Patents

Literature

53results about How to "Consistent heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

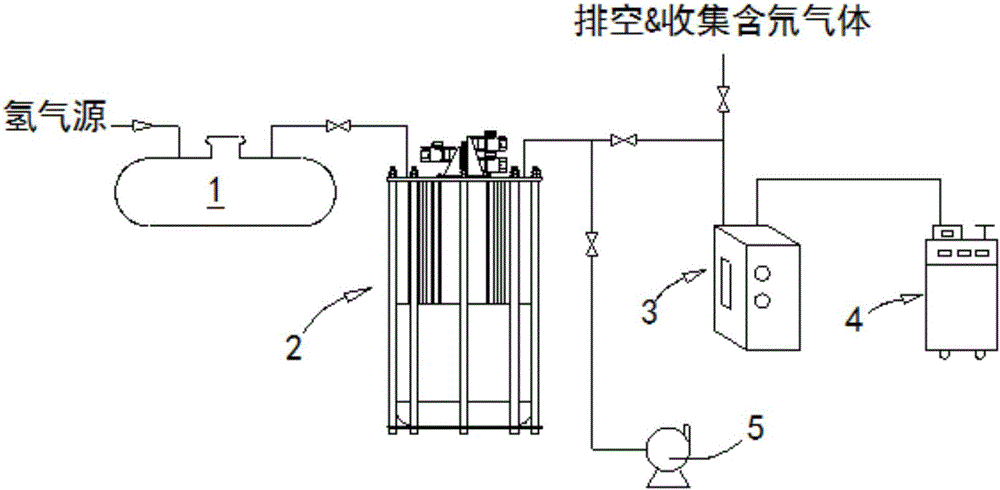

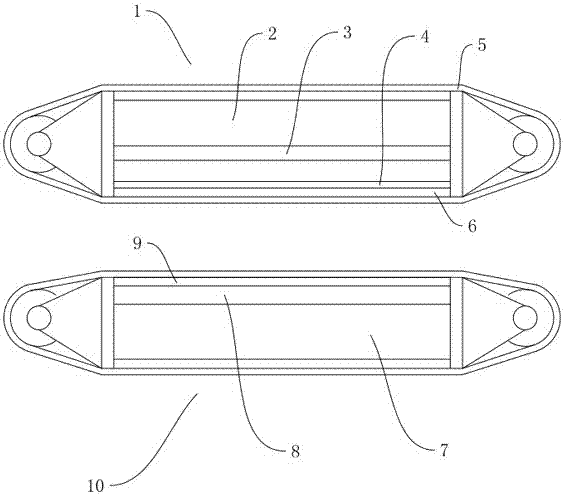

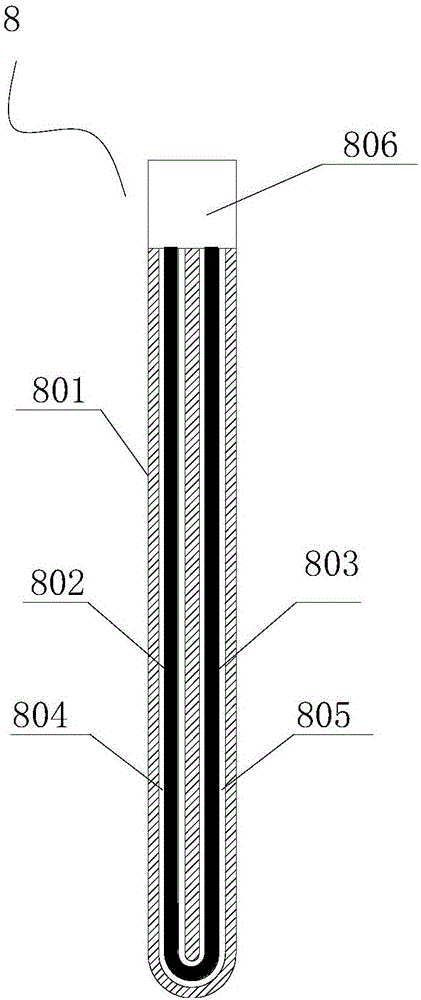

Enrichment separation method of hydrogen isotopes through displacement chromatography

ActiveCN106693704AIncrease the lengthReduce volumeComponent separationIsotope separationLiquid waterDisplacement chromatography

The invention discloses an enrichment separation method of hydrogen isotopes through displacement chromatography. The enrichment separation method comprises the following steps: (1) reducing the temperature: making a molecular sieve column into a spiral coil, loading a container with liquid nitrogen, wholly immersing the molecular sieve column into the liquid nitrogen, and enabling the temperature of a molecular sieve to be maintained to be the temperature of the liquid nitrogen; (2) performing adsorption: enabling hydrogen to be introduced into the molecular sieve column, measuring the quantity of the hydrogen introduced into the molecular sieve, and after the gas pressure in the molecular sieve reaches to a definite pressure, stopping introducing the hydrogen; (3) performing warming for separation: upwards lifting the spiral molecular sieve column, so that the molecular sieve column is separated from the liquid surface of the liquid nitrogen, heating the molecular sieve column with air, and controlling the speed of the molecular sieve column being lifted out of the liquid surface of the liquid nitrogen to be 0.5-5 cm / min; and (4) performing detection and collection: oxidizing hydrogen into liquid water through an oxyhydrogen compositor at a rear end for the hydrogen discharged from the molecular sieve column, and then detecting the deuterium abundance in the liquid water through a magnetic mass spectrometer. According to the enrichment separation method of tritium through displacement chromatography disclosed by the invention, changes in the controlled process of reducing the temperature and raising the temperature have continuity, the hydrogen isotope separation efficiency is extremely high, and the separation effects are good.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

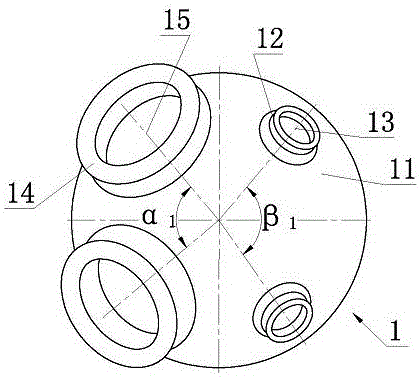

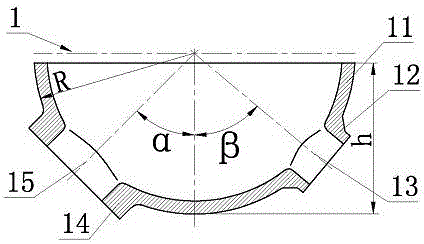

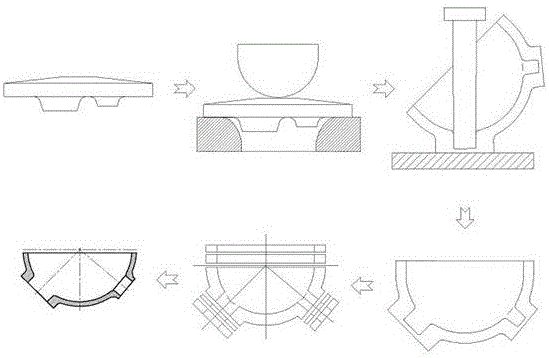

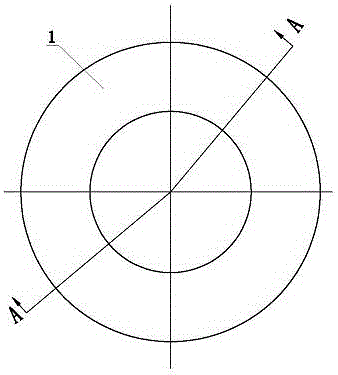

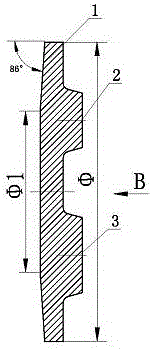

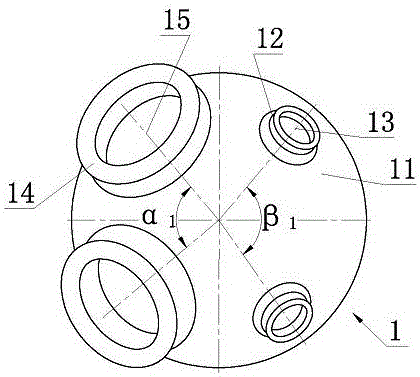

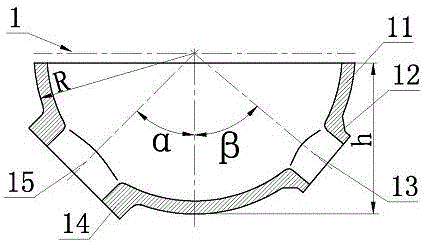

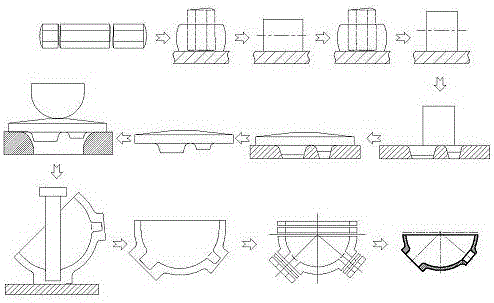

Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

ActiveCN106051721AImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersFiberPunching

The invention discloses a pressure vessel integrated end socket for nuclear power, an end socket plate blank of the pressure vessel integrated end socket and a forging method of the pressure vessel integrated end socket. According to the pressure vessel integrated end socket for nuclear power, a manhole base and a pipe hole base are arranged on an end socket body which is of a spherical crown structure; the manhole base and the pipe hole base are integrated with the end socket body in a forged mode; and the intersection point of the hole center line of a manhole and the hole center line of a pipe hole is located in the center of the sphere where the end socket body is located. A plate blank body of the end socket plate blank is of a circular plate structure, one surface of the plate blank body is provided with two manhole circular truncated cones and two pipe hole circular truncated cones, and the other surface of the plate blank body is a large-cone-angle circular truncated cone surface. The forging method comprises the following steps of steel ingot heating, forged blank blanking, forged blank upsetting and drawing, die forging formation, plate blank heat treatment, plate blank rough machining, end socket formation, end socket punching, forge piece heat treatment, machining of a forge piece, performance heat treatment and finished product machining. The integrated formation of the end socket of a vapor generator is achieved, the forge piece is uniform and compact in texture, the metal flow line is complete, and the fiber texture and the appearance of the forge piece tend to be more coincident.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

