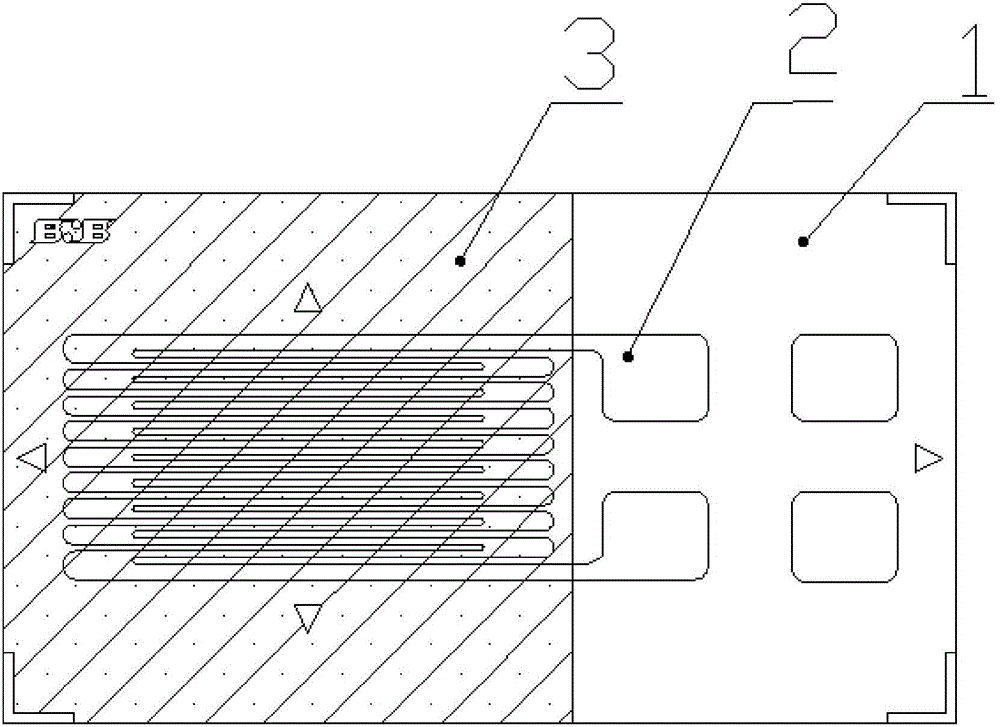

The invention provides a strain meter for a plastic deformation test and a manufacturing and calibration method of the strain meter. The strain meter comprises a substrate, a sensitive grid and a sealing layer, wherein the sensitive grid is obtained by subjecting constantan and tinsel alloy formed in a cold rolling mode to vacuum annealing at 350-550 DEG C for three to six hours. The sensitive grid of the strain meter is obtained by subjecting the constantan and tinsel alloy formed in the cold rolling mode to vacuum annealing, and is good in ductility and elongation and capable of completely meeting measurement requirements of plastic deformation, so that the sensitive grid is not prone to rupture failures in the plastic deformation process.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

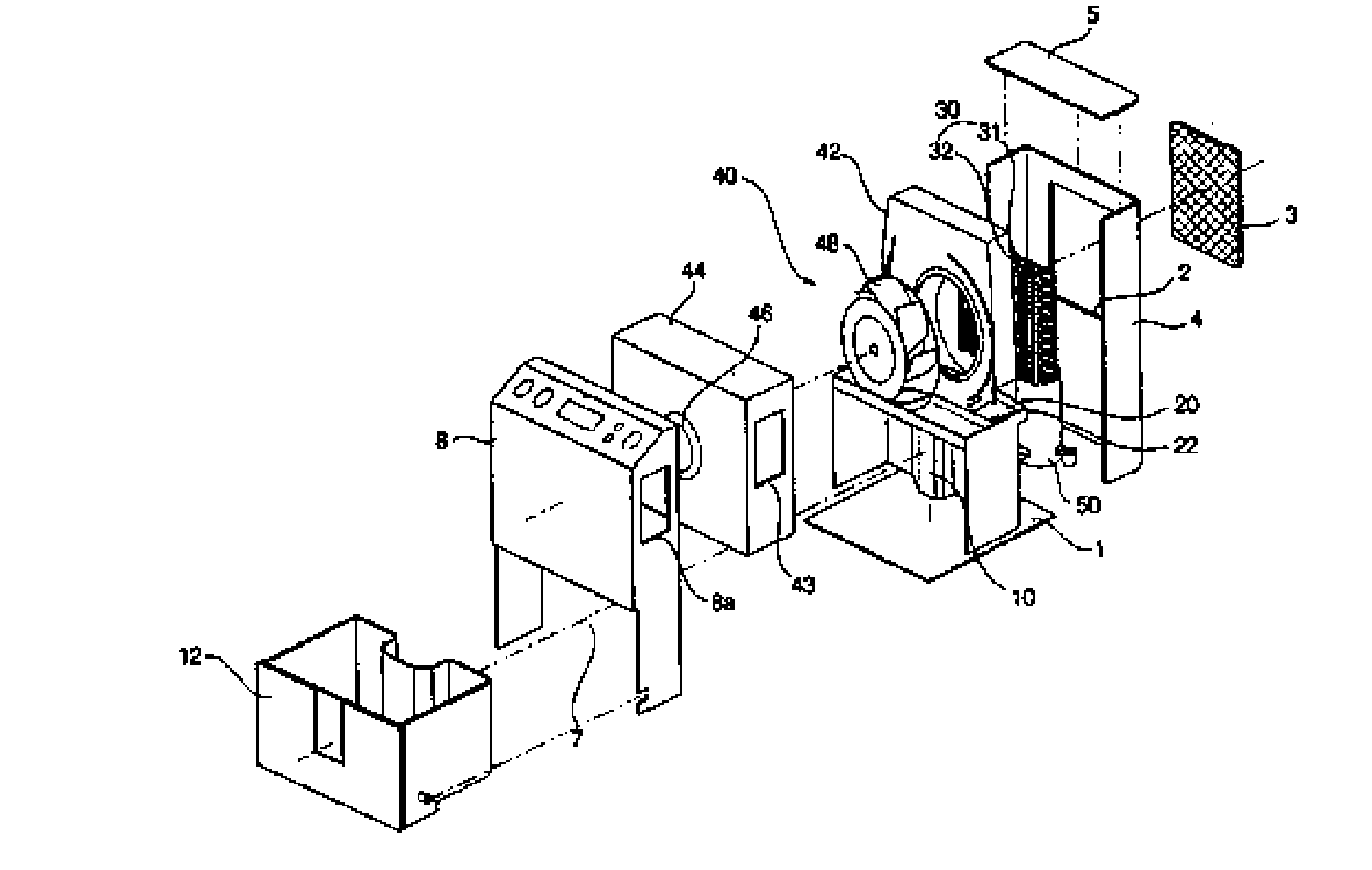

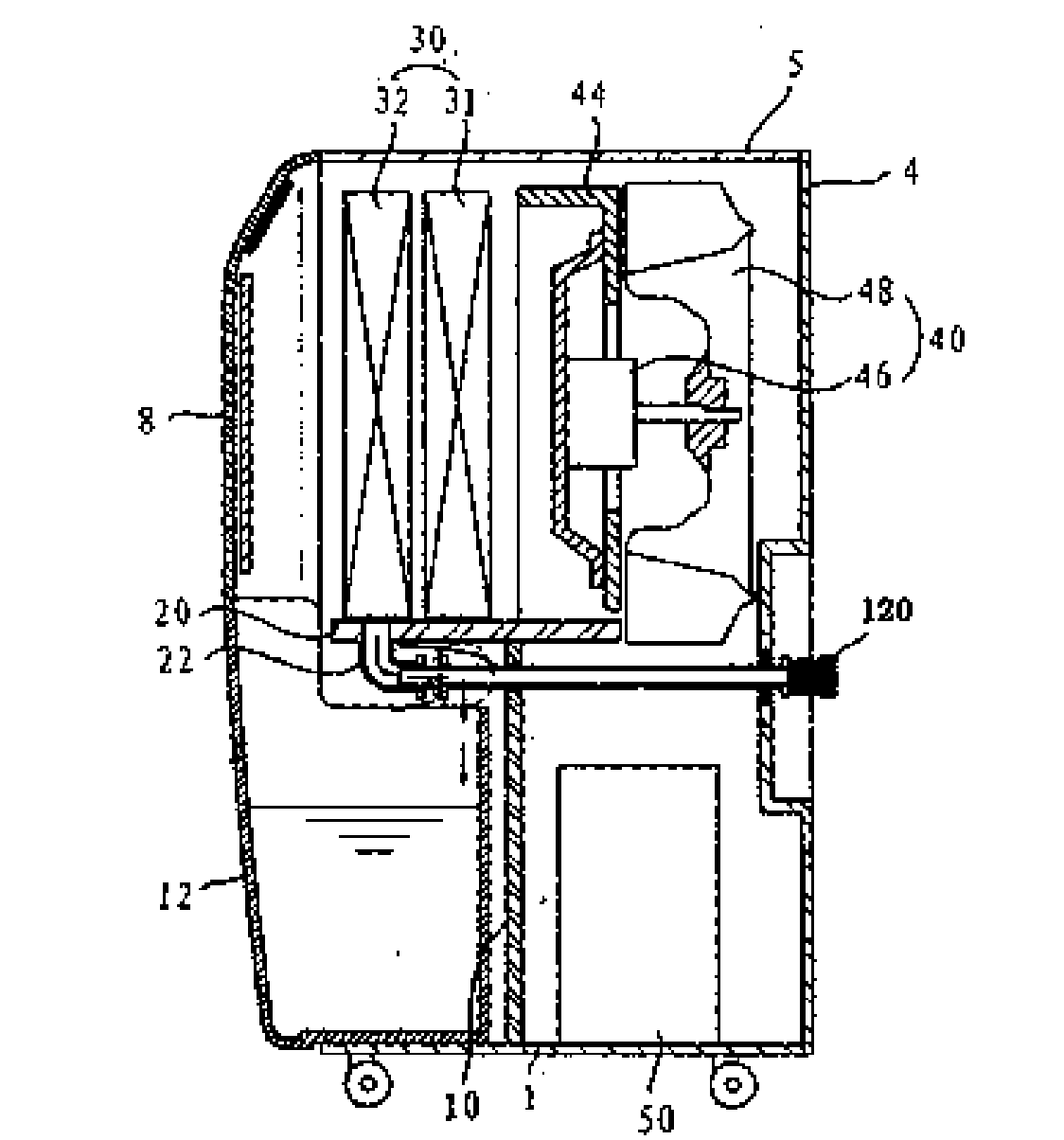

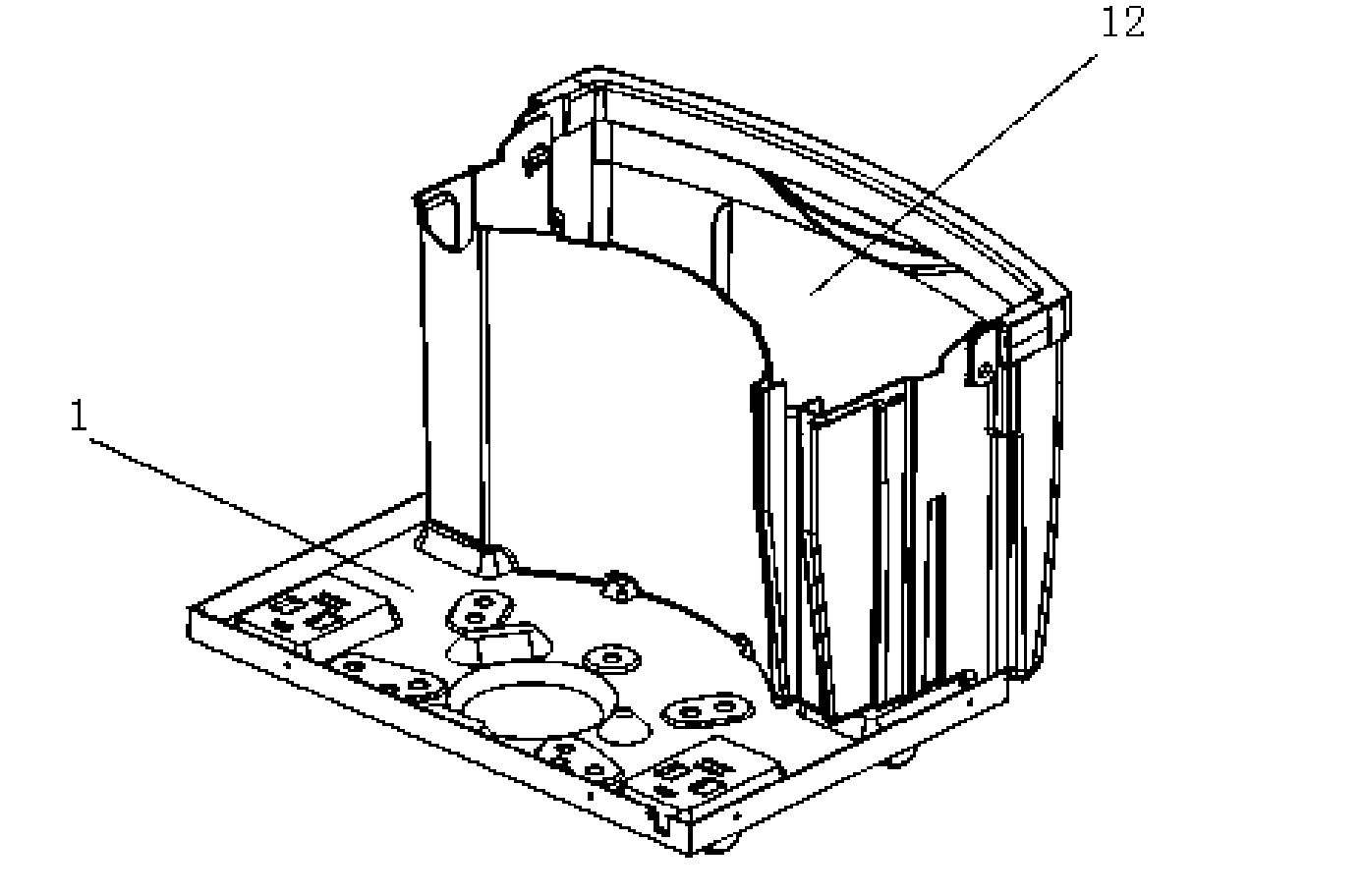

Water receiving disc of dehumidifier

InactiveCN102116519AEasy to fixPrevent overflowCondensate preventionWater dischargeEngineering plastic

The invention provides a water receiving disc of a dehumidifier. The dehumidifier comprises a machine box, an evaporator, a condenser, a water receiving disc, a fan, a water tank, a compressor and a control box, wherein the water tank and a chassis are in an integrally formed structure; the side wall of the water tank is formed by upwards extending the chassis; and the water receiving disc is fixed with the water tank and covers the water tank in a sealed manner. The water receiving disc is integrally formed by engineering plastic, is arranged at the upper part of the water tank, and covers the water tank in a sealed manner; condensed water is guided into the water tank through a water discharging opening; the integrally formed water receiving disc not only can completely bear and guide the condensed water flowing down from the evaporator, but also can play a role as a water tank cover which prevents the condensed water in the water tank from overflowing outwards; and the water tank cover does not need to be additionally assembled in the dehumidifier, so that the development cost of a mould is saved and the total production cost is reduced.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

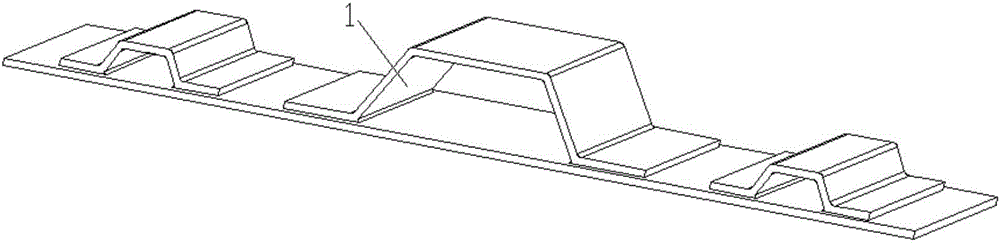

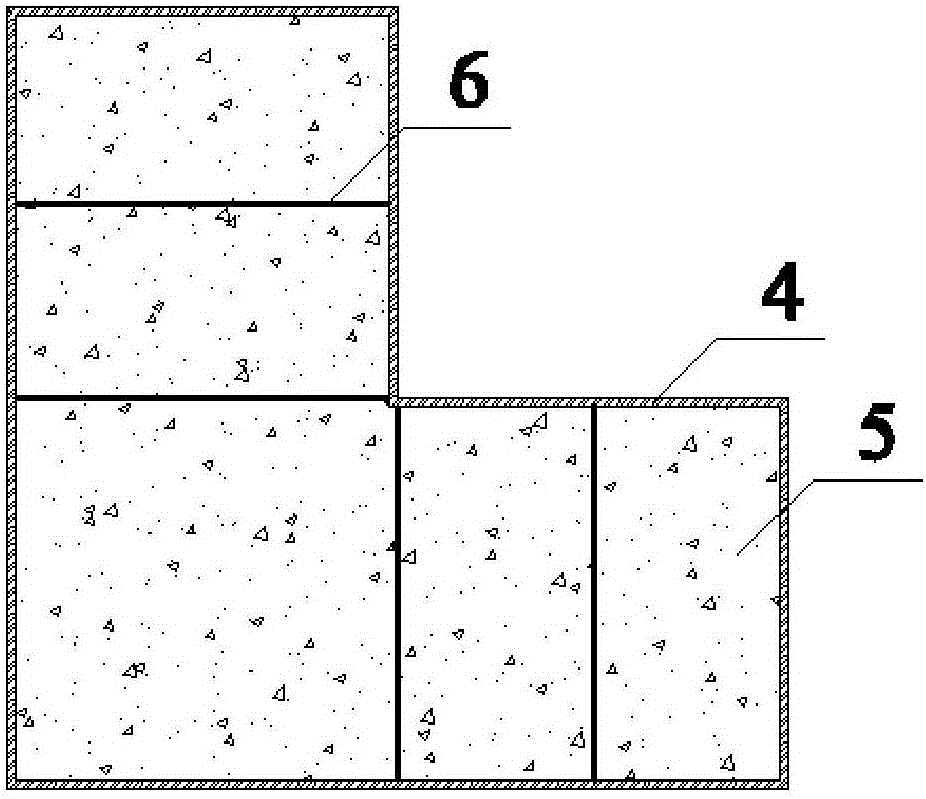

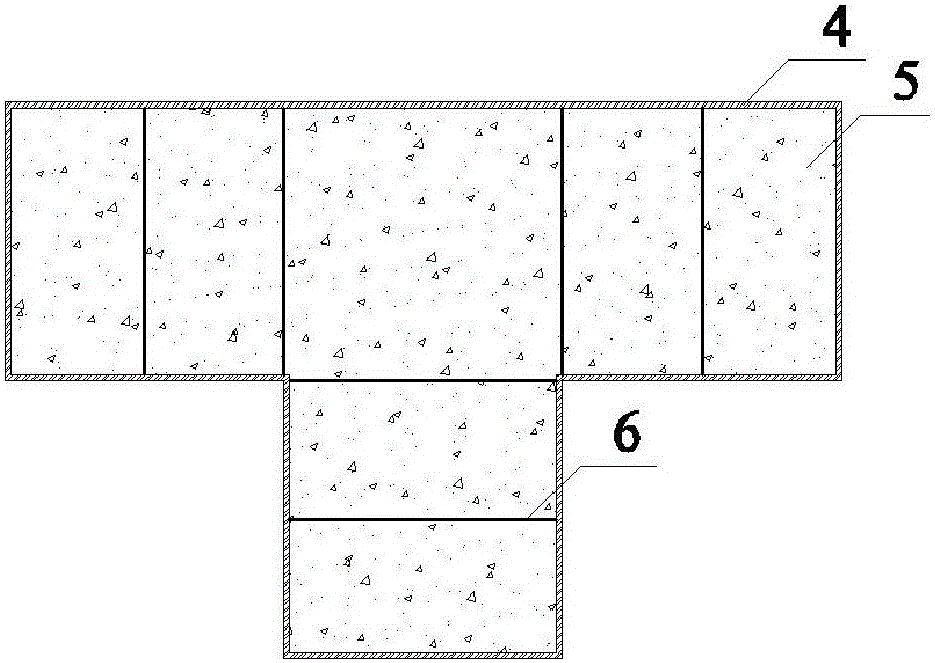

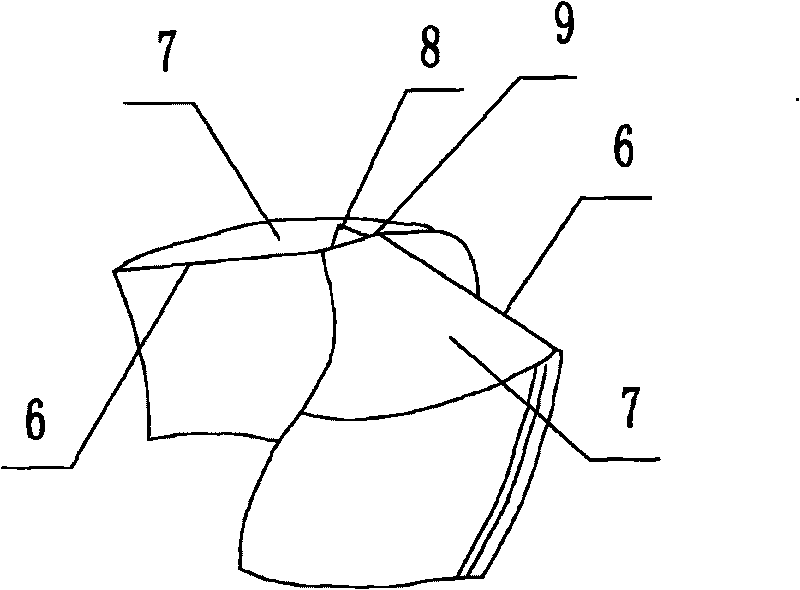

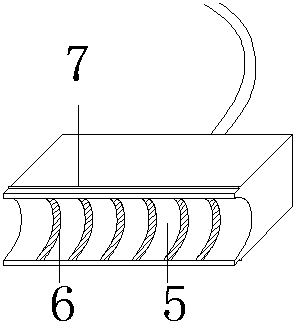

Method for preparing and using fiber-reinforced hat-shaped rib molding soft mold

The invention belongs to the composite molding technology, and relates to the improvement on the technology for preparing hat-shaped ribbed composite wall panel molding soft molds, in particular to a method for preparing and using a fiber-reinforced hat-shaped rib molding soft mold. A traditional pure rubber soft mold is improved, a unidirectional fiber reinforcement body is added in the soft mold in the rib length direction, and therefore the toughness, in the length direction, of the soft mold is increased, transmission of demolding tensile force is facilitated better, the problem of breakage of the fiber-reinforced hat-shaped rib molding soft mold in the demolding process is avoided, and the demolding efficiency is improved. The unidirectional fiber reinforcement body has a large limiting function on deformation, in the length direction, of the fiber-reinforced hat-shaped rib molding soft mold in the demolding process, the fiber-reinforced hat-shaped rib molding soft mold is not prone to being broken and damaged, restoring of deformation in the length direction is easy, the repeated use performance of the fiber-reinforced hat-shaped rib molding soft mold is improved, and the process cost is reduced.

