Patents

Literature

85results about How to "Prevent high temperature deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

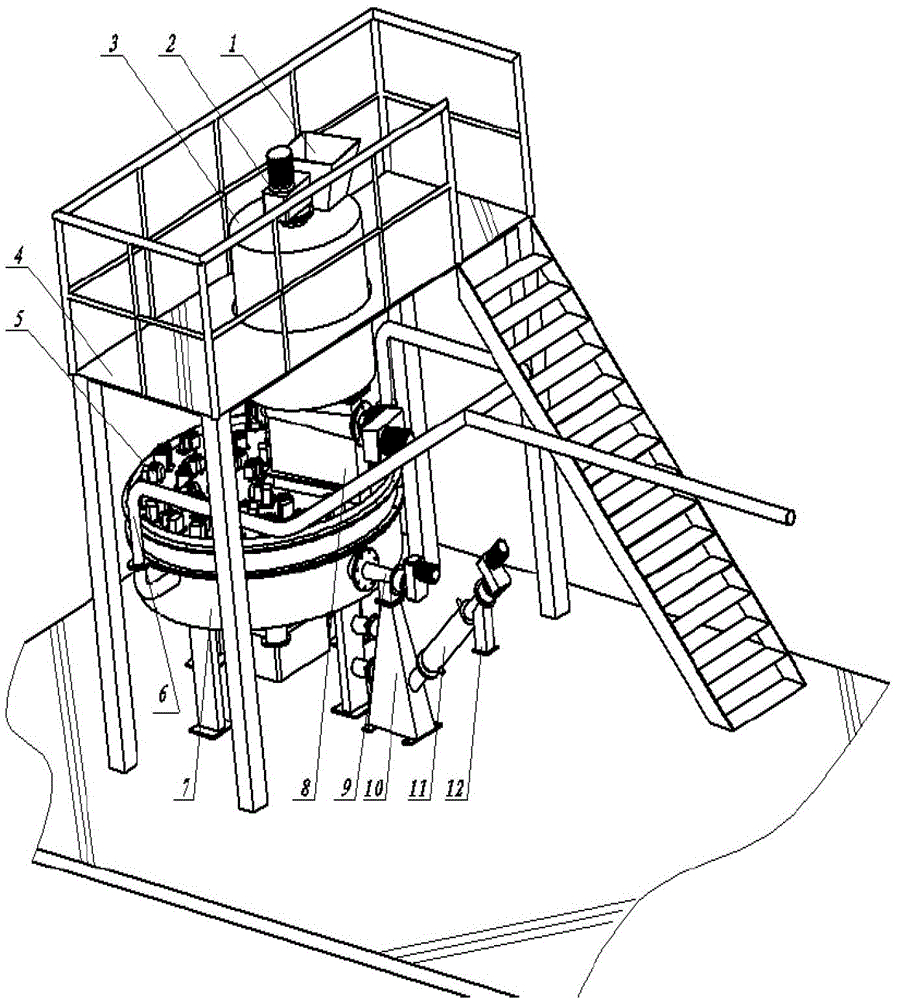

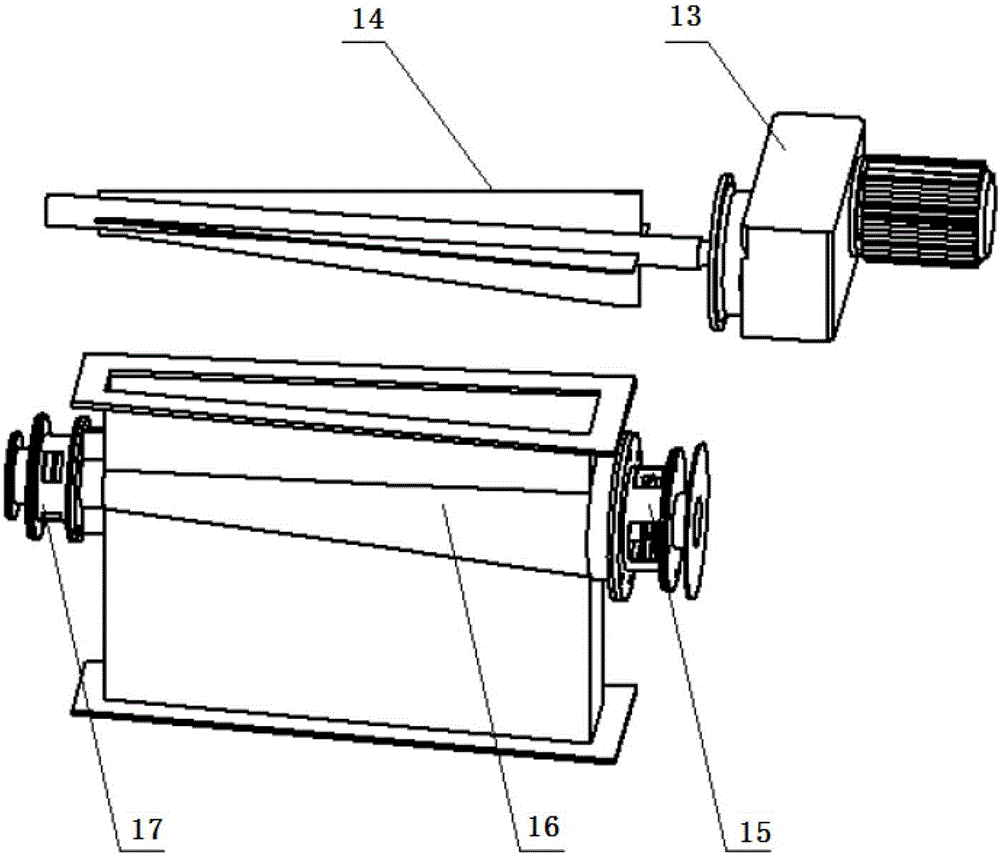

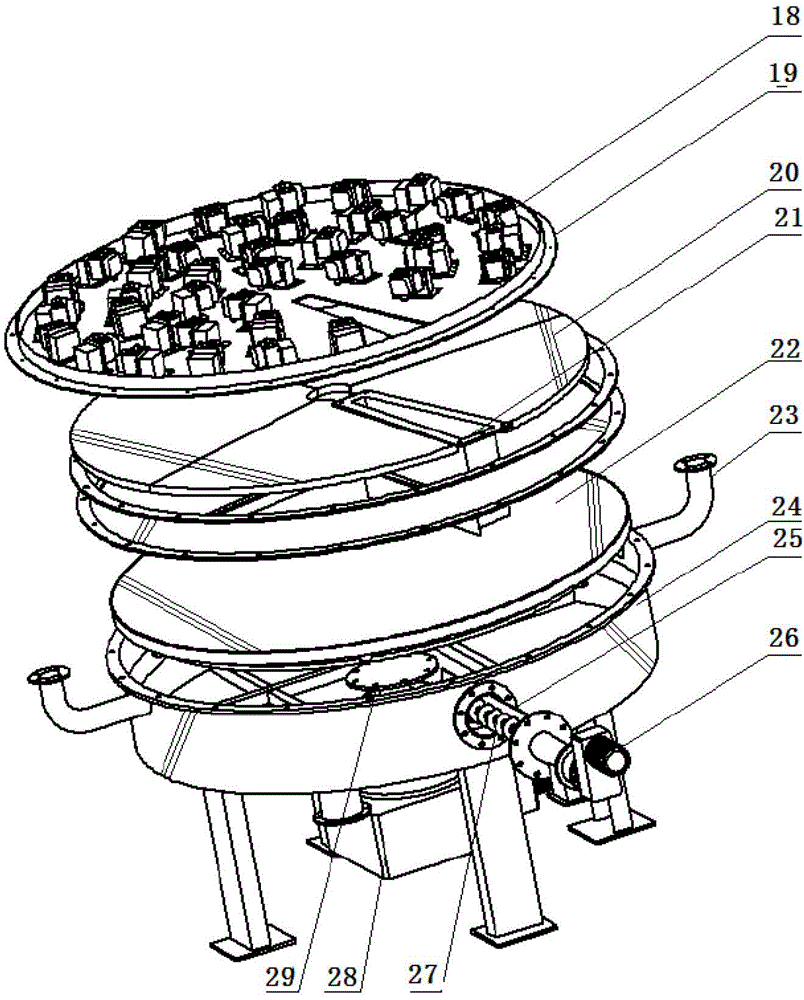

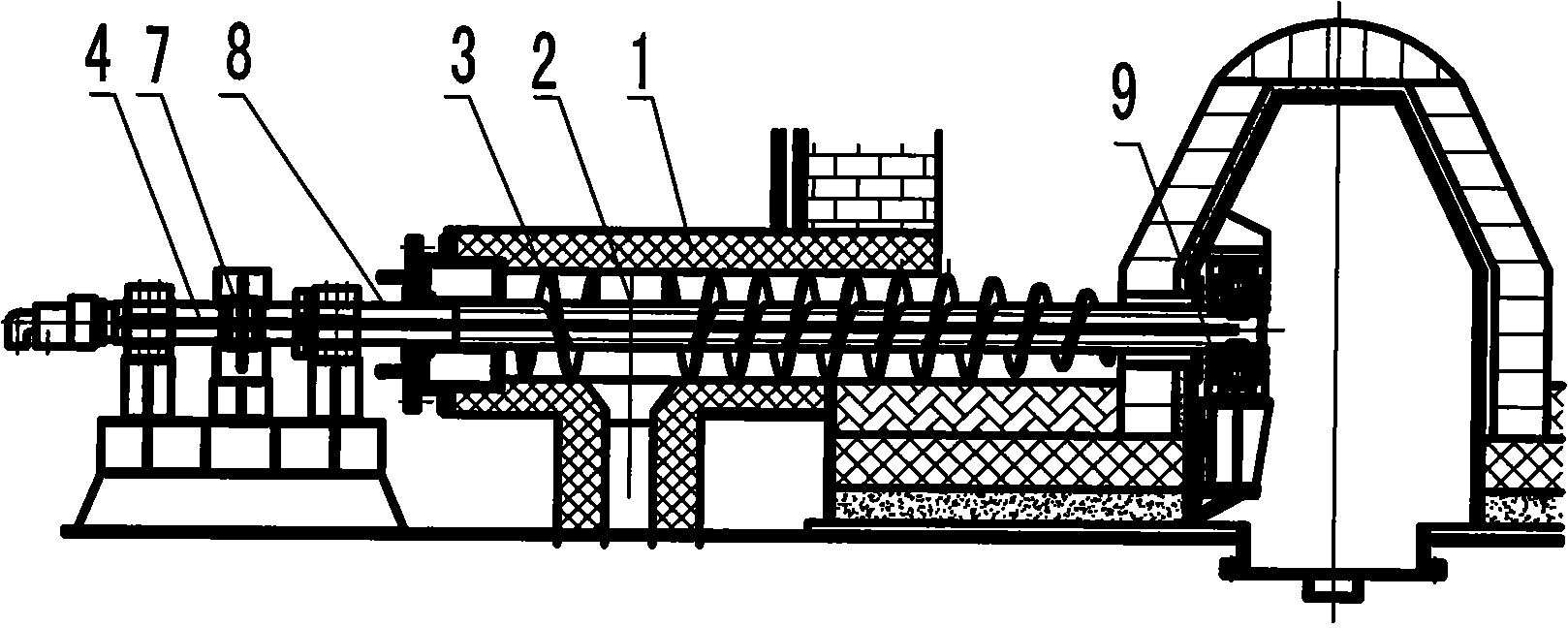

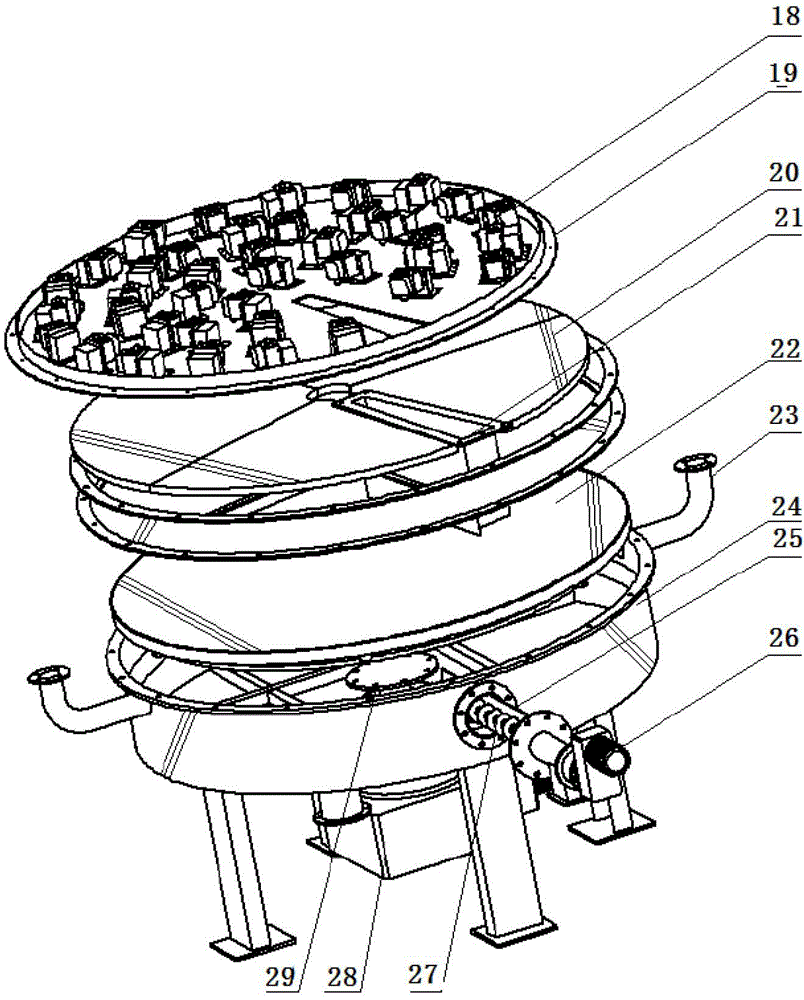

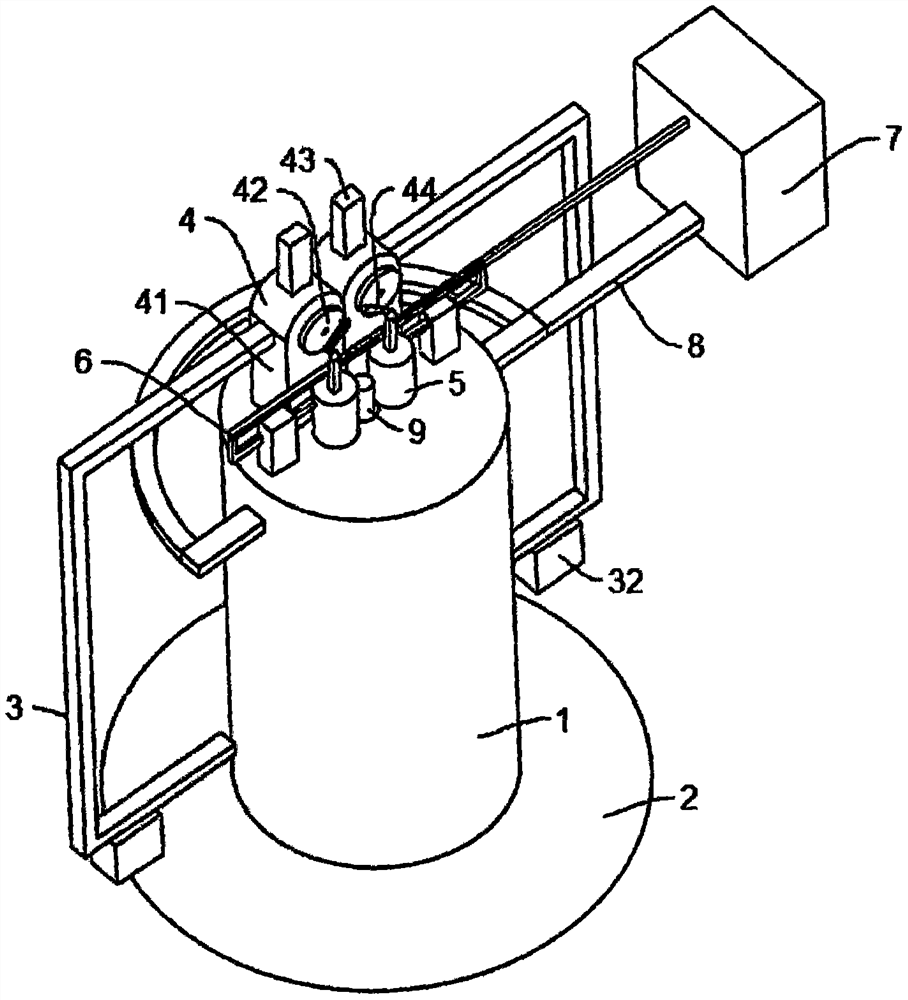

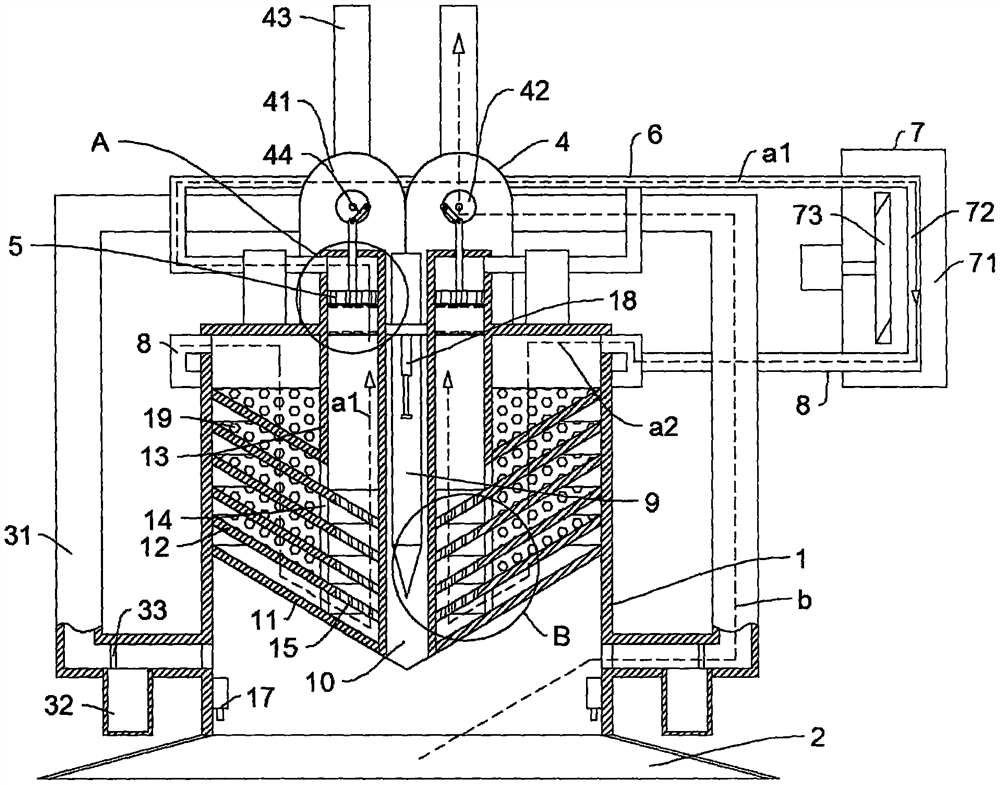

Disc-type microwave continuous splitting device and method for splitting waste rubber

ActiveCN103333709ASmooth runningImprove microwave cracking efficiencyPigmenting treatmentPlastic recyclingMicrowaveWaste rubber

