High-strength rare earth molybdenum tube cold cathode and manufacturing process thereof

A cold cathode, high-strength technology, used in cold cathode manufacturing, discharge tube cold cathode, discharge tube main electrode, etc., can solve the problems of unstable product performance, complex nickel cup production process, affecting performance stability, etc. The effect of increasing thermionic emission performance, low production cost and stable functional output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

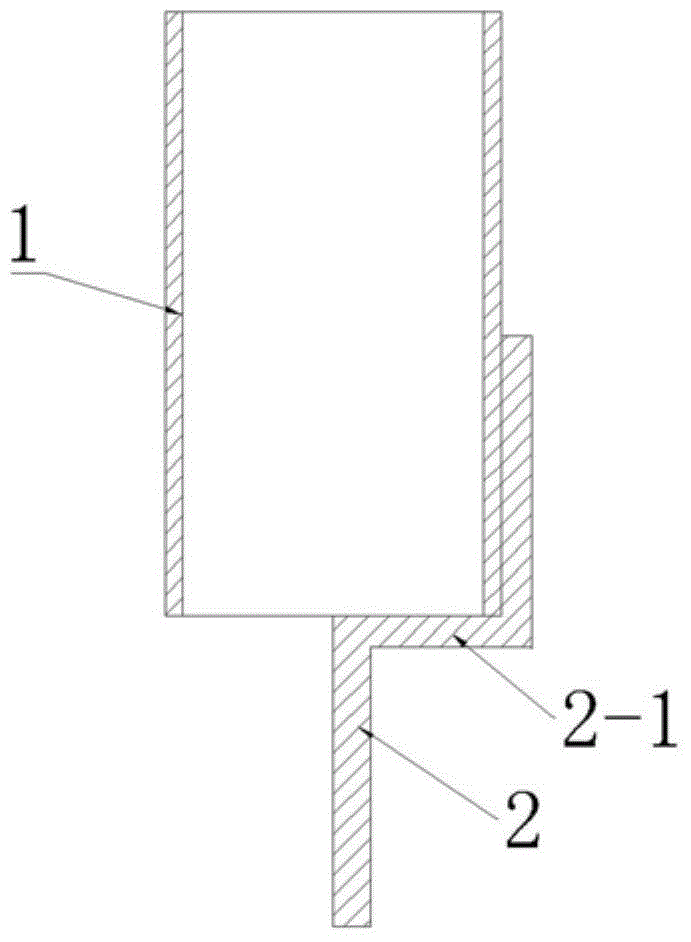

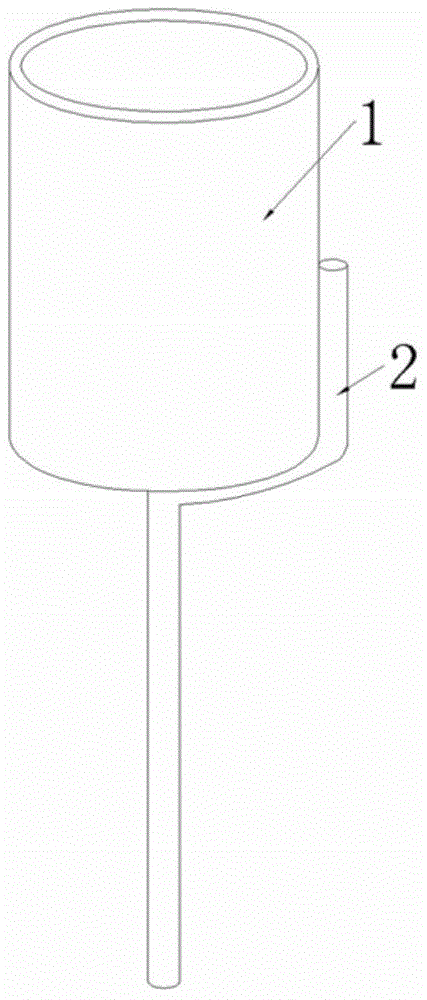

[0038] Such as figure 1 and figure 2 As shown, the present invention is a high-strength rare earth molybdenum tube cold cathode, which includes a rare earth molybdenum tube 1 and a molybdenum wire 2, and the molybdenum wire 2 is welded on the side of the rare earth molybdenum tube 1. One end of the molybdenum wire 2 is welded to the side of the rare earth molybdenum tube 1, and the other end is extended and bent to the bottom of the rare earth molybdenum tube 1 to form a support part 2-1, and the diameter of the bottom surface of the rare earth molybdenum tube 1 is 1 / 3-3 The / 4 position is bent and extended outward to form an inverted Z-shaped molybdenum tube support connection structure. In this embodiment, the molybdenum tube support part 2-1 formed by bending the molybdenum wire is a horizontal support close to the bottom end surface of the rare earth molybdenum tube, and the end of the horizontal support is bent and extended vertically downward. In order to avoid the la...

Embodiment 2

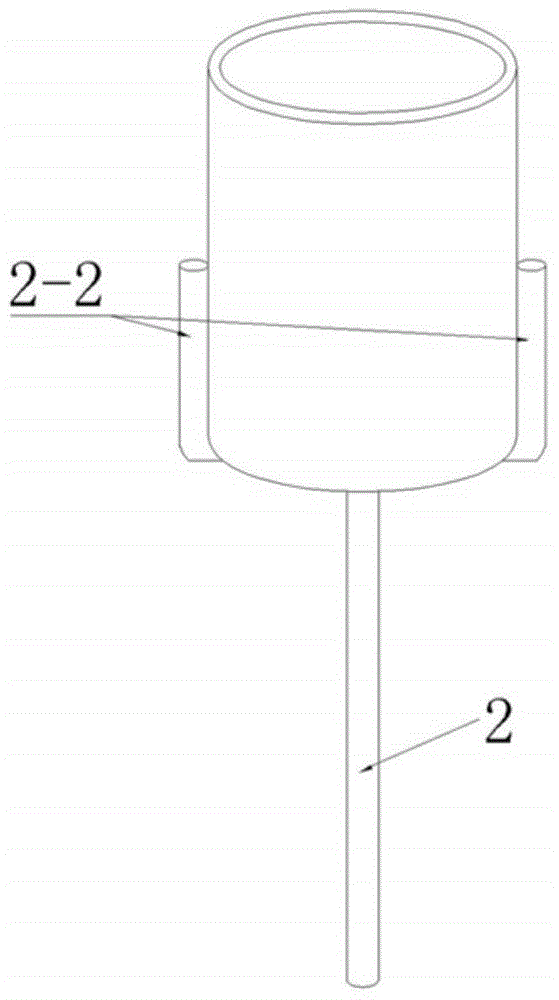

[0046] Such as image 3 and Figure 4 As shown, the molybdenum wire 2 is Y-shaped as a whole, and the two branches 2-2 on its upper part are respectively welded to the two sides of the rare earth molybdenum tube 1, and the two branches of the Y-shaped molybdenum wire 2 are connected with the vertical part. The connection part 2-3, the horizontal connection part spans the bottom end of the rare earth molybdenum tube.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that, in terms of the material of the cold cathode, 100-6000 ppm of rare earth yttrium is added to the rare earth molybdenum tube, and 1200 ppm of rare earth yttrium is added in this embodiment. The purpose of adding rare earth yttrium is to solve the problems of low emission performance and high temperature resistance that are difficult to solve in the prior art, so that the electrodes can be aged slowly in the lamp tube, work more stably, and prolong the service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com