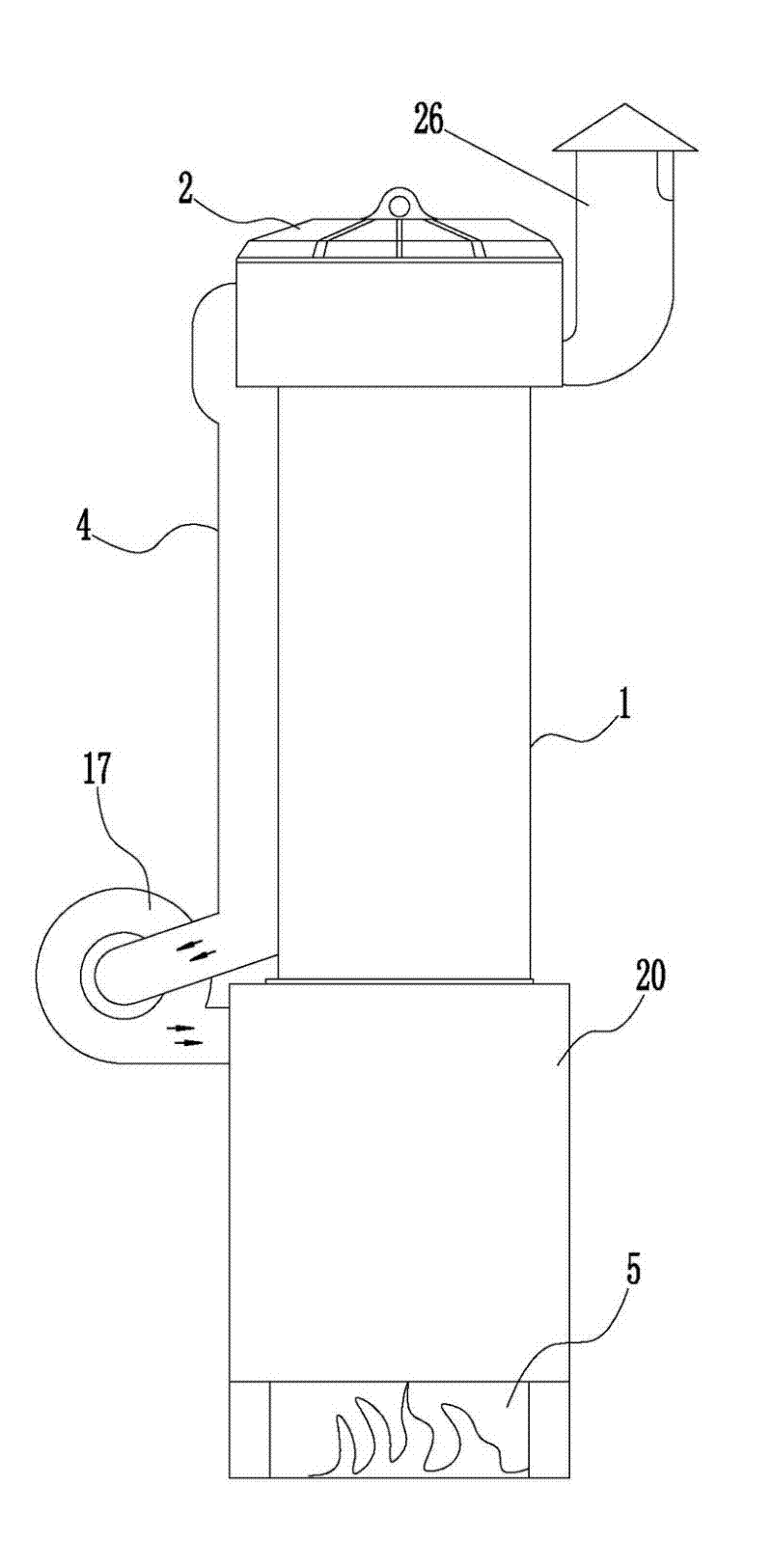

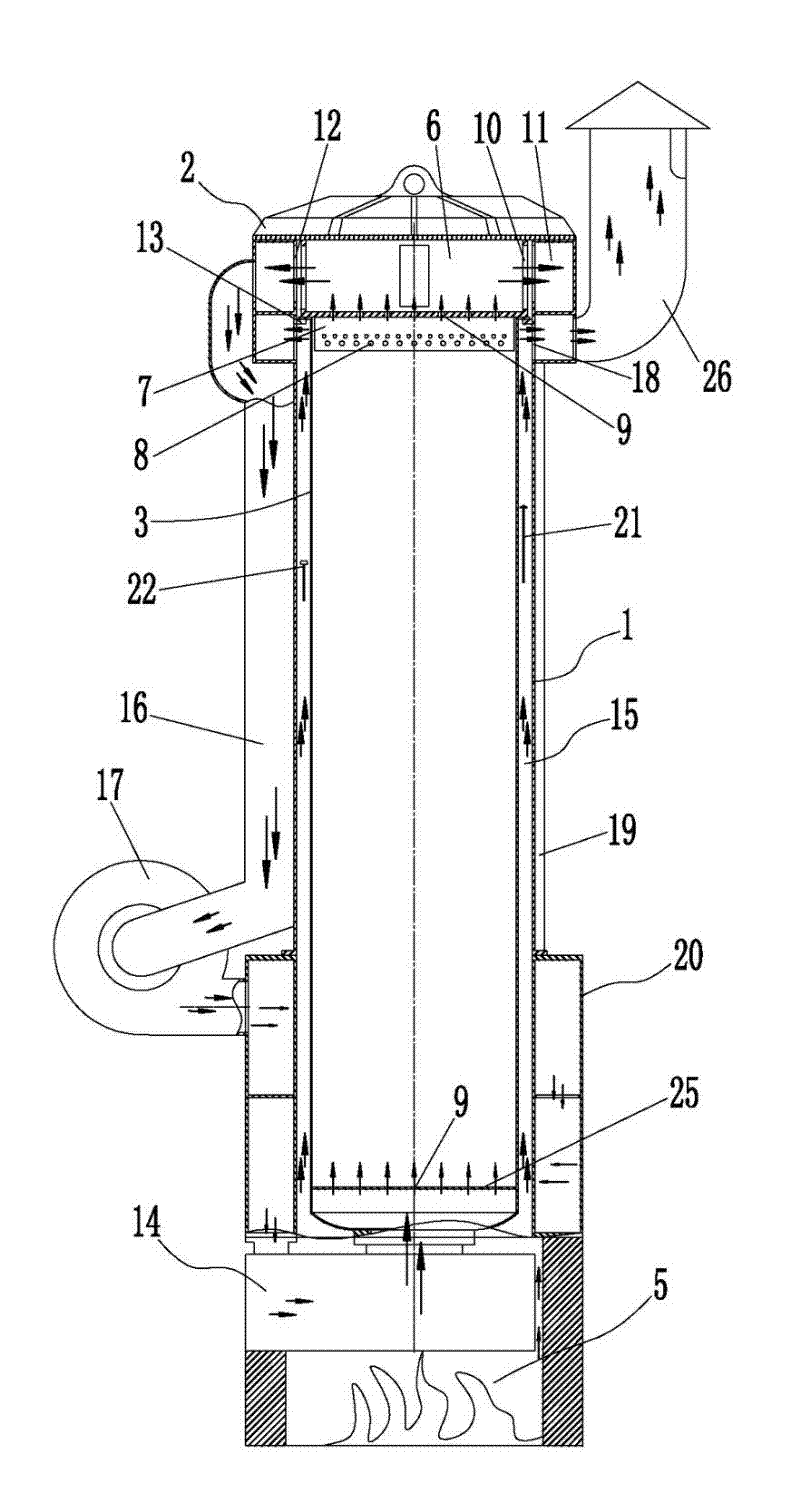

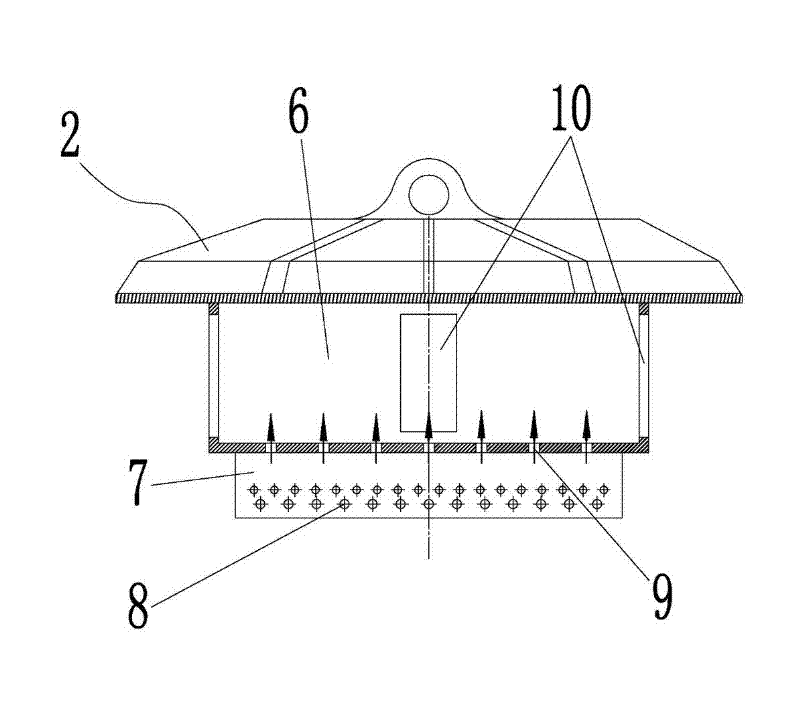

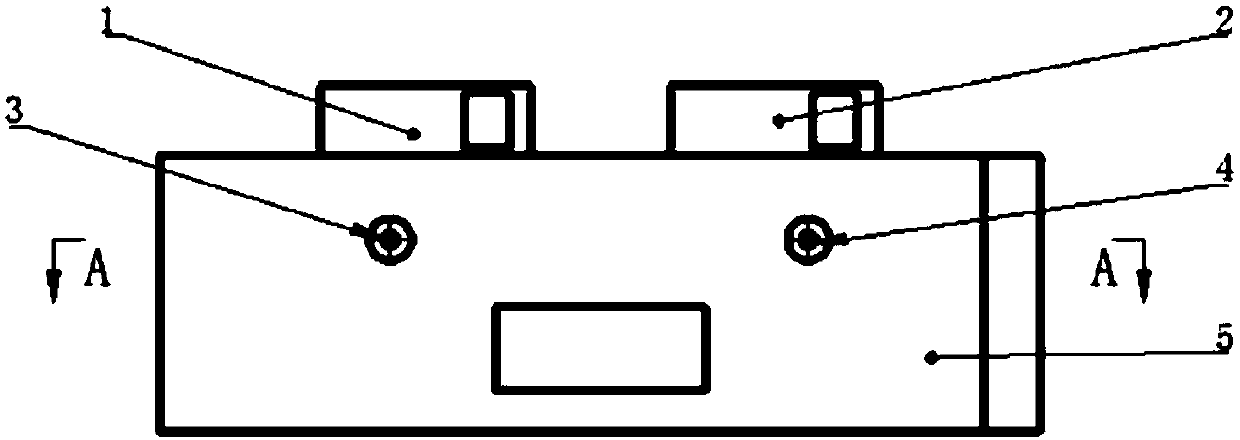

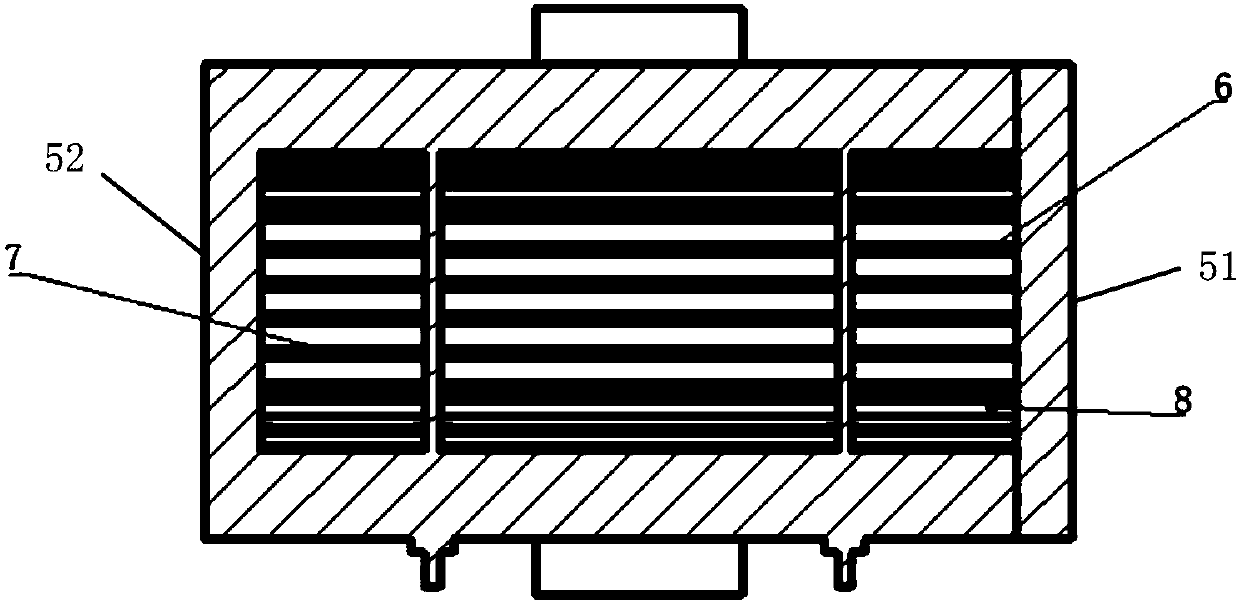

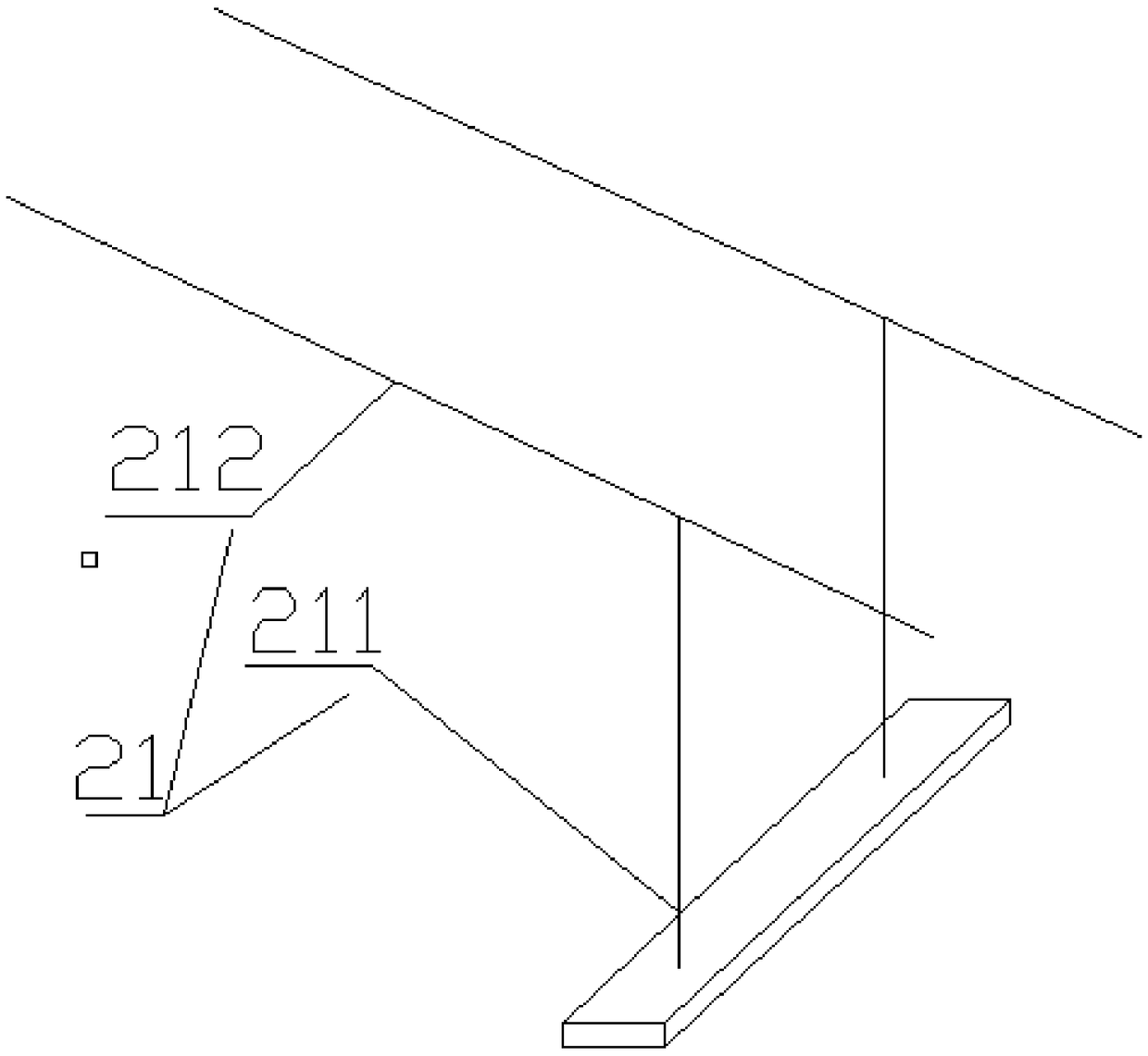

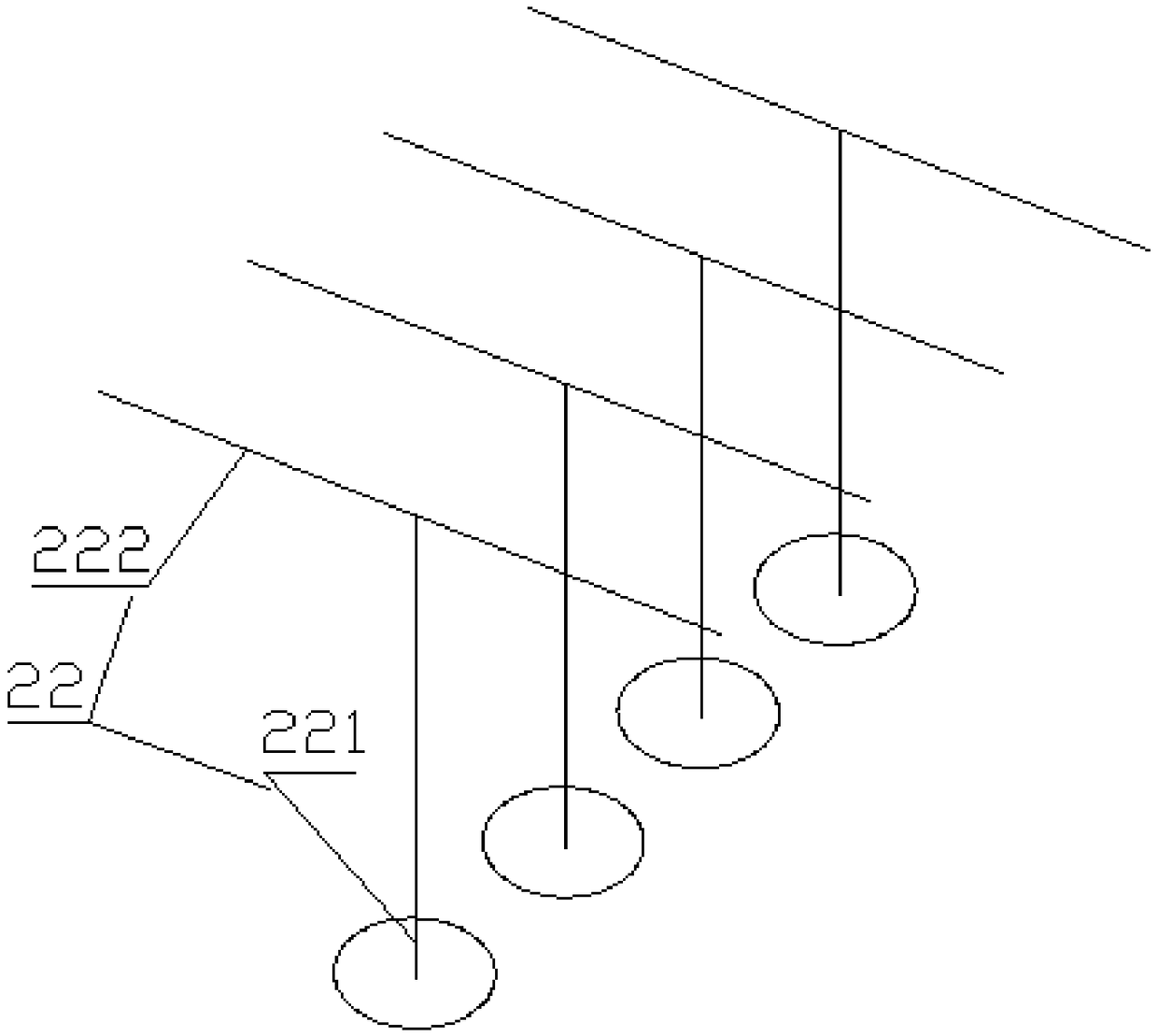

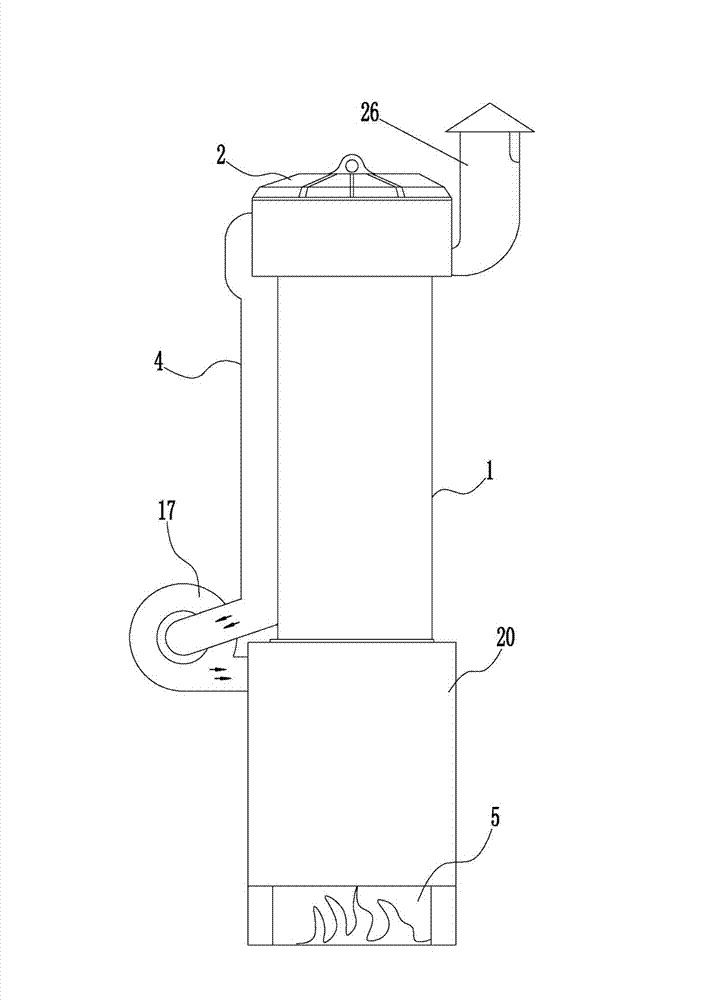

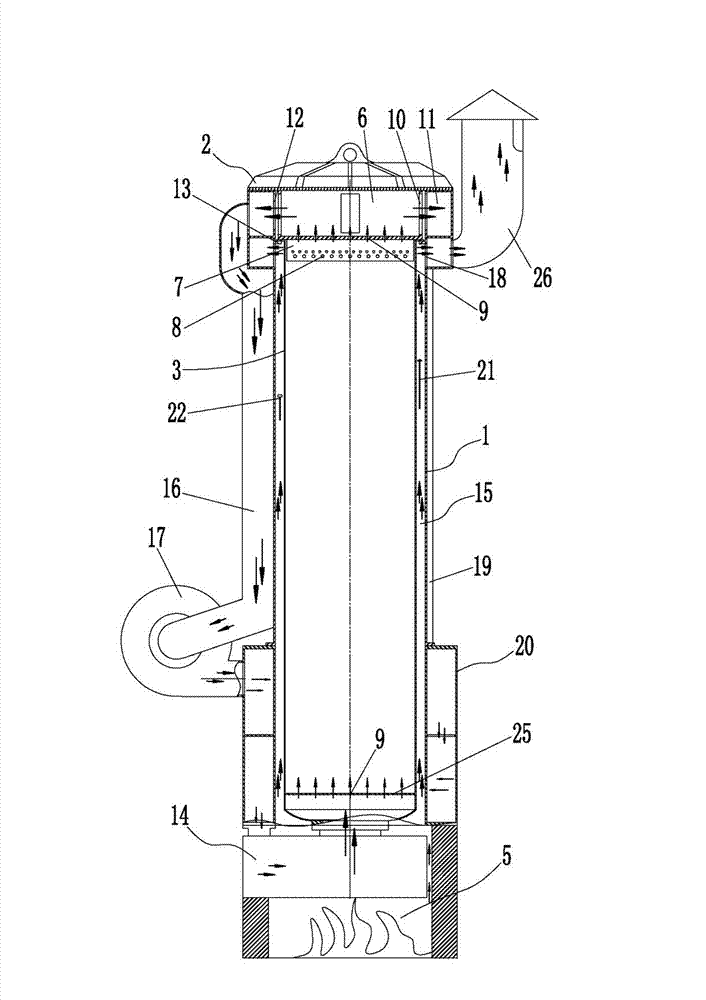

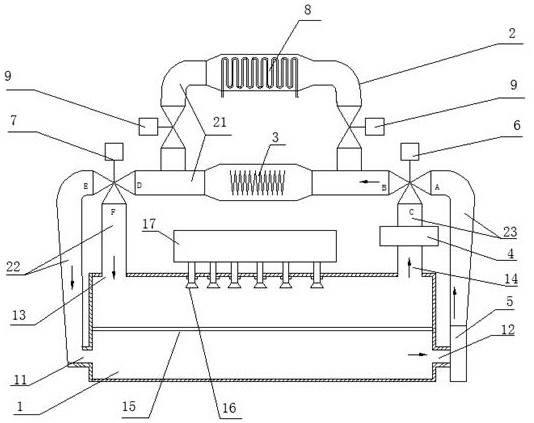

Tempering Furnace

ActiveCN102213544AEasy to control temperatureImprove tempering qualityVertical furnacesHearthEnergy conservation

The invention relates to a tempering furnace. The furnace comprises a furnace body, the top of which is provided with a furnace cover, an inner container is arranged in the furnace body, an air circulating and heating device is arranged on the furnace body, and a hearth is arranged at the bottom end of the furnace body. By properly arranging the furnace cover, the inner container, the air circulating and heating device and the like, the tempering furnace provided by the invention achieves omidirectional tempering of a workpiece which is suspended below the furnace cover by the process of uniformly heating, cycling and preheating the gas in the furnace, thus avoiding tempering blind spot in the furnace, obviously decreasing the temperature deviation in the furnace, and effectively improving the tempering quality of the workpiece in the furnace. Moreover, the tempering furnace maximally utilizes the heat created by burning the fuel, and further improves the furnace tempering effect. The tempering furnace of the invention has the advantages of reasonable and simple structure, low production cost, simplicity of operation, convenience of maintenance, high efficiency and energy conservation, and is suitable for popularization.

