Disposable foreskin cutting stapler

A one-time, stapler technology, applied in surgical instruments, medical science, surgical fixation nails, etc., can solve the problems of inconvenient use of surgical operators, tissue pinched by instruments, small force contact surface, etc., and achieve good cutting and suturing. The effect of preventing the device from pinching the tissue, and the effect of improving the assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

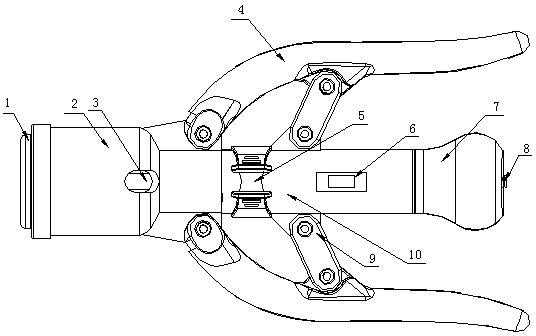

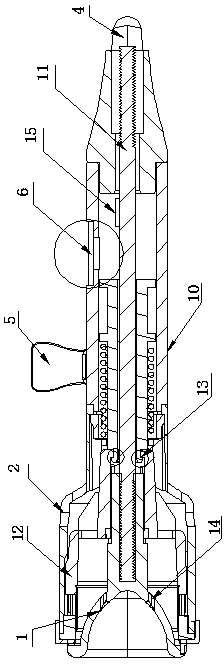

[0024] Such as figure 1 It is a structural schematic diagram of the present invention, a disposable circumcision stapler, including a concave seat 1, a staple cartridge sleeve 2, a sleeve 10, a screw rod 11, a nail pusher 12, a movable handle 4 and a connecting rod 9, the The casing 10 is provided with a screw 11, the left side of the casing 10 is provided with a staple cartridge cover 2, and the staple cartridge cover 2 is provided with a nail pusher 12 and a concave seat 1, and the movable handle 4 is installed On the casing 10, the connecting rod 9 connects the casing 10 and the movable handle 4, the casing 10 is provided with a safety clip 5, the end of the casing 10 is provided with an adjusting nut 7, and the end of the screw rod 11 is An adjusting bolt 8 is provided, an exhaust through hole 14 is provided on the concave seat 1 , and a threaded hole 3 is provided on the magazine cover 2 .

[0025] According to another embodiment of the present invention, it further incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com