Multi-functional auger bit

A kind of twist drill bit, multi-functional technology, applied in the direction of twist drill, etc., can solve the problems of wasting manpower, not being able to form large holes, labor-consuming and time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

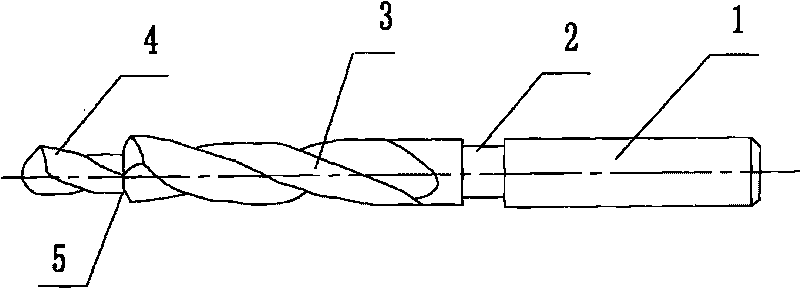

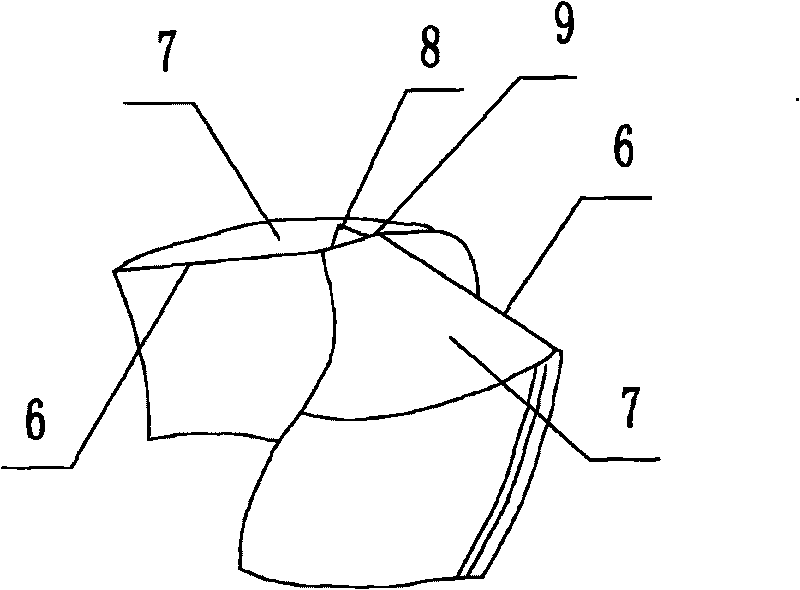

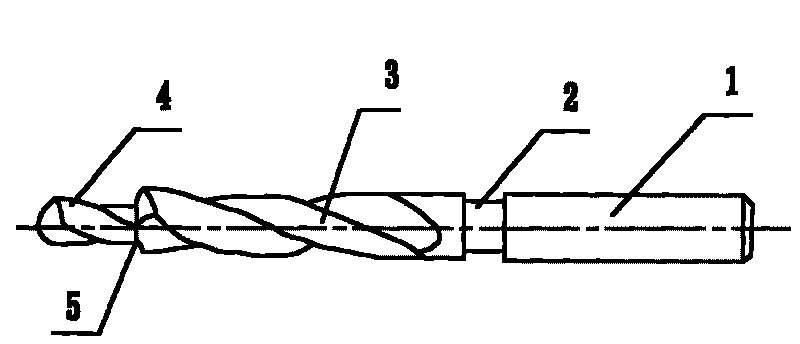

[0009] Such as figure 1 , 2 The multifunctional twist drill shown has a multifunctional twist drill with a shank 1, a neck 2 and a working part 3, the working part includes a guide part and a cutting part, and the cutting part is composed of a main cutting edge 5 and a flank, and the cutting The center of the part has a small-diameter twist drill 4 extending out. The small-diameter twist drill 4 has a guide part and a cutting part. The central position is provided with positioning tip 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com