Owner:LISHUI HUAYI AUTOMATION TECH

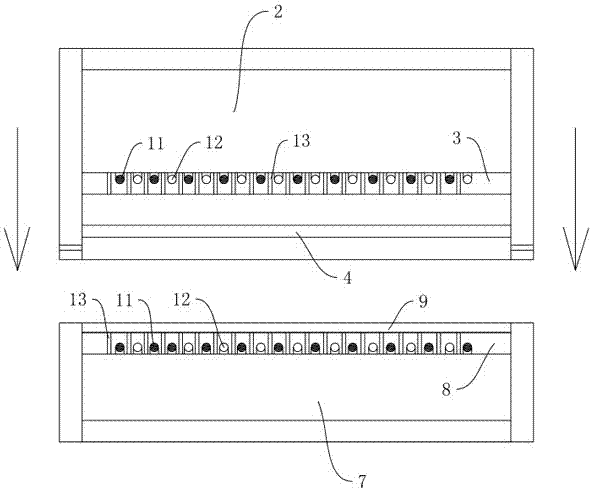

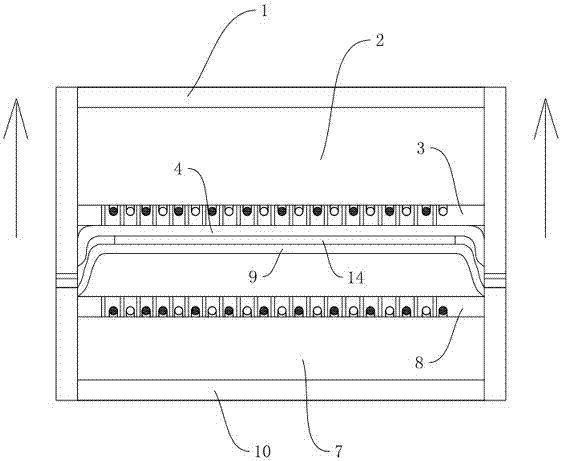

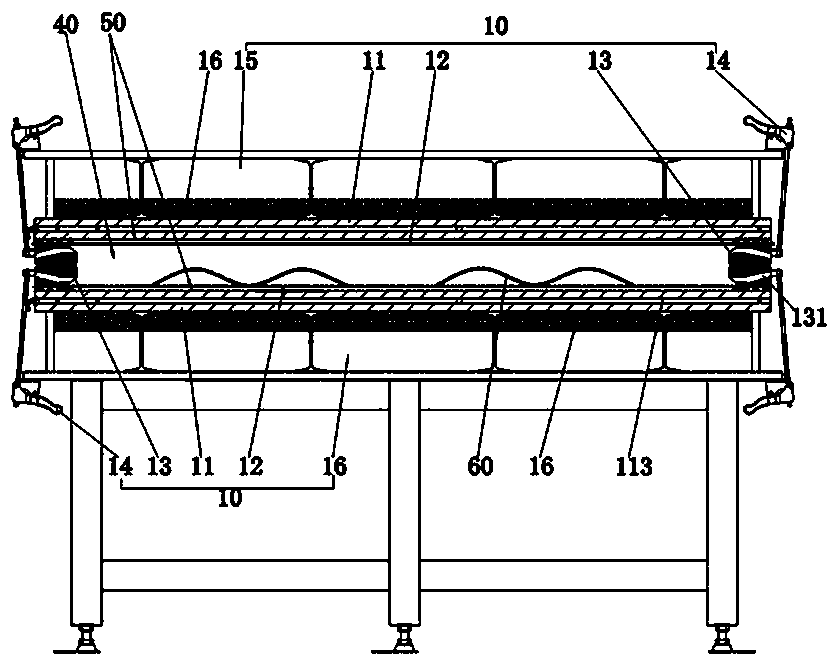

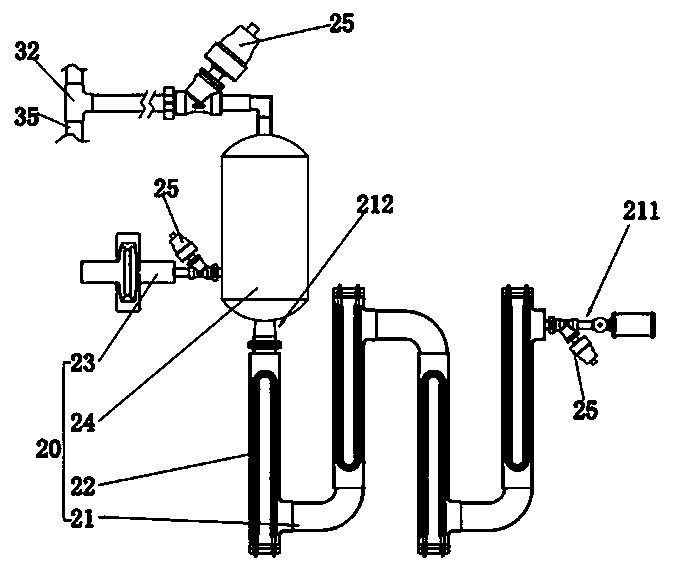

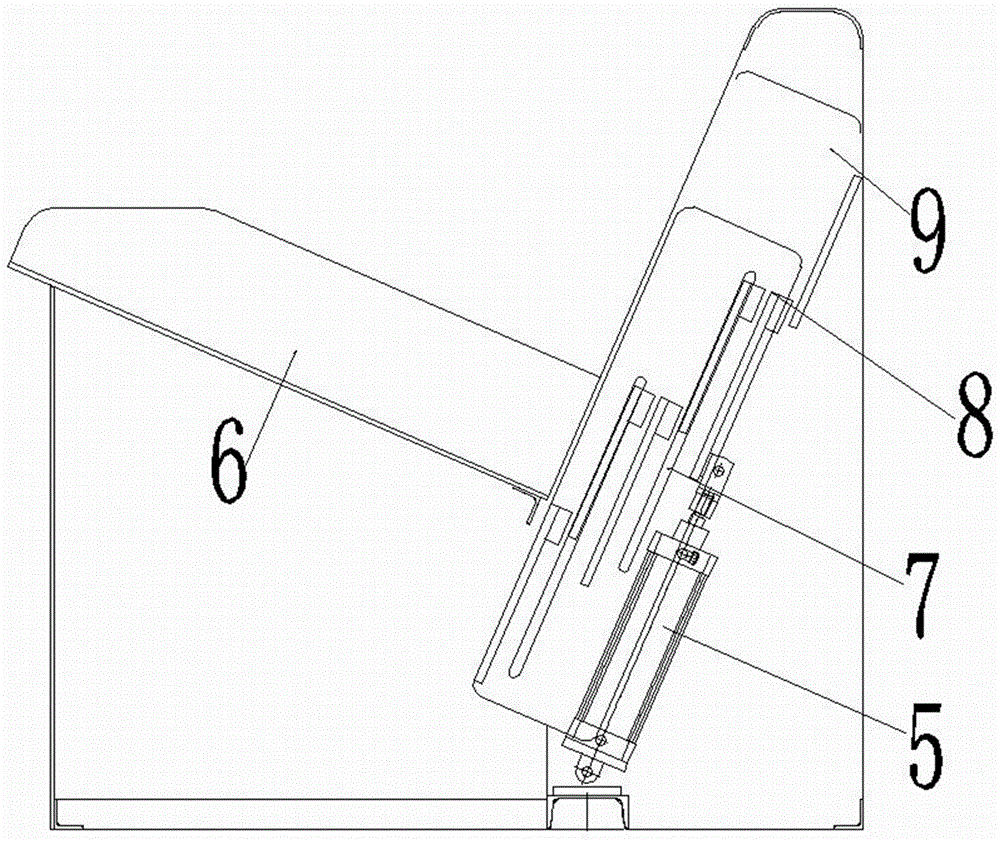

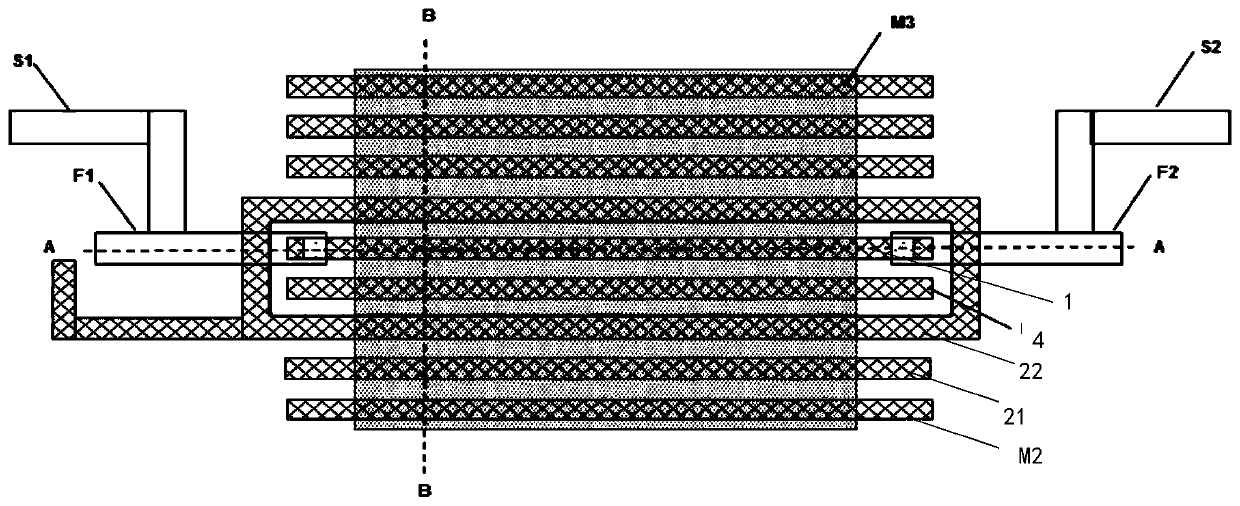

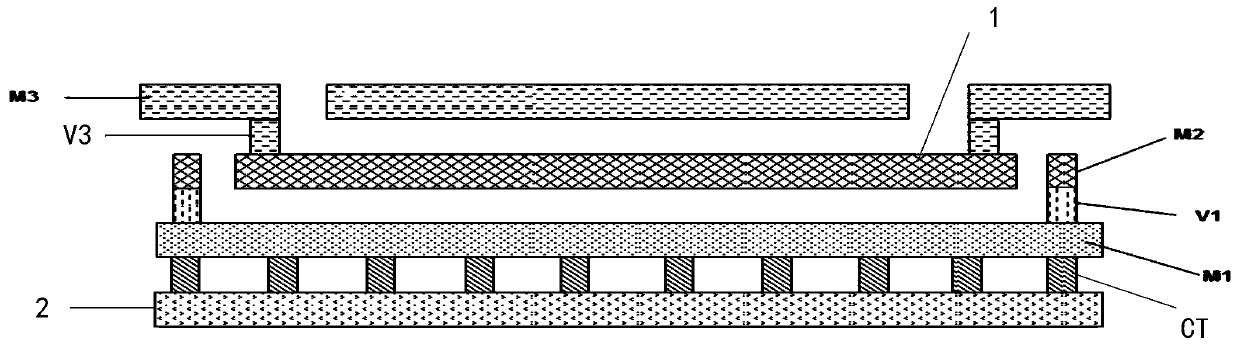

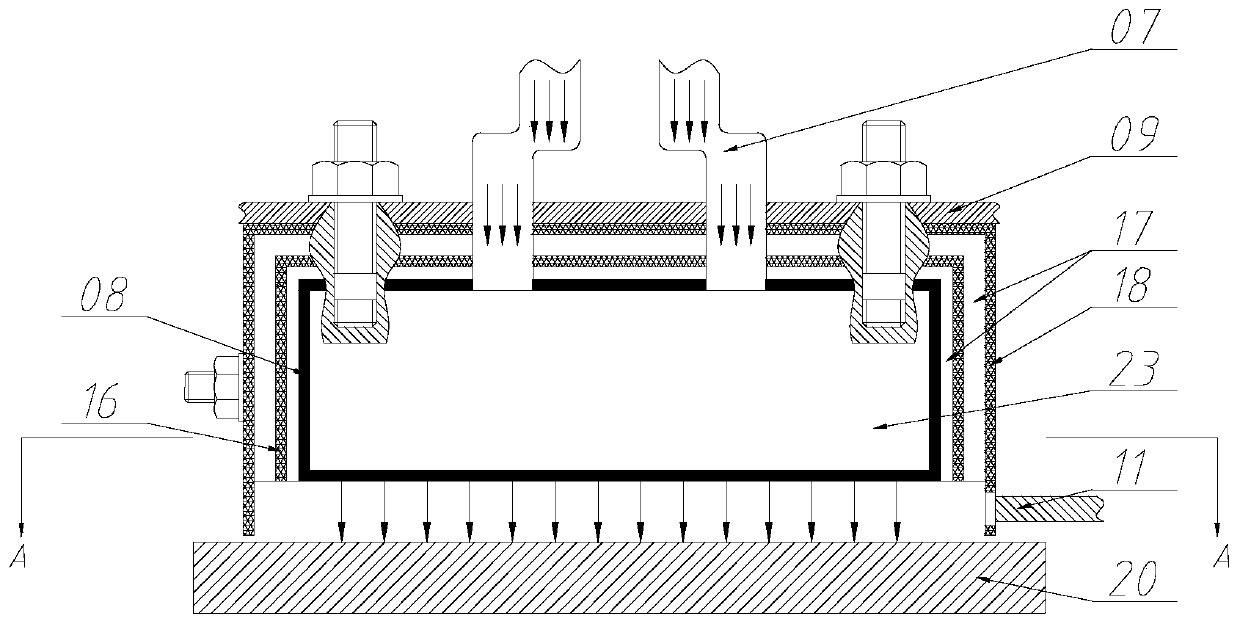

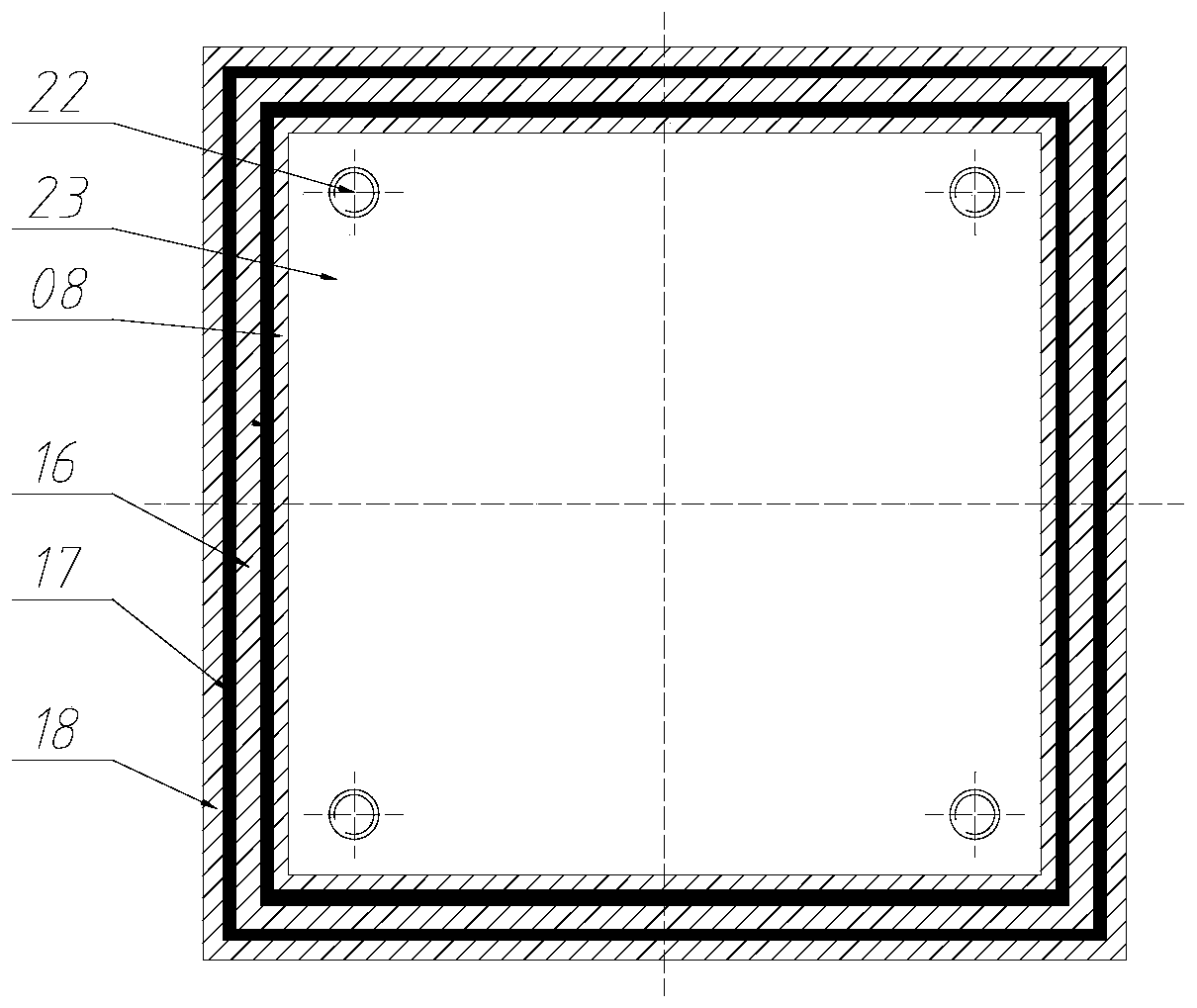

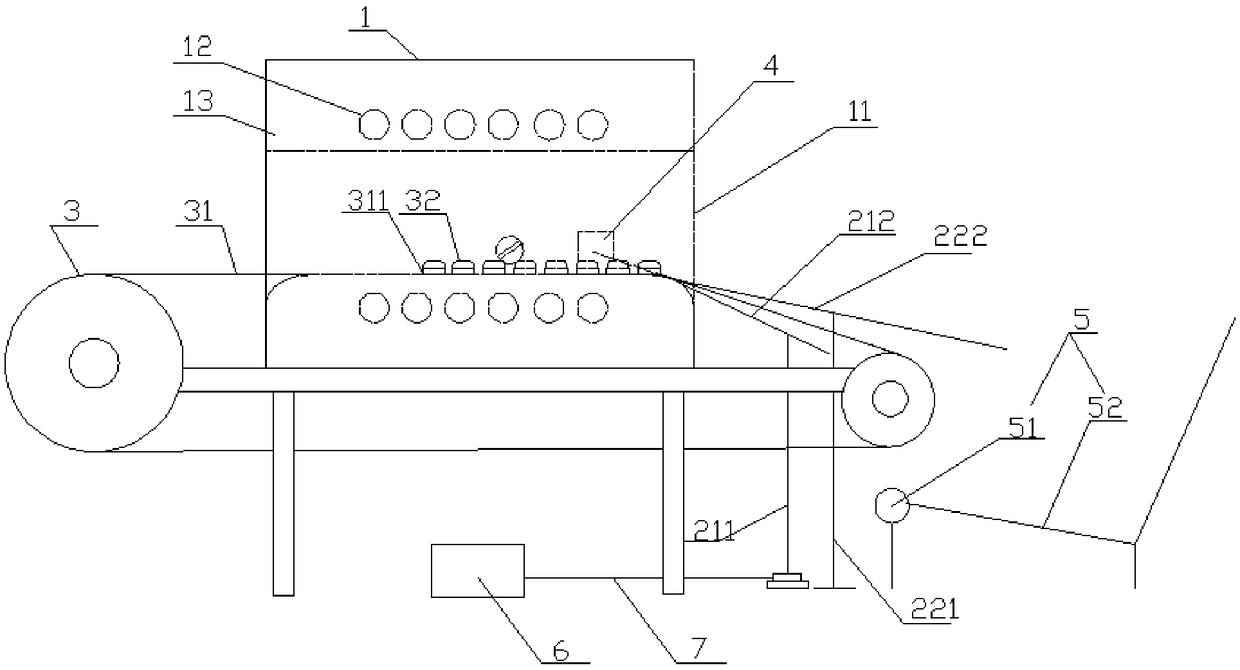

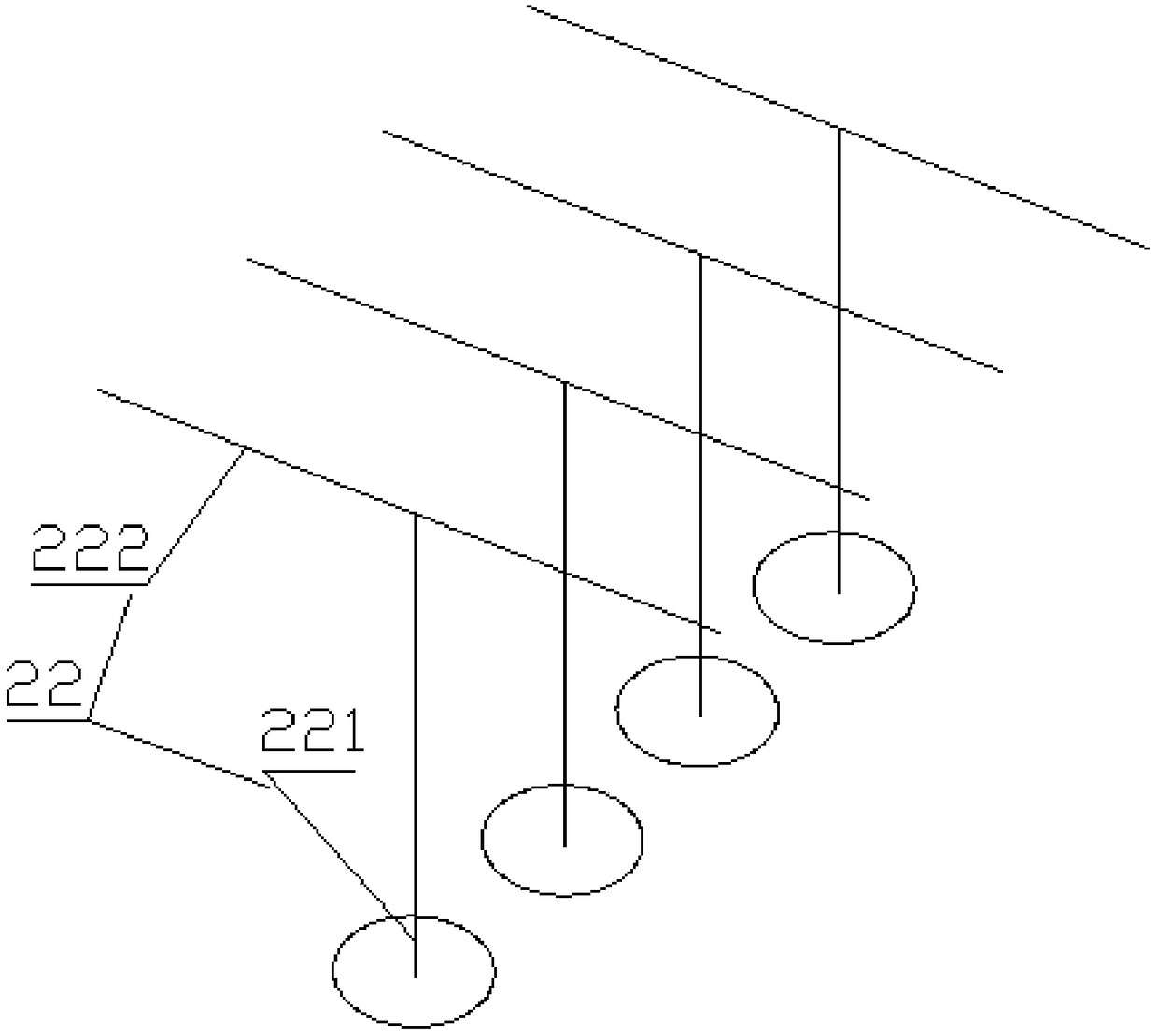

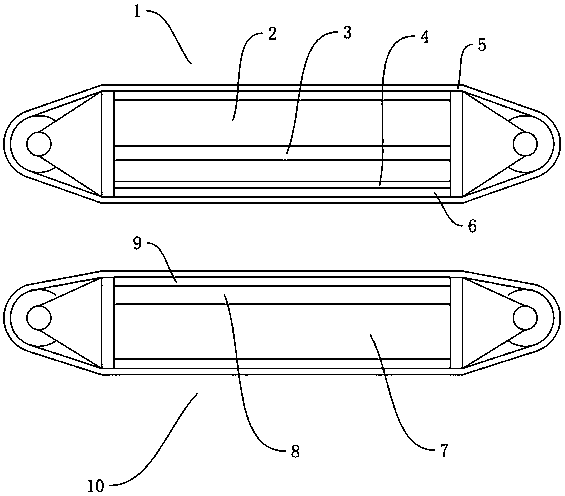

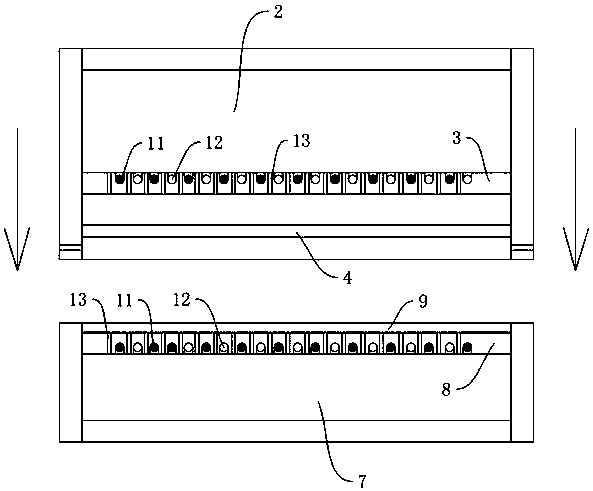

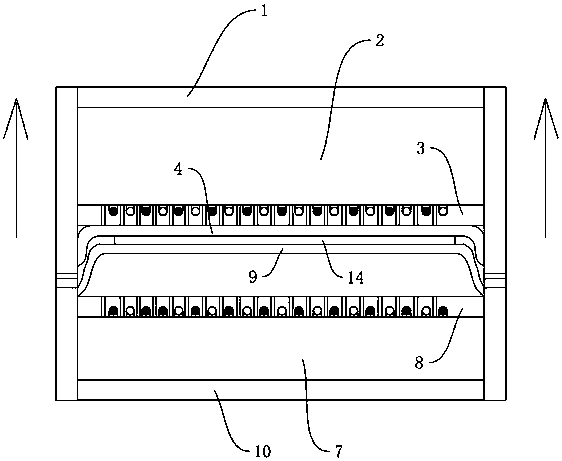

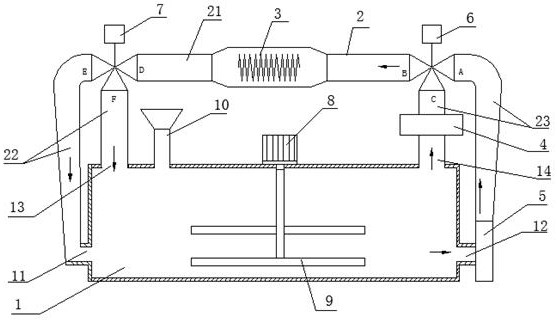

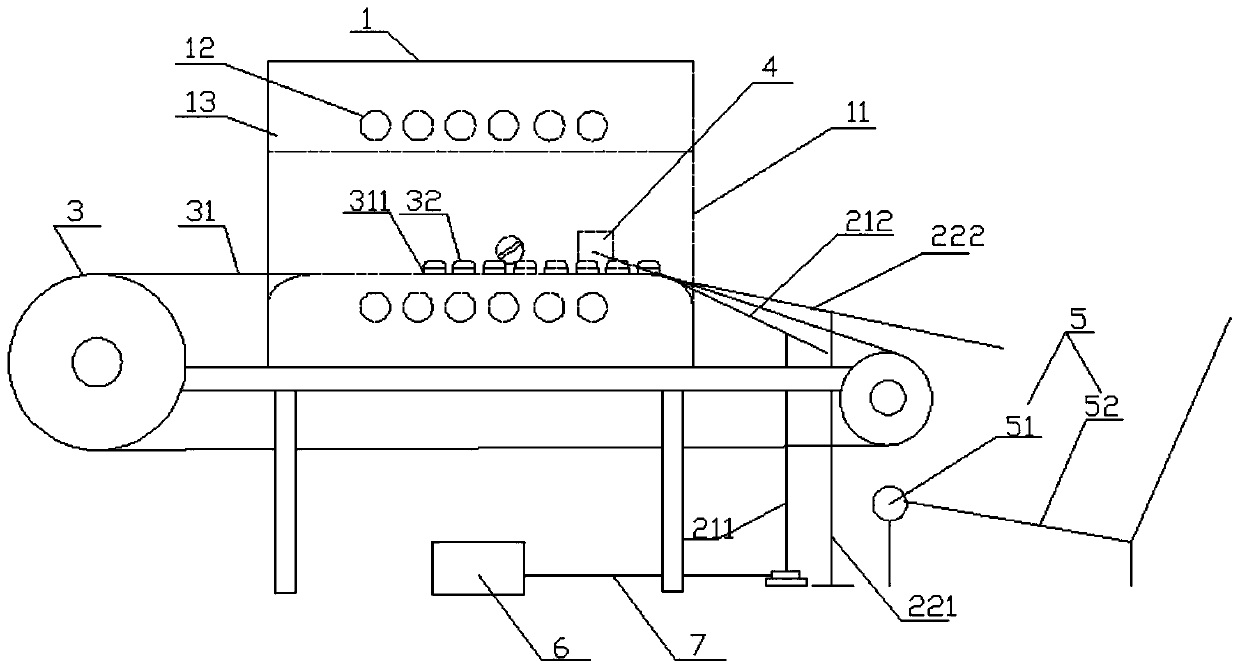

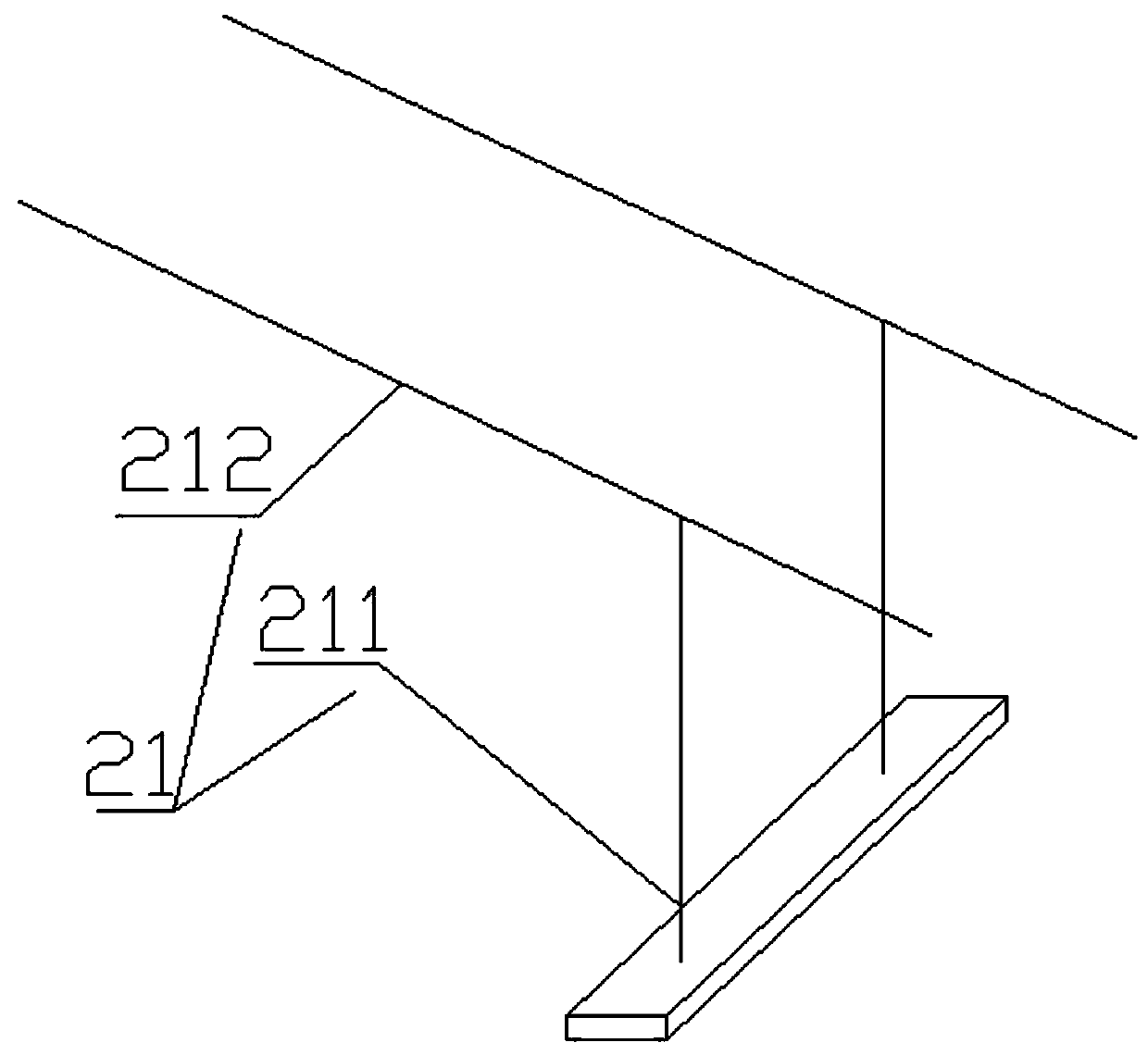

Hot pressing device for flexible solar battery component

ActiveCN106976297AConsistent heating temperatureSame heating timeFinal product manufactureLaminationControl systemElectrical battery

The invention relates to a hot pressing device for a flexible solar battery component, and solves the defect that due to long-term heating at high temperature, gases produced in a solar battery component are difficult to discharge, and bubbles are produced on the outer surface of the solar battery component to affect product appearance, the hot pressing device comprises an upper component and a lower component, a heating system, a vacuumizing system and a control system, the upper component and the lower component can be mutually laminated to form a closed shaped hot pressing cavity used for lamination of a non flat or curved flexible solar battery component, the heating system is used to provide heating temperature for hot pressing of the solar battery component, the vacuumizing system is used for vacuumizing the upper component and the lower component and overall floating the solar battery component for hot pressing, and the control systemis used for controlling the heating system and the vacuumizing system. The heating system is used for heating the hot pressing cavity, the vacuumizing system is used for vacuumizing the upper component and the lower component, the solar battery component floats in the hot pressing cavity, only after the solar battery component completely enters the hot pressing cavity and up floats, the hot pressing is performed, the lamination degree of the whole piece of the solar battery component can be ensured, and quality is stable.

Owner:浙江尚越新能源开发有限公司

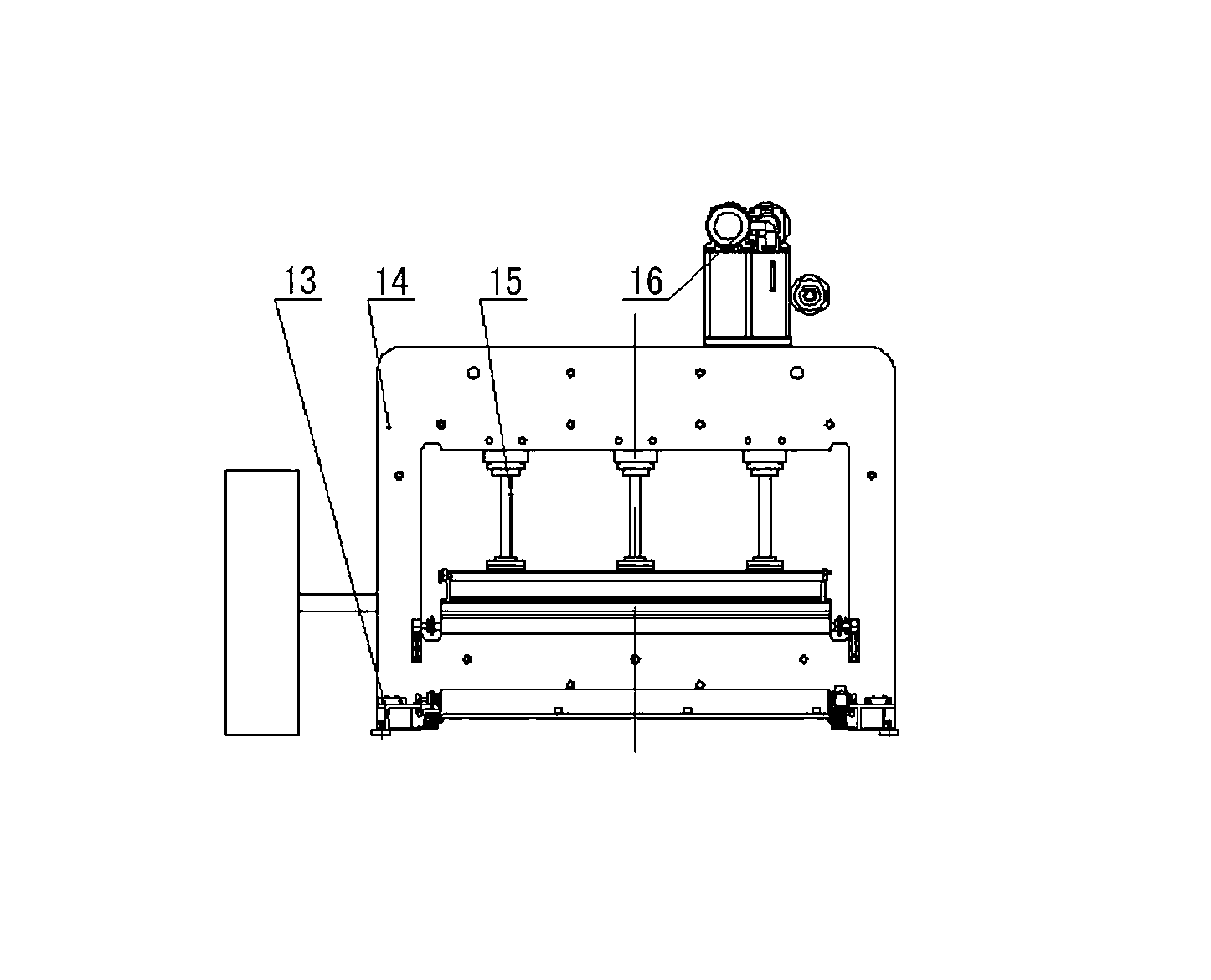

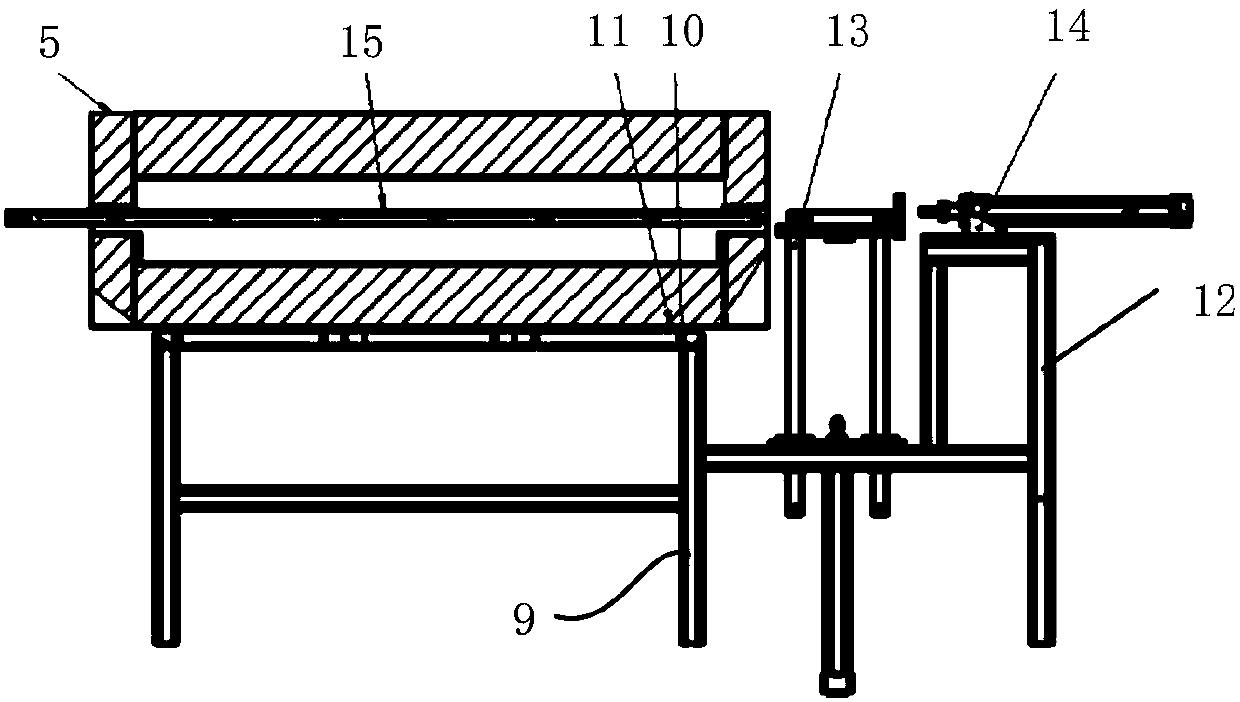

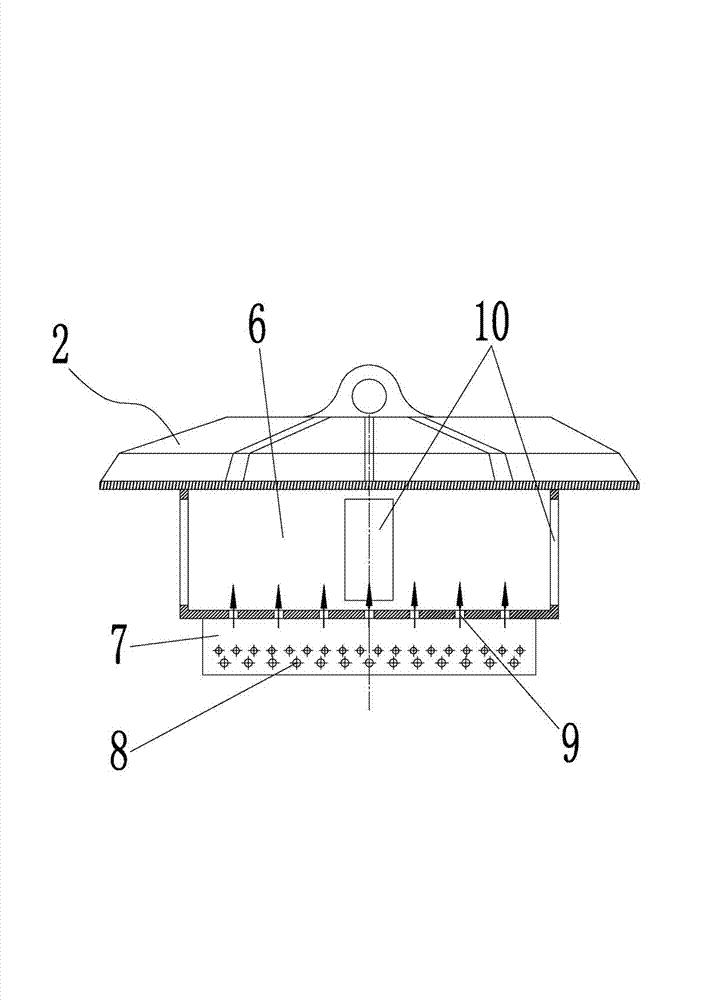

Positive pressure encapsulation device of building integrated photovoltaics (BIPV) solar energy component

InactiveCN103022250AStable structureSimple structureFinal product manufactureSemiconductor devicesHydraulic cylinderPositive pressure