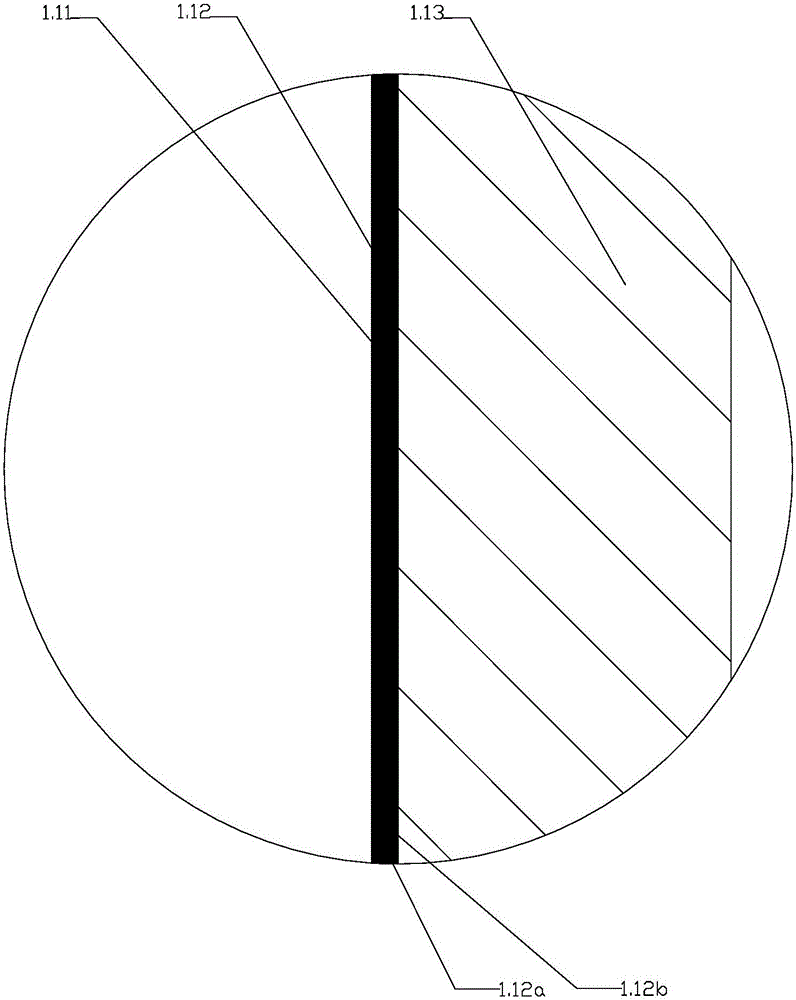

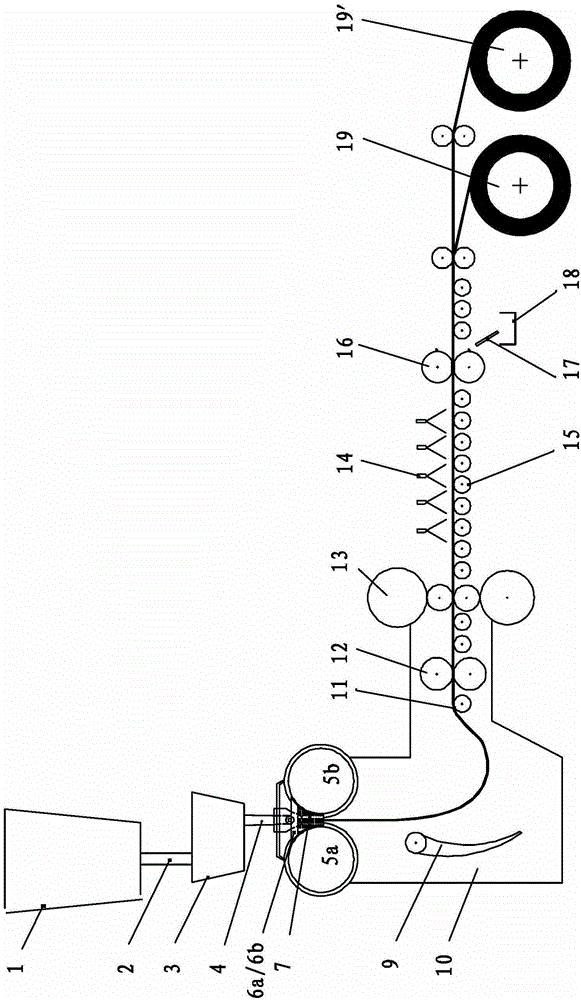

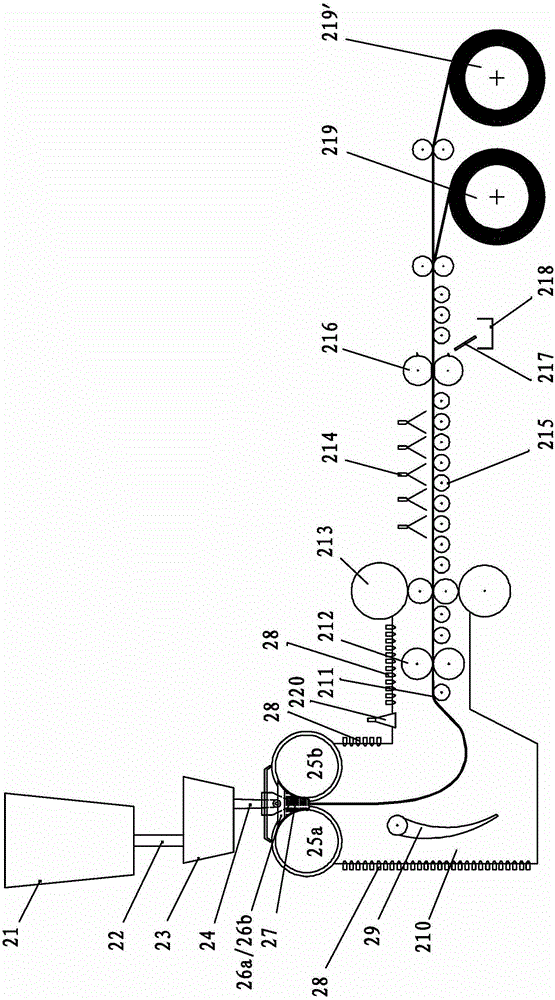

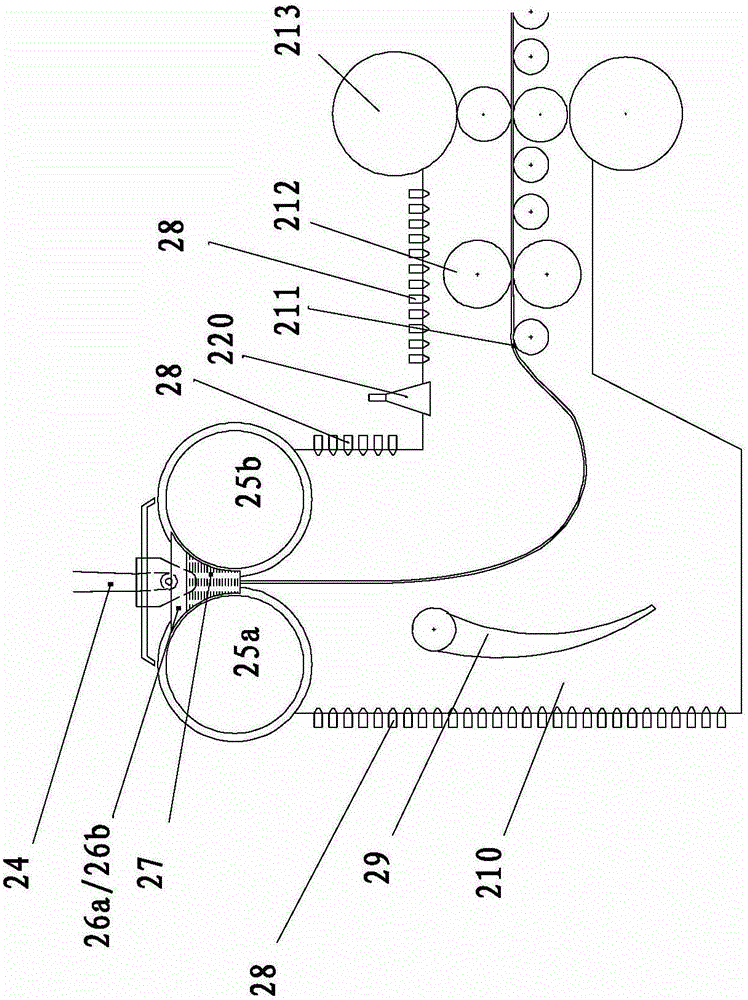

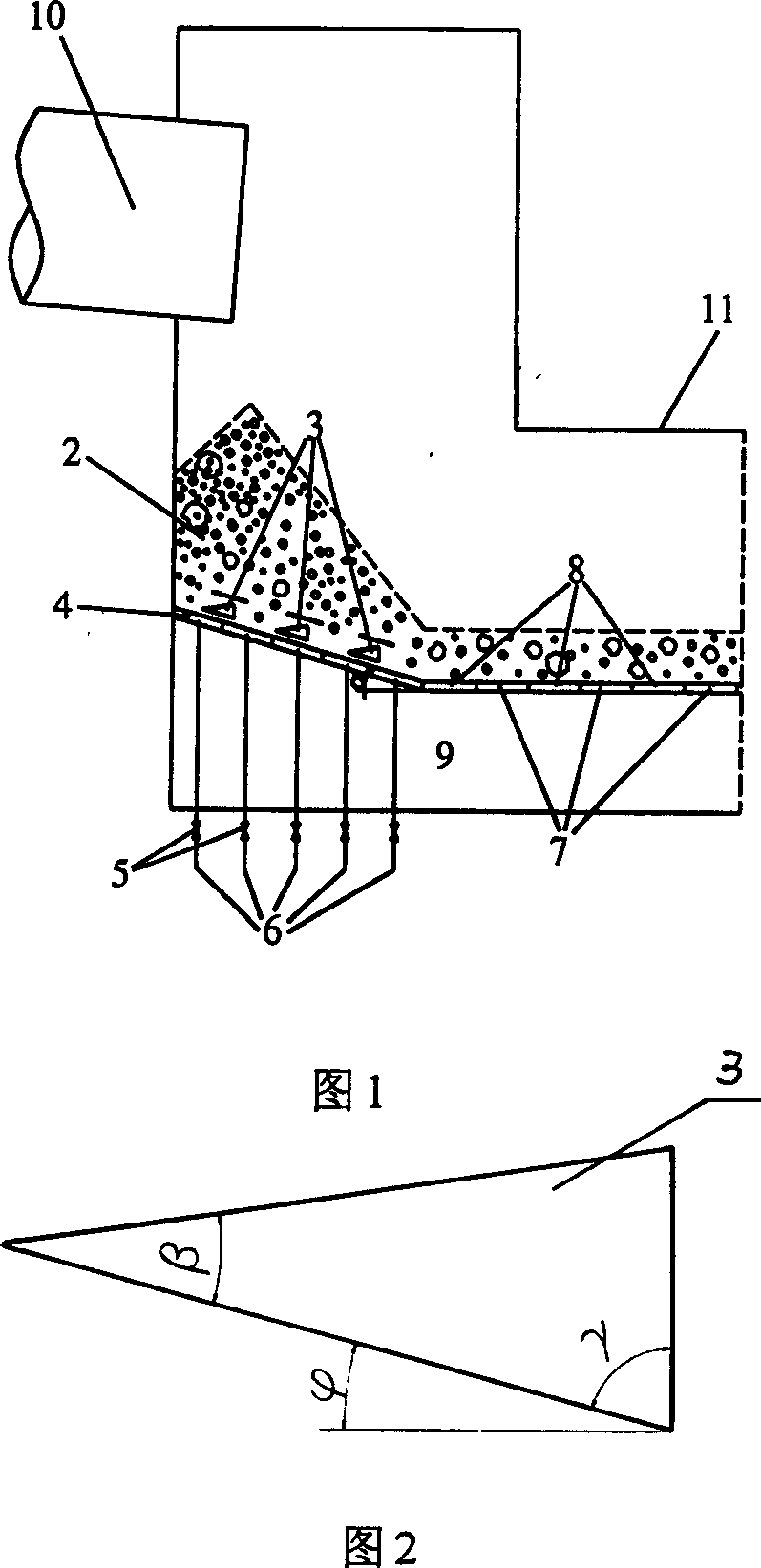

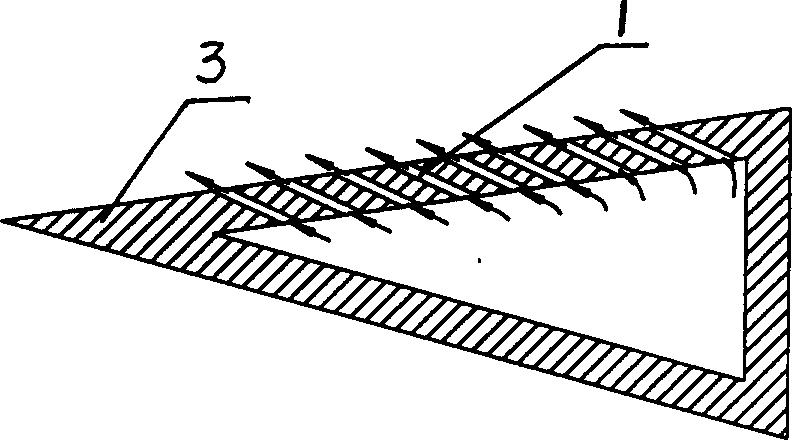

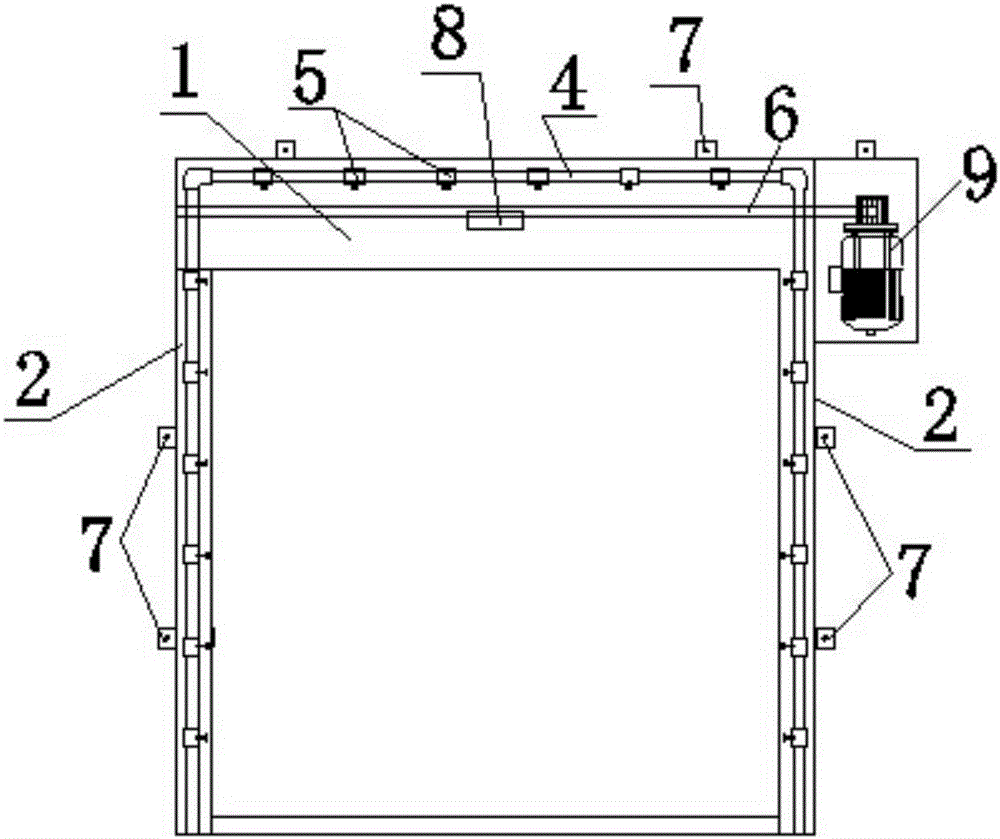

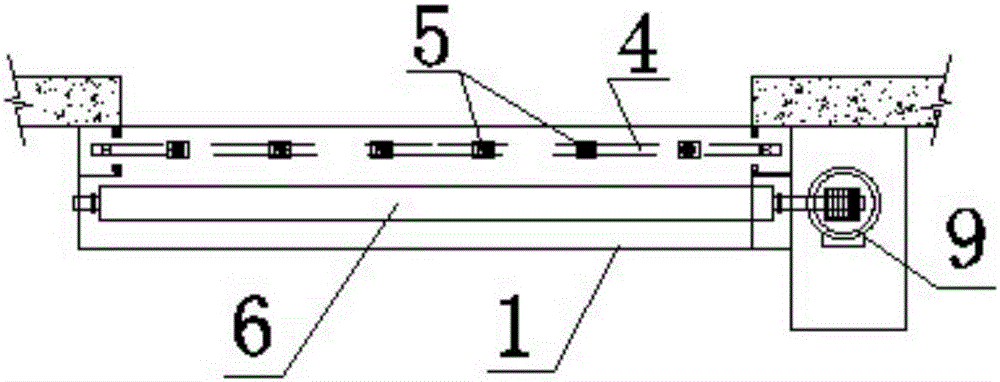

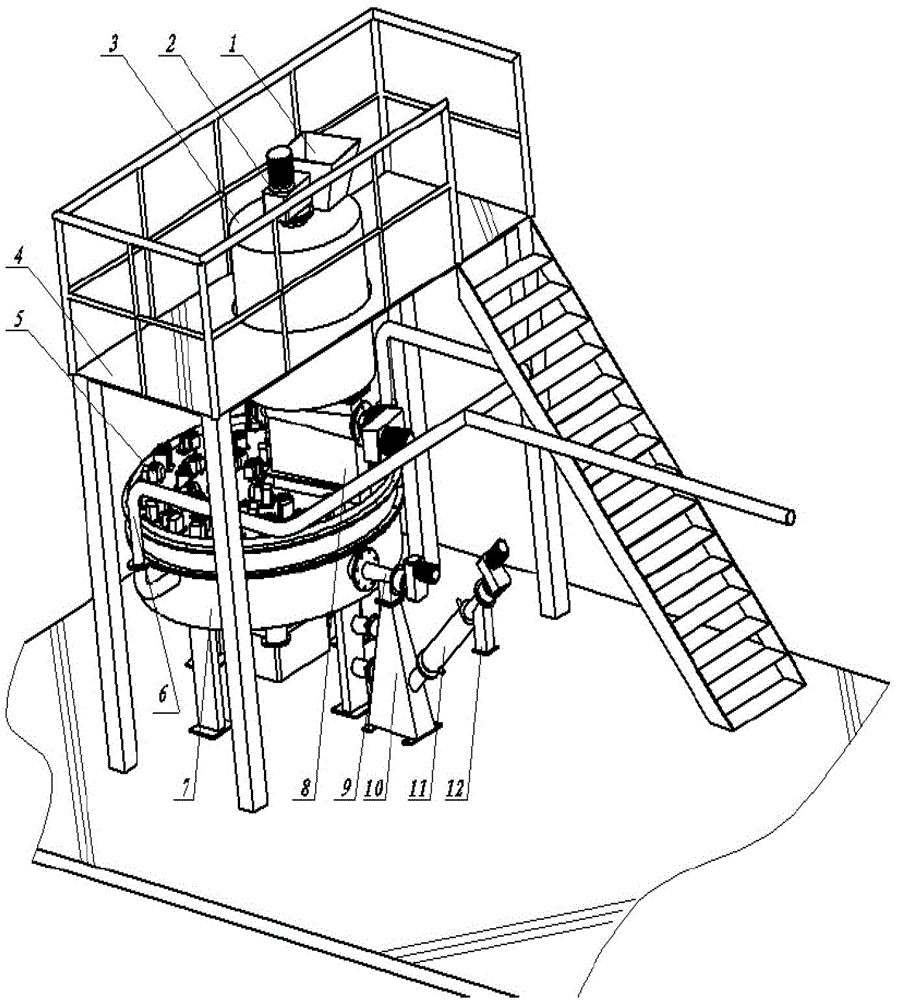

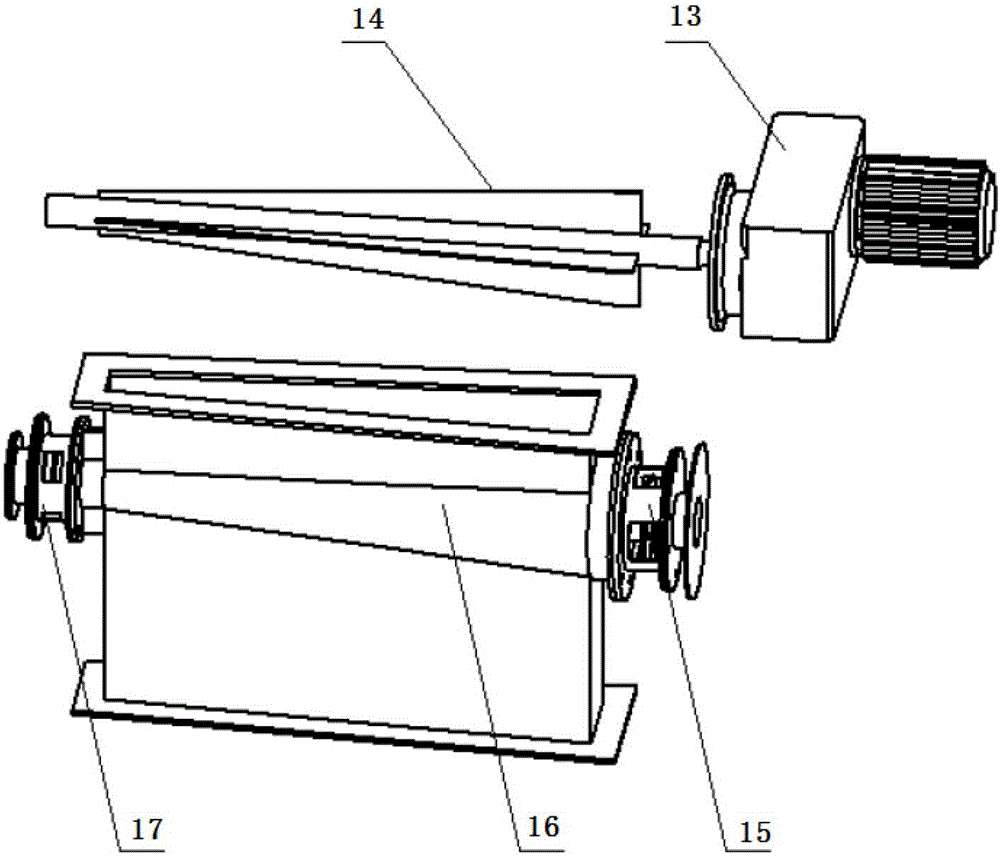

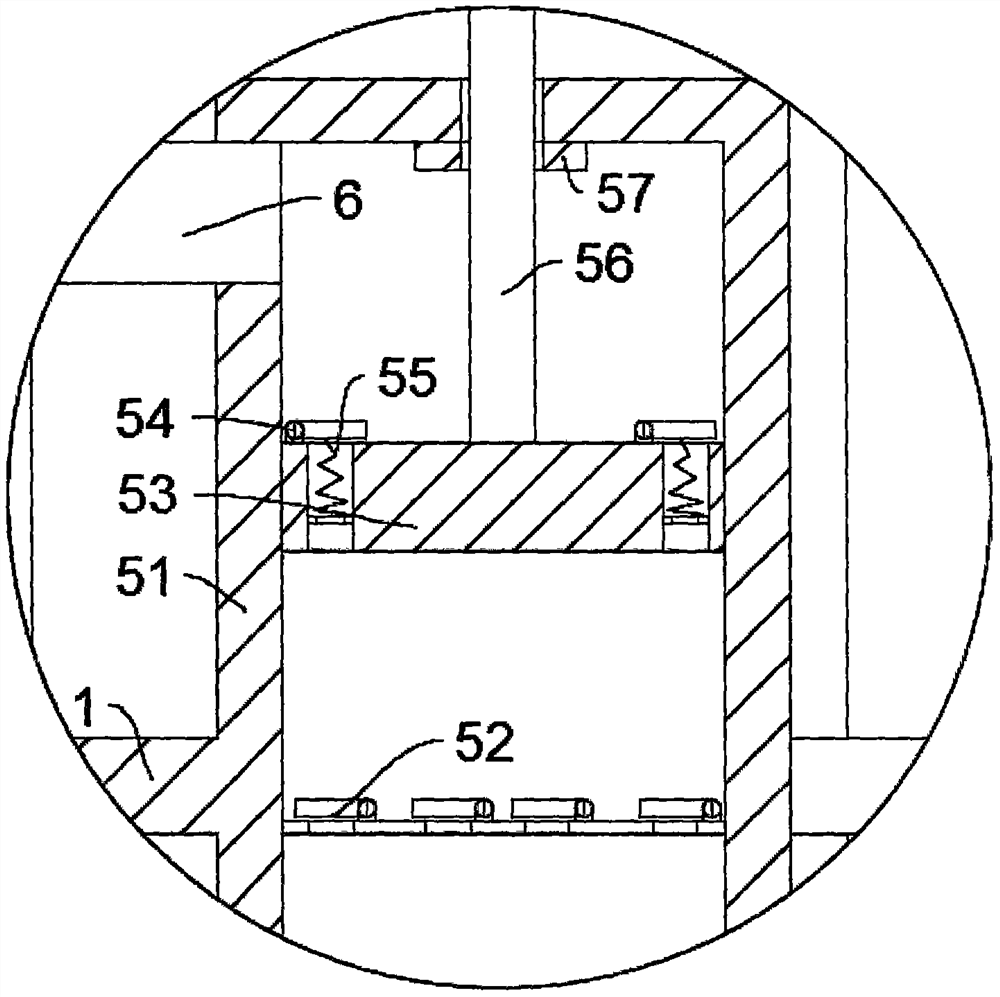

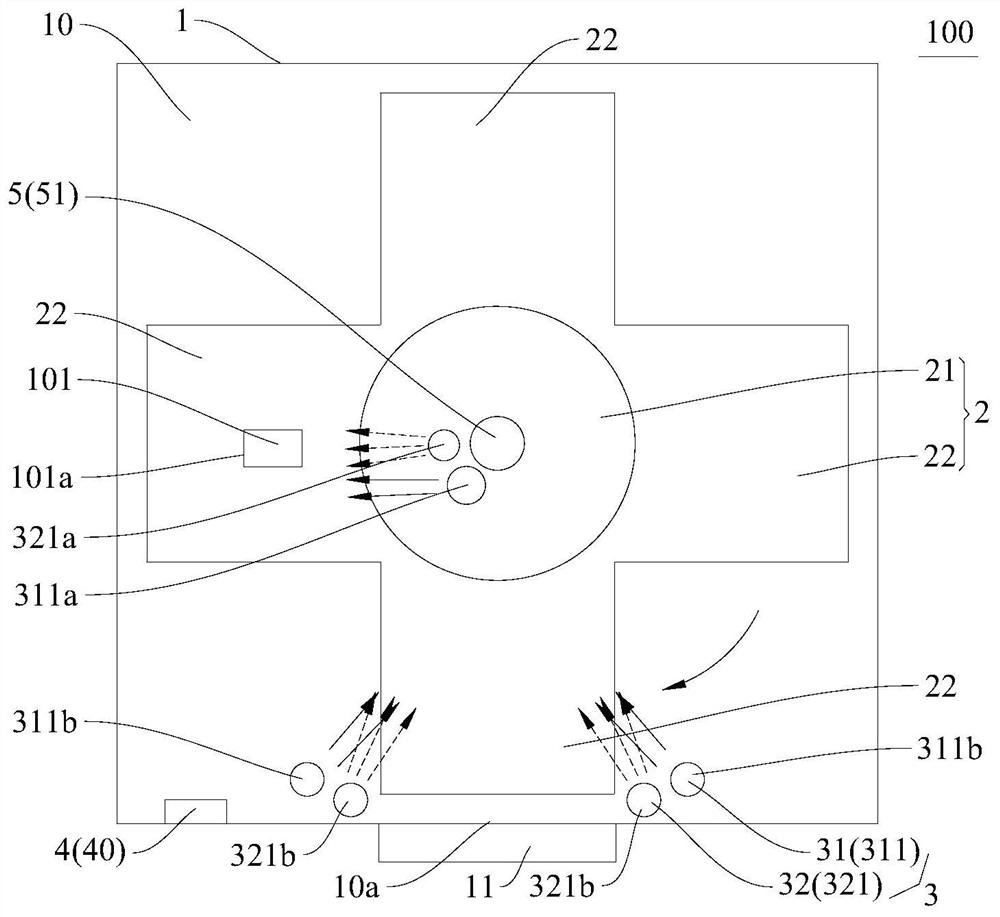

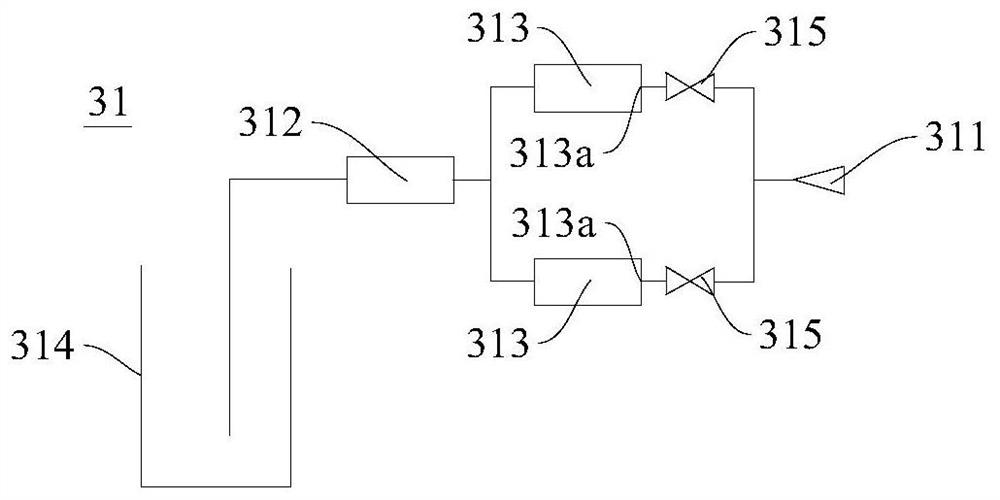

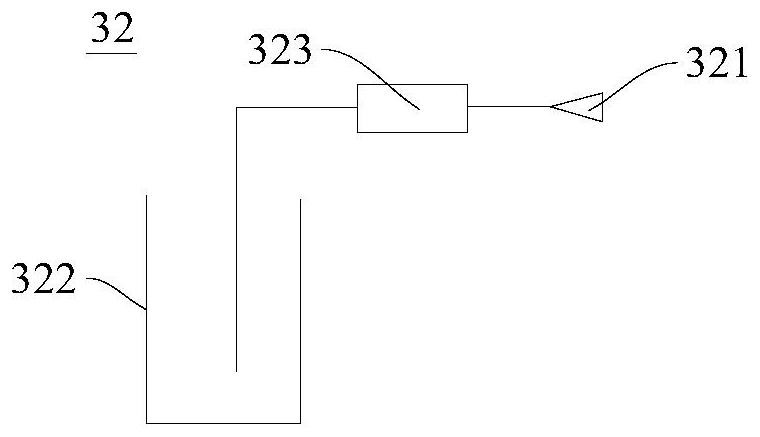

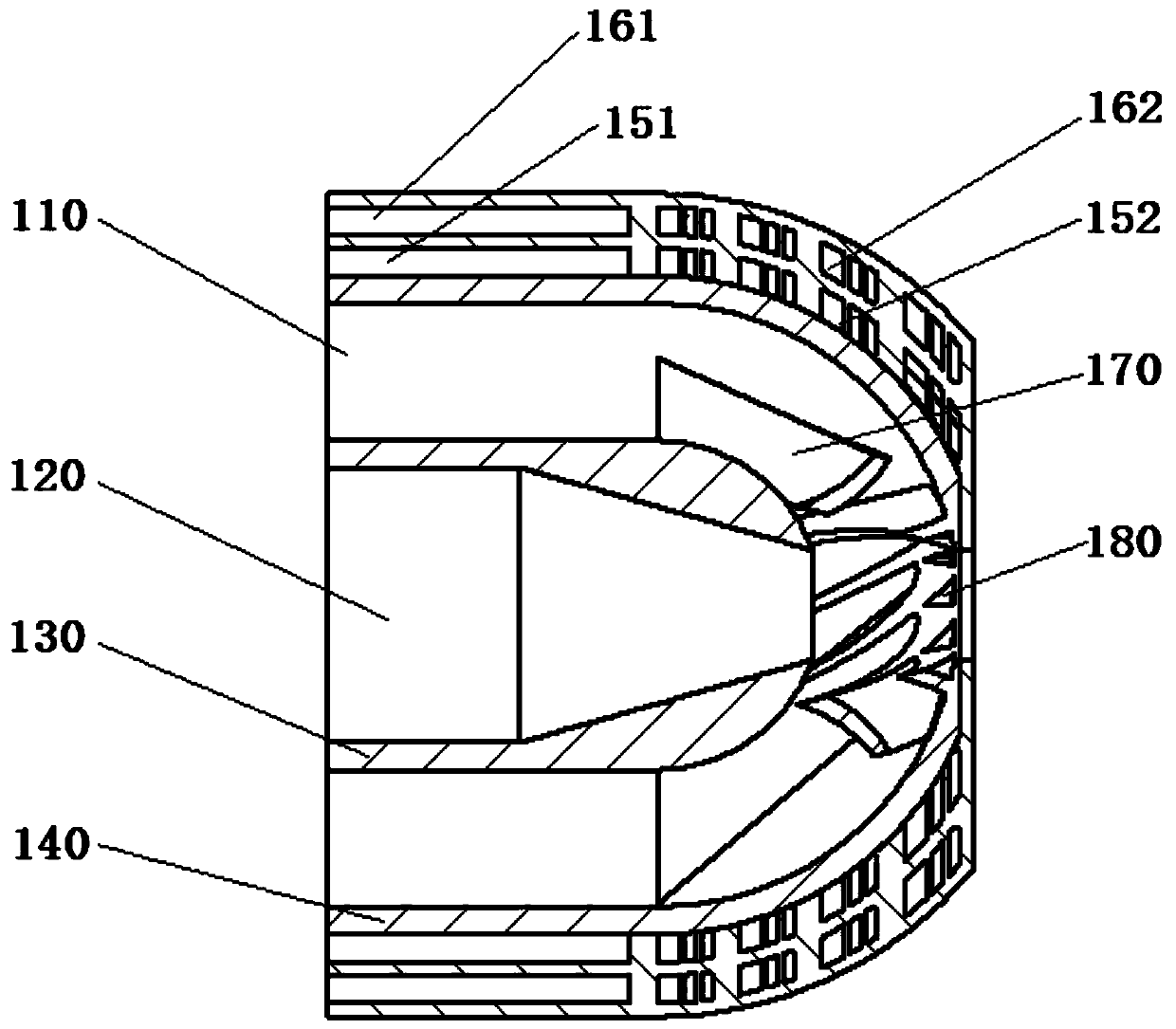

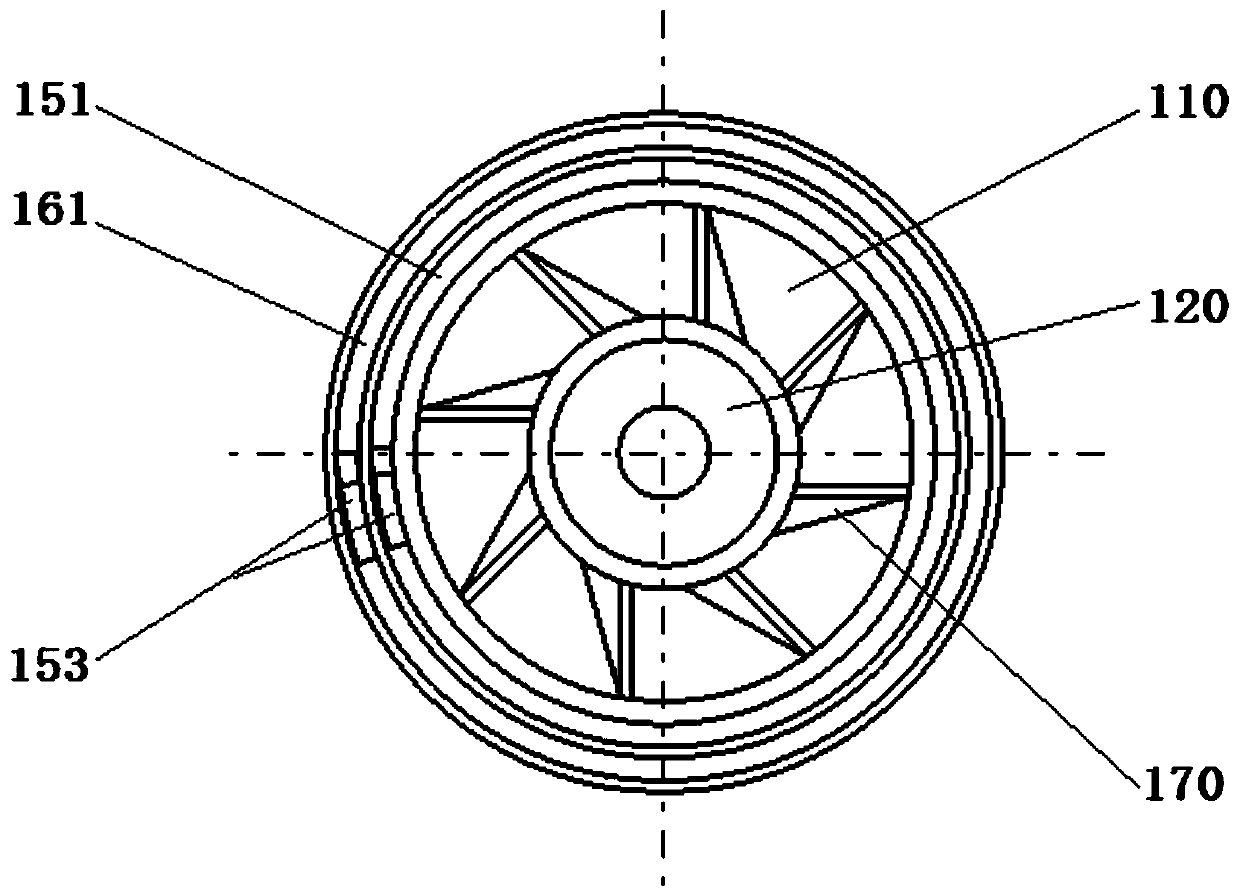

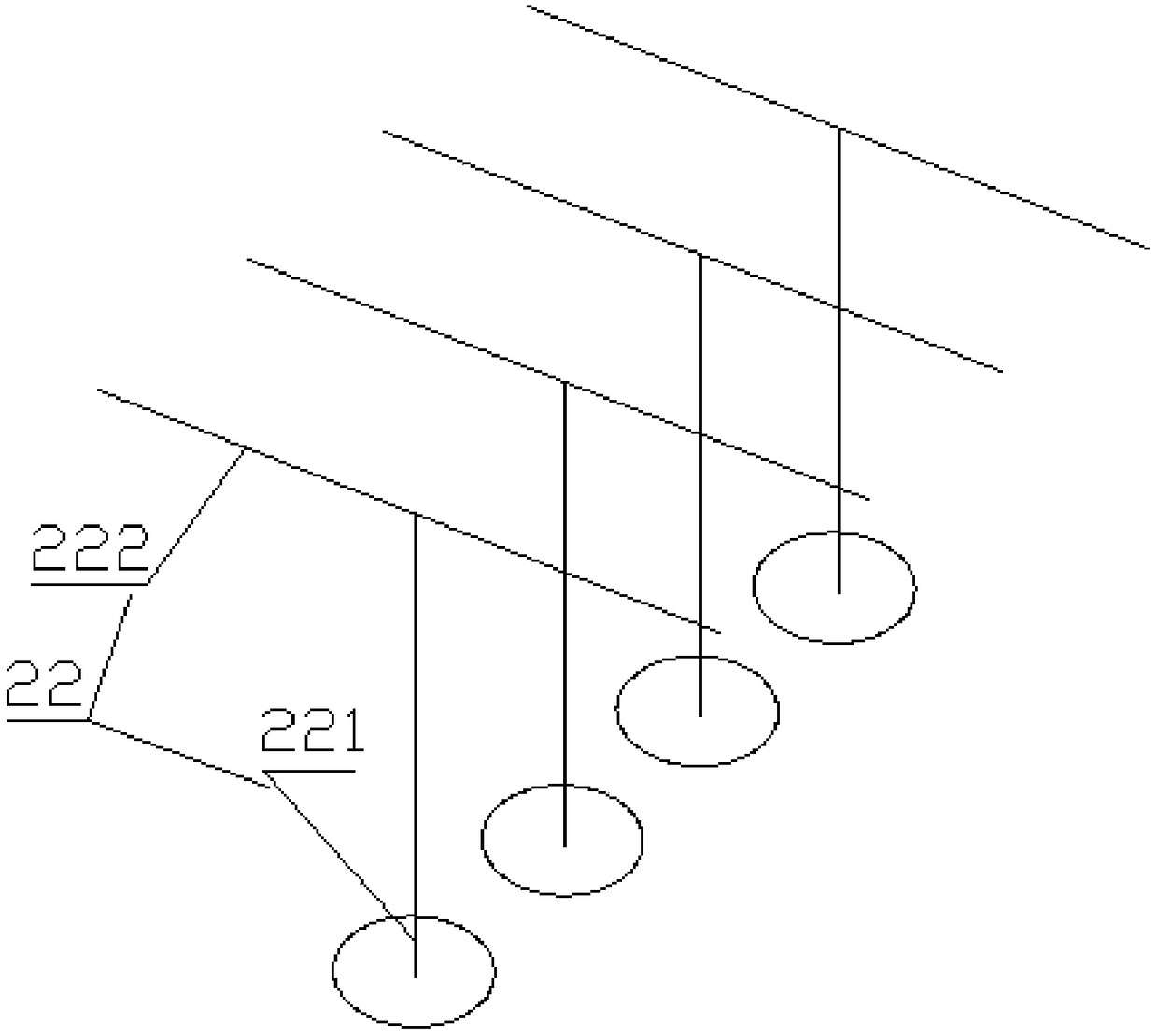

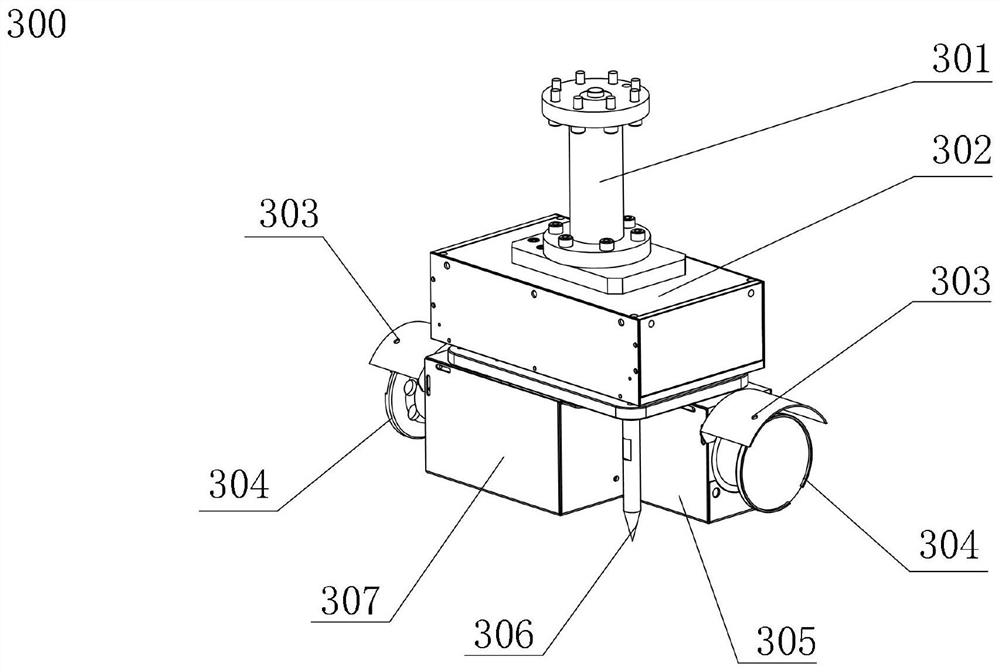

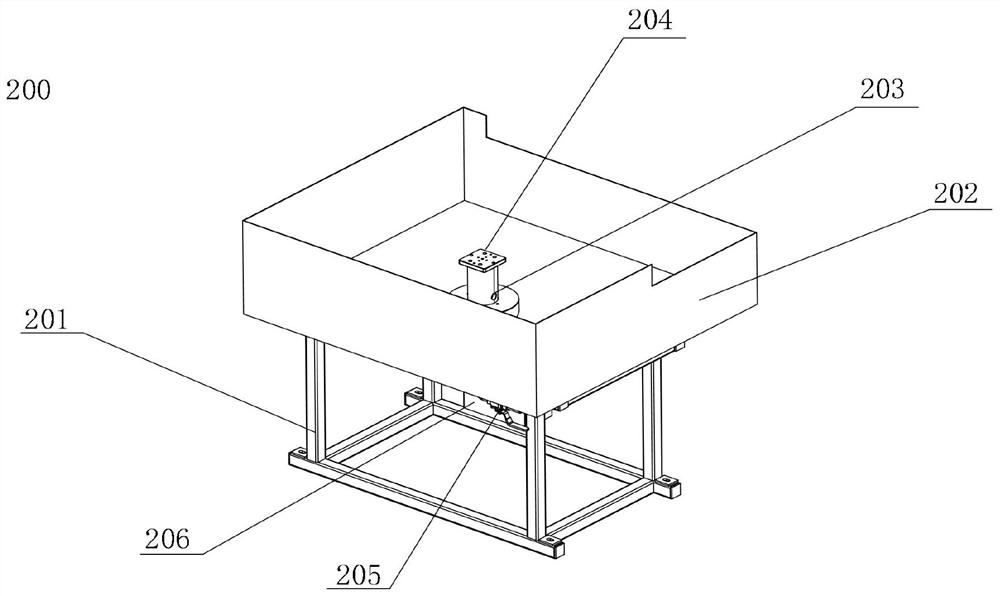

The invention discloses a disc-type microwave continuous splitting device. The disc-type microwave continuous splitting device comprises a feeding assembly, a microwave splitting assembly, a discharging assembly and a control assembly which are sequentially communicated with one another, wherein the microwave splitting assembly comprises a microwave generator, a nonmetal sealing plate, a splitting cavity, a rotating disk and a disk driving motor, the nonmetal sealing plate is used for dividing the splitting cavity into an upper part and a lower part, the rotating disk is arranged at the lower part of the splitting cavity and is matched with the disk driving motor in a driving rotation manner, and the microwave generator is arranged on a circular flange on the splitting cavity. The invention aslo discloses a method for splitting waste rubber by using the splitting device; the disc-type