Owner:AVIC BASIC TECH RES INST

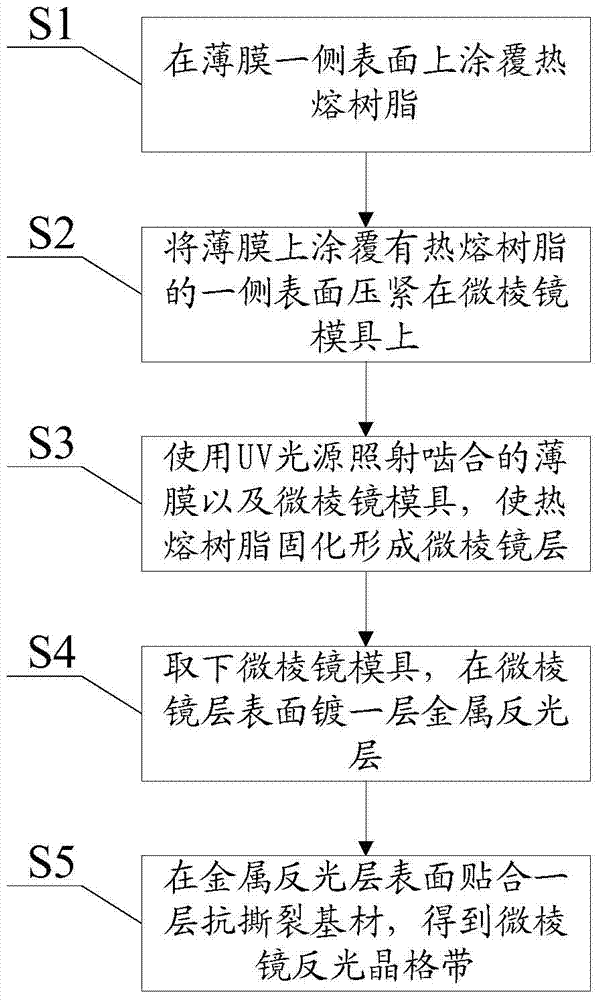

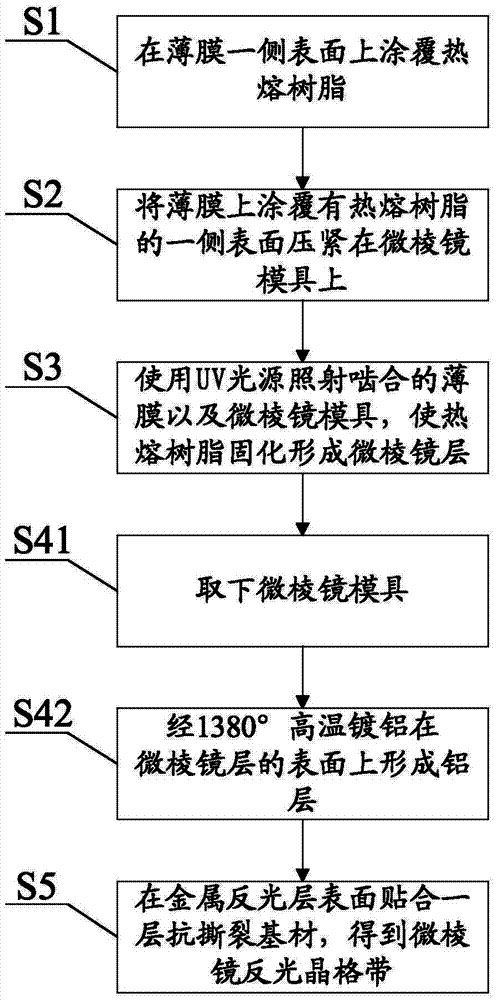

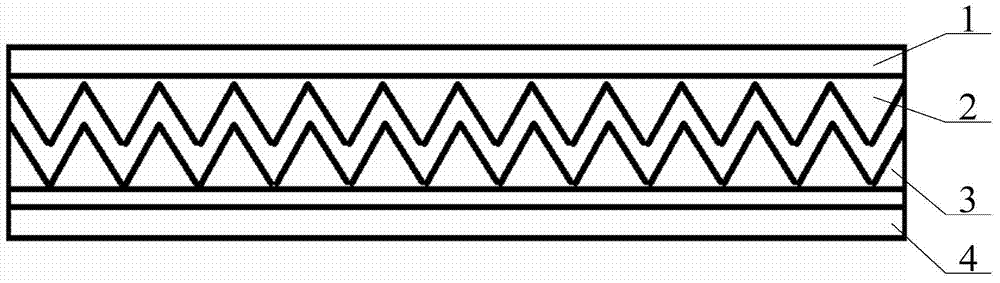

Process for producing microprism reflective crystal lattice strip and microprism reflective crystal lattice strip

InactiveCN103513310AHigh tensile tear strengthImprove folding resistanceSynthetic resin layered productsLaminationUltravioletPrism

The invention discloses a process for producing a microprism reflective crystal lattice strip. Compared with a pyramid subjected to hot press molding in the prior art, a resin pyramid subjected to ultraviolet (UV) light source radiation curing has higher hardness and is firmly bound to a film. In addition to a reflective effect, a metal reflection layer forms a protective layer with a tear-resistant base material, so that the tensile tearing strength of the produced microprism reflective crystal lattice strip is greatly improved, the folding resistance and wear resistance are improved, and the microprism reflective crystal lattice strip is difficultly broken and damaged and can be repeatedly washed at a moderate temperature. When the microprism reflective crystal lattice strip produced by the production process is influenced by external factors such as washing, extruding, scraping and temperature change, a good reflective effect is always kept, and a safety protection effect is achieved. The invention also discloses a microprism reflective crystal lattice strip.

Owner:YEAGOOD INC

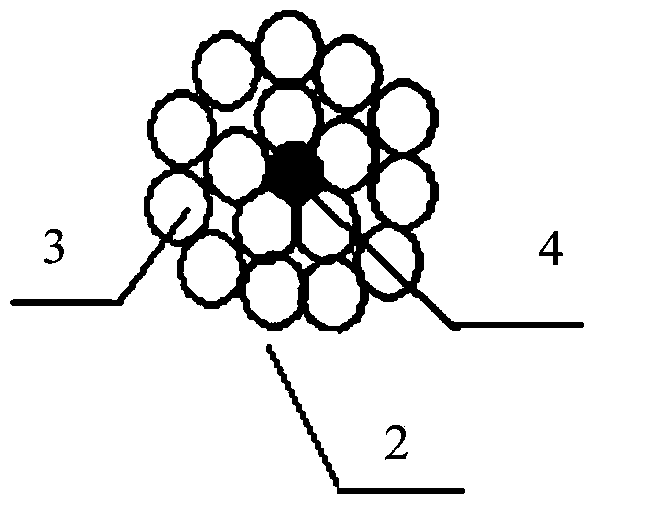

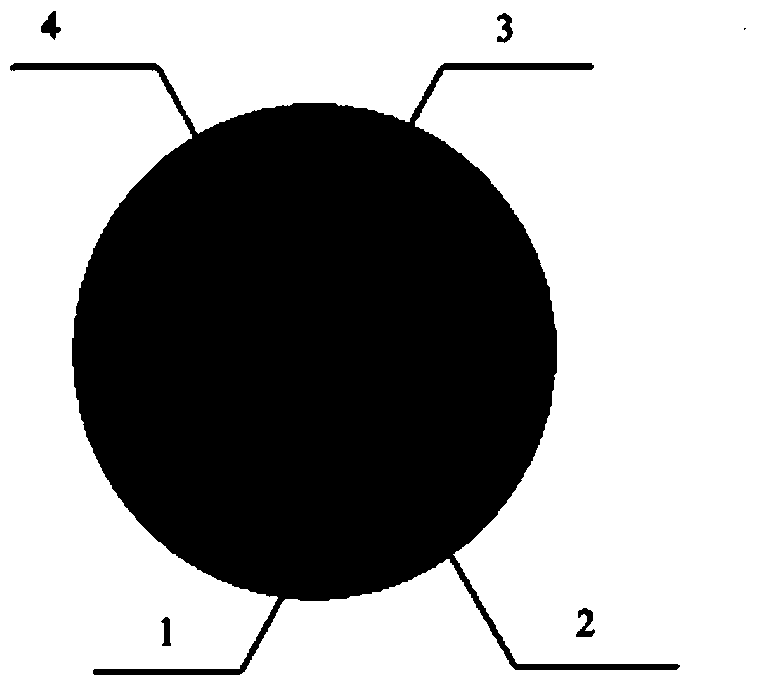

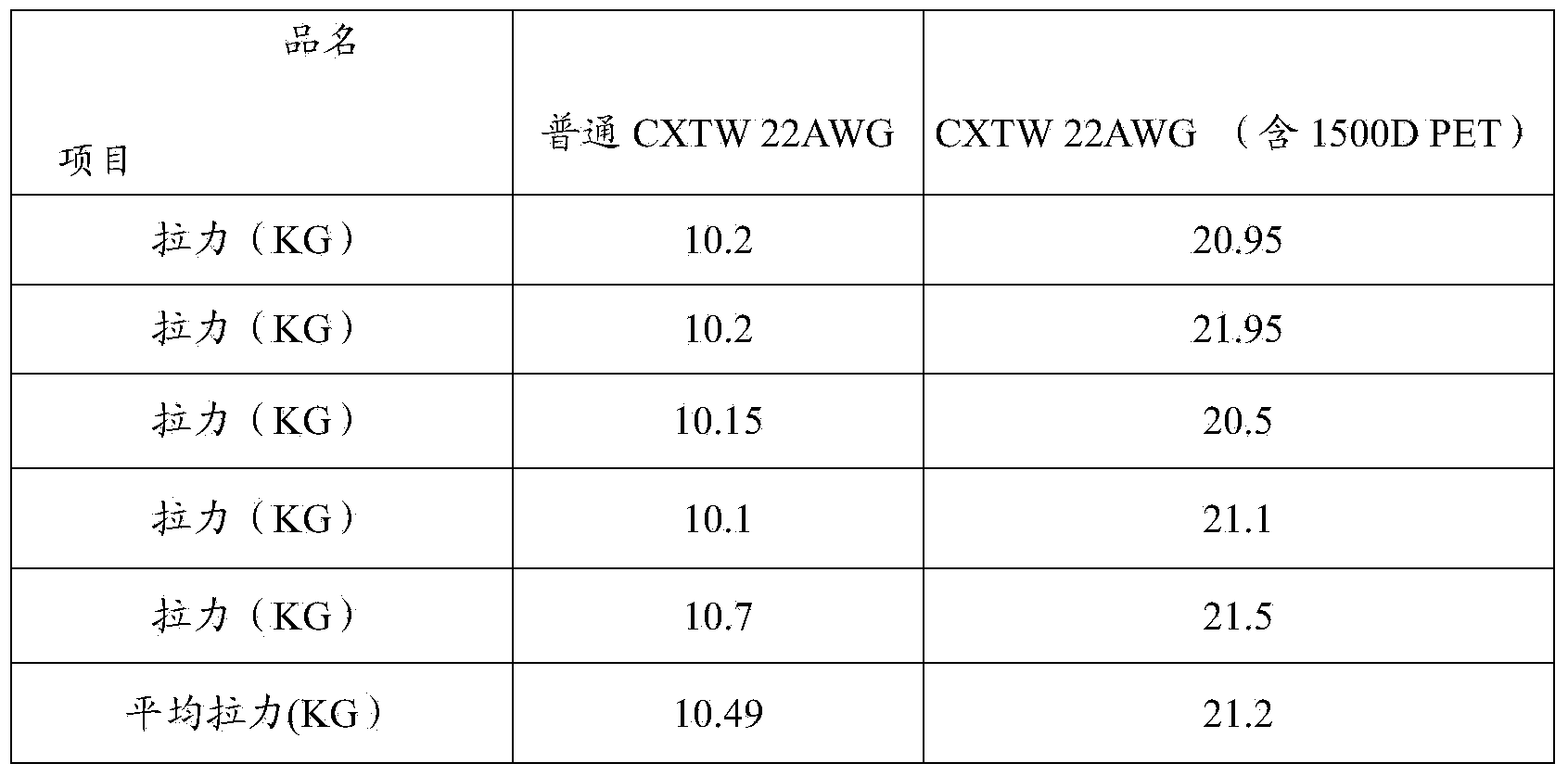

Tensile cable and method for manufacturing same

ActiveCN103680693AImprove tensile propertiesNot easy to break and damageInsulated cablesCable/conductor manufacturePolyethylene terephthalateEngineering

The invention discloses a tensile cable and a method for manufacturing the same, and belongs to the technical field of cables and wires. The tensile cable comprises an insulating outer layer and a conductor inner core. The insulating outer layer covers the conductor inner core, the conductor inner core is a stranded wire, and a plurality of metal wires and at least one PET (polyethylene terephthalate) wire are stranded to form the stranded wire. The tensile cable and the method have the advantages that the tensile strength of the tensile cable can be obviously improved on the premise that the conductivity of the tensile cable is guaranteed, and the tensile cable cannot be broken or damaged easily and is firm and durable.

Owner:DONGGUAN KUNPOINT LIGHT & WIRE

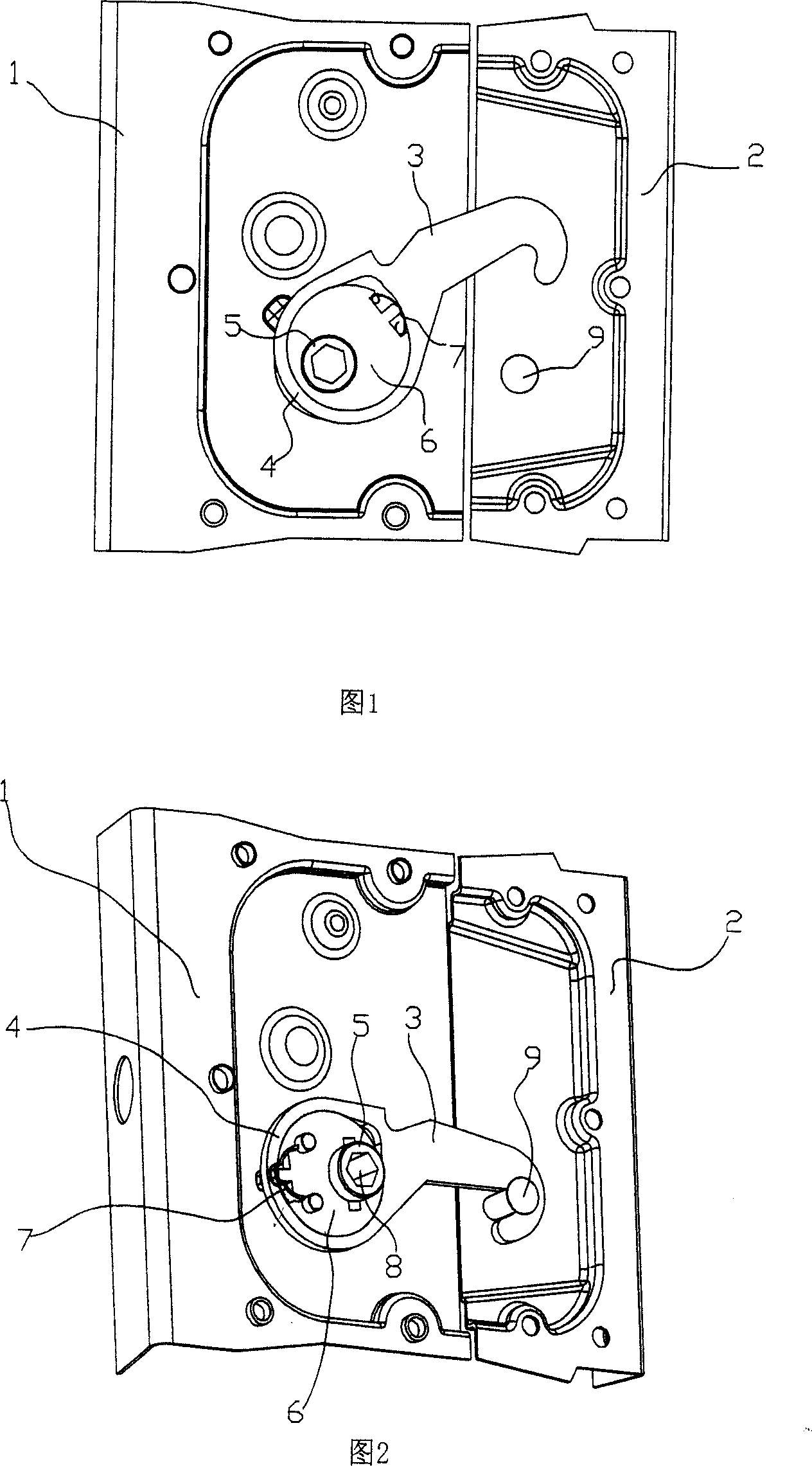

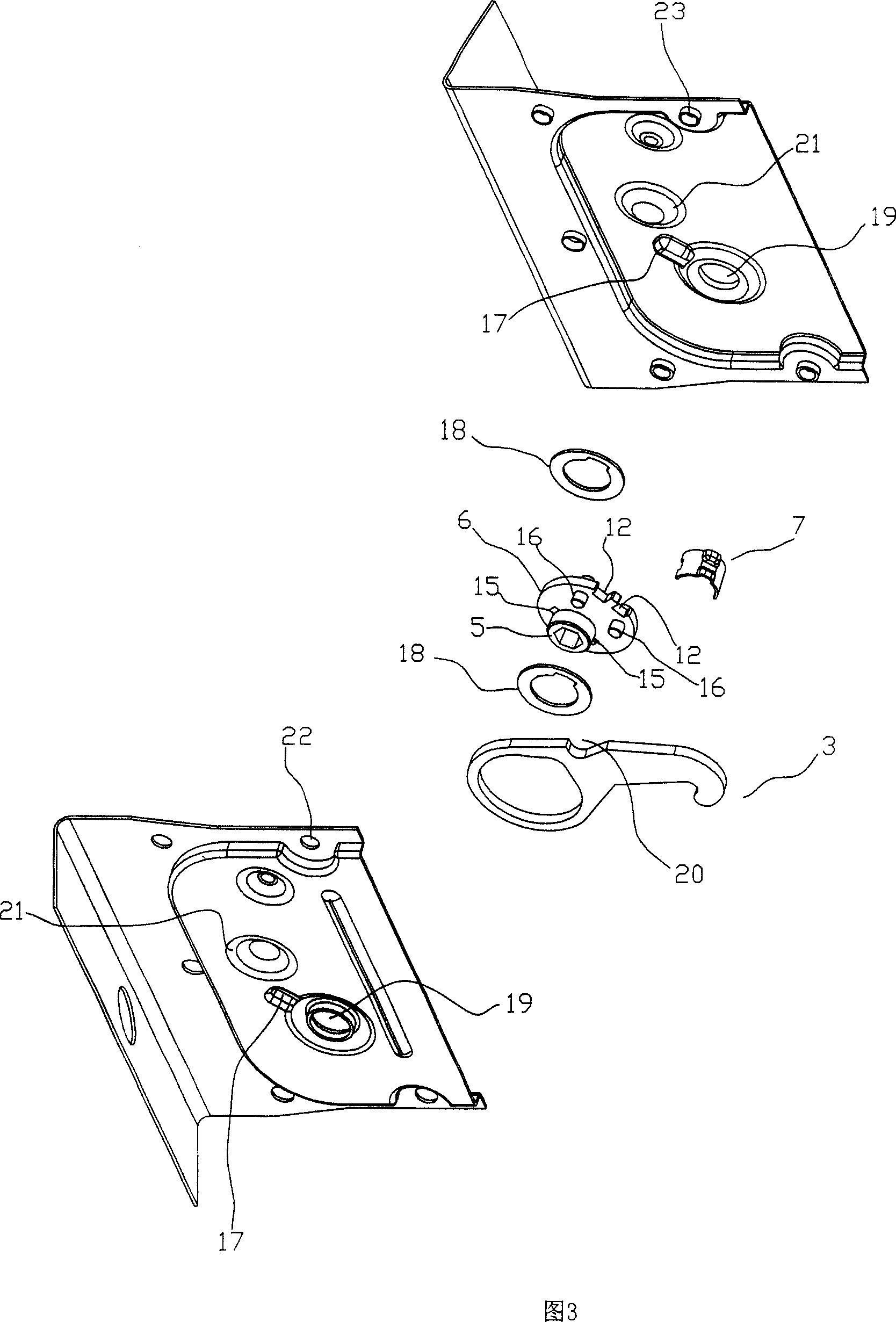

Tension lock

InactiveCN101153528AReliable cooperationNo breakageDomestic cooling apparatusLighting and heating apparatusPull forceEngineering

A tension lock comprises a first base and a second base which are matched with each other. A lock hook having a unciform head and an annular tail is arranged inside the first base, an eccentric cam having an eccentric shaft is arranged inside the annular tail of the lock hook, a spring enabling the eccentric cam and the lock hook to be interlocked with each other is arranged between the eccentric cam and the inner wall of the lock hook, the shaft end of the eccentric shaft is internally hexagonal, the lock hook is movably arranged inside the first base through the eccentric shaft of the eccentric cam, and correspondingly a fixed shaft is arranged inside the second base. The invention is characterized in that: the eccentric cam and the eccentric shaft are both made of steel material, and the eccentric shaft travels into an eccentric cam connecting hole and is welded securely in the connecting hole. The invention is applicable to tension locks with greater locking strength, reliable operation, long service life and the cam which is not easy to break.

Owner:顾新虎

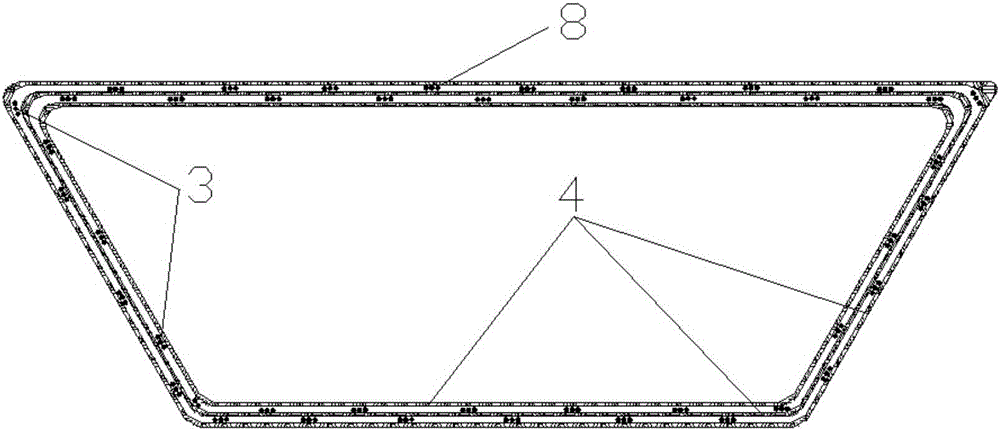

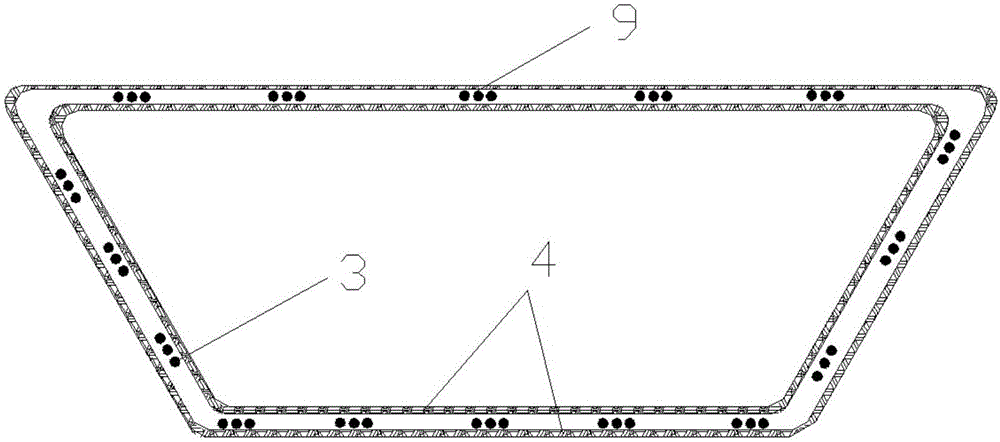

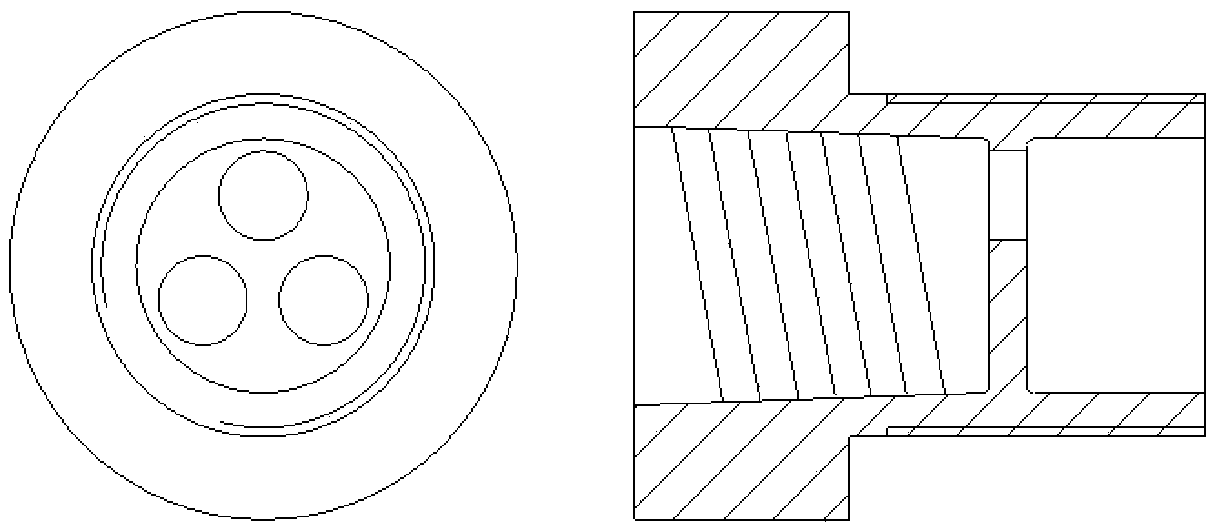

Slotted head fast connector

The invention relates to a slotted head fast connector belonging to the technical field of perfusion tube connectors and mainly solving the problems of mechanized laying and burglary prevention of steel pipelines. The slotted head fast connector is characterized in that two sealing rings 3 positioned at the inner side of a connector body 5 are respectively arranged on the interface position of two connected steel pipes; a fixed clip key 1 is fixedly connected with a slotted head of one steel pipe, and a stop block 2 is used for closing an inlet provided with the fixed clip key 1; a movable clip key 8 and a reed 9 are arranged between the connector body 5 and a connector body cover 7 and are used for limiting and fixing the slotted head of the other steel pipe. The invention limits the movement of the steel pipes by adopting the fixed clip key 1 and the movable clip key 8, thereby ensuring the use safety and the reliability by limiting; the slotted head fast connector can be disassembled by adopting a special tool, thereby realizing the mechanized laying of the steel perfusion pipelines; in addition, the invention has reliable work and pressure resistance more than or equal to 6.0 MPa, is mainly used for the delivery of oils (gasoline, kerosene, diesel oil, motor oil, and the like) and can be also used for the delivery of water and other non-corrosive liquids.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +1

