Patents

Literature

141results about How to "Increase clamping strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

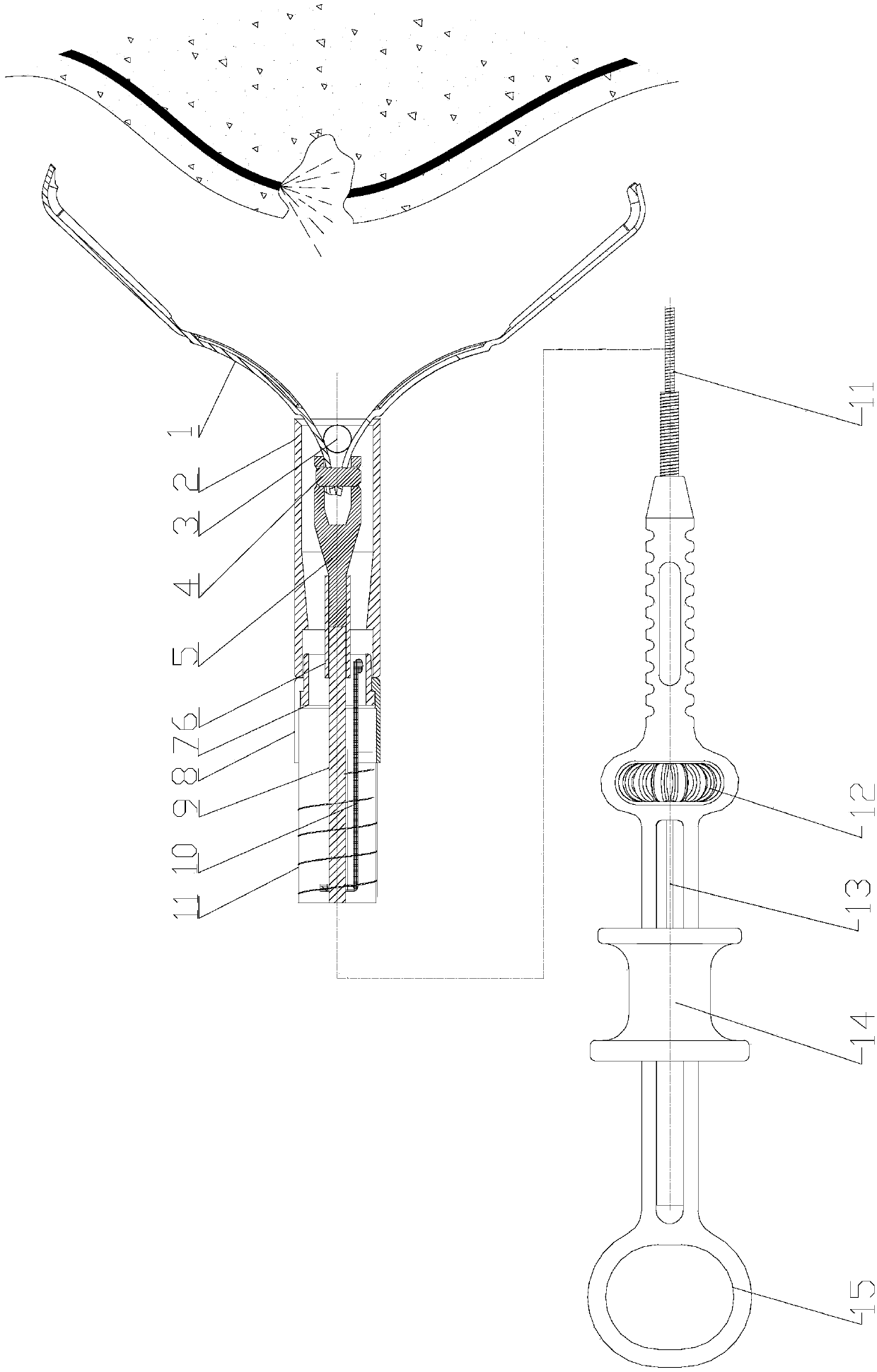

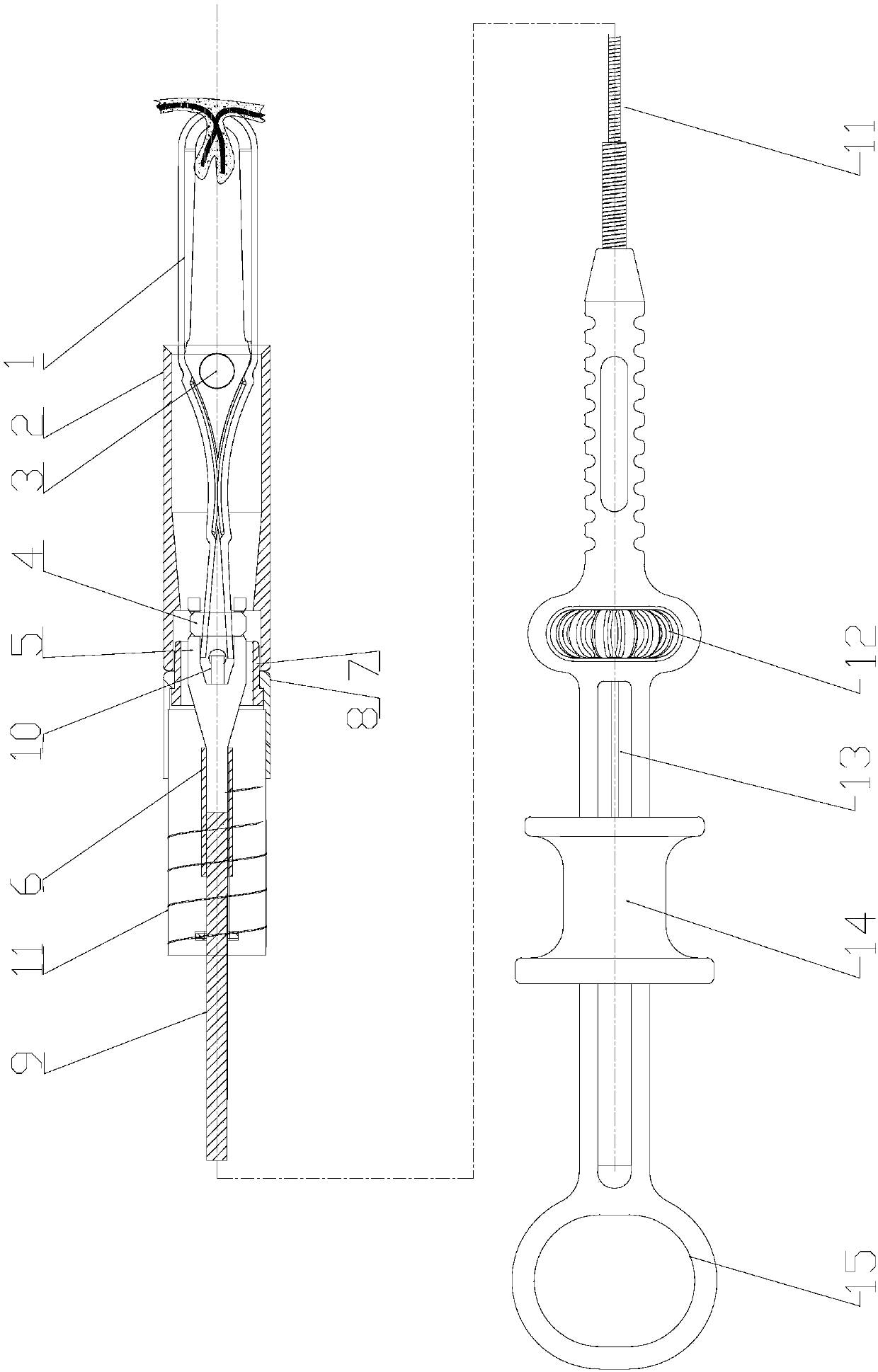

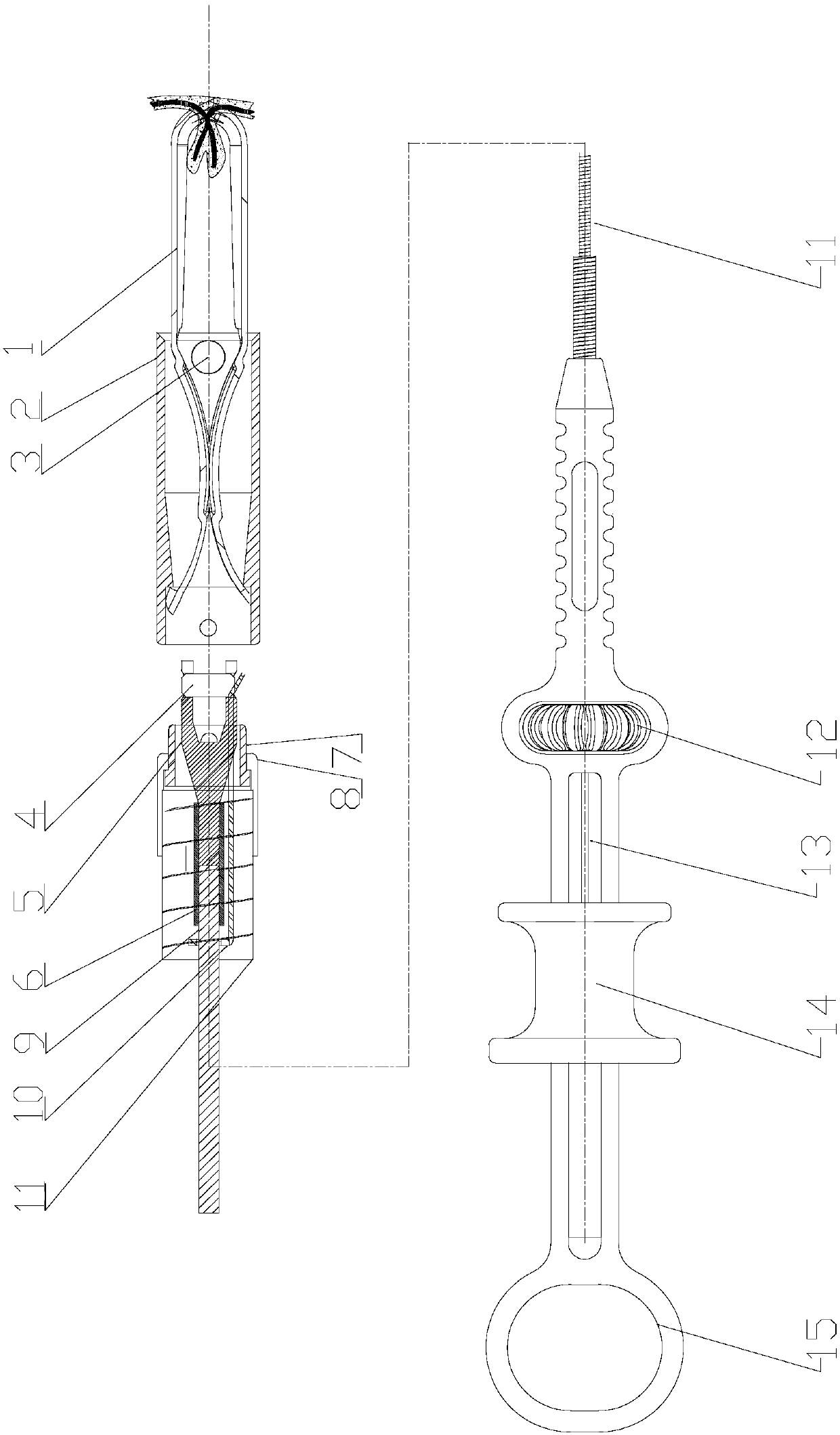

