Ratchet wrench reversing structure

A ratchet wrench and ratchet technology, which is applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of inconvenient production and assembly, short service life, poor structural strength, etc., and achieve low processing cost, simple production, and good use safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

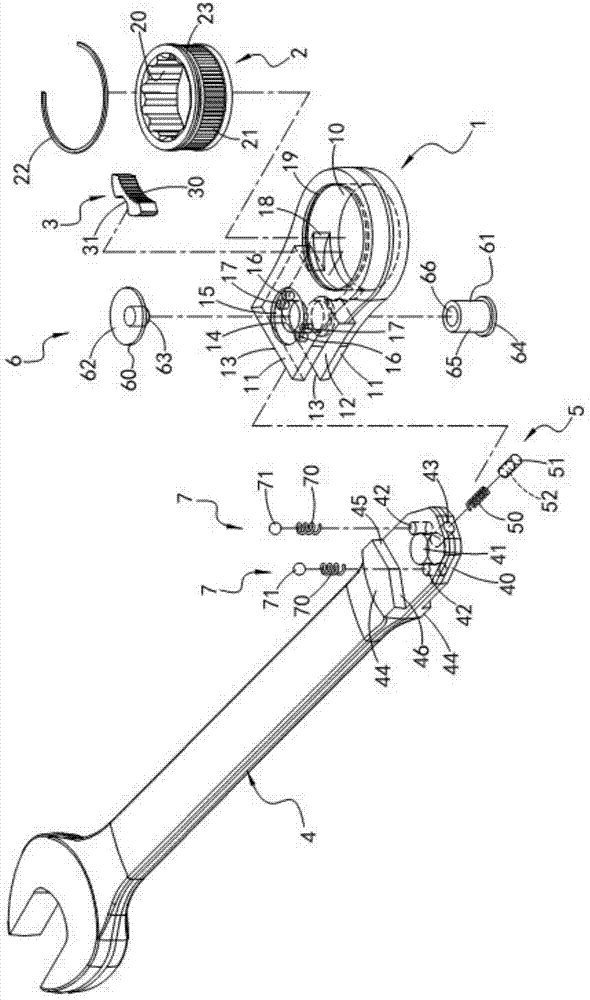

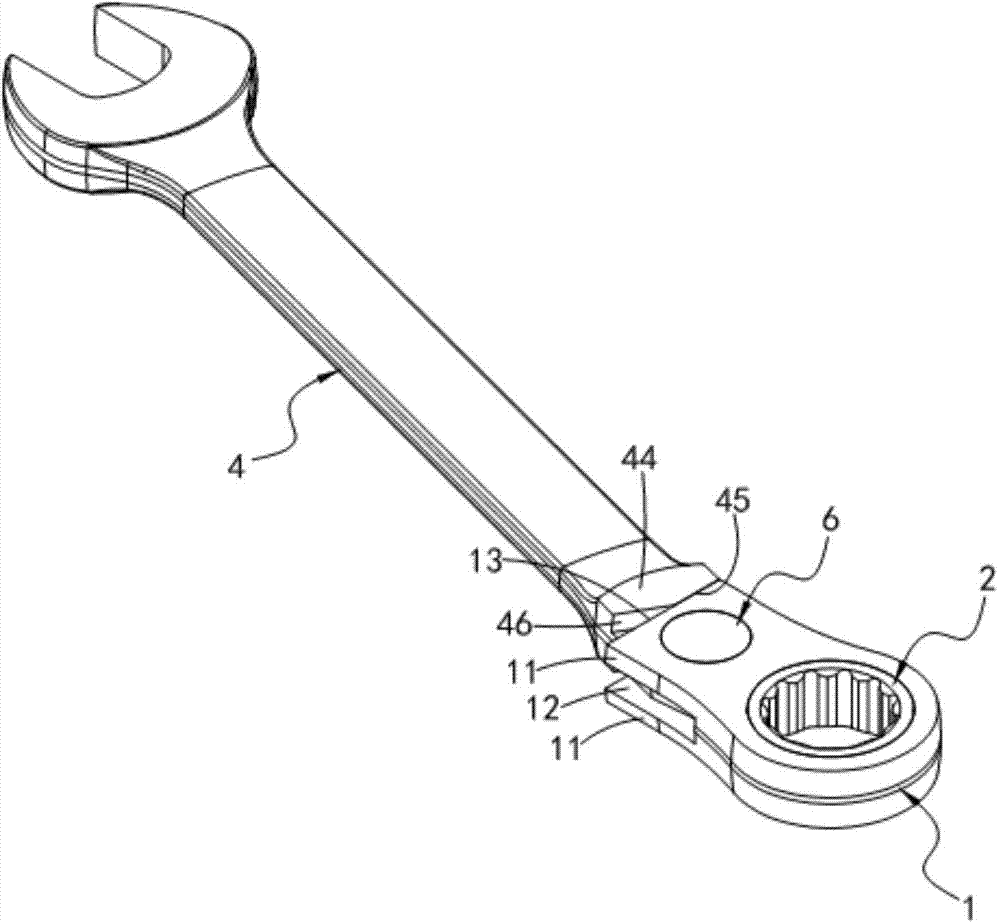

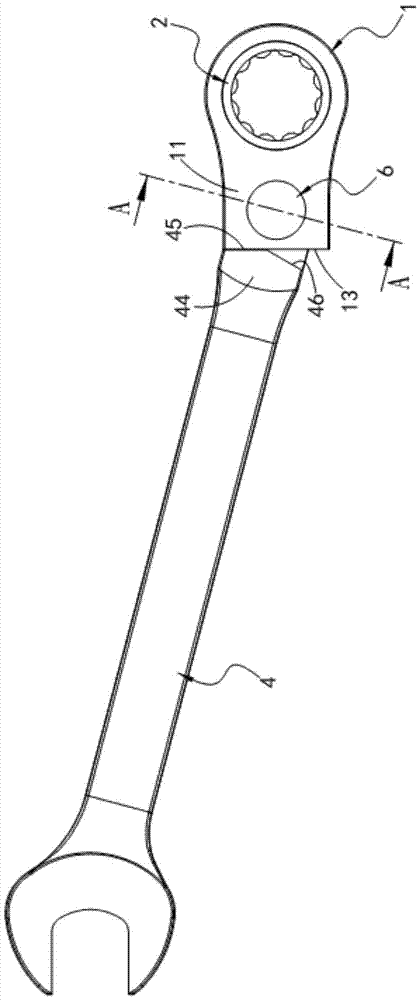

[0035] The reversing structure of the ratchet wrench, as shown in Figures 1 to 4, includes a head seat 1, a ratchet 2, a locking member 3, a handle 4, an elastic linkage assembly 5, a pivot 6 and two elastic positioning Component7. in:

[0036] The head seat 1 is provided with an accommodating hole 10 passing through the upper and lower surfaces of the head seat 1. The head seat 1 is provided with two parallel ear pieces 11 and a pivot groove 12 formed between the two ear pieces 11. The ear pieces 11 The side far away from the accommodation hole 10 is the abutment surface 13, and the ear piece 11 is provided with a shaft hole 14 passing through the pivot groove 12 and penetrating the upper and lower surfaces of the head seat 1, and the side of the accommodation hole 10 is provided with a shaft hole 14 through the pivot groove 12. The catch slot 18 of the slot 12. A groove 15 with an inner diameter larger than the shaft hole 14 is formed on the top surface of the upper lug 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com