Patents

Literature

175results about How to "Increase the stress point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

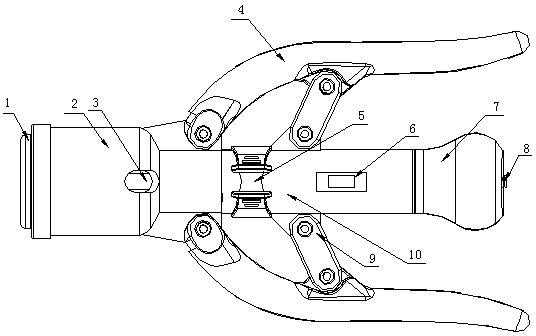

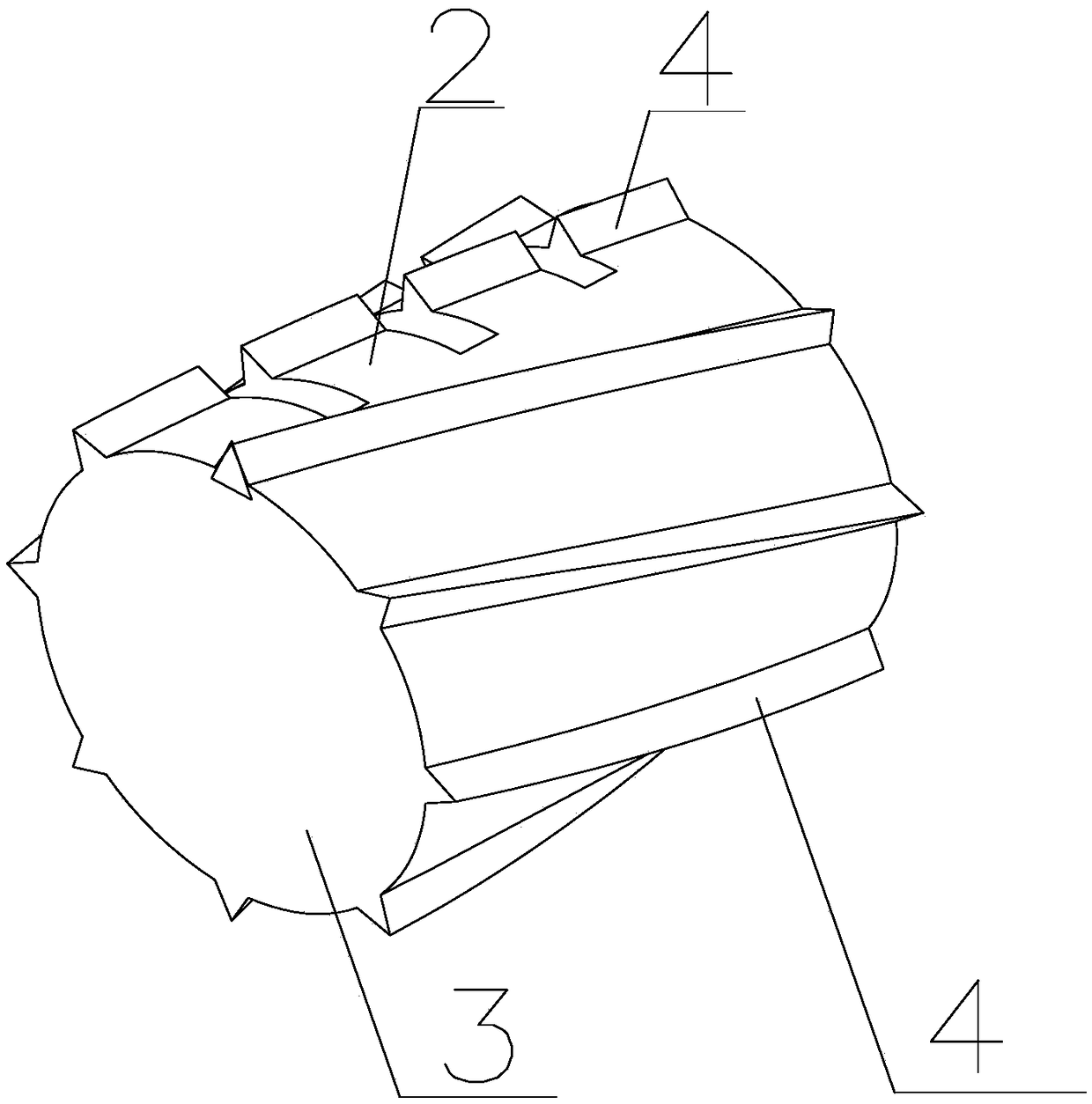

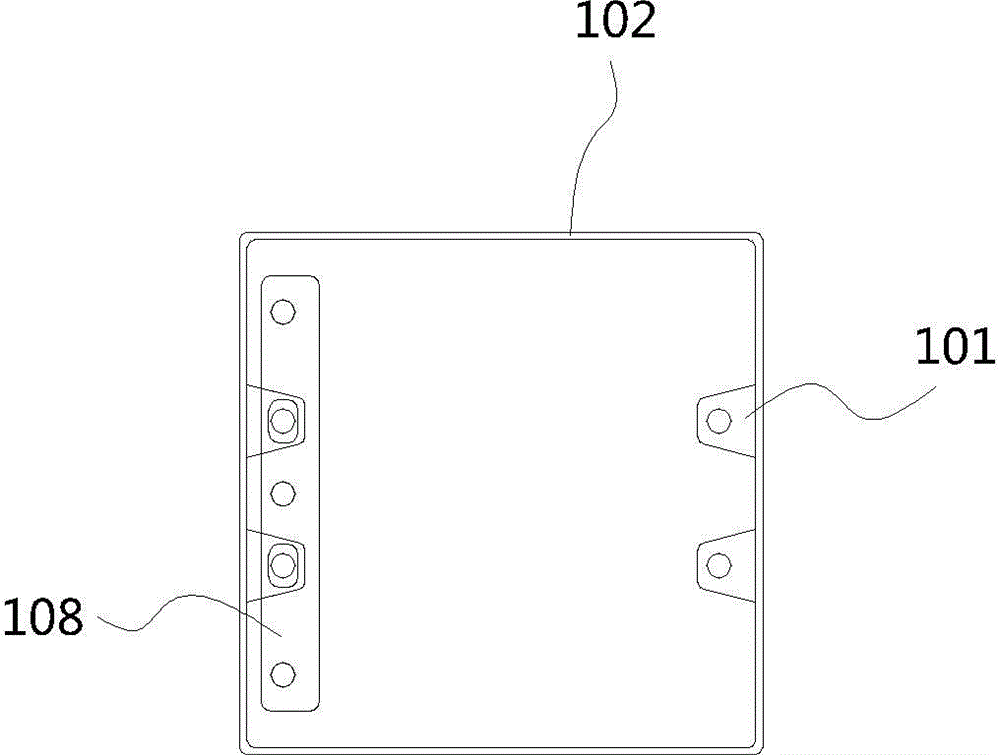

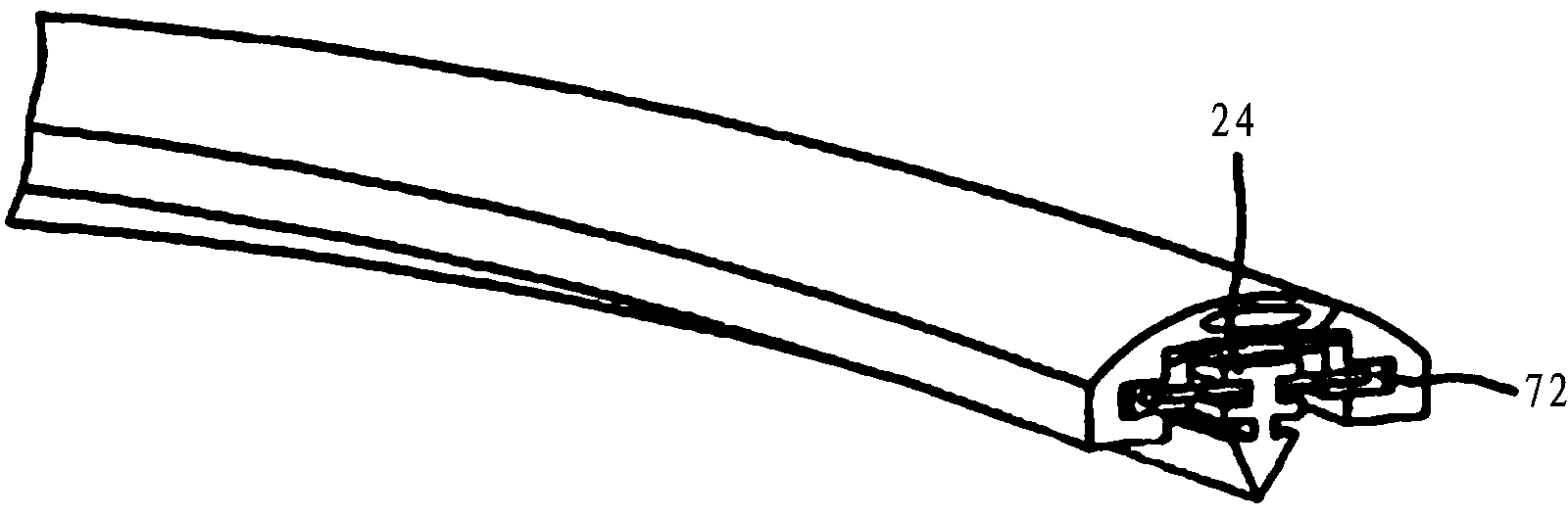

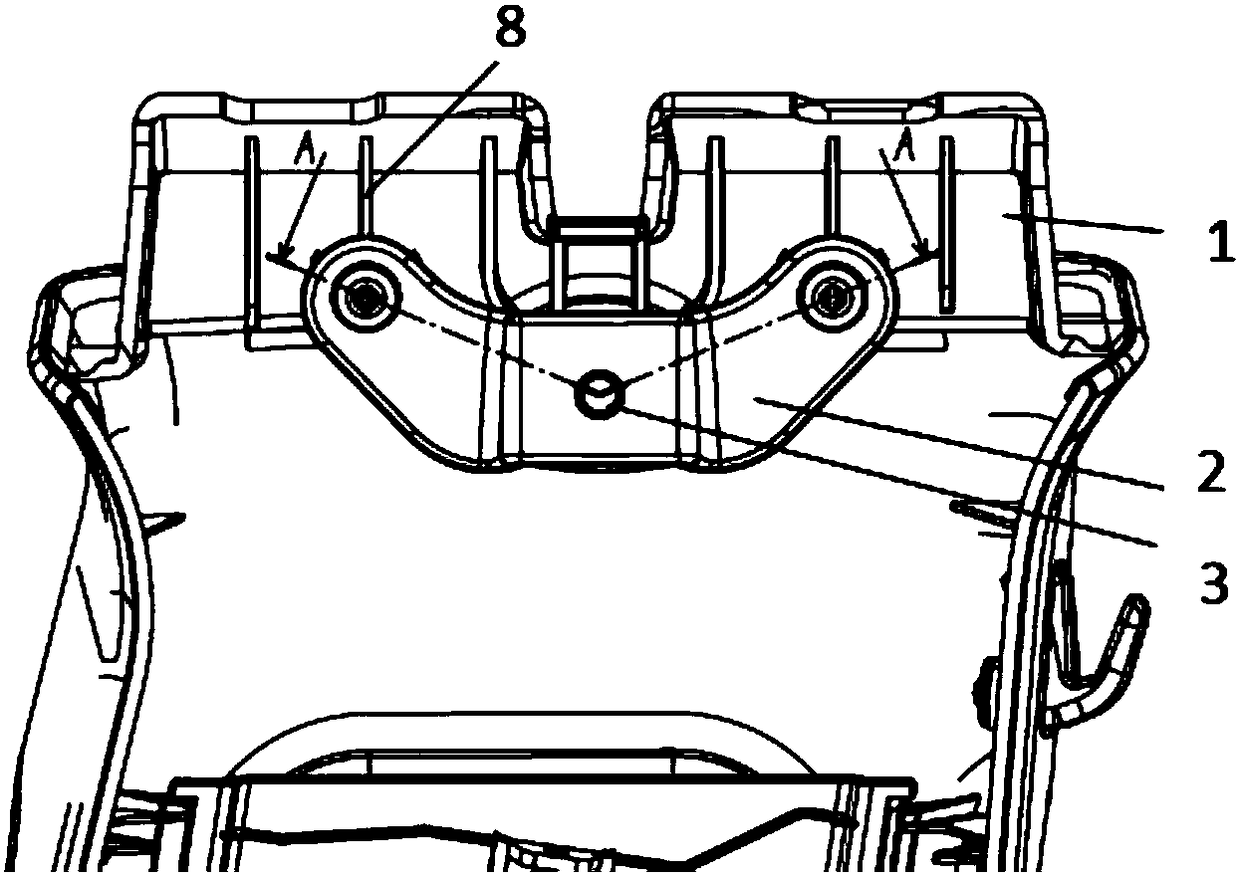

Disposable foreskin cutting stapler

InactiveCN104224286AShorten operation timeEasy to operateSuture equipmentsSurgical staplesMedical equipmentForeskin

The invention relates to the technical field of medical equipment, in particular to a disposable foreskin cutting stapler. The disposable foreskin cutting stapler comprises a concave seat, a staple chamber sleeve, a casing, a lead screw, a staple pushing piece, a movable handle and a connecting rod, wherein the lead screw is arranged in the casing, the staple chamber sleeve is arranged on the left side of the casing, the staple pushing piece and the concave seat are arranged in the staple chamber sleeve, the movable handle is installed on the casing, the connecting rod is connected with the casing and the movable handle, a safety clip is arranged on the casing, an adjusting nut is arranged at the tail end of the casing, an adjusting bolt is arranged at the end of the lead screw, exhaust through holes are formed in the concave seat, and a suture carrying hole is formed in the staple chamber sleeve. The disposable foreskin cutting stapler has the advantages that the operation time is effectively shortened during use, the stapler is convenient for a doctor to operate, the stapler is not only safe but also practical, the stress area is increased through the fish-tail-shaped adjusting nut, the stress points are increased, the appearance is attractive and the operating hand feeling is improved.

Owner:常州杰瑞尔医疗器械有限公司

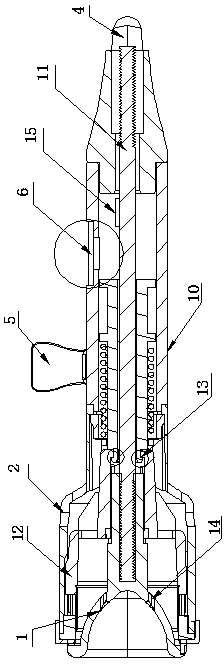

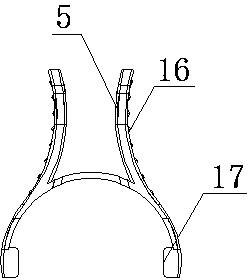

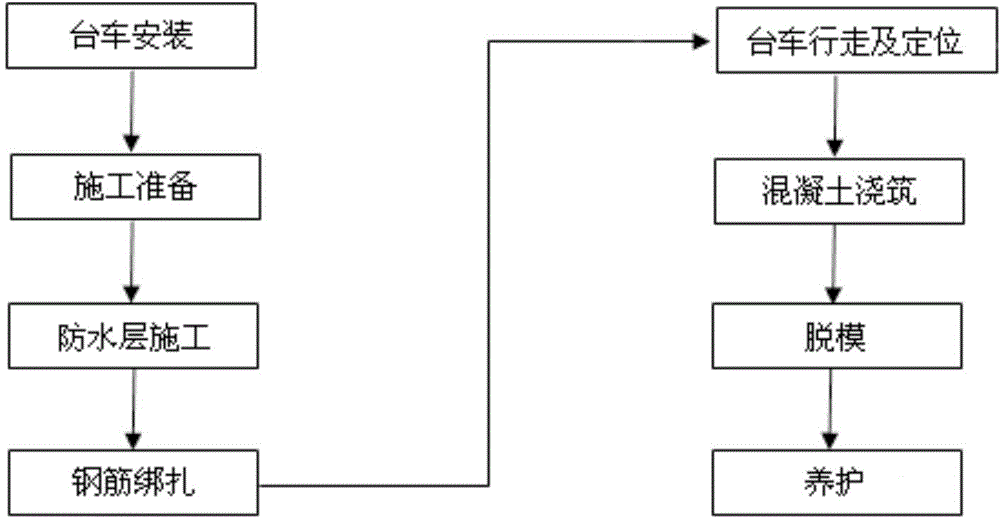

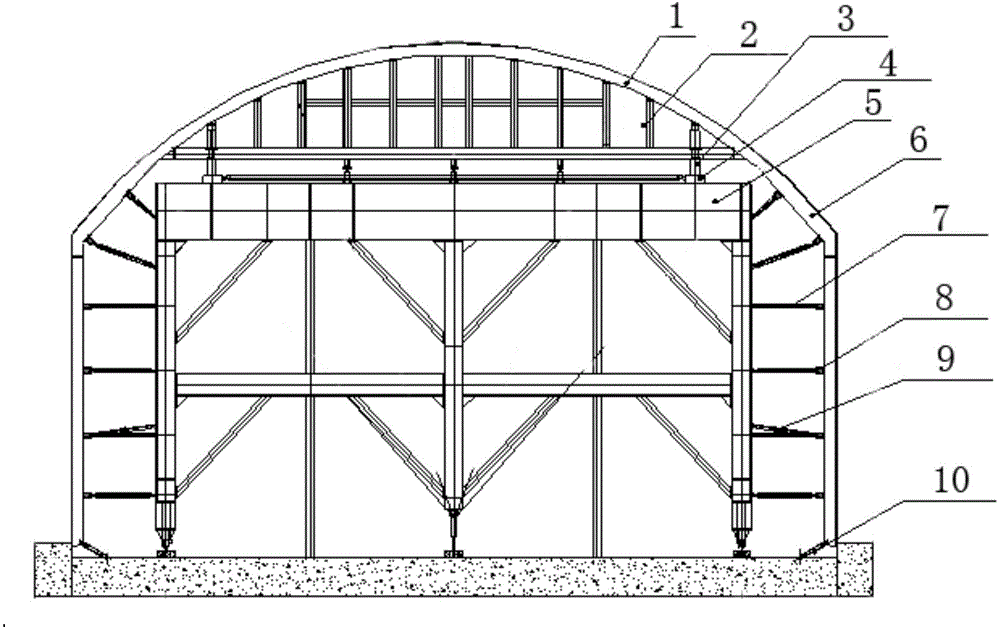

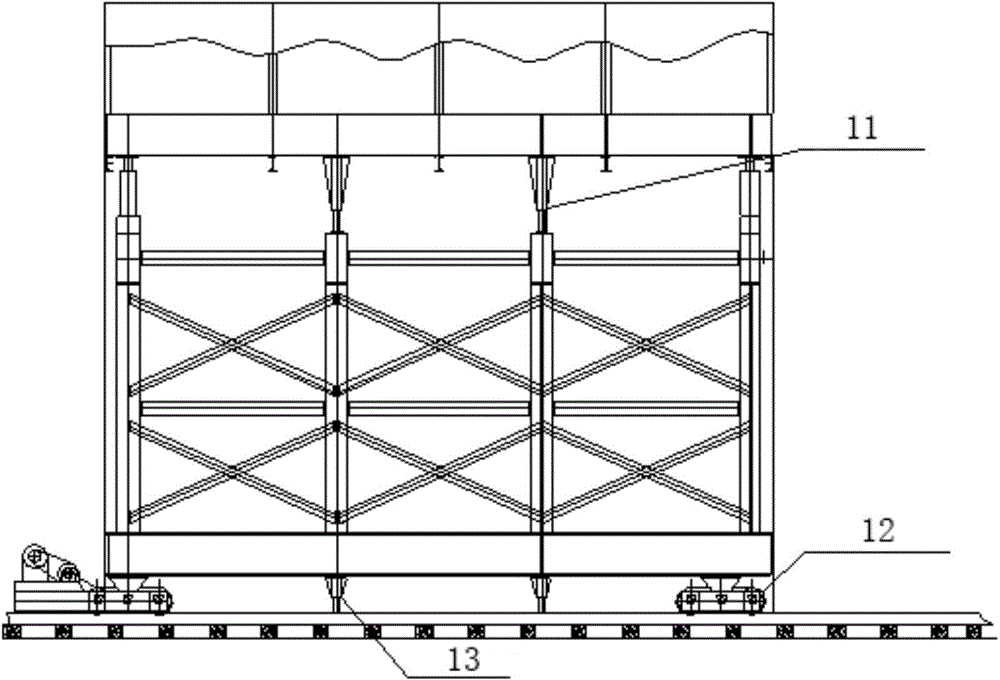

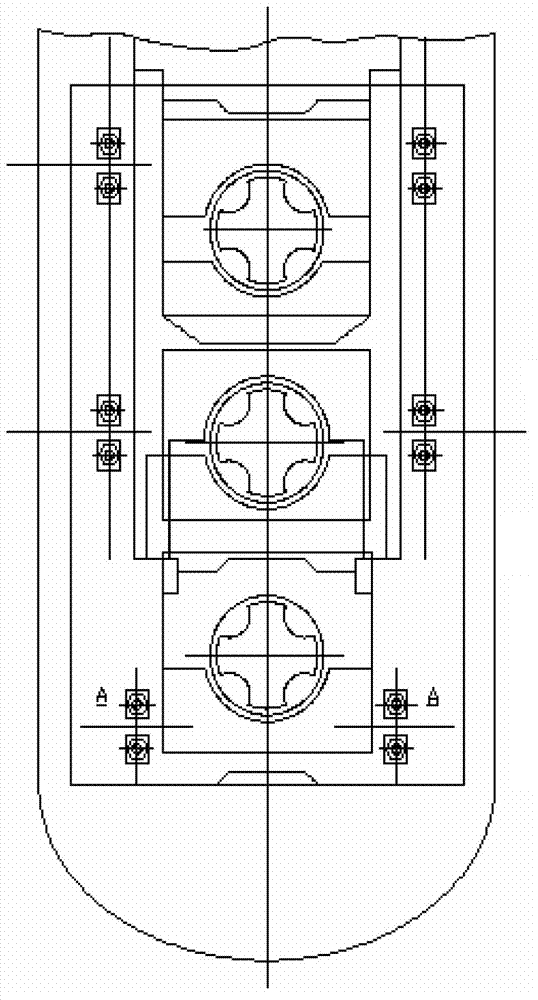

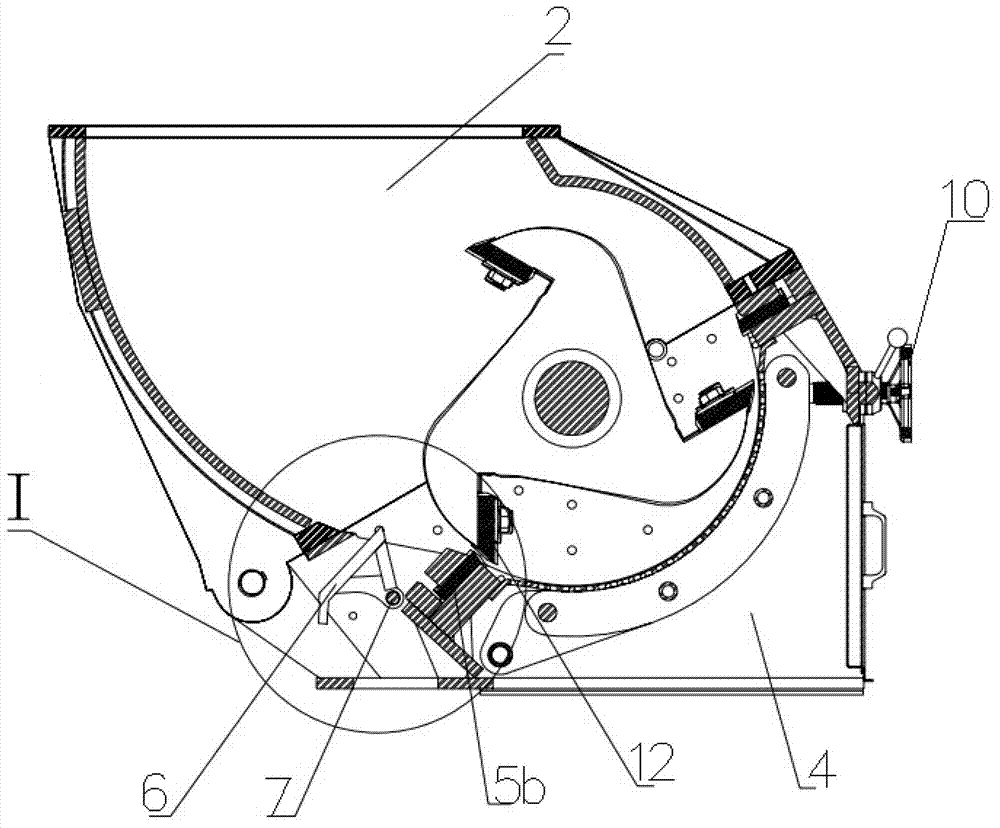

Super-large section chamber reinforced concrete modelling construction method

ActiveCN104533456AMove fastFast positioningUnderground chambersTunnel liningReinforced concreteMotor drive

The invention relates to the technical field of construction, in particular to a reinforced concrete modelling construction method which is applicable to a large section chamber. According to the super-large section chamber reinforced concrete modelling construction method, a multi-vertical-rod type lining trolley is adopted to control the integral rigidity of a rack, a motor drives a walking mechanism to drive the trolley to move, formwork in place and tunnel reinforced concrete forming of closing mold are adjusted through a hydraulic oil cylinder and a screw jack, the multi-rod type lining trolley adopts a method of pouring the side wall and the arc portion together or separately pouring the arc wall according to the size, the construction period and the concrete supply conditions of the tunnel section. According to the reinforced concrete modelling construction method, the multi-rod type lining trolley is adopted, the side wall and the arc portion can be poured separately and simultaneously, the construction period and costs are saved, the splicing time and material reshipment are reduced, the trolley movement and positioning speed is rapid, and personnel operation is facilitated; the multi-rod trolley adopts full-hydraulic vertical closing mold, the motor driving is matched with walking of the rail, accurate positioning is easy, braking is convenient, movement safety risks are small, and the structure is reasonable.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