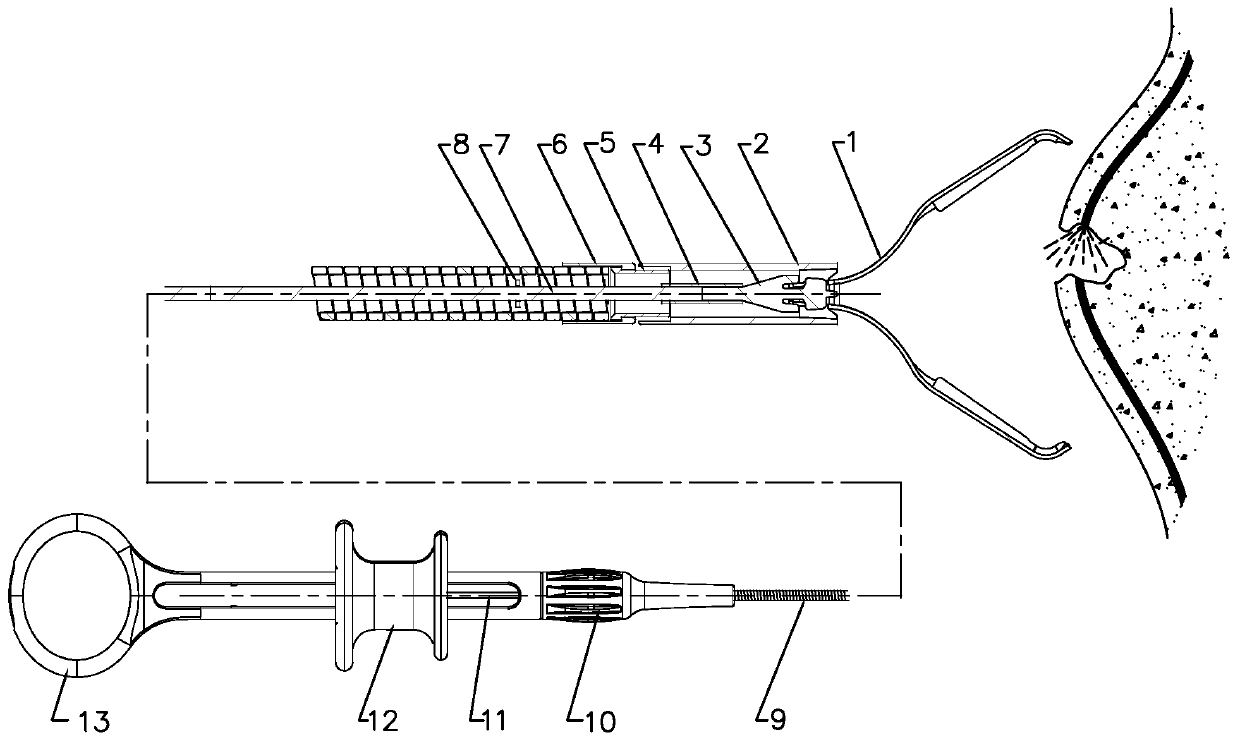

Improved hemostasis clamp for being used under endoscope and clamp part thereof

ActiveCN108013914AAvoid damageIncrease clamping strengthWound clampsAgainst vector-borne diseasesEngineeringEndoscope