splitting cavity is adopted in the method and is divided into an upper cavity and a lower cavity through the nonmetal sealing plate, so that the microwave splitting efficiency of waste tires is improved; and in order to ensure the stable operation of a disk and prevent the high-temperature deformation, one or a plurality of annular guide rails are arranged on the lower surface of the rotating disk and are used for supporting the rotating disk, so that the rotating disk rotates on a guide rail so as to optimize the splitting effect.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

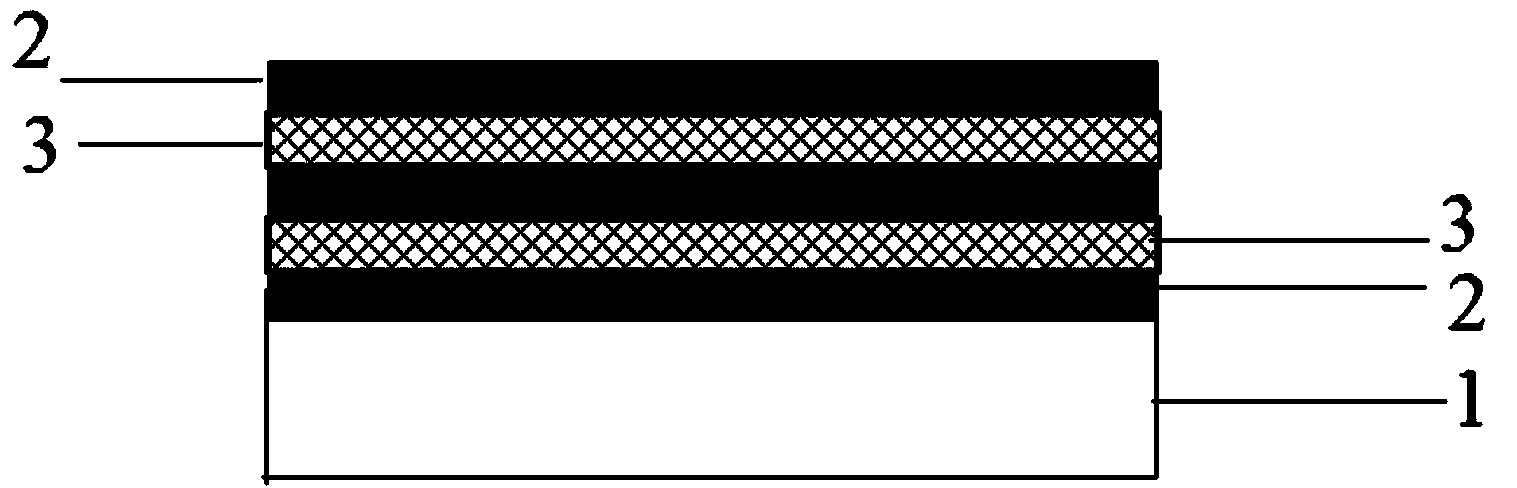

Display device, flexible substrate and manufacturing method of flexible substrate

ActiveCN103531724AImprove bending strengthHigh compressive strengthSolid-state devicesSemiconductor/solid-state device manufacturingFiberDisplay device

The invention relates to the technical field of flexible display, in particular to a display device, a flexible substrate and a manufacturing method of the flexible substrate. The flexible substrate comprises a substrate, wherein the substrate is provided with a plurality of flexible layers; fiber paved layers are formed between two adjacent flexible layers. According to the flexible substrate and the manufacturing method thereof provided by the invention, the flexible layers and the fiber paved layers form the flexible substrate together, so that the flexible layers can be effectively prevented from being deformed at high temperature, stress is reduced, the adhesive force of a film on the substrate is increased to the maximum extent, and the bending and compressing strength of the substrate are improved.

