Structure-improved riveting-free copper pull head

A structure improvement and riveting technology, which is applied in the field of zippers, can solve the problems of easy deformation of shrapnel, and achieve the effects of reliable use, improved stability, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

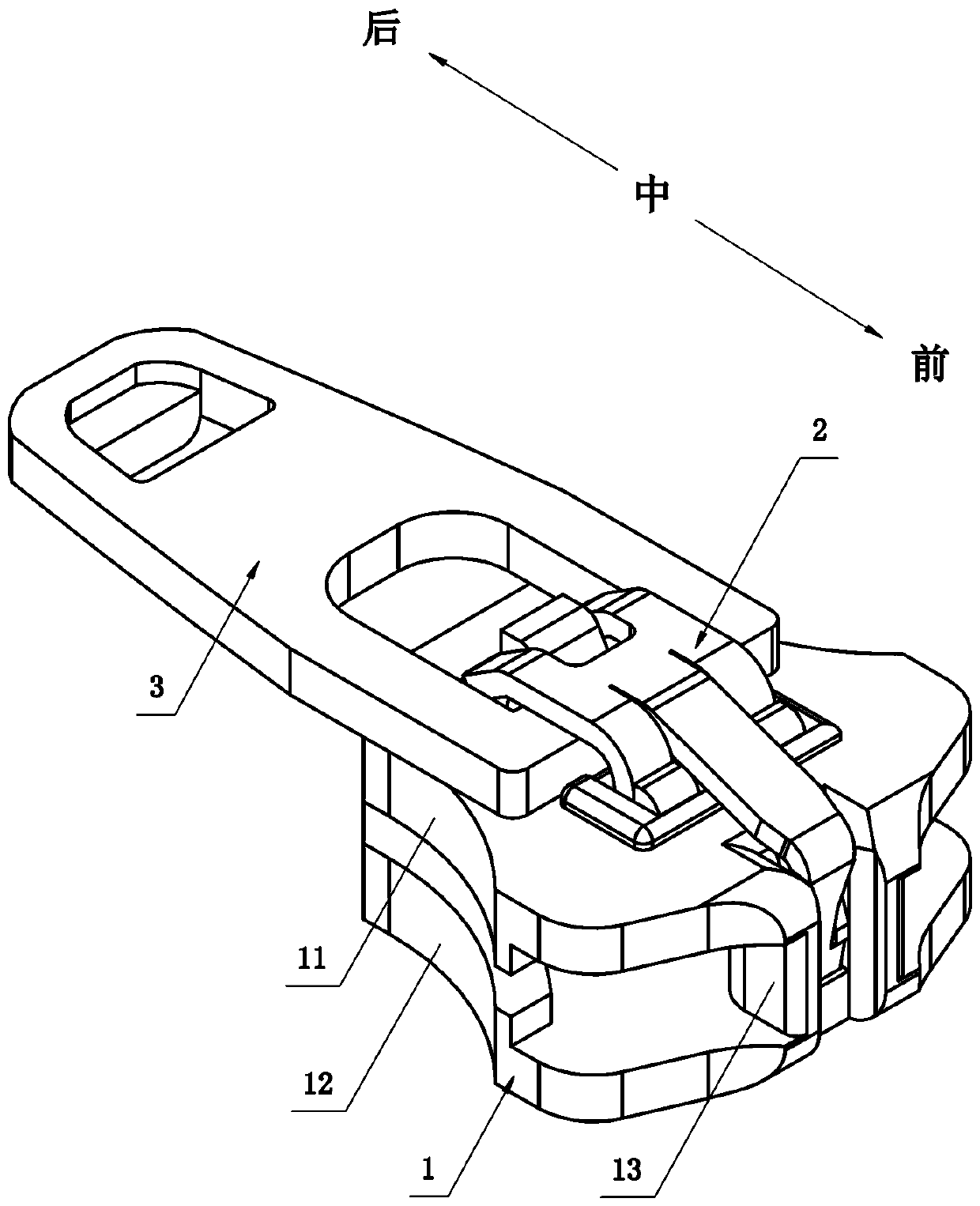

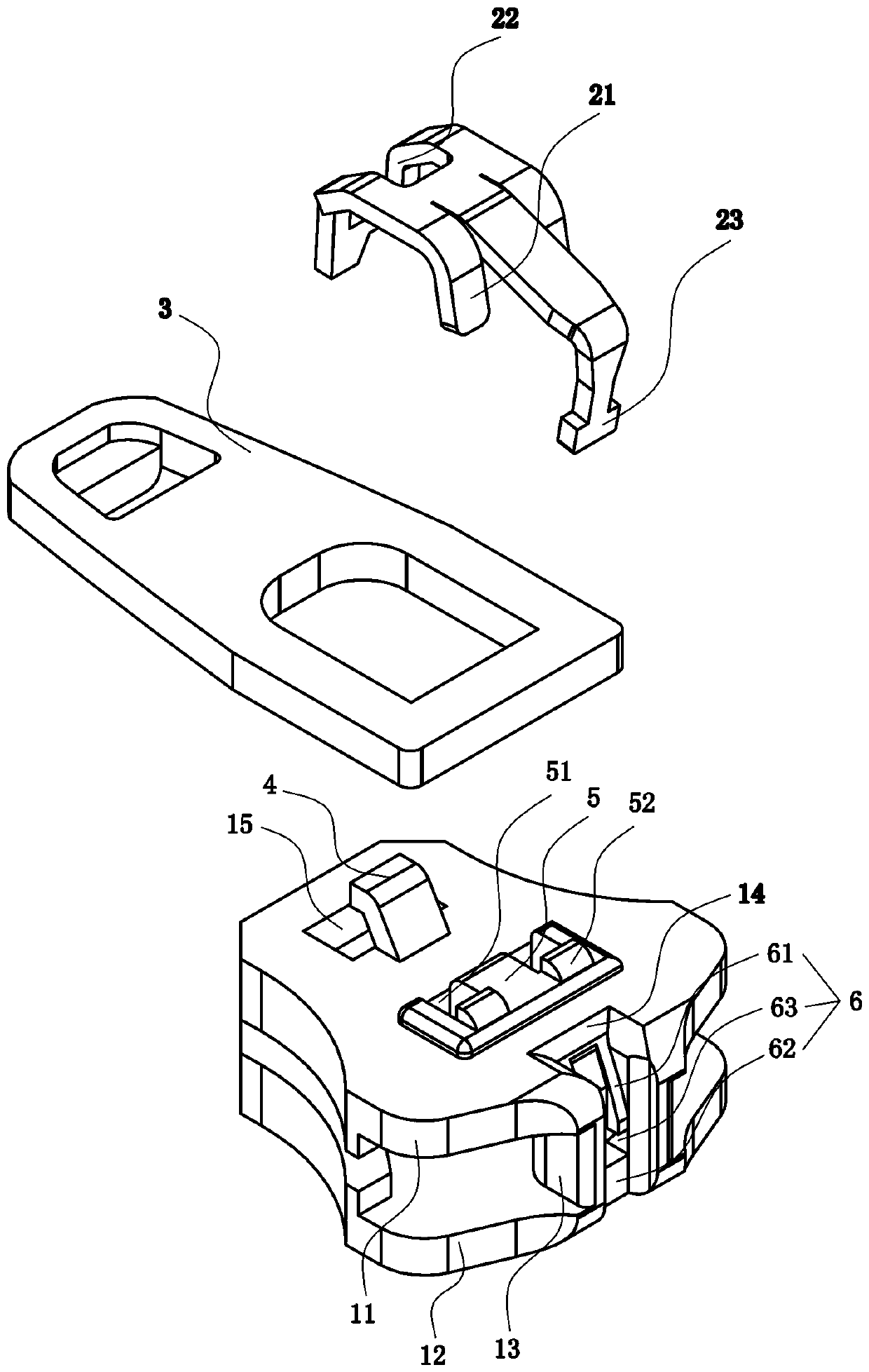

[0027] refer to figure 1 , figure 2 . A riveting-free copper slider with improved structure, including a slider body 1, a shrapnel 2 and a slider 3, the slider body 1 includes an upper wing 11, a lower wing 12, and a front end of the upper wing 11 connected to the lower wing The guide column 13 at the front end of the plate 12, the rear portion of the upper wing plate 13 has a projection 4, wherein,

[0028] The middle part of the upper wing plate 11 has a convex layer 5 protruding upward from the upper surface of the upper wing plate 11, and the convex layer 5 is provided with an insertion hole 51;

[0029] The middle part of the shrapnel 2 has a downwardly bent inserting plate 21, and a through hole 22 is opened in the rear part;

[0030] The shrapnel 2 is movably buckled on the slider body 1, and the insertion plate 21 is inserted into the socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com