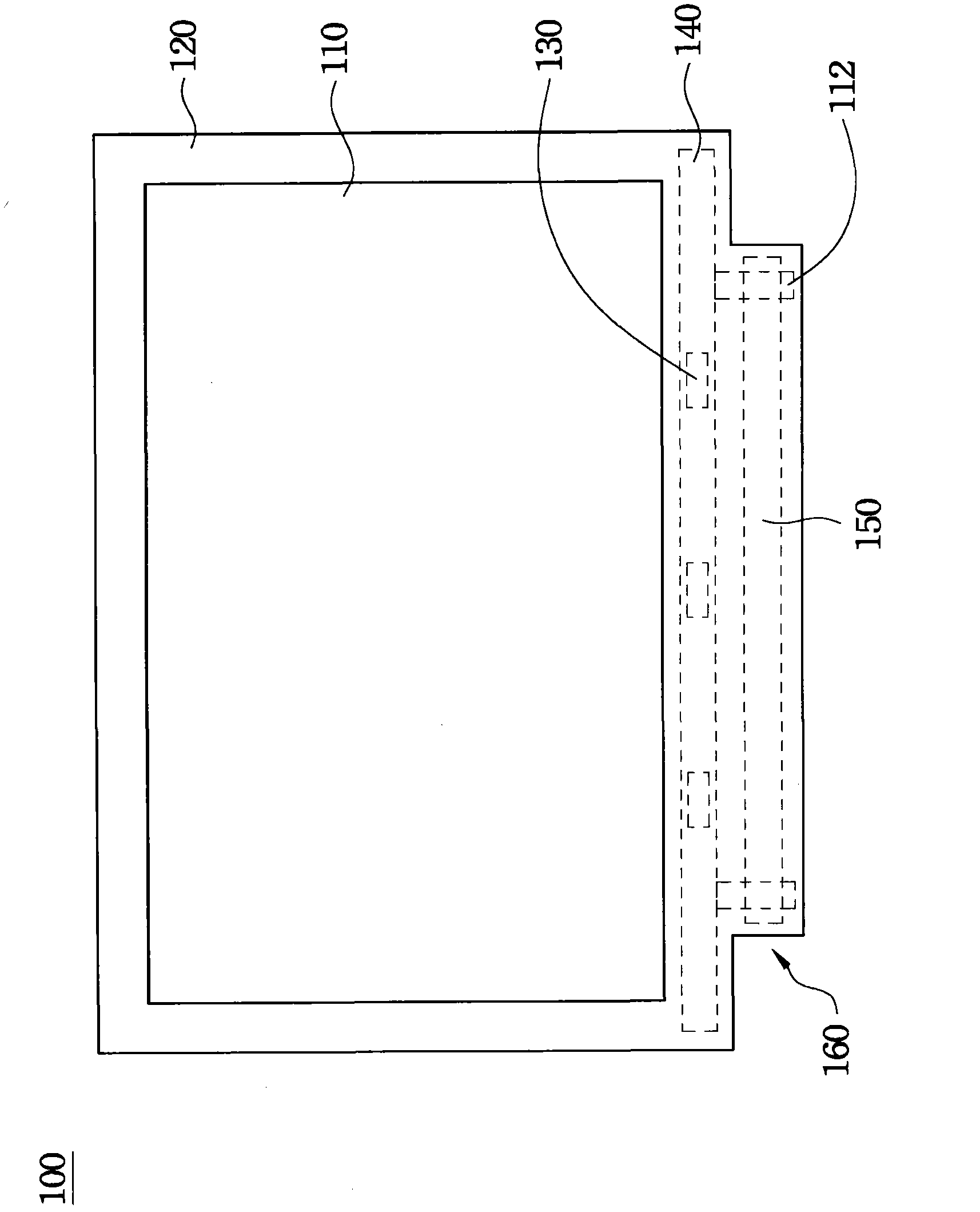

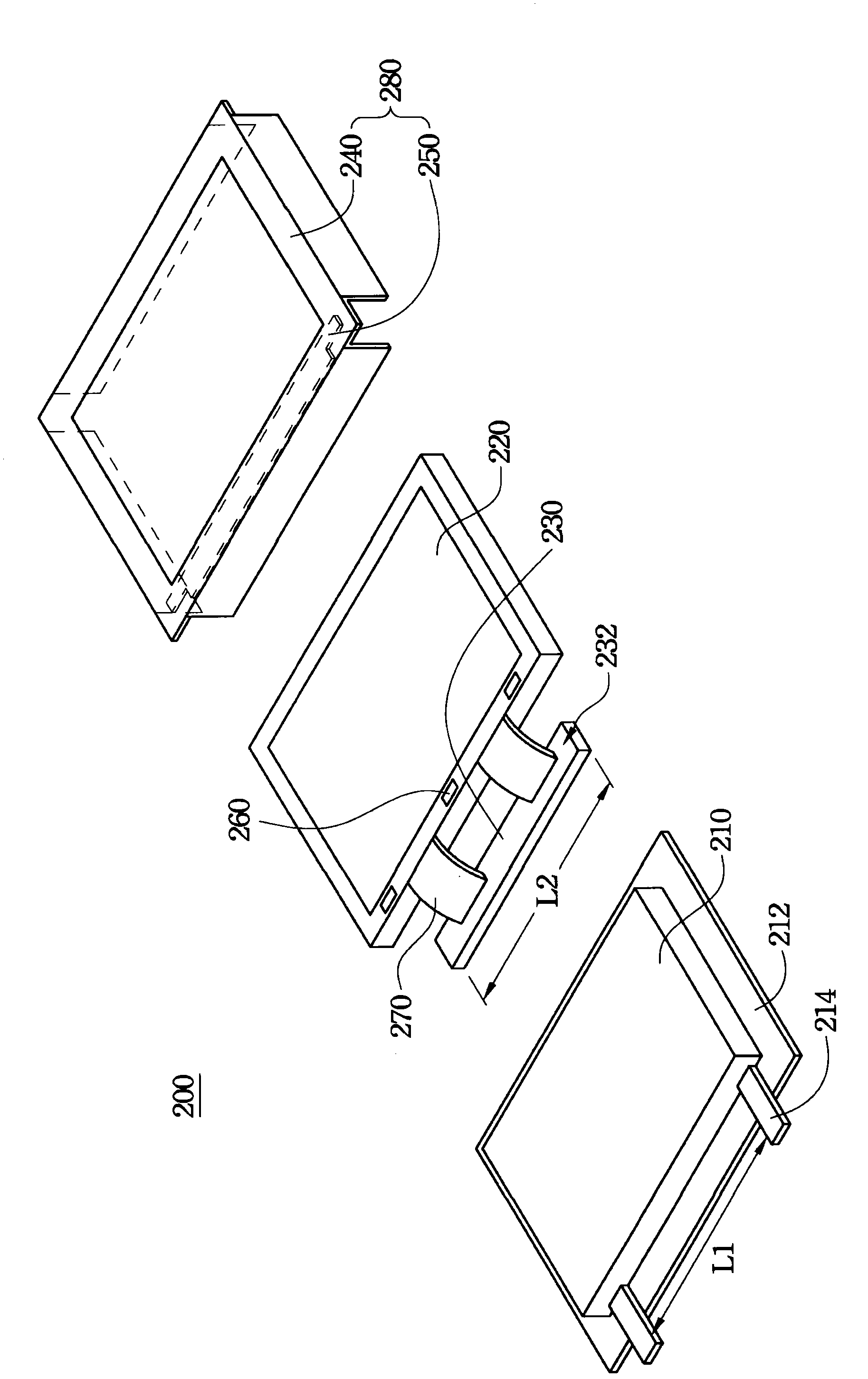

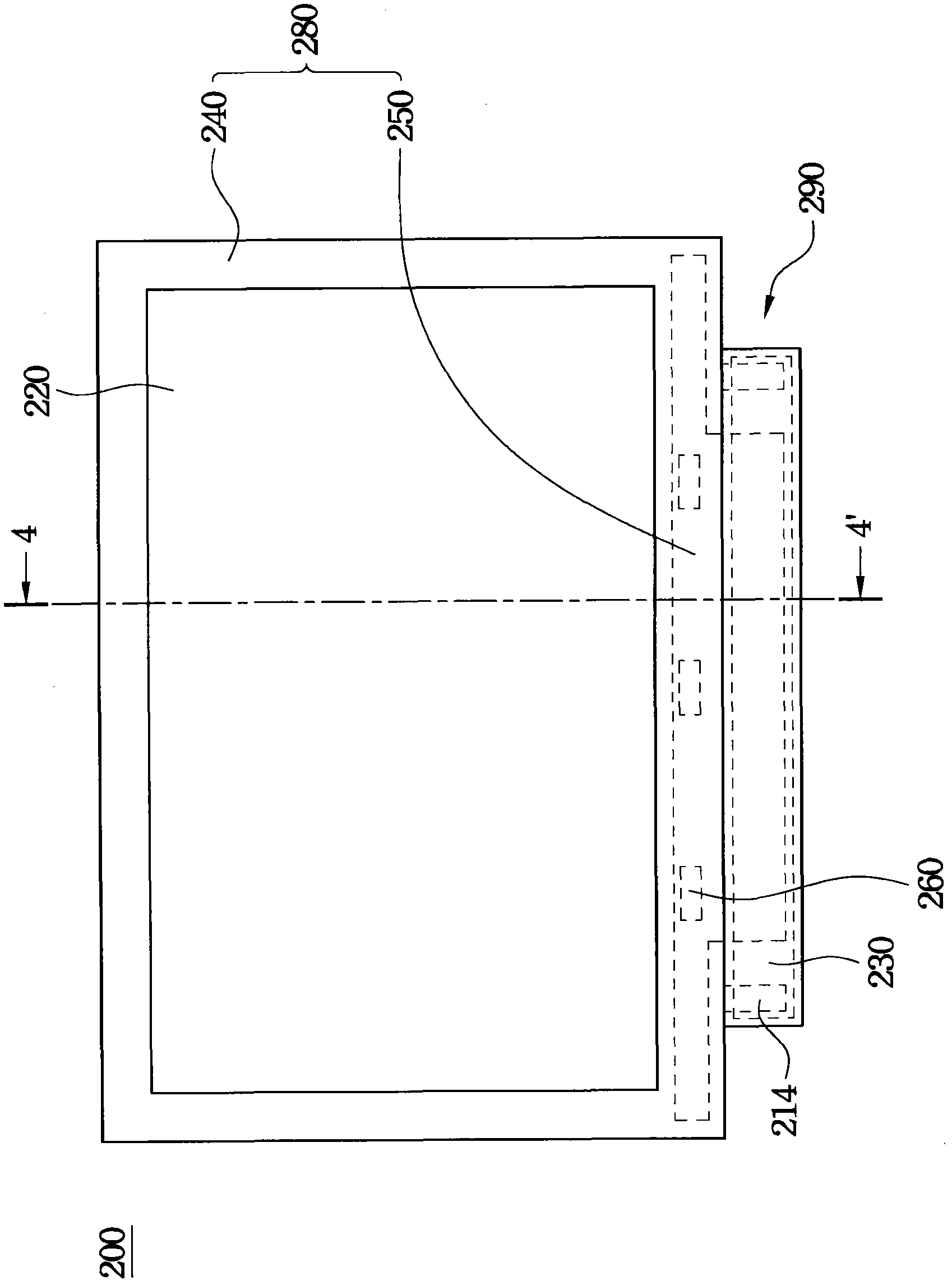

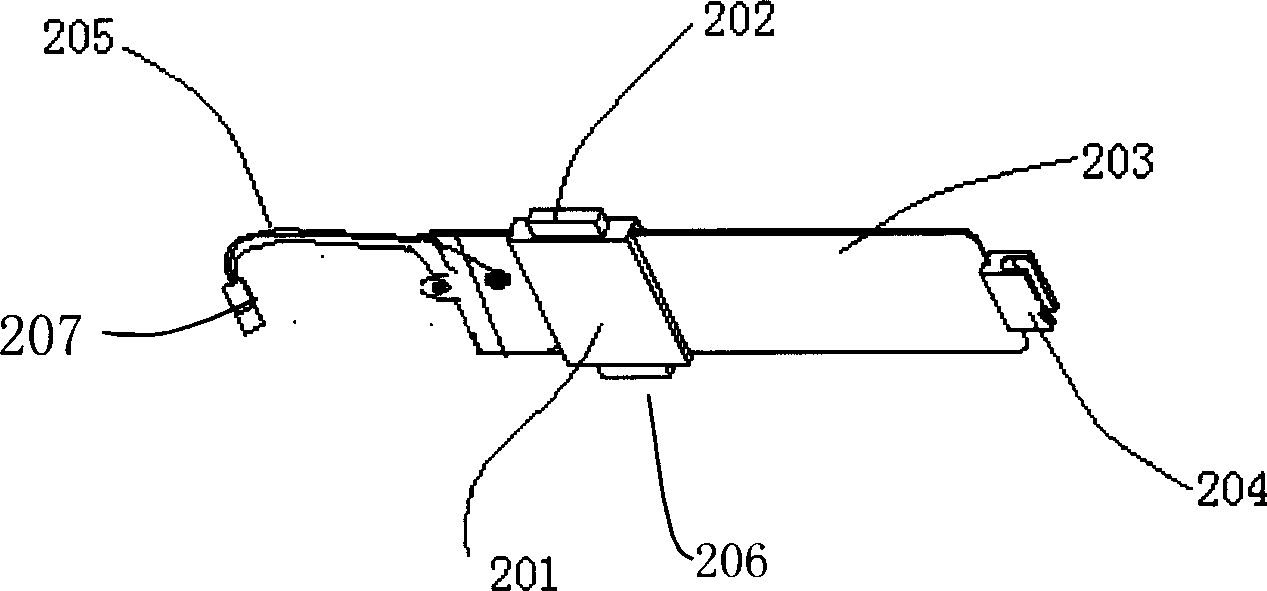

Display device and protective structure therefor

ActiveCN102621740ANot easy to break and damageStatic indicating devicesNon-linear opticsFlexible circuitsDisplay device

The invention discloses a display device and a protective structure therefor. The display device comprises a backlight module, a liquid crystal panel, a driving circuit board, and a light-shielding adhesive tape. The backlight module comprises a frame which forms two projecting portions. The liquid crystal panel is located on the backlight module. The driving circuit board has two end portions respectively fixed on the two projecting portions, and is electrically connected to the liquid crystal panel. The light-shielding adhesive tape is applied along edges of the liquid crystal panel and the backlight module, and has a reinforced material in contact with the liquid crystal panel. The reinforced material is also extended to a position close to the driving circuit board. According to the invention, the reinforced material is used to protect not only a chip on the liquid crystal panel, but also the driving circuit board and a flexible circuit board, so that the driving circuit board and the flexible circuit board are not easy to break or damage.

Owner:AU OPTRONICS CORP

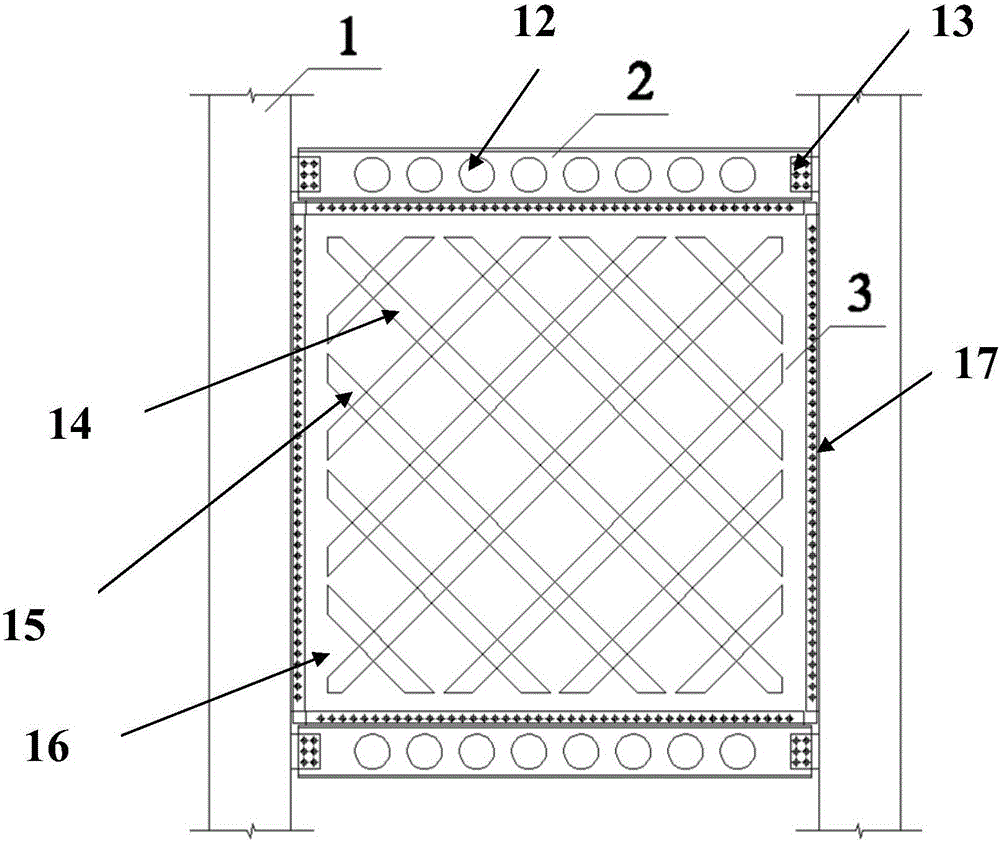

Prefabricated steel structure framework system

ActiveCN105951991AImprove energy consumptionIncrease the amount of deformationWallsGirdersStructure systemBeam column

A prefabricated steel structure framework system comprises stand columns, a steel beam and a shear wall slab. Each stand column comprises a pipe column formed by welding peripheral steel plates, a concrete-filled layer and reinforcing ribs, wherein the pipe column is filled with concrete to form the concrete-filled layer, and the reinforcing ribs are arranged on the inner walls of the peripheral steel plates. The tops of the stand columns are connected with the two ends of the steel beam through friction type high-strength bolts, the cross section of the steel beam is in an H shape, the steel beam comprises an upper flange plate, a lower flange plate and a web for connecting the upper flange plate and the lower flange plate, the web is provided with holes, and a pipeline is arranged through the holes in the web. The shear wall slab is hinged to the outer sides of the peripheral steel plates of the pipe columns and provided with inclined long-strip holes. Hinging is adopted for framework beam-column joints, vertically-distributed force and horizontally-distributed force in the framework shear wall structure system are separated, stress is definite, the energy dissipation performance of the joints is improved, the deformation of the joints is improved, and too early fracture damage of the joints is avoided.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

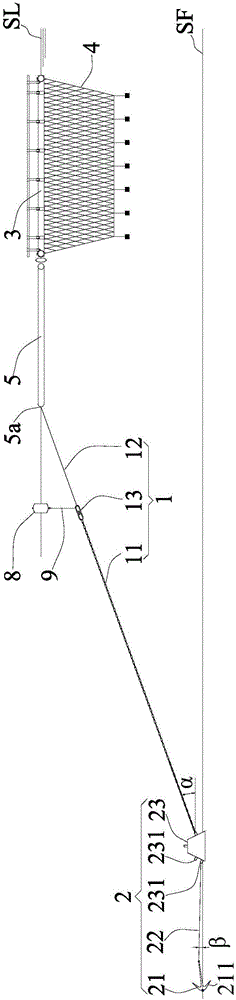

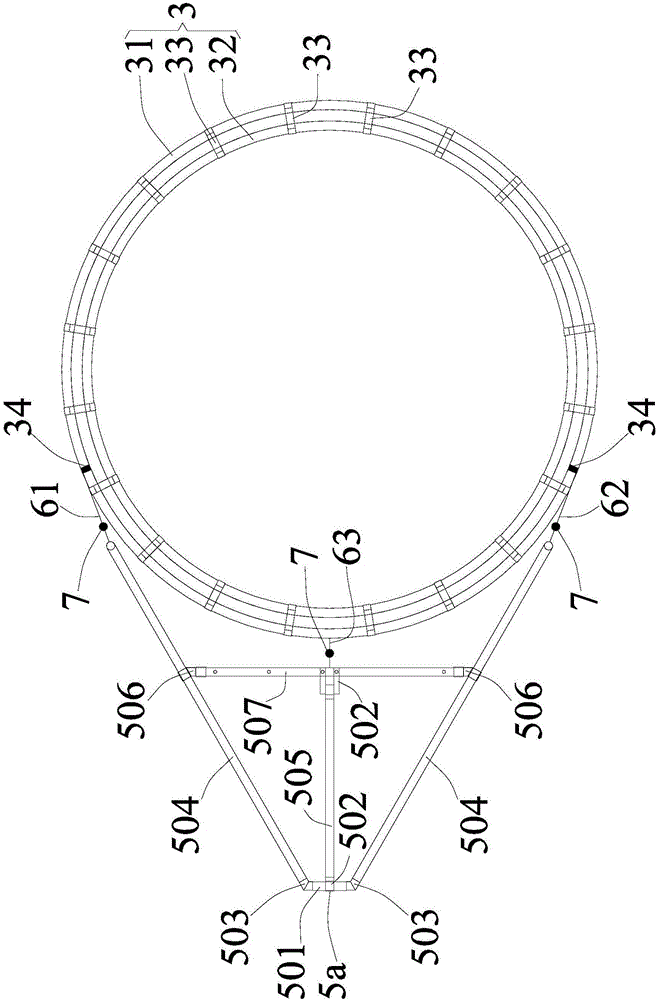

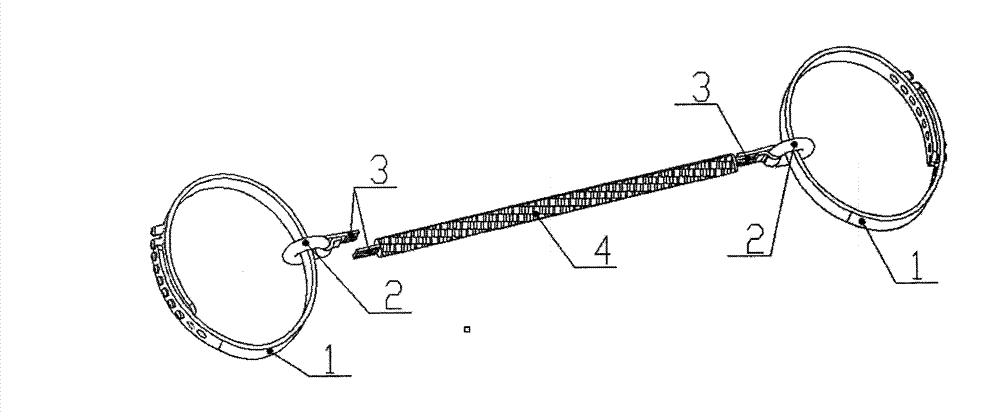

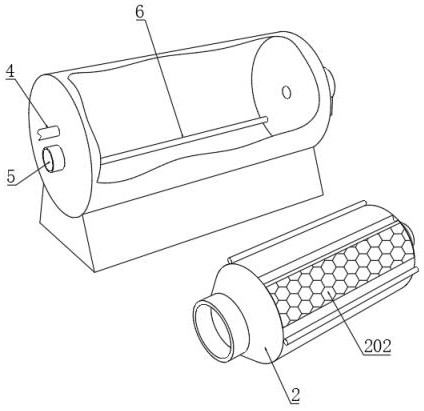

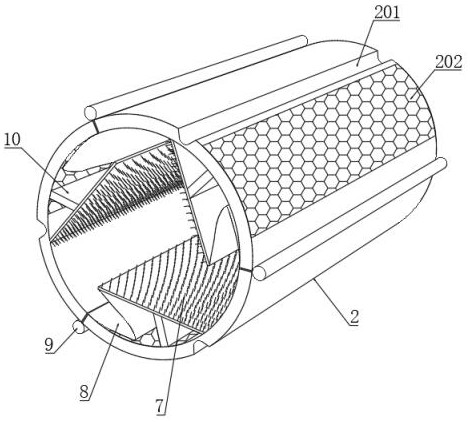

Single-point anchoring type round deep water net cage

ActiveCN106719218AEven by forceAvoid deformationClimate change adaptationPisciculture and aquariaEngineeringSingle point

The invention discloses a single-point anchoring type round deep water net cage. The net cage comprises a framework system, a single-point anchoring system and a netting system. The single-point anchoring system comprises a rope set and an anchoring mechanism, the framework system is provided with a round floating pipe framework, and the netting system is hung on the round floating pipe framework. The net cage is characterized in that the framework system is further provided with an A-like-shaped auxiliary floating pipe framework formed by connecting flowing pipes, the ends, connected with each other, of two bevel edges of the A-like-shaped auxiliary floating pipe framework serve as cage tying points of the framework system, the other ends of the two bevel edges of the A-like-shaped auxiliary floating pipe framework are connected with the round floating pipe framework through a first connection rope and a second connection rope, and the center of a transverse edge of the A-like-shaped auxiliary floating pipe framework is connected with the round floating pipe framework through a third connection rope. By means of the net cage, the round floating pipe framework is not likely to deform or be broken or damaged, and the net cage accords with work features of a single-point anchoring mode.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