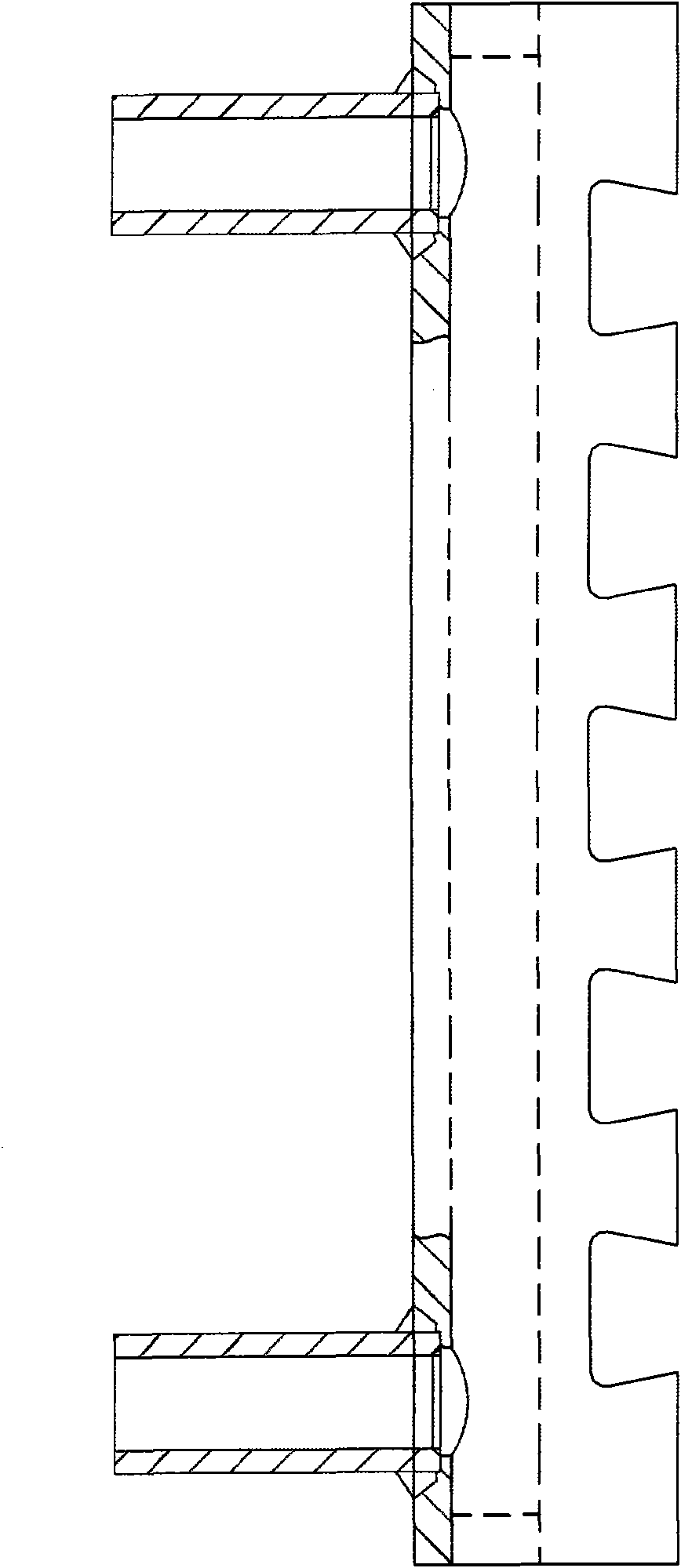

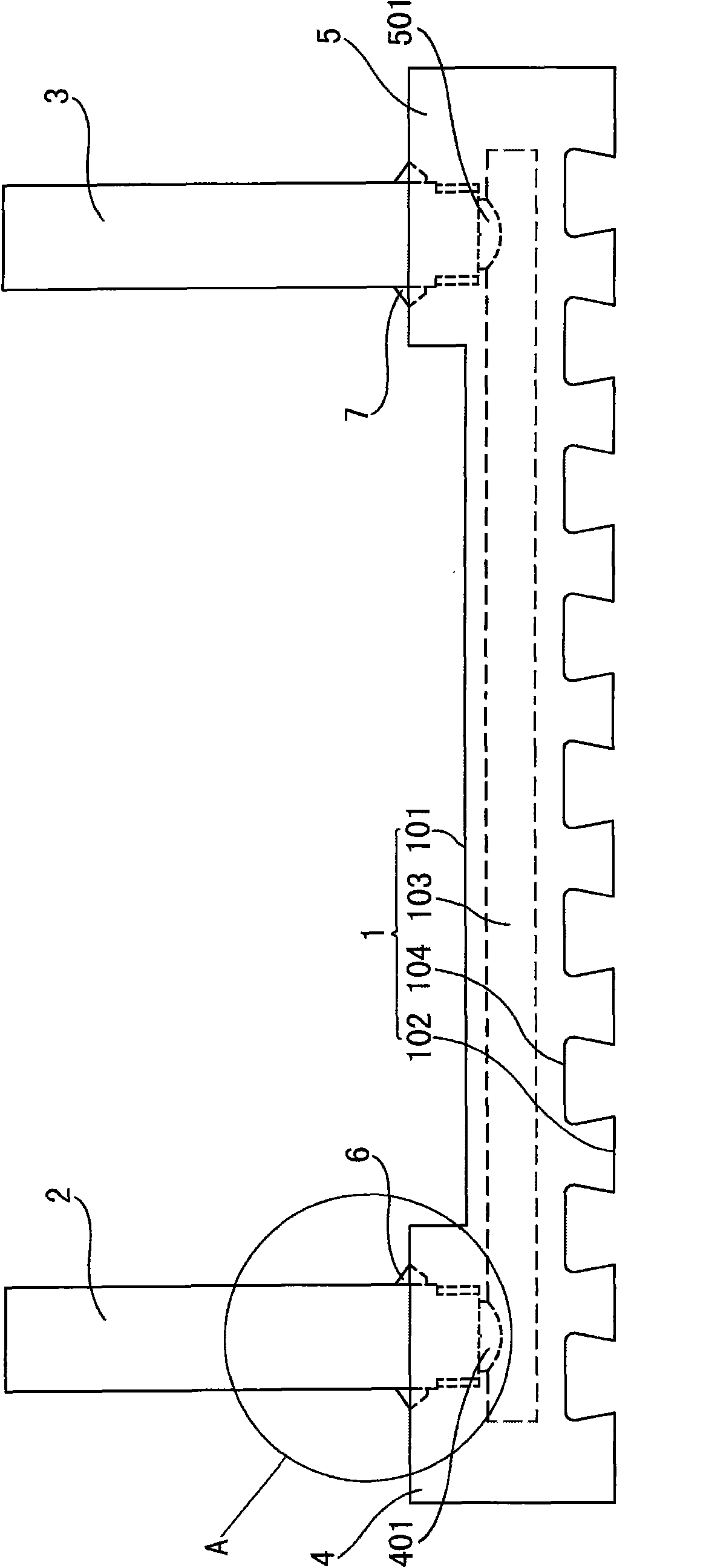

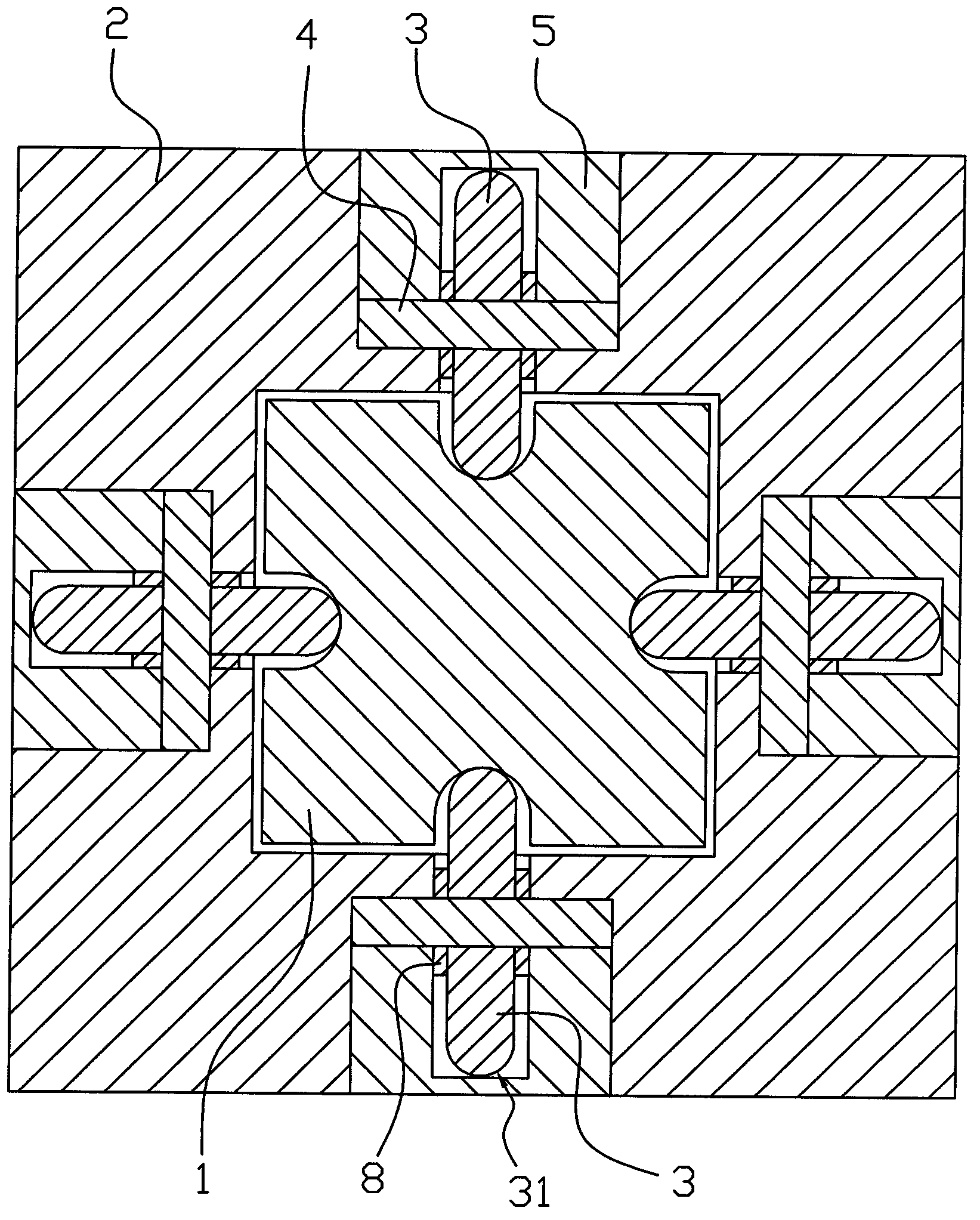

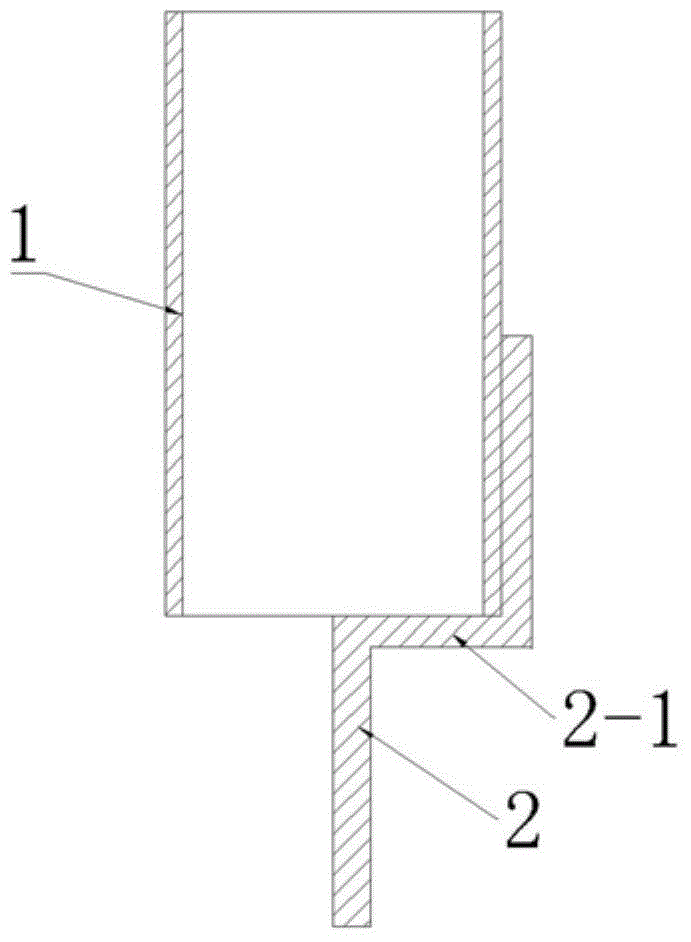

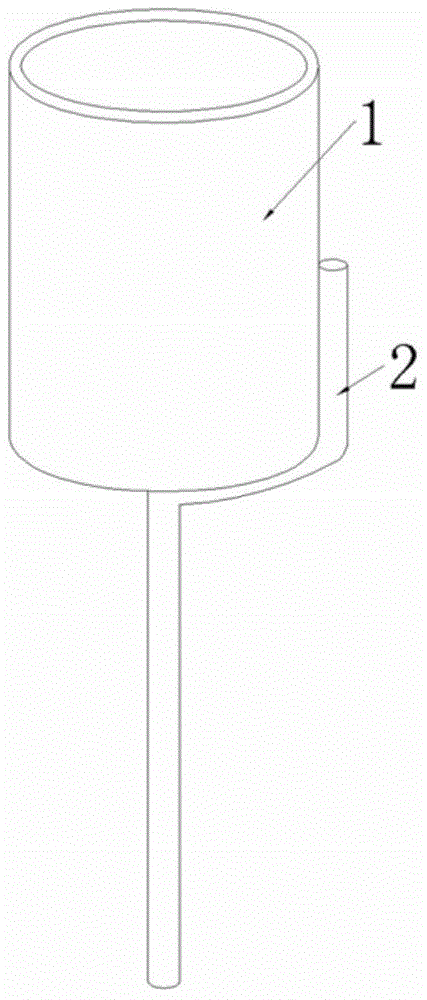

Copper cooling wall with reinforced piping structure

ActiveCN101935723AStressfulIncrease the stress pointCooling devicesManufacturing convertersStress conditionsWater channel

The invention provides a copper cooling wall with a reinforced piping structure. The copper cooling wall comprises a copper cooling wall body, at least one water inlet pipe and at least one water outlet pipe, wherein at least one cooling water channel is reserved in the copper cooling wall body; the water inlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the inlet of the cooling water channel; the water outlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the outlet of the cooling water channel; the water inlet pipe is inserted into the inlet of the cooling water channel, and is in threaded connection with the inner wall of the inlet of the cooling water channel; and the water outlet pipe is inserted into the outlet of the cooling water channel and is in threaded connection with the inner wall of the outlet of the cooling water channel. The copper cooling wall has the advantages of increasing stress points of the water pipe, and improving the stress condition of the water pipe to ensure that the stress of the water pipe is more uniform and a welding seam is hard to destroy; and because of lugs, the quality and the strength of the welding seam can be effectively improved, the consumption of copper can be greatly reduced, and the manufacturing cost of the copper cooling wall can be effectively controlled on the premise of ensuring the performance.

Owner:SHANTOU HUAXING METALLURGICAL EQUIP CO LTD

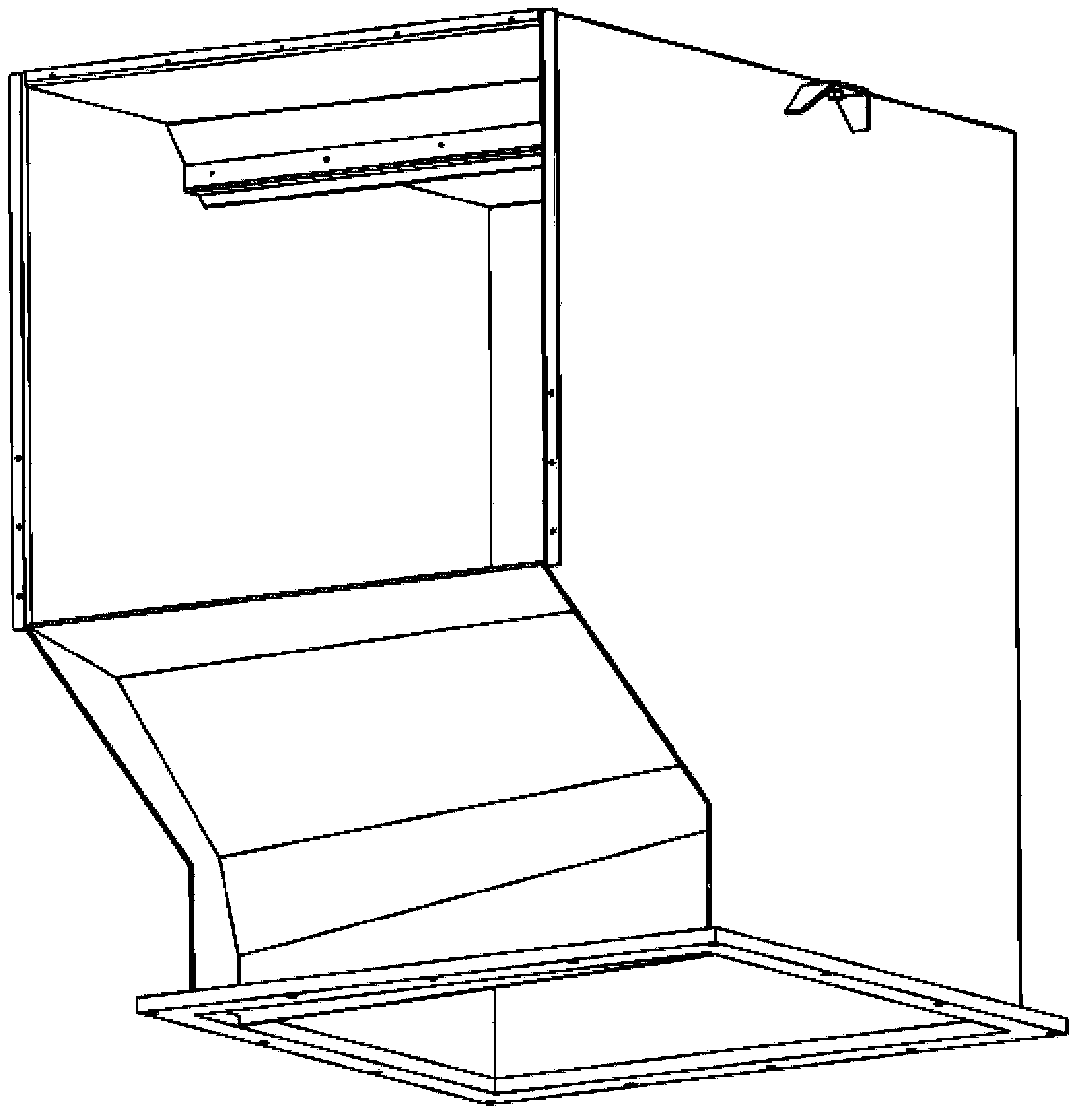

Inserting-connection assembly for air conditioner installation

InactiveCN103940006AEasy to installAvoid outdoor work at heightsLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

An inserting-connection assembly for air conditioner installation comprises a carrying-connection block and an inserting-connection block. The front portion of the inserting-connection block is inserted into the carrying-connection block, the carrying-connection block is fixed to a wall body, and the inserting-connection sliding block is installed on a backing plate of an outdoor unit. The carrying-connection block is provided with an inserting groove which extends from the top end to the bottom, the inserting groove is sealed through the bottom end of the carrying-connection block, and an opening of the inserting groove is flanged inwards; the front portion of the inserting-connection block is inserted into the inserting groove; a plurality of longitudinal protruding edges are erected at the bottom of the inserting groove, the front portion of the inserting-connection block is provided with grooves matched with the protruding edges, and the two sides of the inserting-connection block are provided with clamping connectors matched with the opening of the inserting groove. According to the inserting-connection assembly for air conditioner installation, air conditioner installation is convenient and fast, outdoor work is not needed, and the installation cost and unsafe factors are greatly reduced.

Owner:张书傲

Novel polyamide nanocomposite and preparation method thereof

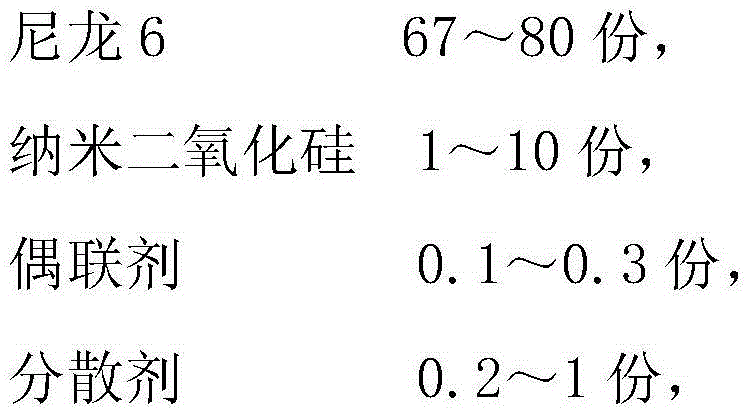

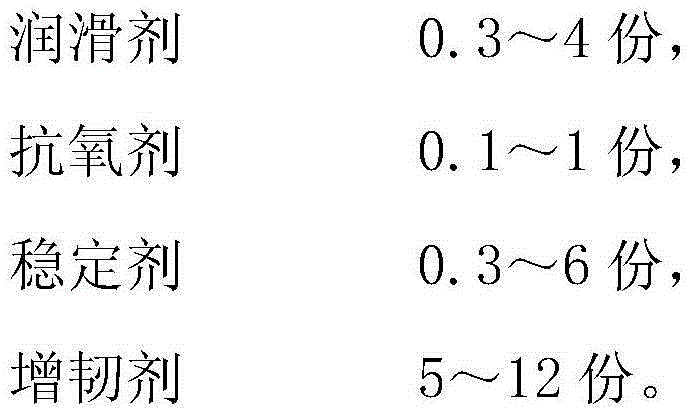

The invention provides a novel polyamide nanocomposite. The components of the novel polyamide nanocomposite in parts by weight are as follows: 67 to 80 parts of nylon 6, 1 to 10 parts of nanosilicon dioxide, 0.1 to 0.3 part of coupling agent, 0.2 to 1 part of dispersant, 0.3 to 4 parts of lubricant, 0.1 to 1 part of antioxidant, 0.3 to 6 parts of stabilizer and 5 to 12 parts of flexibilizer. The invention also discloses a preparation method of the novel polyamide nanocomposite. The novel polyamide nanocomposite provided by the invention has high strength and good impact resistance.