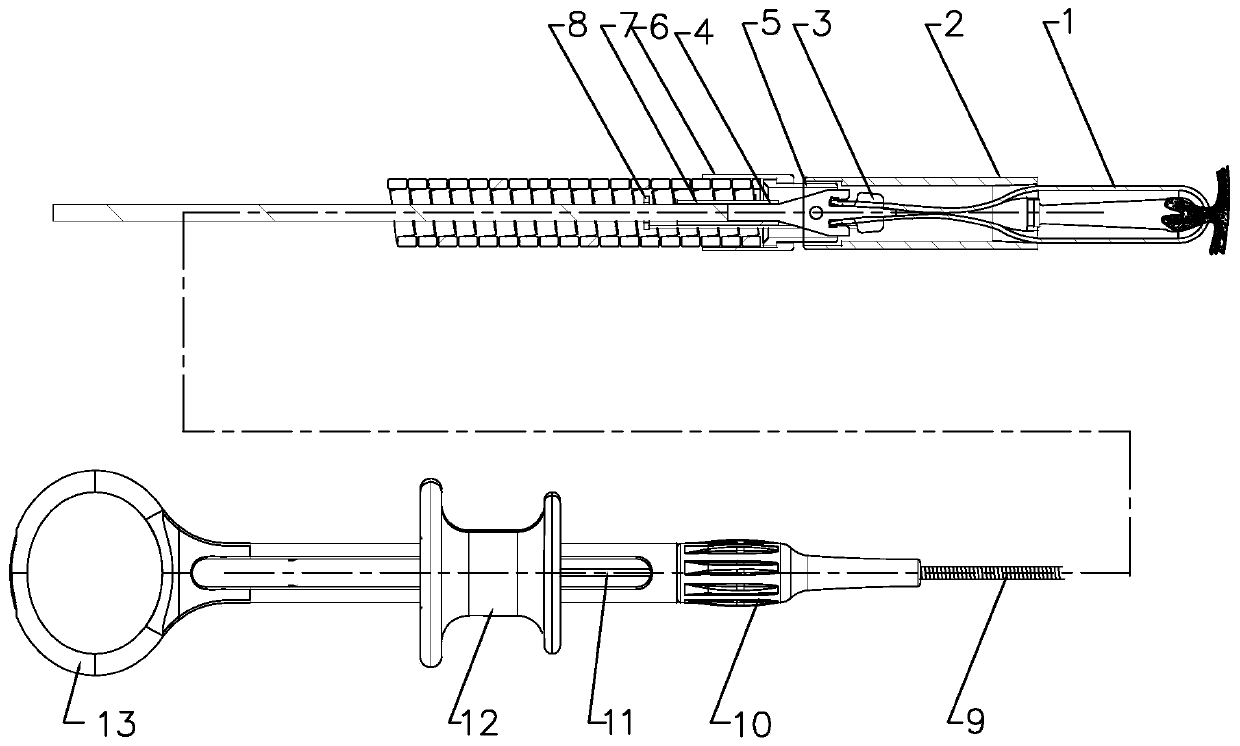

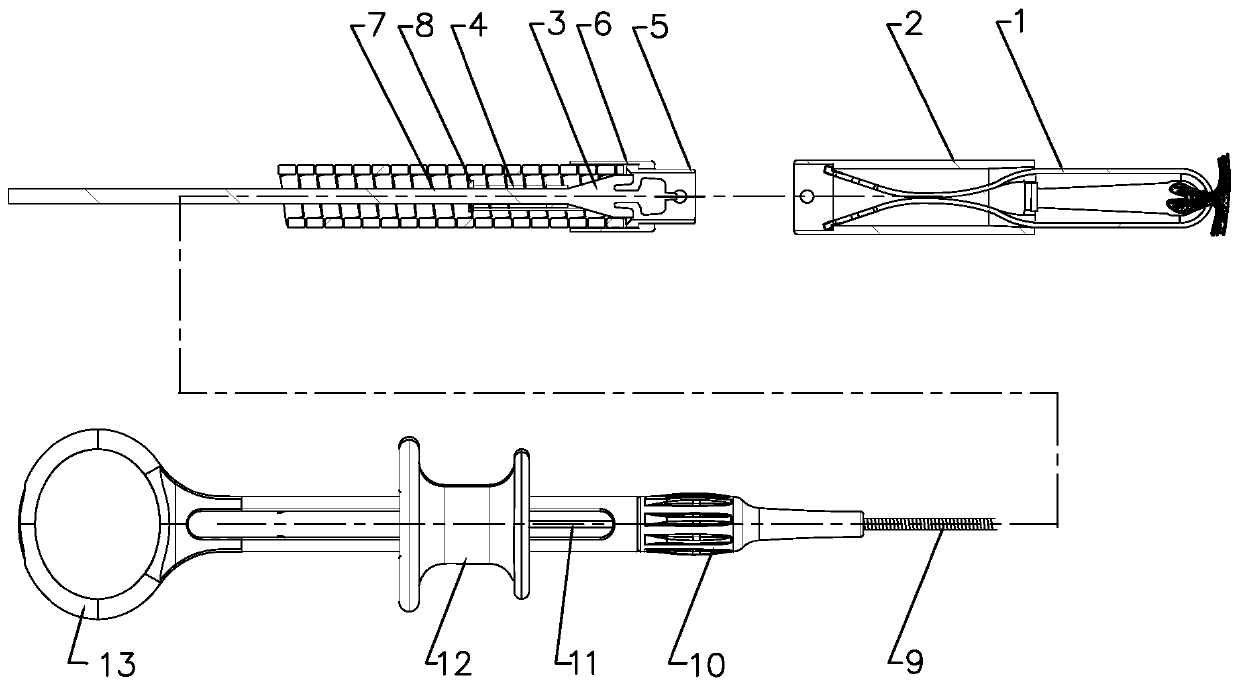

