Motor

A technology of motors and bearings, applied in the field of motors that are easy to assemble, can solve the problem that the bearings cannot provide enough deformation space, so as to improve the convenience of assembly and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

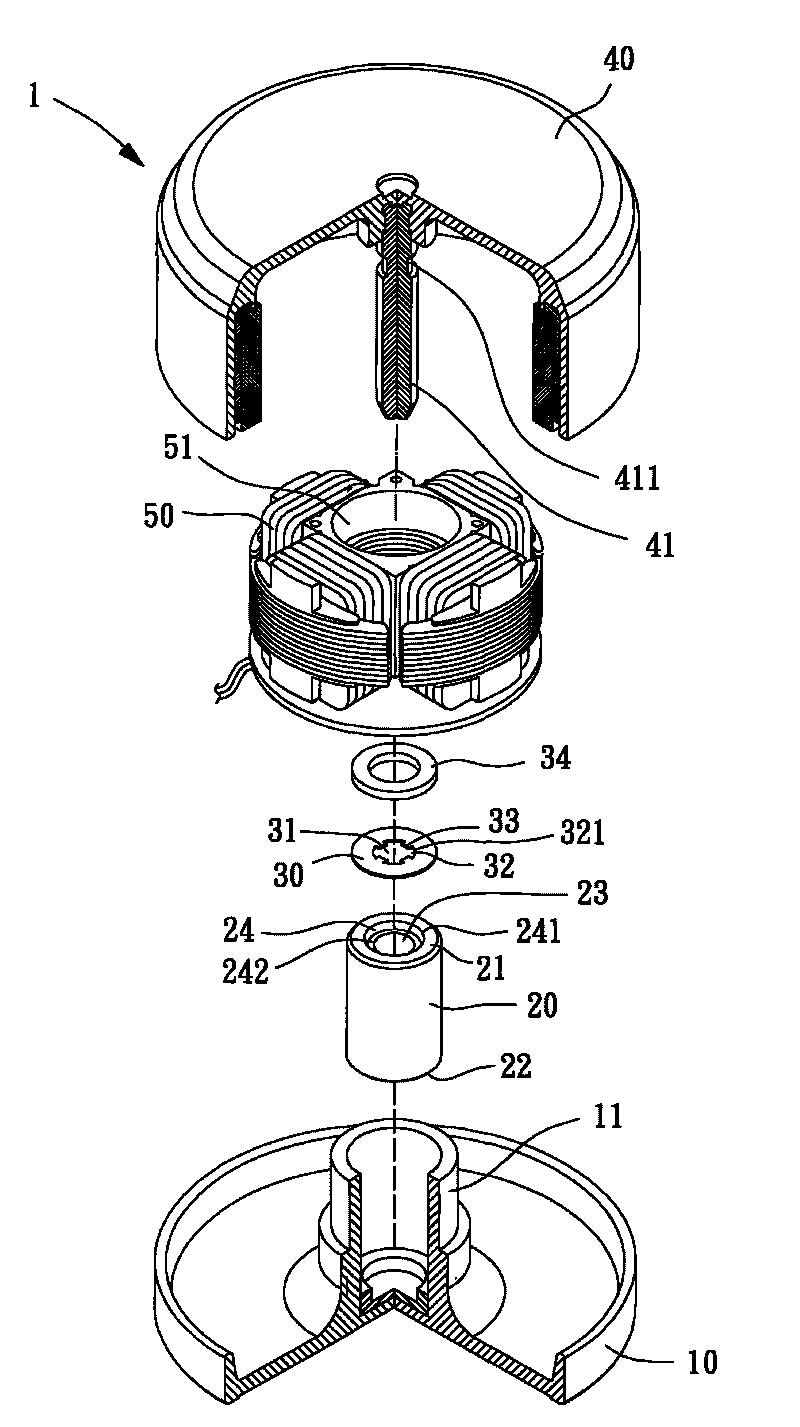

[0033] In order to allow the above-mentioned and other objects, features and advantages of the present invention to be more clearly understood, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, and described in detail as follows:

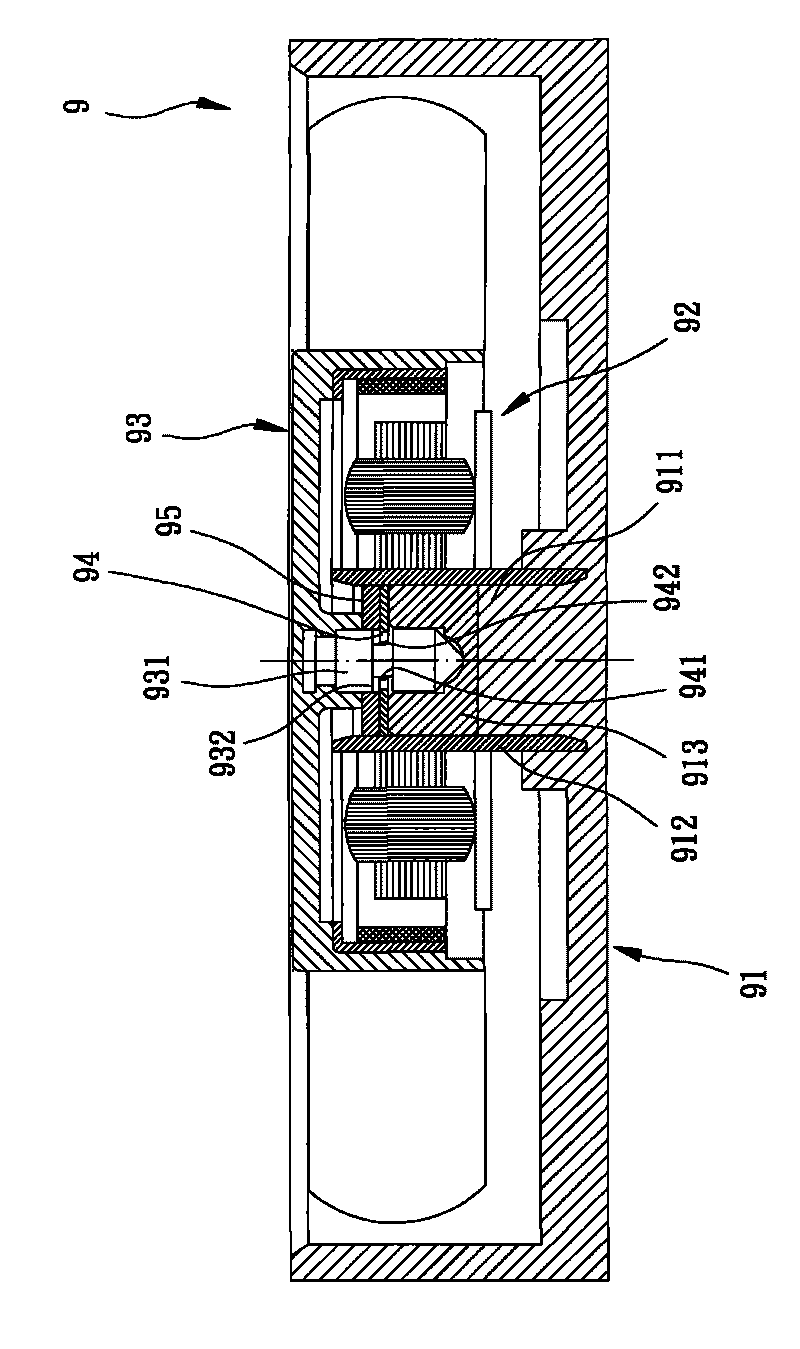

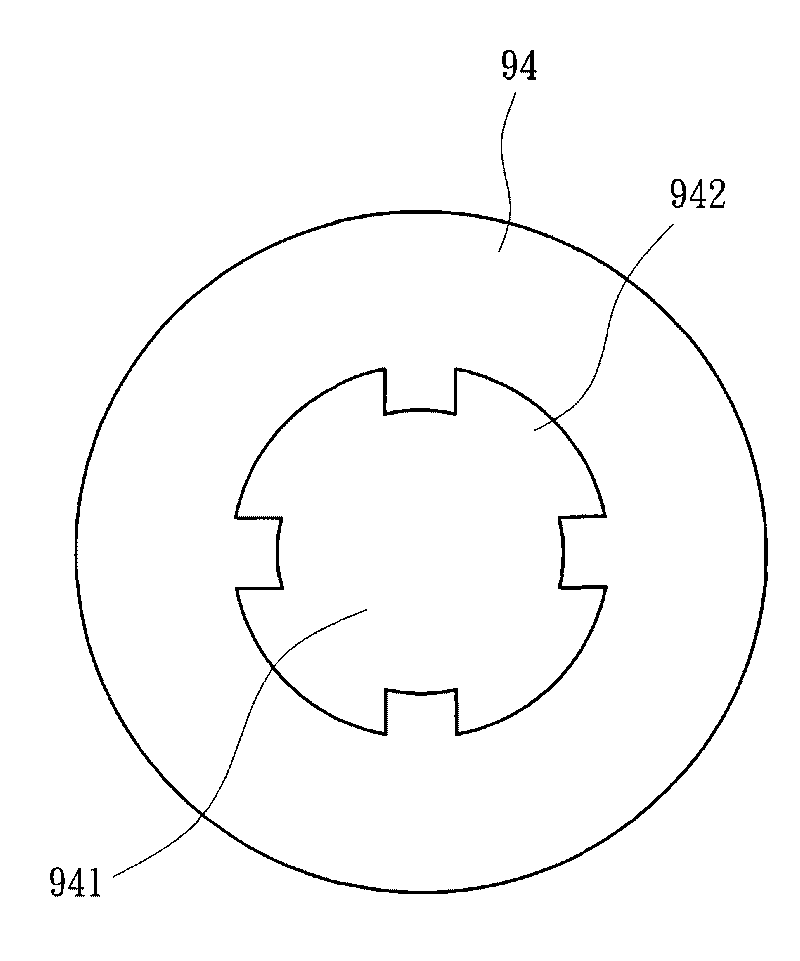

[0034] Please refer to image 3 and Figure 4 As shown, the motor 1 of the first embodiment of the present invention at least includes a base 10 , a bearing 20 , a positioning member 30 , a rotor 40 and a stator 50 . in:

[0035] The base 10 has a shaft tube 11 , one end of the shaft tube 11 is closed, and the other end is opened, for assembling the bearing 20 , the positioning member 30 and other related components.

[0036] The bearing 20 is disposed in the shaft tube 11, the bearing 20 has a first end surface 21 and a second end surface 22, and the bearing 20 is further provided with a through hole 23, the through hole 23 runs through the first end surface 21 to the On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com