The invention discloses a positive pressure encapsulation device of a building integrated photovoltaics (BIPV) solar energy component. The positive pressure encapsulation device comprises a portal frame and a delivery mechanism penetrating through the portal frame, wherein an upper heating plate and a lower heating plate are arranged on the portal frame and connected with corresponding oil heaters, the lower heating plate is provided with a plurality of cambered surface type ejector pins, each cambered surface ejector pin is connected with an air cylinder, the upper surface of the upper heating plate is connected with an upper box, the upper surface of the upper box is connected with a plurality of hydraulic cylinders and connected with a hydraulic pressure station fixed on the top of the portal main frame, and the periphery of a matching end of the upper surface of the upper box and the lower heating plate is provided with an upper lining plate, a lower lining plate, a silica gel plate located between the upper lining plate and the lower lining plate, and an upper and a lower chambers which are formed by combining a silica gel strip inlaid on the upper surface of the upper lining plate with the silica gel plate. A double-glass battery component is simultaneously heated up and down, and is pressed positively, so that encapsulation requirements of a BIPV battery component with a large area and made of thick toughened glass are satisfied.

Owner:秦皇岛瑞晶太阳能科技有限公司

Integral seal punch molding method of nuclear power pressure container

The invention discloses an integral seal punch molding method of a nuclear power pressure container. The punch molding method comprises the following steps: roughening of a plate blank: the heated seal plate blank is machined; heating of the plate blank: the roughened seal plate blank is sent in a heating furnace for heating; molding of a seal: the seal plate blank is shifted to an annular mold with a center hole for punching to mold a semi-spherical seal blank; punching of the seal: a seal punching part with two man holes and two pipe holes is punched; heat treatment of the punched part: the punched part is discharged from a furnace for air cooling when being cooled to 180 DEG C along with the furnace after autoclaving; machining of the punched part: the heated seal punched part is machined as a seal rough finished product; performance heat treatment: the quenching treatment is performed firstly; and then, the thermal refining is performed; and the finished product is machined to a qualified seal finished product. The method realizes integral molding of a steam generator seal, and is uniform and compact in metal structure and complete in streamline.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