Owner:叶芳

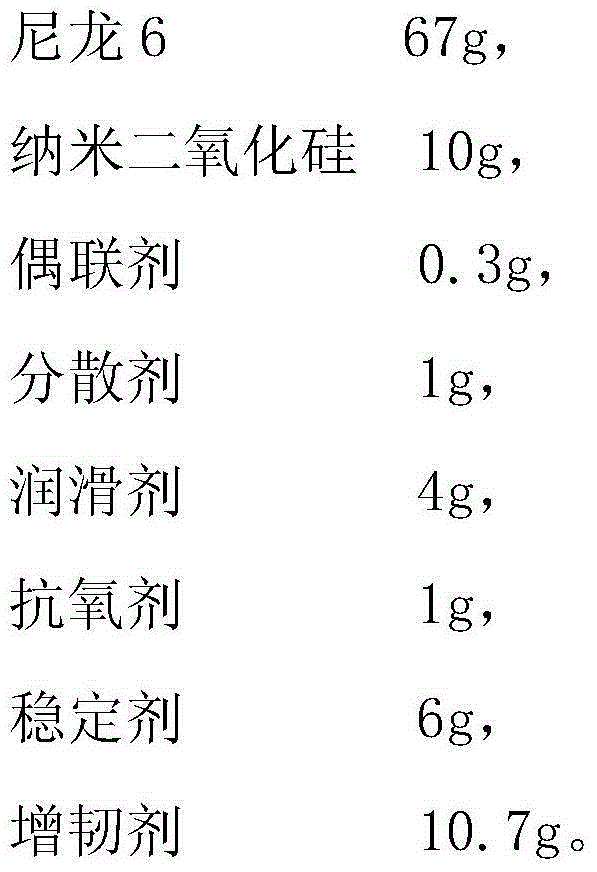

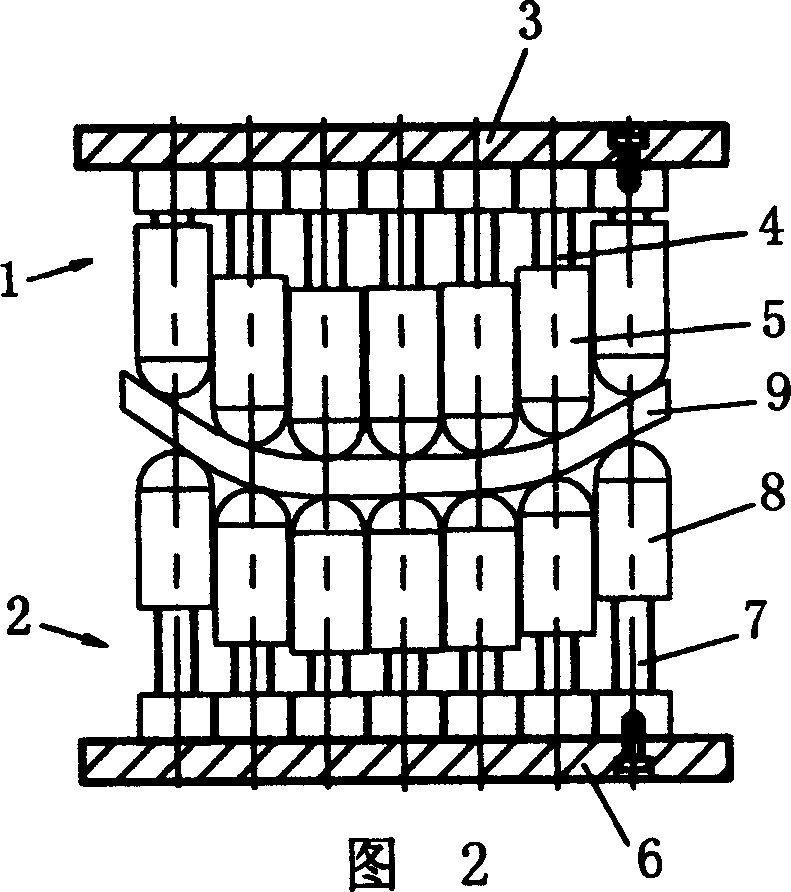

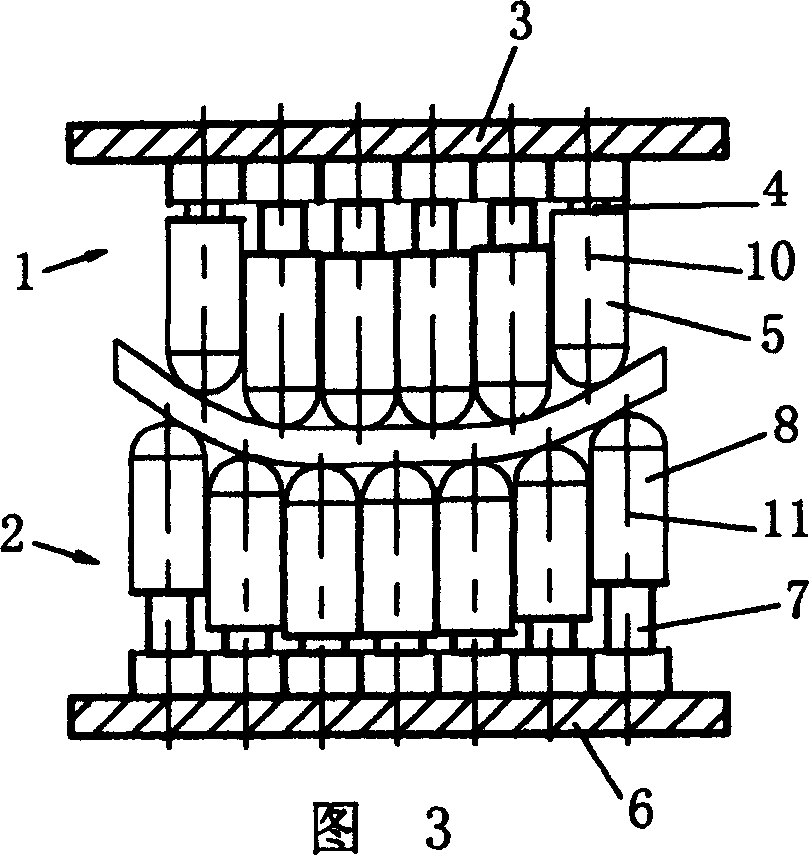

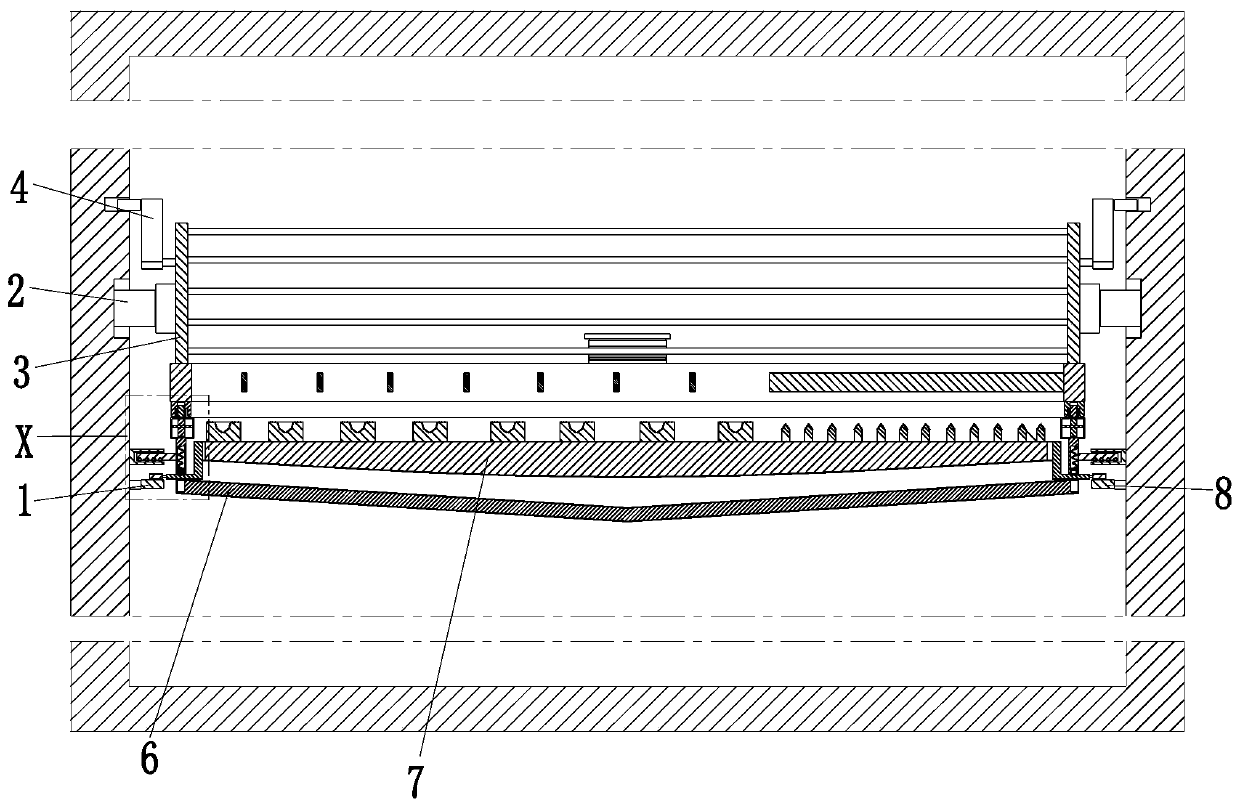

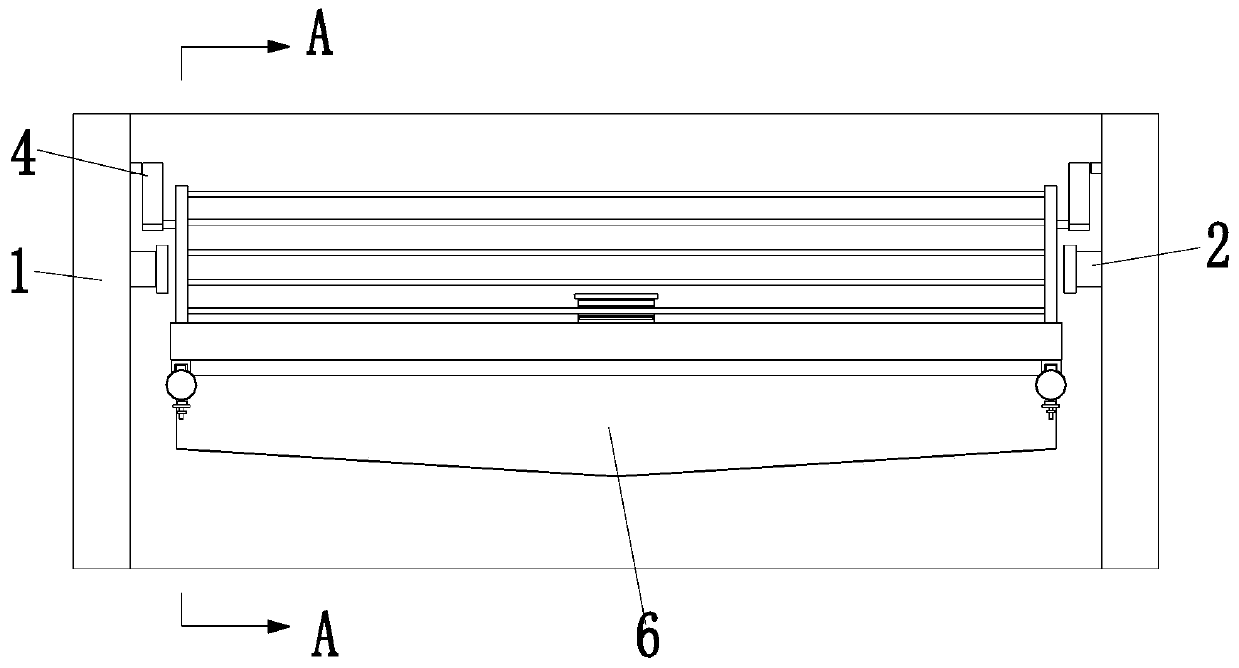

Discrete face mold device for plate material heat forming

Owner:HUNAN UNIV

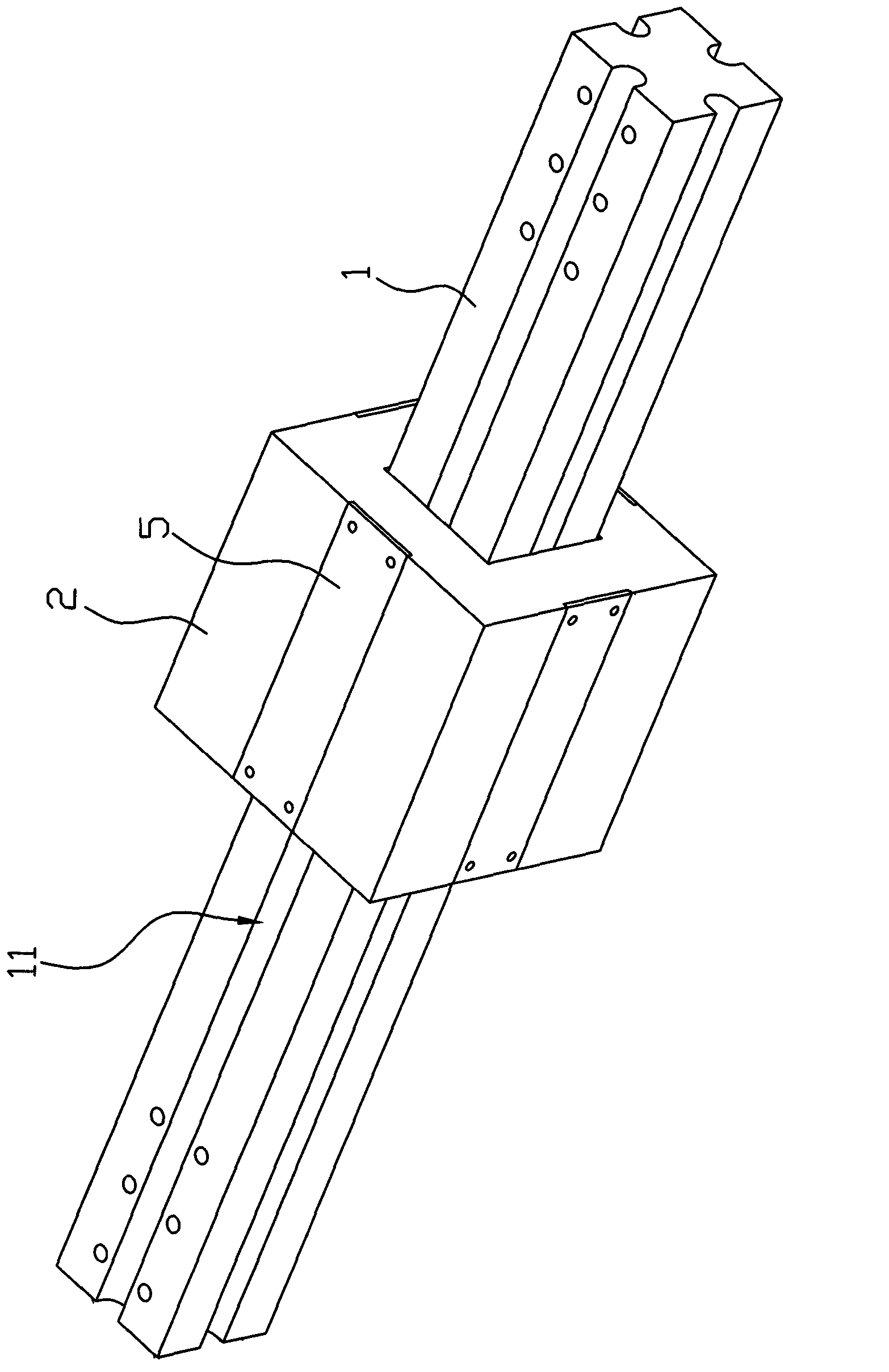

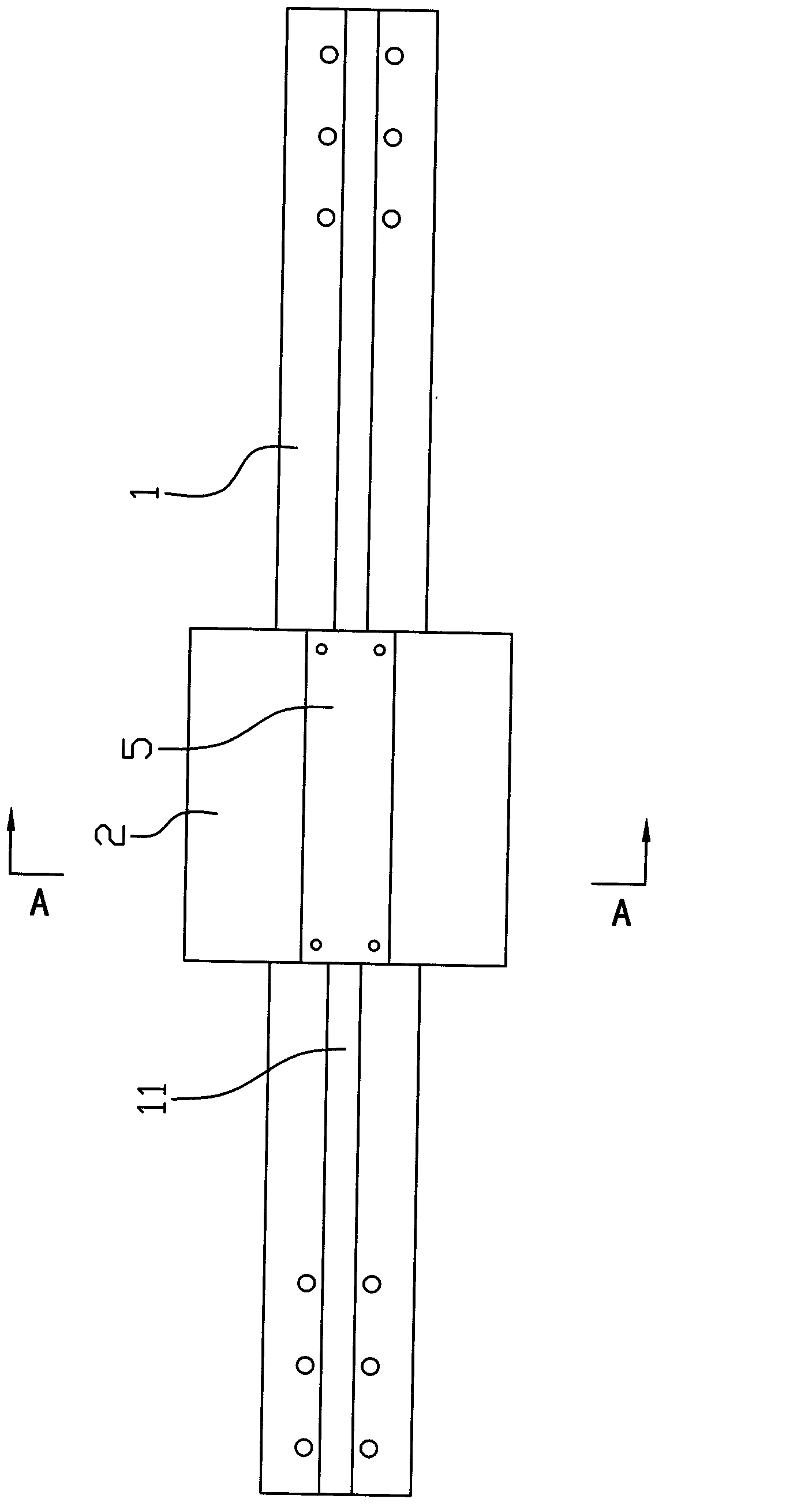

Sliding track device

The invention discloses a sliding track device comprising a slider (2), wherein the slider (2) is mounted on a matching guide track (1) in a sliding manner. The sliding track device is characterized in that the guide track (1) is a rectangular strip, concave sliding chutes (11) are axially formed at the middle of the four sides of the rectangular strip respectively and the two ends of each concave sliding chutes are communicated, the end-face orthographic projection of the guide track (1) is a rectangle having notches at the middle of the four sides, a rectangular cavity (21) is axially formed within the slider (2), wherein the two end of the rectangular cavity are communicated and fits well with the rectangular strip, raised roller wheels (3) are formed on the inner walls of the four sides of the rectangular cavity (21) respectively, and when the slider (2) is mounted on the guide track (1), the roller wheels (3) raised from the inner walls of the four sides can roll in the corresponding sliding chutes (11). The sliding track device has the advantages that the design is smart, the stress points are increased and also distributed on the four sides of the guide track to ensure more uniform stress, and the guide track is enclosed within the rectangular cavity, so as to reduce the frictional force of the slider during movement and ensure that the movement of the slider is more stable and flexible.

Owner:邳州市承鼎机械设备有限公司

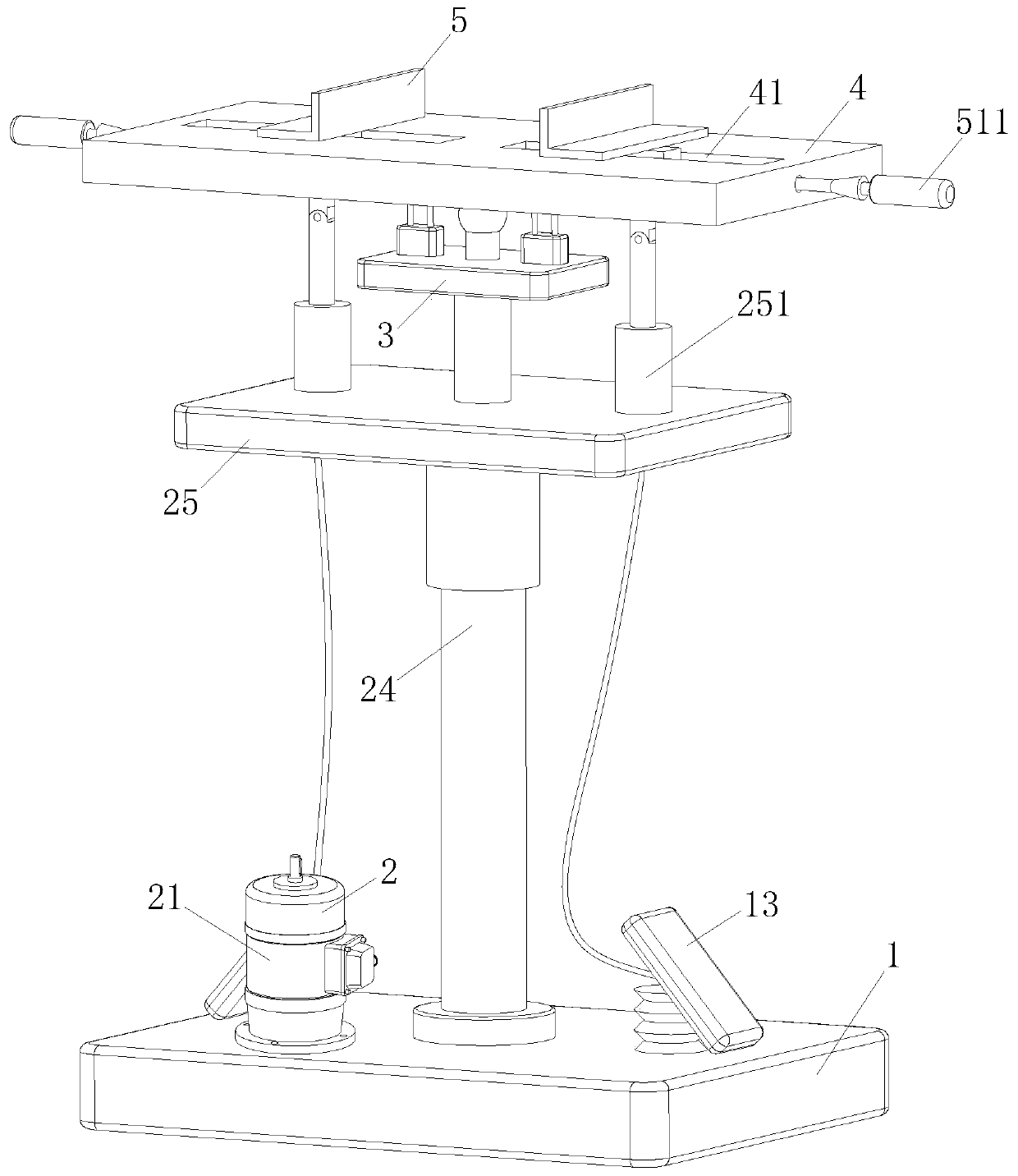

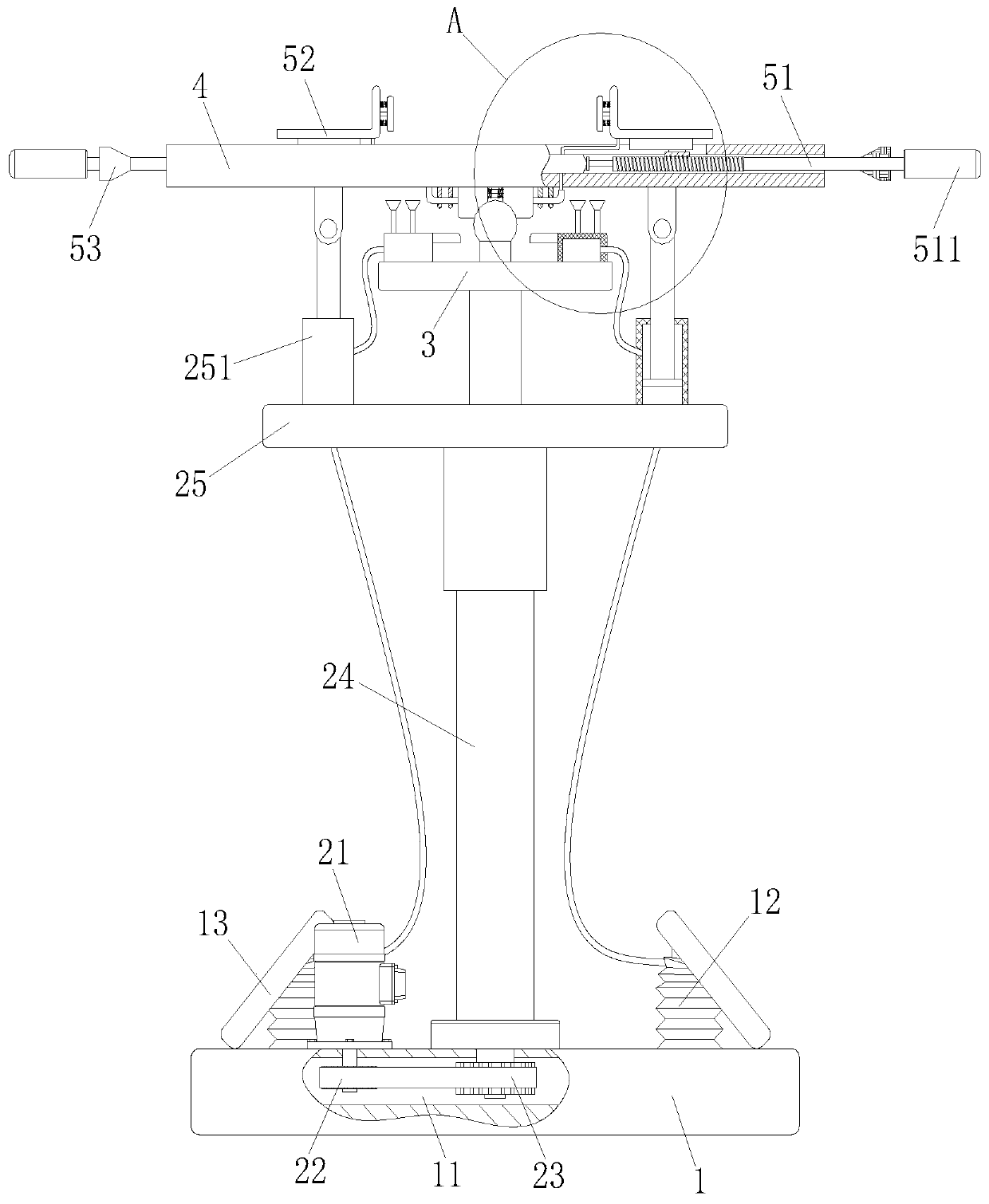

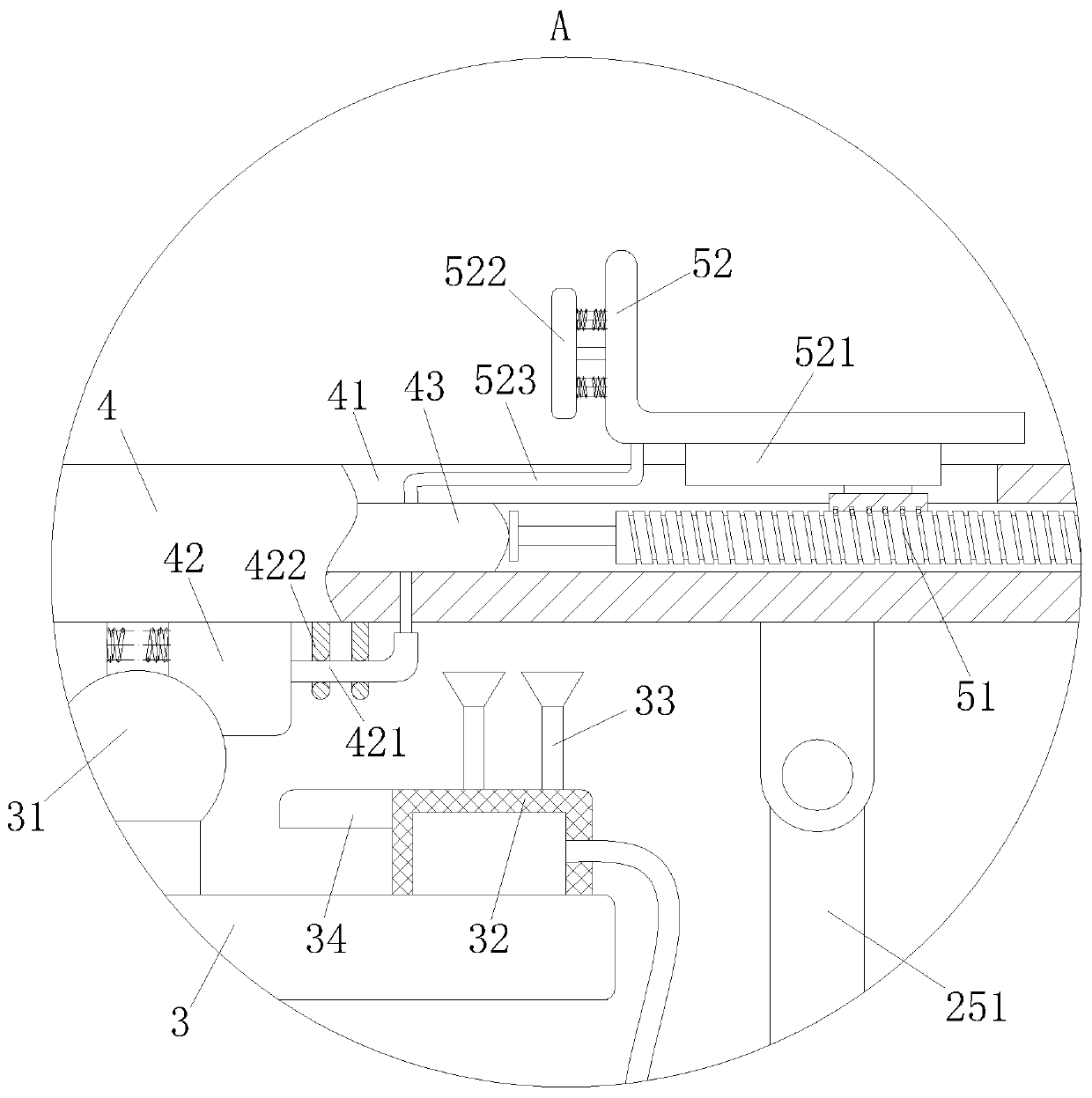

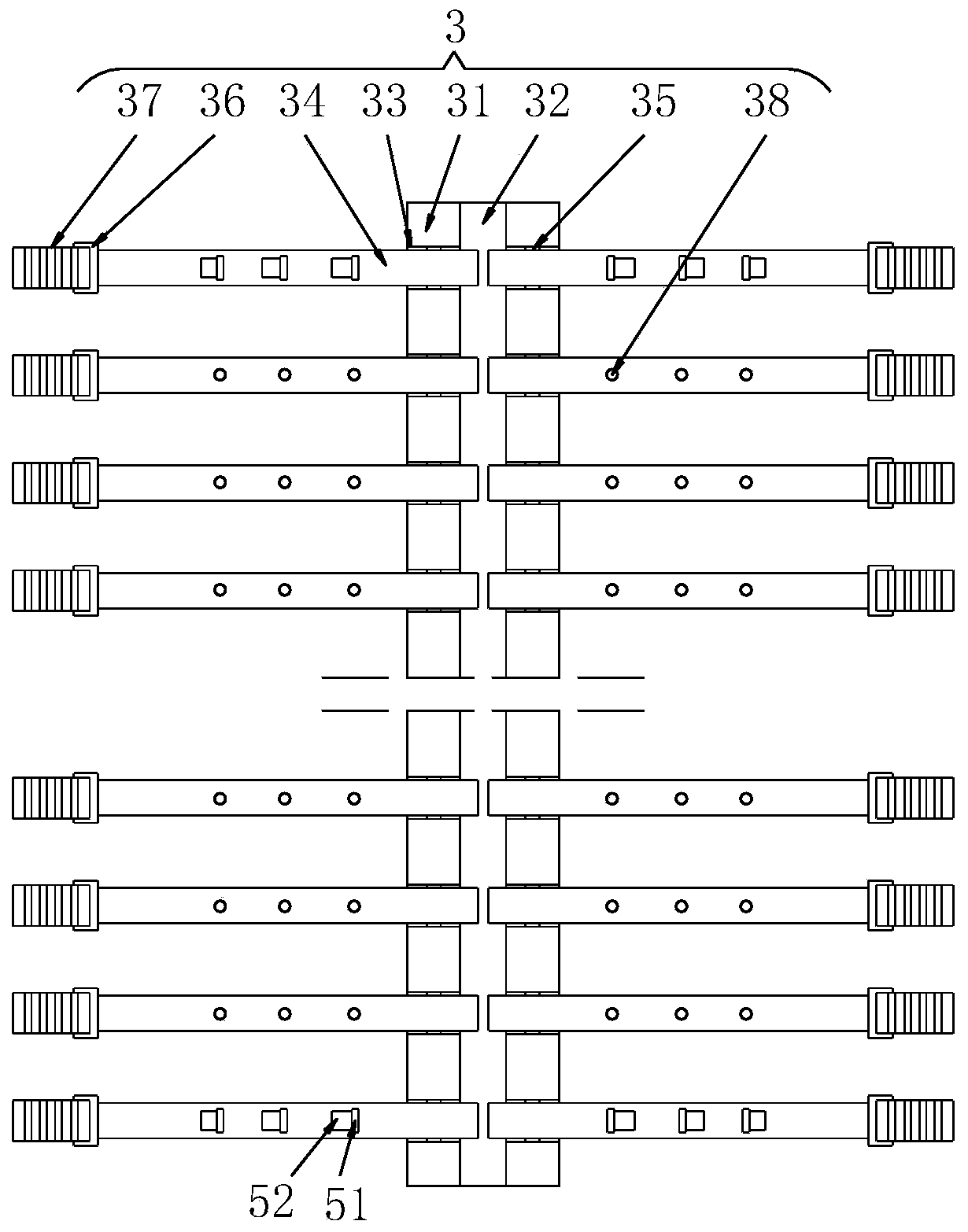

Multifunctional auxiliary device for graphic design teaching

ActiveCN111280979ARealize a full range of displayShow profoundEducational modelsShow shelvesGear wheelElectric machinery

The invention belongs to the technical field of teaching auxiliary equipment, and particularly relates to a multifunctional auxiliary device for graphic design teaching. The device comprises a base, apower unit, a supporting plate, a top plate and a clamping unit; the power unit is installed on the base and comprises a motor, a first gear, a second gear, a rotating shaft and a rotating plate. Theclamping unit is installed on the top plate and comprises a lead screw, a clamping plate and a fixing plug. One end of the lead screw is rotationally connected into the sliding groove, and the otherend extends out of the sliding groove and is provided with a handle. The fixing plug slidably sleeves the side wall, close to the handle, of the lead screw; through cooperation of the base, the powerunit, the support plate, the top plate and the clamping unit, clamping and rotary display of the model are realized, and omnibearing display of the model for students is realized, so that the studentscan perform deeper learning on the graphic design through the three-dimensional model, and convenience is brought to the students to construct three-dimensional thinking.

