Tension lock

A technology of tension and locking hooks, which is applied in the field of tension locks, can solve the problems of large gap between the eccentric wheel and the locking hook, short service life, failure, etc., so that it is not easy to loosen or shift, the overall structure design is reasonable, and it is not easy to break and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

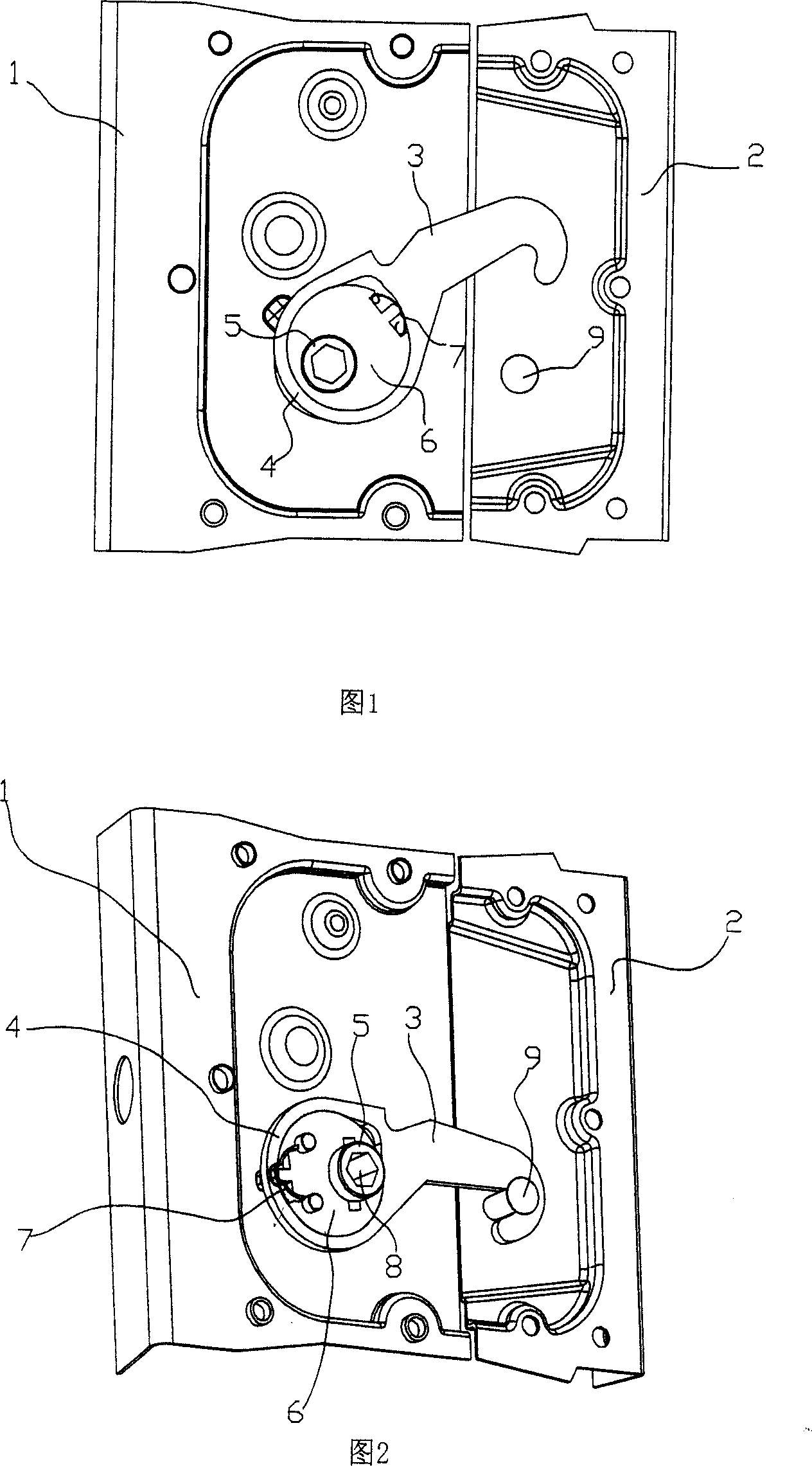

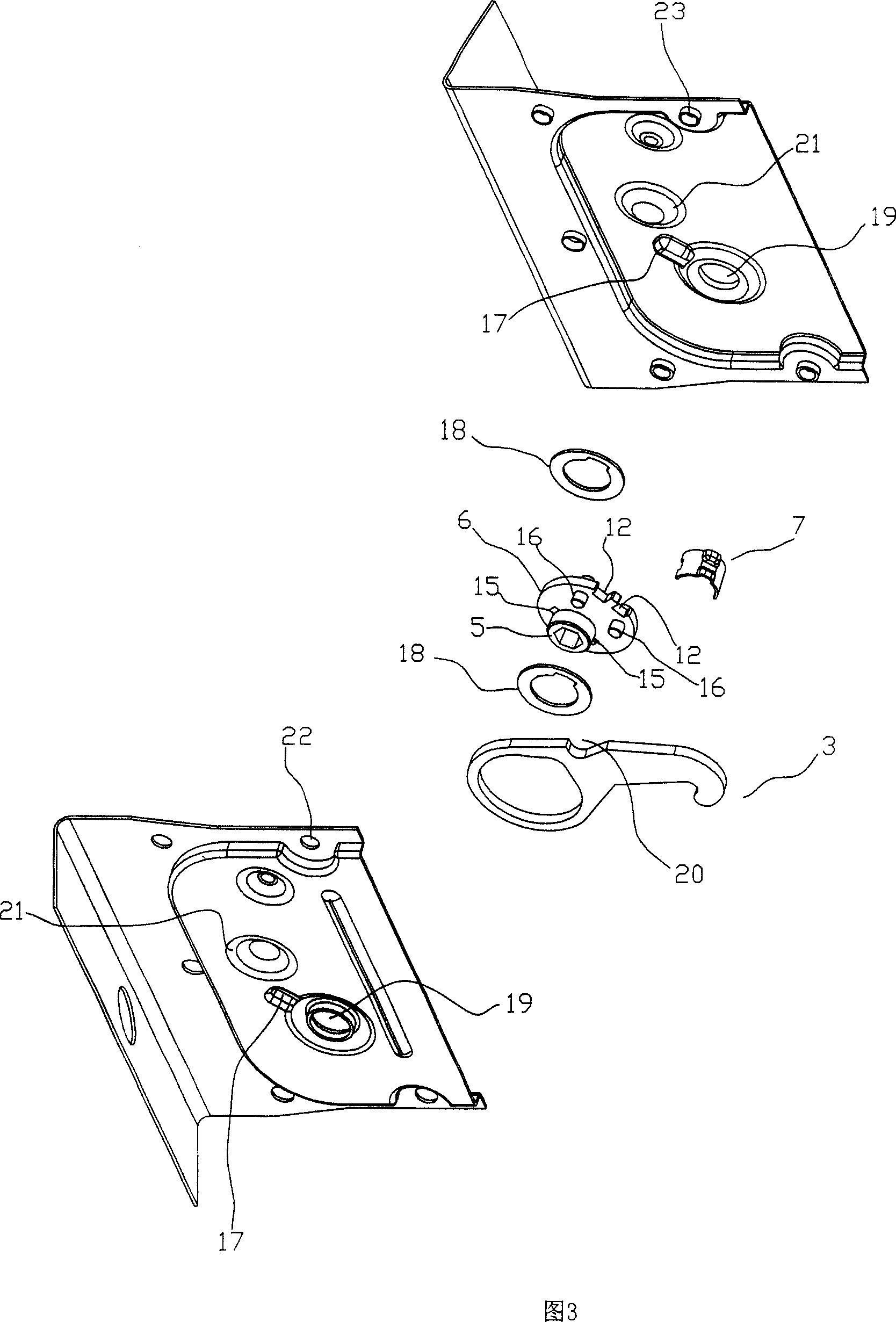