Owner:BOE TECH GRP CO LTD

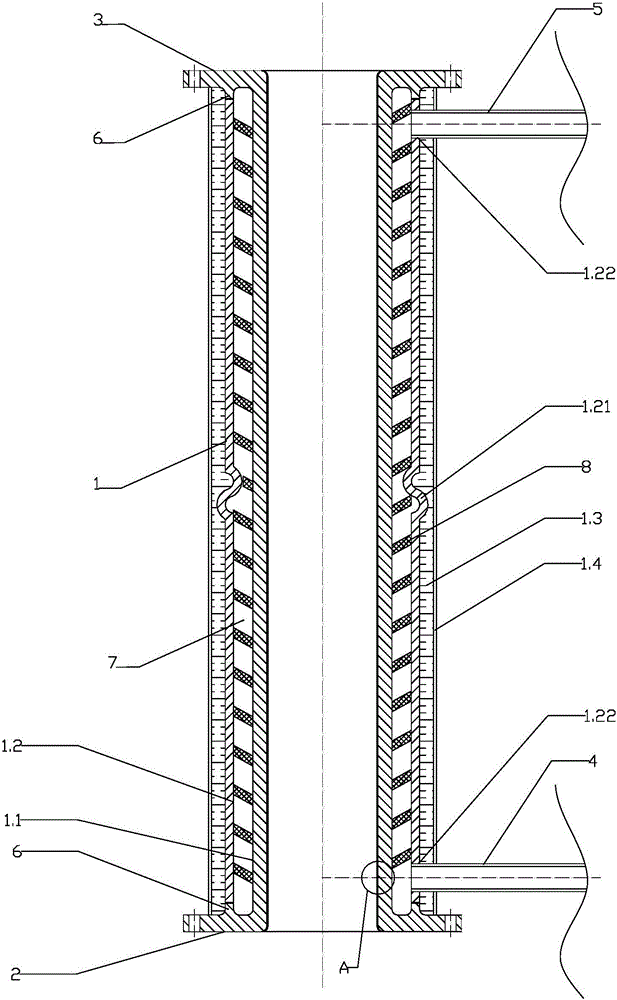

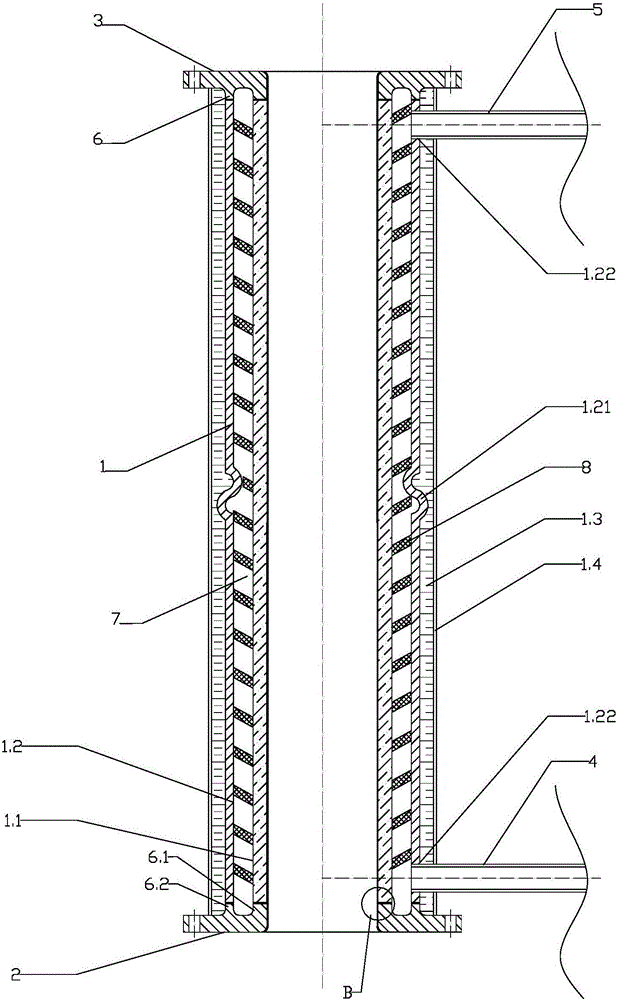

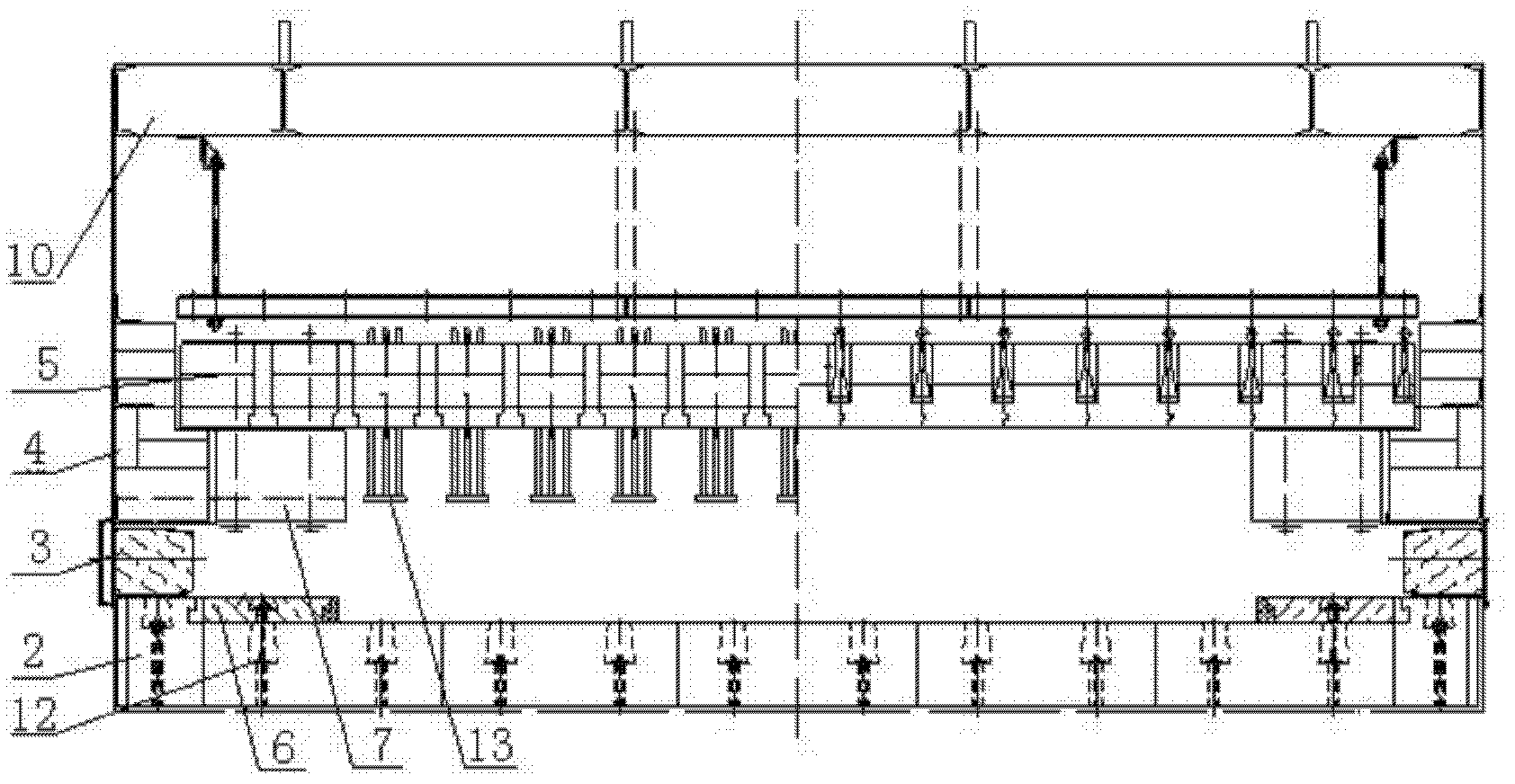

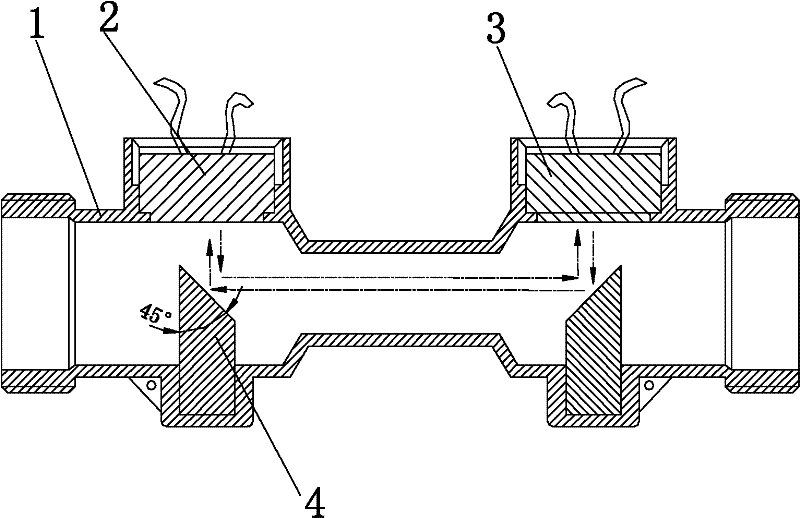

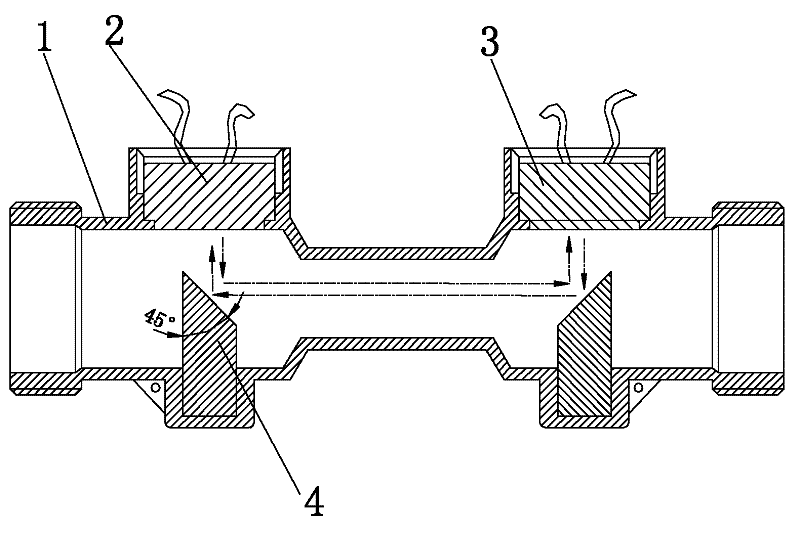

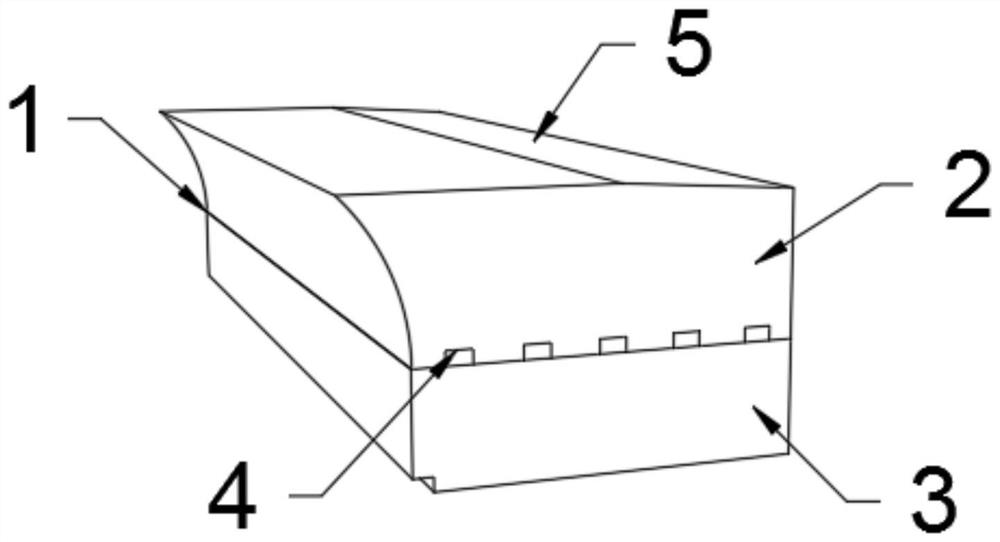

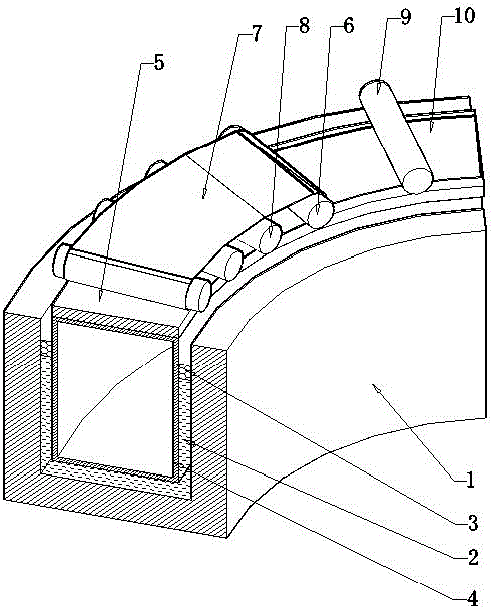

Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

InactiveCN105043117APrevent oxidationAvoid carburizationIncreasing energy efficiencyWaste heat treatmentEngineeringCoke oven

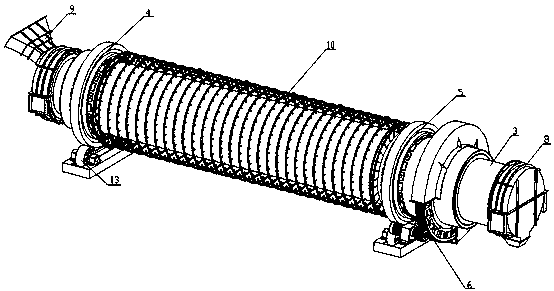

The invention discloses a coke oven ascension pipe raw gas evaporative cooling device and a preparation method thereof. The device comprises a cooling pipe, a raw gas inlet flange and a raw gas outlet flange, wherein the raw gas inlet flange and the raw gas outlet flange are connected with the two ends of the cooling pipe respectively. The cooling pipe is sequentially composed of an inner sleeve, an outer sleeve, a heat preservation layer and a protection layer from inside to outside. Through holes are formed in the two ends of the side wall of the outer sleeve respectively. A water inlet steel pipe is installed on the through hole close to the raw gas inlet flange. A vapor outlet steel pipe is installed on the through hole close to the raw gas outlet flange. An annular expansion joint section is arranged at the portion, between the water inlet steel pipe and the vapor outlet steel pipe, of the outer sleeve. The high temperature structural strength and high temperature breakage resistant capacity of the cooling device are remarkably improved, the heat transfer behavior of the pipe wall of the inner sleeve of the cooling device is improved, the radial temperature distribution of the pipe wall is optimized, the efficient function coordination of multiple layers of materials is achieved, and the comprehensive use performance of the inner sleeve is improved; the aim of long-term efficient and stable running of the ascension pipe raw gas evaporative cooling device is finally achieved.

Owner:武汉钢铁有限公司

Method and device for reducing temperature of thin-strip continuous casting lower closed chamber

The invention discloses a method and device for reducing the temperature of a thin-strip continuous casting lower closed chamber, and relates to the field of thin-strip continuous casting. The problem that an existing process cannot give consideration to strip steel anti-oxidation and rolling temperature reduction of the thin-strip continuous casting lower closed chamber at the same time is solved; the following improvements are performed on the basis of an existing dual-roller thin-strip continuous process, wherein the improvements include that liquid nitrogen is injected into the closed chamber, a plurality of channels leading to the lower closed chamber are evenly distributed on the surrounding wall of the thin-strip continuous casting lower closed chamber, and the liquid nitrogen is injected into the channels; the flow and the pressure of the liquid nitrogen in each channel are adjusted; and closed-loop control over the oxygen concentration of the lower closed chamber is carried out; and closed-loop control over the online rolling temperature is carried out, and the inlet temperature is controlled to range from 900 DEG C to 1150 DEG C. By means of the method and device, the aim of rapid cooling of the thin-strip continuous casting lower closed chamber can be achieved, steel strip oxidation is effectively prevented, the lower steel strip rolling temperature is achieved, the steel strip cooling homogeneity is improved, and the plate shape and the surface quality of strip steel are better improved.

Owner:BAOSHAN IRON & STEEL CO LTD

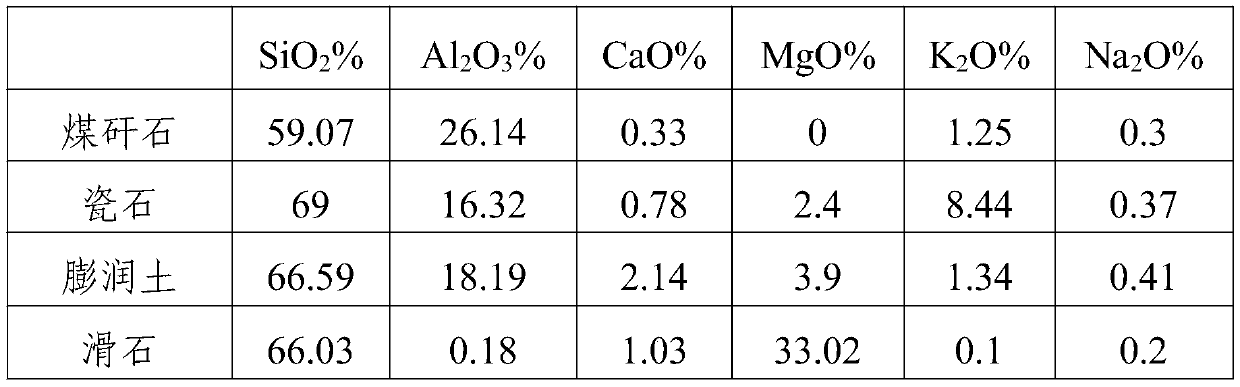

Low-temperature glaze-fired ceramic product and preparing method thereof

The invention provides a low-temperature glaze-fired ceramic product and a preparing method thereof, and relates to the technical field of ceramic products. The low-temperature glaze-fired ceramic product is obtained by coating a ceramic blank with low-temperature glaze and drying and firing the ceramic blank. The ceramic blank comprises, by mass, 30-40 parts of coal gangue, 40-50 parts of chinastone, 5-10 parts of bentonite, 3-8 parts of talc, 6-15 parts of wollastonite, 4-10 parts of clay, 1-3 parts of quartz and 0.2-0.6 part of sodium polyphosphate. The low-temperature glaze comprises, by mass, 5-15 parts of calcite, 30-40 parts of quartz, 10-20 parts of potassium feldspar, 9-15 parts of kaolin, 10-20 parts of talc, 15-25 parts of barium carbonate, 10-20 parts of borax, 5-10 parts of zinc oxide and 0.1-0.5 part of sodium carboxymethyl cellulose. The prepared ceramic product has high glaze surface hardness, color and luster and heat stability, the firing temperature is lowered, energy conservation and emission reduction are reduced, the adopted raw materials are easy to obtain and low in price, and production cost is reduced.