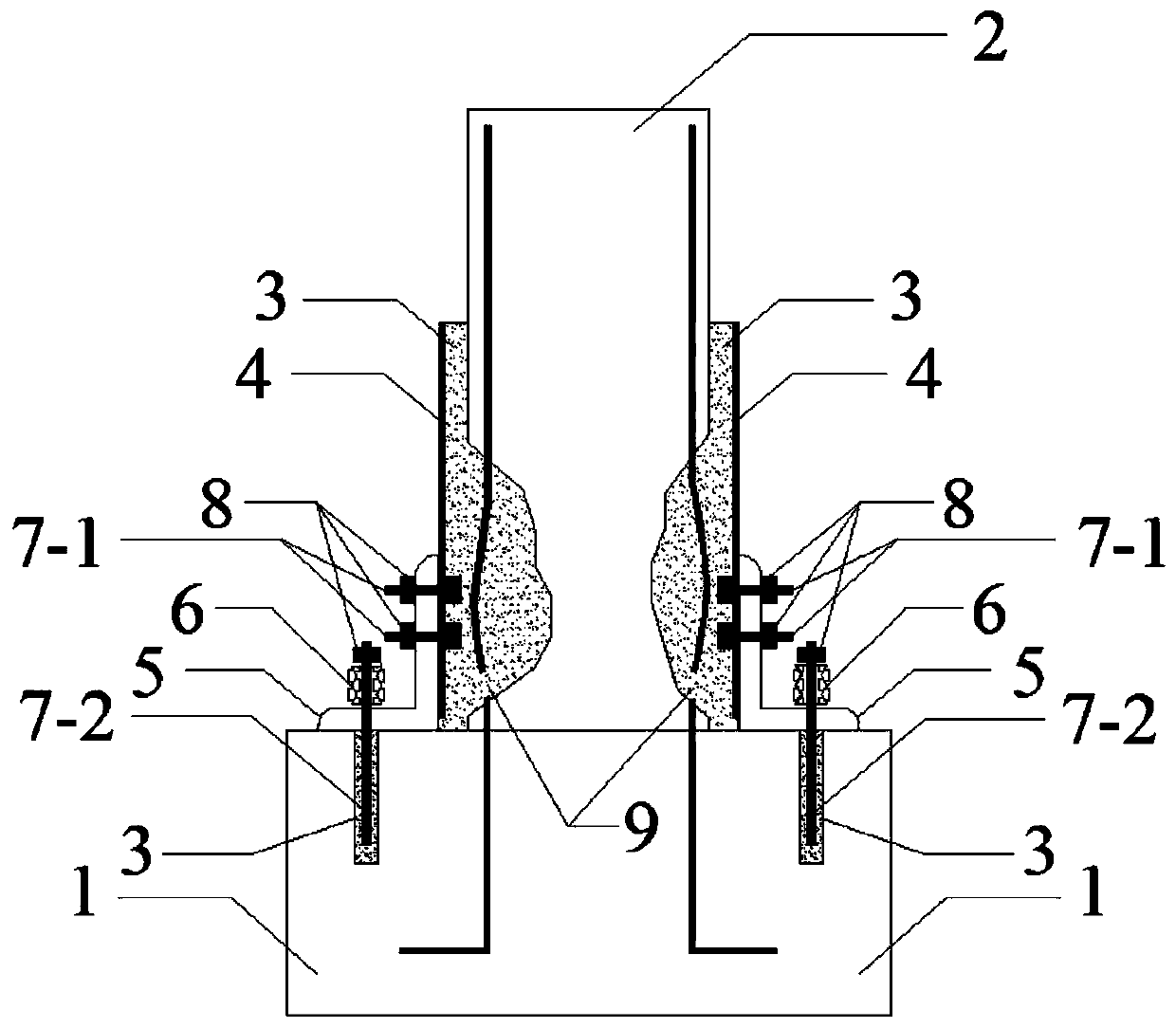

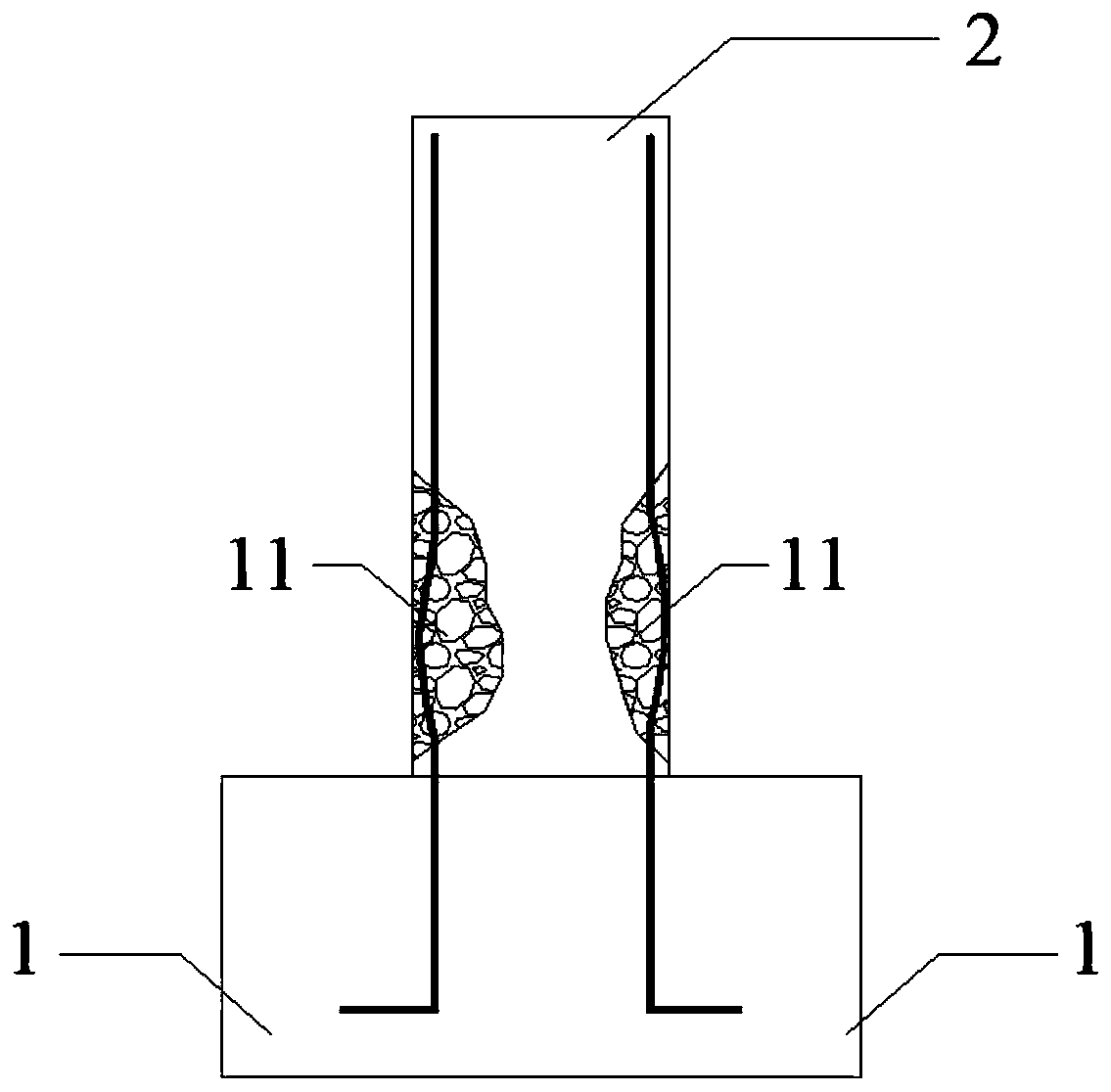

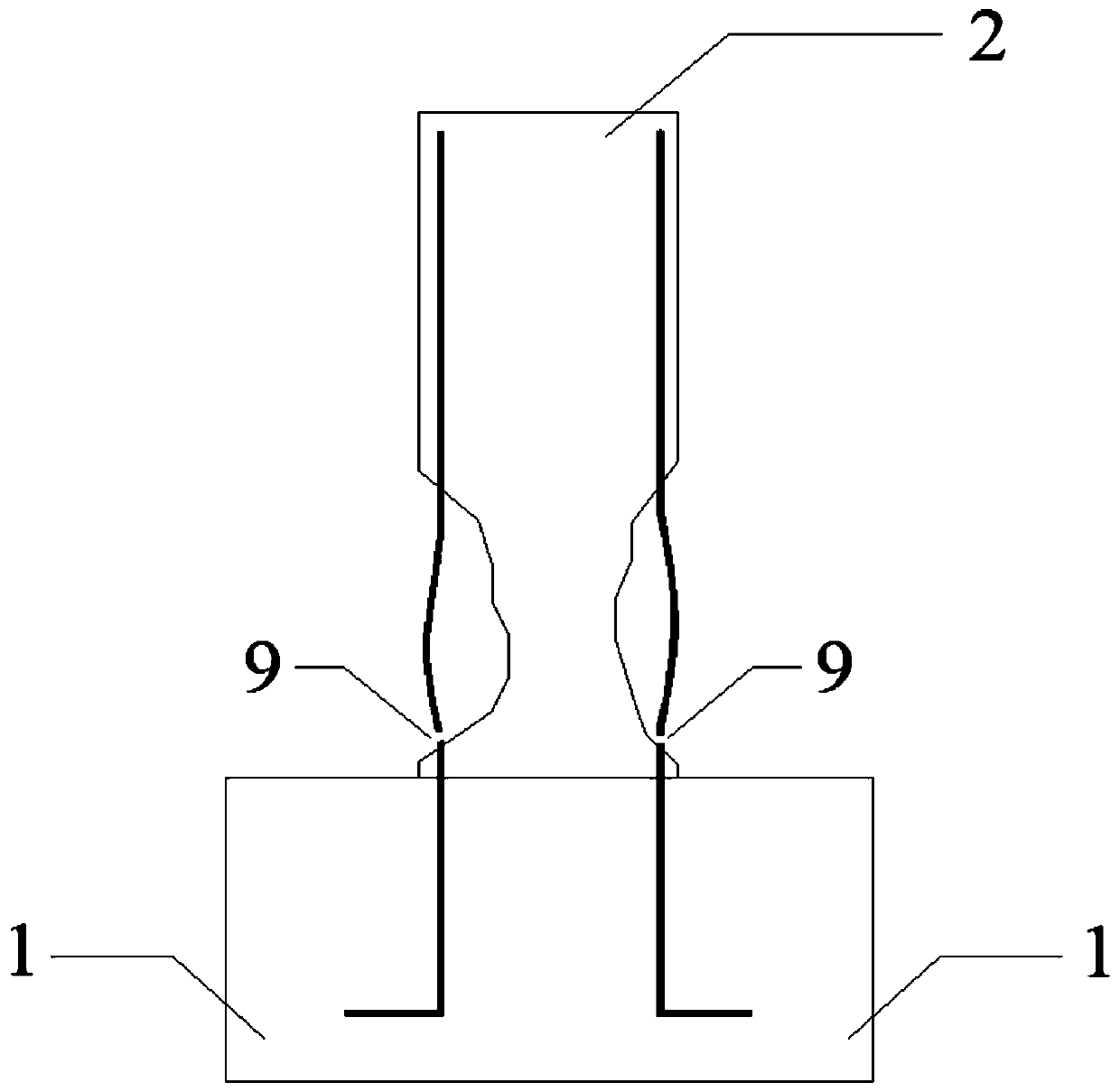

Method for quickly repairing reinforced concrete piers after earthquake

ActiveCN110067212AImprove seismic performanceImprove adhesionBridge structural detailsBridge erection/assemblyExternal energyRebar

The invention discloses a method for quickly repairing reinforced concrete piers after an earthquake, and belongs to the field of civil engineering. According to the method, a bearing platform, piers,high fluidity early strength cement mortar, stainless steel sleeves, energy dissipation angle steel, SMA combined ring springs, horizontal screws, vertical screws, high strength bolts, longitudinal reinforcement and polytetrafluoroethylene films are included. The idea of the method is to change the piers consolidated at original pier bases into swing piers. When repairing is carried out, damagedconcrete is removed first, and the longitudinal reinforcement in a plastic hinge area is cut off at the bottoms of the piers. The plastic hinge area is covered with the stainless steel sleeves, and the high fluidity early strength cement mortar is poured into the sleeve. The energy dissipation angle steel and the SMA combined ring springs form an external energy dissipation system. The method is simple in construction operation and short in required time, the repaired piers become swing systems, and thus re-damage of the repaired piers under strong earthquake is avoided. The stainless steel sleeves significantly improve the durability of repaired bridge piers. The external energy dissipation system has a self-resetting function, the damage of the angle steel is avoided, and the external energy dissipation system is simple and easy to repair.

Owner:INST OF DISASTER PREVENTION

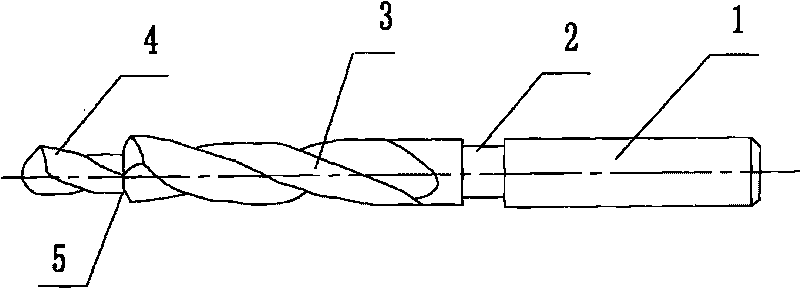

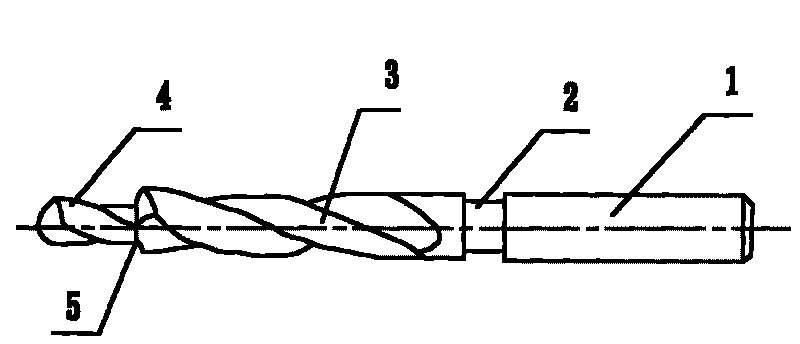

Multi-functional auger bit

InactiveCN101733450ANot easy to break and damageReduce labor intensityTwist drillsEngineeringSelf positioning

The invention discloses a multi-functional auger bit, comprising a handle portion, a neck portion and a working portion; wherein the working portion comprises a guide section and a cutting section and is characterized in that the cutting section is composed of a main blade and a rear tool face, the central part of the cutting section is provided with a small-diameter auger bit which extends to the outside, the small-diameter auger bit is provided with the guide section and the cutting section, the cutting section of the small-diameter auger bit is composed of the main blade, the rear tool face and a chisel edge, the central position of the chisel edge is provided with a positioning apex. Compared with the prior art, the multi-functional auger bit features self-positioning, easy operation and high processing efficiency, can form holes of different diameters at a time when in use and form larger holes at a time.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Improved type of needle selection unit of knitting machine

InactiveCN1696371AShorten the lengthReduce operating frequencyWeft knittingEngineeringMechanical engineering

The invention discloses a knitting machine needle selector driven by piezoelectric ceramic sheet. Said needle selector is formed from machine frame, piezoelectric ceramic driving sheet, positioning plate, needle-selecting blade, latch and cover plate. Said invention adopts the symmetric and parallel type piezoelectric ceramic sheets, and provides its concrete structure, and its working principle and its operation steps.

Owner:潘铁政

Spindle type USB connecting device

ActiveCN104241929AEven by forceNot easy to break and damageEngagement/disengagement of coupling partsCoupling contact membersEmbedded systemCoaxial line

The invention relates to a spindle type USB connecting device. The spindle type USB connecting device comprises a data line output end and a receiving end. The receiving end comprises a cylindrical chip capable of freely rotating around an axis. A plurality of metal pipes coaxial with the chip are distributed inside the chip at equal intervals and are isolated and fixed through insulating materials. Concentric ring metallic brushes are distributed on the part, making contact with the end face of the chip, on a product shell at equal intervals. A plurality of conducting rings are evenly distributed along the axis of the outer surface of the chip, and are connected with the metal pipes inside the chip respectively. The face, making contact with the chip at the receiving end, of the surface of the output end of a data line is a semi-circular cylindrical concave face, and conducting brushes matched with the conducting rings respectively are evenly distributed on the concave face. When an interface is used, the internal chip is not prone to fracture or damage, and the front face and the back face do not need to be distinguished during connecting.

Owner:东莞市长铭电子有限公司

Screen, screen manufacturing method and mobile electronic product

InactiveCN105204680AImprove reliabilityNot easy to break and damageInput/output processes for data processingTouch SensesEngineering

The invention relates to the technical field of electronics, in particular to a screen, a screen manufacturing method and a mobile electronic product. The screen comprises a cover plate layer, a touch sensing layer and a display layer. The display layer at least comprises an upper glass substrate layer and a lower glass substrate layer. The lower glass substrate layer is provided with a protruding portion protruding out of the upper glass substrate layer. A gap is formed between the protruding portion and the touch sensing layer. A protective gasket is arranged in the gap. The mobile electronic product comprises the screen. The screen manufacturing method comprises the steps that the cover plate layer, the touch sensing layer and the display layer are provided, wherein the display layer at least comprises the upper glass substrate layer and the lower glass substrate layer; the protective gasket is arranged on the protruding portion of the lower glass substrate layer; the cover plate layer, the touch sensing layer and the display screen are combined together from top to bottom. The screen and the mobile portable electronic product with the screen are not likely to be broken when impacted by external force, and the reliability of the screen is improved.

Owner:VIVO MOBILE COMM CO LTD

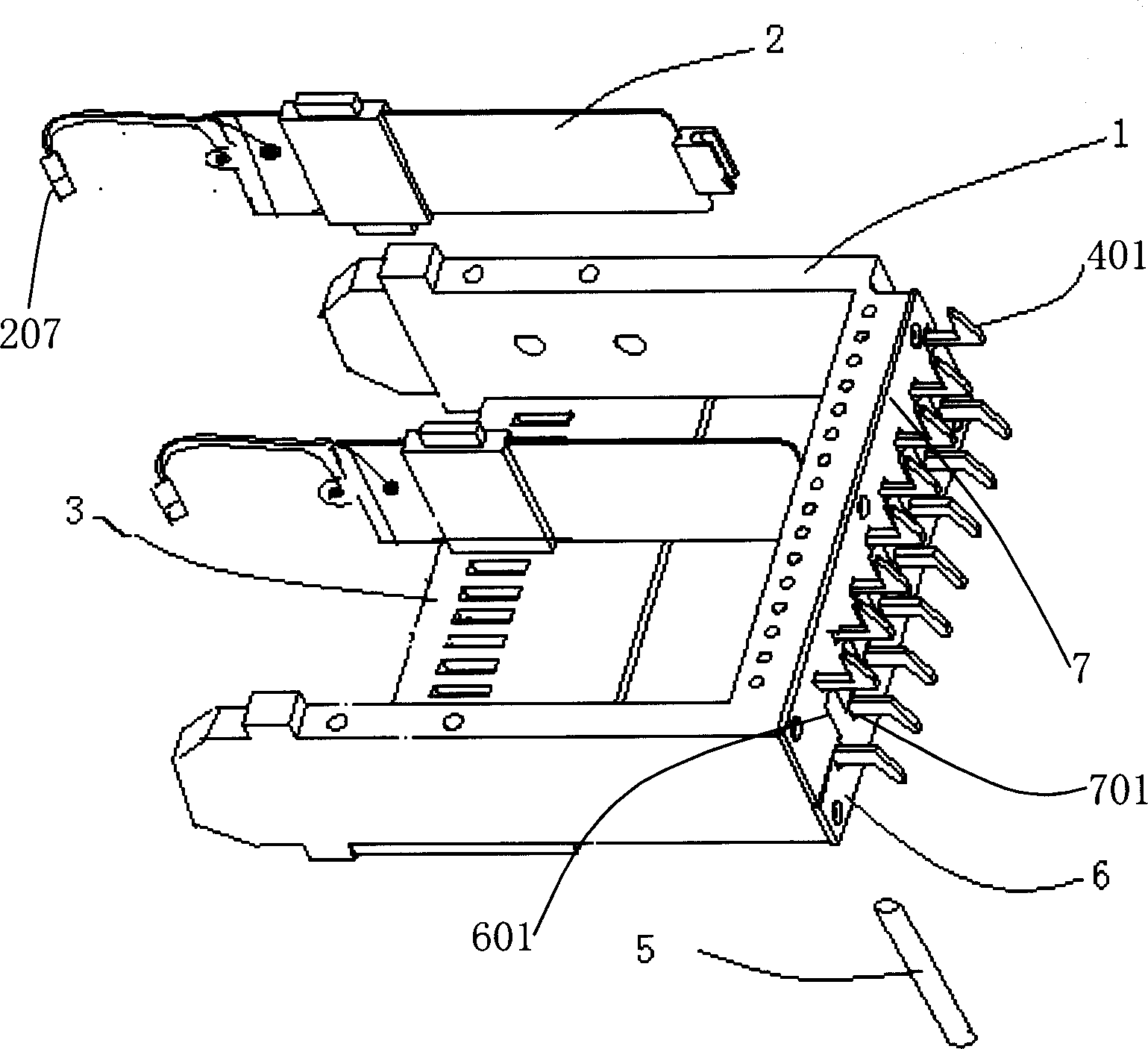

Heat dissipation type single/double-fiber pluggable optical module and assembling method thereof

ActiveCN112285848AImprove thermal conductivityConsistent heating temperatureCoupling light guidesOptical ModuleData transmission

The invention relates to a heat dissipation type single / double-fiber pluggable optical module and an assembling method thereof. The optical module comprises a shell cover, a module circuit board, a base and an outer clamping fastener; the side edge of the module circuit board is clamped and fixed between the shell cover and the base to form two heat convection channels above and below the module circuit board, a heat conduction boss in the shell cover and the outer clamping fastener with a specific structure are utilized, the heat conduction boss is thermally coupled with a chip heating body,and the outer clamping fastener is attached to the shell cover in a heat conduction mode, and is buckled with the base in a heat conduction mode. A heat conduction path from the heat conduction boss to the base through the outer clamping fastener is established, the heat conduction path is an annular path surrounding the two heat convection channels, the air cooling type heat dissipation efficiency of a single / double-fiber pluggable optical module product is improved, and the optical module is suitable for data transmission of high-speed communication.

Owner:SHENZHEN OPTIC KING TECH

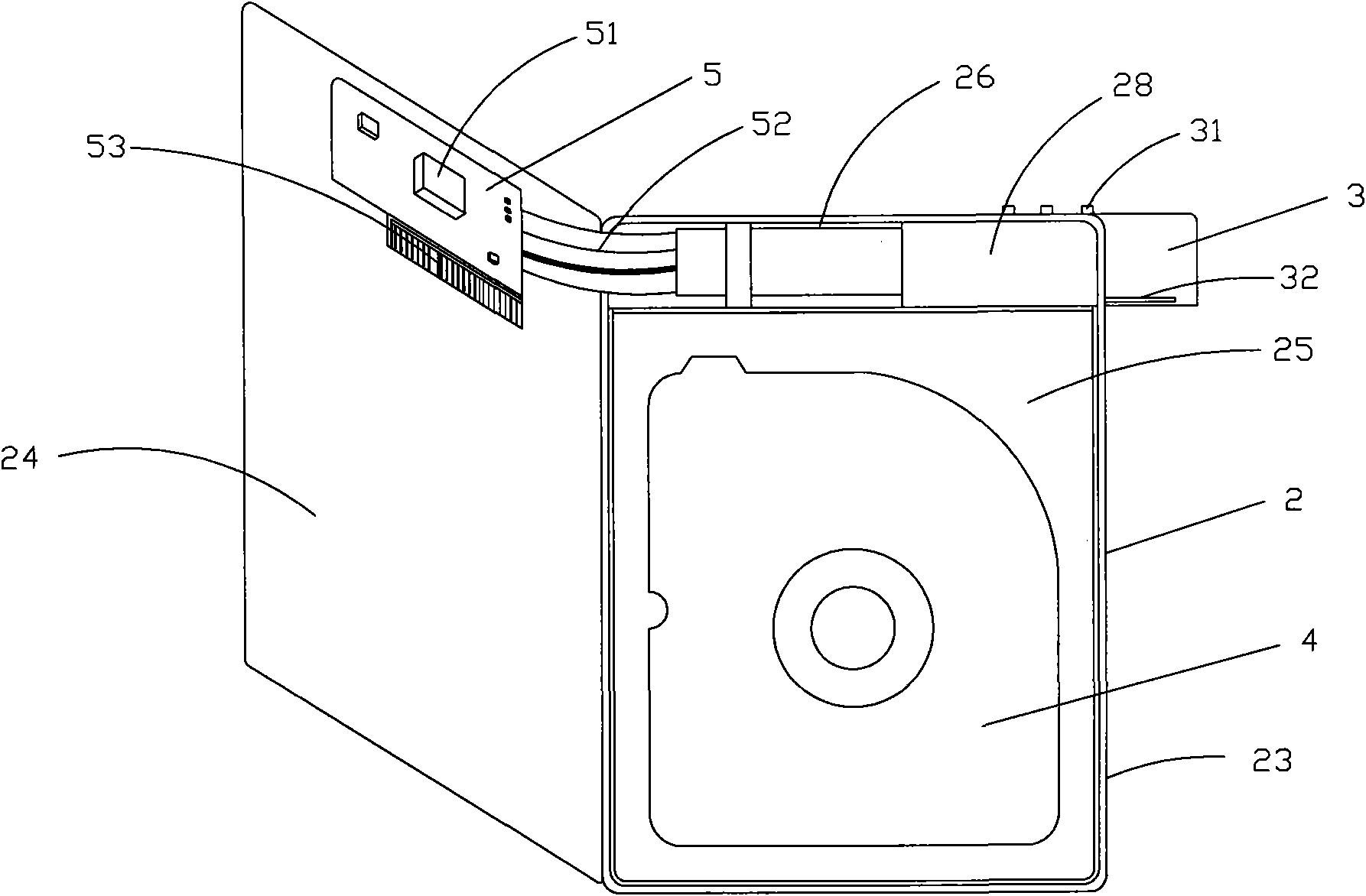

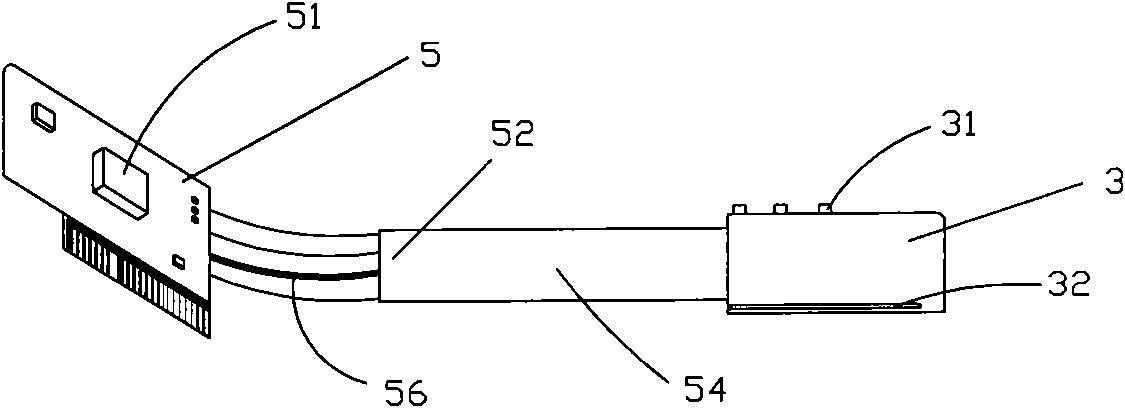

Mobile hard disc

InactiveCN101615419AAdjustable launch lengthNot easy to break and damageCarrier constructional parts dispositionCarrier casesIntegrated designEngineering

The invention relates to a mobile hard disc, which comprises a shell, an opening positioned on the shell, a moveable USB male which is led out from the inside of the shell through the opening, a hard disc accommodated in the shell and a flexible PCB electrically connected with the hard disc, wherein the flexible PCB comprises a hard disc control chip and a circuit and is provided with a slender extension part taken as a USB data wire connected with the USB male; and the USB data wire is bent and accommodated in the shell and is pulled out or pushed in the shell along with the USB male through the opening. The mobile hard disc has the advantages that: firstly, the USB male has a moveable structure and is accommodated in the shell, and in use, the USB male is pushed out from the opening and is connected through the flexible USB data wire which is not easy to break off and damage; secondly, the mobile hard disc is designed by the flexible PCB so as to facilitate the lightness and thinness; thirdly, the mobile hard disc is used for the integrated design of the flexible PCB controlled by the hard disc and the USB data wire so as to improve the production efficiency; and finally, the USB male adopts the unshielded design so as to save the space.

