Slow-speed slow-sliding type low-damage-rate fertilizer drying device

A drying device and retarding technology, applied in the direction of drying gas arrangement, drying of granular materials, drying of solid materials, etc., can solve the problems of fertilizer destruction, low drying efficiency, fragmentation, etc., to improve the adequacy and speed, and improve the drying rate. , the effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

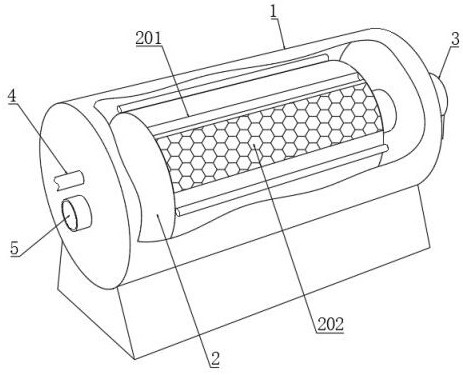

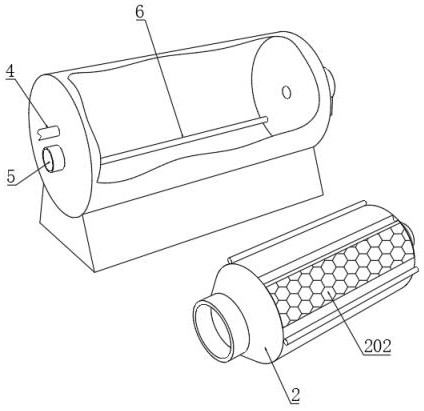

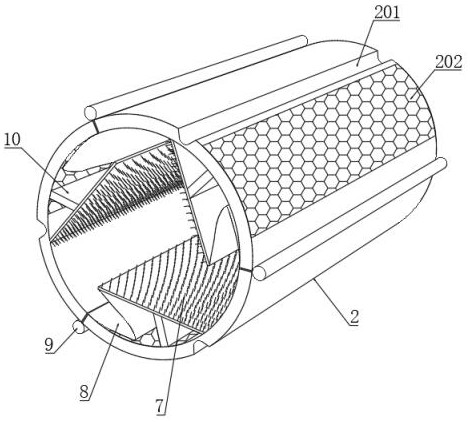

[0043] see figure 1 , a slow-speed and slow-sliding low-loss rate fertilizer drying device, comprising an outer cylinder 1 fixedly connected with a base, a rotating cylinder 2 is arranged inside the outer cylinder 1, a motor 3 is fixedly connected to the right end of the outer cylinder 1, and the motor 3 The output end passes through the outer cylinder 1 and is fixedly connected with the right end of the rotating cylinder 2, please refer to image 3 and Figure 4, the interior of the rotating drum 2 is provided with a plurality of evenly distributed air-permeable and grading soft plates 7, one end of the air-permeable and granulating soft plates 7 is fixedly connected with the inner wall of the rotating drum 2, and the other end of the air-permeable and granulating soft plates 7 is fixedly connected with a soft cloth 8. The soft cloth 8 runs through the inner wall of the drum 2 from the inside to the outside and is fixedly connected with the driving rod 9. The soft cloth 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com