Owner:LIAOCHENG UNIV

Anti-deformation cutting device of metal hose

InactiveCN108856860AActive fixed connectionReduce distortionTube shearing machinesShearing machine accessoriesScrew threadMetal hose

The invention discloses an anti-deformation cutting device of a metal hose. The rotation speed of a cutter body is 0.5N times of the rotation speed of the metal hose, wherein N is a positive integer,and the cutter body only rotates one round; the two ends of the metal hose are placed into a cylindrical placing box with the middle part being hollow, the placing box is provided with four through holes, the through holes are in threaded connection with connection rods, the two ends of the connection rods are at outside of the through holes, the ends, in the placing box, of the connection rods are connected with connection plates, the connection plates on the four connection rods form a hollow cylinder, the connection rods rotate in the through holes to adjust the distance between the connection plates and the inner wall of the placing box, and the metal hose is fixed into the hollow cylinder composed of the four connection plates. The device can effectively relieve the stress when cutting the metal hose to prevent the metal hose from deforming in the cutting process, and thus the metal hose is more convenient to use for a long time.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

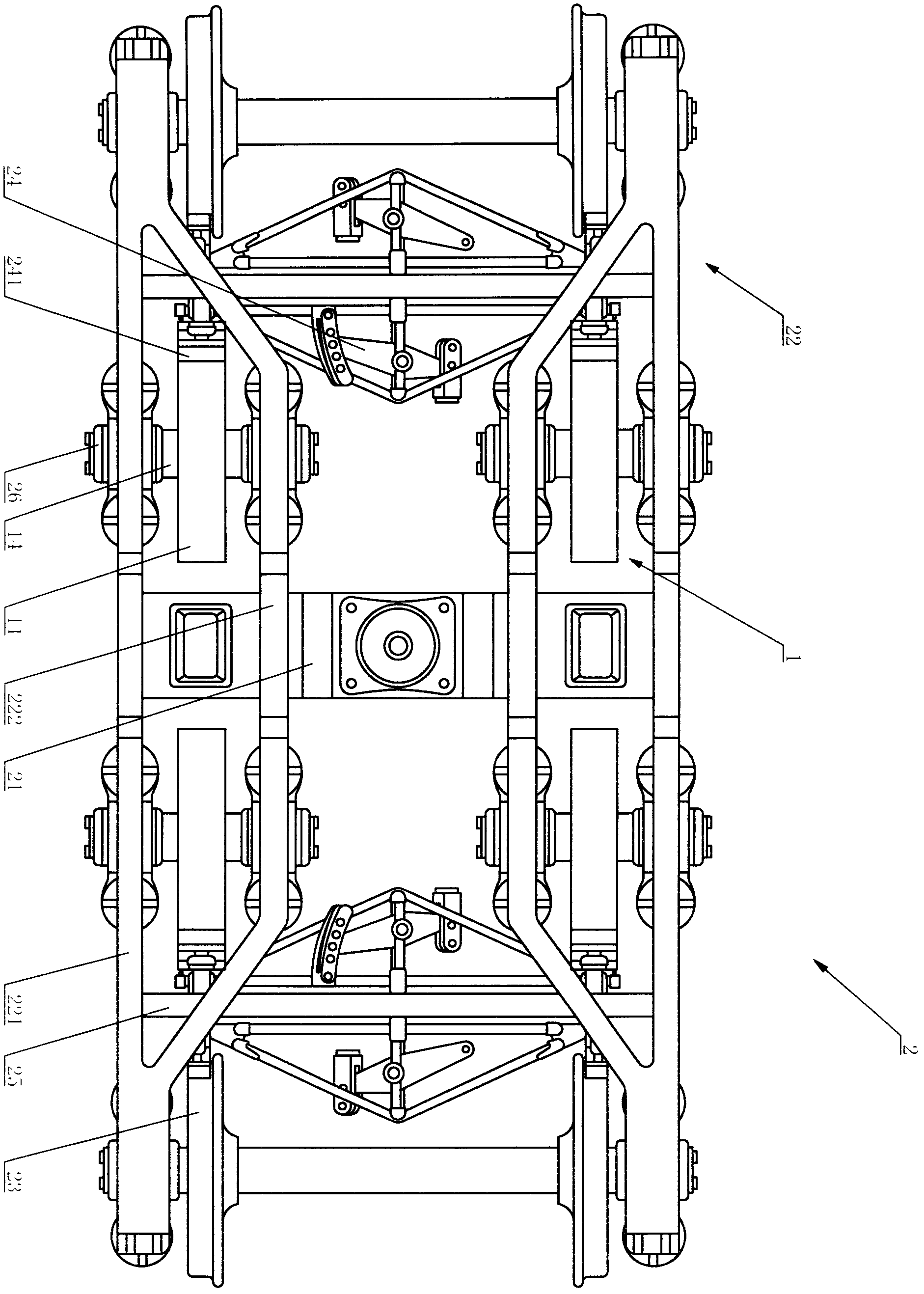

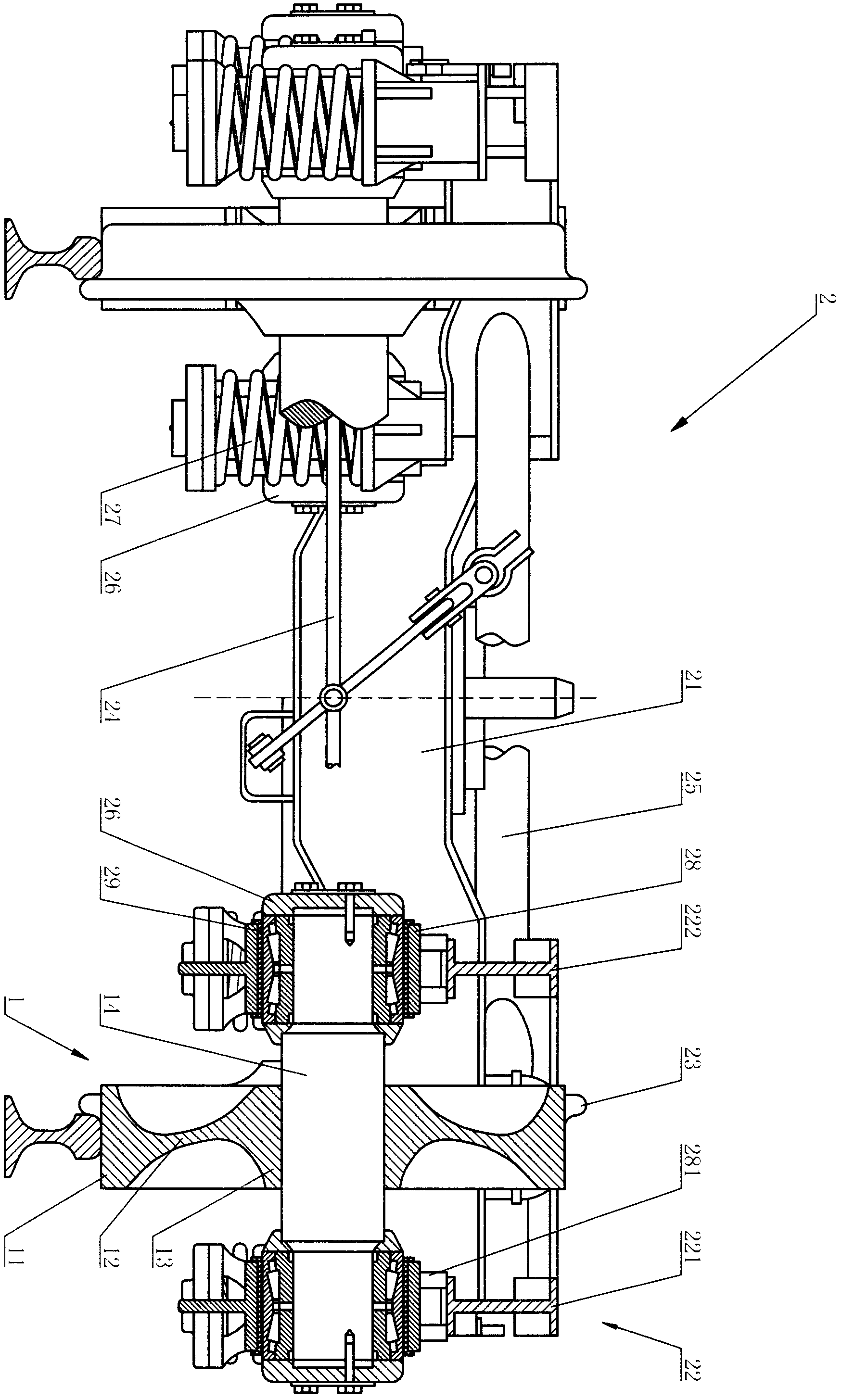

Thrust wheel for heavy-duty railway wagons and bogie thereof

ActiveCN102530007AIncrease load capacityProduce destructive powerBogie-underframe connectionsBogieCarrying capacity

The invention relates to a thrust wheel and a bogie, and in particular relates to a thrust wheel (which is applicable to heavy-duty railway wagons, can reduce loss and unsprung mass, and can reduce the operation cost, improve the quality of operation and greatly increase the carrying capacity) for heavy-duty railway wagons, and a bogie thereof. The bogie comprises a central crossbeam, side frames and wheel sets, wherein the side frames are symmetrically connected to the two ends of the central crossbeam, and the wheel sets are symmetrically arranged at the two ends of each side frame by a wheel set shaft; and the bogie is characterized in that the bogie also comprises at least a pair of thrust wheels arranged between the wheel sets; the thrust wheel is arranged on the side frame and comprises a rim, a radial plate and a hub which are integrally arranged; and the external wheel surface of the rim is not provided with a wheel flange, and the operating surface of the rim is axially horizontal and 115mm in width. The thrust wheel and bogie provided by the invention has the advantages that: the carrying capacity of the bogie is greatly increased, the contact stress to a wheel rail is reduced, the abrasion of the wheel rail is reduced, the quality of operation is improved, and the operating cost is reduced; meanwhile, the bogie is simple in structure, low in manufacturing difficulty, and low in cost.

Owner:张二群

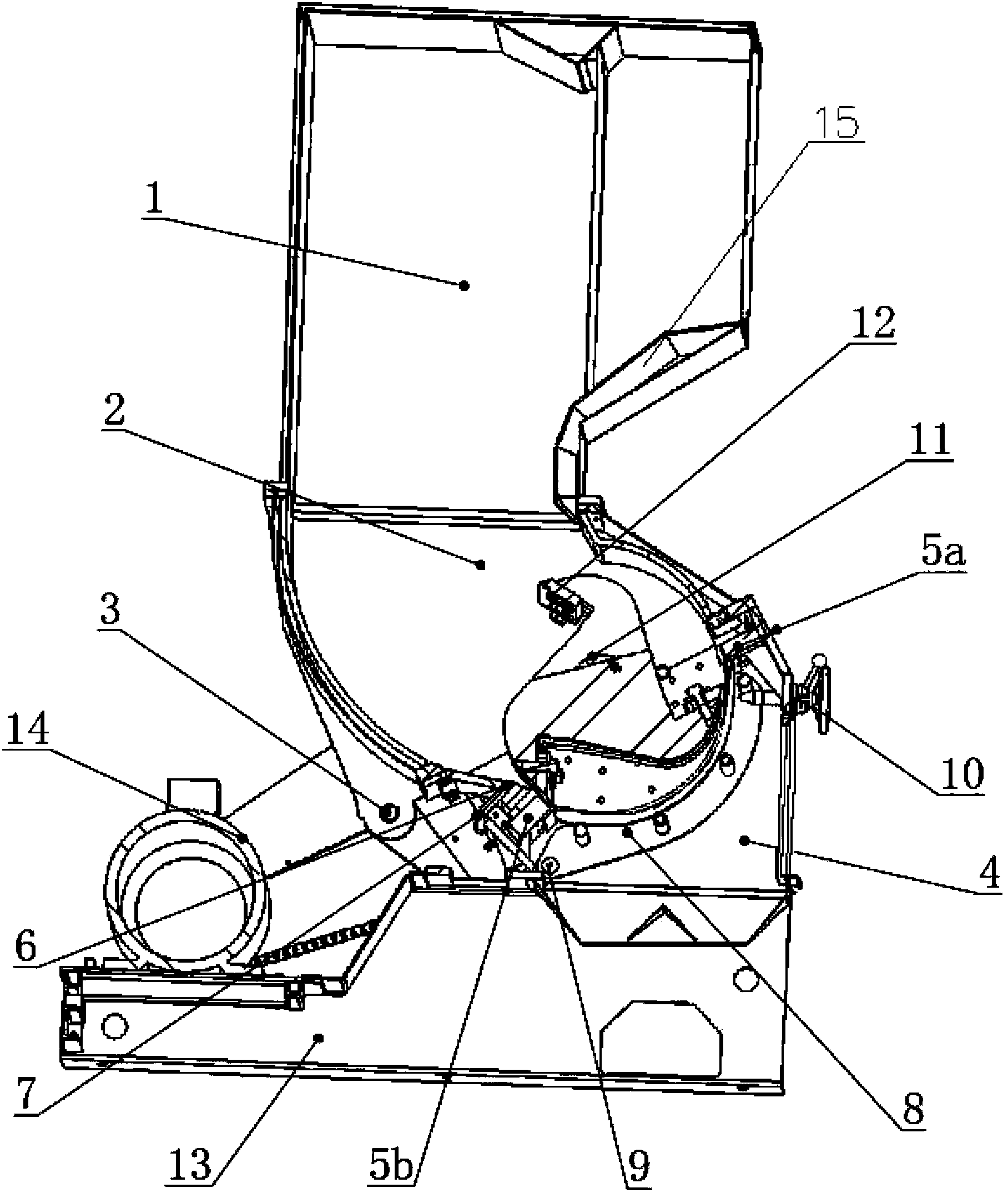

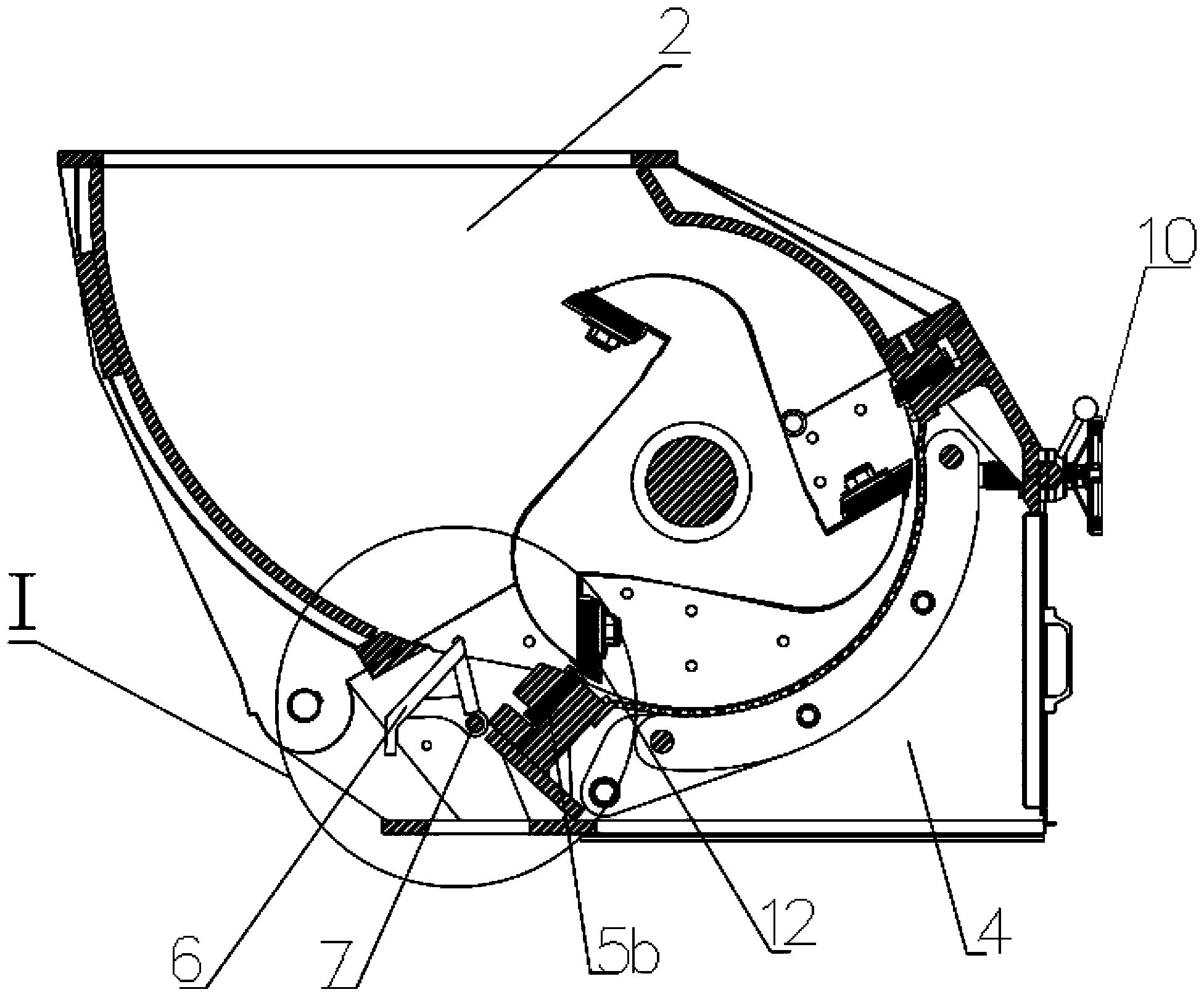

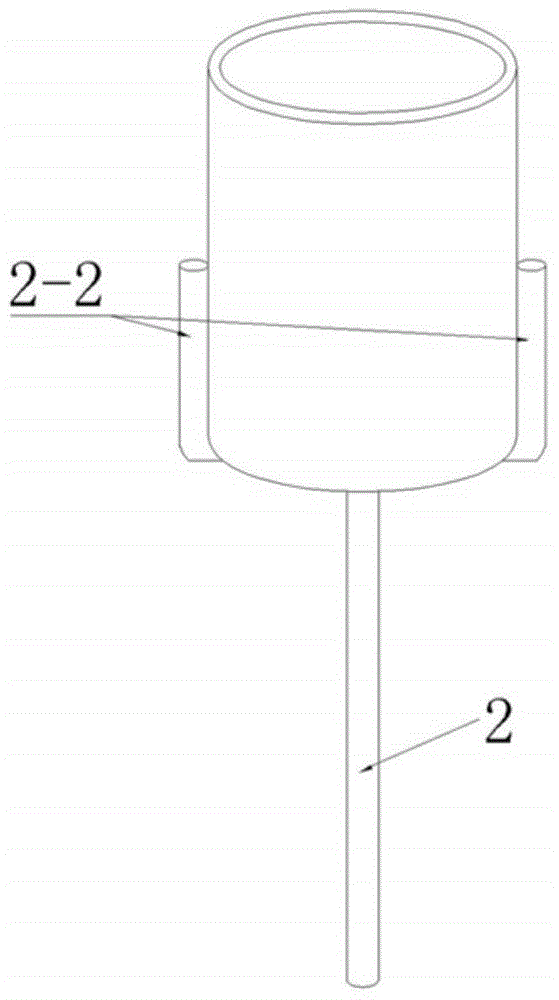

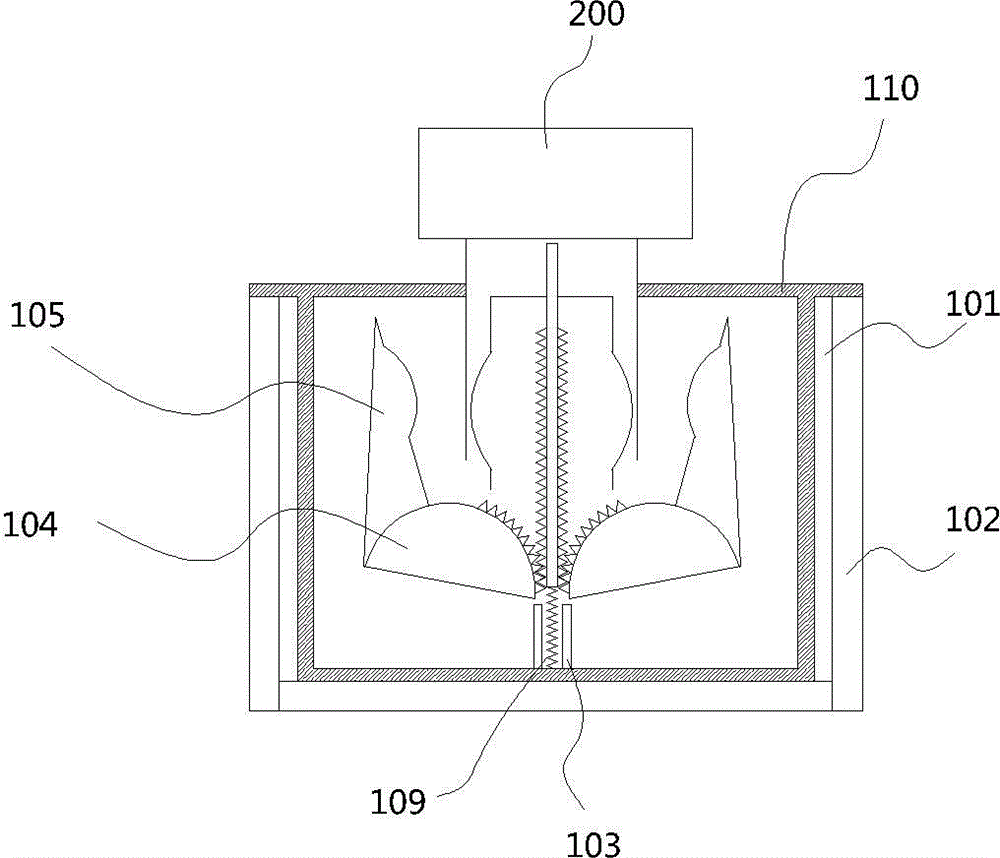

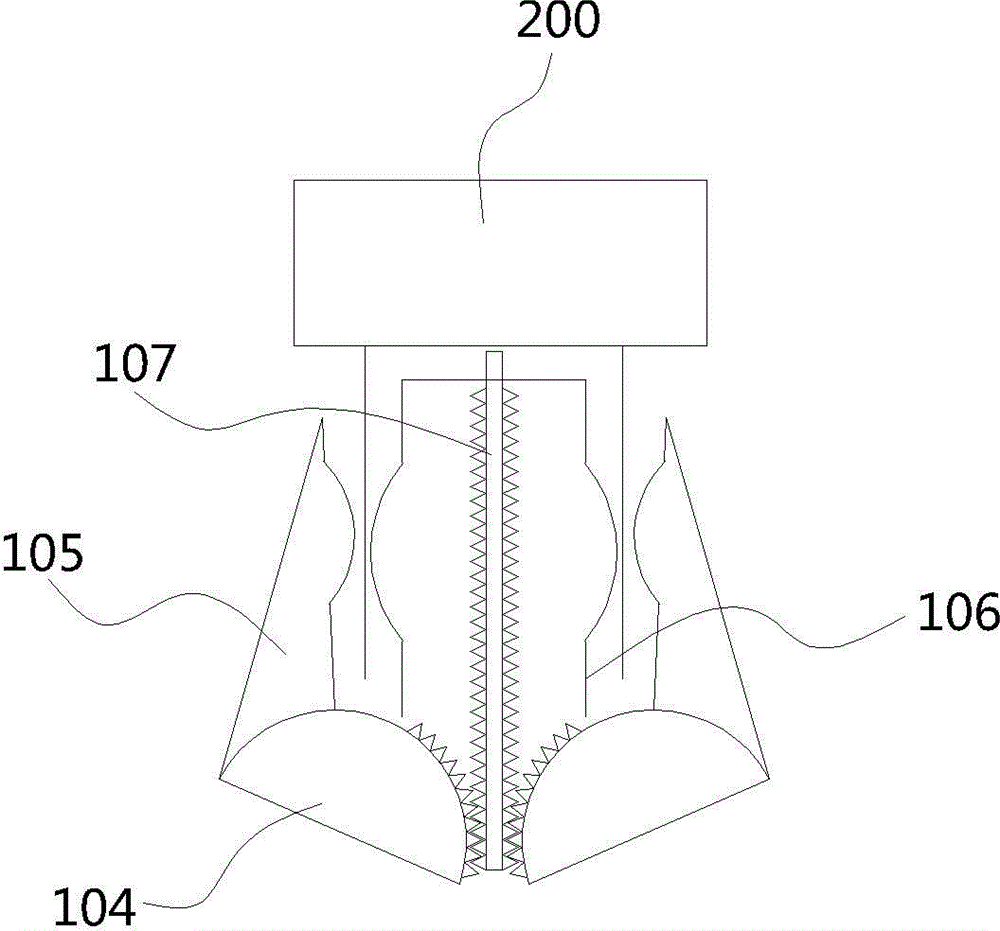

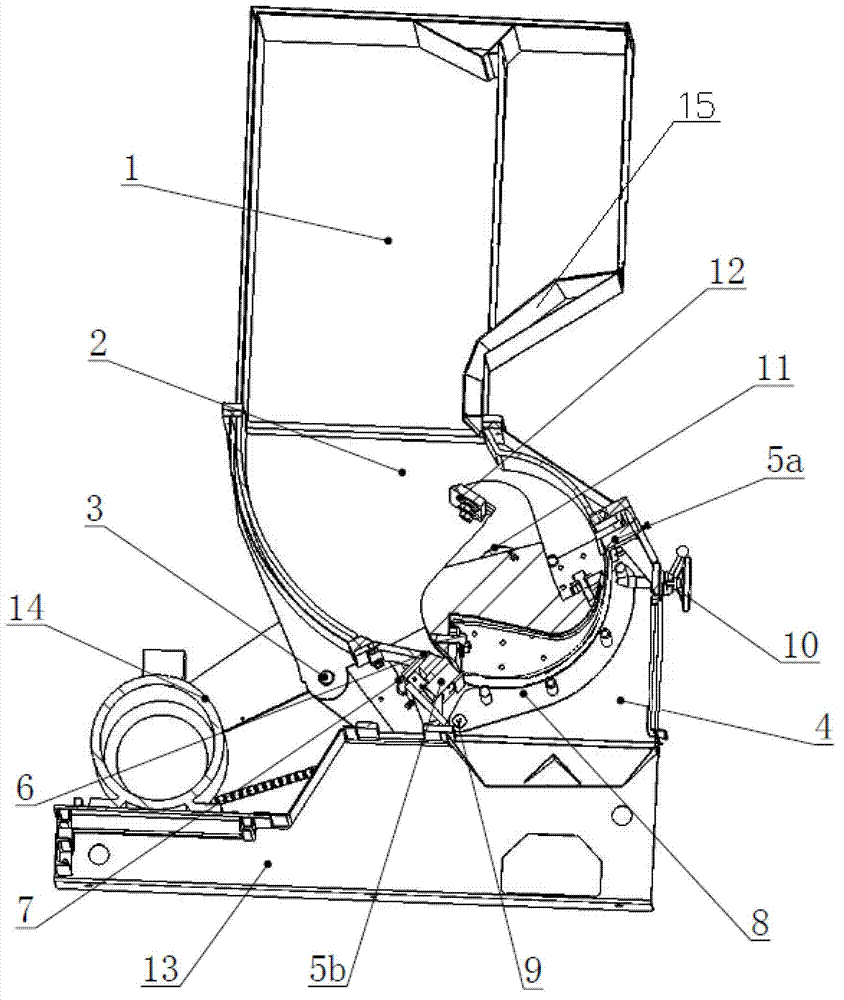

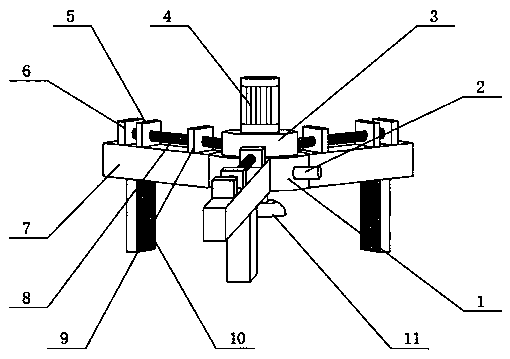

Plastic grinder

ActiveCN102814219BBig spaceIncrease the stress pointPlastic recyclingGrain treatmentsEngineeringPower transmission

The invention relates to a plastic grinder which comprises a feeding hopper installed on a grinding chamber upper body. The front end of the grinding chamber upper body is locked, and the back end of the grinding chamber upper body is in pin connection with a grinding chamber lower body through a rotating shaft. A front fixed cutter and a back fixed cutter are respectively installed at the cutter installation positions in front of and at the back of the grinding chamber lower body. A lower body inside insert is installed at the extending position on the lower portion of a back arc plate of the grinding chamber upper body, the lower body inside insert is in pin connection with the grinding chamber lower body through the rotating shaft and is locked, and a screen device is in pin connection with the grinding chamber lower body through a screen frame rotating shaft and is lifted in spiral mode through a locking rod to be bonded with the lower portion on the front installation cutter face of the grinding chamber lower body. A spindle rotor is installed in the middle of the grinding chamber lower body in suspension mode, a rotating movable cutter is installed on the spindle rotor, the grinding chamber lower body is fixed on a base frame, and a power transmission device is connected with the spindle rotor and can drive the spindle rotor to rotate. By means of the lower body inside insert, the plastic grinder can effectively expand grinding material storing area space, improves cutting material grabbing points, improves grinding efficiency and can grind large-diameter grinding products.

Owner:NINGBO HUARE MACHINERY MFG

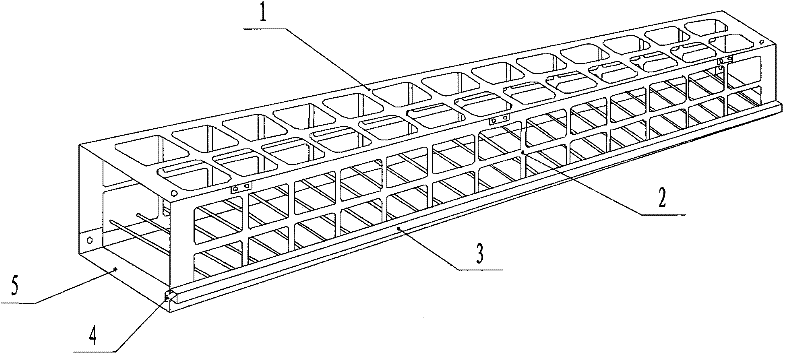

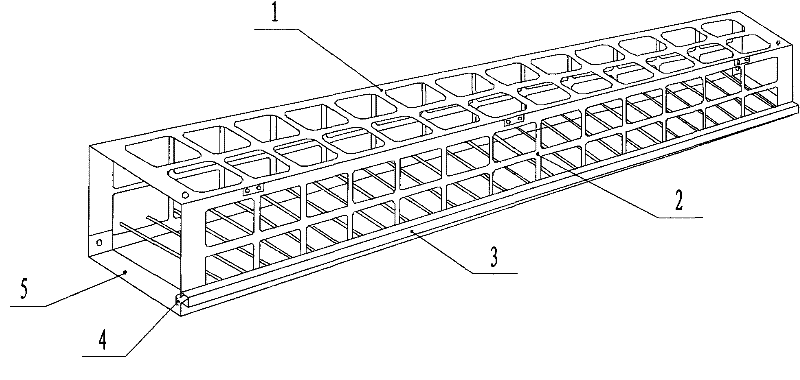

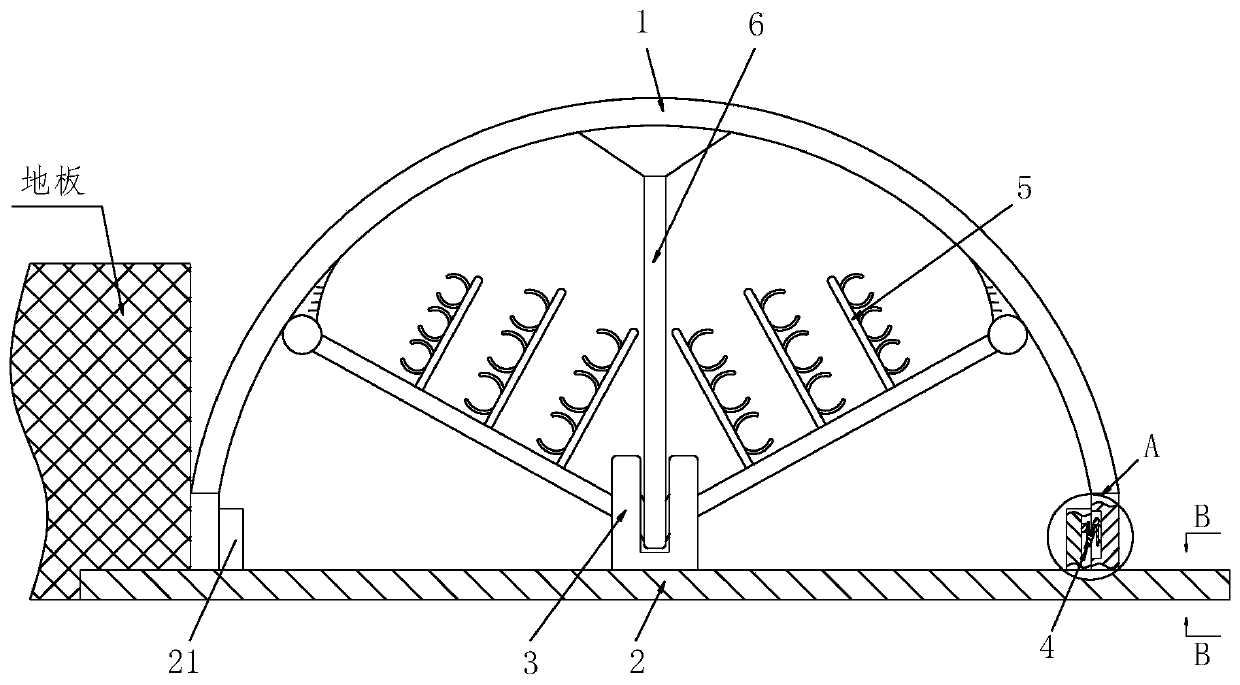

Fast cage type tobacco clamp for bulk curing barn

InactiveCN102228308AIncrease the stress pointUniform yellowingTobacco preparationEngineeringShort life

The invention provides a fast cage type tobacco clamp for a bulk curing barn. A technical scheme of the invention is as follows: a support frame is arranged on two ends of an L-shaped bracket, a movable cover is connected with the L-shaped bracket through a hinge such that the movable cover can rotate, the movable cover after folded is tightly clung on the support frame, contact pins are respectively lapped on lower edges of square holes of the L-shaped bracket and the movable cover after a tobacco fork is inserted, and the tobacco fork and the movable cover are stably clamped on the support frame by using a clip. According to the fast cage type tobacco clamp disclosed by the invention, the tobacco loading efficiency can be largely increased, links of roasting tobacco leaves and technical complexity can be reduced, the labor saving effect is remarkable, and tobacco growers can get rid of complex tobacco weaving links; in addition, the difficulties of poor roasting effect of the prior tobacco clamp and complex and short-life structure of the tobacco clamp are solved at the same time; and when the fast cage type tobacco clamp is matched with a bulk curing barn for use, the volume and the roasting capability of the bulk curing barn can be increased on the premise of ensuring the roasting quality, which is very important to expanding planting scale of each family and factory and professional roasting.