Owner:李凯

High-strength wear-resistant cable material and preparation method thereof

InactiveCN107033492AImprove tensile strengthGood wear resistancePlastic/resin/waxes insulatorsMaleic anhydrideCarbon black

The invention discloses a high-strength wear-resistant cable material. The high-strength wear-resistant cable material comprises the following raw materials by weight: 85-89 parts of polyvinyl chloride, 24-28 parts of nitrile rubber, 18-22 parts of polyvinylidene difluoride, 10-14 parts of datolite, 7-10 parts of silicon carbide fiber, 3-6 parts of polyhexylenediamine, 2-5 parts of triisonyl triglyceride, 4-8 parts of dimethyl methylphosphonate, 2-5 parts of carbon black, 1-2 parts of polystyrolsulfon acid, 8-12 parts of aluminium hydroxide, 4-7 parts of magnesium stearate, 1-3 parts of an antioxidant, 1-2 parts of an antiager, and 2-5 parts of polyethylene grafted maleic anhydride. The invention further discloses a preparation method for the high-strength wear-resistant cable material. The prepared cable material has the high tension resistance strength, good wear-resisting property, and extensive market prospect.

Owner:DONGGUAN JUNHAO WIRE TECH CO LTD

Ecological pipe network connecting port supporting device and construction method thereof

ActiveCN111503369APlay a supporting rolePlay a guiding rolePipe supportsPipe laying and repairButt jointScrew thread

The invention discloses an ecological pipe network connecting port supporting device and a construction method thereof. The ecological pipe network connecting port supporting device comprises a bottomplate, a first fixing frame and a second fixing frame, the first fixing frame and the second fixing frame are each provided with a fixing assembly, the bottom plate is provided with a sliding rail, the second fixing frame is provided with a sliding block, the sliding block is arranged on the sliding rail and slidably connected with the sliding rail, the second fixing frame is provided with a threaded rod, the first fixing frame is provided with a nut, the nut is rotationally connected with the first fixing frame, and the threaded rod penetrates through the first fixing frame to be in threadedconnection with the nut. The method comprises the steps of a, foundation pit excavation; b, fixing a supporting device; c, adjusting the supporting device; d, pipeline preparation; e, pipeline welding; and f, backfilling. The pipeline connecting port can be supported, the strength of the connecting port is improved, the connecting port is not prone to breakage, meanwhile, butt joint between pipelines can be facilitated through the supporting device, the butt joint effect of the connecting port is improved, the method is easy, convenient and rapid to construct, and the construction efficiencyand construction quality can be effectively improved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

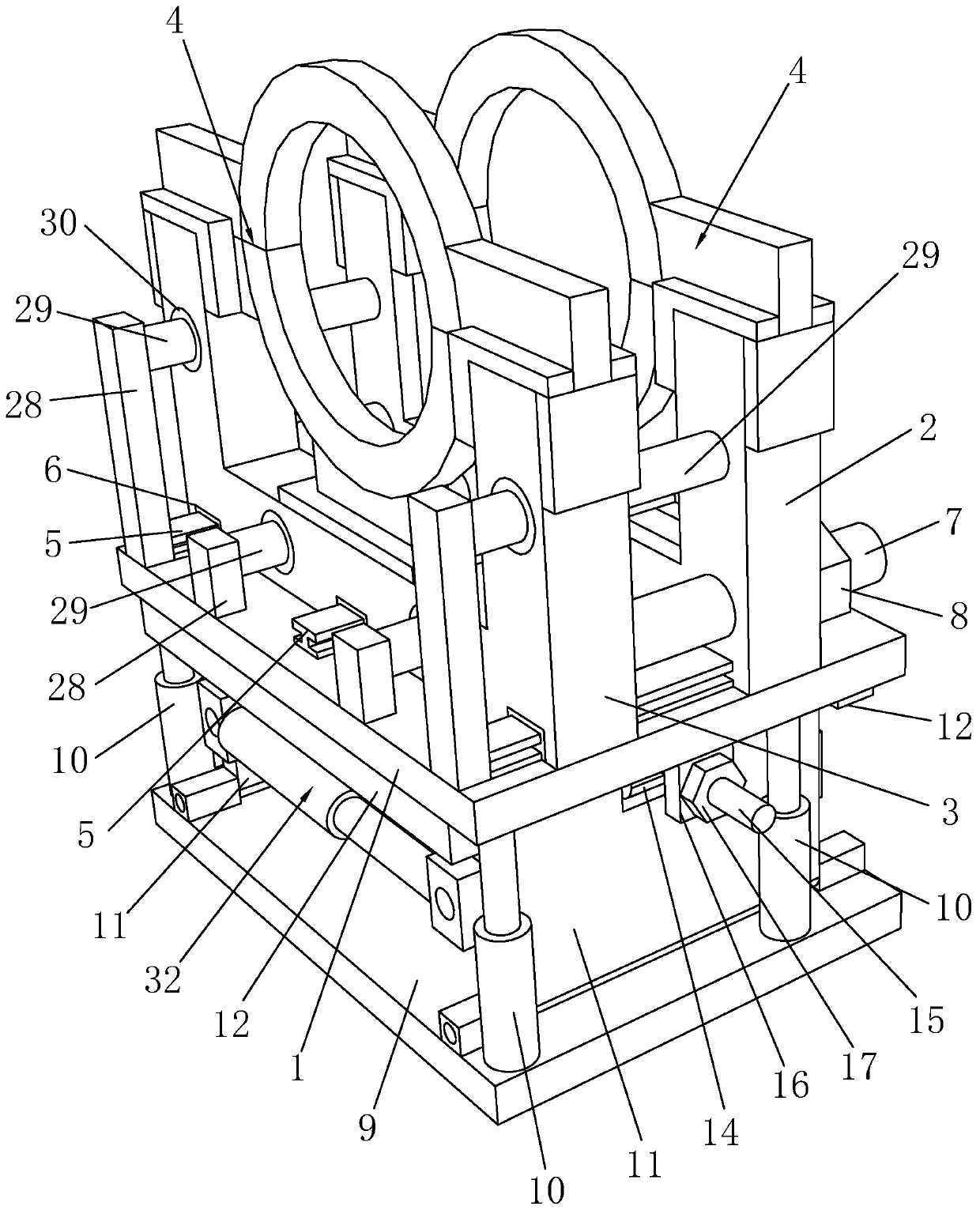

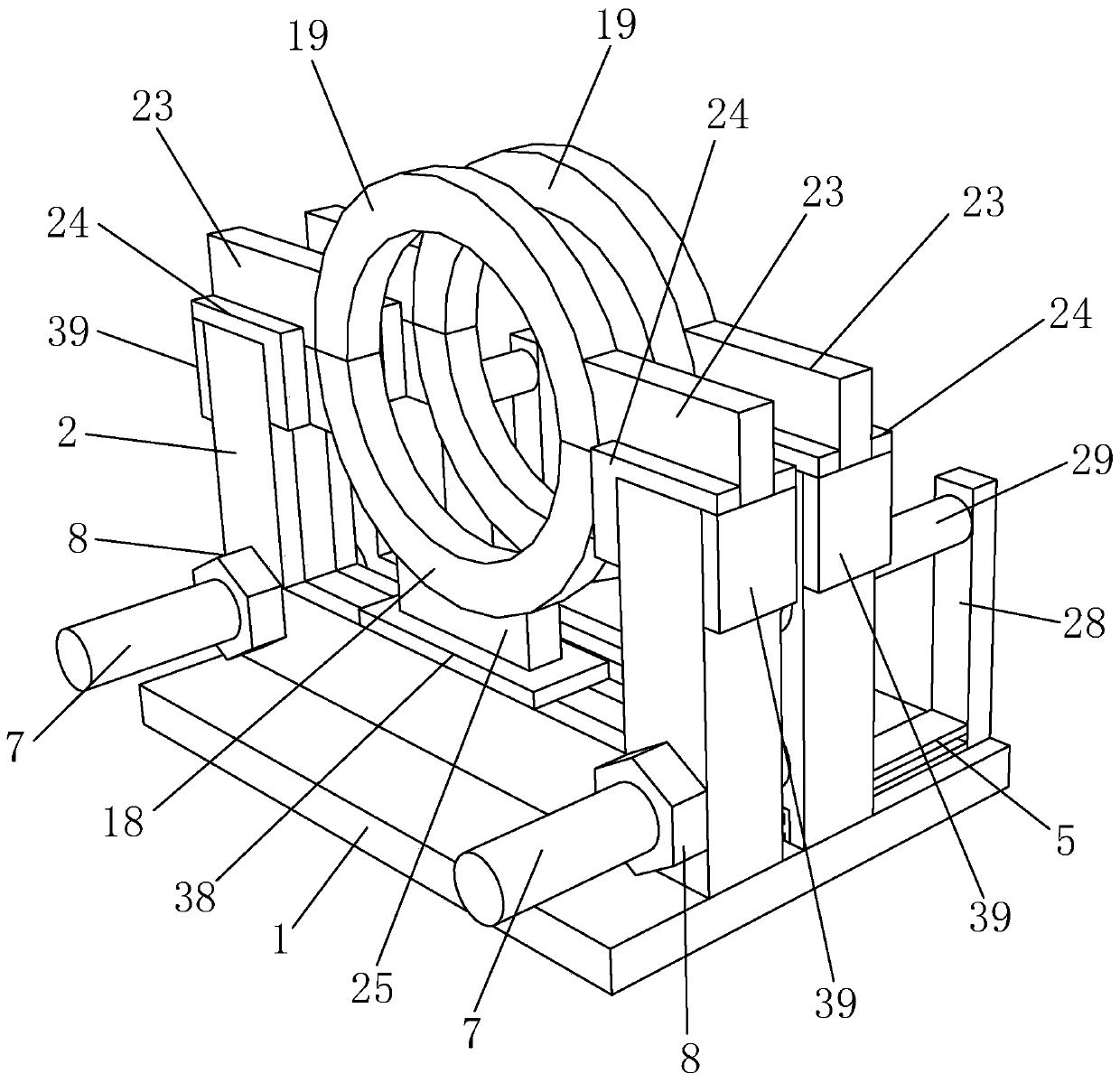

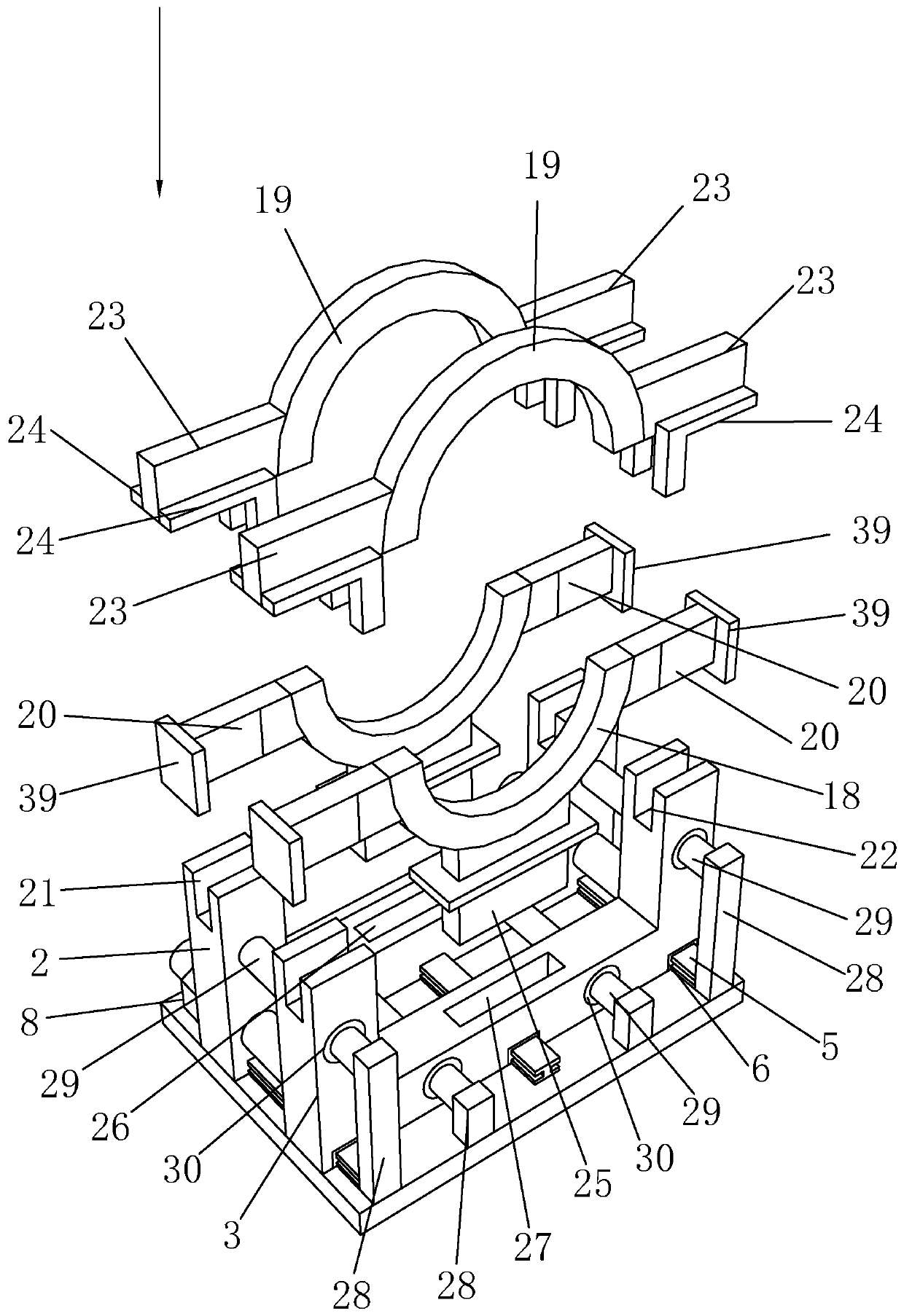

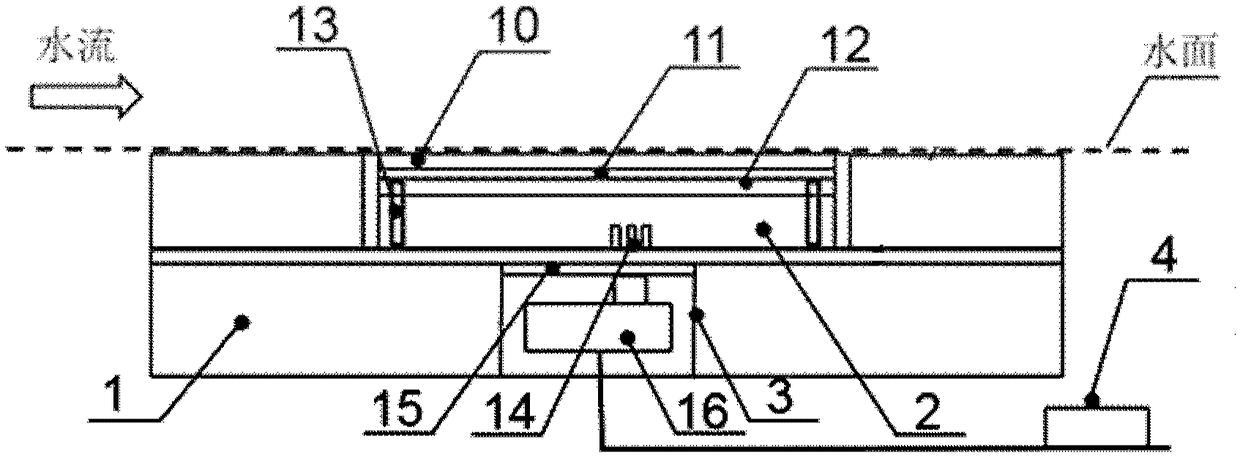

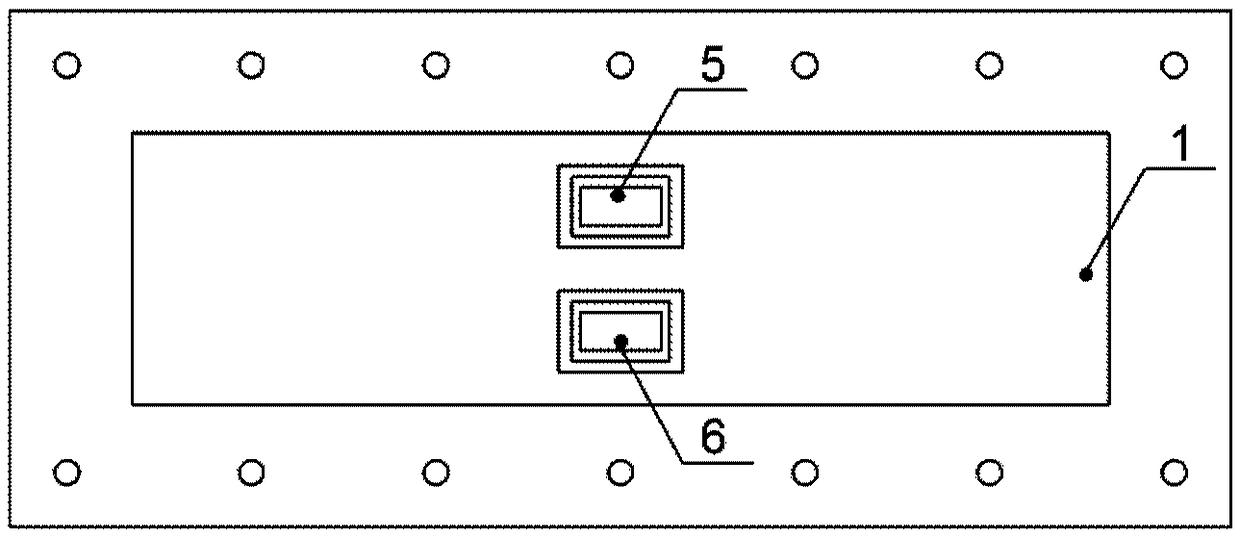

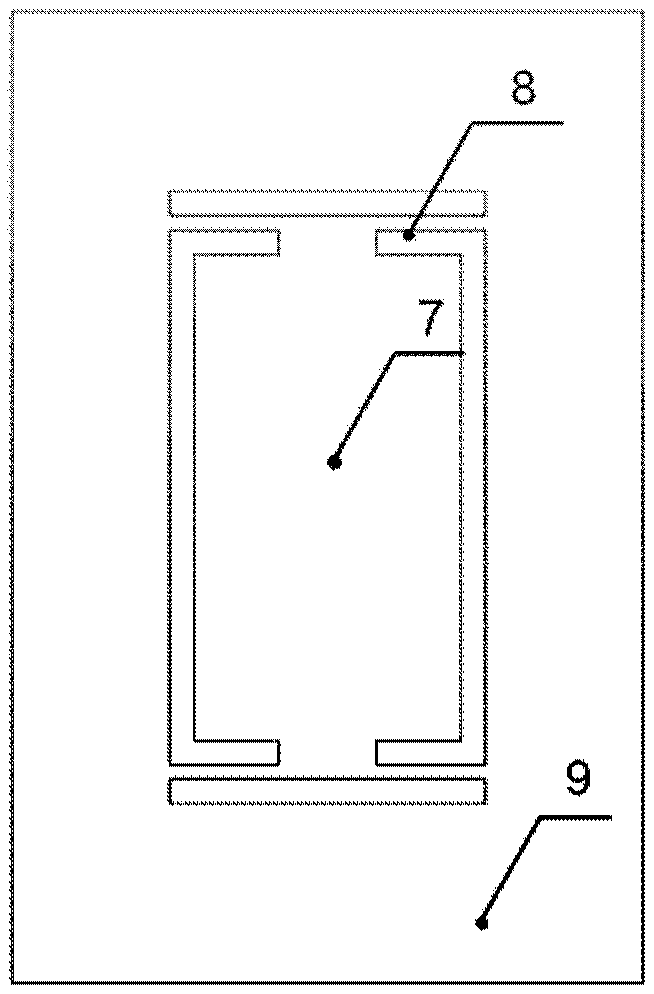

Frictional resistance measuring system and method based on flexible micro beam

PendingCN108955956AIncreased frictional resistance measurement rangeHigh sensitivityForce measurementFluid pressure measurementTest sampleEngineering

A frictional resistance measuring system based on a flexible micro beam comprises a medium platform, a measuring module, and a data processing module. The interior of the medium platform is filled with a fluid medium, the bottom of the medium platform is provided with openings, to-be-tested samples are placed inside the openings, and the fluid medium flows through the to-be-tested samples; the measuring module is located under the to-be-tested samples, the measuring module comprises a flexible micro beam and a floating plate, the flexible micro beam supports the floating plate, the to-be-tested samples are fixed on the floating plate, because the surfaces of the to-be-tested samples are subjected to the fluid frictional resistance in the fluid medium, the to-be-tested samples and the microbeam are enabled to generate displacement along the flow direction, and the measuring module is used to measure the displacement; and the data processing module displays the displacement and determines the frictional resistance according to the displacement. The system can measure the frictional resistance of the to-be-tested samples according to the displacement in the flow direction generated by the to-be-tested samples and the micro beam, and has advantages of high sensitivity, high dynamic response, less interference by external temperature and pressure, easy calibration, high measurementprecision, and the like.