Owner:广东派陶科技有限公司

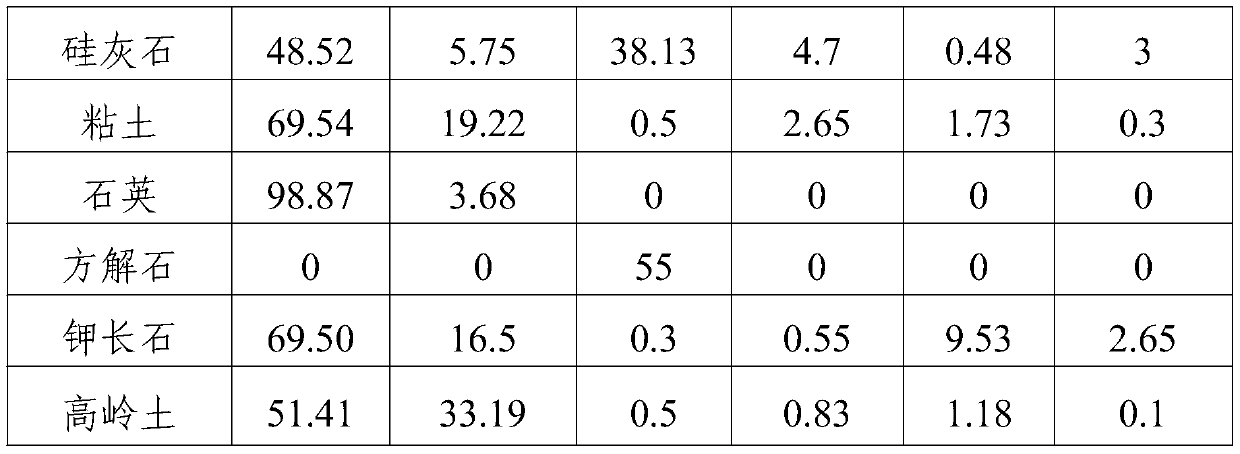

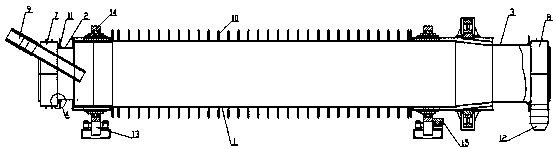

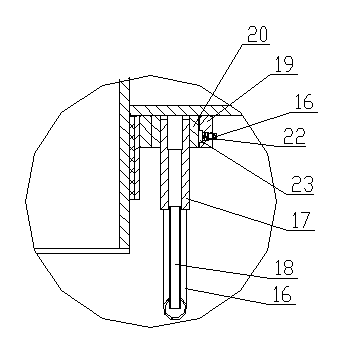

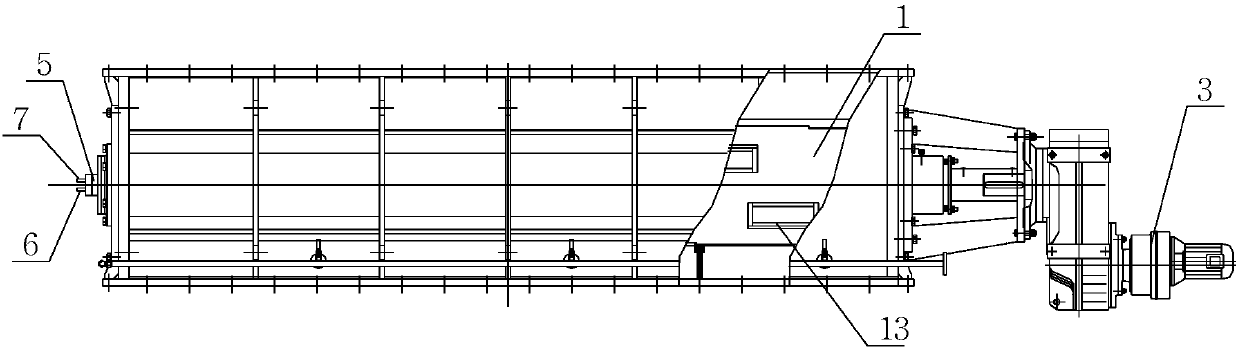

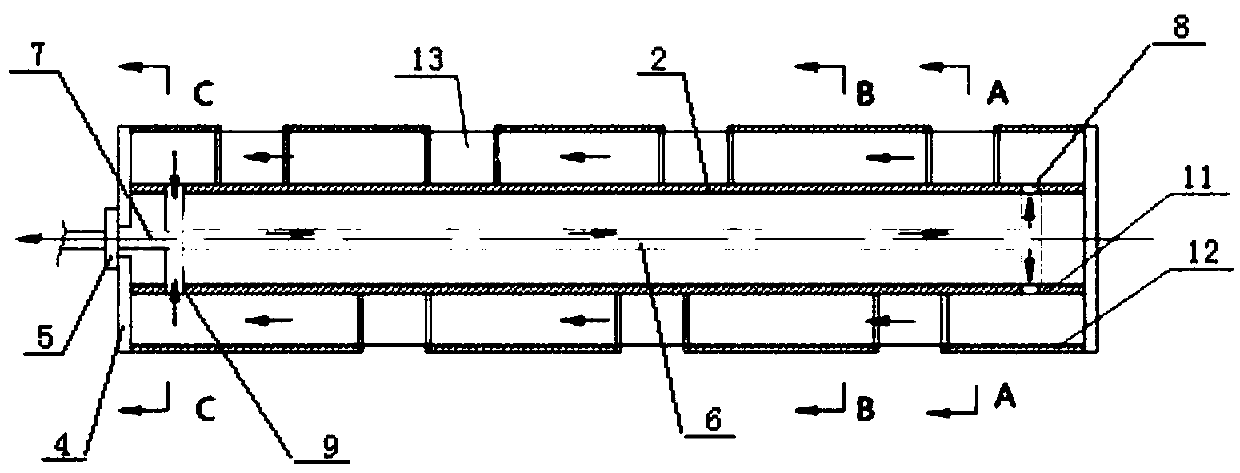

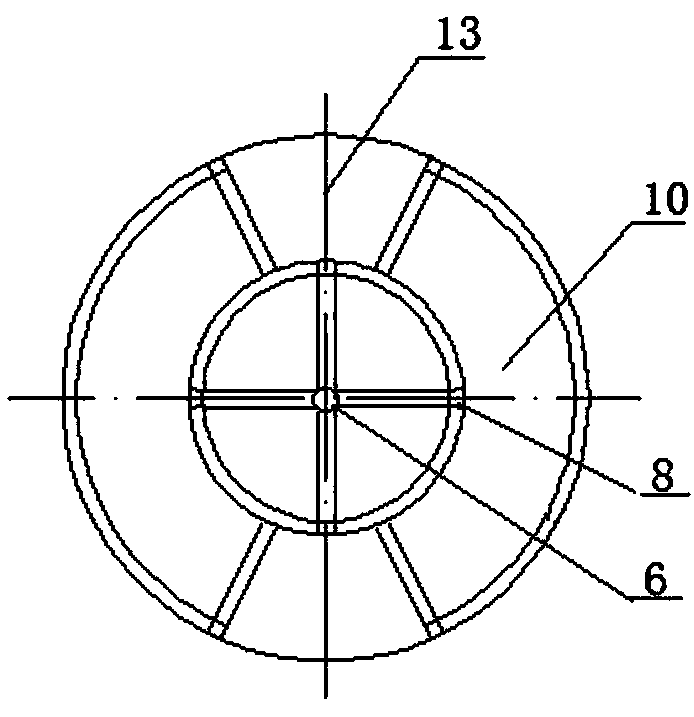

High-temperature water cooling spiral conveyor

InactiveCN101269744ALower working temperaturePrevent high temperature deformationPackagingHelical bladeEngineering

The invention discloses a high temperature water-cooling screw conveyor which comprises an electric motor, a box body and a screw conveying shaft. The screw conveying shaft is arranged in the box body, the electric motor is connected with the screw conveying shaft through a power gearing, the outer side of the screw conveying shaft is provided with helical vanes, and a water-cooling pipe is arranged in the screw conveying shaft. Aiming at the special working condition of high temperature furnace burden conveying, the screw shaft adopts water cooling, the helical vanes and the split structure of the screw shaft are made of refractory steel material to solve the problem of 800-1000 DEG C high temperature furnace burden leading-out and conveying.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

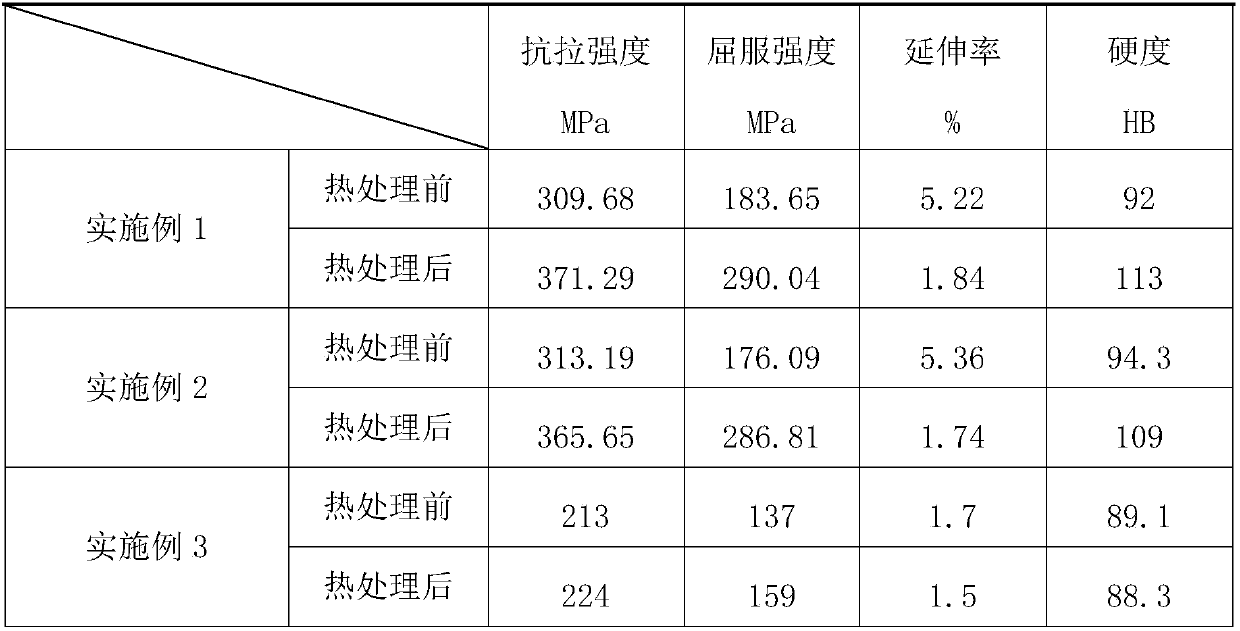

Thermal treatment method of die-casting aluminum alloy and die-casting aluminum alloy material

The invention provides a thermal treatment method of a die-casting aluminum alloy and a die-casting aluminum alloy material. The thermal treatment method of a die-casting aluminum alloy comprises thefollowing steps: placing a die casting into a thermal treatment furnace, warming up at uniform speed to 150-170 DEG C from 20-30 DEG C, carrying out thermal insulation for 300-500 min, taking out thesample, and air cooling. The thermal treatment method of a die-casting aluminum alloy has simple steps and can avoid foaming and high-temperature deformation after thermal treatment of die castings.

Owner:GUANGZHOU ZHIYUAN ALLOY PROD CO LTD

High temperature-resistant and UV (Ultraviolet)-resistant protective film and preparation method thereof

InactiveCN108707432AReduced shrinkage performancePrevent high temperature deformationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneDisplay device

The invention discloses a high temperature-resistant and UV (Ultraviolet)-resistant protective film and a preparation method thereof. The high temperature-resistant and UV-resistant protective film comprises a PE (Polyethylene)-based film layer and an adhesive layer, wherein the adhesive layer is formed by coating the surface of the PE-based film layer with a heat-resistant and UV-resistant pressure-sensitive adhesive and drying; the pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 25 to 35 parts of acrylate resin, 55 to 70 parts of ethyl acetate, 1to 2 parts of isocyanate curing agent, 0.1 to 0.5 part of UV absorbent and 0.4 to 0.7 part of free radial collecting agent. Compared with the prior art, the preparation method disclosed by the invention is reasonable in raw material proportioning and simple in preparation technology, and a release force of the high temperature-resistant and UV-resistant protective film provided by the invention ranges from 7N / m to 9N / m; after long-time irradiation under high temperature and UV, the release force of the high temperature-resistant and UV-resistant protective film changes within + / -35 percent, and the high temperature-resistant and UV-resistant protective film has no wrinkling, no degumming, no adhesive residue and no chromatic aberration after long-time irradiation under the UV; the high temperature-resistant and UV-resistant protective film can be used for protecting the surfaces of backlight displays in electronic products such as a computer, a television and a mobile phone and can beused for protecting an overlaid shipment transportation process of the backlight displays.

Owner:芜湖夏鑫新型材料科技有限公司

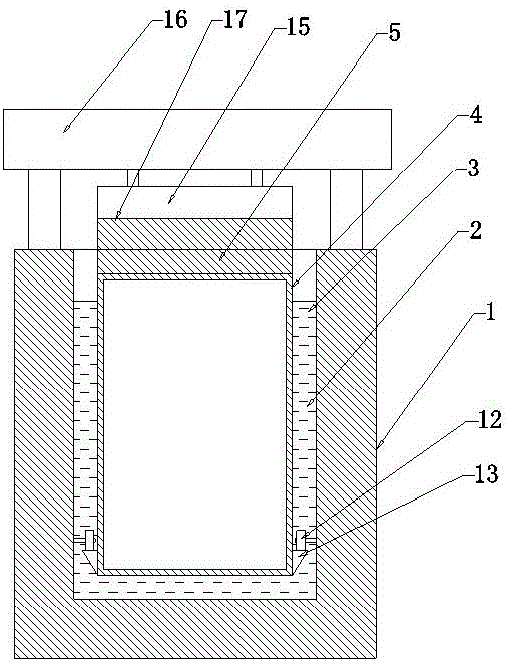

Ultra-thin float glass tin bath

InactiveCN102583969APrevent high temperature deformationPlay a thermal insulation effectBrickThin glass

The invention discloses an ultra-thin float glass tin bath, which is characterized in that a bath body comprises a bath bottom, side walls, edge seals, breast walls and top caps, wherein the bath bottom consists of bottom bricks; the side walls are respectively arranged at both sides of the bath bottom; the edge seals are respectively arranged on the side walls; the breast walls are constructed above the edge seals; the top caps are arranged above the breast walls through hanging; the inner side of each side wall is provided with lining bricks; the lining bricks are fixedly arranged on the bottom bricks of the bath bottom; and insulation cans are respectively hung on the top caps. According to the ultra-thin float glass tin bath disclosed by the invention, through arranging the lining bricks with different thickness in the bath body, modification can be conveniently performed, so that the tin bath has different inner side widths, and thereby, the phenomenon that the exposure area of tin liquor at the edge parts of glass plates is too big because the tin bath is too wide is avoided, and finally, the manufacturing condition of an ultra-thin glass product is met.

Owner:HUAERRUN GLASS IND

Cooling machine high-temp fixed bed anti-stack device for industrial furnace

InactiveCN1560553AImprove cooling efficiencyPrevent high temperature deformationHandling discharged materialFixed bedProduct gas

The invention relates to a cooling device for block or particle type material baked in the industrial oven continuously. It includes wall, cooler grate bed, cooling air pipe, cooling air adjusting valve, wind supplying chamber on the movable bed and high temperature grate bed accumulation resisting device, the cooler grate bed is made up of fixed grate bed and movable grate bed, the fixed grate bed is arranged below the material aperture of the industrial oven, the fixed grate bed leans from up down and forma an angle alpha with the movable grate bed, the high temperature grate bed accumulation resisting device is arranged above the fixed grate bed. The advantages of the invention are avoiding the high temperature material from being blocked or pilled on the fixed bed effectively, the material on the fixed bed is more even.

Owner:NANJING KISEN INT ENG

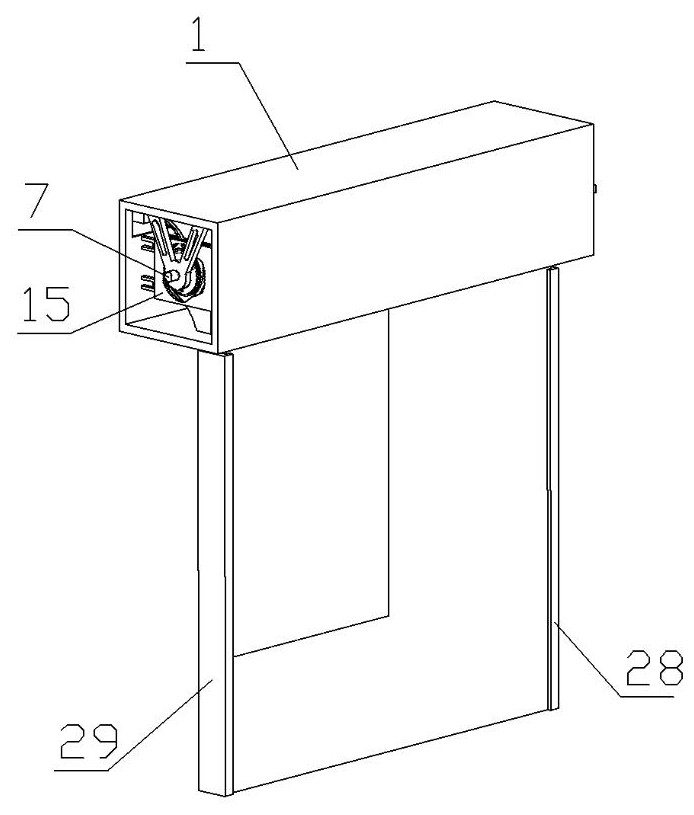

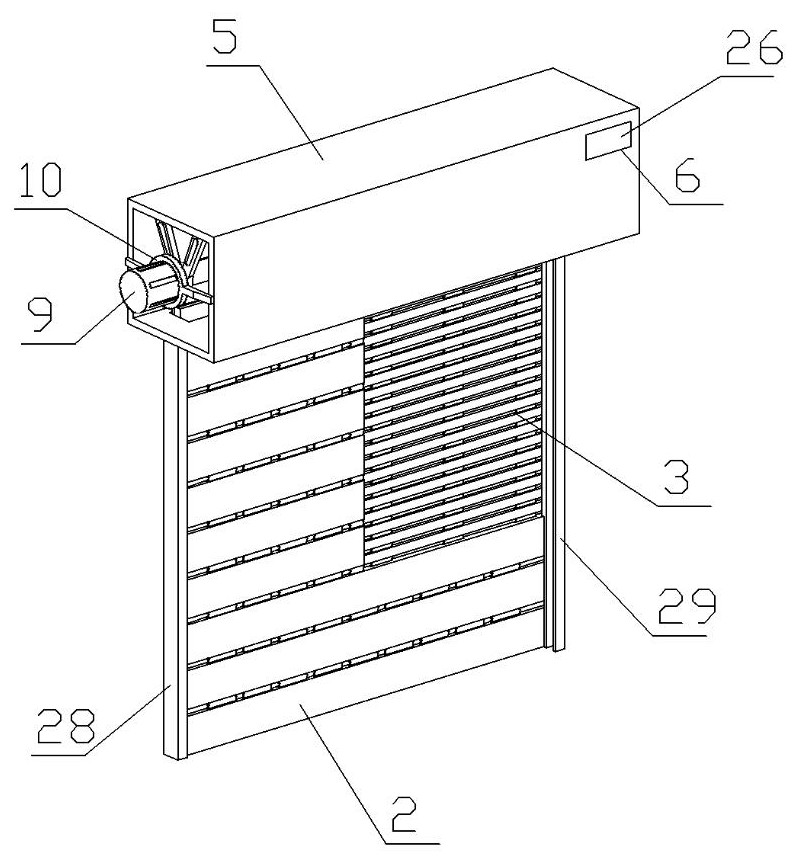

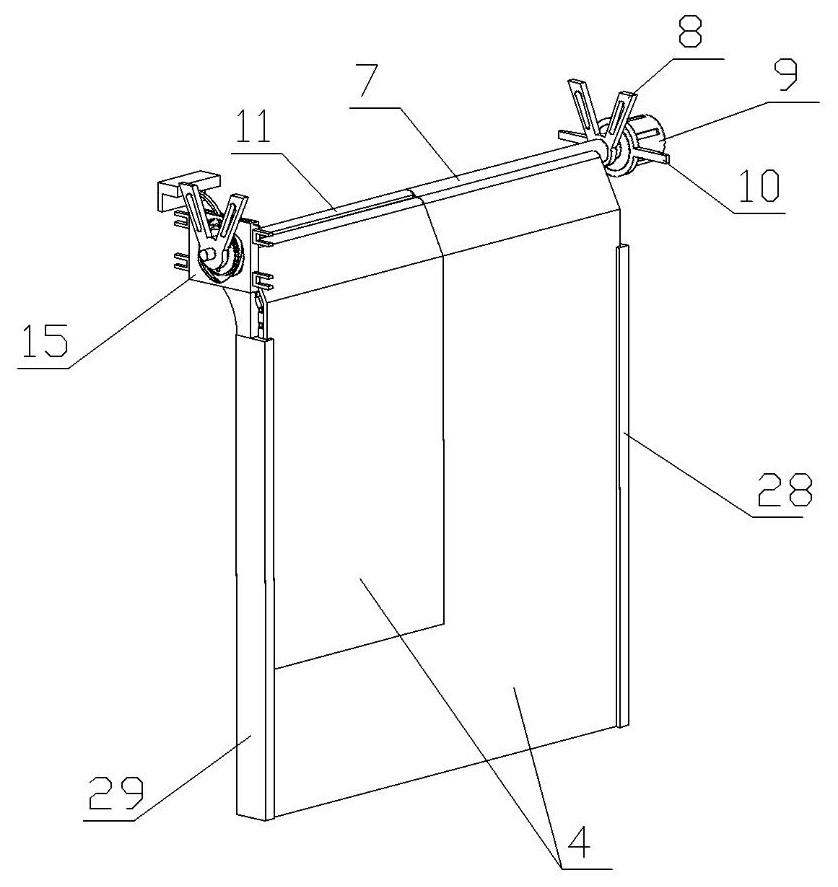

Fast waterproof roller shutter door

InactiveCN106014149APrevent high temperature deformationDoes not serve the purpose of isolating fireDoor/window protective devicesFireproof doorsWater flowPore water pressure

The invention discloses a fast waterproof roller shutter door, which comprises a door head, a door frame, a fireproof door roller shutter and expansion screw bolts, wherein a water supply pipe is arranged in the door head and the door frame; a plurality of sprayers are arranged on the water supply pipe; openings of the sprayers are projected out of the inner side edge of the door head and the door frame and are distributed to form a circle; a smoke detection sensing device is arranged on the outer surface of the door head. The fast waterproof roller shutter door has the advantages that the water supply pipe and the sprayers are arranged in the door head and the door frame; when smoke exists around the roller shutter door and reaches a certain quantity, the smoke detection sensing device detects the smoke and gives out signals, and a firefighting linkage system warns; the fireproof door roller shutter descends to a preset position; after personnel escape, the fireproof door roller shutter continuously descends to be closed, so that the inside and the outside are isolated; water flow with the water pressure being 5 to 8kg is generated in the water supply pipe; a water curtain is formed around the door head and the door frame through the spraying in the three directions; the high-temperature deformation of the roller shutter door is prevented.