Owner:中国烟草总公司广西壮族自治区公司

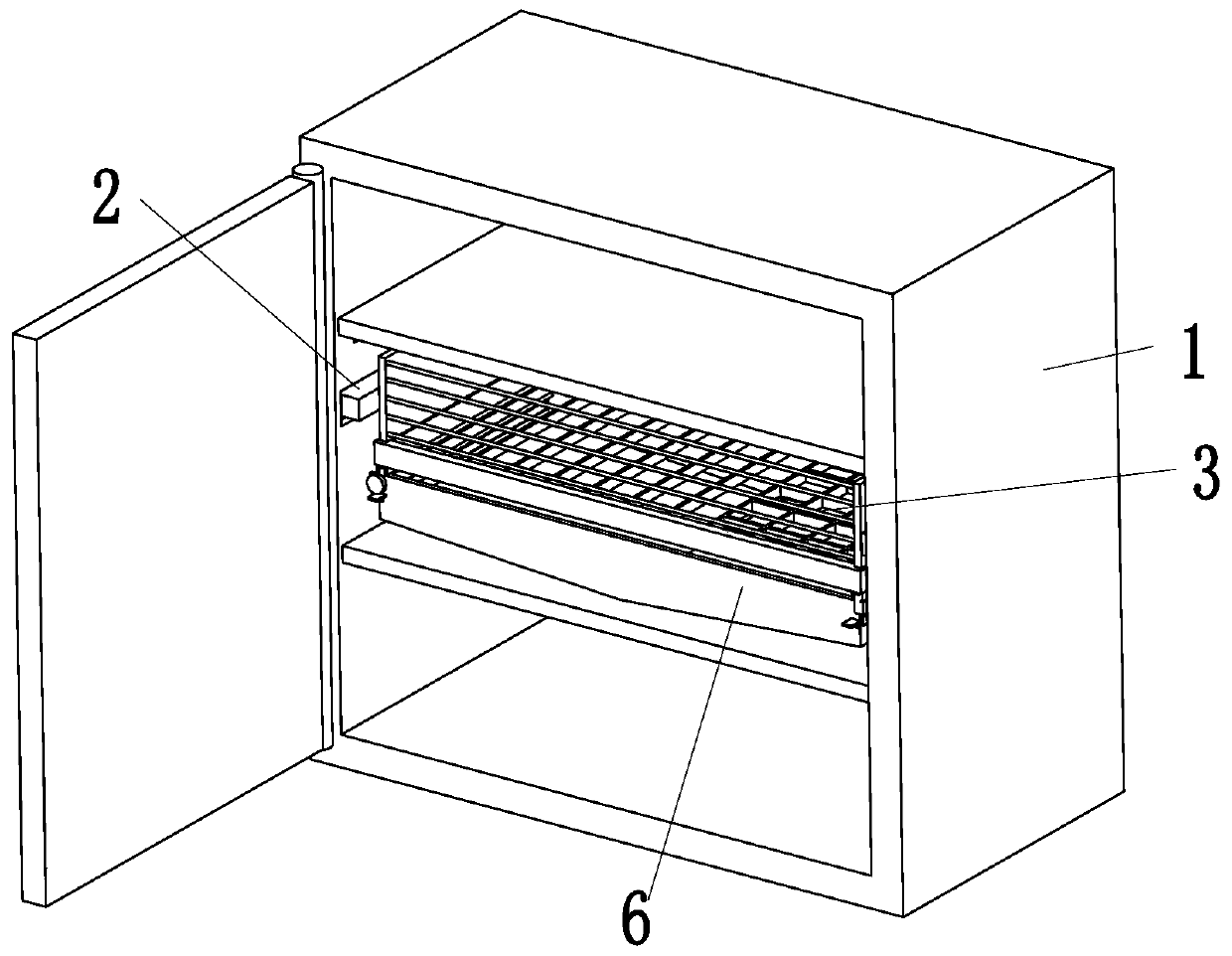

Intelligent cabinet

ActiveCN110169664APrevent deformationAvoid dripping onto the inner bulkheadFurniture partsKitchen cabinetsEngineeringMechanical engineering

Owner:广东亿科不锈钢制品有限公司

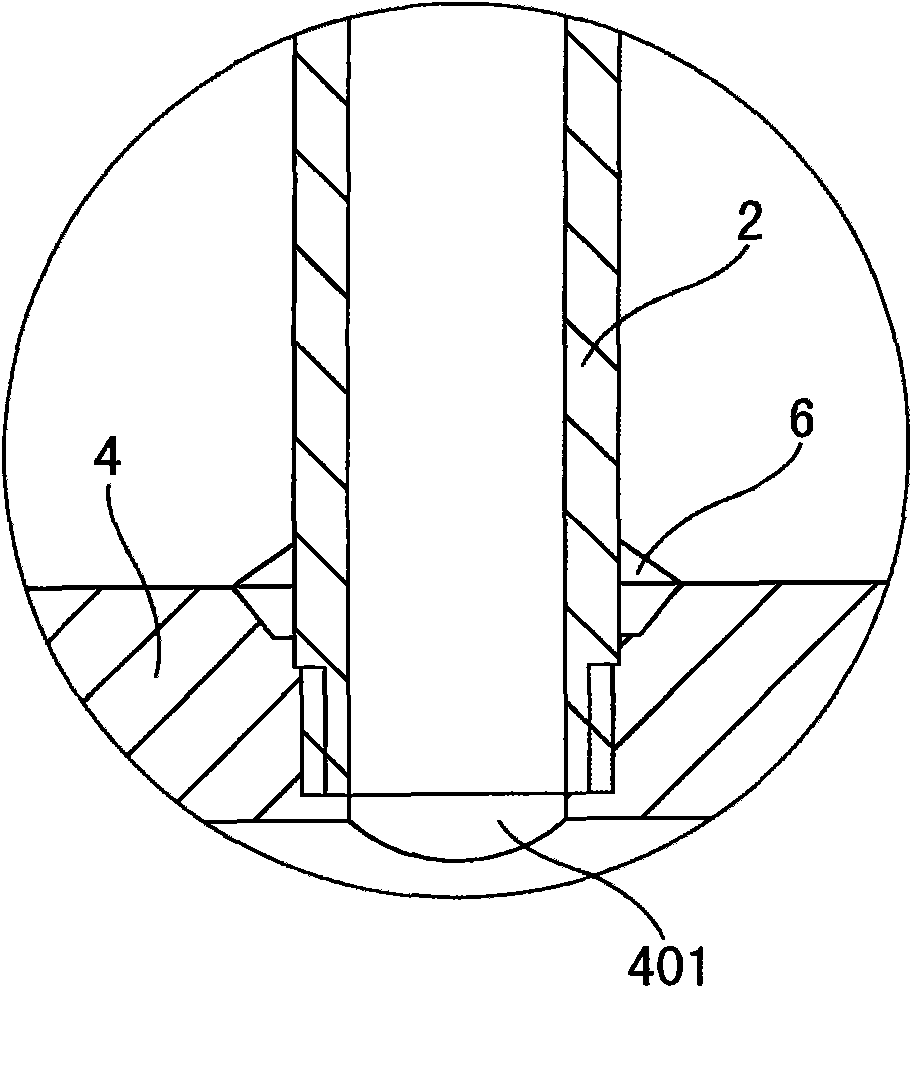

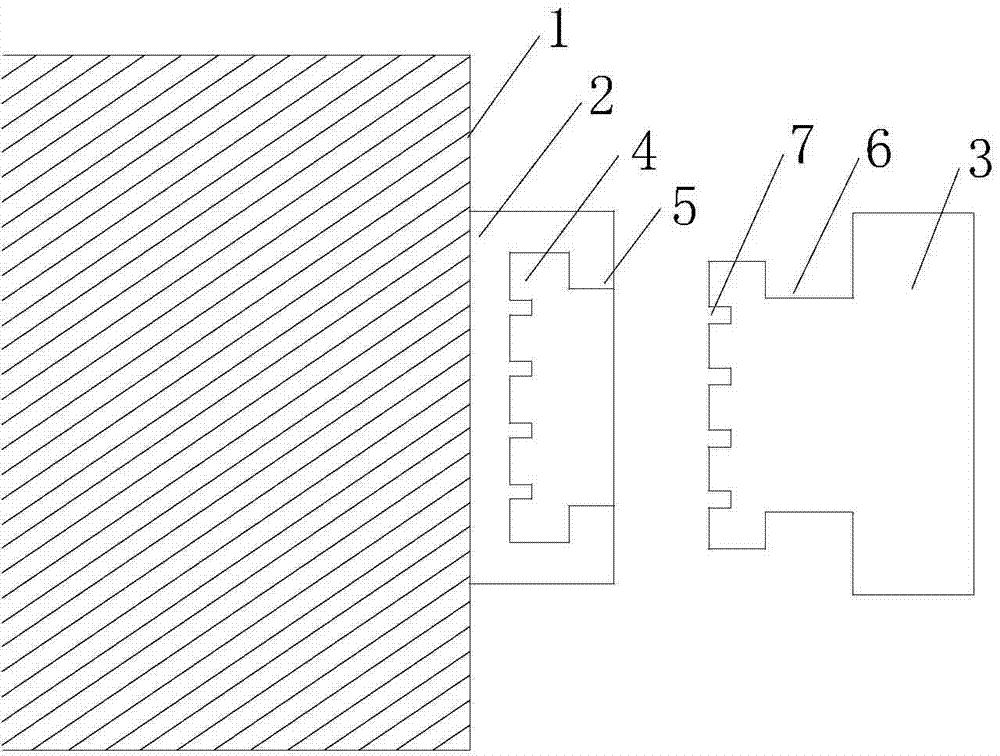

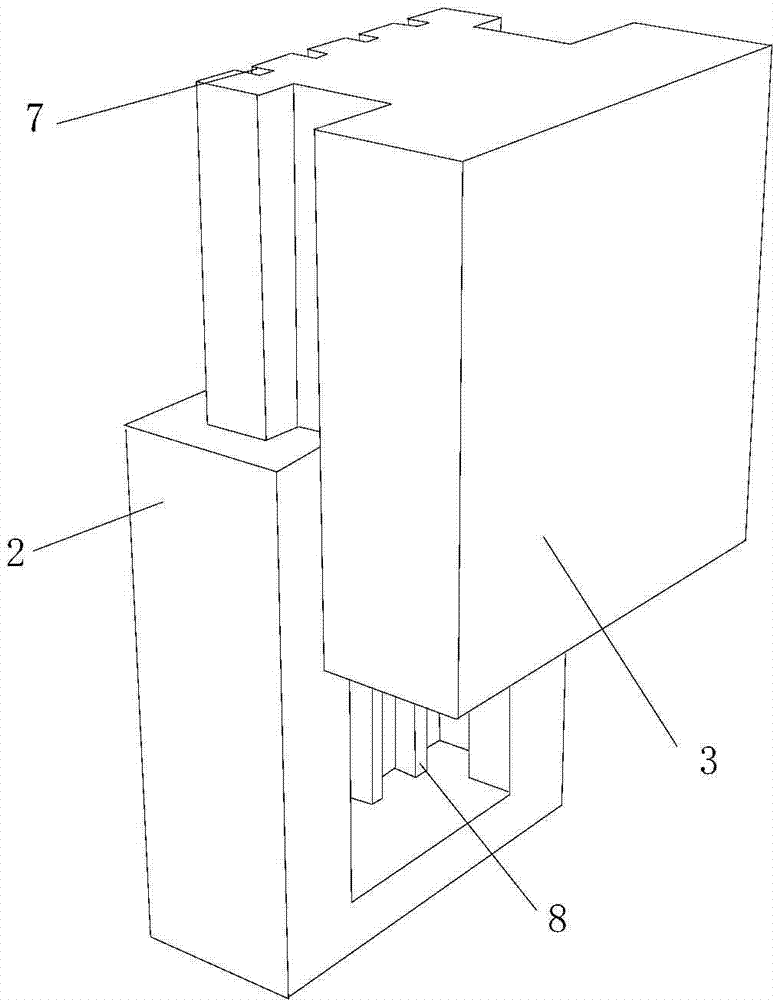

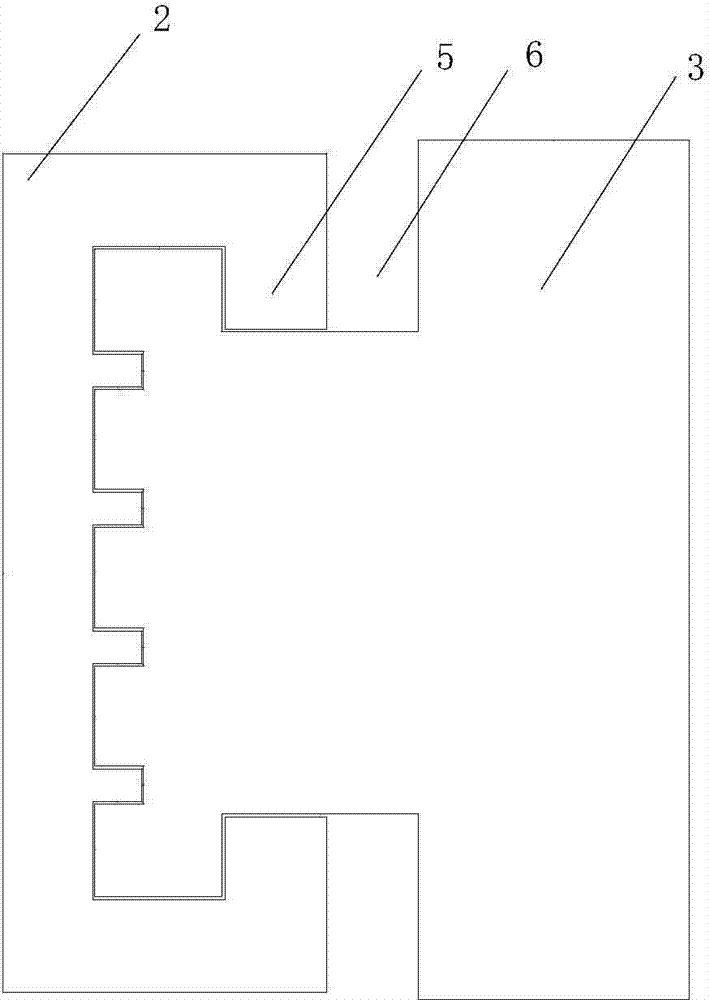

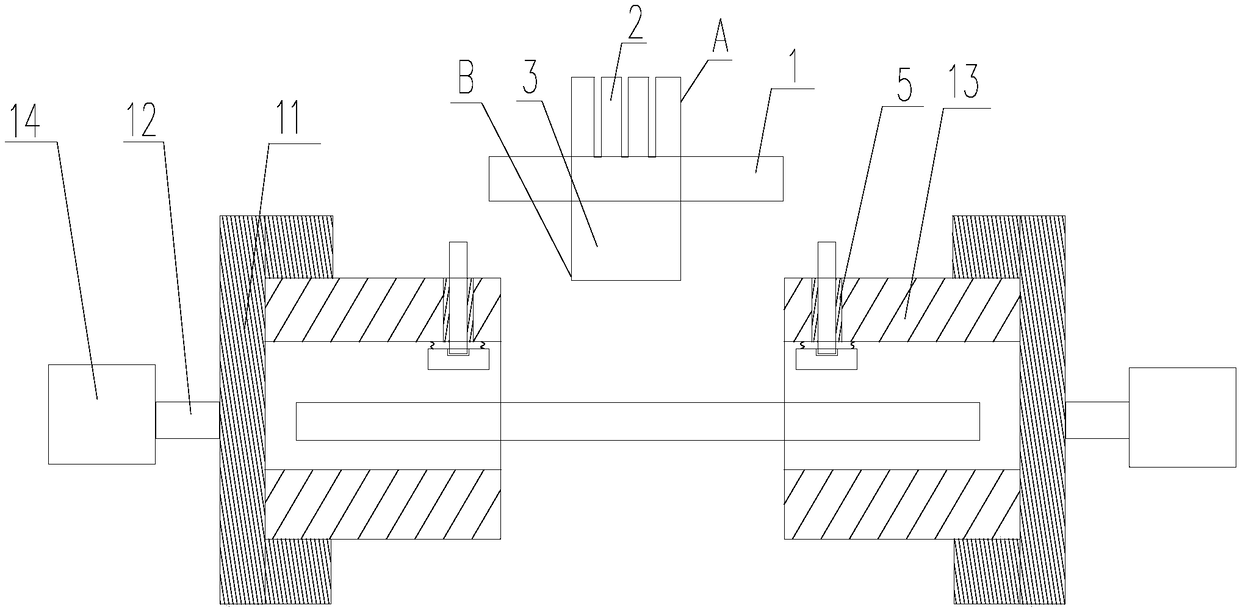

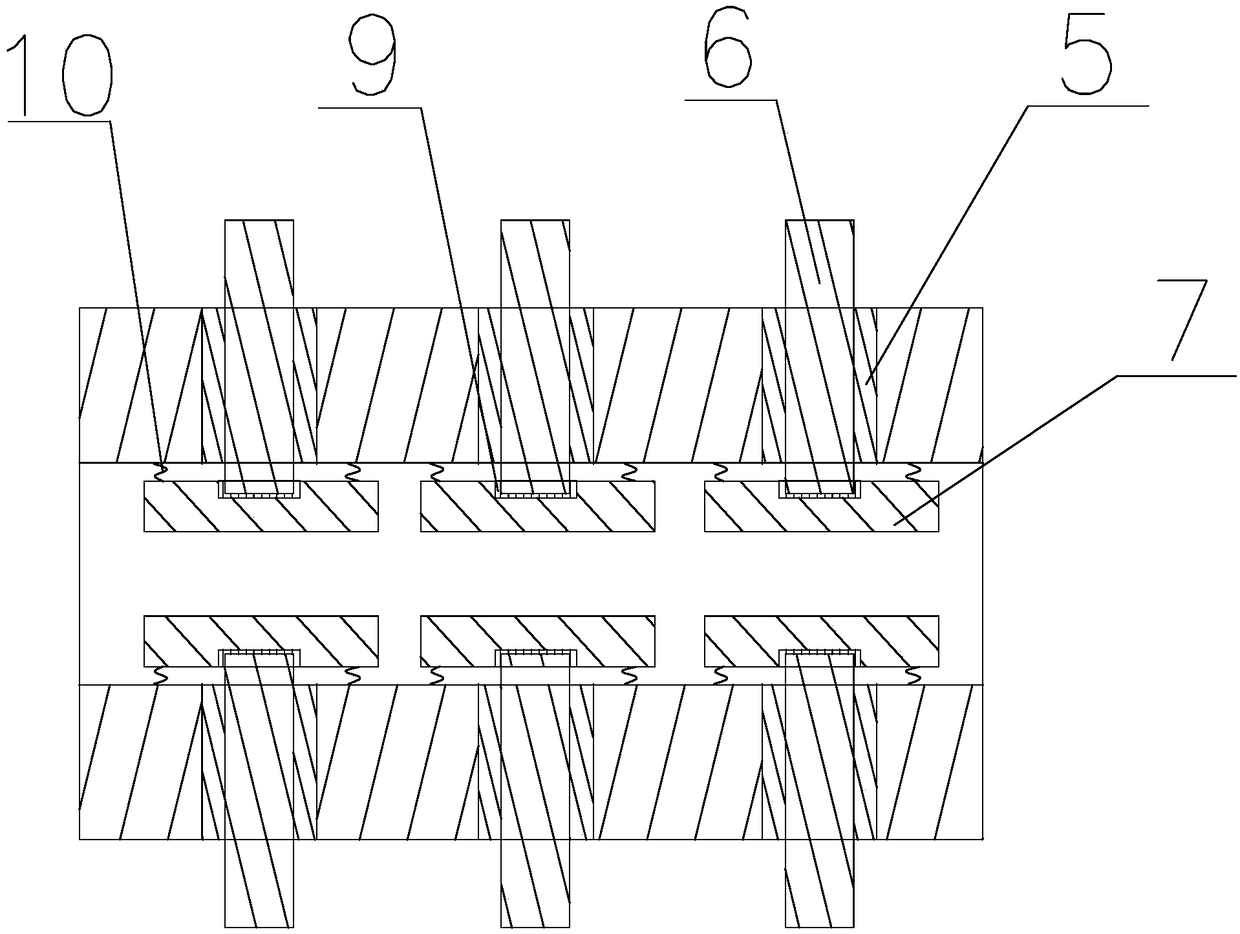

Integral type rolling machine axial adjusting device

InactiveCN102764768AEasy to fixIncrease contact areaMetal rolling stand detailsMetal rolling arrangementsAxial pressureEngineering

The invention provides an integral type rolling machine axial adjusting device, comprising a rolling machine upright (1), a roller bearing block (3), multiple cup head bolts (4) which are inserted into a through hole (5) of the rolling machine upright (1), an integral type axial pressure plate (6) used for fixing and adjusting the roller bearing block (3) and multiple flat hole slots (7) which are formed on the integral type axial pressure plate (6), wherein the integral type axial pressure plate (6) is sheathed on the multiple cup head bolts (4) which penetrate through the through hole (5) of the rolling machine upright by virtue of multiple flat hole slots (7), the multiple cup head bolts (4) are respectively added with half cylindrical pads (8), and the half cylindrical pads are respectively fastened and located by virtue of nuts (9).

Owner:LAIWU IRON & STEEL GRP

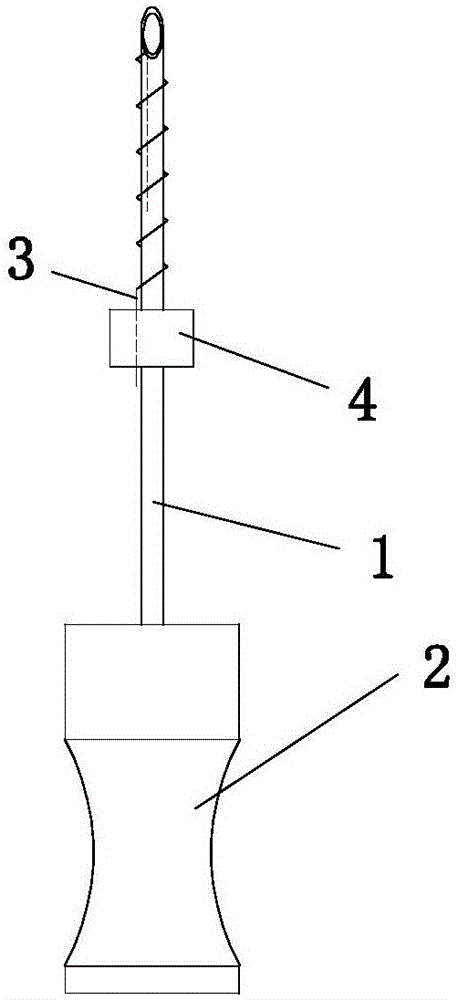

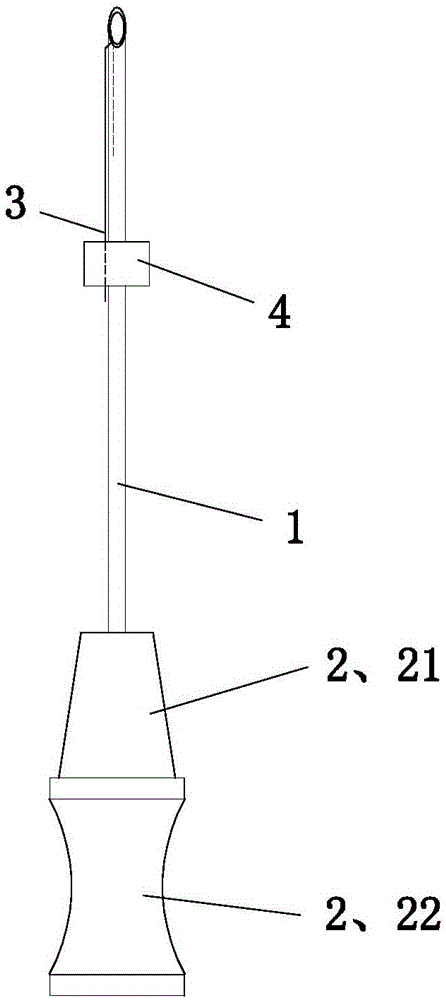

Novel acupoint catgut embedding needle instrument

The invention discloses a novel acupoint catgut embedding needle instrument. The novel acupoint catgut embedding needle instrument consists of a puncture needle tube, a needle tube seat, an embedding catgut and a positioning block, wherein the tail portion of the puncture needle tube is installed in the needle tube seat, a part of the embedding catgut is arranged in the puncture needle tube, the other part of the embedding catgut is arranged outside the puncture needle tube through the positioning block, the portion, located outside the puncture needle tube, of the embedding catgut is spirally wound outside the puncture needle tube, and the length of the portion, located outside the puncture needle tube, of the embedding catgut is 50%-80% of the total length of the embedding catgut. The novel acupoint catgut embedding needle instrument directly performs catgut embedding through the puncture needle tube without a needle core and is simple in structure and more convenient to operate, especially the portion located outside the puncture needle tube is spirally wound outside the puncture needle tube, and the length of the embedding catgut outside the puncture needle tube is greater than that of the embedding catgut in the puncture needle tube through arrangement, so that the catgut embedding effect is obviously improved, especially in the cosmetic fields of facial reshaping, rhytidectomy and the like.

Owner:蔡会萍

High-strength rare earth molybdenum tube cold cathode and manufacturing process thereof

InactiveCN104091740AIncrease the stress pointNo sheddingDischarge tube cold cathodesCold cathode manufactureRare earthCold cathode

The invention discloses a high-strength rare earth molybdenum tube cold cathode and a manufacturing process thereof. The high-strength rare earth molybdenum tube cold cathode is characterized by comprising a rare earth molybdenum tube and a molybdenum wire, wherein the molybdenum wire is welded on the side portion of the molybdenum tube. The high-strength rare earth molybdenum tube cold cathode is simple in structure, convenient to manufacture and stable in performance and saves the cost.

Owner:佛山宁宇科技股份有限公司

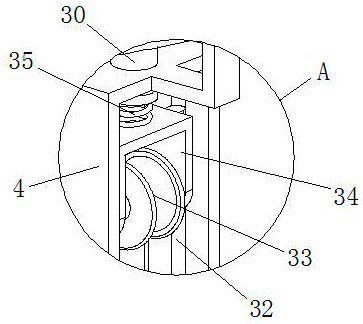

Cassette clamping socket

InactiveCN105449473AIncrease the stress pointEasy to installCoupling parts mountingEngineeringCopper

The invention discloses a cassette clamping socket which comprises a cassette body and a socket embedded in the cassette body. The cassette clamping socket is characterized in that a trapezoidal slope internally provided with a through hole is arranged on the inner side wall of the cassette body; a spring is arranged at the center of the socket; a drive rod surrounded by a tooth-shaped structure is arranged above the spring; pressing plates are arranged on both sides of the bottom; clamping pieces are mounted on both sides of the pressing plates; and copper pieces are mounted on both sides of the drive rod. The cassette clamping socket provided by the invention has the advantages of simple structure, prolonged service life and the like, and has broad market prospects.