Owner:PEKING UNIV

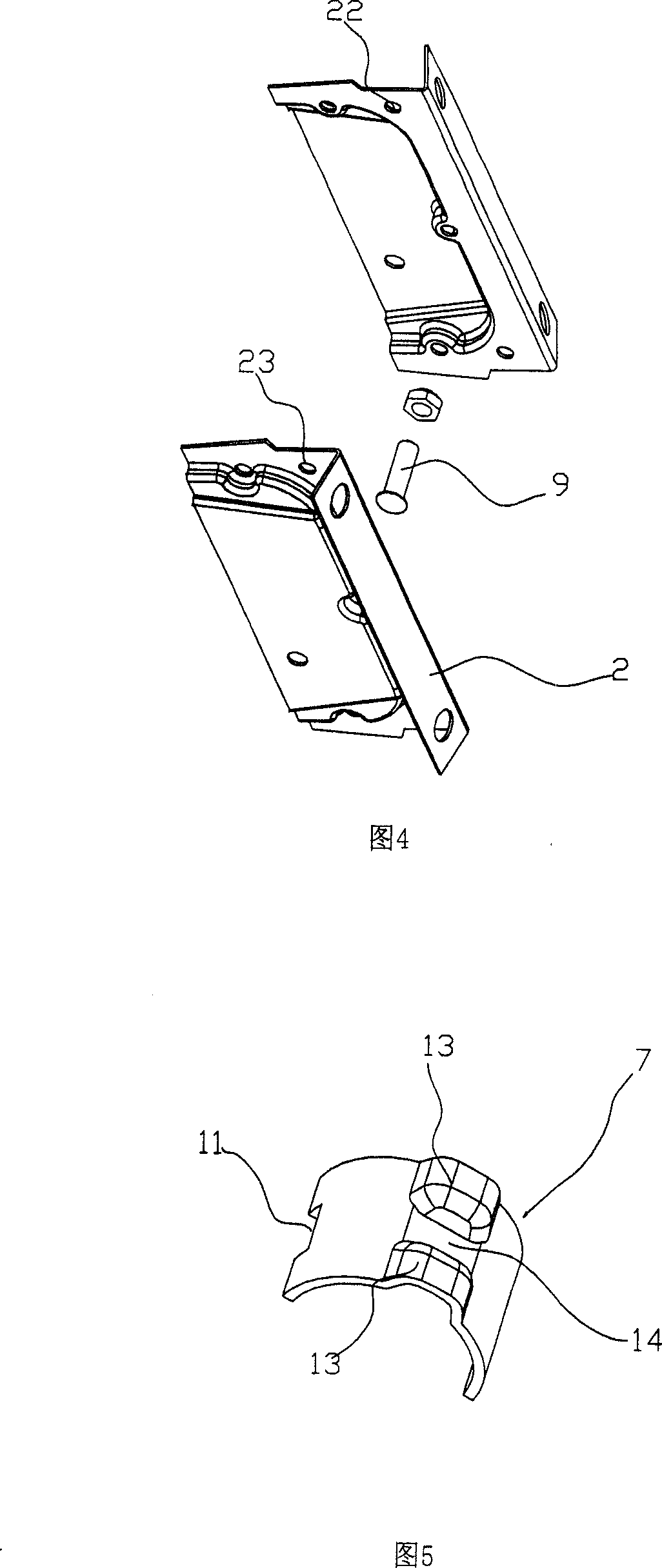

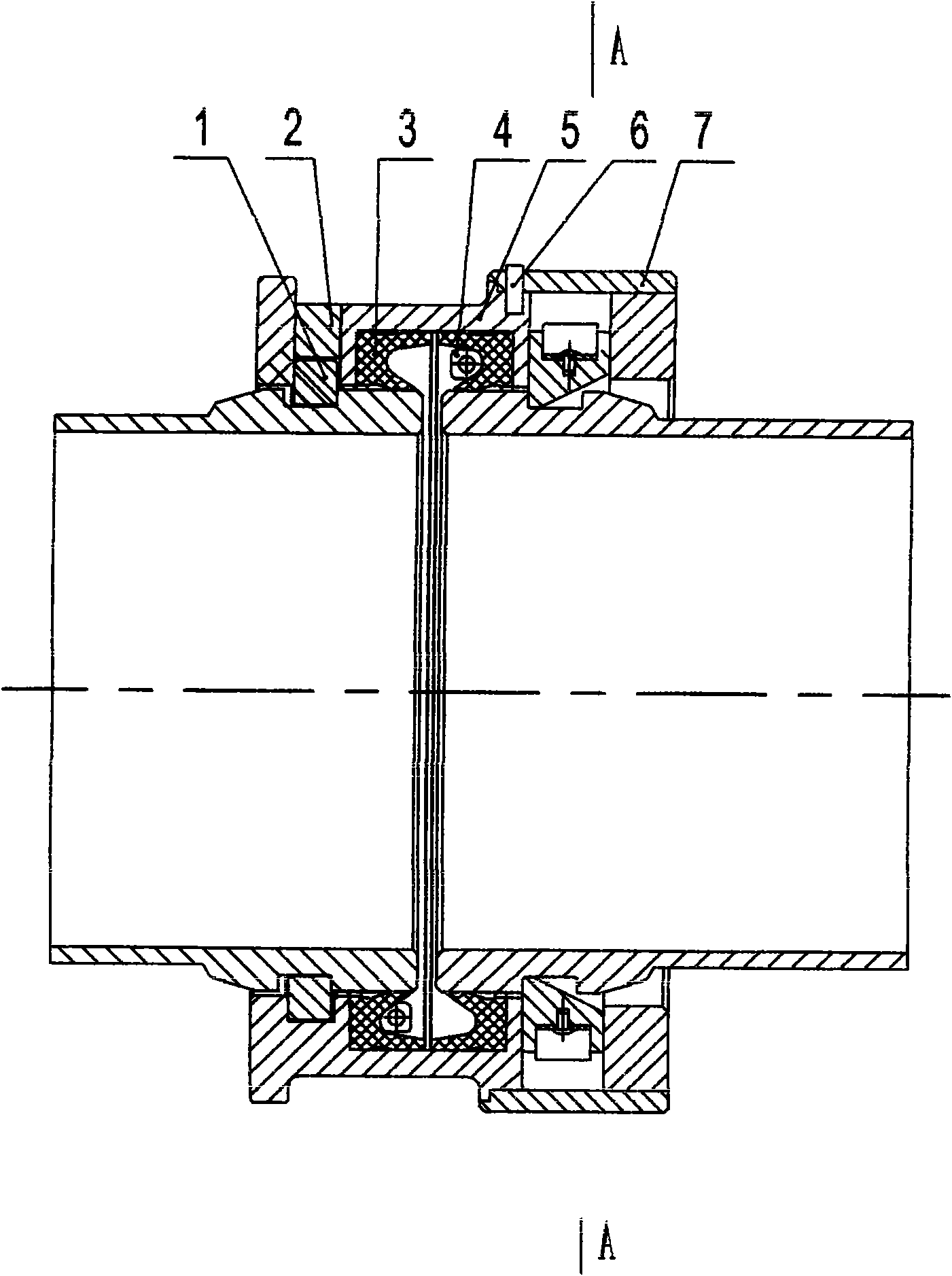

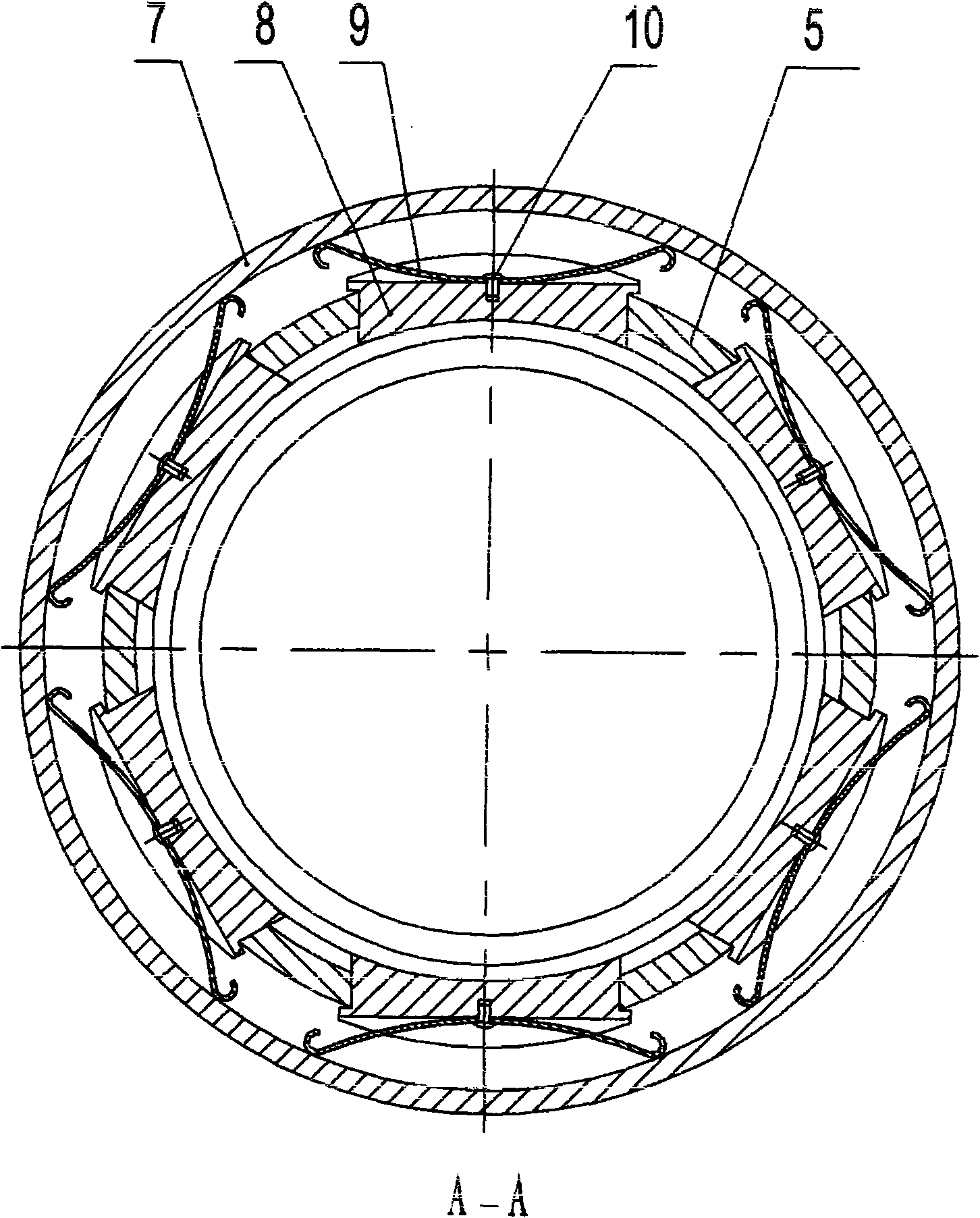

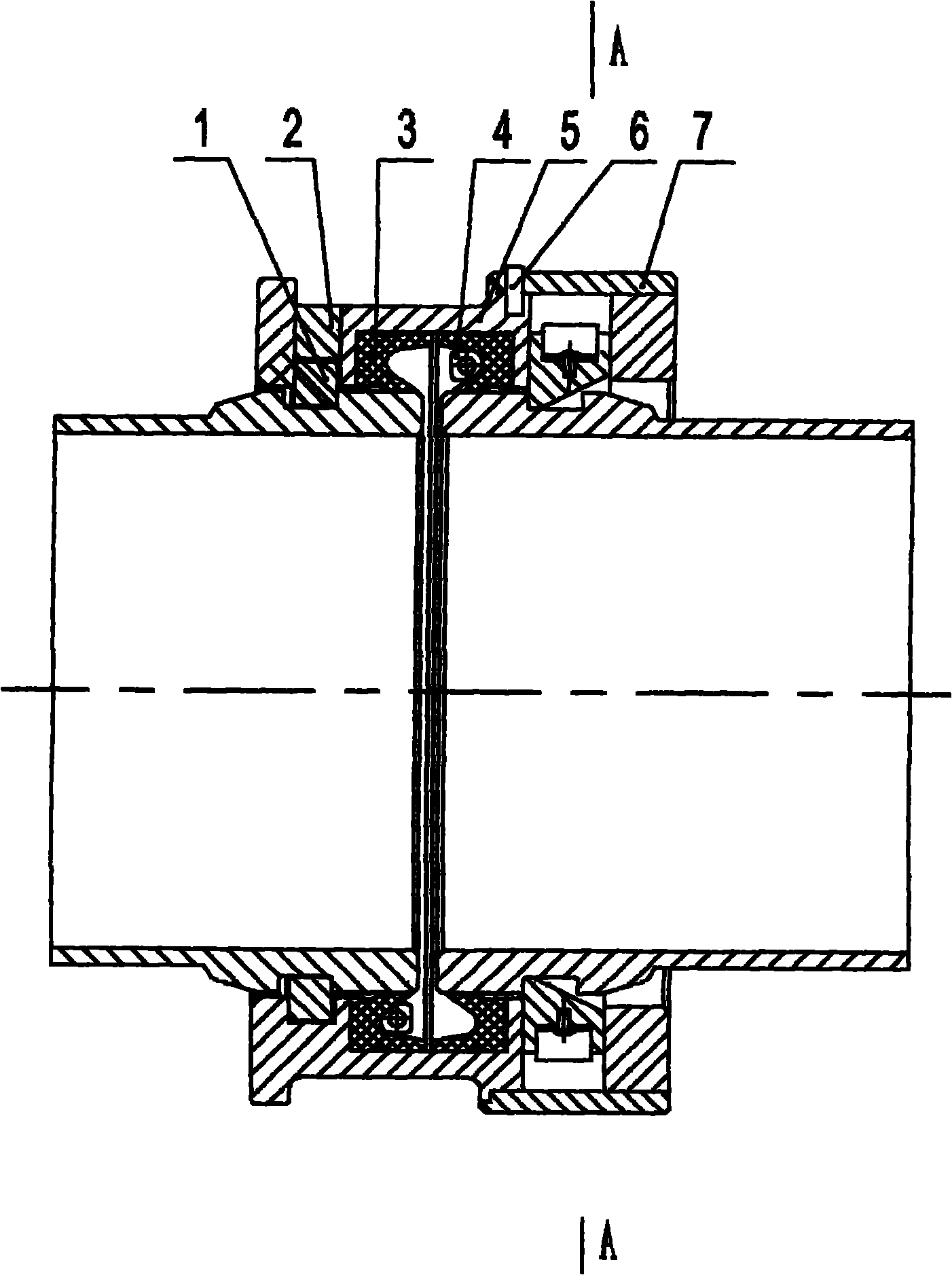

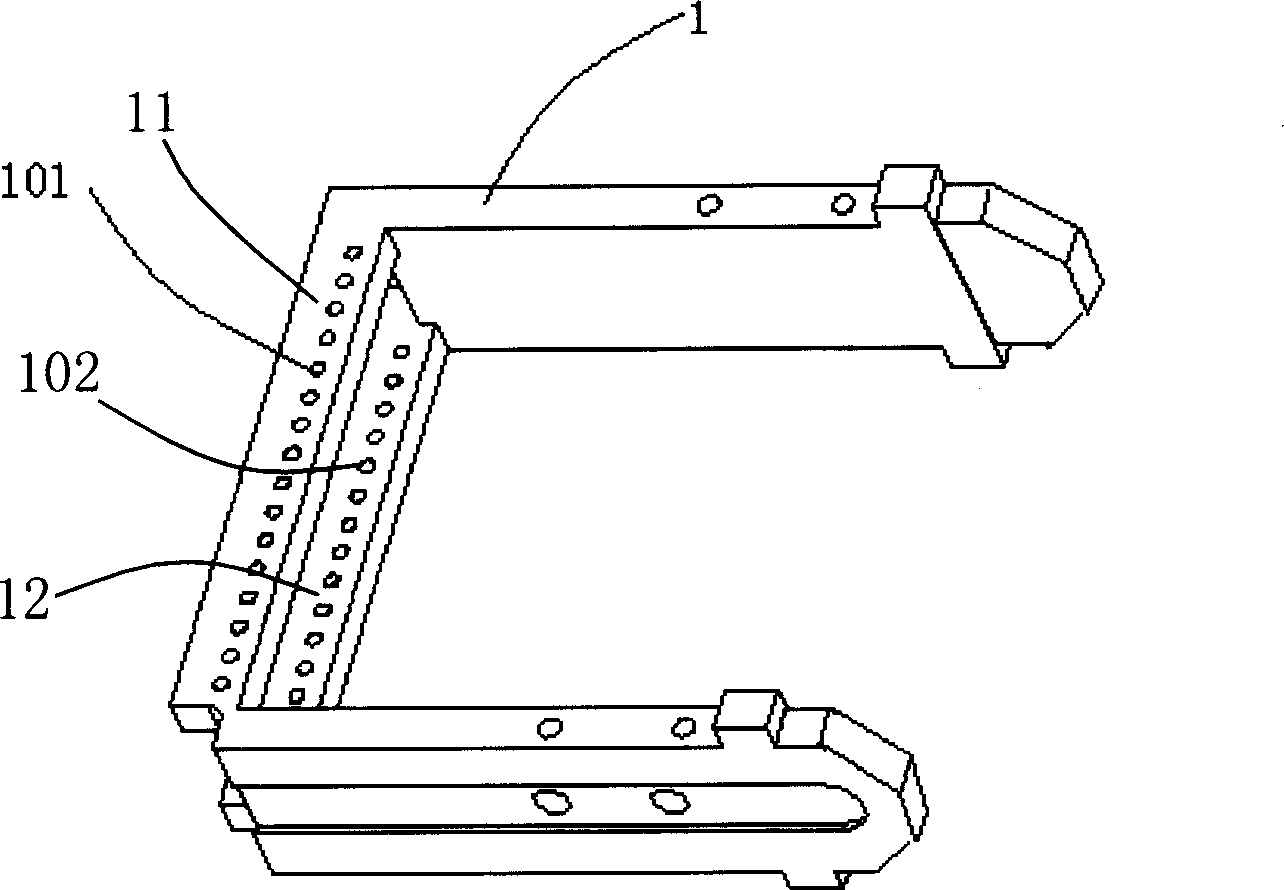

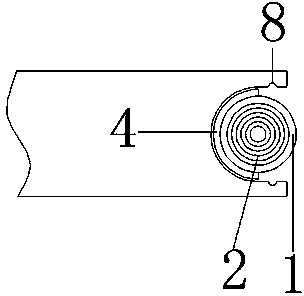

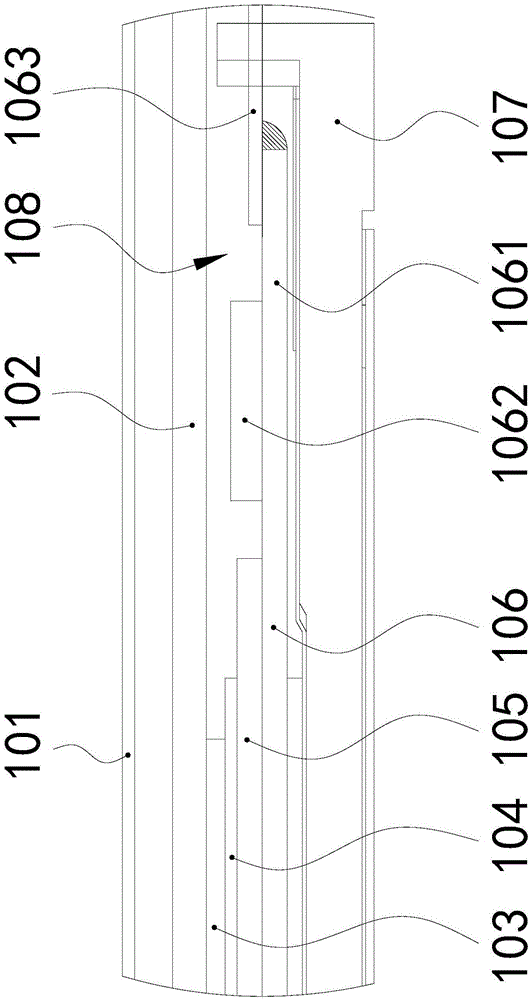

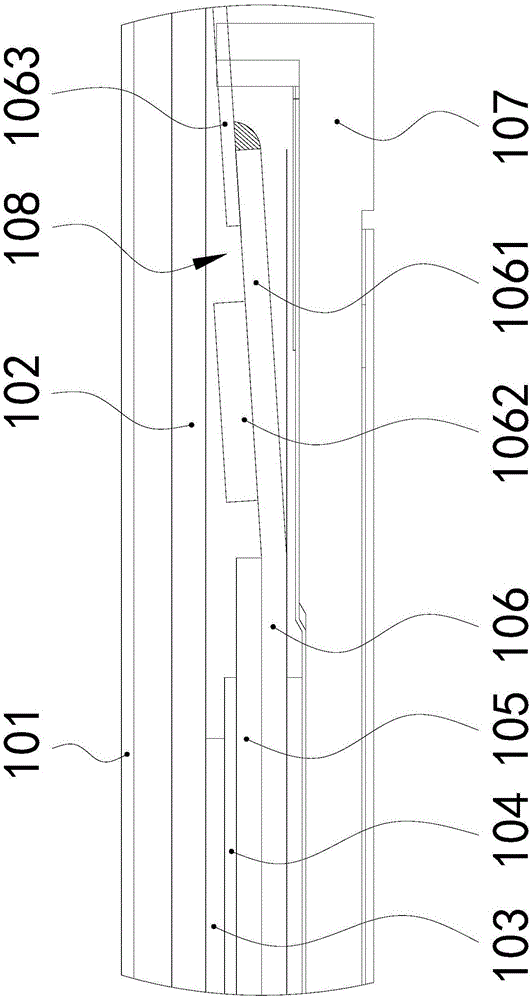

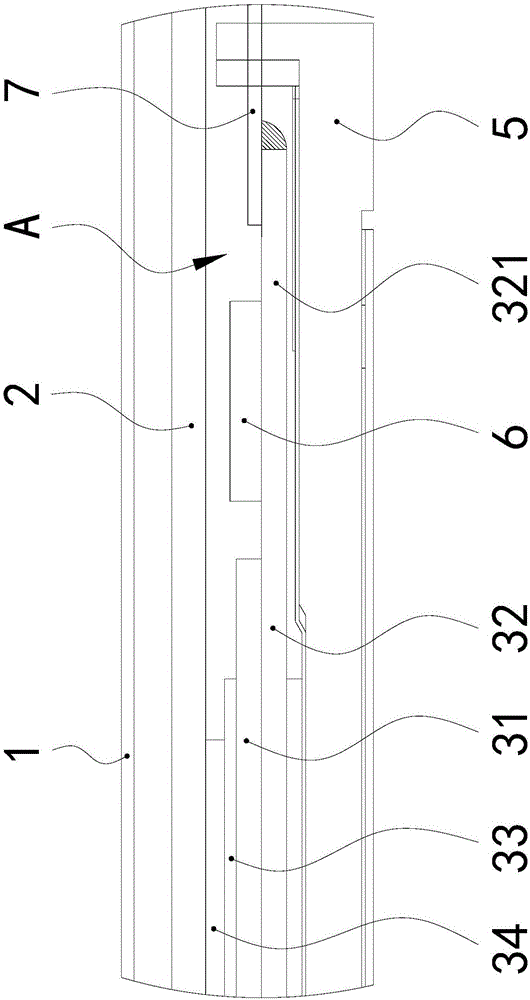

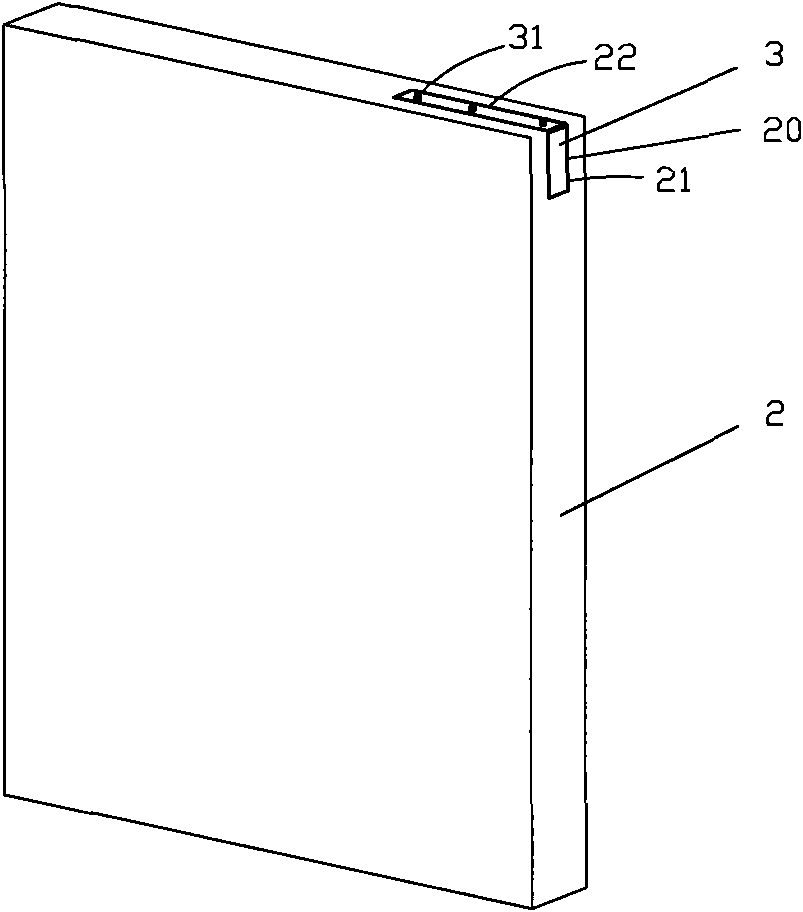

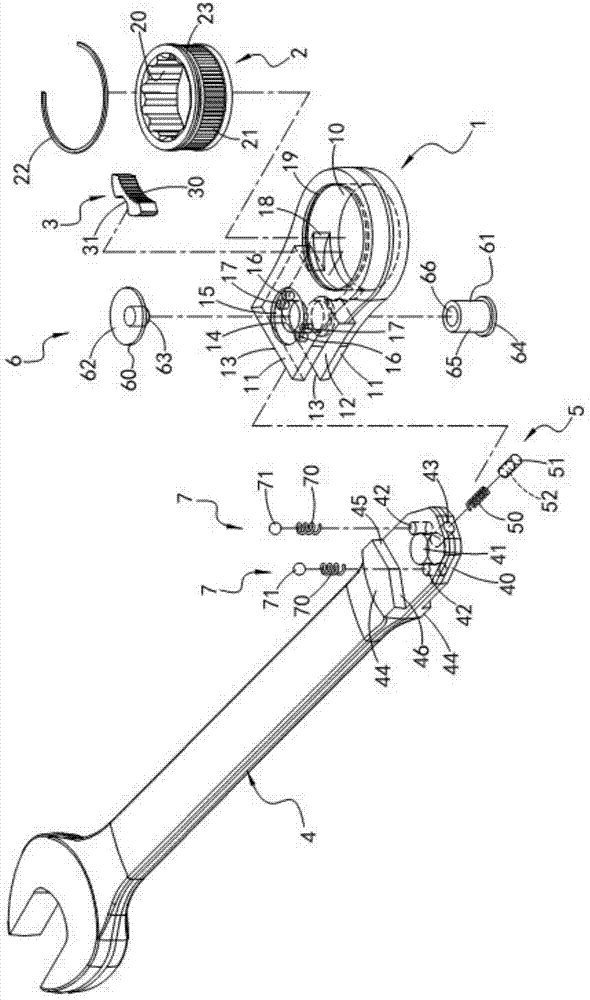

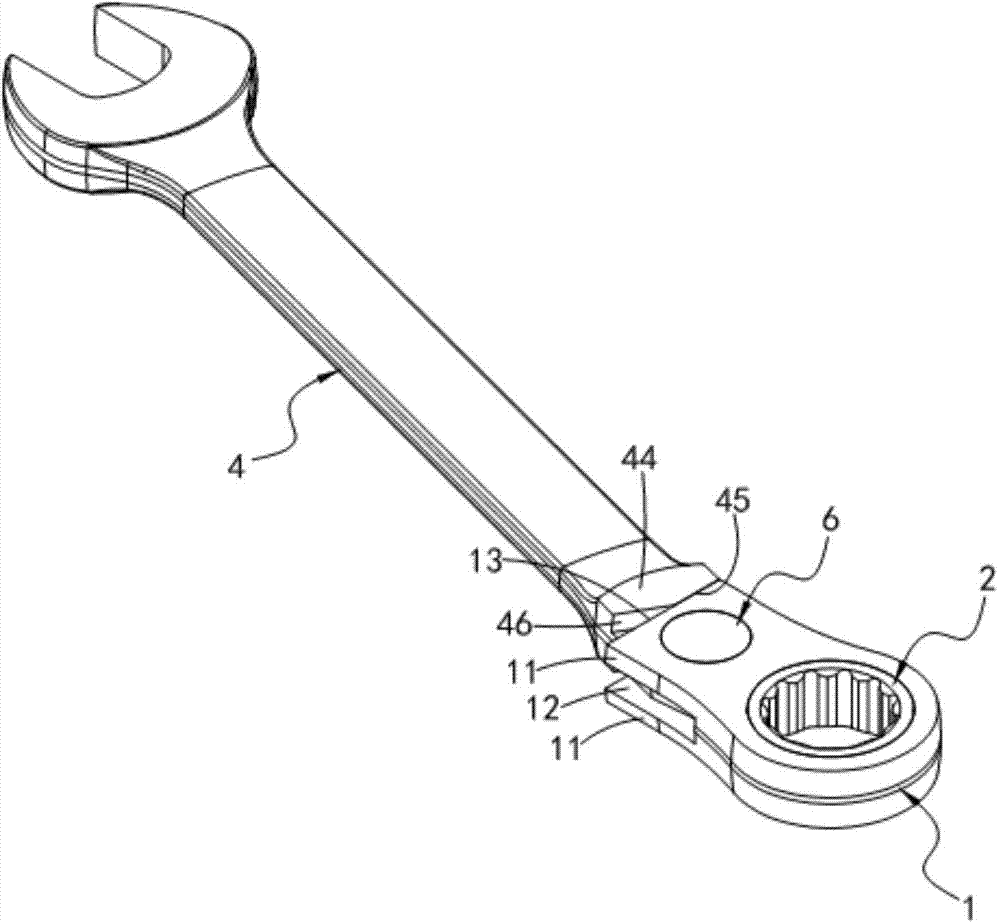

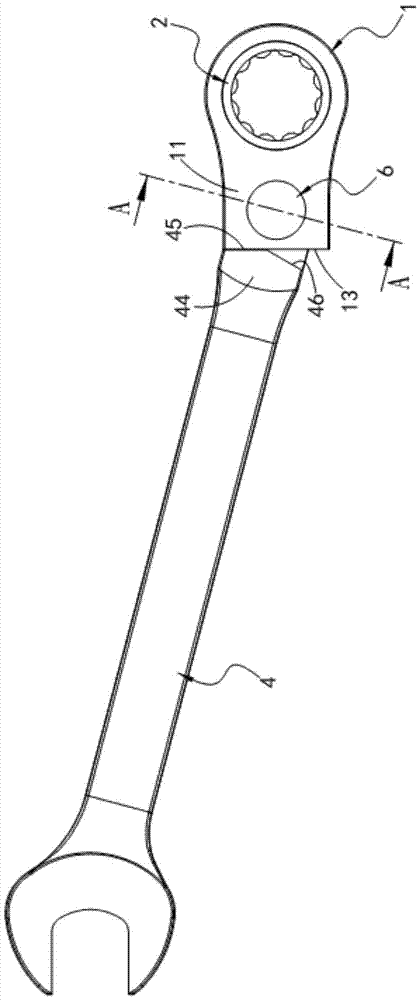

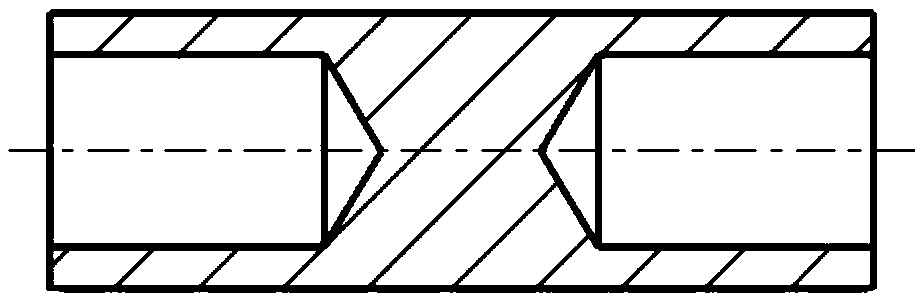

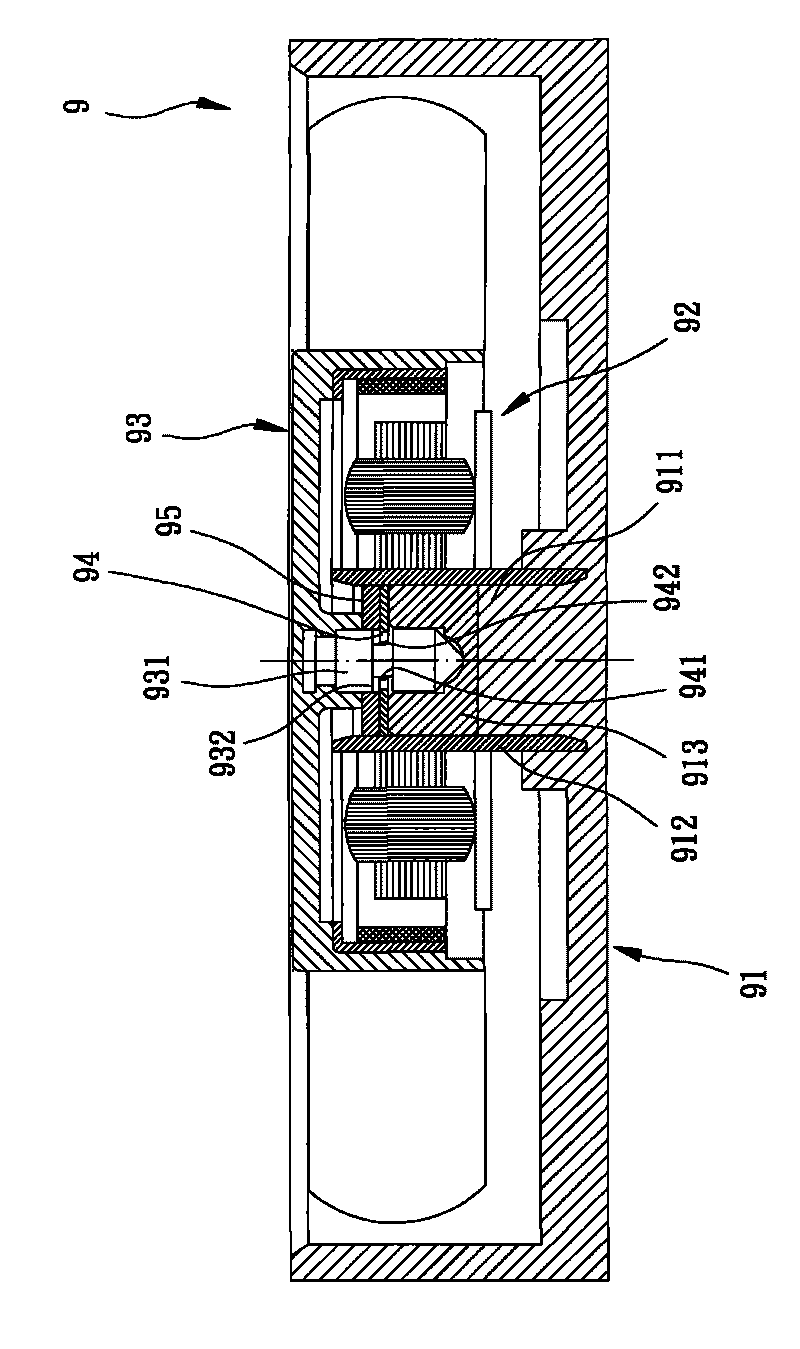

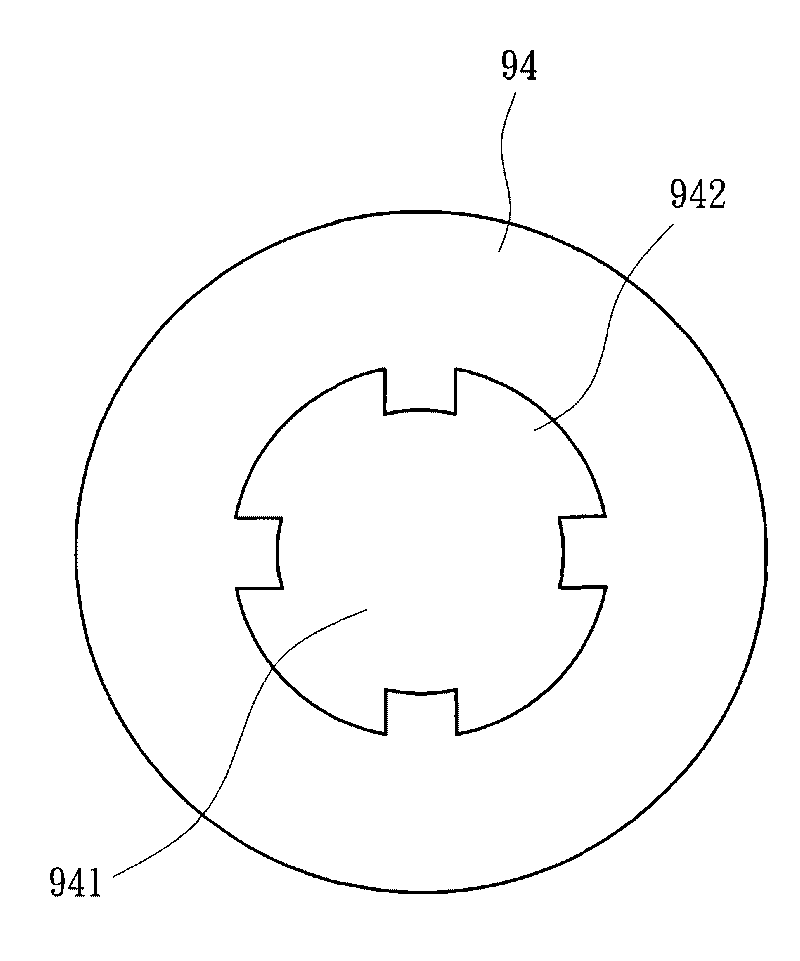

Ratchet wrench reversing structure

ActiveCN104760013ANot easy to break and damageImprove structural strengthSpannersWrenchesHead holderUltimate tensile strength

The invention relates to a ratchet wheel and discloses a ratchet wrench reversing structure. The ratchet wrench reversing structure comprises a head holder (1), a ratchet (2), a clamping part (3), a handle (4), an elastic linkage component (5), a pivot (6) and two elastic positioning components (7), wherein an accommodating hole (10) for penetrating through the upper and lower surfaces of the head holder (1) is formed in the head holder (1); two parallel lugs (11) and a pivot groove (12) formed between two lugs (11) are arranged on the head holder (1); a clamping groove (18) penetrating through the pivot groove (12) is formed in the lateral side of the accommodating hole (10); the racket (2) is rotationally combined in the accommodating hole (10) of the head holder (1); the racket (2) comprises a drive part (20) and an external toothed part (21) at the periphery of the racket (2). The ratchet wrench reversing structure has good structural strength, increasing of service life, is easy in manufacturing and assembling and low in cost and the like.

Owner:ZHEJIANG YIYANG TOOL MFG

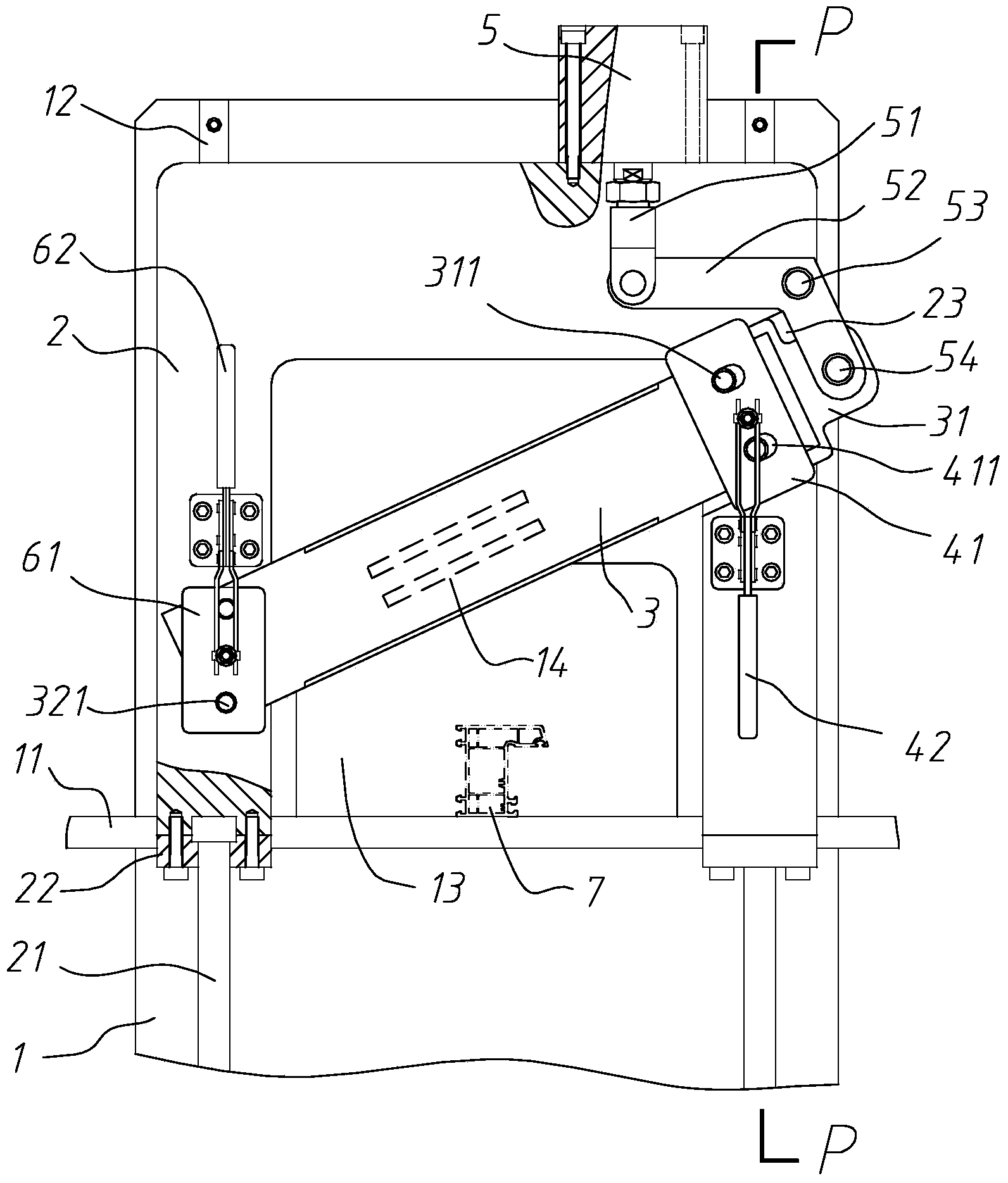

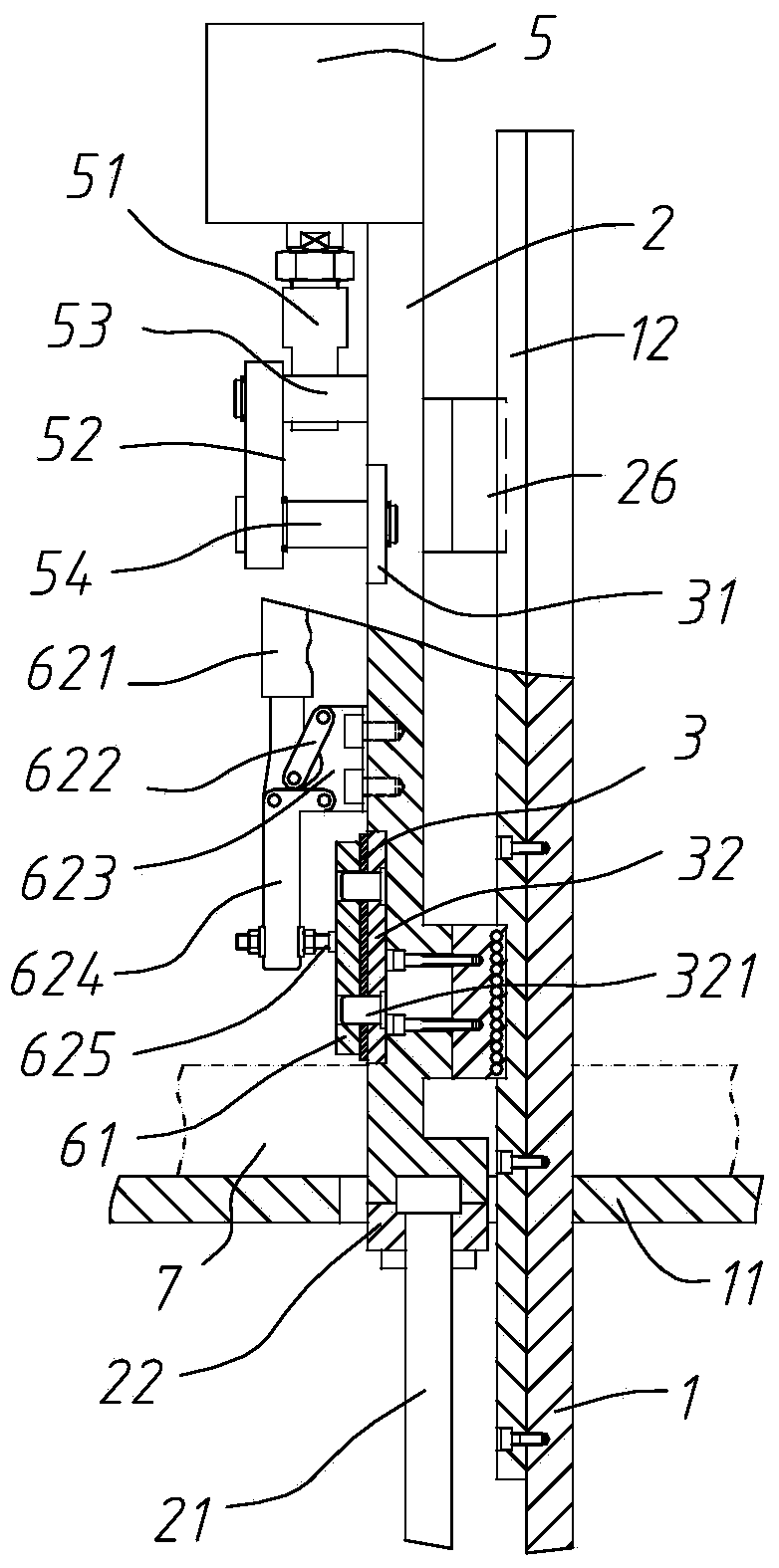

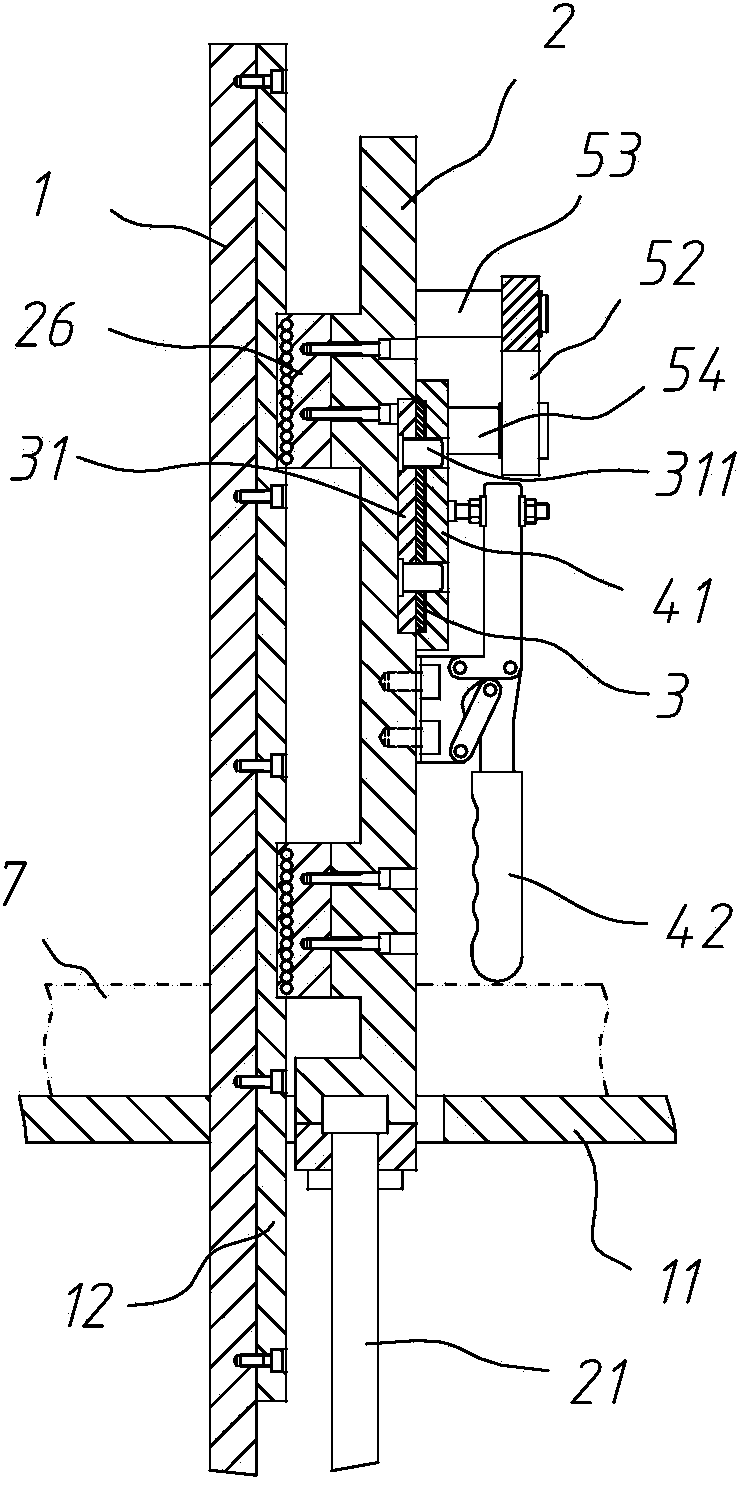

Blade tensioning device of plastic-profile thermal cutting device

ActiveCN103770150ASolve the problem of thermal expansion and deformationNot easy to break and damageMetal working apparatusEngineeringThermal expansion