Owner:苏州鑫家豪门业有限公司

Disc-type microwave continuous splitting device and method for splitting waste rubber

InactiveCN103333709BSmooth runningImprove microwave cracking efficiencyPigmenting treatmentPlastic recyclingMicrowaveWaste rubber

The invention discloses a disc-type microwave continuous splitting device. The disc-type microwave continuous splitting device comprises a feeding assembly, a microwave splitting assembly, a discharging assembly and a control assembly which are sequentially communicated with one another, wherein the microwave splitting assembly comprises a microwave generator, a nonmetal sealing plate, a splitting cavity, a rotating disk and a disk driving motor, the nonmetal sealing plate is used for dividing the splitting cavity into an upper part and a lower part, the rotating disk is arranged at the lower part of the splitting cavity and is matched with the disk driving motor in a driving rotation manner, and the microwave generator is arranged on a circular flange on the splitting cavity. The invention aslo discloses a method for splitting waste rubber by using the splitting device; the disc-type splitting cavity is adopted in the method and is divided into an upper cavity and a lower cavity through the nonmetal sealing plate, so that the microwave splitting efficiency of waste tires is improved; and in order to ensure the stable operation of a disk and prevent the high-temperature deformation, one or a plurality of annular guide rails are arranged on the lower surface of the rotating disk and are used for supporting the rotating disk, so that the rotating disk rotates on a guide rail so as to optimize the splitting effect.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

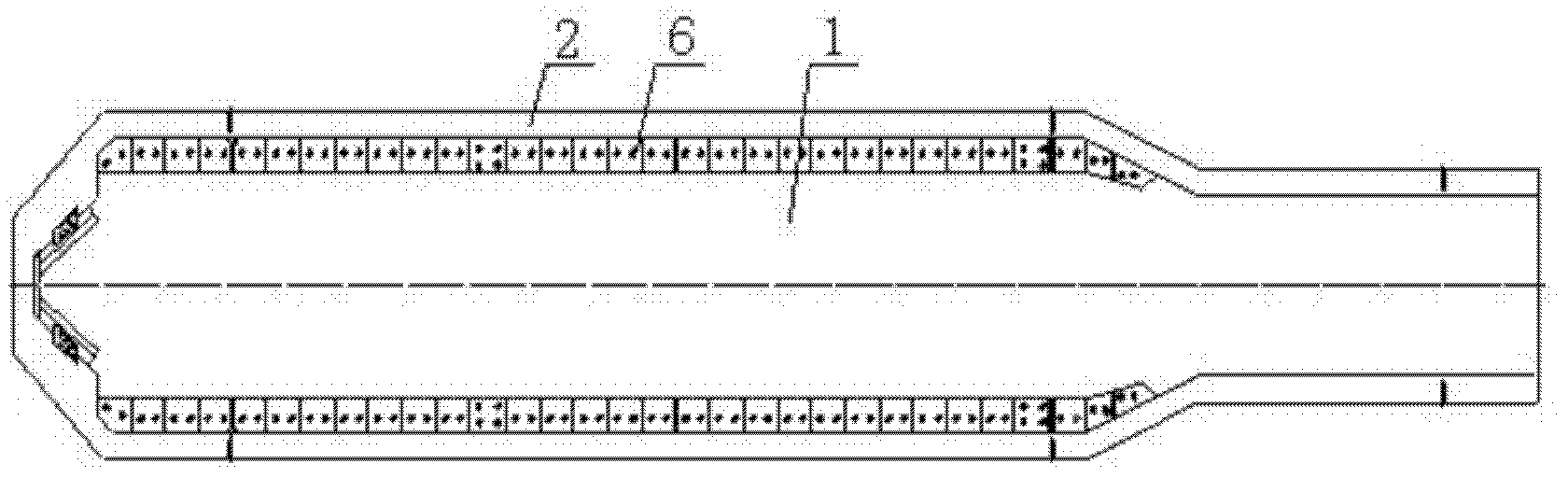

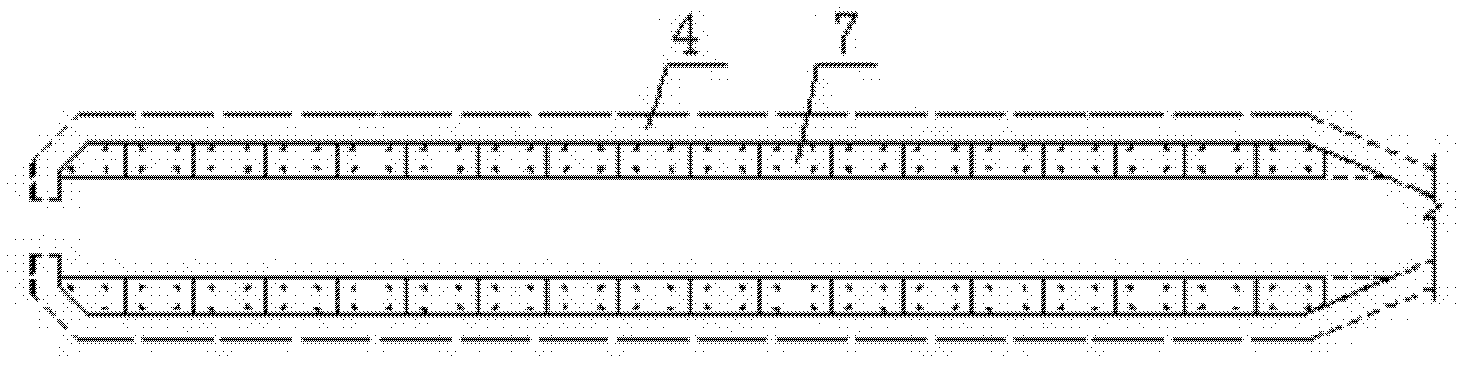

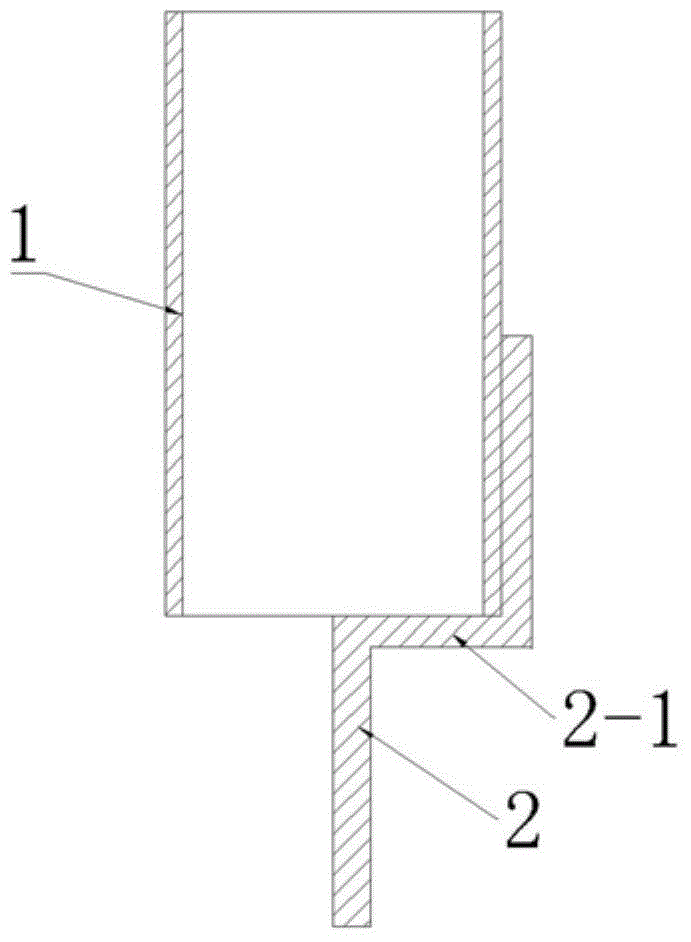

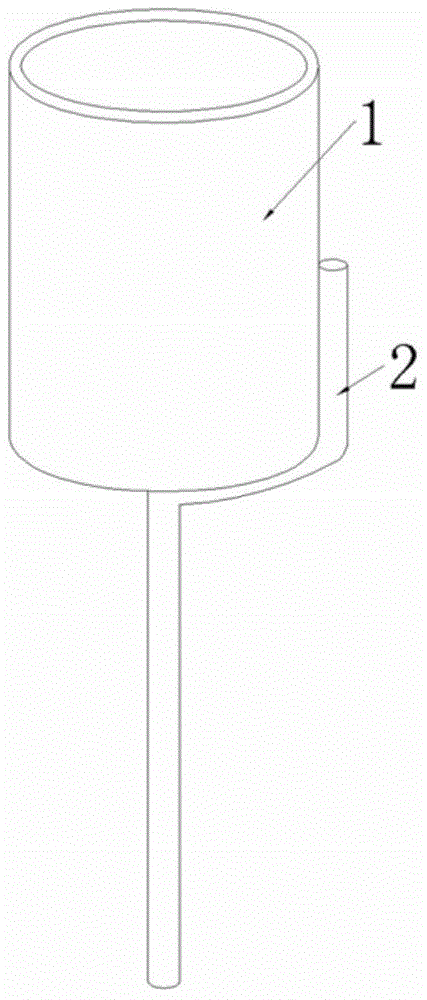

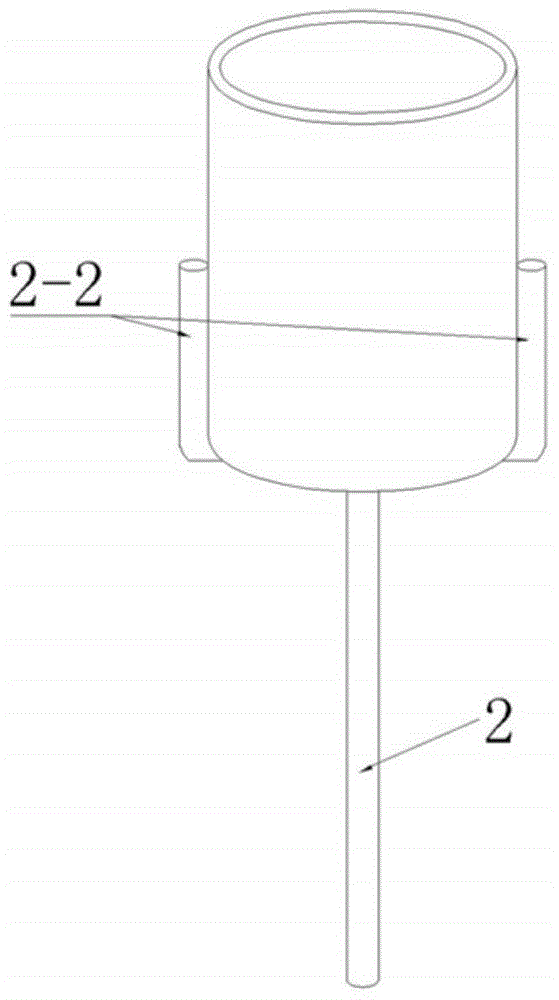

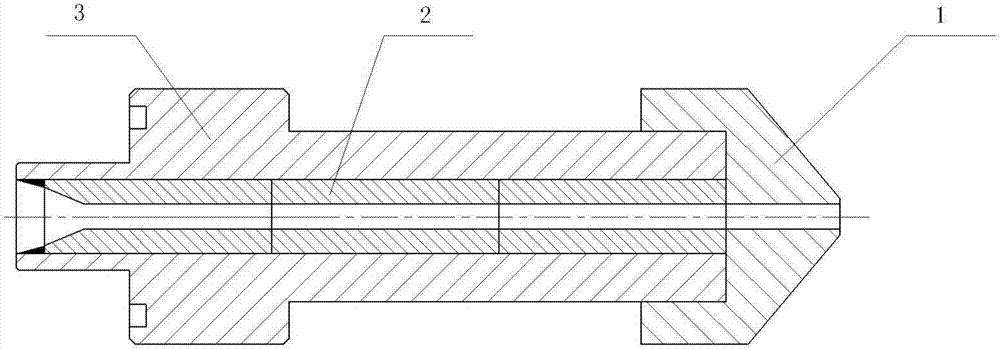

An ultrasonic heat meter base tube

InactiveCN102288328AReduce resistanceStable signalVolume/mass flow measurementCalorimeterCurrent transducerEngineering

The invention discloses a base tube of an ultrasonic heat meter, which comprises a tube body [1], a forward flow transducer [2] and a counterflow transducer [3]. The tube body [1] is provided with a reflective block. The reflective block [4] is two metal cylinders, the two metal cylinders are fixed on the pipe wall in the pipe body [1], the upper end of the cylinder is provided with a reflective slope, and the reflective surfaces of the two reflective blocks are opposite , so that the ultrasonic waves emitted by the downstream transducer [2] can be received by the upstream transducer [3] after being reflected by the two reflection blocks [4]. The invention has stable signal, accurate measurement, little resistance to the fluid in the pipeline and no blockage.

Owner:TONGLING DERUIMAN ELECTRONICS TECH

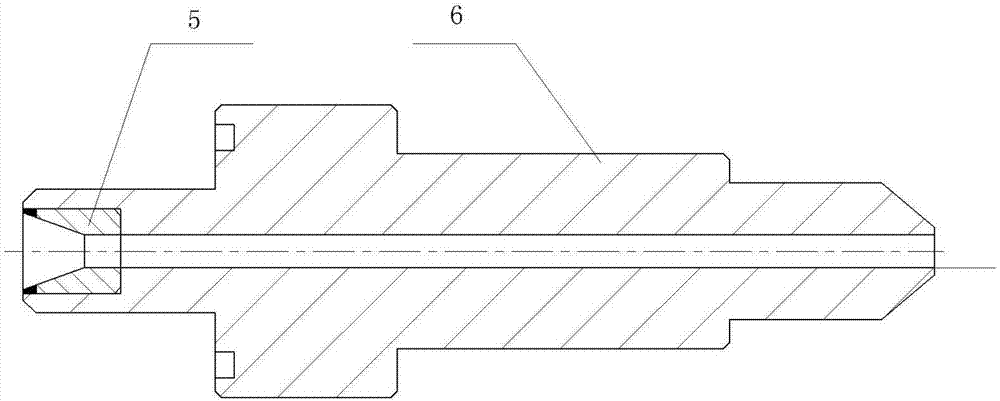

High-strength rare earth molybdenum tube cold cathode and manufacturing process thereof

InactiveCN104091740AIncrease the stress pointNo sheddingDischarge tube cold cathodesCold cathode manufactureRare earthCold cathode

The invention discloses a high-strength rare earth molybdenum tube cold cathode and a manufacturing process thereof. The high-strength rare earth molybdenum tube cold cathode is characterized by comprising a rare earth molybdenum tube and a molybdenum wire, wherein the molybdenum wire is welded on the side portion of the molybdenum tube. The high-strength rare earth molybdenum tube cold cathode is simple in structure, convenient to manufacture and stable in performance and saves the cost.

Owner:佛山宁宇科技股份有限公司

Numerical control laser cutting control system for power battery pole piece

InactiveCN113059286AIncrease vaporization rateIncrease temperatureLaser beam welding apparatusNumerical controlPower battery

The invention relates to the field of numerical control laser cutting control equipment, in particular to a numerical control laser cutting control system for a power battery pole piece. The system comprises a cylindrical sleeve and further comprises a conical dust hood, dust collection pipelines, a pneumatic piston cylinder, a steam pipe, a liquid pipe and a high-pressure laser gun, wherein the conical dust hood is connected to the bottom of the cylindrical sleeve; the dust collection pipelines are symmetrically connected to the outer side of the lower half section of the cylindrical sleeve, and the dust collection pipelines are connected with an air blowing structure; the pneumatic piston cylinder is connected to the coaxial position of the air blowing structure; the steam pipe is connected to the pneumatic piston cylinder, and the steam pipe is connected with air-cooling and water-cooling equipment; the liquid pipe is connected to the air-cooling and water-cooling equipment; and the high-pressure laser gun is installed at the center position of the cylindrical sleeve, and a heat dissipation structure is arranged inside the cylindrical sleeve. According to the device, real-time cooling in the laser cutting process can be achieved, the suction-force-variable smoke dust absorption effect is achieved, kinetic energy generated by vaporization of a cooling agent is converted to provide mechanical energy for dust collection, heat emitted by laser is effectively utilized, energy is saved, and laser distance measurement is automatically adjusted, so that the system is convenient and practical.

Owner:JINAN G WEIKE SCI & TECH

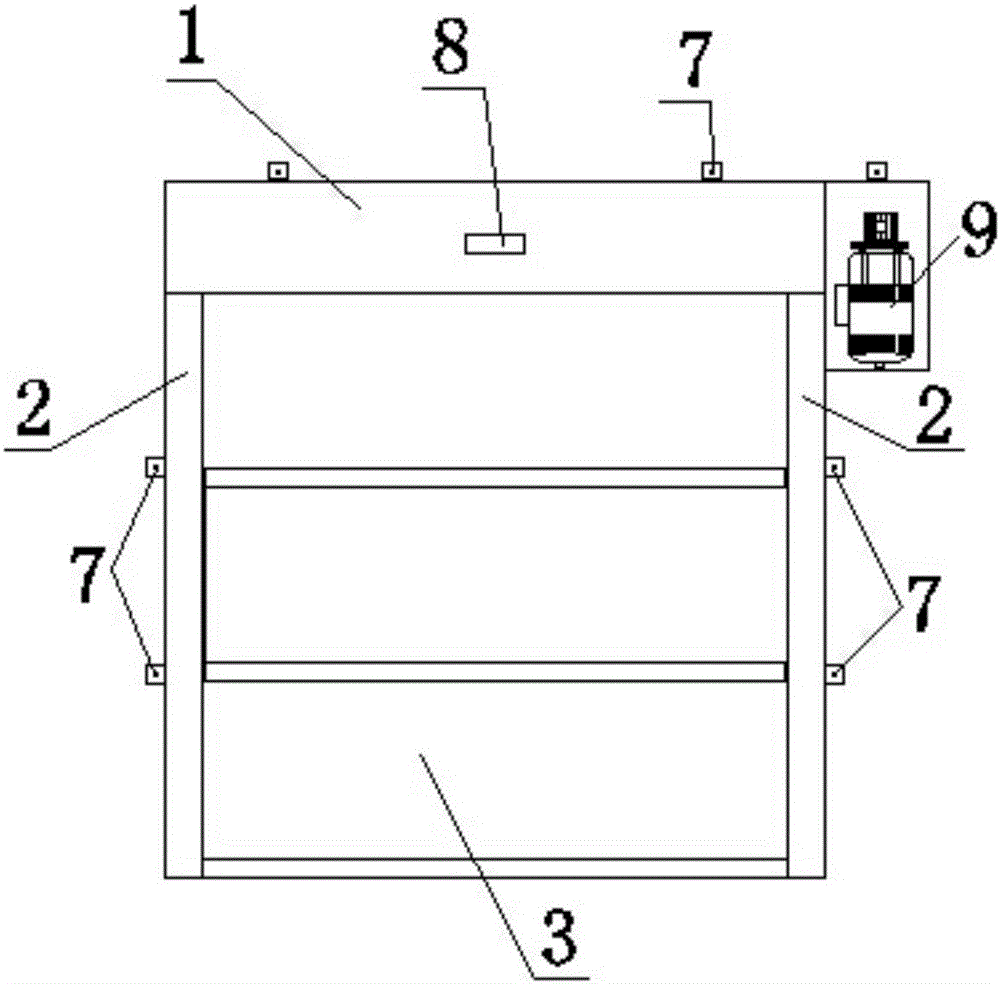

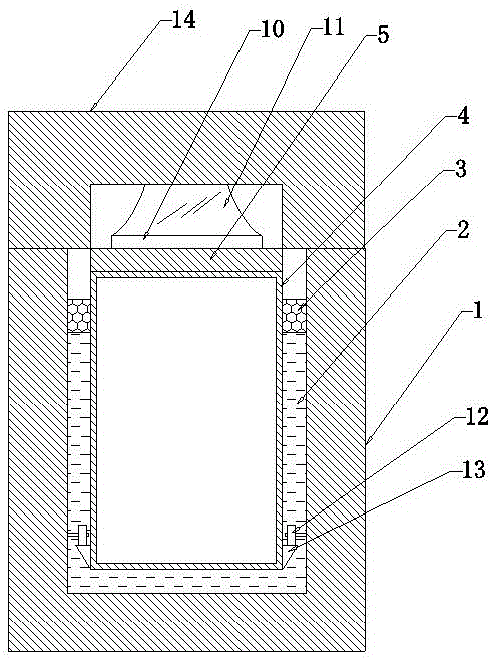

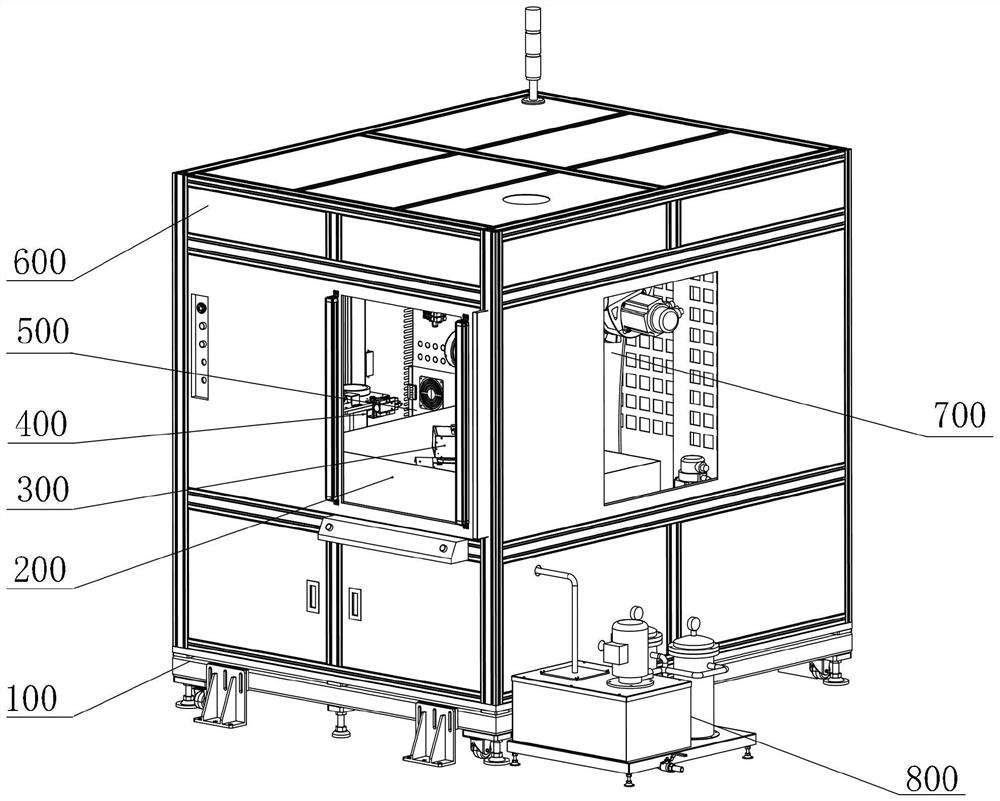

Wafer cassette cleaning device and control method of wafer cassette cleaning device

ActiveCN111842380APrevent high temperature deformationQuick breakdownHollow article cleaningEngineeringMechanical engineering