Owner:SUQIAN SANYI BAISHI COMMERCE & TRADE CO LTD

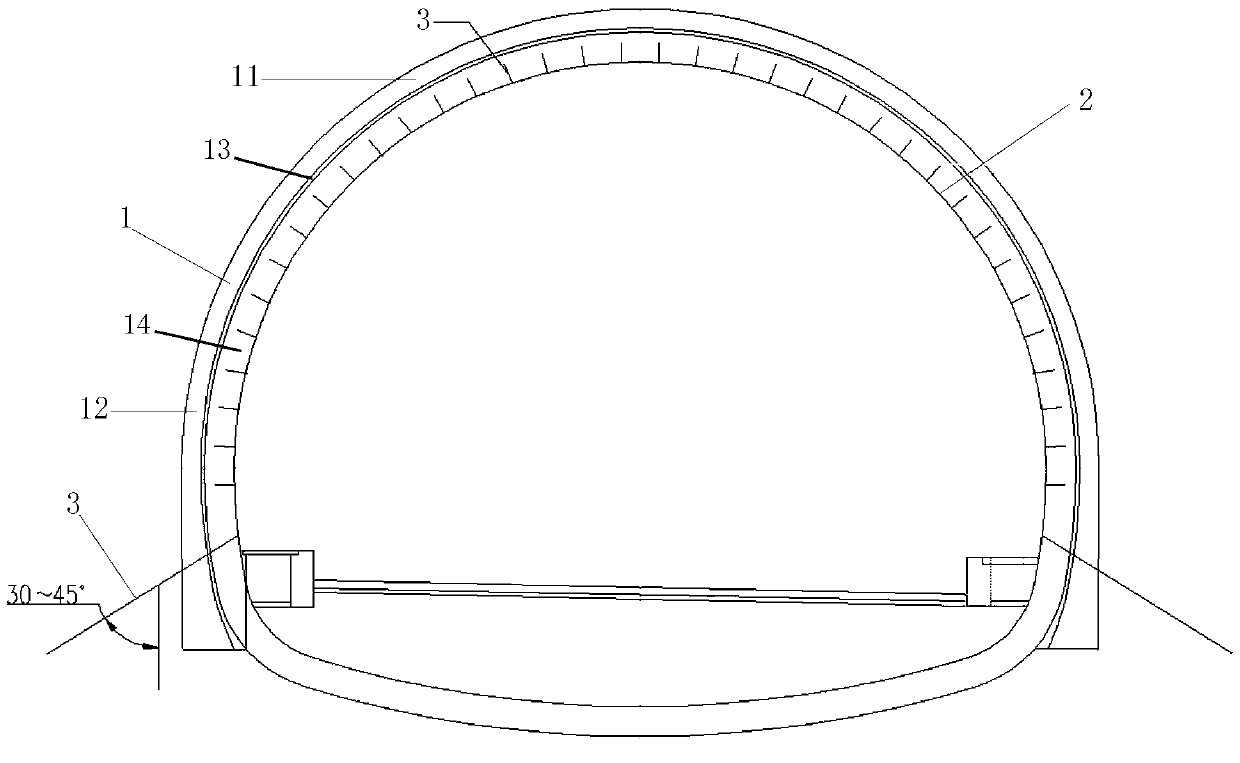

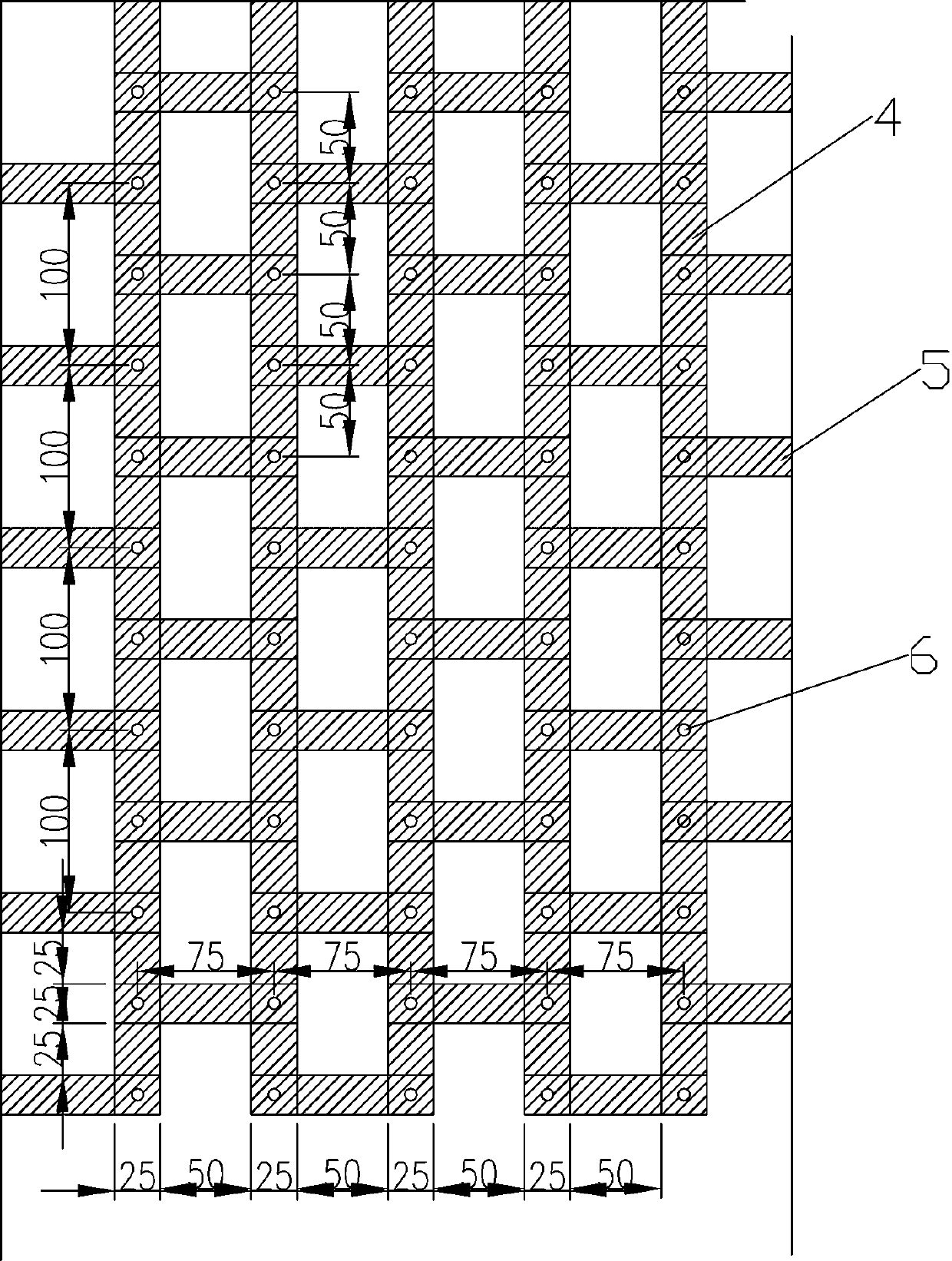

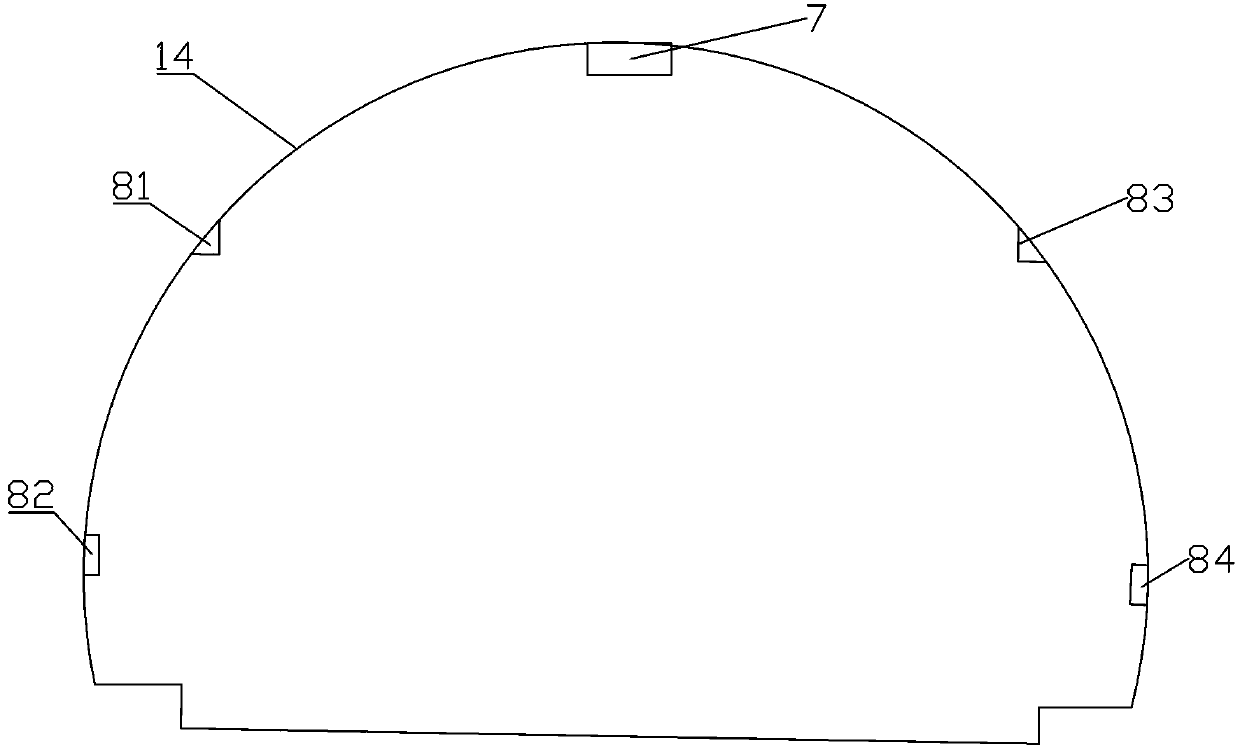

Tunnel lining steel belt reinforcing structure and construction method

ActiveCN110685722AIncrease the stress pointStrong tunnel lining structureUnderground chambersTunnel liningSteel beltRock bolt

The invention discloses a tunnel lining steel belt reinforcing structure and a construction method. The technical problems that an existing steel belt reinforcing method is not reliable enough, and construction is not convenient are solved. The reinforcing structure comprises annular steel belts, longitudinal steel belts and feet-lock bolts, the annular steel belts are intermittently arranged in the longitudinal direction of a tunnel and separately fixed to the outer wall of a lining, the longitudinal steel belts are distributed intermittently in the annular direction of the tunnel and fixed to the adjacent annular steel belts, the longitudinal steel belts at the two sides of the same annular steel belt are distributed alternately, and the feet-lock bolts are arranged on the feet of wallsat the two sides of the annular steel belts and anchored to the lining. The construction method comprises the following steps of performing surveying, setting-out and positioning; cleaning the surfaceof the lining; installing the annular steel belts and the longitudinal steel belts; arranging the feet-lock bolts at the feet of the walls at the two sides of the annular steel belts and anchored tothe annular steel belts and the lining. The longitudinal steel belts and the annular steel belts are distributed alternately, the tunnel lining structure is firmer, feet-lock bolts are only arranged at the corners at the two sides of the annular steel belts, and construction is easier.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Plastic grinder

ActiveCN102814219ABig spaceIncrease the stress pointPlastic recyclingGrain treatmentsEngineeringPower transmission

The invention relates to a plastic grinder which comprises a feeding hopper installed on a grinding chamber upper body. The front end of the grinding chamber upper body is locked, and the back end of the grinding chamber upper body is in pin connection with a grinding chamber lower body through a rotating shaft. A front fixed cutter and a back fixed cutter are respectively installed at the cutter installation positions in front of and at the back of the grinding chamber lower body. A lower body inside insert is installed at the extending position on the lower portion of a back arc plate of the grinding chamber upper body, the lower body inside insert is in pin connection with the grinding chamber lower body through the rotating shaft and is locked, and a screen device is in pin connection with the grinding chamber lower body through a screen frame rotating shaft and is lifted in spiral mode through a locking rod to be bonded with the lower portion on the front installation cutter face of the grinding chamber lower body. A spindle rotor is installed in the middle of the grinding chamber lower body in suspension mode, a rotating movable cutter is installed on the spindle rotor, the grinding chamber lower body is fixed on a base frame, and a power transmission device is connected with the spindle rotor and can drive the spindle rotor to rotate. By means of the lower body inside insert, the plastic grinder can effectively expand grinding material storing area space, improves cutting material grabbing points, improves grinding efficiency and can grind large-diameter grinding products.

Owner:NINGBO HUARE MACHINERY MFG

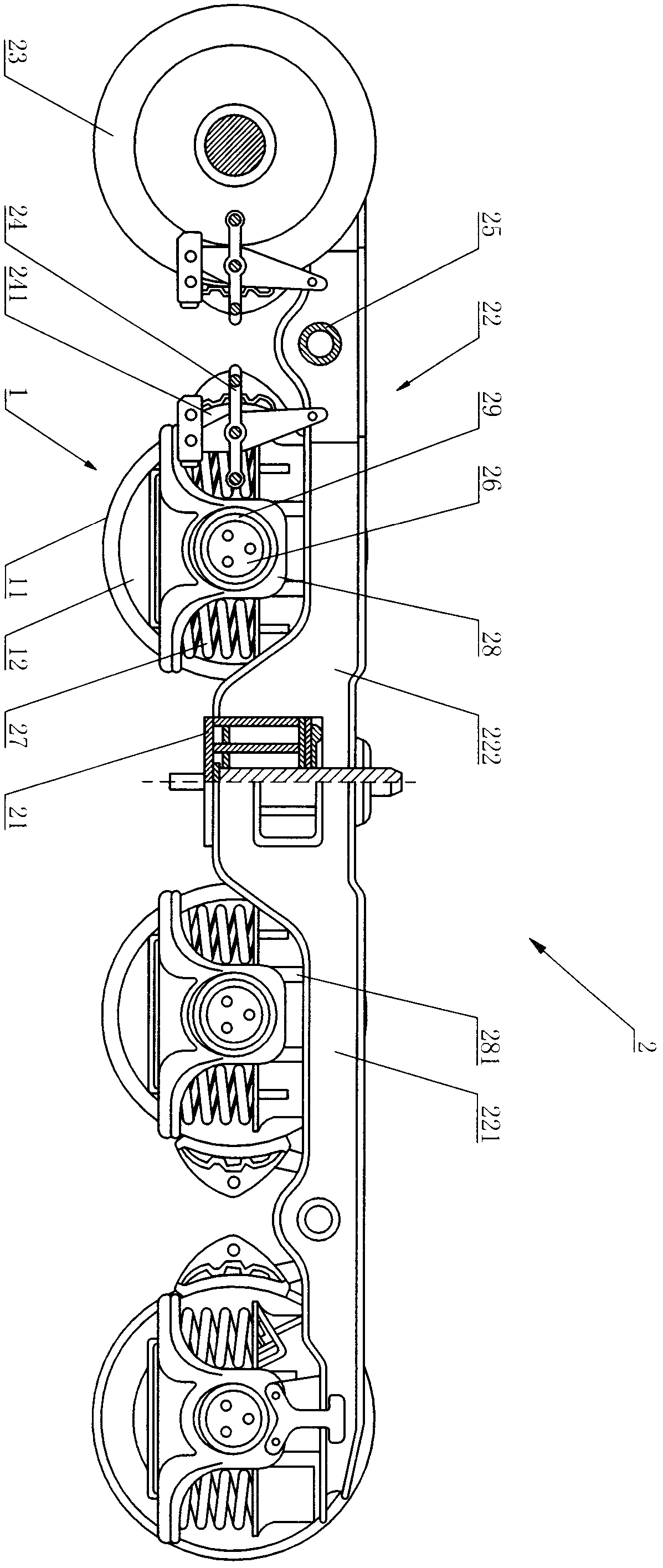

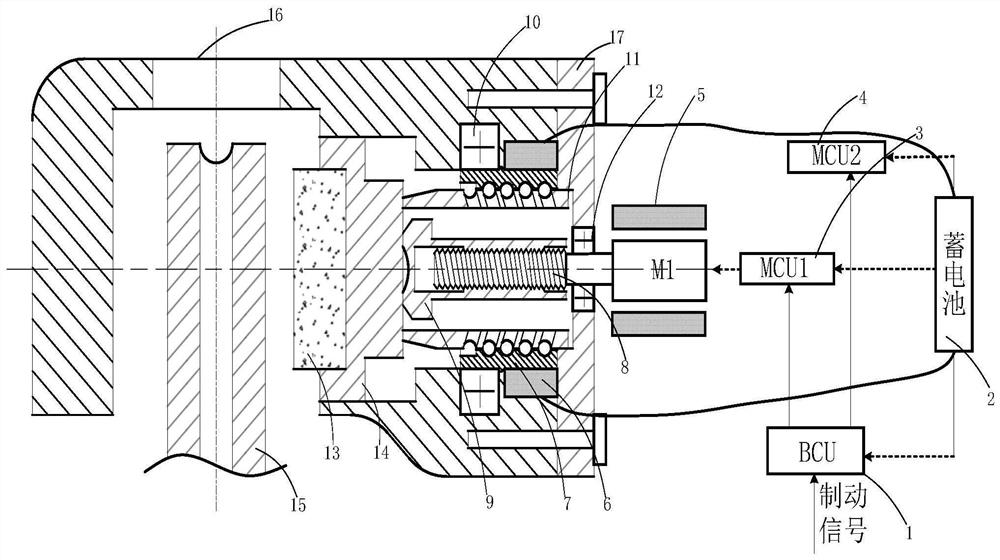

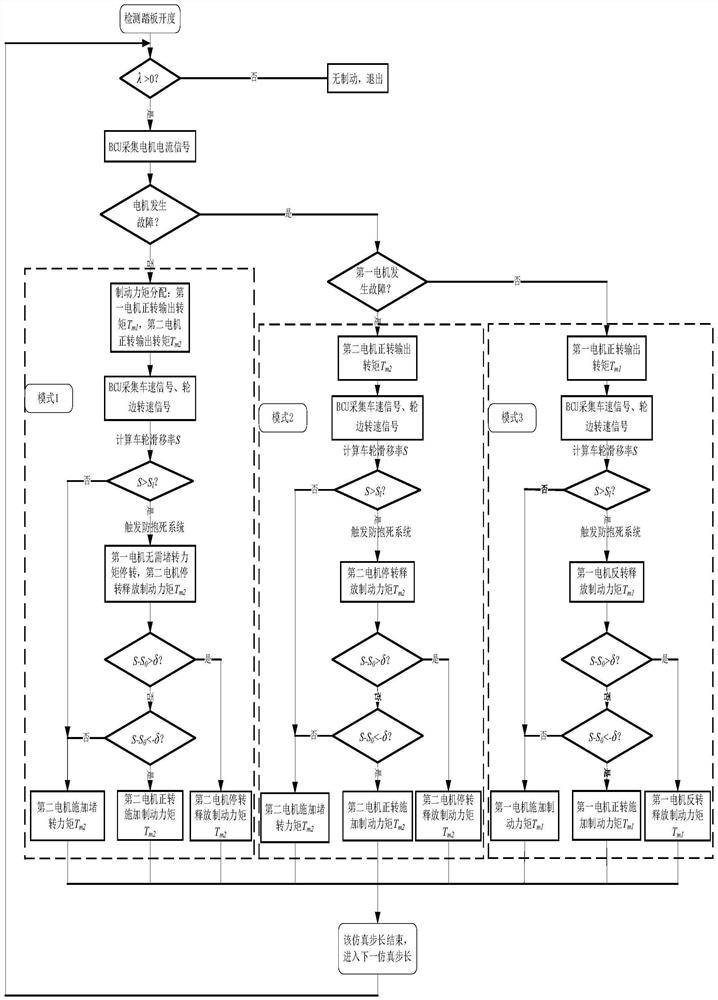

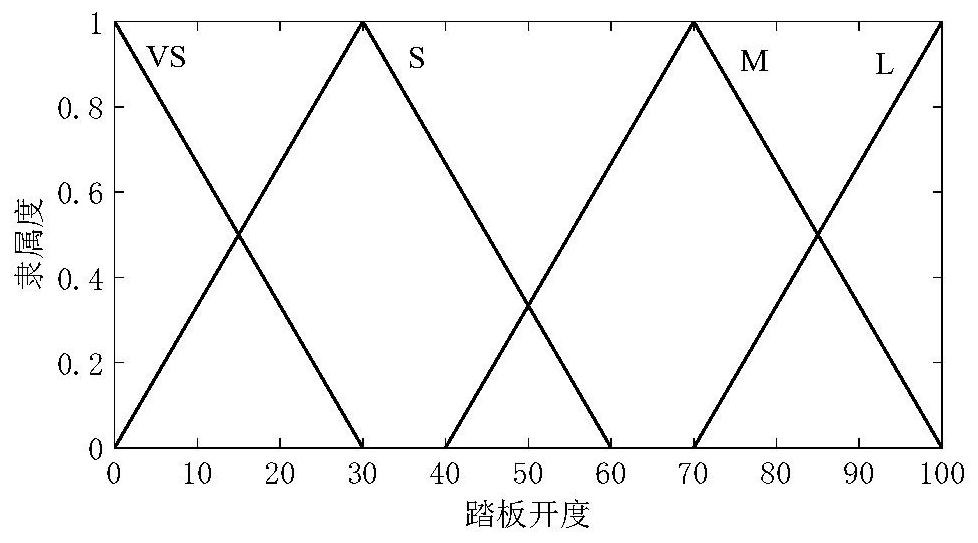

High-stability EMB brake-by-wire system suitable for ABS and control method of high-stability EMB brake-by-wire system

ActiveCN112550256AAchieve reliabilityImprove reliabilityBraking action transmissionBrake torqueBall screw

The invention provides a high-stability EMB brake-by-wire system suitable for an ABS and a control method of the high-stability EMB brake-by-wire system, and belongs to the technical field of automobile braking. The brake-by-wire system comprises an electronic control unit and a brake unit. The electronic control unit comprises a BCU, a first motor controller and a second motor controller. The brake unit comprises a first motor, a second motor, a threaded screw transmission part, a ball screw transmission part, a friction plate and a brake disc, the first motor is arranged on the outer side ofthe brake shell, and the second motor is arranged in the brake shell. A dual-motor structure is adopted, and dual-motor redundancy is achieved on the premise that brake-by-wire is achieved; during ABS anti-lock, the characteristics of self-locking of the threaded screw transmission part and non-self-locking of the ball screw transmission part are utilized, so that the first motor does not need locked-rotor braking torque, the second motor does not need to rotate reversely to release braking torque, the anti-lock purpose is achieved, the service life of the motor is prolonged, and braking is more stable.

Owner:JIANGSU UNIV

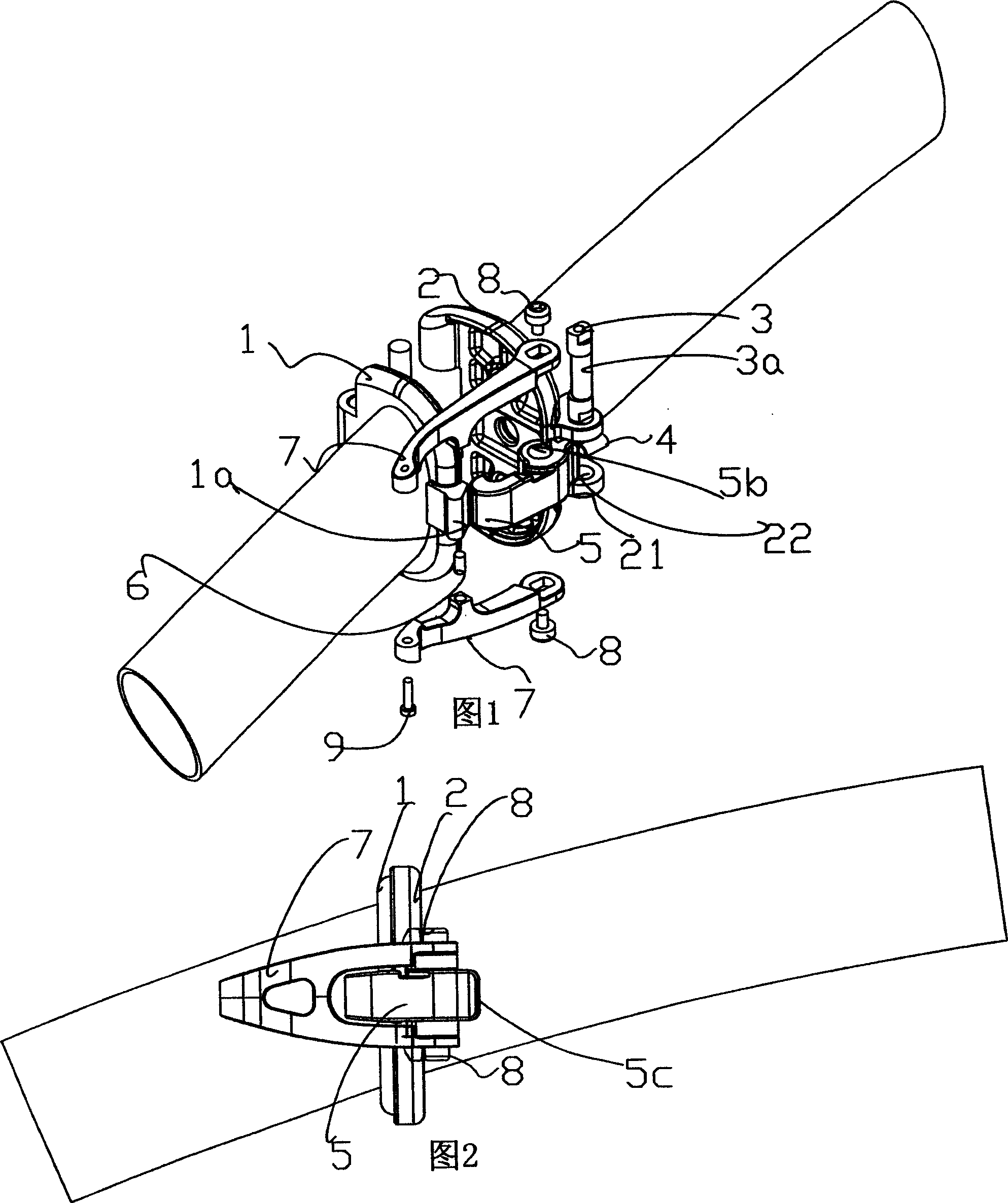

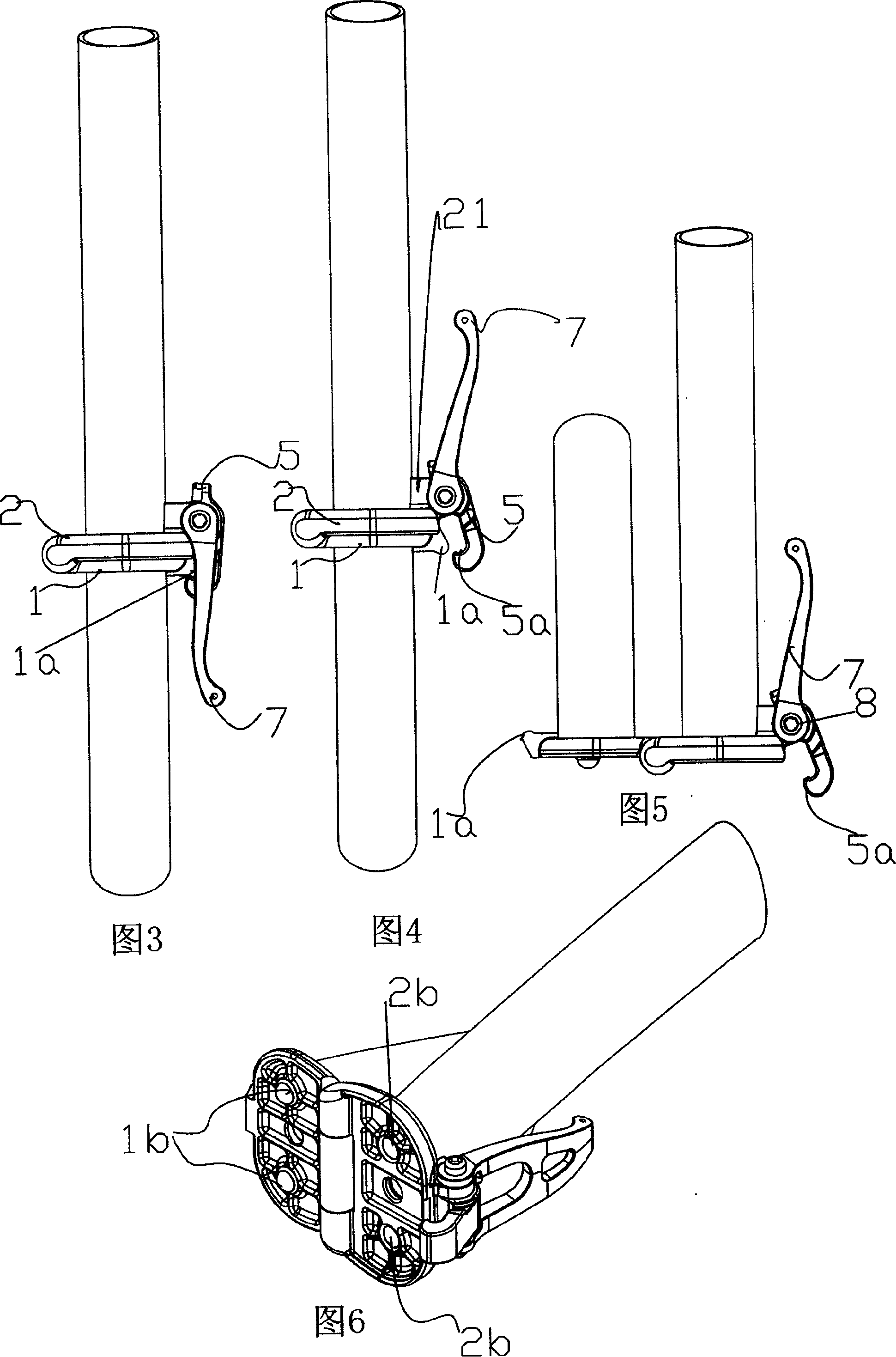

Folding joint

InactiveCN1915736AIncrease the stress pointSimple and beautiful appearanceFoldable cyclesEngineeringScrew thread

A foldable jointer is composed of the hinge linked bottom plate with two lugs and a locking hook between the holes of two lugs and cover plate with a boss between said two lug, an eccentric rotary axle with drive mechanisms and screw bolts at its both ends, and the fixing rod and fixing screw bolt at the tail of said drive mechanism.