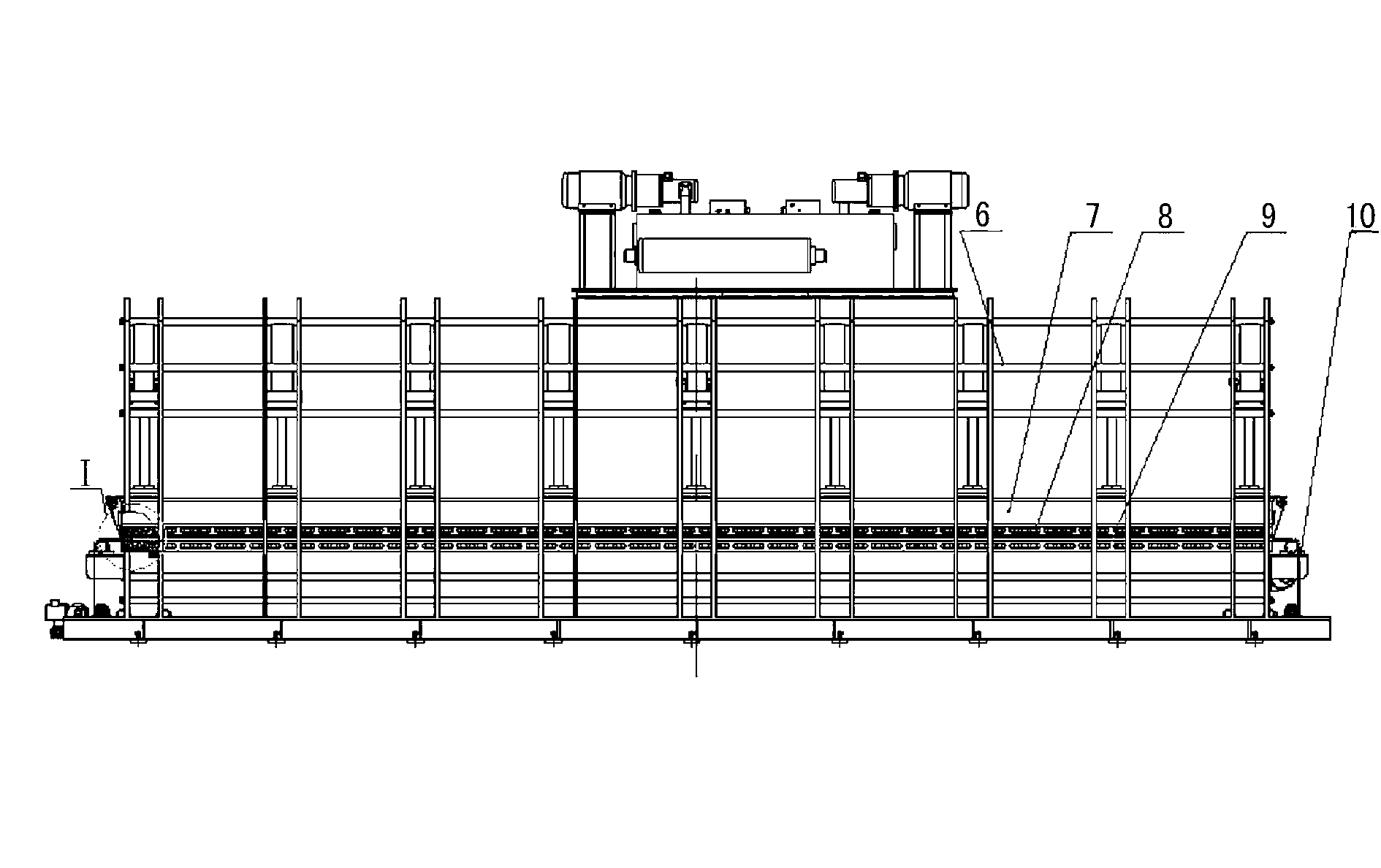

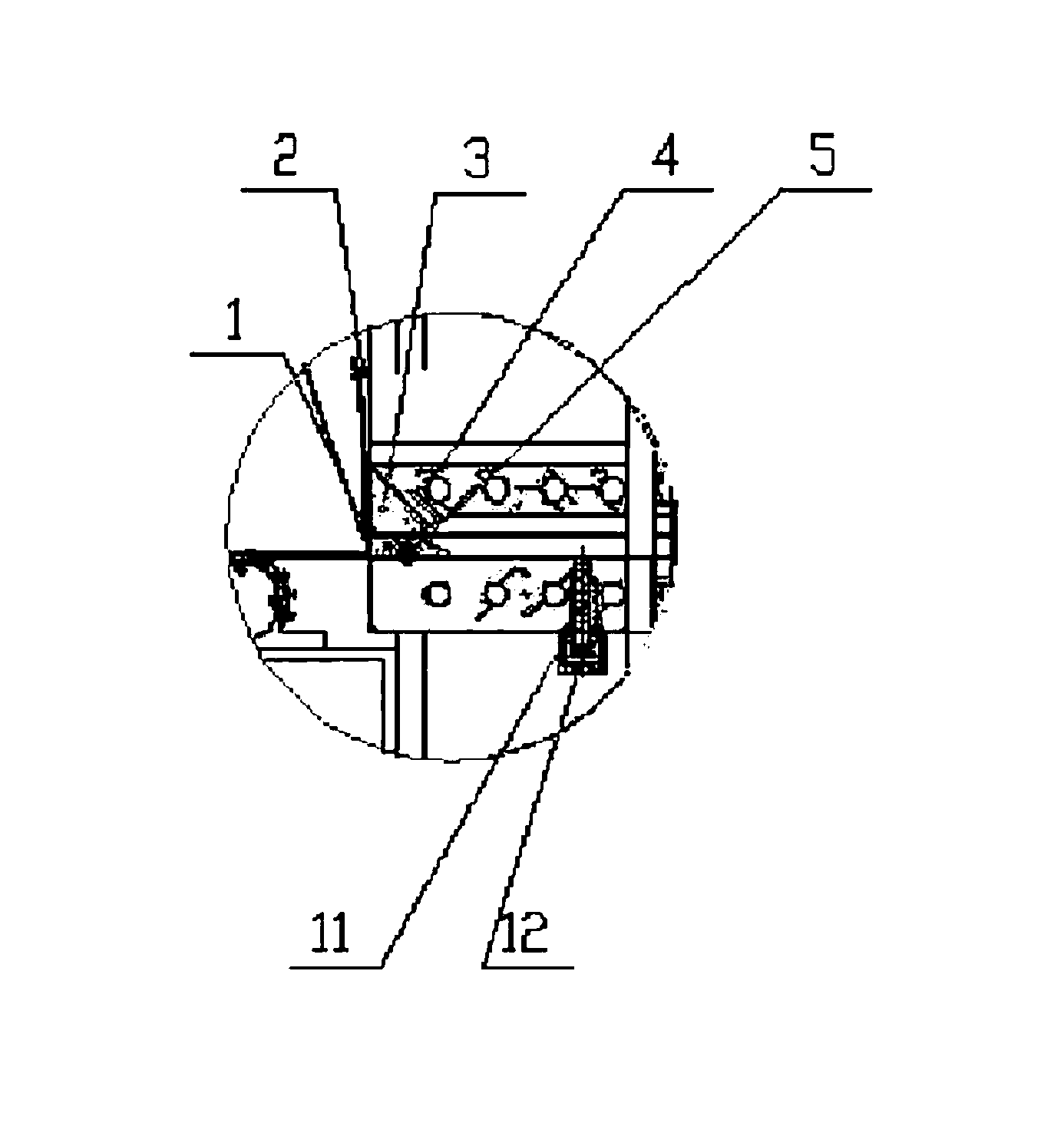

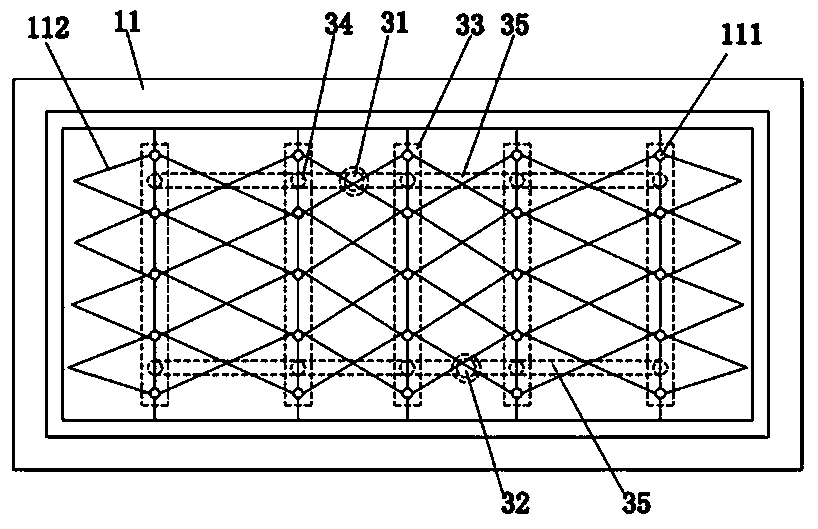

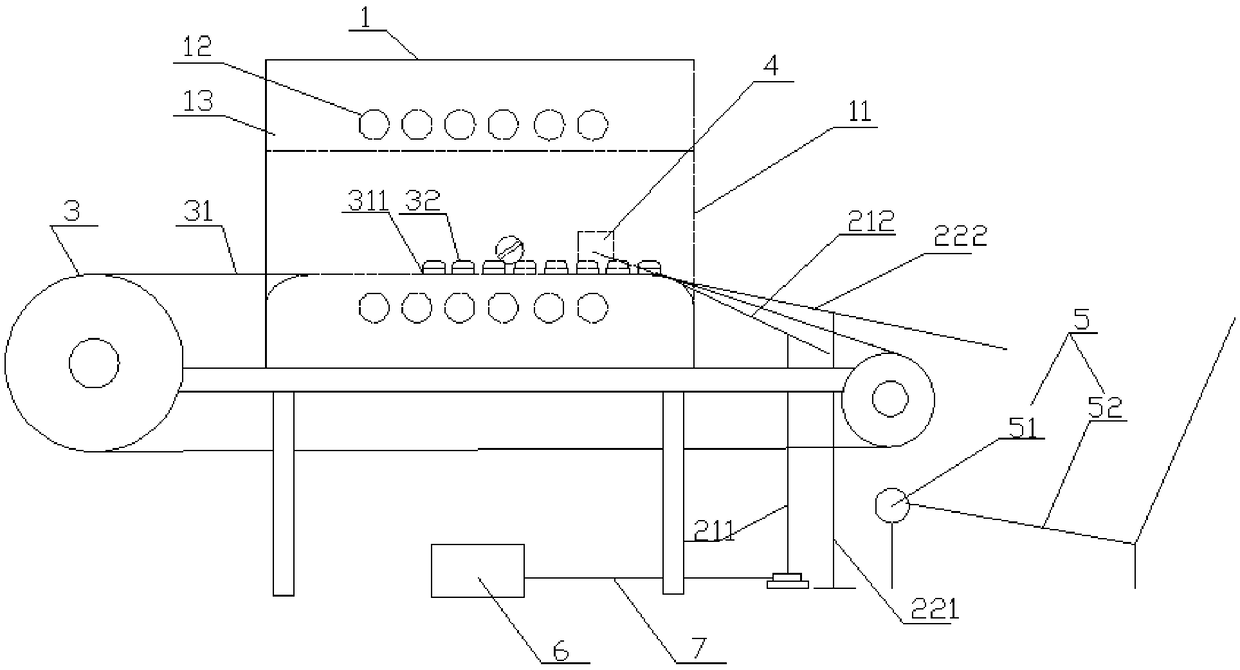

Novel surface photovoltaic module laminating machine and machining method thereof

PendingCN109461792AExtended service lifeGuaranteed contact areaFinal product manufacturePhotovoltaic energy generationState of artEngineering

The invention aims at the problem that in the prior art, the heating efficiency of a laminating machine in the laminating process is low, and provides a surface photovoltaic module laminating machine.The surface photovoltaic module laminating machine comprises an upper heating box and a lower heating box which are arranged face to face, a gas supplying, heating and pressurizing device and a vacuumizing device; each heating box comprises a cavity top plate, an elastic cavity partition plate and pressing strips which arrange the edges of the cavity partition plate on the cavity top plate in a sealing mode, wherein a heating cavity is formed between the cavity partition plate and the cavity top plate; the pressing strips of the two heating boxes face each other, the two cavity partition plates which are arranged face to face and the pressing strips form a sealed laminating cavity when the upper heating box and the lower heating box are closed, and the vacuumizing device is communicated with the two heating cavities and the laminating cavity; the gas supplying, heating and pressurizing device is communicated with the heating cavities and can fill heated and pressurized gas into the heating cavities; and the cavity partition plates are directly heated while pressure is generated by means of the heated gas, and therefore the heating efficiency in the laminating process is greatly improved.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

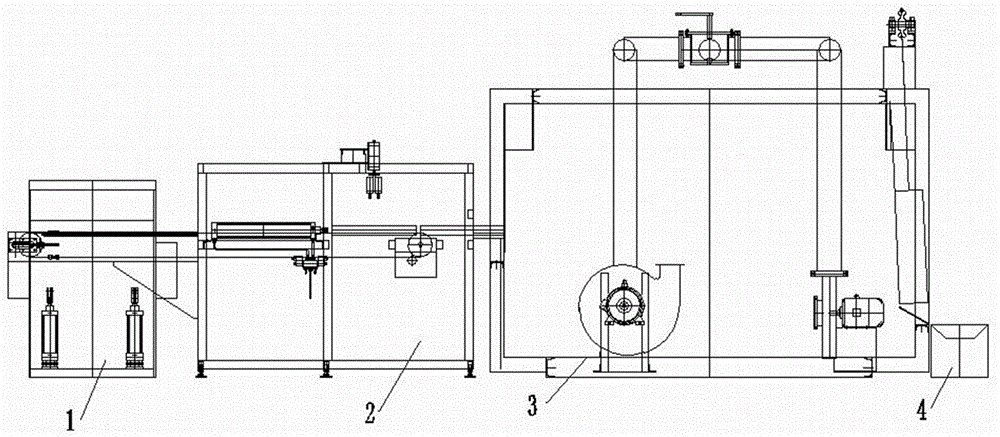

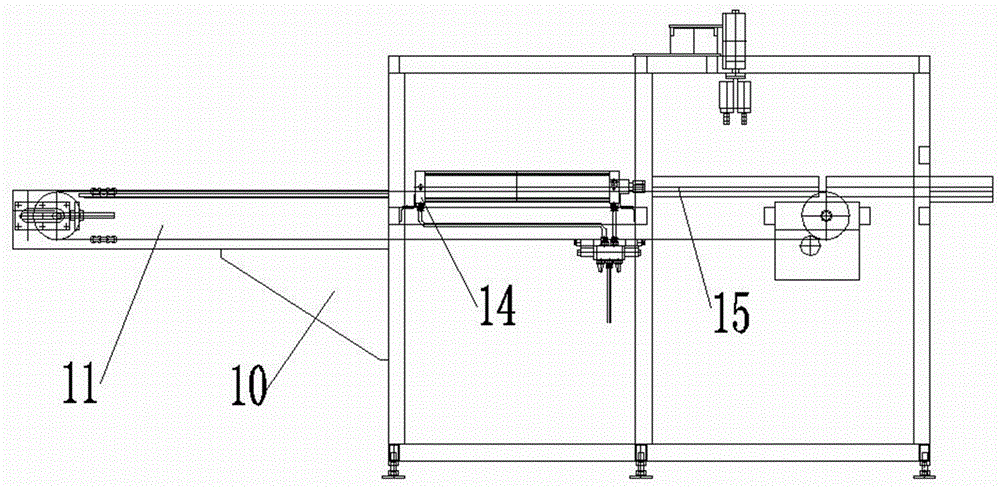

Fully-automatic continuous heating furnace for bars

InactiveCN106322993AIncrease productionSignificant energy savingCrucible furnacesGas emission reductionProcess engineeringRED MATERIAL

The invention provides a fully-automatic continuous heating furnace for bars and relates to the field of forging heating equipment. Through overcoming defects of a natural gas straight-flow furnace, the loading, furnace feeding and red material conveying of the bars for forging products are automatically finished, and the heating quality of the bars and the automation degree of equipment are improved. The fully-automatic continuous heating furnace for bars is characterized by sequentially comprising a storing and loading machine, a distributing and pushing machine, a natural gas heating furnace and a red material conveyer from front to rear according to an arrangement sequence. The working of the fully-automatic continuous heating furnace for bars, provided by the invention, is a continuous heating process, continuous forging can be realized, a periodic heating process of an old gas heating furnace is changed, the productivity is increased, natural gases are saved, and the production cost is reduced.

Owner:开封现代工业炉有限公司

Explosion-proof electric heater

The invention provides an explosion-proof electric heater. The explosion-proof electric heater is characterized in that a heating cavity is formed in a container body; a first circular clamping groove of which the radius is matched with that of the container body is formed in the inner side of a container cover; the open end of the container body is clamped in the first circular clamping groove; a second circular clamping groove of which the radius is matched with that of an explosion-proof junction box is formed in the inner side of an explosion-proof cover; the open end of the explosion-proof junction box is clamped in the second circular clamping groove; one end of each sleeve is in seal connection with the container cover; the other end of each sleeve penetrates through the bottom of the explosion-proof junction box and extends into the an explosion-proof cavity; each sleeve is in seal connection with the explosion-proof junction box; a plurality of electric heating elements are arranged in the heating cavity; the quantity of the electric heating elements is consistent with that of the sleeves; and one end of each electric heating element penetrates through the corresponding sleeve, extends into the explosion-proof cavity, and is connected with a corresponding power interface through a corresponding wire. The explosion-proof electric heater provided by the invention is good in sealing property and heating effect, high in heating speed, and stable in heating temperature.