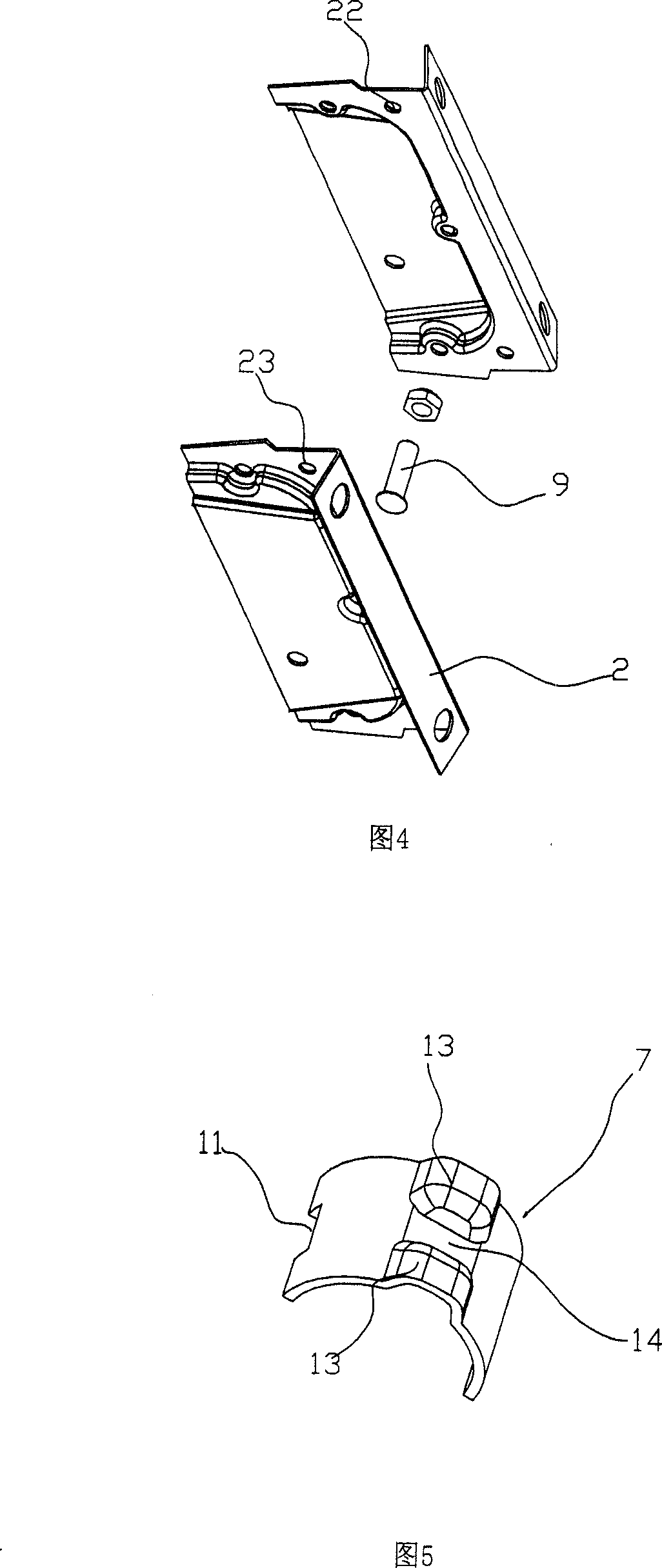

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] As shown in Figure 2-5, a pull lock includes a first base 1 and a second base 2 that cooperate with each other, wherein the metal shell of the first base 1 is formed by connecting two side panels. , the metal side panel punches out connecting holes 22 and connecting sleeves 23 on its surrounding edges such as the upper side, the lower side and the left side respectively, and the connecting sleeve 23 of one side panel is inserted into the connecting hole 22 of the other side panel, and is fixed by riveting. Become the first base 1, the cavity inside the first base 1 becomes the installation space. There is a rotatable lock hook 3 in the first base 1, the head of the lock hook 3 is hook-shaped, and the tail 4 is ring-shaped, which is manufactured by stamping a steel plate. A matching eccentric wheel 6 is arranged in the annular tail port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com