The invention discloses a wafer cassette cleaning device and a control method of the wafer cassette cleaning device. The wafer cassette cleaning device comprises a cavity, a rotating frame, a cleaningcomponent and a temperature measuring structure, wherein a cleaning cavity is defined in the cavity, the rotating frame is rotatably arranged in the cleaning cavity and used to fix the wafer cassette, the cleaning component is arranged on the cavity and comprises a steam cleaning structure and a water cleaning structure, the steam cleaning structure is communicated with the cleaning cavity through a first nozzle to spray steam to the cleaning cavity, the water cleaning structure is communicated with the cleaning cavity through a second nozzle to spray water into the cleaning cavity, and the temperature measuring structure is used to detect the wall surface temperature of the wafer cassette. According to the wafer cassette cleaning device provided by the invention, the cleaning efficiencyand cleaning effect of the wafer cassette can be improved, while avoiding high-temperature deformation of the wafer cassette and ensuring the stability of the wafer cassette structure.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

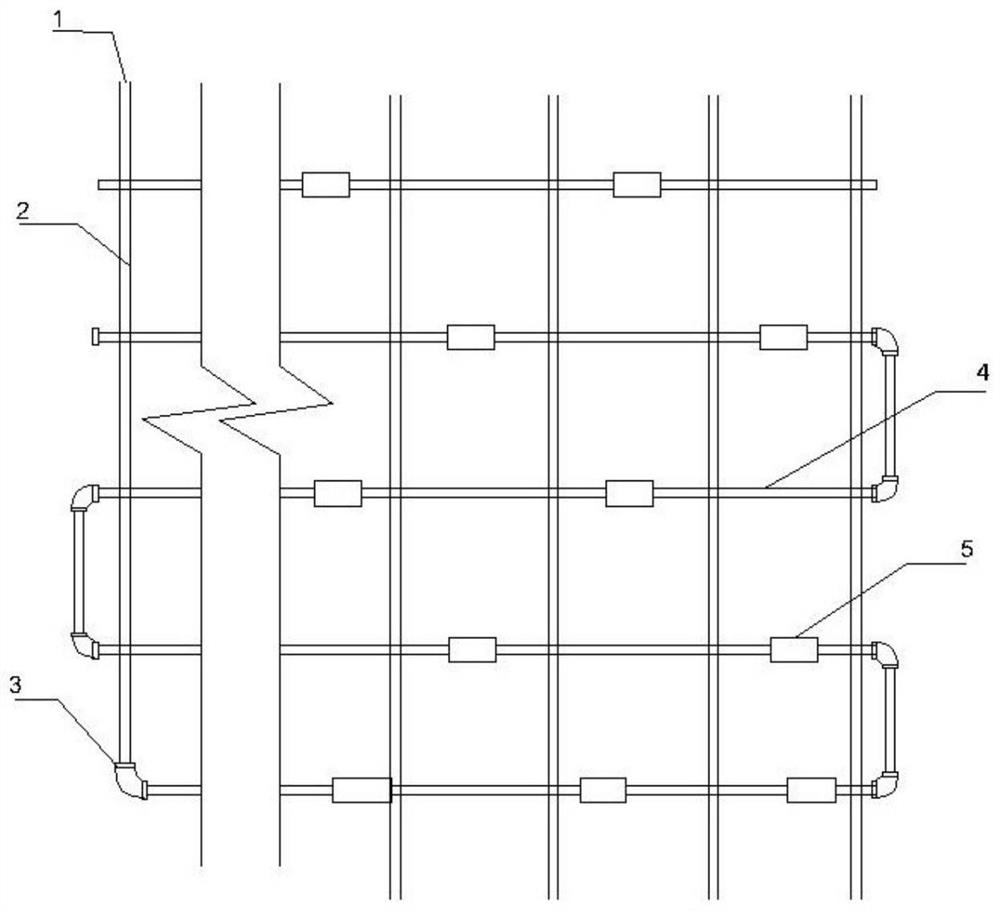

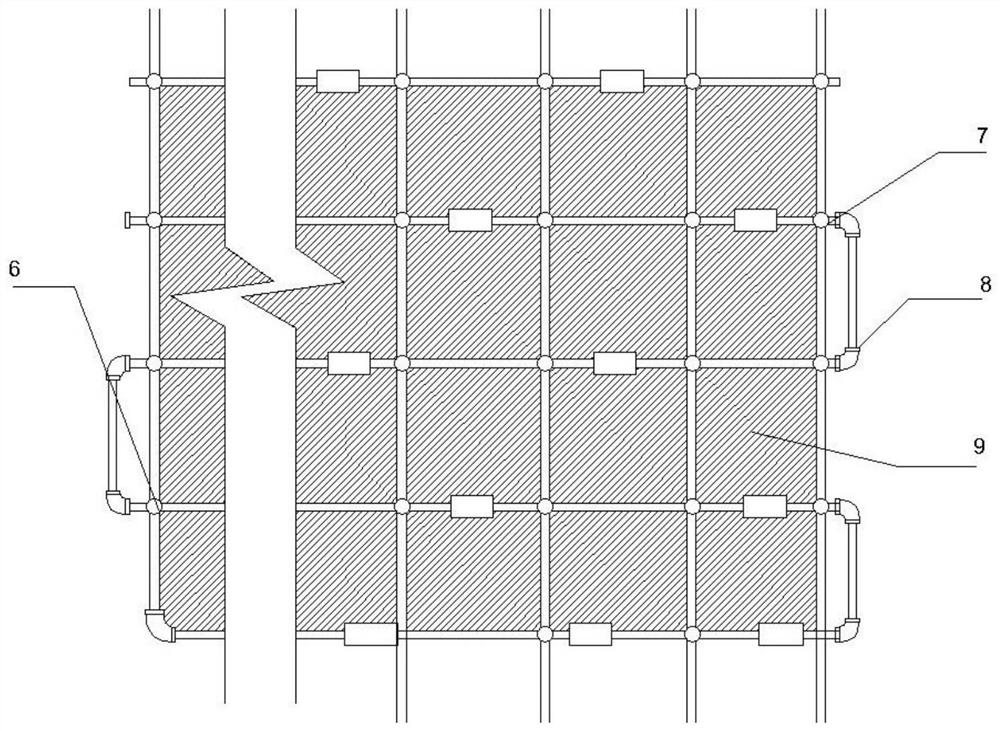

Mass concrete reinforcement support doubling as circulating water cooling system

PendingCN111980416AGuaranteed to workGuaranteed stabilityBuilding material handlingWater leakageRebar

The invention discloses a mass concrete reinforcement support doubling as a circulating water cooling system. The mass concrete reinforcement support comprises a cold water inlet, a reinforcement bracket, an elbow pipe, a water delivery pipe, a steel pipe sleeve, a cold water input pipe, a hot water output pipe, a sealing tape and a grid frame. The mass concrete reinforcement support has the beneficial effects that the workload of welding is reduced by the reinforcement bracket, the stability and sealing of the connection between cooling pipes are ensured by the elbow pipe, the normal operation of the circulating water cooling system is ensured, water leakage is prevented, the strength and bearing capacity of the cooling pipes are ensured by the steel pipe sleeve, so that the cooling pipesare completely integrated into the reinforcement bracket to play roles, the stability of the overall connection is ensured, the circulating water cooling function is added on the basis of support positioning function by the cold water input pipe and the hot water output pipe, the overall pipeline structure and concrete are conveniently cooled, the high-temperature deformation of the pipeline is prevented, the occurrence of cracks is reduced, and the service life of each pipeline is prolonged.

Owner:中铁建设集团华东工程有限公司

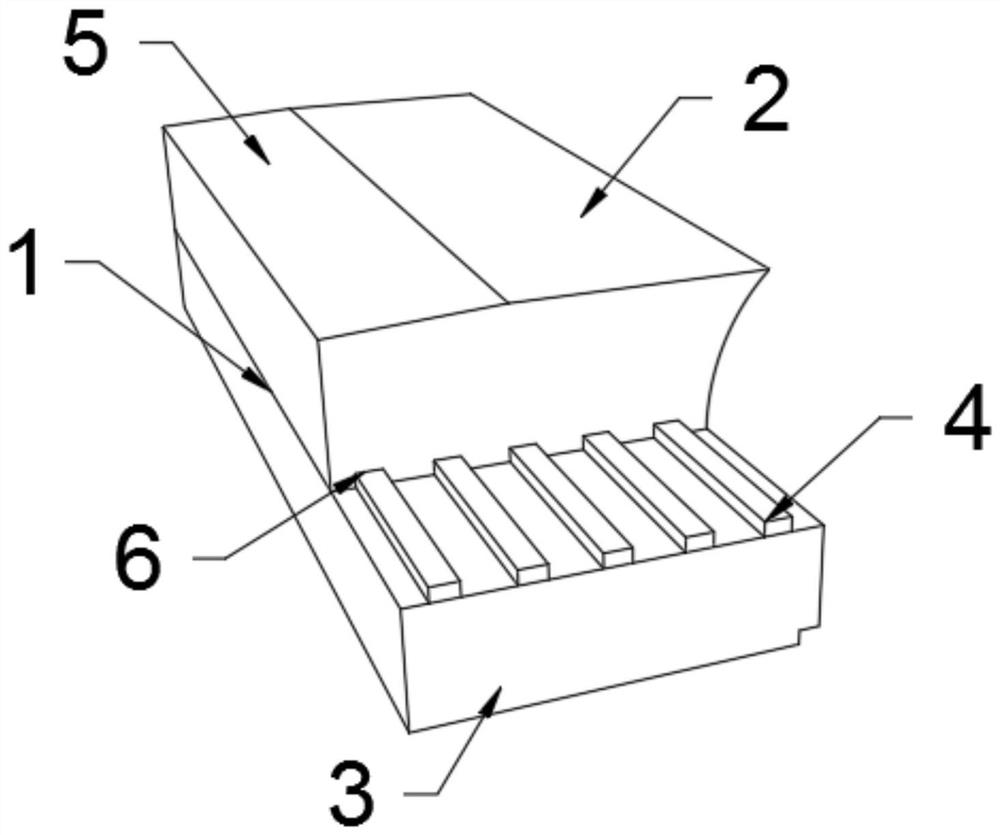

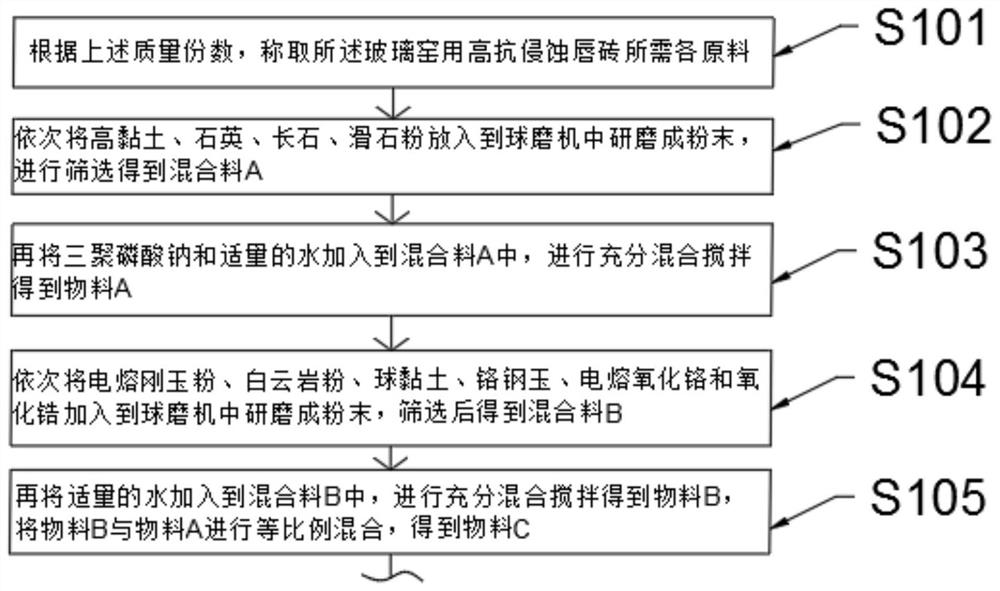

High-erosion-resistance lip brick for glass kiln and preparation method of high-erosion-resistance lip brick

ActiveCN114230141AAvoid air bubblesImprove corrosion resistanceGlass furnace apparatusCoatingsBrickEngineering

The invention discloses a high-erosion-resistance lip brick for a glass kiln and a preparation method of the high-erosion-resistance lip brick, the high-erosion-resistance lip brick comprises a lip brick body, the lip brick body is composed of an upper lip brick and a lower lip brick, fixing strips are arranged on the lower lip brick at equal intervals, fixing grooves are formed in the lower portion of the upper lip brick at equal intervals, the fixing grooves are clamped with the fixing strips, and an inclined plane is arranged on the upper lip brick. Two layers are arranged during processing of the lip brick, the upper lip brick has excellent corrosion resistance and fire resistance, good thermal shock resistance, low porosity, good volume stability and high strength can be guaranteed, corrosion of glass to the lip brick can be improved, the overall service life is prolonged, the lower lip brick is made of basic materials, and the cost is low. Not only can the processing cost be reduced, but also proper lip bricks can be produced according to actual conditions and can be reasonably utilized.

Owner:江苏诺明高温材料股份有限公司

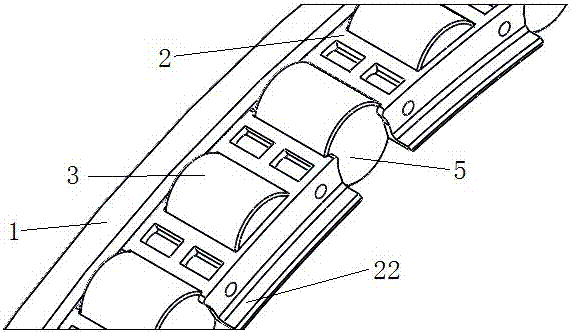

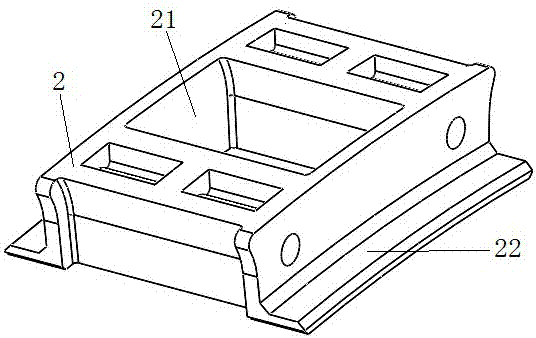

Bearing retaining frame

ActiveCN104806636AAvoid noiseImprove the lubrication effectRoller bearingsShaftsEngineeringMechanical engineering

The invention relates to a bearing retaining frame. The bearing retaining frame comprises two retainer rings which are axially and symmetrically arranged, wherein a plurality of isolation blocks made of self-lubrication materials are arranged between the two retainer rings; each isolation block is fixedly arranged between the two retainer rings; each isolation block forms a ring-shaped structure between the two retainer rings; at least one first rolling groove is formed in each single isolation block; a first rolling pillar is arranged in each first rolling groove of each isolation block. According to the bearing retaining frame, the rolling pillars are arranged in the rolling grooves made of the self-lubrication materials; the high lubrication performance can be still retained between the rolling pillars and the isolation blocks after the rolling pillars rotate for a long time; the noise generated by the retaining frame because of the rotation of the rolling pillars is avoided.

Owner:CHANGZHOU CRONOS SPECIAL BEARING MFG

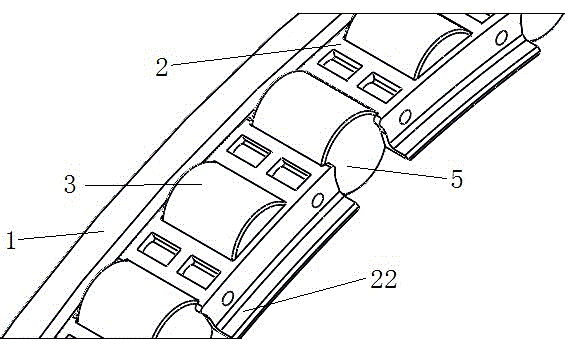

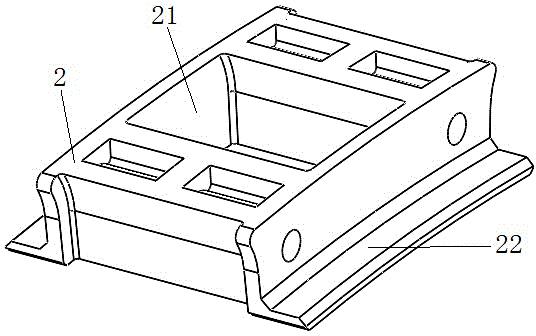

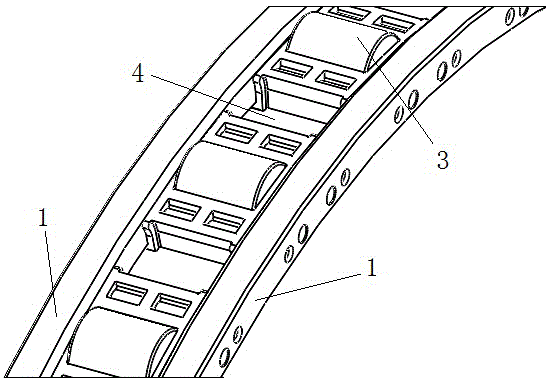

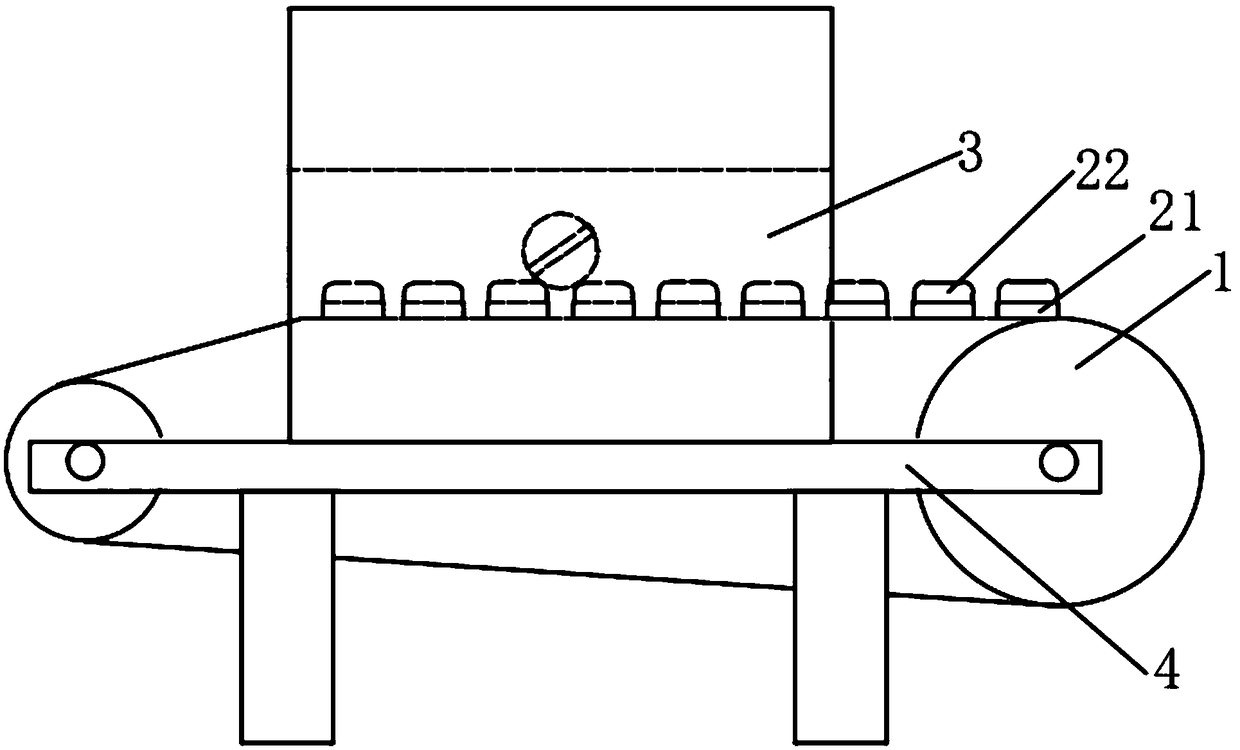

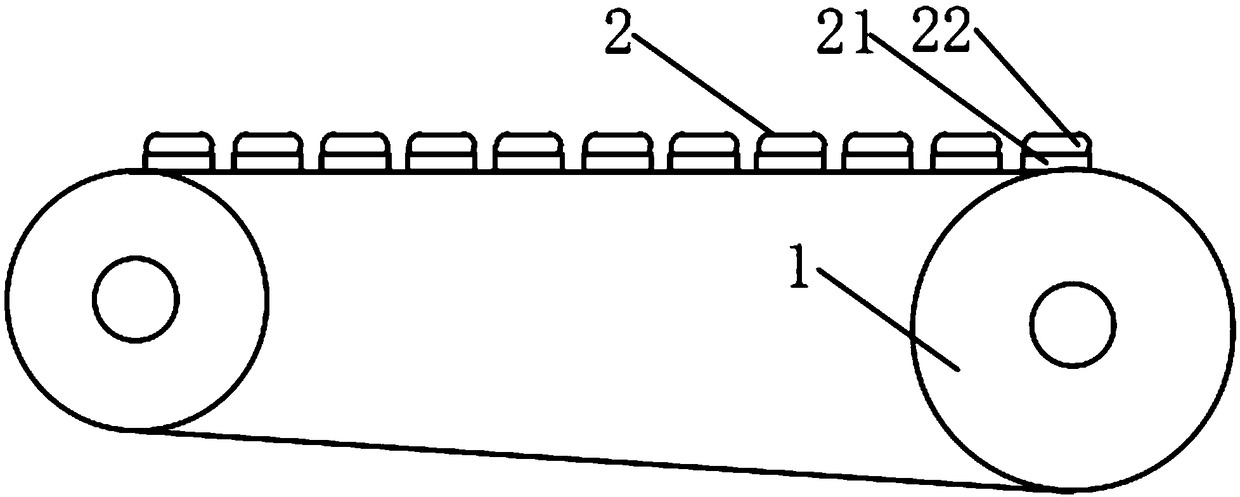

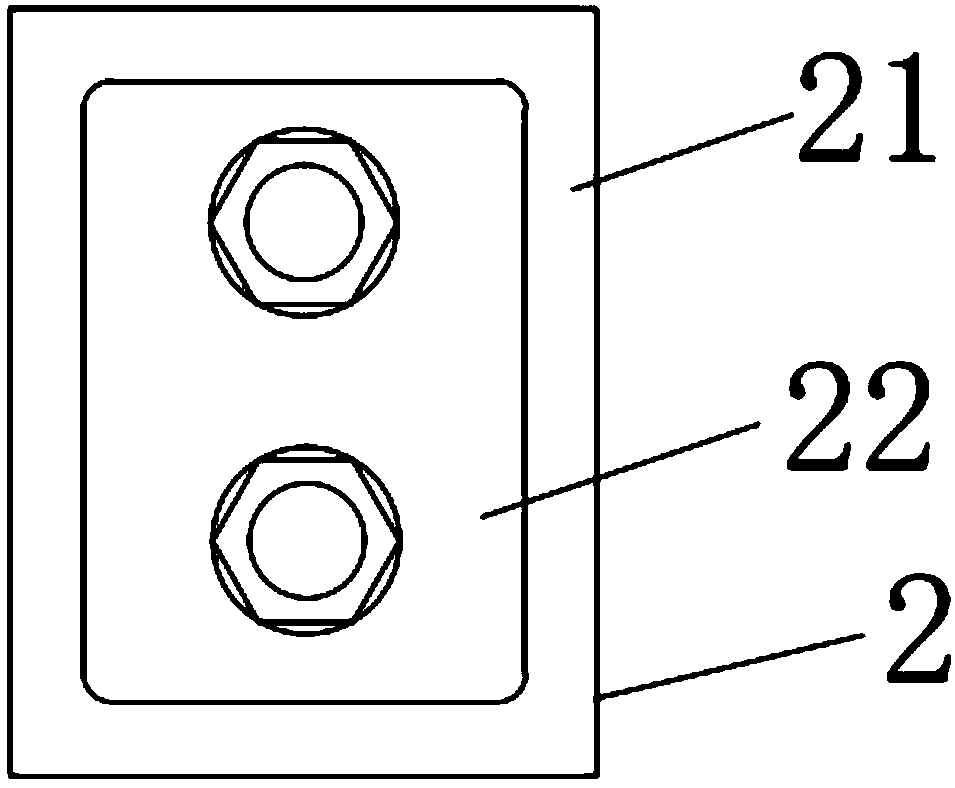

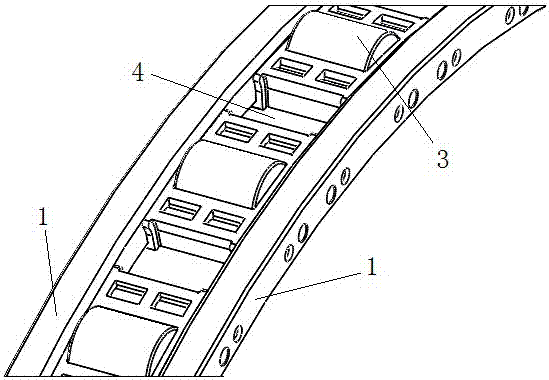

Transferring device with ceramic part

InactiveCN108689079APrevent high temperature deformationExtend your lifeConveyorsMagnetizationConveyor belt