The invention relates to a blade tensioning device of a plastic-profile thermal cutting device. The blade tensioning device comprises a rack, a knife rest and a blade, wherein the rack is fixed on the rack by a linear guide-rail mechanism in a liftable manner; one end of the blade is fixedly connected with the knife rest, and the other end of the blade is fixed on a sliding block; the knife rest is provided with a sliding groove matched with the sliding block; the sliding groove is arranged along the thermal-expansion lengthening direction of the blade; the blade tensioning device also comprises a sliding-block driving device, wherein the sliding-block driving device is fixed on the knife rest and can drive the sliding block to move along the thermal-expansion lengthening direction of the blade. The blade tensioning device has the advantages that since the tensioning mechanism is arranged for tensioning the blade, the cutting quality and the production efficiency can be improved, and the blade is not easily broken up and damaged, so that the production cost is reduced.

Owner:TONGLING GREAT EXTRUSION TECH

Basketball halftime joint defense training device

The invention relates to an assistant device in sports teaching and particularly relates to a basketball halftime joint defense training device. The device consists of a waist ring, a circular ring, magic tapes and an elastic band, wherein the magic tapes are arranged at two ends of the elastic band and on the circular ring. In wearing, the waist ring is tied on the waist and connected with the waist ring of another person together by the elastic band through the circular ring and the magic tapes. When one person moves, the waist ring of a defender connected with the person can be pulled through the elastic band to remind the other defender to timely move and adjust a defense position. In order to keep the elastic band continuously tensioned and prevent the elastic band from being avulsed, and the distance between the defenders cannot be too short or too long so as to avoid the errors such as too long or too short stance distance between trainers and untimely or too slow movement of the defenders. The basketball halftime joint defense training device has the advantages that structure is simple and use is comfortable, and is economical and durable. The waist ring and the circular ring are made of plastic so as not to increase the load of athletes due to light weight and not to cause damage on the skin and muscle due to good flexibility. In addition, the training device can be worn by 2-5 persons simultaneously according to the requirements of basketball halftime joint defense tactic, and is applicable to the teaching of all basketball halftime joint defenses.

