Novel polyamide nanocomposite and preparation method thereof

A nano-composite material and polyamide technology, applied in the field of polyamide materials, can solve the problems of poor strength, impact resistance, and limited application range, etc., and achieve the effect of improving impact strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

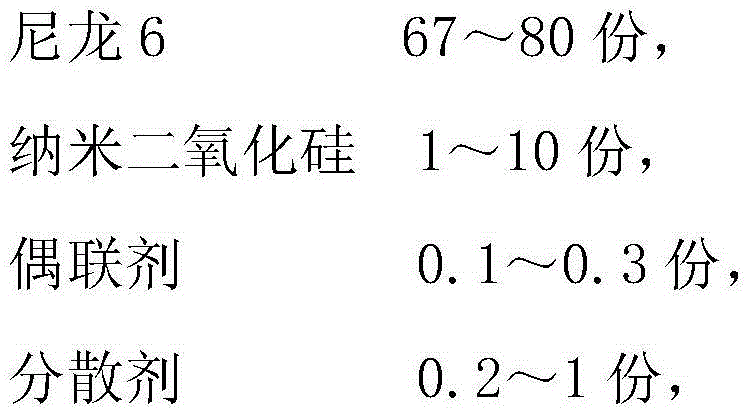

[0023] A kind of novel polyamide nanocomposite material, its component and parts by weight are as follows:

[0024]

[0025] Its preparation method comprises the following steps:

[0026] (1) Dissolving nano-silica in an organic solvent, ultrasonically dispersing for 2 hours, adding a coupling agent, continuing ultrasonically dispersing for 4 hours, washing away the solvent, and obtaining modified nano-silica after drying;

[0027] (2) Place the modified nano silicon dioxide obtained in step (1) and other components in a twin-screw extruder according to the formula, and obtain a polyamide nanocomposite material after melting, extruding and granulating, and the rotating speed is 200-400rpm, temperature 200-300°C.

Embodiment 2

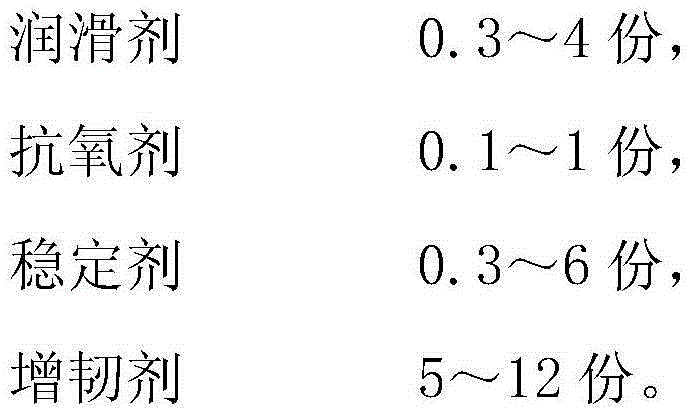

[0029] A kind of novel polyamide nanocomposite material, its component and parts by weight are as follows:

[0030]

[0031] Its preparation method comprises the following steps:

[0032] (1) Dissolving nano-silica in an organic solvent, ultrasonically dispersing for 2 hours, adding a coupling agent, continuing ultrasonically dispersing for 4 hours, washing away the solvent, and obtaining modified nano-silica after drying;

[0033] (2) Place the modified nano silicon dioxide obtained in step (1) and other components in a twin-screw extruder according to the formula, and obtain a polyamide nanocomposite material after melting, extruding and granulating, and the rotating speed is 200-400rpm, temperature 200-300°C.

Embodiment 3

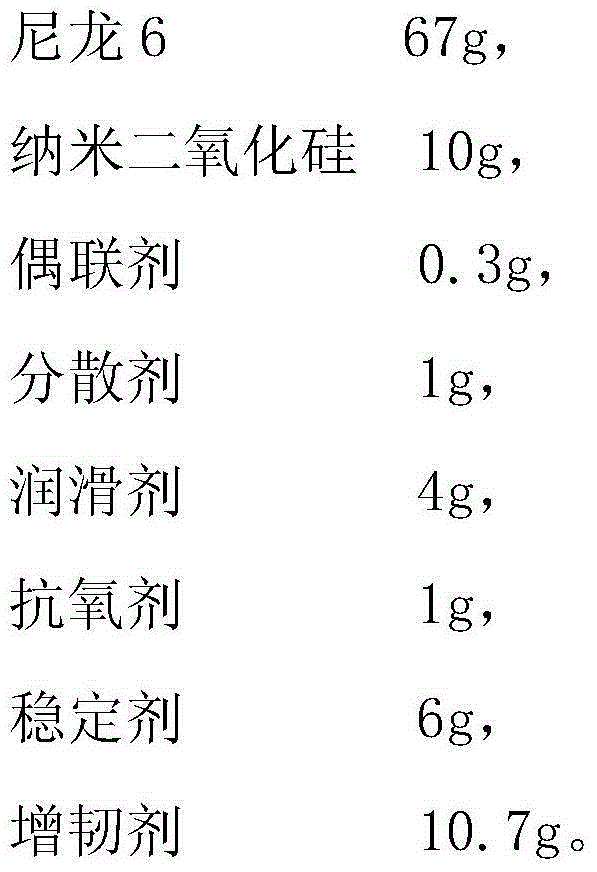

[0035] A kind of novel polyamide nanocomposite material, its component and parts by weight are as follows:

[0036]

[0037]

[0038] Its preparation method comprises the following steps:

[0039] (1) Dissolving nano-silica in an organic solvent, ultrasonically dispersing for 2 hours, adding a coupling agent, continuing ultrasonically dispersing for 4 hours, washing away the solvent, and obtaining modified nano-silica after drying;

[0040] (2) Place the modified nano silicon dioxide obtained in step (1) and other components in a twin-screw extruder according to the formula, and obtain a polyamide nanocomposite material after melting, extruding and granulating, and the rotating speed is 200-400rpm, temperature 200-300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com