The invention discloses a transferring device with a ceramic part. The transferring device comprises a driving mechanism and a crawler-type conveyor belt. The crawler-type conveyor belt comprises a crawler plate and the ceramic part. The ceramic part is fixed to the crawler plate. The transferring device with the ceramic part can be used in ultrasonic-frequency heating equipment. Compared with theprior art, ceramic has the high melting point, the high high-temperature strength, the small high-temperature creep property, good thermal shock resistance, corrosion resistance, oxidation resistance, structural stability and the like. The ceramic part is used on the conveyor belt, the conveyor belt can be prevented from being subjected to ultrasonic-frequency induced magnetization, and high-temperature deformation of the conveyor belt is prevented. Compared with a traditional metal conveyor belt, the service life of the conveyor belt with the ceramic part is prolonged greatly, and meanwhileit can be ensured that the deformation amount of a heated workpiece is decreased to be the minimum through the structurally-stable conveyor belt with the ceramic part.

Owner:滁州硕燊机械制造有限公司

Manufacturing method and application of superlarge, superlong and superflat continuous bearing motion table-board

InactiveCN106141909AEfficient use ofExtended service lifeGrinding carriagesGlass pressing apparatusEngineeringLiquid tank

A manufacturing method and application of an ultra-large, ultra-long, and ultra-flat continuous load-carrying tabletop, which is characterized in that: a large annular (or circular) floating body is placed in a liquid tank, and liquid is added to the liquid tank to make it float , make it centered and rotate slowly, and use the counterweight method to adjust the buoyancy imbalance caused by the uneven mass of the floating body along the circumference, so that the outer wall of the ring-shaped (or circular) floating body can be engraved along the circumference with a laser, etc. Then, cooperate with the laser leveling instrument, etc., adjust the ring-shaped precision limit guide rail and the limit wheel horizontally and fix them on the outer wall of the floating body; then continue to add liquid to make the floating body generate greater buoyancy, so that it can withstand loads The workpiece will not settle when it is under load and pressure; then rotate the floating body, and use milling, milling, grinding and other processing techniques to manufacture a super-large, super-long, super-flat, continuous bearing motion table that is located on the upper plane of the floating body and performs circular rotation.

Owner:徐林波

Aluminum-coated steel pressure die

PendingCN107511403APrevent high temperature deformationExtended service lifeDrawing diesAlloyEngineering

The invention discloses an aluminum-coated steel pressure die. The aluminum-coated steel pressure die comprises a pressure die head, a pressure die core and a pressure die sleeve. The pressure die head is internally provided with a groove. One end of the pressure die sleeve is mounted in the groove of the pressure die head. The pressure die sleeve is internally provided with a pressure die body. The pressure die core penetrating through the interior of the whole pressure die sleeve is embedded in the pressure die sleeve. The pressure die core is formed by machining at least three hard alloys at a time. The pressure die head is formed by selecting and using heat resistant steel. High-temperature deformation can be effectively prevented, the service life can be prolonged, and wear resistance can be improved. The pressure die core is formed by machining the multiple hard alloys at a time. The wear resistance is greatly improved. The aluminum-coated steel pressure die can generate stable pressure during operating, so that the production speed is increased, and the die replacement frequency is reduced.

Owner:无锡金宸合环机械装备有限公司

A fire-resistant rolling shutter door that is convenient for fire fighting

ActiveCN112343489BEase of fire controlQuick Balance RestorationShutters/ movable grillesFireproof doorsGlass fiberFire - disasters

The invention discloses a fireproof rolling shutter door which is convenient for fire fighting. A composite steel fire shutter II is arranged on the side, and the lower end of the composite steel fire shutter II is hinged with the composite steel fire shutter I. The device uses three rollers in the sliding plate to balance the gravity to ensure the rolling and unwinding of the main body of the rolling shutter door under normal circumstances. The disc rotates to make the card shaft fall down. After the upper end of the composite steel fire shutter II is folded downward to form an opening, firefighters can put out the fire in time through the opening. The high silica glass fiber layer has good resistance to fire. High temperature resistance to prevent high temperature deformation of equipment.

Owner:LINYI HAOQUAN SILICA SAND TECH

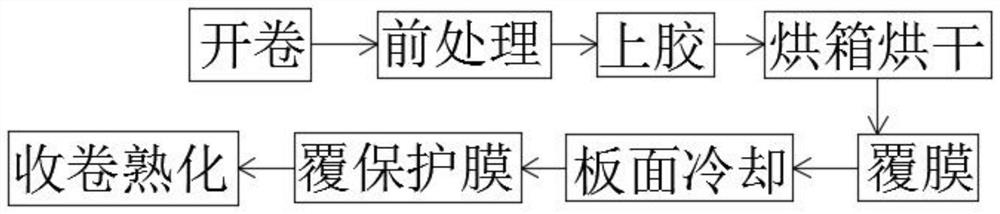

Radiation refrigeration metal plate and production process

InactiveCN111823669AFirm filmClean thoroughlySynthetic resin layered productsMetal layered productsCold chainEngineering

The invention discloses a radiation refrigeration metal plate, which is formed by compounding a radiation refrigeration film and a metal base material plate through a special process and radiates energy outwards in the form of infrared electromagnetic waves, and a production process of the radiation refrigeration metal plate is disclosed. The process comprises the steps of uncoiling, pretreatment,gluing, oven drying, film coating, plate surface cooling, protective film coating and coiling curing. The radiation refrigeration metal plate is formed by compounding the high-tech radiation refrigeration film and a metal substrate through a special process, the energy consumption is low, and energy is radiated outwards in an infrared electromagnetic wave mode, so that the refrigerating and cooling effects are achieved, the maximum radiation refrigeration power can reach 93W / m<2> under the direct irradiation of sunshine at noon, according to the production process, the temperature of an object in contact with the radiation refrigeration metal plate can be reduced by 10-16DEG C, high-temperature deformation is effectively prevented, the structural stability is improved, the decorative effect is good, the service life is long, the cold-chain container refrigeration effect is good after application of the radiation refrigeration metal plate, and the production process cleans the plate thoroughly, and is stable in film coating and high in performance.

Owner:安徽墙煌科技股份有限公司

Ear cap type high-temperature-resistant premixed combustion nozzle and control method thereof

PendingCN111059529AStable combustionPrevent high temperature deformationBurner coolingPulverulent fuel combustion burnersEngineeringMechanics

The invention discloses an ear cap type high-temperature-resistant premixed combustion nozzle. The muzzle comprises a first shell, a plurality of flow guide plates, a first channel, a second shell, asecond channel, a water inlet mechanism and a water outlet mechanism, wherein the plurality of flow guide plates are uniformly distributed along the outer surface of one end of the first shell; the first channel is coaxially formed inside the first shell, one end of the first channel is of a cylindrical structure, and the other end of the first channel is of a circular-truncated-cone-shaped structure with the radius gradually decreasing; the second shell is coaxially arranged outside the first shell in a sleeving mode, and the second channel is coaxially arranged between the first shell and the second shell; and the water inlet mechanism is arranged outside the second shell in a sleeving mode, and the water outlet mechanism is arranged between the water inlet mechanism and the second shelland communicates with the water inlet mechanism. Through cooperation between the first channel and the second channel, inlet fuel is premixed, a nozzle is cooled through the water inlet mechanism, and the nozzle is prevented from deforming. The invention further provides a control method of the ear cap type high-temperature-resistant premixed combustion nozzle.

Owner:JILIN UNIV

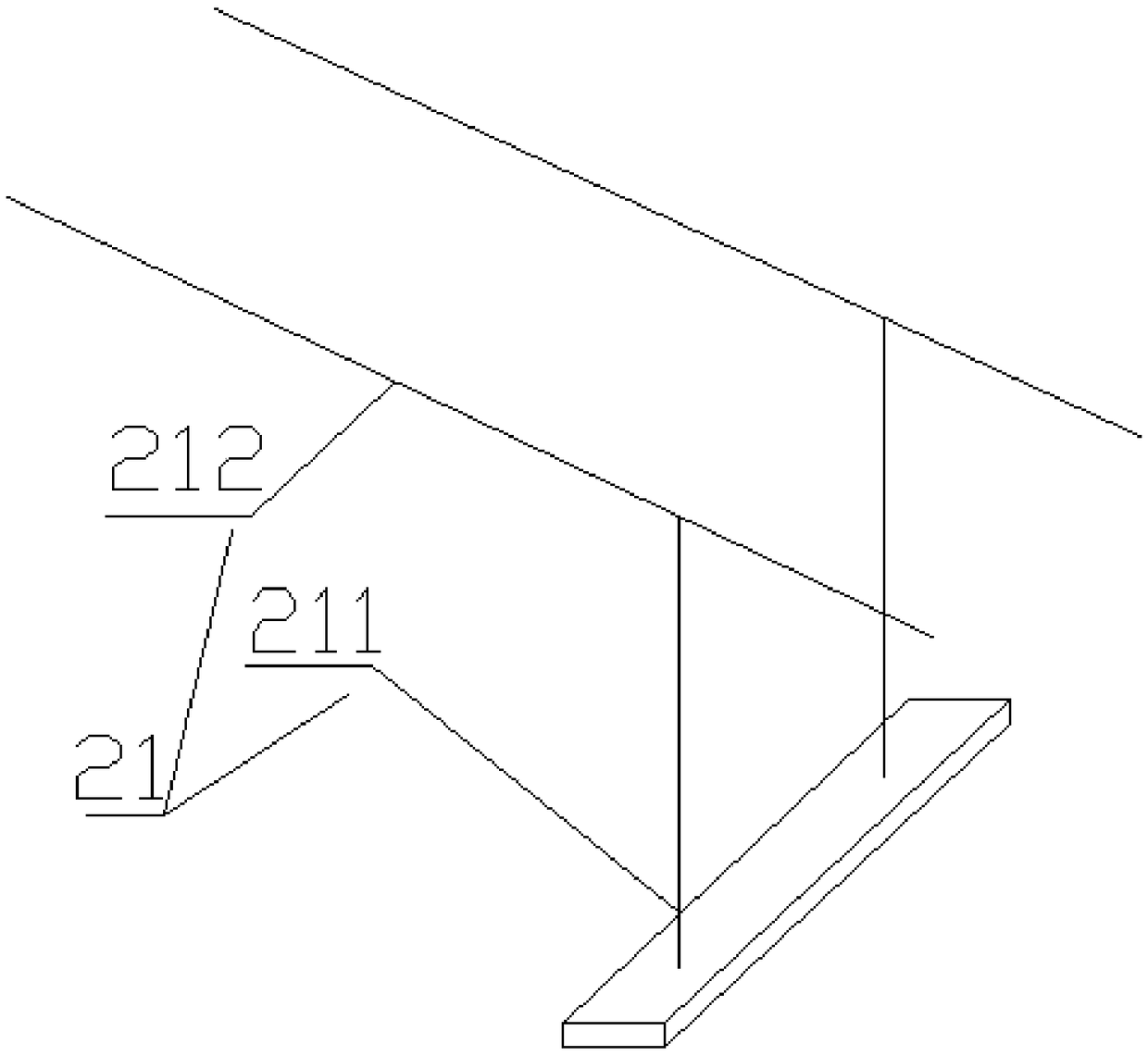

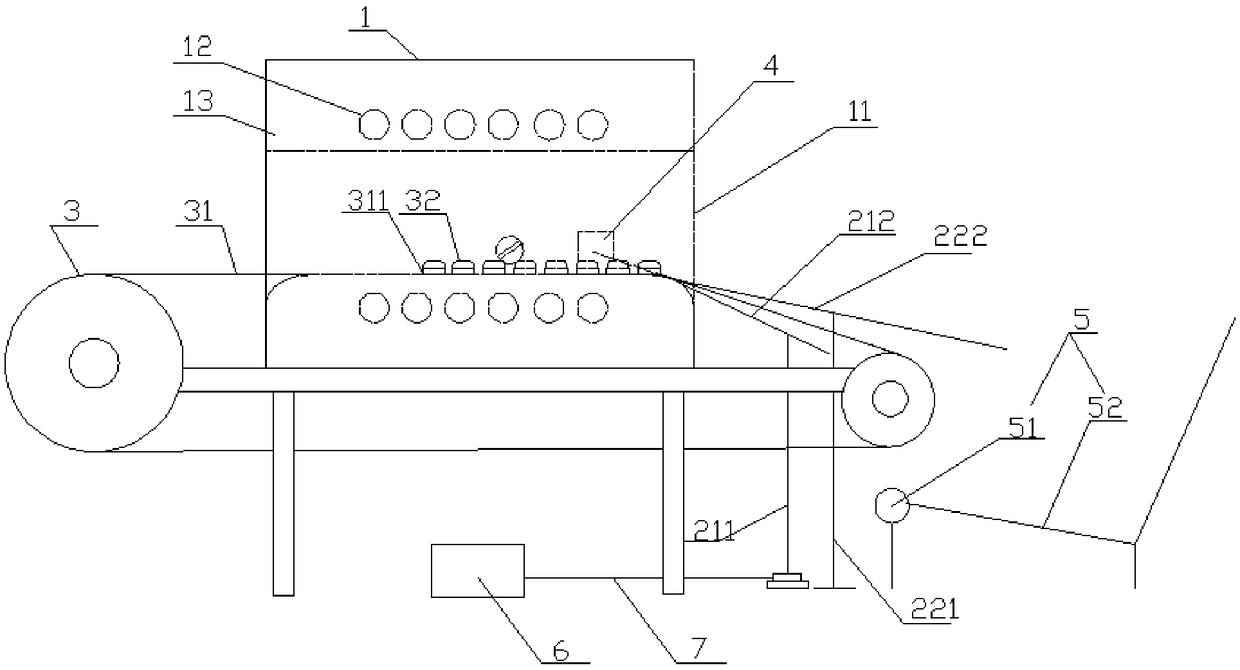

Horizontal rotary tube cooked ball air water spray cooling machine

The invention relates to a horizontal type rotary tube cooked ball air water spray cooling machine. The horizontal type rotary tube cooked air water spray cooling machine comprises a cooling tube body as well as an input tube body and an output tube body which are respectively connected with the left end and the right end of the cooling tube body, wherein a support device I and a support device II are respectively arranged at outer circles of the left end and the right end of the cooling tube body, a transmission device is arranged at the right side of the supporting device II, the left end of the input tube body is connected with a feeding tube, the right end of the output tube body is connected with a discharging tube, a feeding pipe is arranged on the feeding tube, an air water spray ring is arranged on the outer surface of the cooling tube body, a nitrogen positive pressure cavity device is respectively adopted for sealing between the input tube body and the feeding tube as well as between the output tube body and the discharging tube, a high aluminium flame retardant layer is arranged on the inner wall of the feeding pipe, a discharging hopper is arranged at the lower end of the discharging tube, a double-layer combined discharge valve is arranged in the discharging hopper, and a high temperature resistant lining is arranged on the inner wall of the left end of the cooling tube body. The horizontal type rotary tube cooked ball air water spray cooling machine is simple in structure, good in cooling effect and good in sealing property, cooked balls can be efficiency cooled in an oxygen-free environment, and meanwhile high temperature deformation, caused by the cooked balls, of the cooling tube body can be reduced.

Owner:JIANGSU BOJI SPRAYING SYST HLDG CO LTD

Overall ultrasonic frequency heating method of variable-cross-section rod

ActiveCN108941283AHigh melting pointPrevent high temperature deformationVehicle componentsElectricityLap joint

The invention discloses an overall ultrasonic frequency heating method of a variable-cross-section rod. The overall ultrasonic frequency heating method of the variable-cross-section rod comprises thesteps: workpieces to be heated are successively conveyed to a heater of a heating device through a conveyor belt, and a limiting piece limits the workpieces to be heated in a heating area of the heater; a motor is started after the workpieces are heated so as to drive a shifting fork to circularly move toward the direction of a discharge hole; a support I is gradually elevated and gets close to the discharge hole; a driving lever is basically at the horizontal state finally under the drive of the support I, and an electrode starts to reset at the time so as to drive the support I to be far away from the discharge hole and reduce the height of the support I; and under the drive of the support I, a lap-joint point of the driving lever and the discharge hole is adopted as a support point, thefree end of the driving lever starts to lower down, a lap-joint end of the driving lever and the discharge hole starts to raise upwards so as to lift the heated workpieces, and the lifted workpiecesslide off along a lever body of the driving lever until falling into a receiving device. The overall ultrasonic frequency heating method of the variable-cross-section rod provided by the invention hasthe advantages that the service life of the conveyor belt is greatly prolonged, and the deformation amount of the variable-cross-section rod after being heated is reduced to the minimum.

Owner:ANHUI LIBA POWER LITHIUM BATTERY TECH

Circulating water cooling structure and method for coke discharging device of dry distillation furnace

ActiveCN108020002AExtended service lifeReduce operating temperatureLighting and heating apparatusCooling fluid circulationEngineeringDry distillation

The invention relates to a circulating water cooling structure and method for a coke discharging device of a dry distillation furnace. The coke discharging device comprises a shell, a coke dischargingroller, a rotor shaft and a driving device, wherein the driving device drives the coke discharging roller to rotate through the rotor shaft, a plurality of hoppers are arranged on the coke discharging roller in the axial direction and the circumferential direction, and the rotor shaft is a rotor hollow shaft; and the portion, except for the hoppers, of a roller body of the coke discharging rolleris provided with a water-cooling jacket composed of an inner-layer roller body and an outer-layer roller body, the inner-layer roller body is provided with water inlets to be connected with a water inlet pipe and is provided with water outlets to be connected with a water outlet pipe, and the water inlet pipe and the water outlet pipe are arranged in the rotor hollow shaft in a penetrating mode and are connected with an external circulating water inlet pipeline and an external circulating water return pipeline through rotary sealing joints correspondingly. According to the structure and the method, circulating cooling water is introduced into the coke discharging roller to play a role in cooling the rotor shaft and the coke discharging roller of the coke discharging device and play a rolein cooling and complementally quenching semi-coke in the hoppers, so that smoothness of discharging and uniformity of temperature are guaranteed, and the service life of the coke discharging device is effectively prolonged.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Bearing cage

ActiveCN104806636BAvoid noiseImprove the lubrication effectRoller bearingsShaftsLubricationAxial symmetry

The invention relates to a cage for bearings, which comprises two axially symmetrical retaining rings, spacers are arranged between the two retaining rings, and each spacer is fixedly arranged between the two retaining rings; a single spacer is provided with At least one first rolling groove, the first rolling groove of each spacer block is respectively provided with first rollers; there is a gap between the end faces of the adjacent two spacer blocks; the gap is between two adjacent spacer blocks Second rolling grooves are formed between the spacer blocks, and second rollers are respectively arranged in the second rolling grooves formed between the spacer blocks. By arranging the rollers in the self-lubricating rolling grooves, the rollers can still maintain good lubrication performance between the rollers and the spacer after rotating for a long time, so as to avoid the noise generated by the rollers rotating on the cage.

Owner:CHANGZHOU CRONOS SPECIAL BEARING MFG

Titanium alloy part grinding equipment and grinding method

PendingCN113649899AAvoid overgrindingGuaranteed grinding qualityGrinding wheel securing apparatusGrinding drivesIndustrial roboticsElectric control

The invention relates to titanium alloy part grinding equipment and a grinding method. The titanium alloy part grinding equipment comprises an industrial robot; a grinding tail end tool, wherein the grinding tail end tool is connected with the execution end of the industrial robot, the industrial robot drives the grinding tail end tool to move freely in the working space, and the grinding tail end tool is used for grinding titanium alloy parts; a grinding working platform, wherein the grinding working platform is used for fixing the titanium alloy parts and is matched with the grinding tail end tool to move to grind the titanium alloy parts; an automatic abrasive paper replacing module, wherein the automatic abrasive paper replacing module is matched with the grinding tail end tool to replace waste abrasive paper on the grinding tail end tool with new abrasive paper; and an electric control system, wherein the electric control system is electrically connected with the industrial robot, the grinding tail end tool, the grinding working platform and the automatic abrasive paper replacing module, and all the components are integrally controlled to act. By means of the titanium alloy part grinding equipment and a grinding method, the titanium alloy parts are automatically polished, and the production efficiency is improved.

Owner:重庆智能机器人研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com