Owner:刘涛

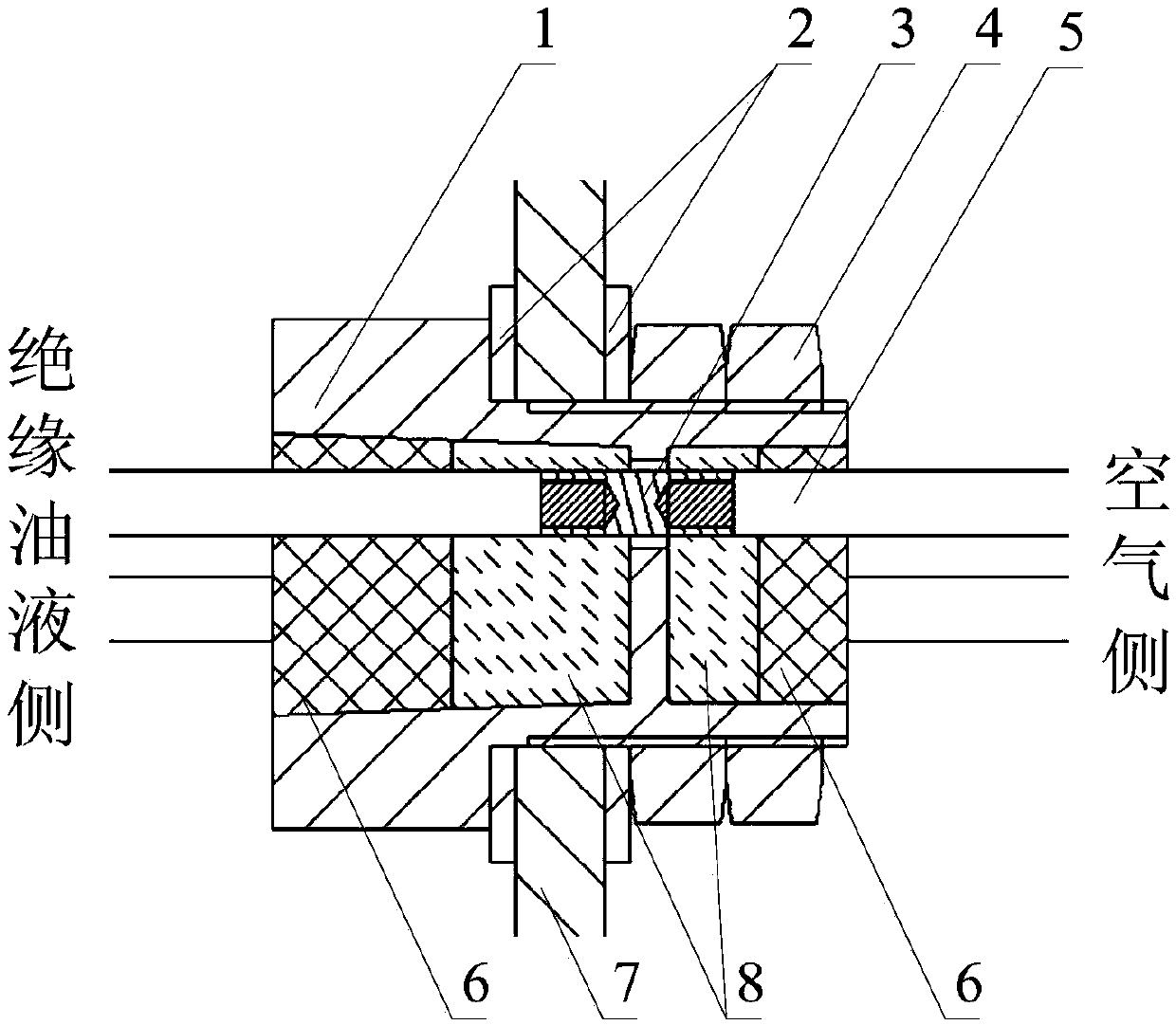

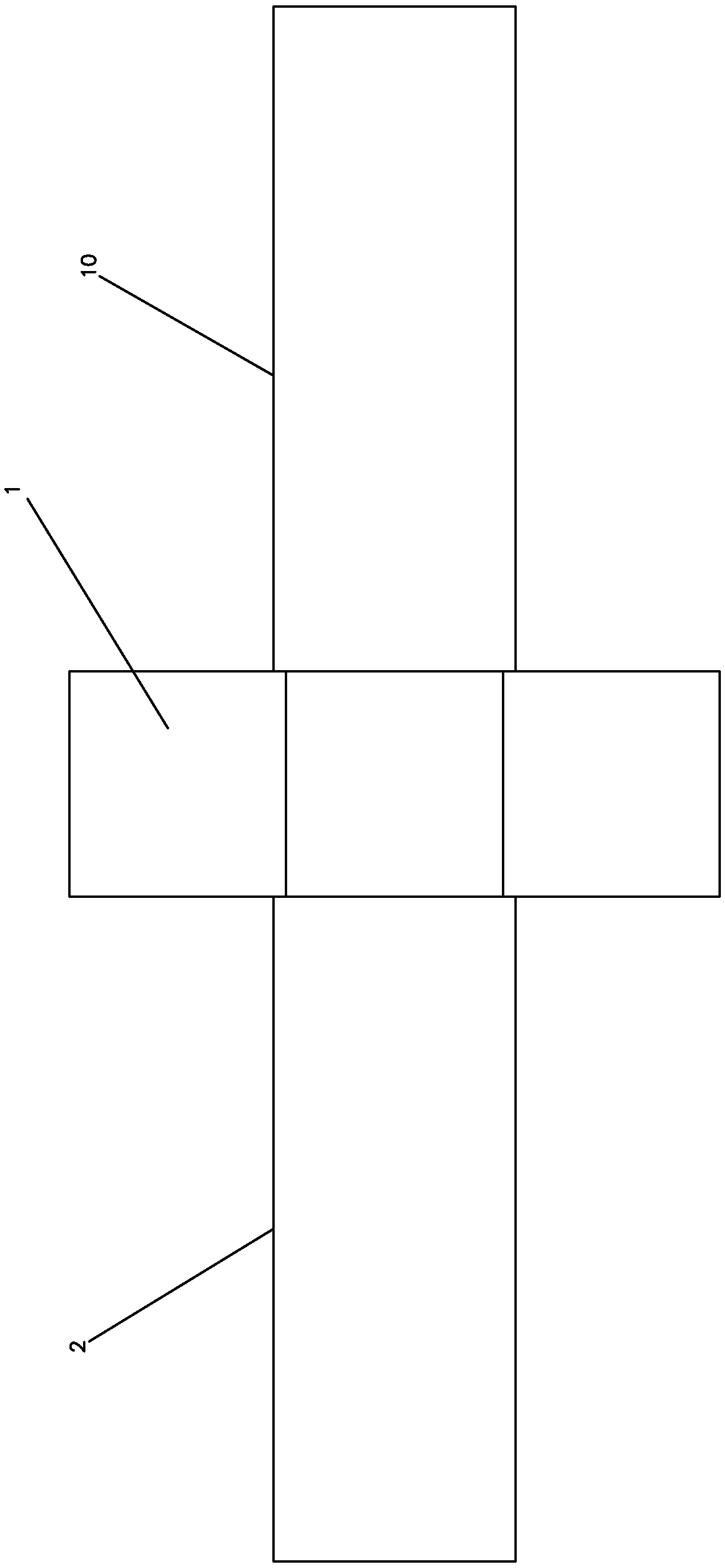

A potted cable sealing penetration structure

ActiveCN109103833AIncrease contact areaImprove pressure bearing capacityPipesCoupling device detailsElectrical and Electronics engineeringEngineering

The invention relates to a potted cable sealing penetration structure, comprising a penetration shell, an adapter copper core and a potting material. The penetration shell is a cylinder, the two endsof the cylinder are provided with blind holes, and a partition plate structure is formed between the blind holes at the two ends; the penetration shell passes through the outer bulkhead and is sealedand fixed with the outer bulkhead; N through holes are arranged in the partition structure to penetrate the spaces on both sides of the outer bulkhead; n cable adapters are respectively inserted inton through holes of the penetration shell partition structure, The two ends of the cable adapter are fixedly connected with the cables at the two ends of the outer bulkhead respectively, the blind holes at the two ends of the cylinder of the penetration shell are filled with potting material, and the end face of the cable adapter is not higher than the end face of the penetration shell. The invention realizes the sealing penetration of the cable through the potted penetration structure.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

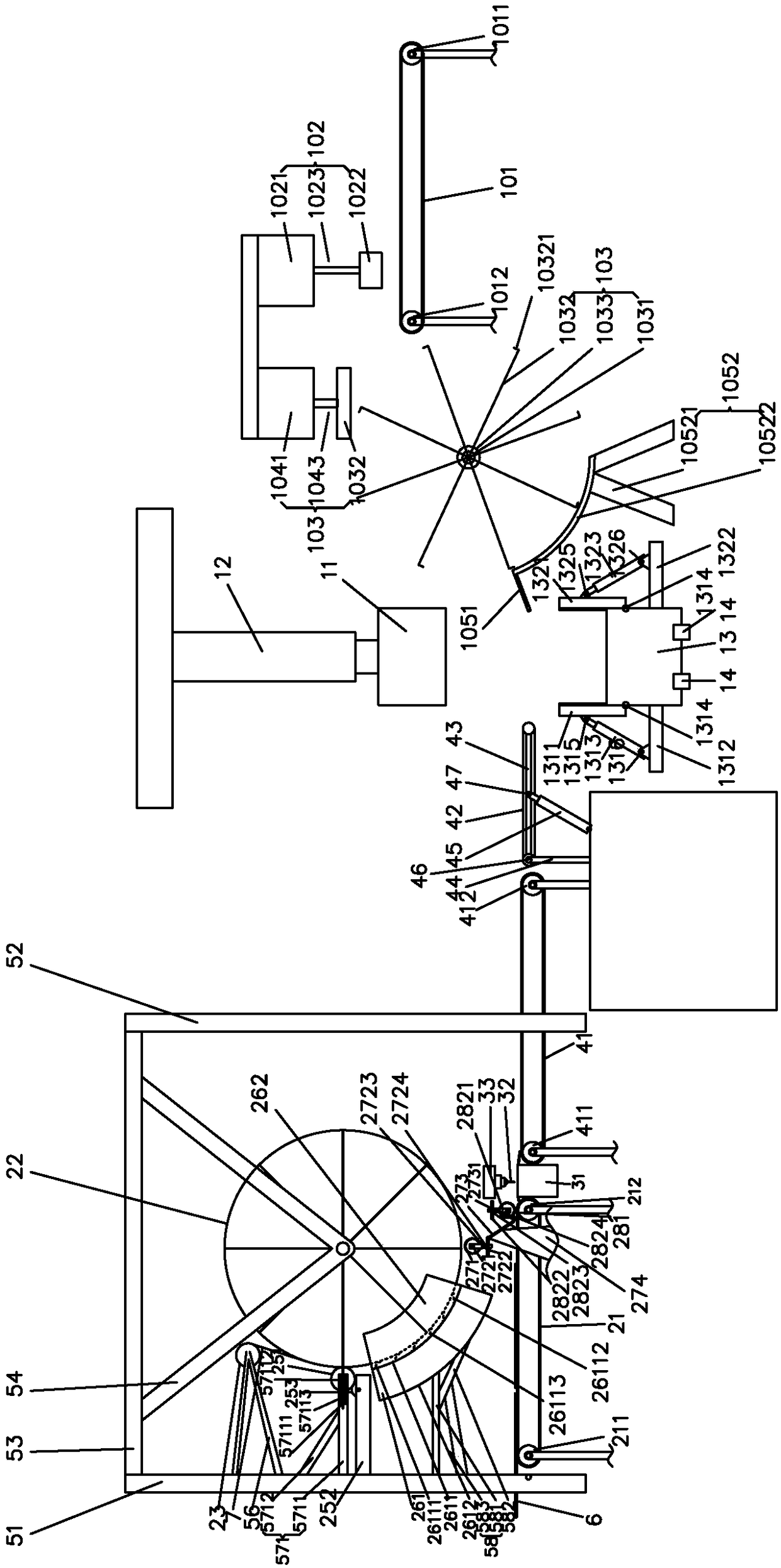

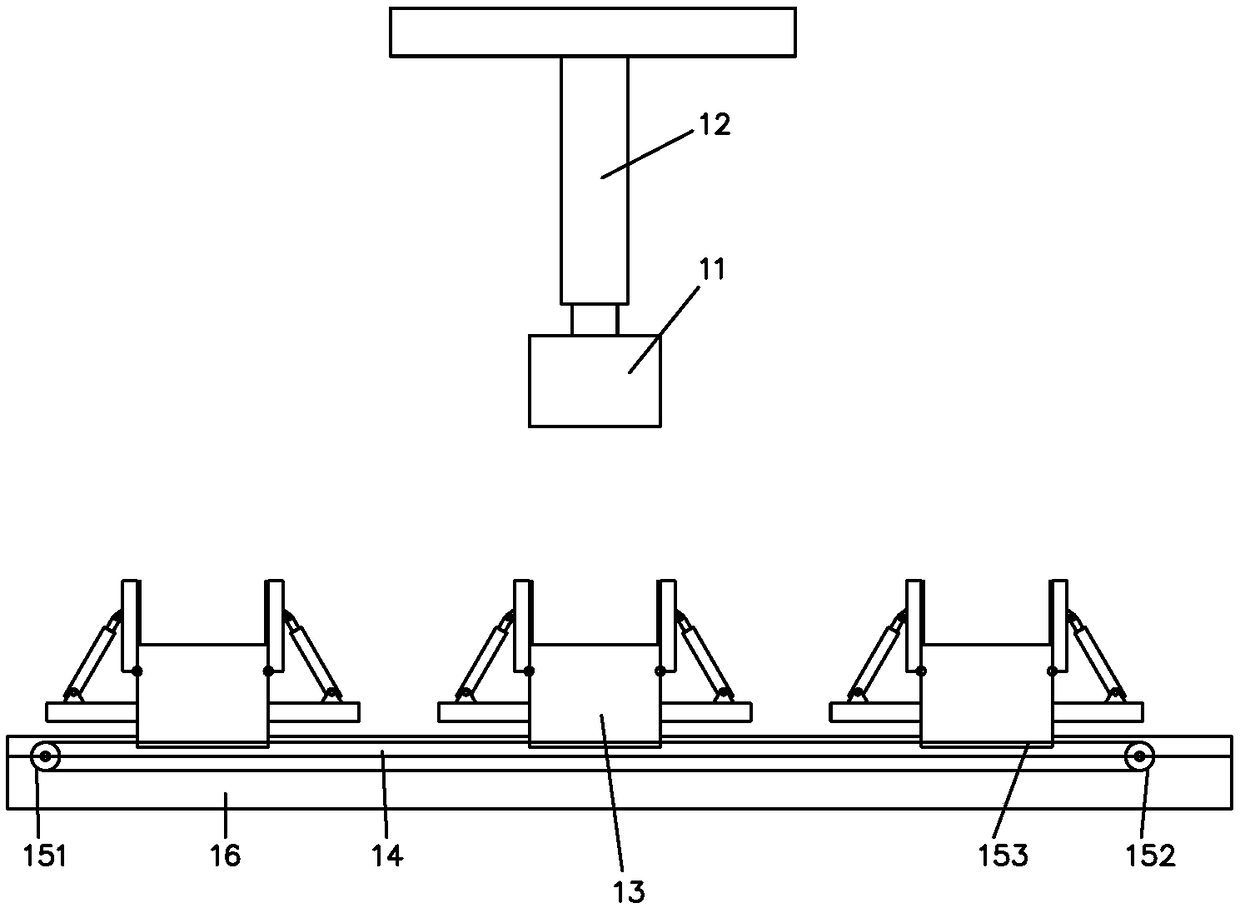

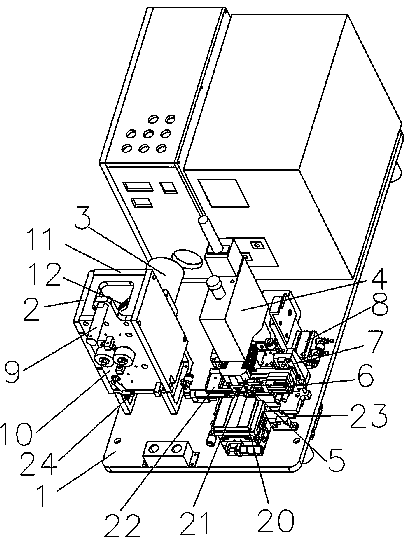

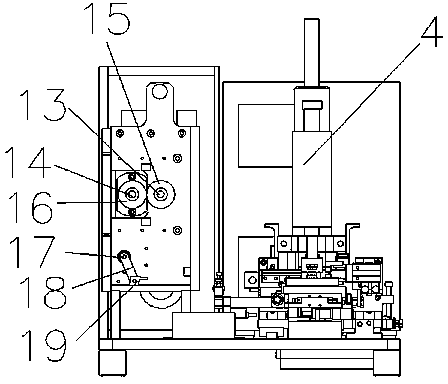

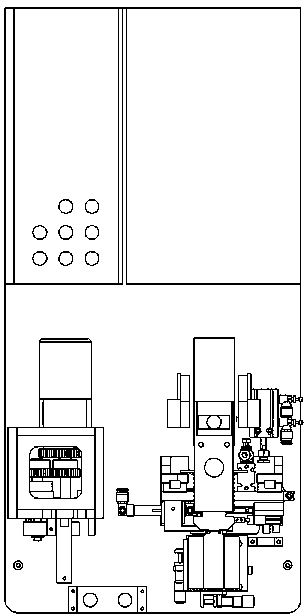

Uninterrupted full-automatic plywood hot press production line

ActiveCN109129759ASufficient and uniform penetrationReduce the temperatureOther plywood/veneer working apparatusPlywood pressesProduction lineSurface layer

The invention provides an uninterrupted full-automatic plywood hot press production line. According to thee uninterrupted full-automatic plywood hot press production line, the structural form of a traditional plywood hot press is broken through, in the actual working process, under the control of a master controller, a glue brushing production line section is used for brushing glue on template blanks to form template blocks subjected to glue brushing then and conveying the template blocks subjected to glue brushing to a hot press forming production line section, a supply production line section is used for conveying interlayer and the uppermost-layer template blank to the hot press forming production line section so that the uppermost-layer template blank can be arranged above the corresponding number of the template blocks subjected to glue brushing in a cushioning mode to serve as a surface layer, the interlayer can be arranged above the corresponding uppermost-layer template blank in a cushioning mode to separate the uppermost-layer template blank located at the upper portion from the several template blocks subjected to glue brushing and separate the uppermost-layer template blank located at the lower portion and the several template blocks subjected to glue brushing, finally, the hot press forming production line section is used for performing hot press forming, and multiple plywood can be formed at a time. According to the uninterrupted full-automatic plywood hot press production line, uninterrupted, continuous and smooth hot press forming can be performed on the template blanks, the mechanical degree is high, and the strength of the finished-product plywood is higher.

Owner:漳州鑫华成机械制造有限公司

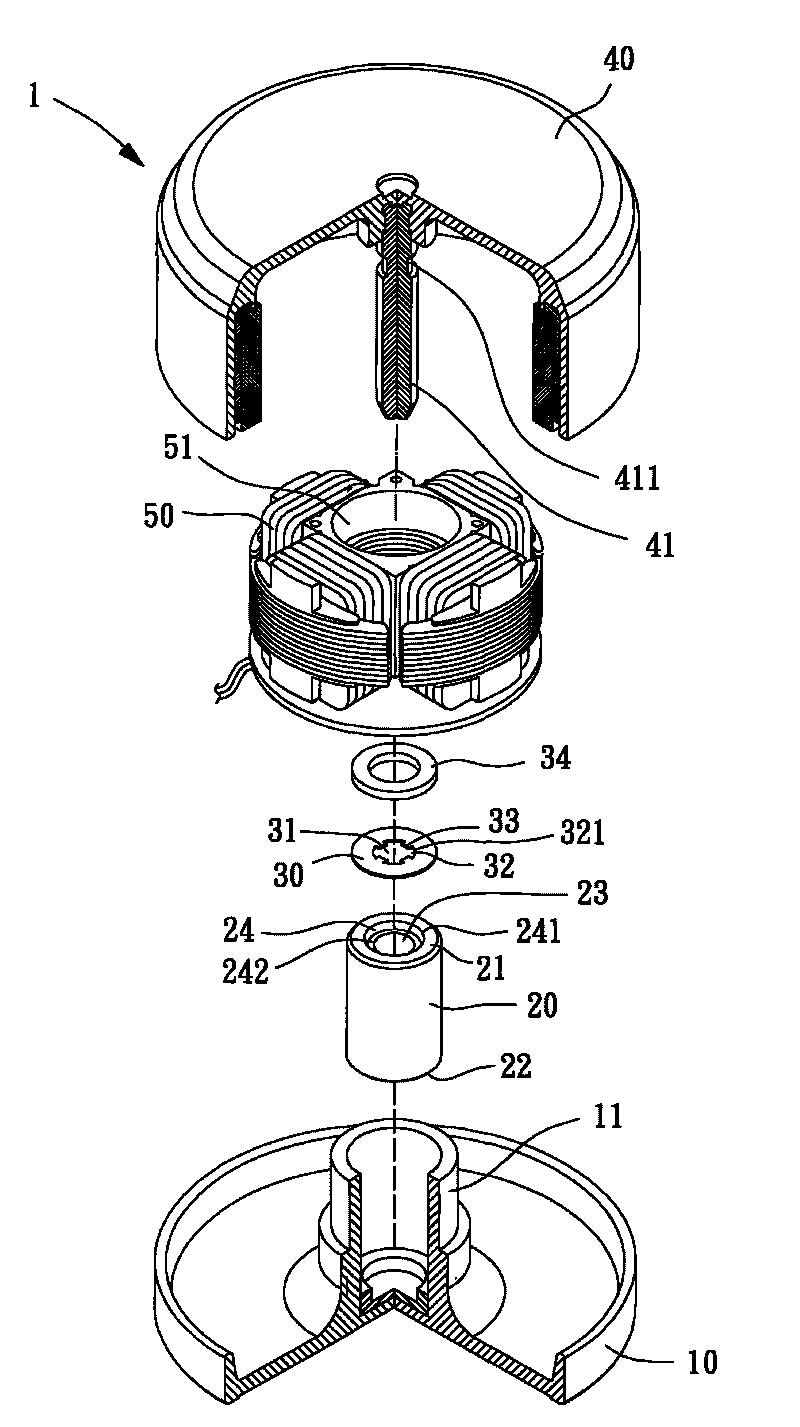

Motor

ActiveCN101714795AGuarantee product qualityPrevent disengagementMechanical energy handlingSupports/enclosures/casingsEngineeringMechanical engineering

The invention relates to a motor comprising a base, a bearing, a positioning piece, a rotor and a stator. The base is provided with a shaft tube; the bearing is arranged in the shaft tube and provided with a through hole and a concave part having an axial direction; the positioning piece is combined with the bearing, provided with a perforation and a plurality of grooves and has a radial direction from the inner hole wall of the perforation to the inner hole wall of the through hole of the bearing, wherein the radial direction is no more than the axial direction; the rotor is provided with a rotating shaft which is combined with the through hole of the bearing; and the stator is sleeved on the outer peripheral surface of the bearing. Accordingly, the invention can utilize the concave part of the bearing to provide the positioning piece with an enough deformation space, thereby facilitating the assembly operation of the rotor and the positioning piece and effectively preventing the positioning piece from being damaged in the assembly process.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Manufacture method of grass cloth for Chinese painting and calligraphy

InactiveCN104358061AChange processChange the manufacturing methodSucessive textile treatmentsHeating/cooling textile fabricsAnti bacterialEngineering

The invention relates to a manufacture method of grass cloth for Chinese painting and calligraphy. The manufacture method comprises the following steps: (1) desizing; (2) degreasing and degumming; (3) locating in a crossed manner; (4) opening pores and keeping humidity by steam; and (5) rolling and shaping at high temperature under high pressure; the desizing technology of the grass cloth, the degreasing and degumming technology of the grass cloth, the cross locating technology of wefts and warps of the grass cloth, the steam pore-opening technology of the grass cloth and the high-temperature high-pressure shaping technology are additionally adopted, the traditional technological process and the manufacture method of the grass cloth for the Chinese painting and calligraphy are completely changed, the thickness, the density and the smooth finish of the grass cloth are improved, the manufactured grass cloth is suitable for traditional mounting, machine mounting and remounting of the Chinese painting and calligraphy, the painting and calligraphy effect of the grass cloth is consistent to that of the untreated and treated Xuan paper, and the grass cloth is superior to the Xuan paper in physical and chemical properties, tensile strength and pressure resistance, has good infrared ray and uvioresistant resistance and anti-bacterial and antiseptic properties, is suitable for collection, anti-counterfeiting and long-term preservation of the Chinese painting and calligraphy, and can play a role of manufacturing the Chinese painting and calligraphy.

Owner:王少农

Wire harness welding machine

ActiveCN103551695AGuaranteed unobstructedNot easy to break and damageLine/current collector detailsMetal working apparatusEngineeringMoving frame

The invention discloses a wire harness welding machine, which comprises a base, a material placing frame, a motor and a welding machine body. The wire harness welding machine is characterized in that the material placing frame is arranged on the base, a support shaft is arranged on the top of the material placing frame, the back end of the material placing frame is provided with the motor, the front end of the material placing frame is provided with a driving press wheel and a driven press wheel, the motor drives the driving press wheel and the driven press wheel to rotate, a carrier table is arranged at the side surface of the material placing frame, a moving frame is arranged at the back end of the carrier table and can slide along a guide rail, a clamping air cylinder is arranged on the moving frame, the clamping air cylinder controls a clamp claw to tightly clamp tin wires, a welding machine body is arranged at the back end of the moving frame, and a welding head is arranged on the welding machine body. The wire harness welding machine solves the problems that a wire harness and a connector are welded, the tin wires can easily rotate, the welding precision is low, the tin consumption is great, the tin adhesion is not uniform enough, and in addition, the tin wires can easily fracture and can be easily damaged in the processing process. The invention provides the wire harness welding machine with the advantages that the processing is convenient, the welding precision is improved, the tin wire consumption is reduced, and the cost is reduced.

Owner:KUNSHAN SYSTRONICS AUTOMATION TECH CO LTD

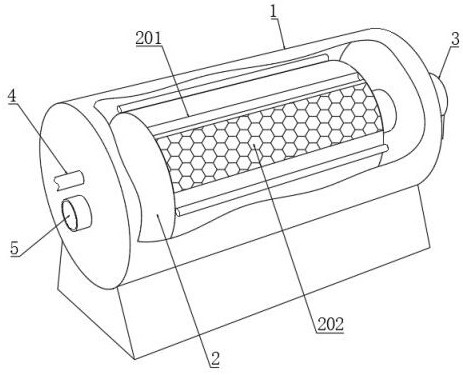

Slow-speed slow-sliding type low-damage-rate fertilizer drying device

ActiveCN113566523AQuality assuranceQuality improvementGranular material dryingDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention discloses a slow-speed slow-sliding type low-damage-rate fertilizer drying device, and belongs to the field of fertilizer drying devices. By arranging a breathable grain-dividing soft plate and soft cloth, the process that fertilizer particles are bagged by the soft cloth and slowly roll downwards and are dispersed along the surface of the breathable grain-dividing soft plate can be repeatedly achieved; on one hand, the fertilizer particles are in full contact with hot air, and the drying sufficiency and speed are effectively improved; on the other hand, the breathable grain-dividing soft plate provides flexible buffering and supporting for the fertilizer particles, the rolling speed of the fertilizer particles is reduced, flexible contact between the fertilizer particles and the breathable grain-dividing soft plate is achieved, and effective dual protection is provided for the fertilizer particles; and in addition, the breathable grain-dividing soft plate has a further flexible dispersing effect on agglomerated fertilizer in the rolling process, and the drying speed is further increased. According to the slow-speed slow-sliding type low-damage-rate fertilizer drying device, the damage rate of the fertilizer particles in the drying process is greatly reduced while the fertilizer particles are dispersed and drying is accelerated, the quality of the fertilizer particles is effectively guaranteed, and the high-quality and high-efficiency drying process is achieved for the fertilizer.

Owner:江苏联海生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com