Owner:ANBANG ELECTRICAL GRP

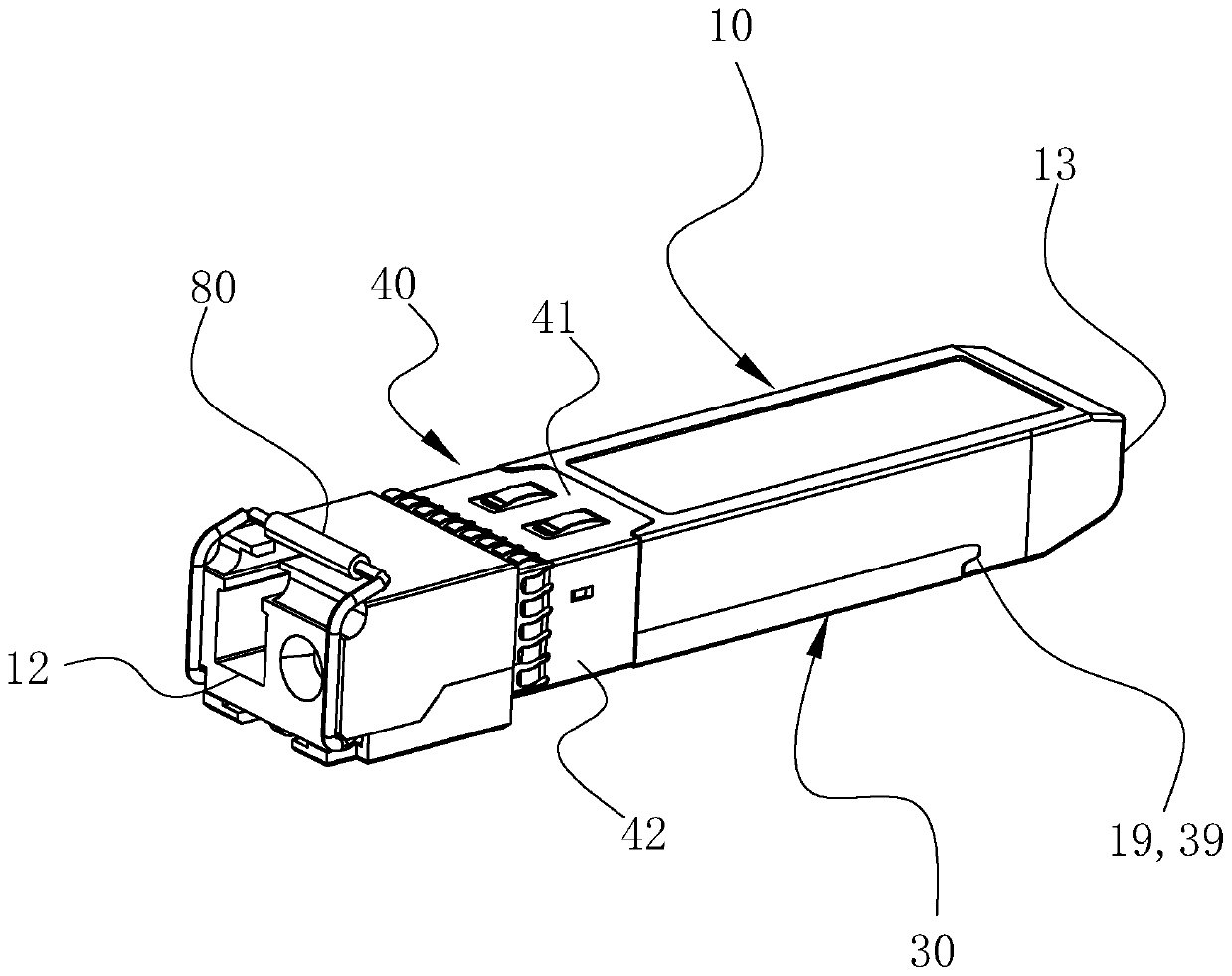

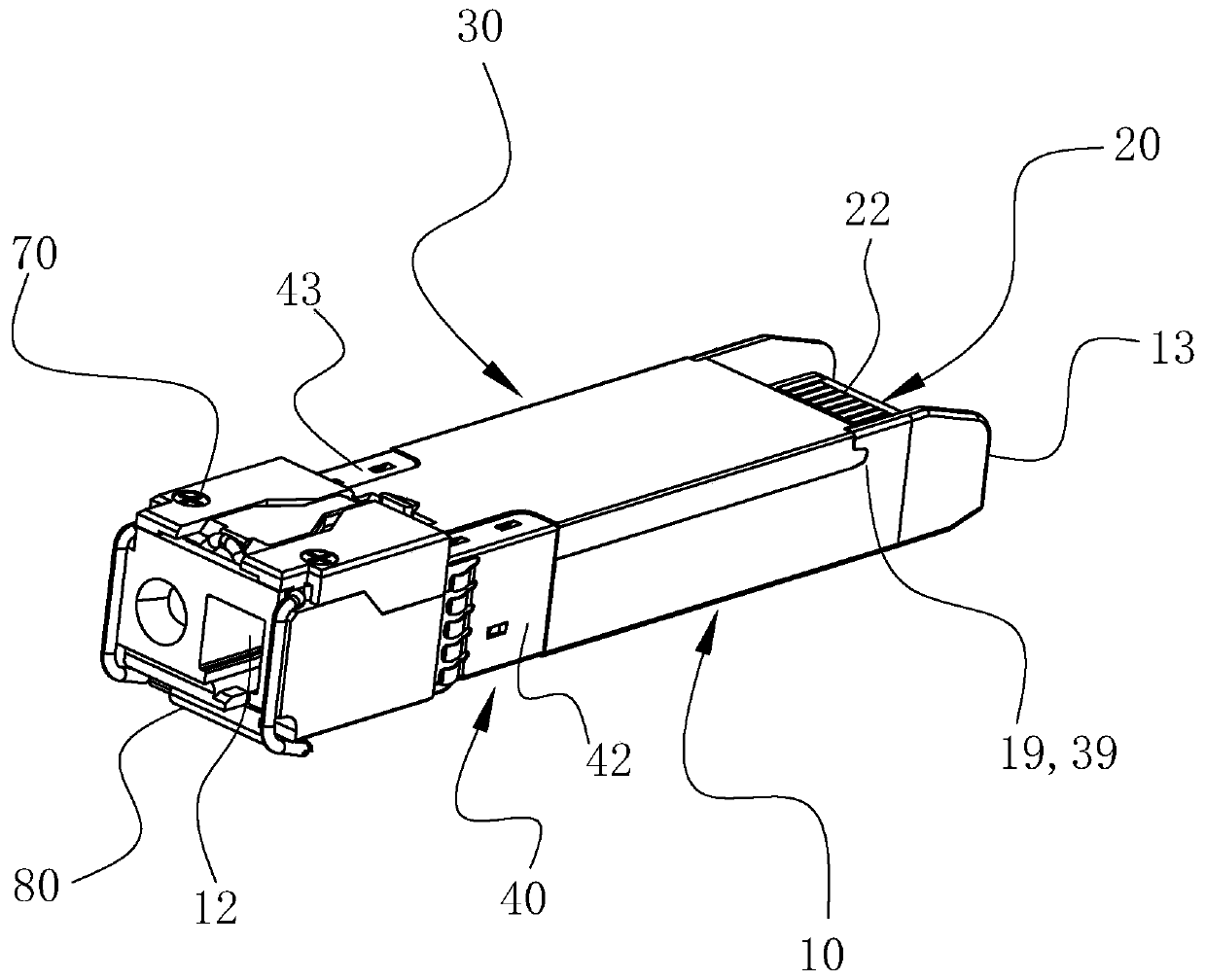

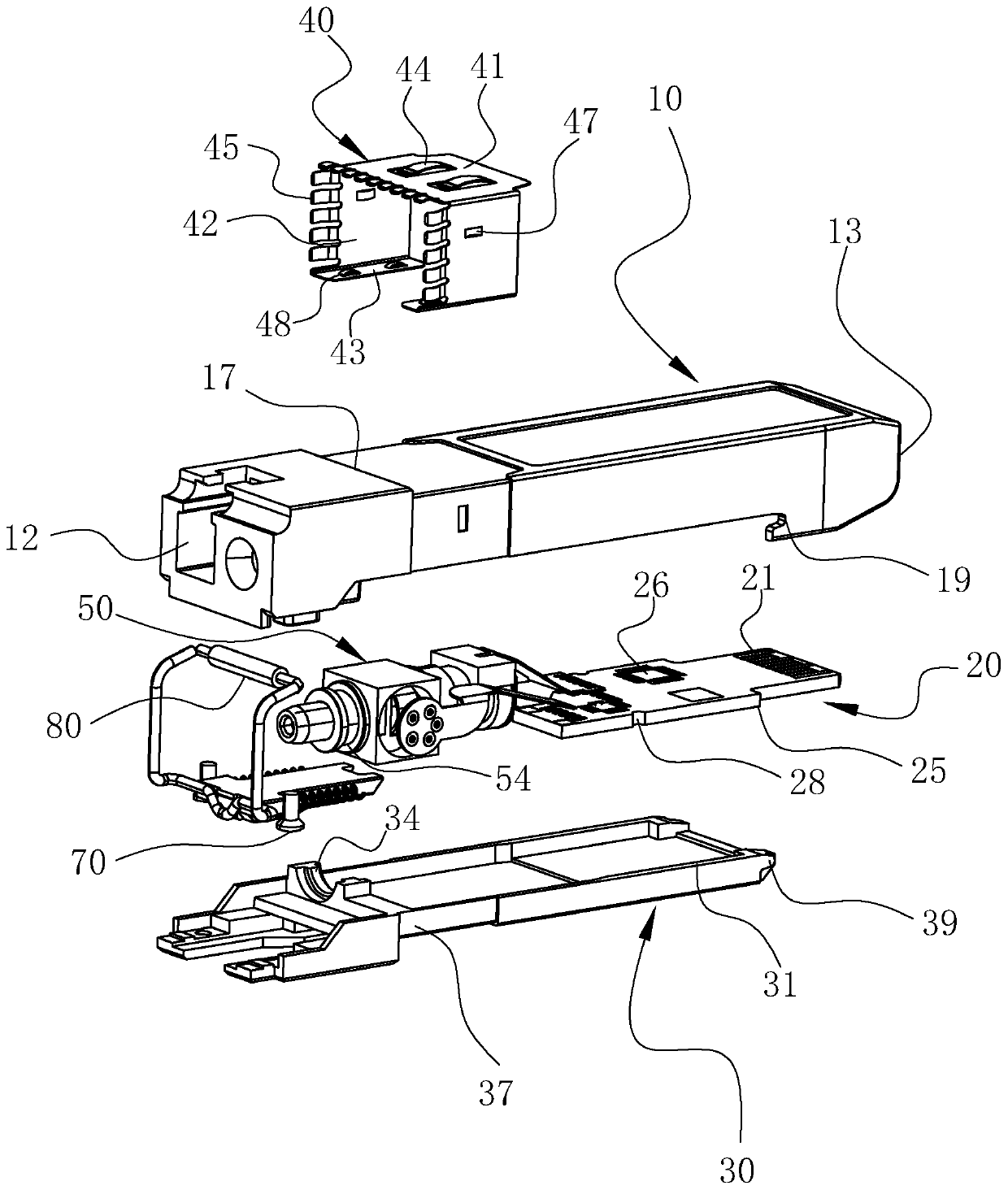

Heat dissipation type single/double-fiber pluggable optical module and assembling method thereof

ActiveCN112285848AImprove thermal conductivityConsistent heating temperatureCoupling light guidesOptical ModuleData transmission

The invention relates to a heat dissipation type single / double-fiber pluggable optical module and an assembling method thereof. The optical module comprises a shell cover, a module circuit board, a base and an outer clamping fastener; the side edge of the module circuit board is clamped and fixed between the shell cover and the base to form two heat convection channels above and below the module circuit board, a heat conduction boss in the shell cover and the outer clamping fastener with a specific structure are utilized, the heat conduction boss is thermally coupled with a chip heating body,and the outer clamping fastener is attached to the shell cover in a heat conduction mode, and is buckled with the base in a heat conduction mode. A heat conduction path from the heat conduction boss to the base through the outer clamping fastener is established, the heat conduction path is an annular path surrounding the two heat convection channels, the air cooling type heat dissipation efficiency of a single / double-fiber pluggable optical module product is improved, and the optical module is suitable for data transmission of high-speed communication.

Owner:SHENZHEN OPTIC KING TECH

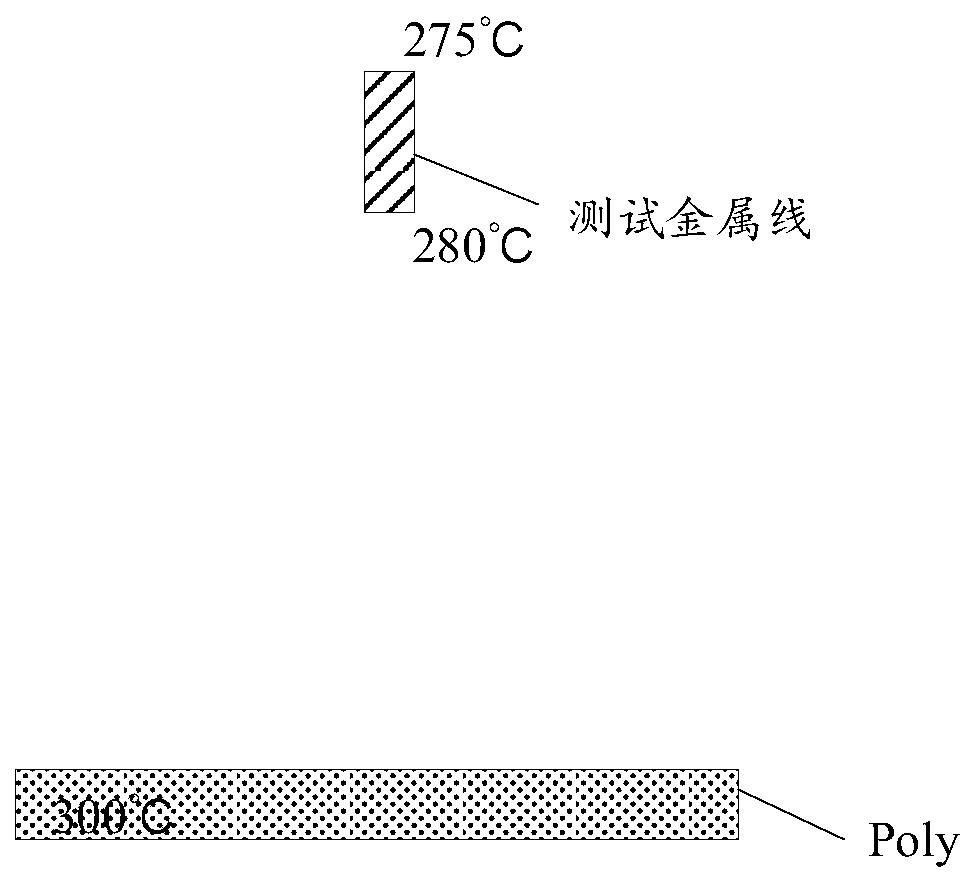

Electromigration test structure and method

ActiveCN110379725AConsistent heating temperatureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringHeating temperature

The invention provides an electromigration test structure and method. Heat is generated by utilizing a polysilicon heater to provide a temperature for performing an electromigration test on a test metal wire, and the heat generated by the polysilicon heater is conducted to the periphery of the test metal wire by utilizing a heat conduction structure so as to uniformly heat the test metal wire. Compared with the prior art, the heat conduction structure can efficiently conduct the heat generated by the polysilicon heater and can conduct the heat to the periphery of the test metal wire, so that the heating temperatures of different parts of the test metal wire can be consistent with the target heating temperature.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

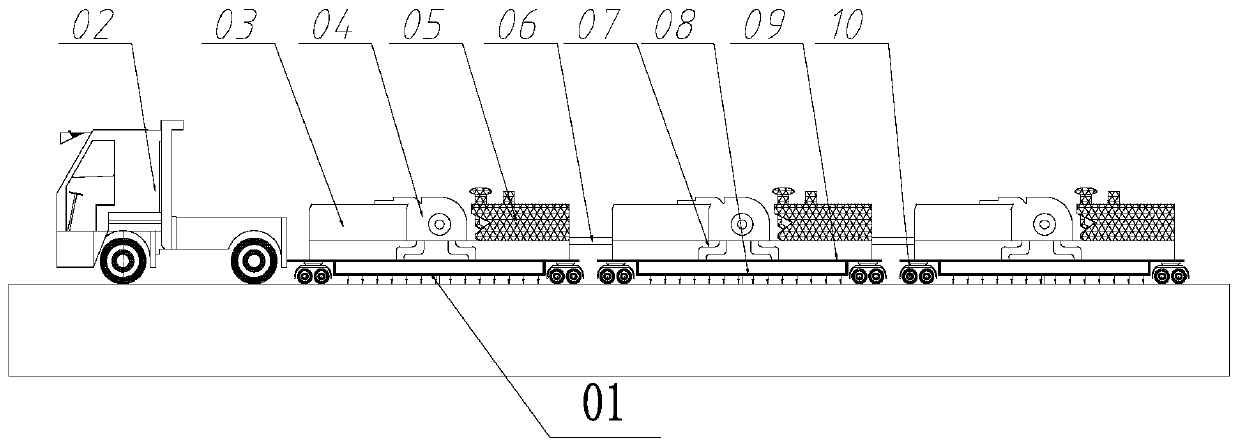

Series type hot air heating device for bituminous pavement and heating control method of device

ActiveCN110004811AImprove recycling ratesPrecise temperature controlRoads maintainenceEcological environmentAtmospheric air

The invention provides a series type hot air heating device for bituminous pavement and a heating control method of the device. A plurality of hot air heating plates are connected, a heating mode of continuous variable power is utilized, heating power of all heating units is determined, the heating units output different heating power to the bituminous pavement in the driving process, and thus temperature of the surface of the bituminous pavement and temperature at the 4cm depth position are accurately controlled; at the same time, the multiple heating units are switched on, hot air dischargedto the environment by a former heating unit re-enters an air inlet of a next heating unit through a circulating pipeline, the circulating utilization rate of the hot air is further improved, discharging of the hot air carrying harmful gases from the heating units to the surrounding atmosphere is reduced, and the ecological environment is protected.

Owner:CHANGAN UNIV

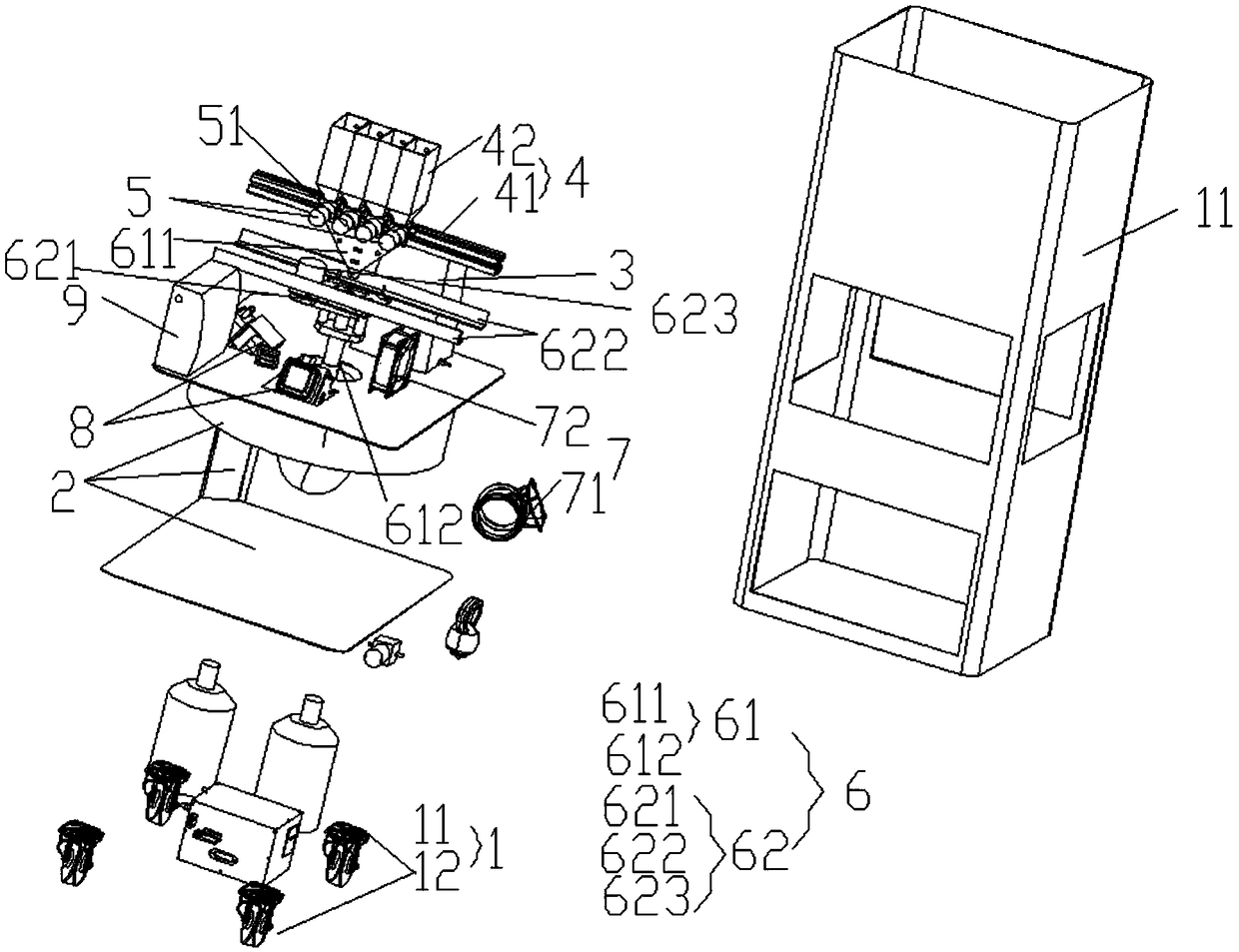

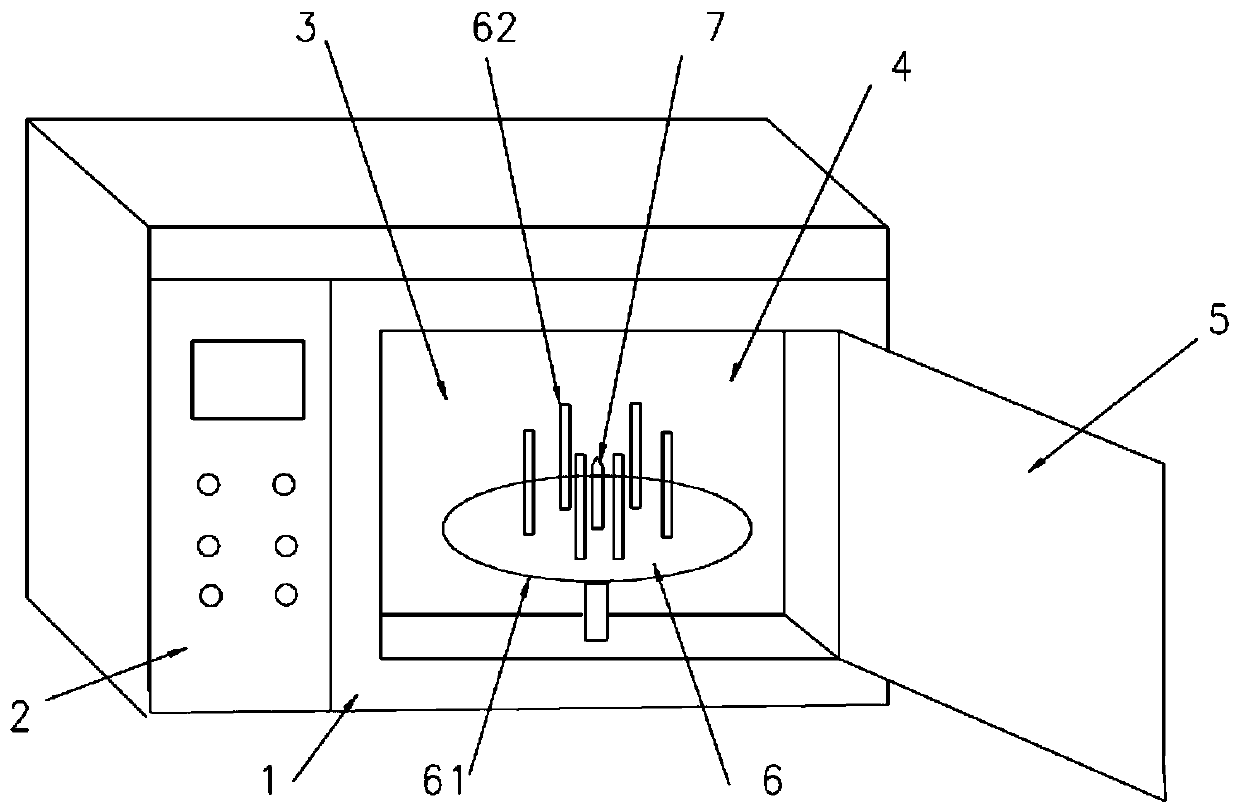

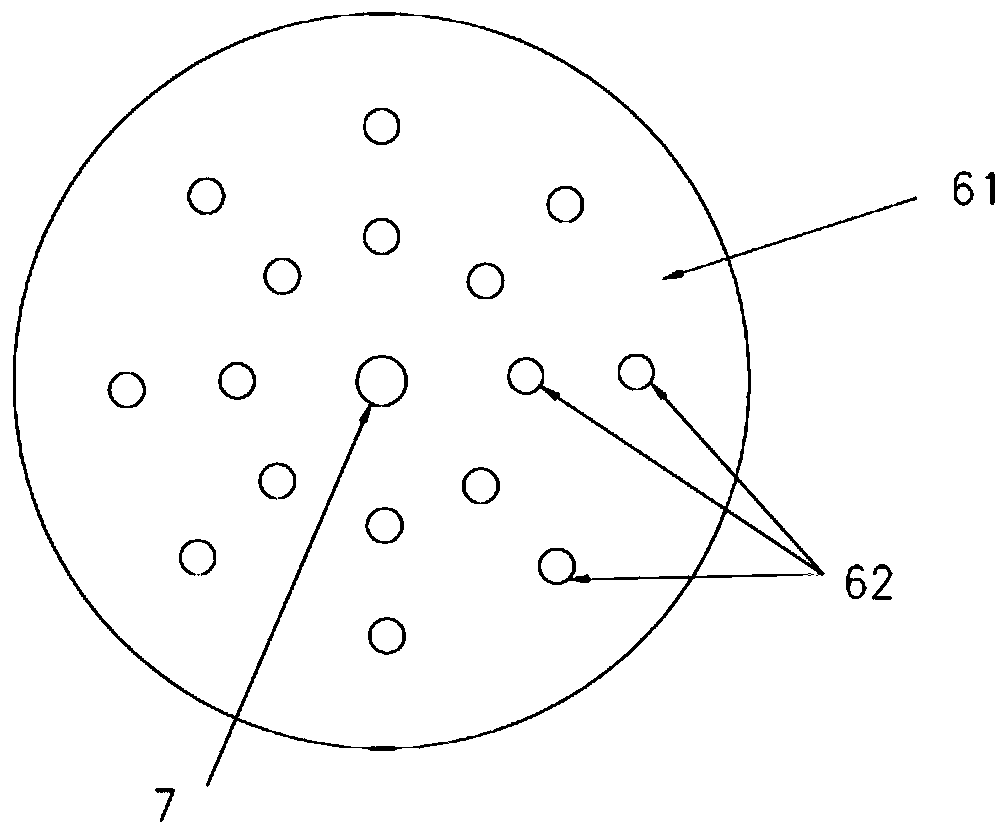

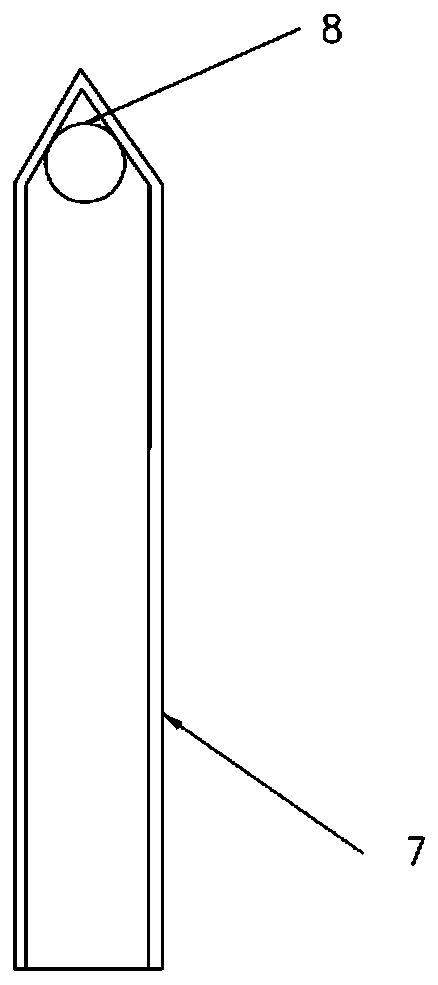

Automatic candy supply system of cotton candy machine

PendingCN108850385AReduce maintenance costsEase of production and maintenanceConfectionerySweetmeatsMicrowaveCOTTON CANDY

The invention relates to the technical field of automatic equipment and in particular relates to an automatic candy supply system of a cotton candy machine. The automatic candy supply system comprisesa fixed frame mechanism, a supporting frame mechanism, a humidifier candy box module, a candy amount control mechanism, a candy output device control mechanism, a fan mechanism, a microwave emitter module and a control electric box; microwave heating is adopted so that the heating temprature of candy is prone to be consistent and the control on candy melting is more fine and smooth; the size anduniformity of candy filaments are controlled and a sugar burning phenomenon is avoided; a separation type design of the fan and a candy output utensil is utilized and the utensil is easy to detach andconvenient to wash, so that the maintenance cost of a cotton candy output system can be greatly reduced and the transportation of the candy is realized through self gravity of the candy; the candy supply system is simplified and is convenient to produce and maintain; meanwhile, the viscosity of the candy also can be regulated and controlled, different cotton candy shapes can be convenient to design and so on.