Owner:魏文士 +2

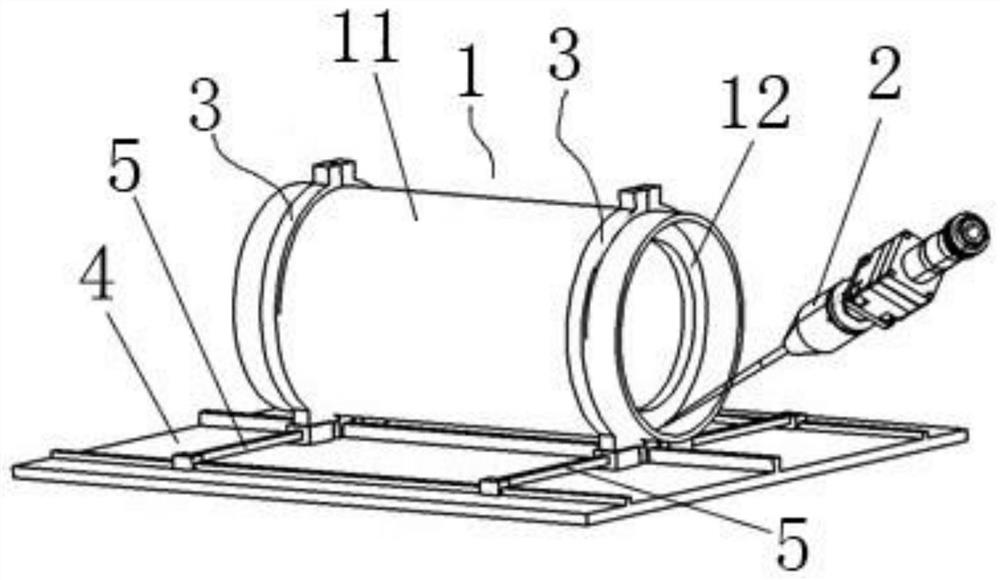

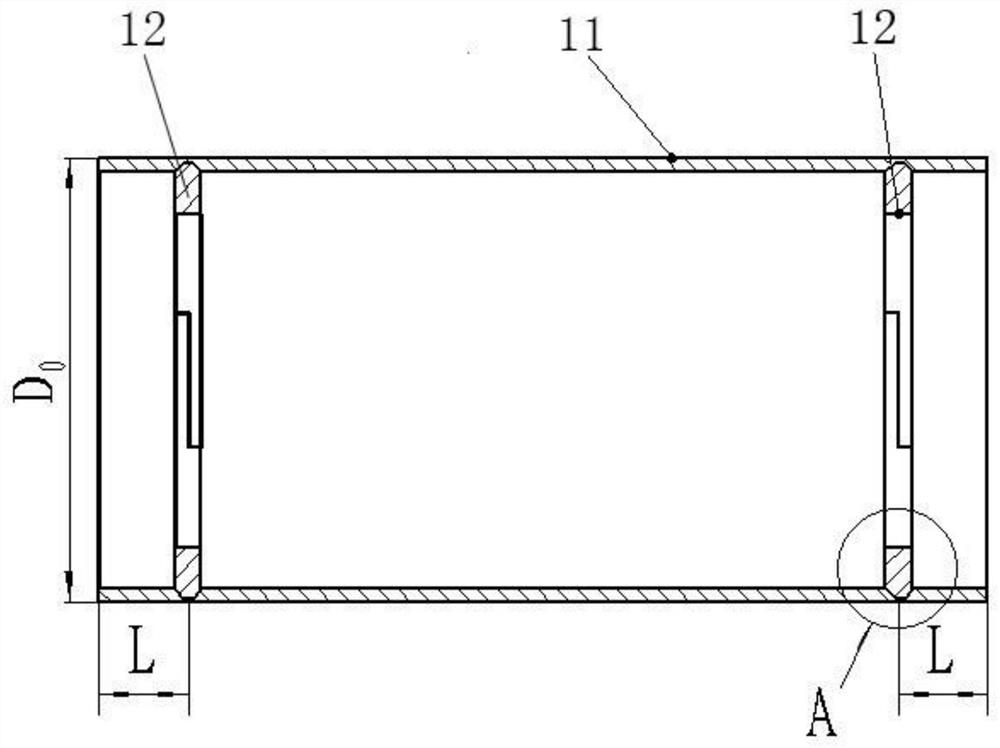

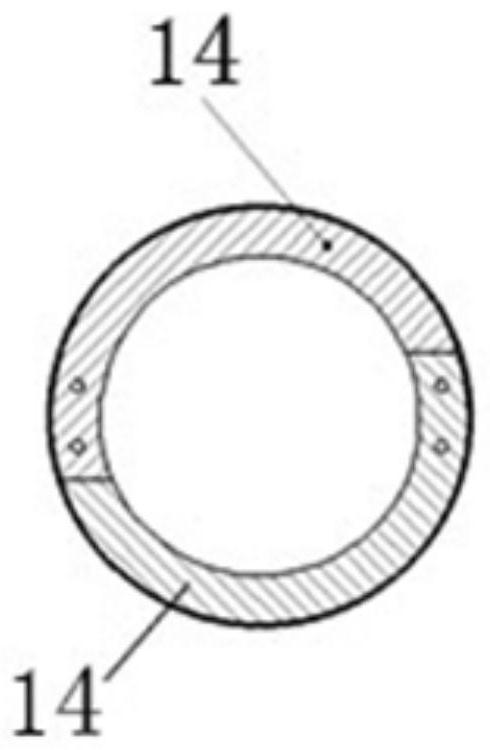

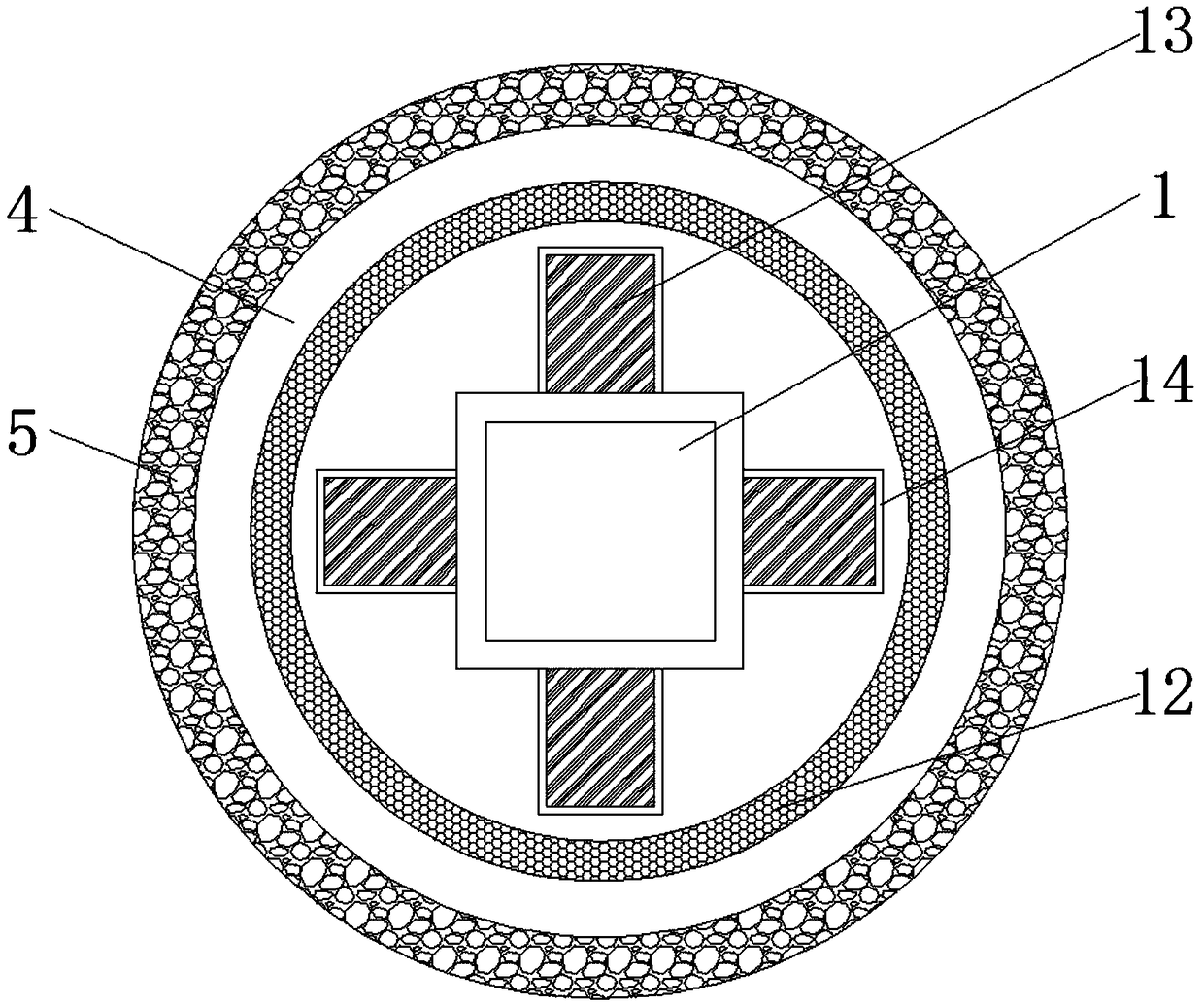

Cylindrical plastic casing with wide ribs arranged inside and welding method of cylindrical plastic casing

InactiveCN111805915AIncrease the stress pointEliminates the need for transparencyDomestic articlesThermal dilatationStructural engineering

The invention discloses a cylindrical plastic casing with wide ribs arranged inside. The cylindrical plastic casing comprises a plastic casing body, a shape controlling mechanism and a laser device; the plastic casing body comprises a hollow cylinder, at least one wide rib and at least one groove formed in the inner wall of the cylinder; the edge of the at least one wide rib is placed inside the at least one groove; the shape controlling mechanism comprises at least one shape controlling sleeve piece; the periphery of the cylinder is sleeved with the at least one shape controlling sleeve piece; and the at least one shape controlling sleeve piece corresponds to the at least one wide rib. The invention further discloses a welding method of the cylindrical plastic casing with the wide ribs arranged inside. According to the cylindrical plastic casing and the welding method, the force bearing points of the cylinder in the axial direction are increased by the aid of the wide ribs, so that the possibility is created for increasing component or structure characteristics inside the cylinder; the requirement for the light transmittance of the cylinder material is eliminated, and deformationof the surface of the cylinder due to input heat during welding is reduced; fixture-free welding of the wide ribs can be realized; and the gaps between trapezoidal bulges and the grooves can store overflows formed by thermal expansion of the material during welding, so that deformation of the cylinder can be avoided.

Owner:SUZHOU UNIV

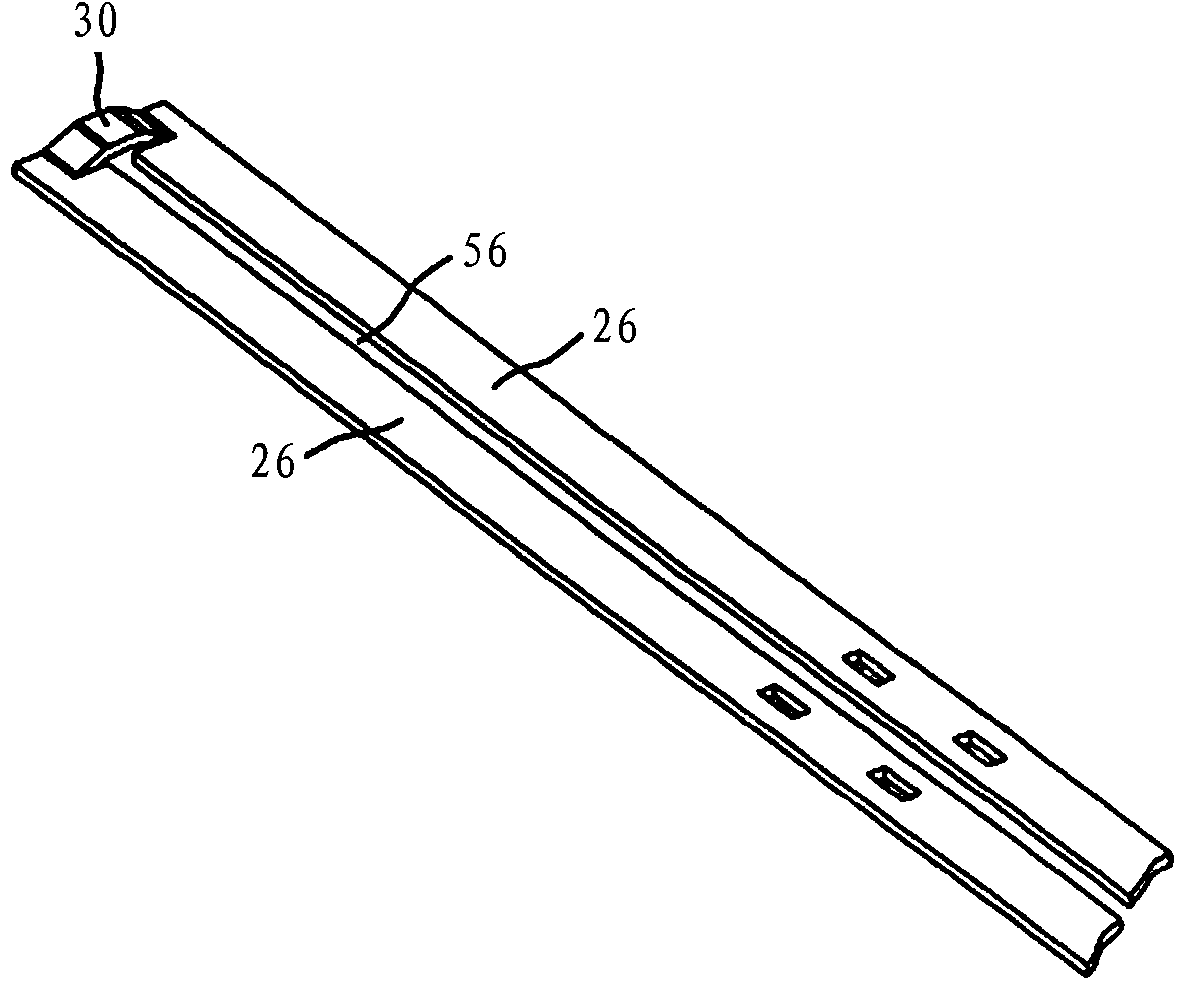

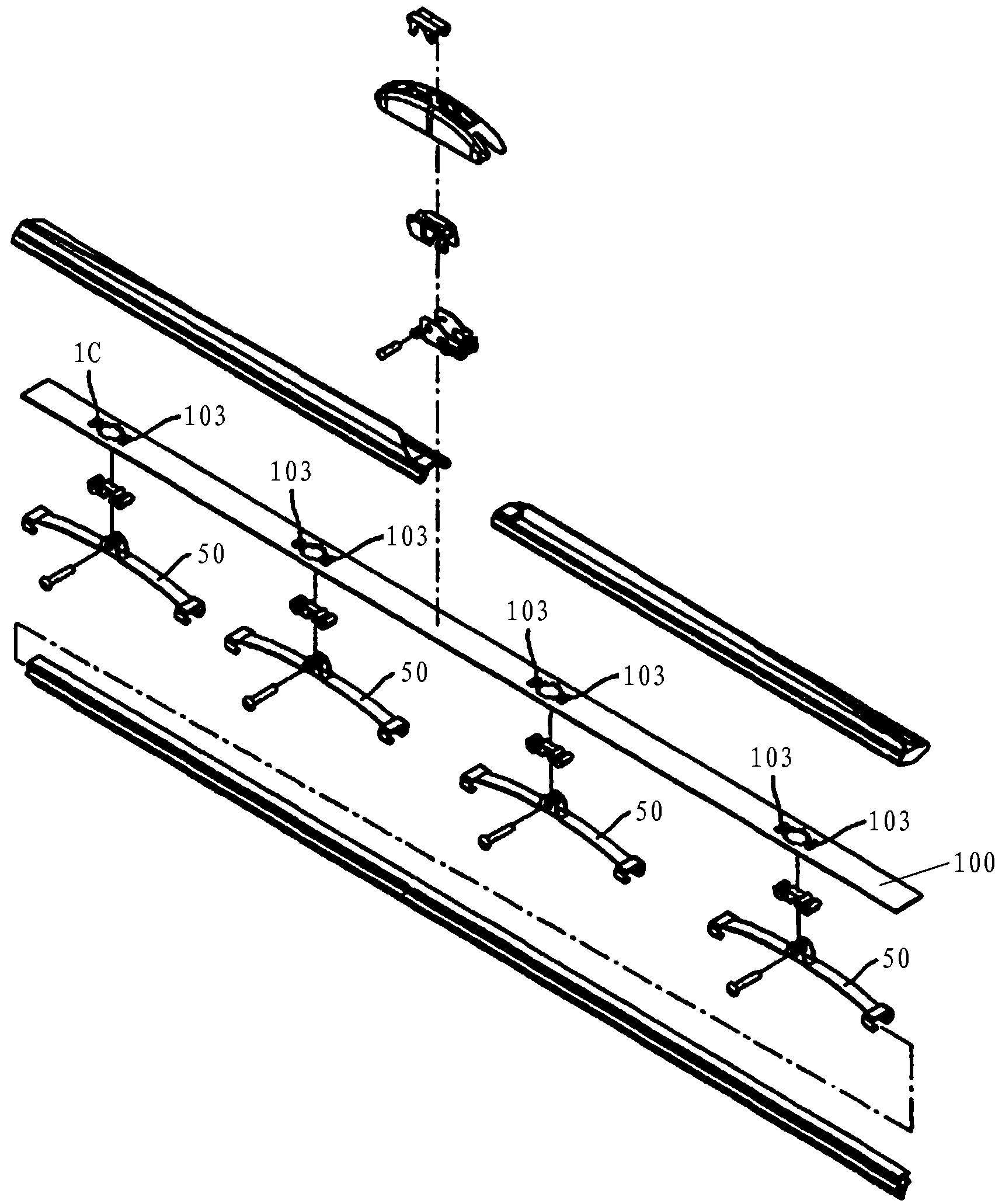

Windshield wiper

InactiveCN103879382ASolve the problem of insufficient lateral rigidityIncrease the stress pointVehicle cleaningWindshieldWindscreen wiper

The invention discloses a windshield wiper which comprises a windshield wiper elastic supporting part, a windshield wiper scraping strip, a connecting seat and clamping buckles. Multiple T-shaped grooves are equidistantly arranged on the windshield wiper elastic supporting part along the length direction at intervals, the windshield wiper scraping strip is composed of a connecting portion and a scraping and brushing portion, and the connecting portion is composed of multiple upwards-protruding T-shaped buckles which are fixed at the top surface of the scraping and brushing portion. When the windshield wiper is assembled, the T-shaped buckles are connected in the T-shaped grooves of the windshield wiper elastic supporting part in a clamped manner respectively, the connecting seat is connected in the middle of the windshield wiper elastic supporting part in a buckled manner, and the clamping buckles are connected at two ends of the windshield wiper elastic supporting part and the windshield wiper scraping strip which are assembled together in a sleeved manner. The T-shaped grooves are arranged on the windshield wiper elastic supporting part, and the windshield wiper scraping strip is provided with the upwards-protruding T-shaped buckles, so that assembling of the windshield wiper can be completed only by enabling the T-shaped buckles to be connected in the T-shaped grooves of the windshield wiper elastic supporting part in a clamped manner respectively. The windshield wiper is quite simple and easy to assemble.

Owner:XIAMEN FLATECH AUTO PARTS

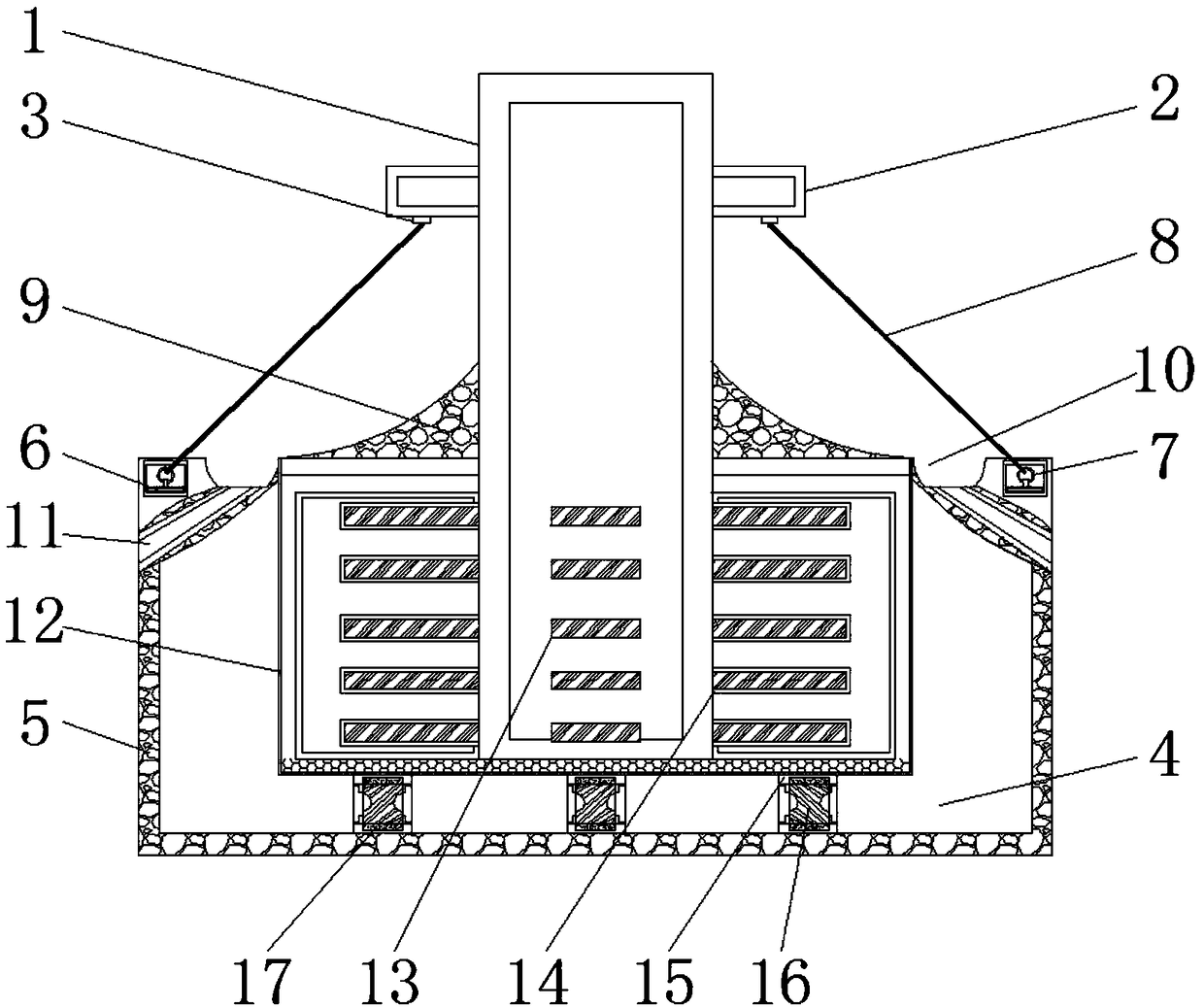

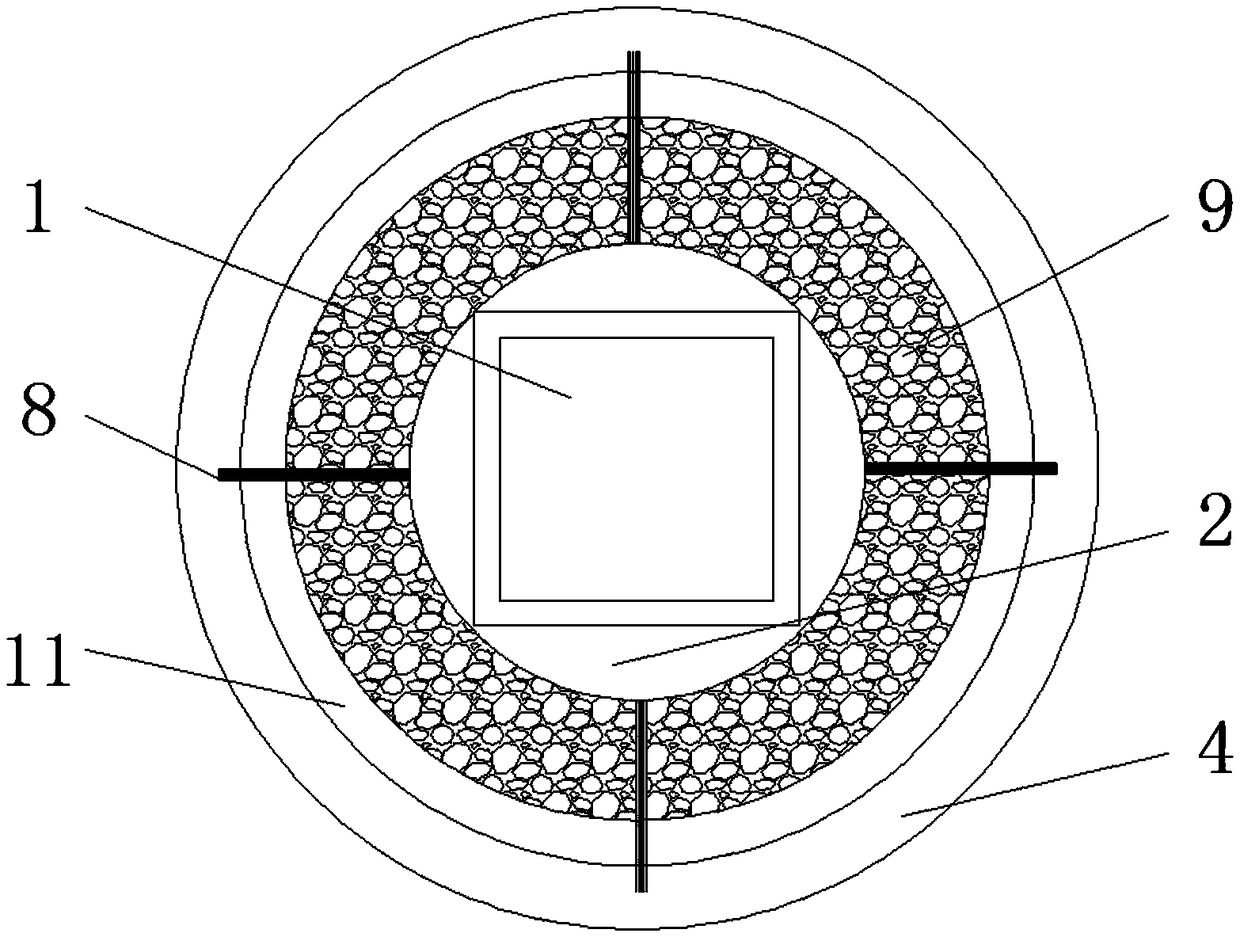

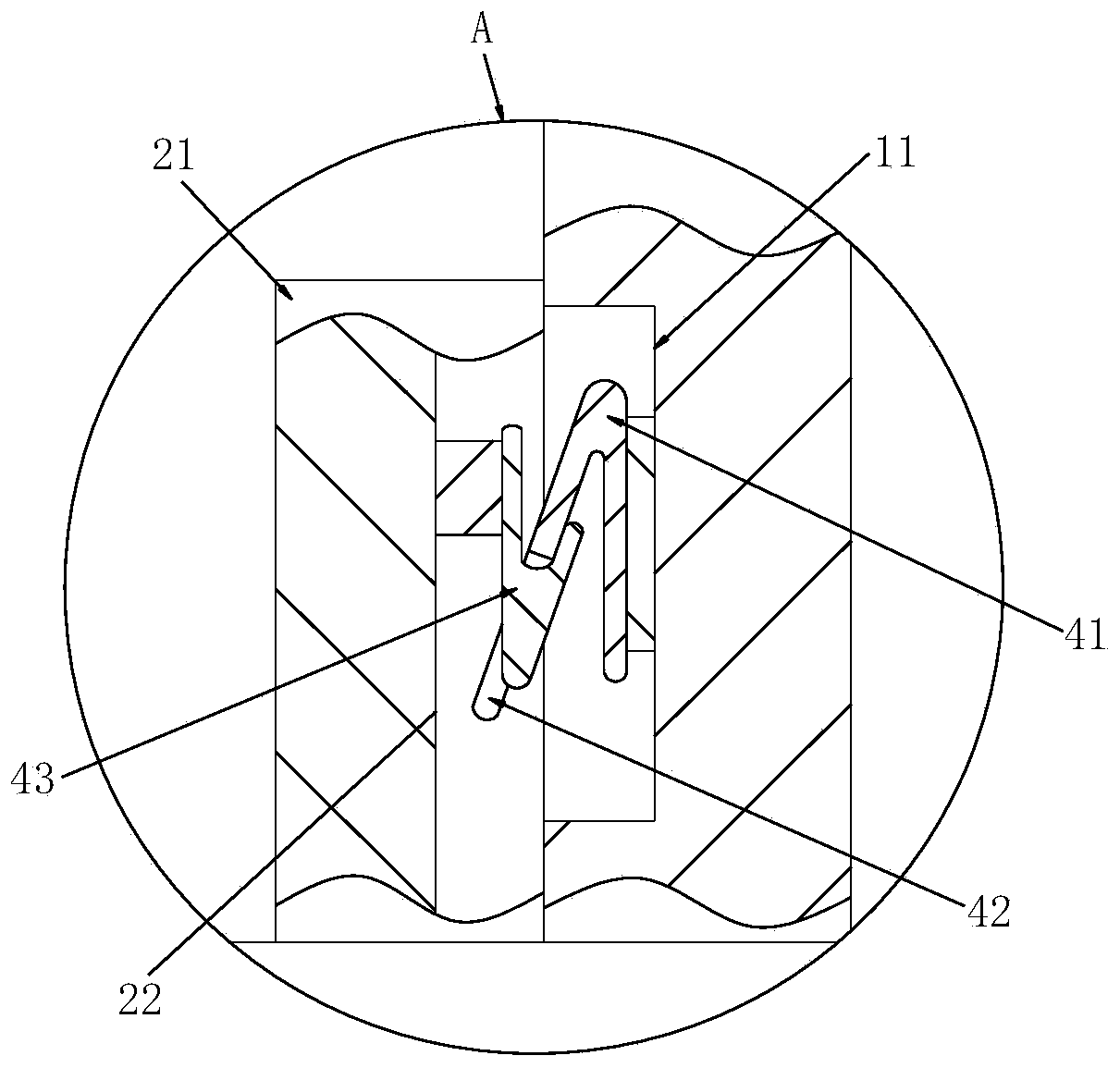

Broadcast iron frame foundation reinforcement structure

InactiveCN109339556AImprove stabilityIncrease contact areaProtective foundationTowersInsulation layerFrame based

The invention discloses a broadcast iron frame foundation reinforcement structure, which comprises an iron frame base, a foundation main body, clamp buckles and clamp grooves, wherein fixing discs arearranged at the outer surface of the top end of the iron frame base; four hanging rings are uniformly arranged at the bottom end of the fixing discs; the foundation main body is arranged at the bottom end of the iron frame base; a foamed concrete heat insulation layer is arranged inside the foundation main body; the bottom end of the iron frame base passes through the top end of the foundation main body to extend to the bottom end of the inside of the foamed concrete heat insulation layer; and the clamp buckles are uniformly arranged at four outer surfaces of the bottom end of the iron framebase. The clamp buckles are clamped into the clamp grooves formed inside the foundation main body, so that the contact area between the iron frame base and the foundation main body is increased; the stress point is increased, so that the fastness between the iron frame base and the foundation main body is enhanced; and the top end of the iron frame base is pulled through a steel rope between the fixing discs and iron blocks, so that the fastness between the iron frame base and the foundation main body is further enhanced.

