Plastic grinder

A shredder and plastic technology, which is applied in the fields of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of large pieces, crushed objects that are easy to block the machine, and the effect of crushing is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

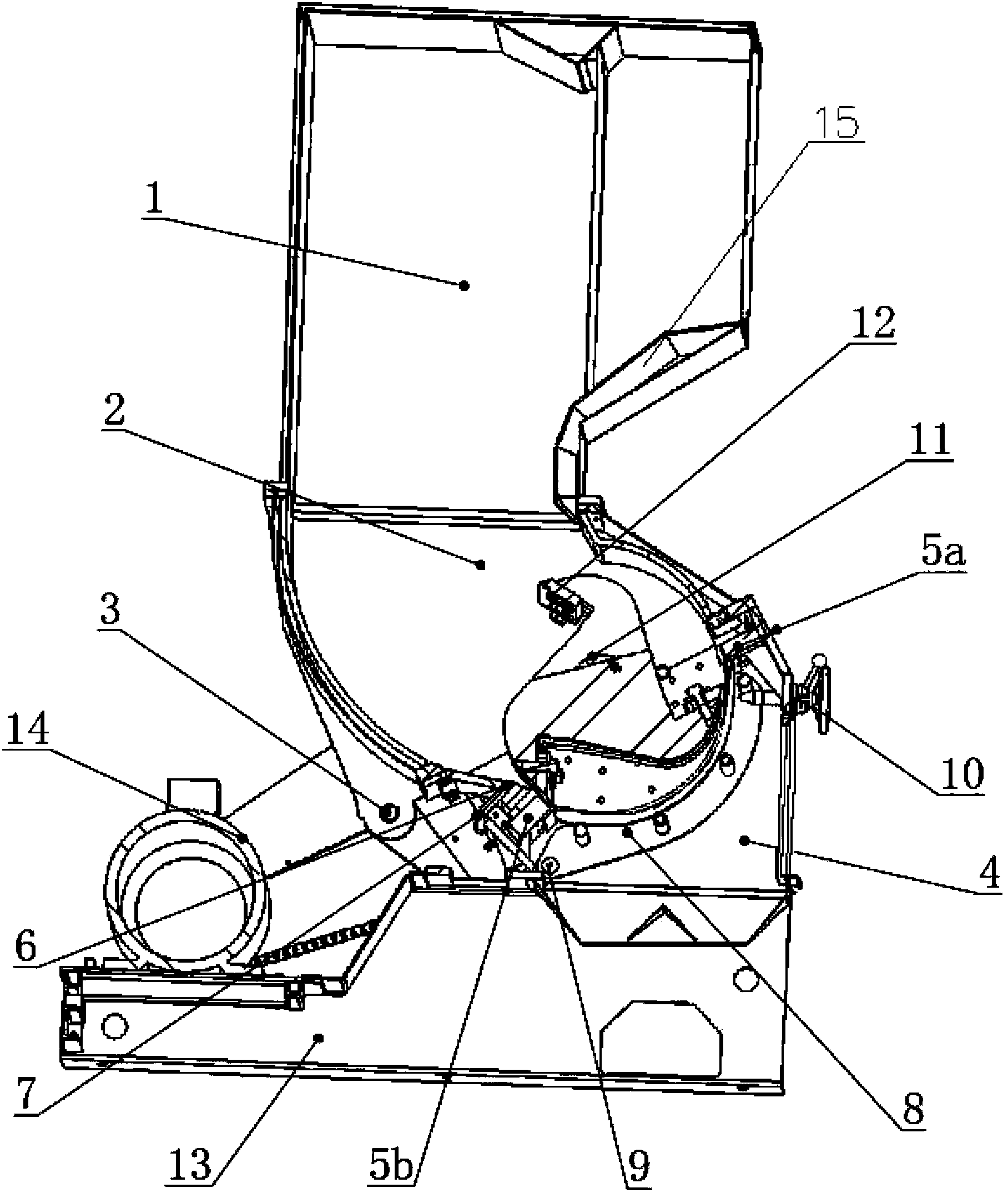

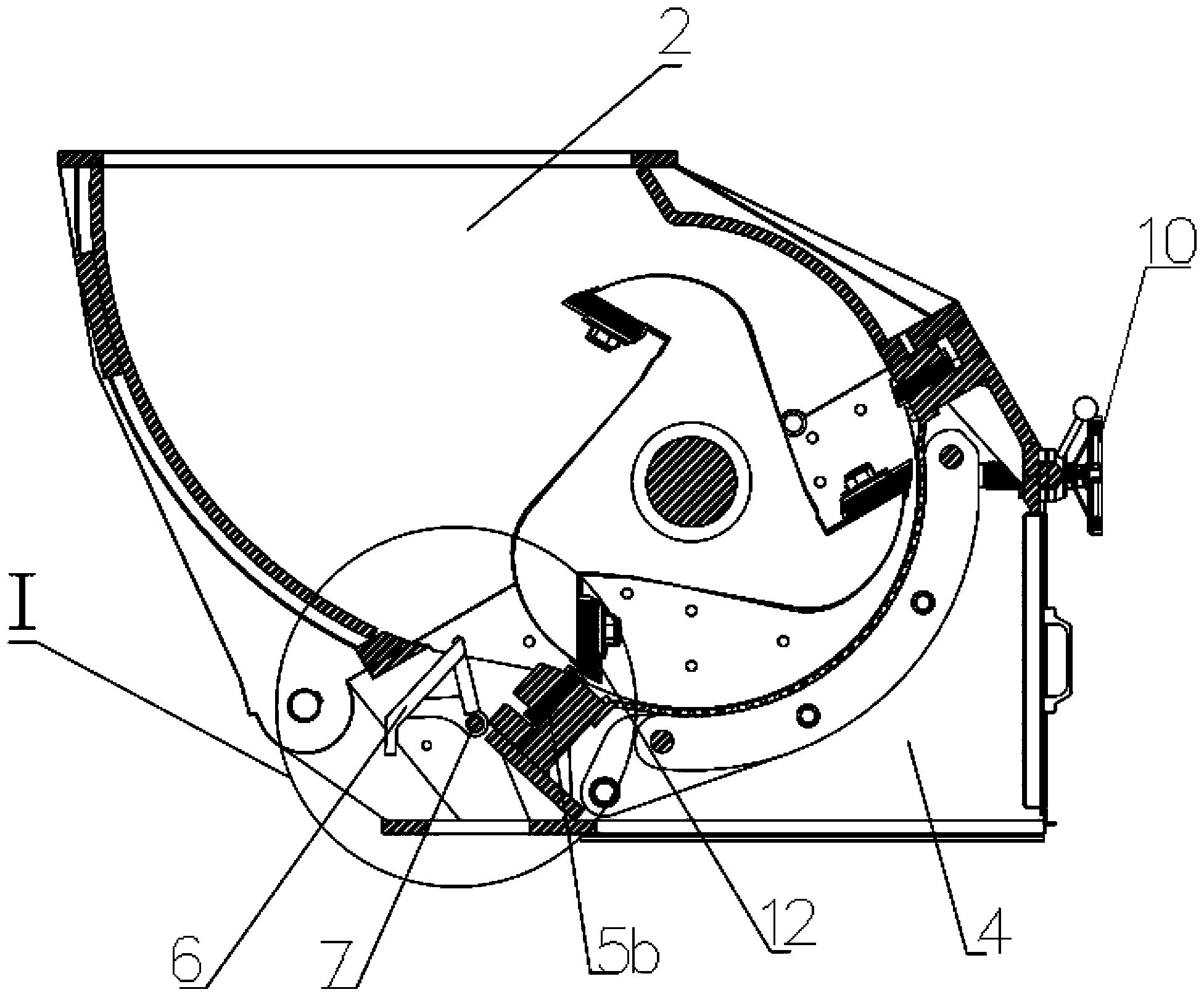

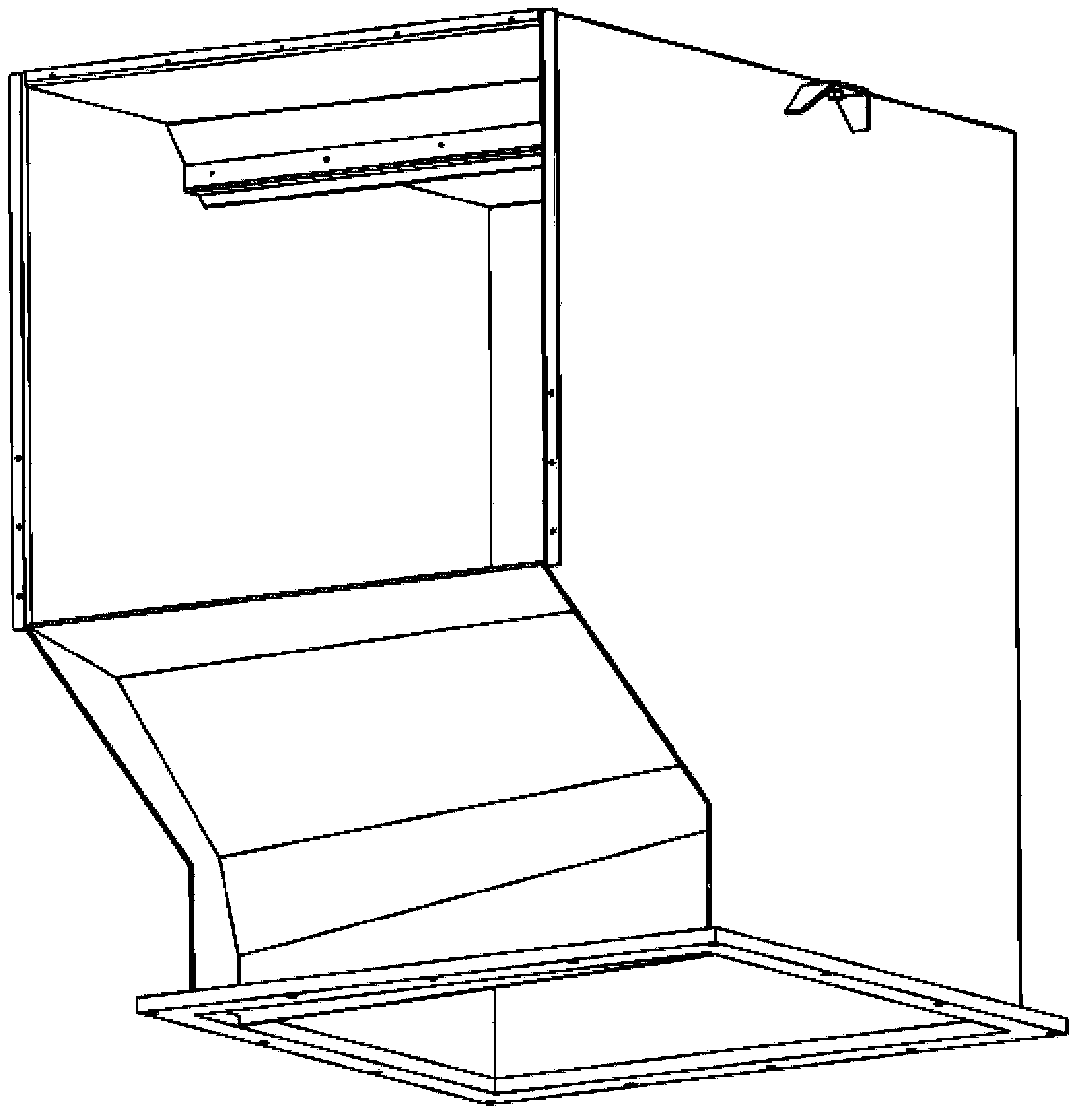

[0021] like Figure 1-7 As shown, a plastic pulverizer includes a feed hopper 1, an upper body 2 of the crushing chamber, a rotating shaft 3, a lower body 4 of the crushing chamber, a front fixed knife 5a, a rear fixed knife 5b, an insert 6 in the lower body, and a rotating shaft 7 for the inner insert , screen device 8, screen frame shaft 9, locking rod 10, main shaft rotor 11, rotating knife 12, chassis 13, power transmission device 14, folding plate 15;