Owner:深圳市合泰英龙科技有限公司

Automatic electrothermal pasting machine for pearl wool

InactiveCN102689485BIncrease productivityImprove yieldLaminationLamination apparatusMicrocomputerElectricity

The invention relates to an automatic electrothermal pasting machine for pearl wool, which electrothermally pastes and processes a pearl wool material to be processed. The pasting machine comprises a rack, a workbench, an electrical heating plate, an upper material adsorption device, an air pressure mechanism, an electrical heating plate pushing device and a microcomputer. With the adoption of the automatic electrothermal pasting machine for the pearl wool, the pearl wool is simple, convenient and efficient to paste, the qualified rate of a pearl wool pasting product is improved, waste of a large amount of raw materials caused by manual operation is reduced, the product cost is lowered, and a production environment of operating workers is improved.

Owner:叶正键 +1

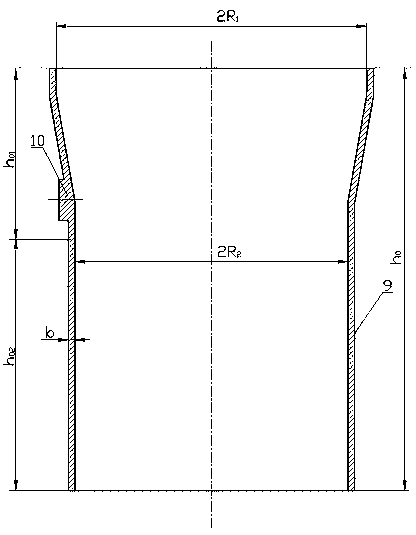

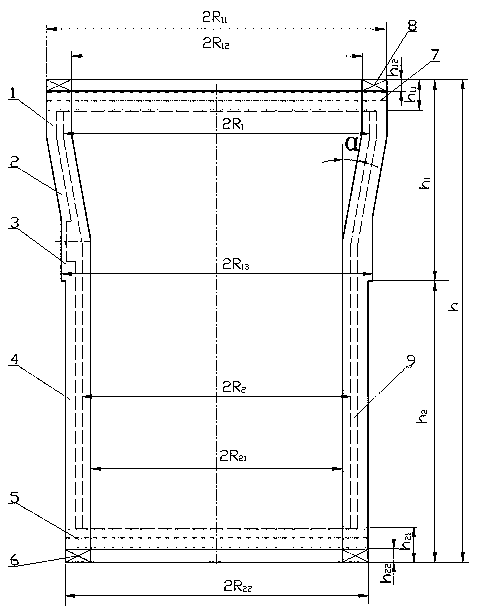

Nuclear island evaporator reducing cylinder integral forge piece and forging forming method thereof

InactiveCN110947900AFully heatedReduce the amount of machiningMetal-working apparatusFurnace typesPunchingBobbin

The invention discloses a nuclear island evaporator reducing cylinder integral forge piece. The forge piece body is composed of a conical cylinder and a cylinder, wherein the cylinder is arranged at the lower end of the conical cylinder; the conical cylinder comprises a conical pipe upper opening section, a conical pipe section and a conical pipe lower opening section which are sequentially arranged from top to bottom; the cylinder comprises a main cylinder pipe section, and the ratio h1 / h2 of the height h1 of the conical cylinder to the height h2 of the cylinder is equal to 0.60-0.70. The forming method for forging a nuclear island evaporator reducing cylinder integral forge piece comprises the following steps of: (1) selecting a steel ingot, (2) segmented heating, (3) blanking the blank,(4) forging blank upsetting and drawing, (5), forging blank forming, (6) punching a bobbin hole, (7) heat treatment after forging. In the upsetting, drawing and punching processes, the initial forging temperature is 1210-1250 DEG C, the final forging temperature is 830-870 DEG C and the normalizing temperature is 1030-1060 DEG C. The forge piece and the method disclosed in the invention have theadvantages of uniform metal microstructure and mechanical property, reliable forging safety and good economy.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

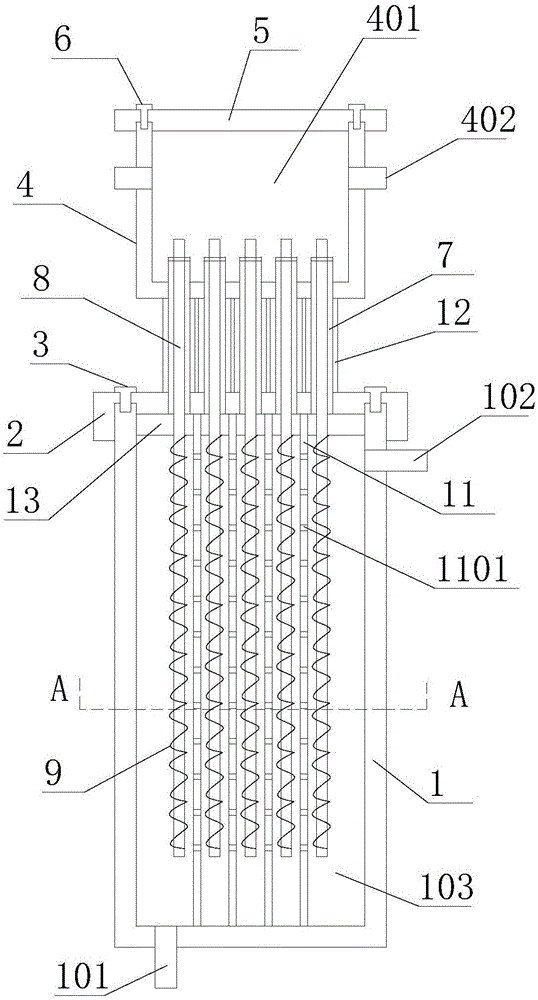

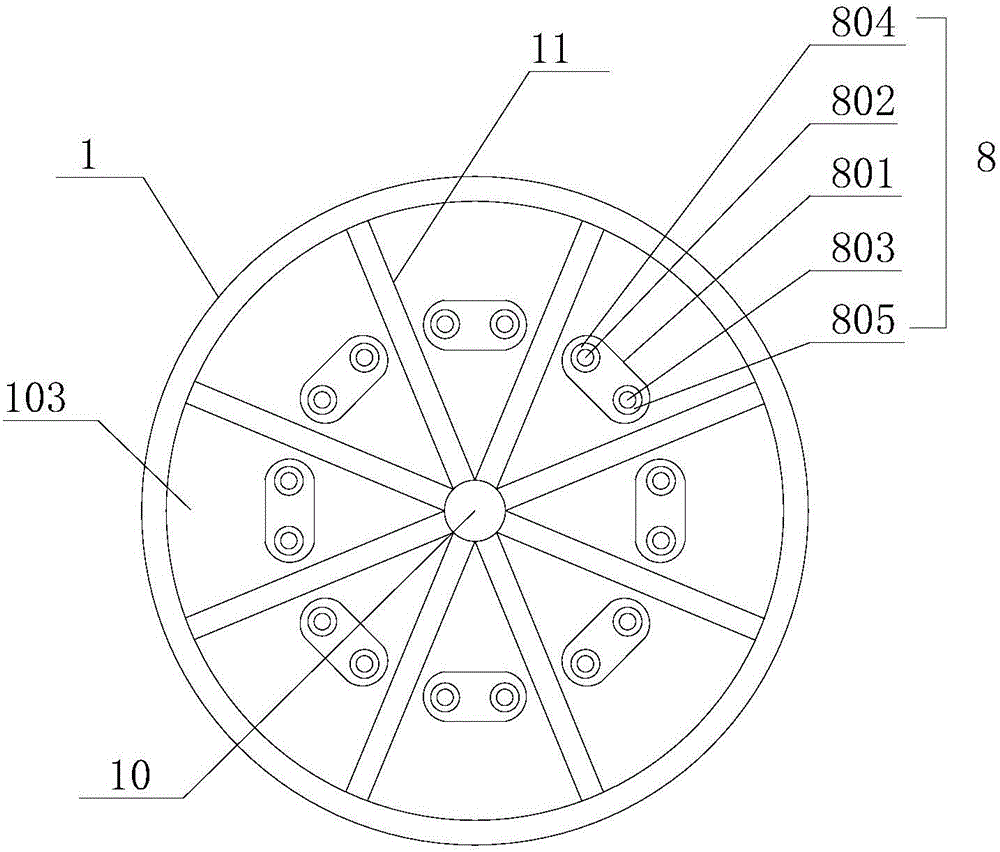

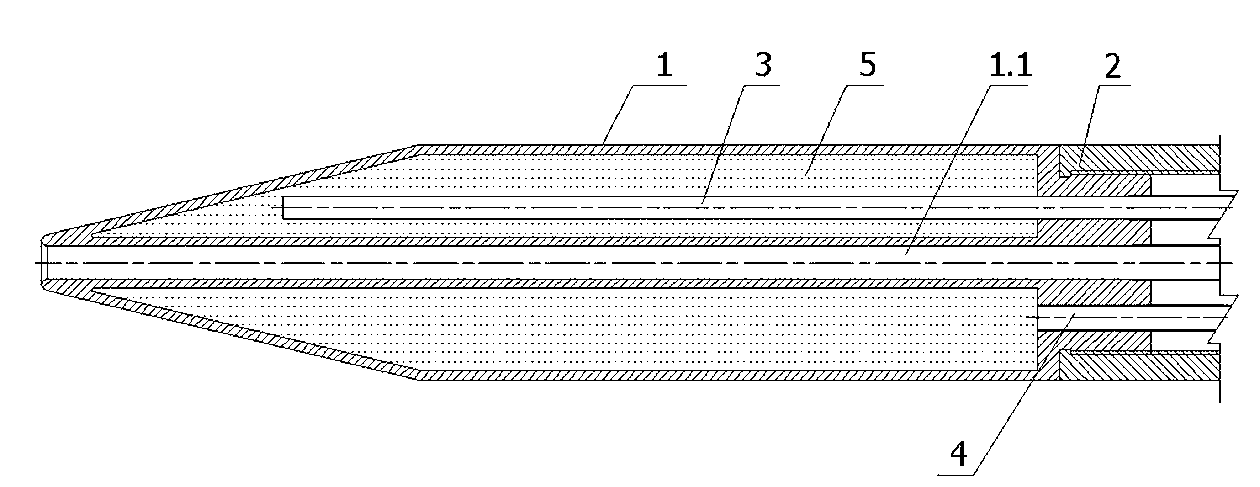

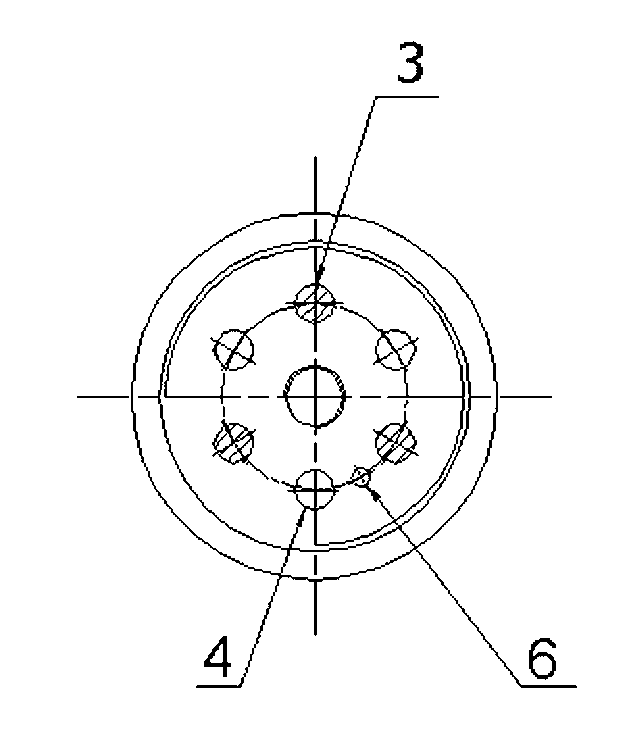

Hot oil type tubular heater

The invention discloses a hot oil type tubular heater which comprises a tube shell, tube joints, leading-in tubes, return tubes, a heat medium and sensors, wherein the tube shell is in a jacket tube structure; an internally arranged axial inner tube is arranged in the middle; an outer tube wall and an inner tube are coaxially sheathed and both ends are hermetically connected with each other; the outer tube wall consists of a truncated cone and a cylinder; one end taking the inner tube as a beginning point is the small end of the truncated cone, and a beam segment of the cylinder at the other end is provided with a screw thread matched with the tube joints to form positioning installation; and annular inner tubes at the end surface of the beam segment of the tube shell are alternately and hermetically connected with the leading-in tubes and the return tubes at equal intervals. The heat medium forms a circular flow passage through the leading-in tubes and the return tubes, and the sensors are coaxially placed between any leading-in tube and adjacent return tube. The hot oil type tubular heater is simple in structure, quick and uniform to heat, so that no temperature difference exists between sizing material and alkali-free glass fiber inside a leading-in die cavity, and synchronous solidification of inner and outer layers is achieved. The hot oil type tubular heater is particularly suitable for producing epoxy pultrusion core rods with the diameters of 50 to 200mm.

Owner:泰州华东绝缘材料有限公司

Overall ultrasonic frequency heating method of variable-cross-section rod

ActiveCN108941283AHigh melting pointPrevent high temperature deformationVehicle componentsElectricityLap joint

The invention discloses an overall ultrasonic frequency heating method of a variable-cross-section rod. The overall ultrasonic frequency heating method of the variable-cross-section rod comprises thesteps: workpieces to be heated are successively conveyed to a heater of a heating device through a conveyor belt, and a limiting piece limits the workpieces to be heated in a heating area of the heater; a motor is started after the workpieces are heated so as to drive a shifting fork to circularly move toward the direction of a discharge hole; a support I is gradually elevated and gets close to the discharge hole; a driving lever is basically at the horizontal state finally under the drive of the support I, and an electrode starts to reset at the time so as to drive the support I to be far away from the discharge hole and reduce the height of the support I; and under the drive of the support I, a lap-joint point of the driving lever and the discharge hole is adopted as a support point, thefree end of the driving lever starts to lower down, a lap-joint end of the driving lever and the discharge hole starts to raise upwards so as to lift the heated workpieces, and the lifted workpiecesslide off along a lever body of the driving lever until falling into a receiving device. The overall ultrasonic frequency heating method of the variable-cross-section rod provided by the invention hasthe advantages that the service life of the conveyor belt is greatly prolonged, and the deformation amount of the variable-cross-section rod after being heated is reduced to the minimum.

Owner:ANHUI LIBA POWER LITHIUM BATTERY TECH

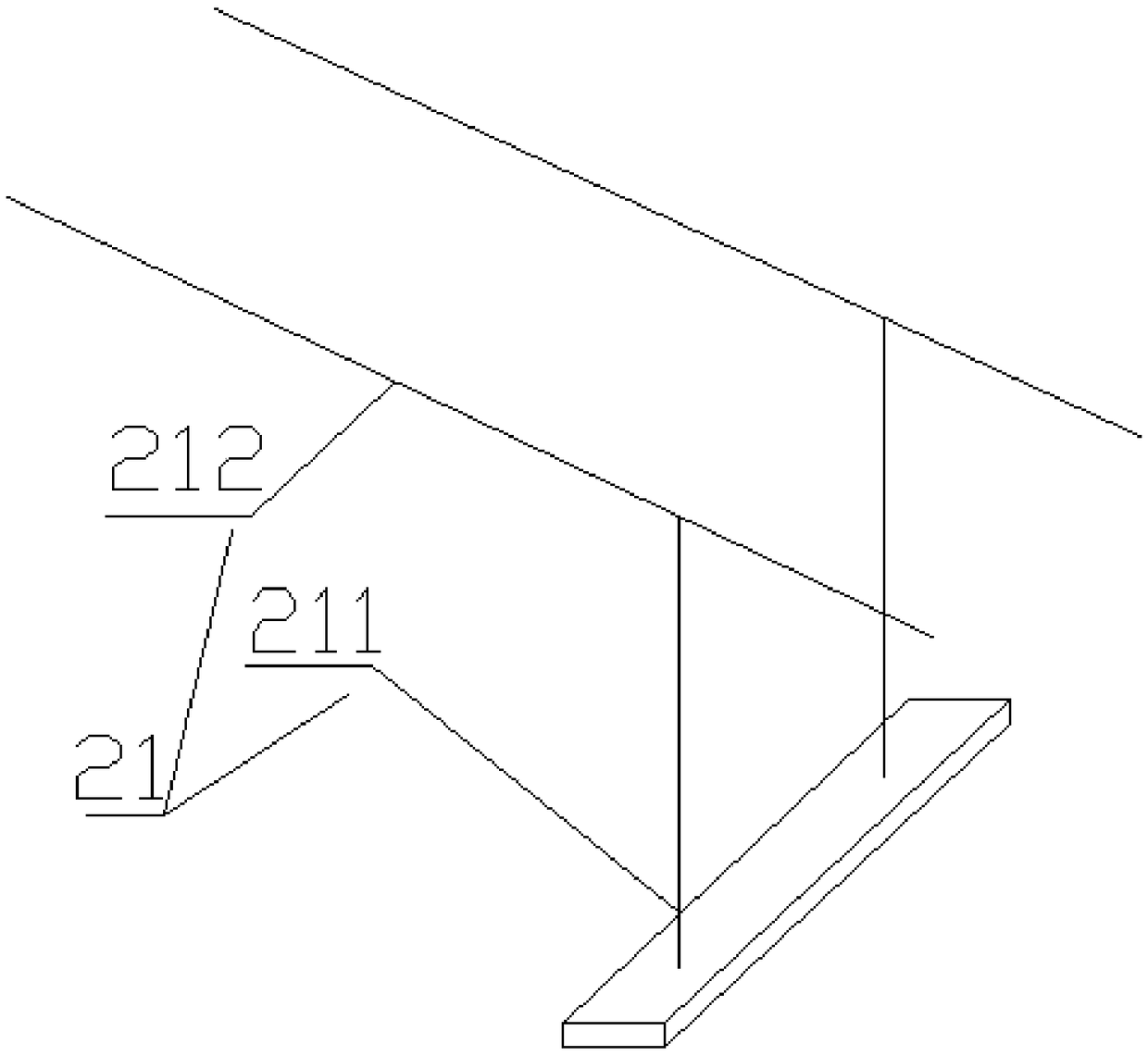

Mold baking heating method, heating process method and heating furnace production device

PendingCN107812924AReduced manufacturing time impactReduce distortionTemperature controlInterior space

The invention provides a heating furnace production device. The heating furnace production device comprises a box and a heating device; a cavity is formed in the box; heating space is formed in the internal space of the cavity; the end surfaces of two ends of the box in the length direction respectively form a first end surface and a second end surface; the cavity penetrates through the first endsurface and the second end surface; an inlet and an outlet are respectively formed in the first end surface and the second end surface; the heating device heats the heating space; a passing route of heated objects passes through the inlet, the heating space and the outlet in sequence; and the passing route in the heating space forms arrangement positions of multiple heated objects in the passing direction. The invention further provides a mold baking heating method and a heating process method. A heat radiation baking mode is adopted to realize uniform heating of molds, so that the failure caused by nonuniform heating of the molds due to local overheating is prevented. Meanwhile, a heating furnace has a temperature control function, so that the heating temperatures of the molds are basically consistent, and the production process requirements are met.

Owner:SHANGHAI UNIV OF ENG SCI +1

Processing technology of corn wine

InactiveCN109055086AInto the uniformGuarantee sufficiencyAlcoholic beverage preparationSteamingChemistry

The scheme provided by the invention discloses a processing technology of a corn wine in the technical field of baijiu production. The processing technology of the corn wine comprises the following steps: step 1: soaking the corns for 10 to 15 hours with cold water having a temperature of 10 to 20 DEG C, then taking the corns out, and freezing the corns at -10 to 0 DEG C for 3 to 5 hours; step 2,steaming the frozen corn for the first time at a temperature of 150 to 200 DEG C for 0.2 to 0.3 h, and then steaming again at a temperature of 100 to 120 DEG C for 1.5 to 2 hours; step 3, cooling thesteamed corn to 10 to 28 DEG C, putting distiller's yeast into the corns, mixing uniformly, and fermenting; and step 4, distilling the fermented corns to obtain the corn wine. The scheme provided by the invention significantly improves the yield of the corn wine by optimizing the production process of the corn wine.

Owner:仁怀市春华秋实科技有限公司

Bread oven

The present invention discloses a bread oven. The bread oven comprises an oven body, a heating device, a control panel, a baking chamber, a heat insulation layer, and a heat insulation door. The baking chamber is provided with a rotating rack; the rotating rack is provided with a baking rack and a driver which is arranged below the oven body and is configured to drive the rotation and movement ofthe rotating rack; the rotating rack comprises a base tray, the baking rack arranged at the center of the base tray, and a plurality of insertion rods; the base tray is provided with a plurality of bayonets; and the plurality of insertion rods are correspondingly inserted and fixed in the plurality of bayonets one by one. According to the bread oven disclosed by the present invention, the insertion rod is a straight tube with a hollow interior and two ends open; the wall of the insertion rod is evenly provided with a plurality of small holes; the airflow in the baking chamber can flow into theinsertion rods through the end portion and then into the ingredients through the small holes; and during baking, the ingredients are inserted into the plurality of insertion rods, so that the purposeof uniformly heating the inside and outside of the bread placed on the rotating rack is achieved.