Owner:冯婷

Reinforced aluminum alloy floor wire duct

ActiveCN110676776AIncrease the stress pointNot easy to damageElectrical apparatusStructural engineeringManufacturing engineering

The invention relates to a reinforced aluminum alloy floor wire duct, which comprises an arc plate, a connecting base, a supporting assembly, a connecting assembly, bunch assemblies, a straight plateand first mounting grooves. The connecting base is fixed to the lower end face of the floor. The arc plate is installed at the upper end of the connecting base through the connecting assembly. The straight plate is connected to the inner central position of the arc plate; inserting plates are connected to the two ends of the bottom of the arc plate respectively; the first mounting grooves are formed in the inner walls of the inserting plates; the supporting assembly is arranged in the center of the top of the connecting base; the supporting assembly and the straight plate are matched structures; the upper end of the supporting assembly is provided with the bunch assemblies in sequence; a fixing plate is installed in the center of the top of the connecting base; an inserting groove is formed in the center of the top of the fixing plate; and rectangular grooves are symmetrically formed in the positions, located at the two sides of the inserting groove, of the top of the fixing plate. Thereinforced aluminum alloy floor wire duct has the characteristic of large bearing capacity, and ensures that the arc plate is not prone to damage, so that the service life is guaranteed, and the safety performance is high.

Owner:沧州佳通电讯器材有限公司

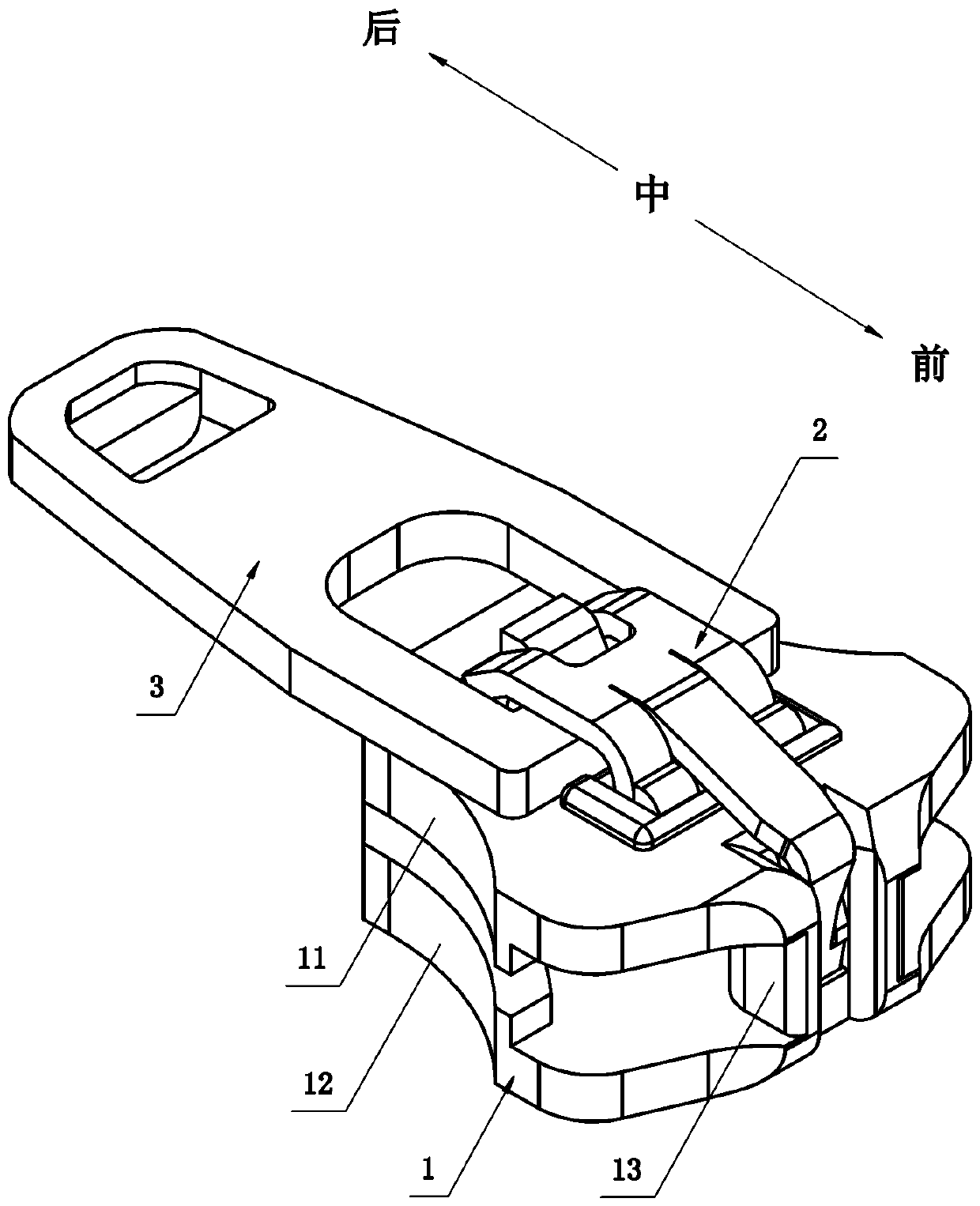

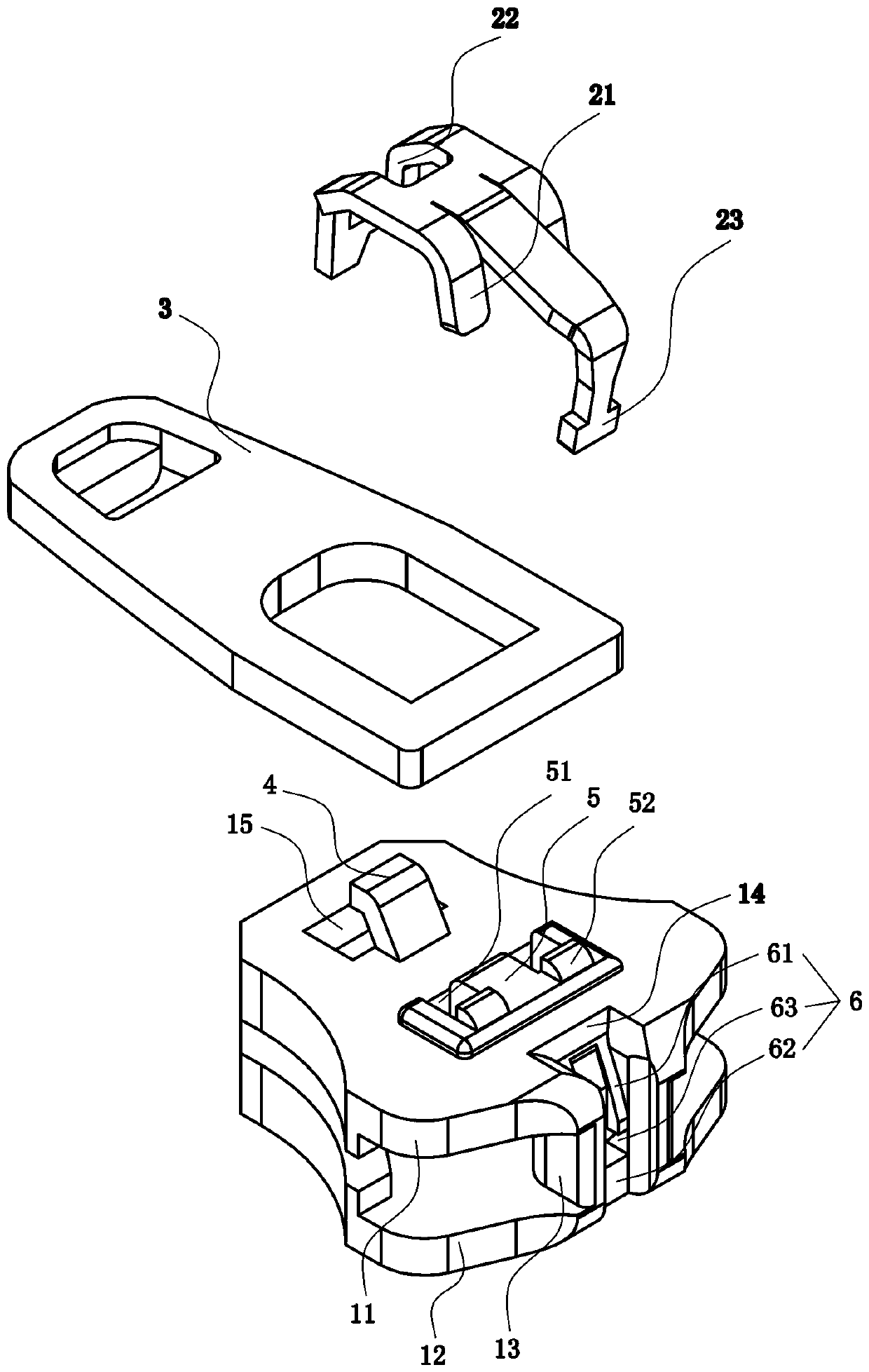

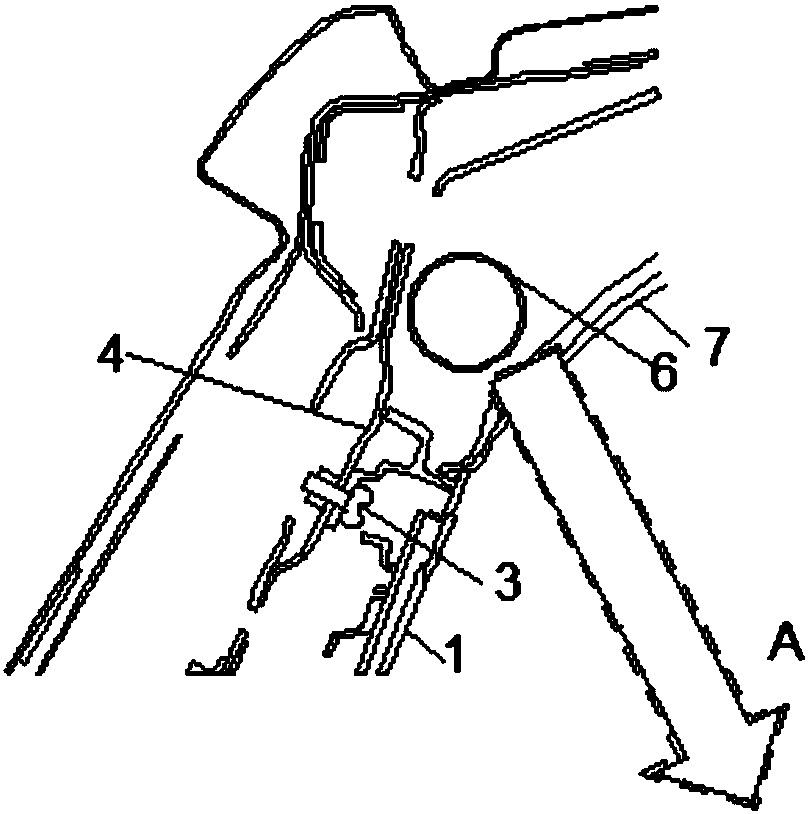

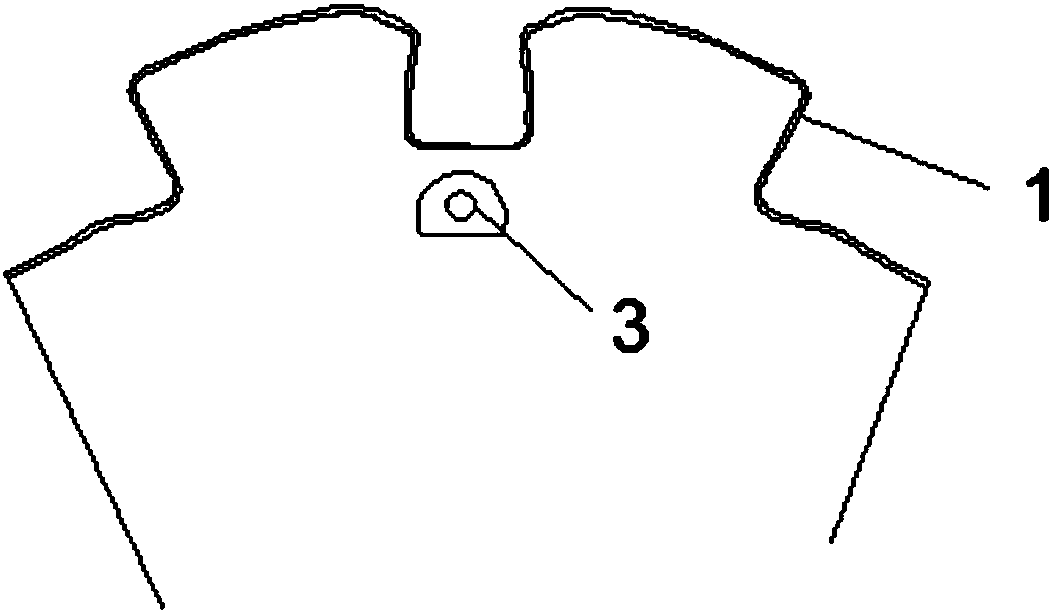

Structure-improved riveting-free copper pull head

A structure-improved riveting-free copper pull head comprises a pull head body, a elastic sheet and a pull sheet, wherein the pull head body comprises an upper wing plate, a lower wing plate and a guiding column, a convex block is arranged at the rear portion of the upper wing plate, and a protruding layer protruding out of the upper surface of the upper wing plate is arranged in the middle of theupper wing plate and is provided with an insertion hole. An insertion plate bent downwards is arranged in the middle of the elastic sheet, and a through hole is formed in the rear portion. The elastic sheet can be movably buckled and pressed on the pull head body, the insertion plate is inserted into the insertion hole to abut against the inner side wall of the protruding layer, and the convex block penetrates through the through hole to limit movement of the elastic sheet. The pull sheet can be clamped between the upper wing plate and the elastic sheet in a front-back rotatable way. When thepull sheet is turned and pulled forwards, the pull sheet abuts against the outer side wall of the protruding layer. By arranging the protruding layer, the pull sheet can directly abut against the outer side wall of the protruding layer without pressure exertion on the elastic sheet when rotating. Therefore, plastic deformation of the elastic sheet can be effectively prevented, and the service life of a zipper can be prolonged.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

B-pillar plaque strengthening structure and vehicle

InactiveCN108313128AHigh strengthReduce the burden onSuperstructure subunitsManufacturing technologyEngineering

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Clamping device for lithium battery processing

InactiveCN110695884AStable clampingIncrease clamping strengthAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a clamping device for lithium battery processing. The clamping device comprises a support, the lower part of the support is glidingly connected with a lifting air pipe, and thelower end of the lifting air pipe communicates with a sucking disc. A second motor is arranged in the support, and an output shaft of the second motor is connected with a second threaded rod in a transmitting mode. The side face of the lifting air pipe is fixedly connected with a third fixed block. When the clamping device is used, a lithium battery needing to be clamped is placed among three clamping plates, the lithium battery is clamped by the three clamping plates, and force bearing points are increased. When the lithium battery is clamped, the lifting air pipe moves downward. At the moment, the sucking disc contacts the clamped lithium battery and inhales through a connecting air pipe at the same time, so that the sucking disc absorbs the lithium battery, and the lithium battery canbe clamped more stably. Compared with the existing clamping device, the novel clamping device for lithium battery processing improves the clamping force for the lithium battery by increasing the forcebearing points and increasing adsorption force, so that the lithium battery is not easy to fall off.

Owner:天津鼎鑫缘新型材料科技有限公司

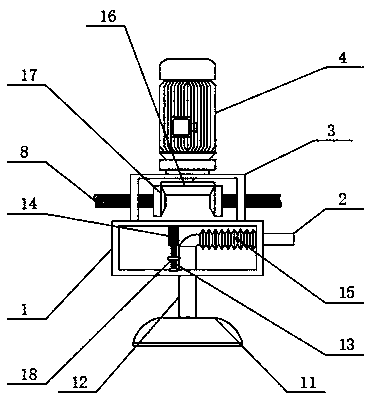

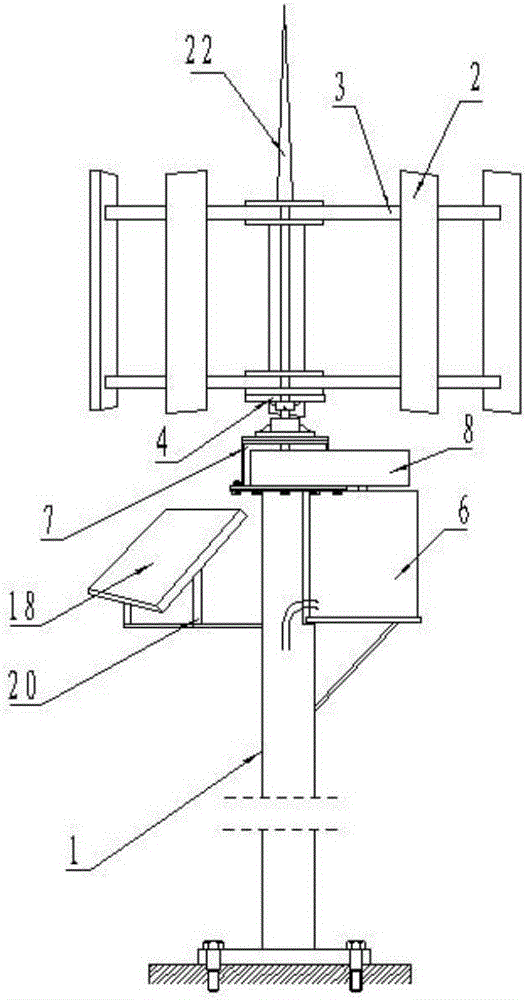

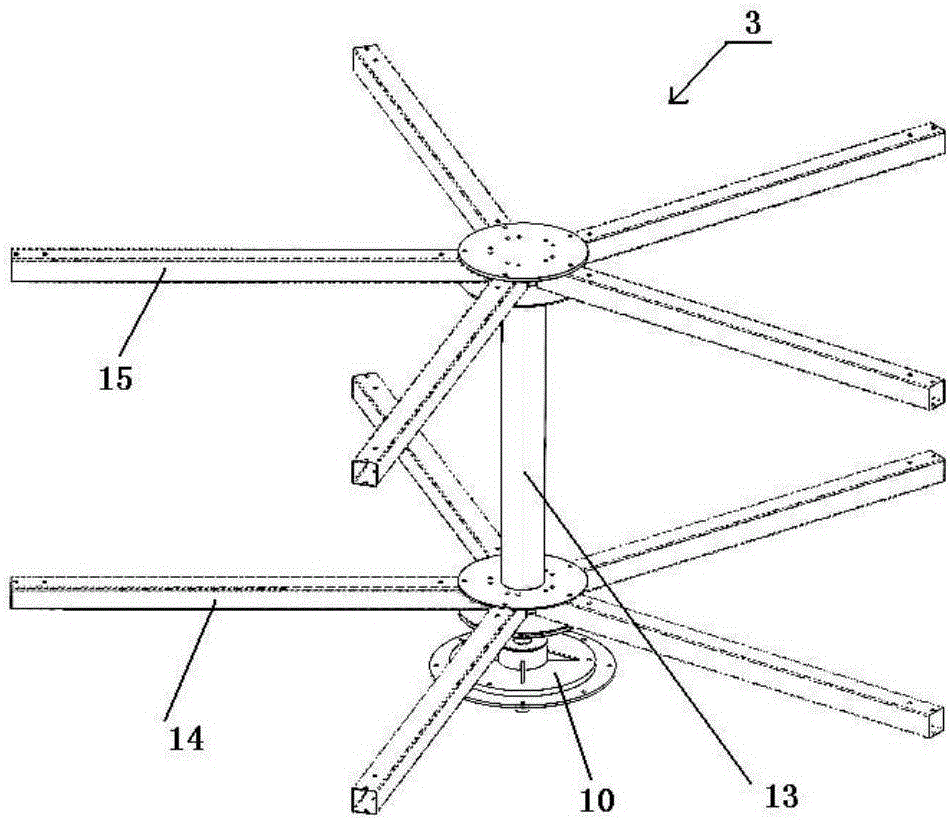

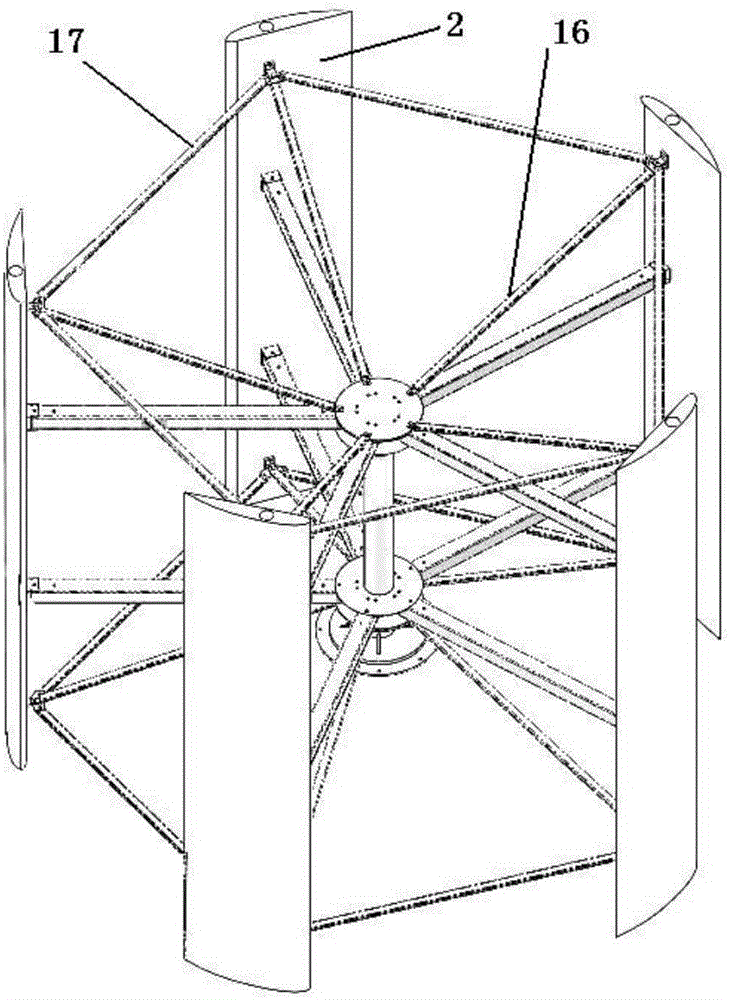

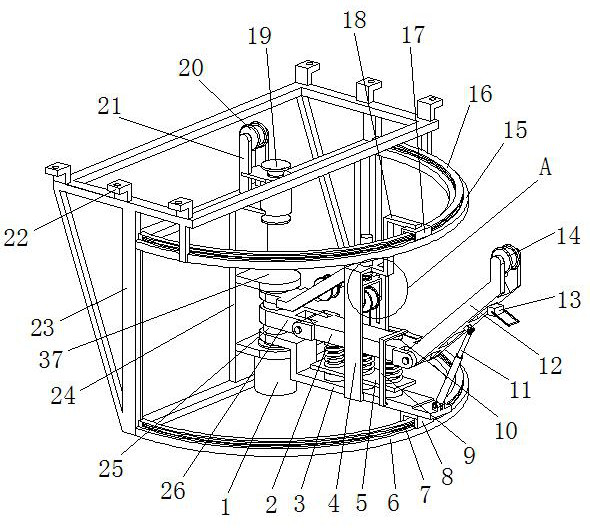

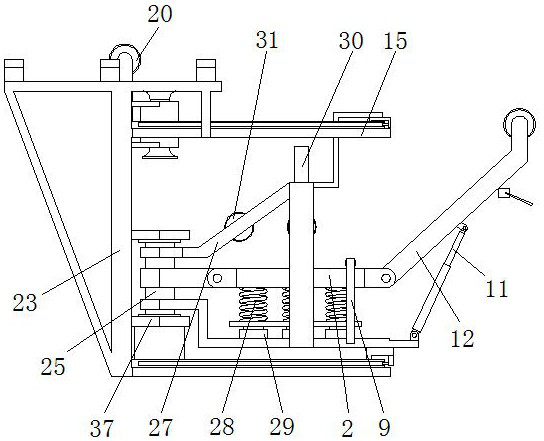

Breeze wind-solar complementary energy storage unit

PendingCN105715455AMeet needsReasonable arrangementWind energy with electric storageEnergy storageFixed frameGear wheel

The invention relates to a breeze wind-solar complementary energy storage unit. A bearing chamber fixed frame consists of a bearing chamber and a connecting disc arranged at the middle part of the bearing chamber and integrally molded with the bearing chamber, wherein a tower is connected with a ground fixed base; a gear box bracket is fixed at the top of the tower; a gear box is mounted in the gear box bracket; a generator is fixed on one side of the upper part of the tower, and is positioned below the gear box; a connecting ring is fixed at the upper end of the gear box bracket; a connecting disc of a bearing chamber fixed frame is connected with the connecting ring; a connecting shaft penetrates through the bearing chamber, and is connected with the bearing chamber through a bearing; the lower end of the connecting shaft is connected with an input shaft of the gear box; an output shaft of the gear box after gear transmission is connected with a rotating shaft of the generator; a wind wheel base is connected with the upper end of the connecting shaft; the lower end of a blade connecting module is coaxially connected with the wind wheel base; and blades are fixed at the outer periphery of the blade connecting module at equal intervals. The breeze wind-solar complementary energy storage unit has the advantages of environmental protection, energy conservation, reasonable structure, safety, stability and long life.

Owner:李拯

Crane lifting adjusting device

ActiveCN114057104AReduce the impact of orientationIncreased ability to withstand gravityVibration suppression adjustmentsCranesRotational axisControl engineering

The invention discloses a crane lifting adjusting device, which comprises a vibration reduction arm, a rotary supporting arm, a lifting adjusting arm, a lifting rope limiting bush, a mounting frame and a rotary fixing frame, wherein the rotary fixing frame is arranged on the mounting frame, a rotary shaft is arranged on the rotary fixing frame, a connecting arm is arranged in the middle of the rotary shaft, the left end of the vibration reduction arm is rotationally connected with the connecting arm, the left end of the lifting adjusting arm is rotationally connected with the vibration reduction arm, the rotary supporting arm is arranged under the vibration reduction arm, the left end of the rotary supporting arm is fixedly connected with the rotary shaft, a weight detection table is arranged between the rotary supporting arm and the vibration reduction arm, and a weight sensor is arranged between the weight detection table and the rotary supporting arm. According to the invention, the crane lifting adjusting device is novel in structural design, double protection is conducted on lifting equipment, goods are prevented from rushing to the top, safe operation of lifting work is guaranteed, operation is convenient, the working efficiency is greatly improved, the position of the lifting hook can be finely adjusted, and the practicability of the lifting device is improved.

Owner:新乡市起重设备厂有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com