[0022] The lower part of the front side of the feed hopper 1 is concave inward to form a continuous folded plate 15, and the feed hopper 1 is fixedly installed on the upper body 2 of the crushing chamber. The front and rear sides of the upper body 2 of the crushing chamber are curved plates or approximate arcs. type folded plate;

[0023] The front end of the upper body 2 of the crushing chamber is locked and the rear end is pinned to the lower body 4 of the crushing chamber through the rotating shaft 3. The lower body 4 ...

Embodiment 2

[0034] The whole crushing process is as follows: plastic parts enter the feed hopper 1 from the entrance, and fall on the folding plate 15 in turn. Since the folding plate 15 is connected by several inclined surfaces at a certain angle to form a continuous transition surface, the plastic parts, especially the barrel-shaped plastic When it falls from the feed hopper 1 and rolls down along the folding plate 15, it will automatically turn horizontally; at this time, the power transmission device 14 drives the main shaft rotor 11 to rotate, and several groups of rotating knives 12 on the main shaft rotor 11 also rotate accordingly, and It forms a shearing movement with the front fixed knife 5a and the rear fixed knife 5b at the lower part of the front and rear arc-shaped plates of the upper body 2 of the crushing chamber; because the insert 6 in the lower body expands the space of the crushing storage area, the plastic parts are placed on the crushing chamber. The stress point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com