Owner:MINNAN NORMAL UNIV

Heat dissipation type single/double-fiber pluggable optical module, and assembling method and outer clamping fastener thereof

ActiveCN111190255AExcellent external heat conduction effectImprove thermal conductivityCoupling light guidesPhysicsData transmission

The invention relates to a heat dissipation type single / double-fiber pluggable optical module, and an assembling method and outer clamping fastener thereof. The optical module comprises a shell cover,a module circuit board, a base and the outer clamping fastener. The side edge of the module circuit board is clamped and fixed between the shell cover and the base so as to form two heat convection channels over and under the module circuit board respectively; a heat conduction boss in the shell cover and the outer clamping fastener with a specific structure are utilized; the heat conduction bossis thermally coupled with a chip heating body, the outer clamping fastener is attached to the shell cover in a heat conduction manner, the base is buckled in a heat conduction manner, a heat conduction path from the heat conduction boss to the base through the outer clamping fastener is established and is a bad path surrounding the two heat convection channels, the air cooling type heat dissipation efficiency of a single / double-fiber pluggable optical module product is improved, and the optical module is suitable for high-speed communication data transmission.

Owner:SHENZHEN OPTIC KING TECH

Deep hole punching method and deep hole punch head thereof for large forging

The invention discloses a deep hole punching method, which comprises the following steps of (1) heating a steel ingot; (2) discharging a forging blank, wherein the cutting amount of the head end is equal to the 16-20% of the weight of the steel ingot, and the cutting amount of the tail end is equal to the 8-12% of the weight of the steel ingot; (3) upsetting and drawing the forging blank, wherein the forging blank is upset and drawn to form a forging; (4) performing primary punching, wherein the press-down amount of a punch head is equal to 30% of the depth of a finished hole; (5) performing secondary punching, wherein the end of the punch head is applied with combustible matter and then is pressed down; (6) performing third punching, wherein the end of the punch head is applied with the combustible matter and then is pressed down; (7) trimming a hole; (8) performing heat treatment after forging. A deep hole punch head comprises a punch rod, wherein the punch rod is a cylindrical rod, the front end of the punch rod is a semispherical end, and a finishing ring is arranged on the punch rod, and is separated from the semispherical end. The deep hole punching method has the advantages that the production efficiency is high, the internal tissues are uniform and dense, and the utilization rate of materials is high. The deep hole punch head has the advantages that the structure design is skillful, the hole forming accuracy is high, and the quality is high.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

Flexible solar cell module hot pressing device

ActiveCN106976297BConsistent heating temperatureSame heating timeFinal product manufactureLaminationControl systemElectrical battery

The invention relates to a hot pressing device for a flexible solar battery component, and solves the defect that due to long-term heating at high temperature, gases produced in a solar battery component are difficult to discharge, and bubbles are produced on the outer surface of the solar battery component to affect product appearance, the hot pressing device comprises an upper component and a lower component, a heating system, a vacuumizing system and a control system, the upper component and the lower component can be mutually laminated to form a closed shaped hot pressing cavity used for lamination of a non flat or curved flexible solar battery component, the heating system is used to provide heating temperature for hot pressing of the solar battery component, the vacuumizing system is used for vacuumizing the upper component and the lower component and overall floating the solar battery component for hot pressing, and the control systemis used for controlling the heating system and the vacuumizing system. The heating system is used for heating the hot pressing cavity, the vacuumizing system is used for vacuumizing the upper component and the lower component, the solar battery component floats in the hot pressing cavity, only after the solar battery component completely enters the hot pressing cavity and up floats, the hot pressing is performed, the lamination degree of the whole piece of the solar battery component can be ensured, and quality is stable.

Owner:浙江尚越新能源开发有限公司

Variable cross-section rod piece overall superaudio frequency heating equipment

ActiveCN108746470AHigh melting pointPrevent high temperature deformationIncreasing energy efficiencyHeating/cooling devicesMagnetizationEngineering

The invention discloses variable cross-section rod piece overall superaudio frequency heating equipment which comprises a superaudio frequency heating device used for heating an overall variable cross-section rod, a receiving device and a conveying mechanism. The heating device comprises a heating zone and a discharging opening, the conveying mechanism comprises a conveying belt used for feeding the variable cross-section rod to the heating zone, and the conveying belt is provided with a ceramic piece; and the receiving device is provided with an opening, and the output end of the conveying mechanism is located above the opening. Compared with the prior art, ceramic has the high melting point, the high high-temperature strength, the small high temperature creep property, the good resistance to heat shocks, good resistance to corrosion, good resistance to oxidation and the good structure stability and the like. The ceramic piece is used on the conveying belt, the conveying belt is prevented from being subjected to superaudio frequency induced magnetization, and high temperature deformation of the conveying belt is prevented. Compared with a traditional metal conveying belt, the service life of the conveying belt with the ceramic piece is greatly prolonged. Meanwhile, the conveying belt which is stable in structure and provided with the ceramic piece can guarantee that the deformation is reduced to be minimum after the variable cross-section rod is heated.

Owner:滁州宇美塑业有限公司

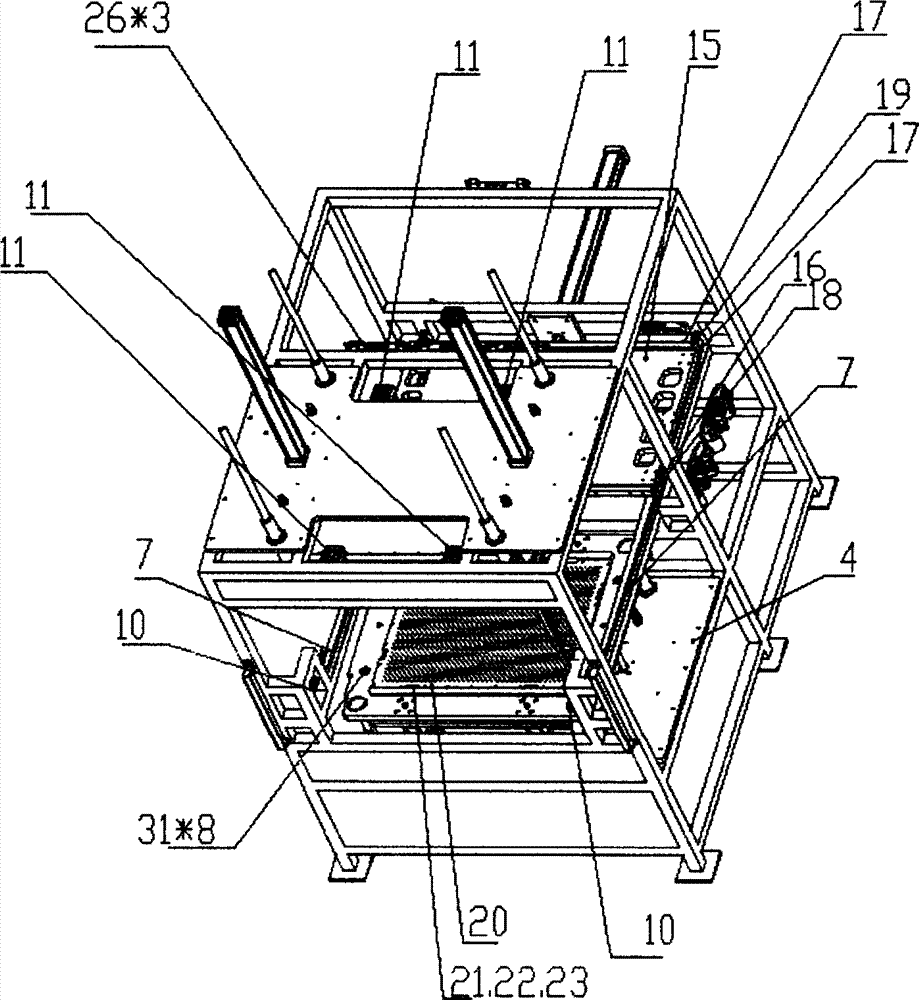

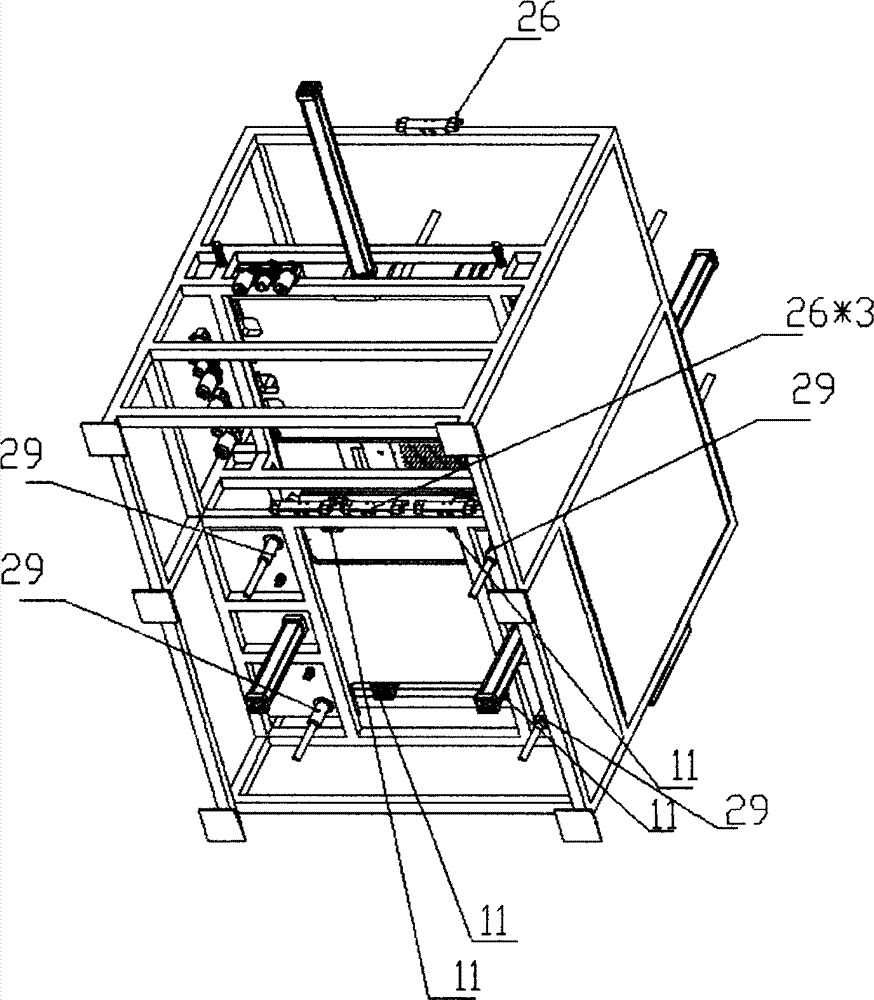

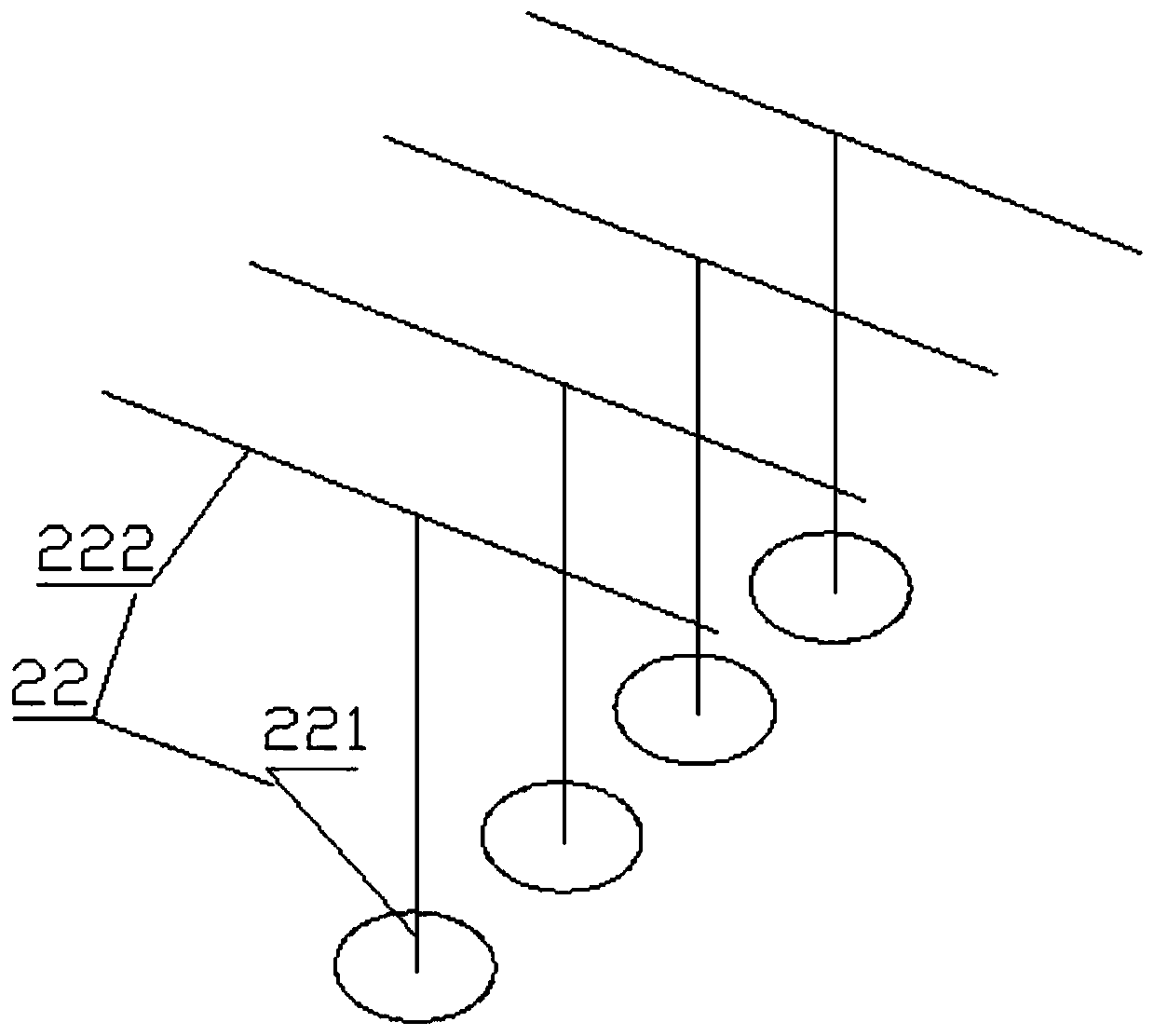

Tempering Furnace

ActiveCN102213544BConsistent heating temperatureImprove the tempering effectVertical furnacesHearthEnergy conservation

The invention relates to a tempering furnace. The furnace comprises a furnace body, the top of which is provided with a furnace cover, an inner container is arranged in the furnace body, an air circulating and heating device is arranged on the furnace body, and a hearth is arranged at the bottom end of the furnace body. By properly arranging the furnace cover, the inner container, the air circulating and heating device and the like, the tempering furnace provided by the invention achieves omidirectional tempering of a workpiece which is suspended below the furnace cover by the process of uniformly heating, cycling and preheating the gas in the furnace, thus avoiding tempering blind spot in the furnace, obviously decreasing the temperature deviation in the furnace, and effectively improving the tempering quality of the workpiece in the furnace. Moreover, the tempering furnace maximally utilizes the heat created by burning the fuel, and further improves the furnace tempering effect. Thetempering furnace of the invention has the advantages of reasonable and simple structure, low production cost, simplicity of operation, convenience of maintenance, high efficiency and energy conservation, and is suitable for popularization.

Owner:LISHUI HUAYI AUTOMATION TECH

Dried balsam pear preparation device

PendingCN111887291ASmall footprintLow costFruits/vegetable preservation by dehydrationAnimal scienceBitter gourd

Disclosed is a dried balsam pear preparation device. The dried balsam pear preparation device comprises a cylinder body, an outer circulation pipeline, a heater and a cooler, wherein the heater and the cooler are arranged outside the cylinder body; a first air inlet and a second air outlet are formed in the lower part of the cylinder body; a second air inlet and a first air outlet are formed in the upper part of the cylinder body; the first air outlet is connected with a first draught fan; the second air outlet is connected with a second draught fan; the first draught fan and the second draught fan are connected with a first three-way valve through the outer circulation pipeline, and the first air inlet and the second air inlet are connected with a second three-way valve through the outercirculation pipeline; the heater is connected between the first three-way valve and the second three-way valve through the outer circulation pipeline; and two sides of the heater are connected with the cooler through two-way valve pipelines. All treatment devices are integrated in one device, the occupied area is greatly reduced, the cost is low, the whole treatment process from fresh bitter gourds to dried bitter gourds is carried out in the cylinder body, the processing efficiency is greatly improved, and the transfer time is shortened.

Owner:湖南新发食品有限公司

Daylily deactivating device and deactivating process thereof

PendingCN111838716AThe heating temperature is close to the sameConsistent heating temperatureFood treatmentEngineeringMechanical engineering

The invention relates to a daylily deactivating device and a deactivating process thereof. The daylily deactivating device comprises a cylinder body, an outer circulation pipeline and a heater arranged outside the cylinder body, a first air inlet and a second air outlet are formed in the lower part of the cylinder body; a second air inlet and a first air outlet are formed in the upper part of thecylinder body; the first air outlet is connected with a first draught fan, the second air outlet is connected with a second draught fan, the first draught fan and the second draught fan are connectedwith a first three-way valve through the outer circulation pipeline, and the first air inlet and the second air inlet are connected with a second three-way valve through the outer circulation pipeline; the heater is connected between the first three-way valve and the second three-way valve through the outer circulation pipeline. The invention also comprises the daylily deactivating process. By supplementing high-temperature gas from the reverse direction, the temperature in the cylinder body can be uniform so that the heating temperature of the daylily is close to be consistent, and the deactivating efficiency and the deactivating quality are greatly improved.

Owner:湖南新发食品有限公司

Integrated head of pressure vessel for nuclear power, its head slab and forging method

ActiveCN106051721BImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersPunchingNuclear power

A monoblock forging of a nuclear power steam generator housing comprises a monoblock forging body, and a forging manhole seat and a forging pipe hole seat provided on the monoblock forging body, the monoblock forging body having a spherical cap structure, a forging manhole and a forging pipe hole being provided on the forging manhole seat and on the forging pipe hole seat respectively, the forging manhole seat and the forging pipe hole seat being integrated, by forging, with the monoblock forging, the hole centerline of the forging manhole and the hole centerline of the forging pipe hole intersecting at the center of the sphere where the monoblock forging body is located. A method for molding the monoblock forging of the nuclear power steam generator housing by forging comprises the following steps: heating a steel ingot; forging stock blanking; forging stock upsetting and stretching; die forging molding; slab heat treatment; slab roughing; forging molding; forging punching; forging heat treatment; forging machining; performance heat treatment; and finished product processing. The molding method by forging not only realizes the integral molding of the steam generator forging, but also realizes a uniform and dense forging structure and a complete metal flow line, and enables the forging fiber structure to be more consistent with the appearance.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

Nuclear Island Evaporator Kit Hole Forming Method

The invention discloses a nuclear island evaporator sleeve part hole forming method. The nuclear island evaporator sleeve part hole forming method comprises the steps of (1), steel ingot heating; (2),forging stock blanking; (3), forging stock upsetting and pulling; (4), primary punching; (5), secondary punching, specifically, a demoulding expanding agent is filled into the inner cavity of a punching head, and the demoulding expanding agent makes contact with the high temperature forging part hole bottom to be expanded to push the punching head out of a hole; (6), three-time punching, specifically, the demoulding expanding agent is filled into the inner cavity of the punching head again, and the punching head is pushed out after expanding; (7), four-time punching, specifically, the demoulding expanding agent is further filled into the inner cavity of the punching head, and the punching head is pushed out after expanding; (8), hole trimming; (9), heat treating after forging. The demoulding expanding agent comprises the ingredients of, in percentage by mass, 8-12% of tung oil, 20-25% of saw powder, 10-15% of graphite, 3-5% of water and the balance blind coal, and the filling amount of the demoulding expanding agent at a time is 200-500g. By means of the nuclear island evaporator sleeve part hole forming method, longhole punching performed on nuclear forging parts is realized, andthe nuclear island evaporator sleeve part hole forming method has the advantages that the demoulding speed is fast, the tissue of the forging parts is uniform and dense, and the material utilizationrate is high.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

A Whole Ultrasonic Heating Method for Variable Cross-section Rods

ActiveCN108941283BHigh melting pointPrevent high temperature deformationVehicle componentsElectric machineryConveyor belt

The invention discloses an overall ultrasonic frequency heating method of a variable-cross-section rod. The overall ultrasonic frequency heating method of the variable-cross-section rod comprises thesteps: workpieces to be heated are successively conveyed to a heater of a heating device through a conveyor belt, and a limiting piece limits the workpieces to be heated in a heating area of the heater; a motor is started after the workpieces are heated so as to drive a shifting fork to circularly move toward the direction of a discharge hole; a support I is gradually elevated and gets close to the discharge hole; a driving lever is basically at the horizontal state finally under the drive of the support I, and an electrode starts to reset at the time so as to drive the support I to be far away from the discharge hole and reduce the height of the support I; and under the drive of the support I, a lap-joint point of the driving lever and the discharge hole is adopted as a support point, thefree end of the driving lever starts to lower down, a lap-joint end of the driving lever and the discharge hole starts to raise upwards so as to lift the heated workpieces, and the lifted workpiecesslide off along a lever body of the driving lever until falling into a receiving device. The overall ultrasonic frequency heating method of the variable-cross-section rod provided by the invention hasthe advantages that the service life of the conveyor belt is greatly prolonged, and the deformation amount of the variable-cross-section rod after being heated is reduced to the minimum.

Owner:ANHUI LIBA POWER LITHIUM BATTERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com