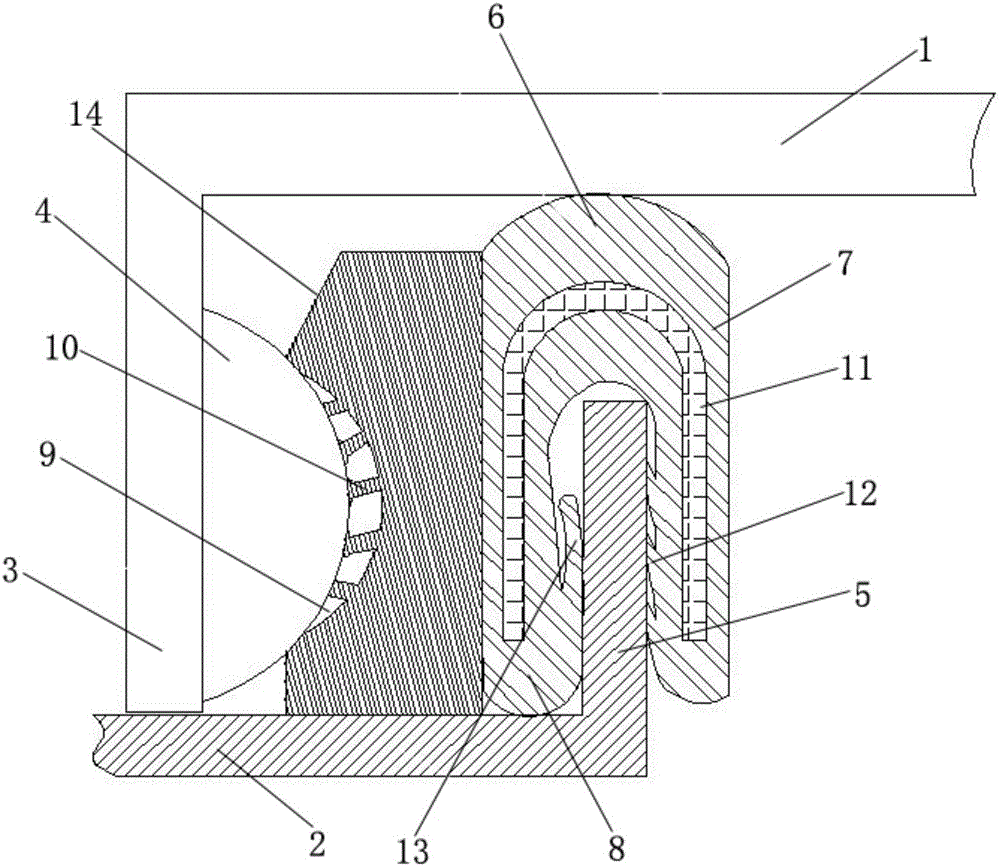

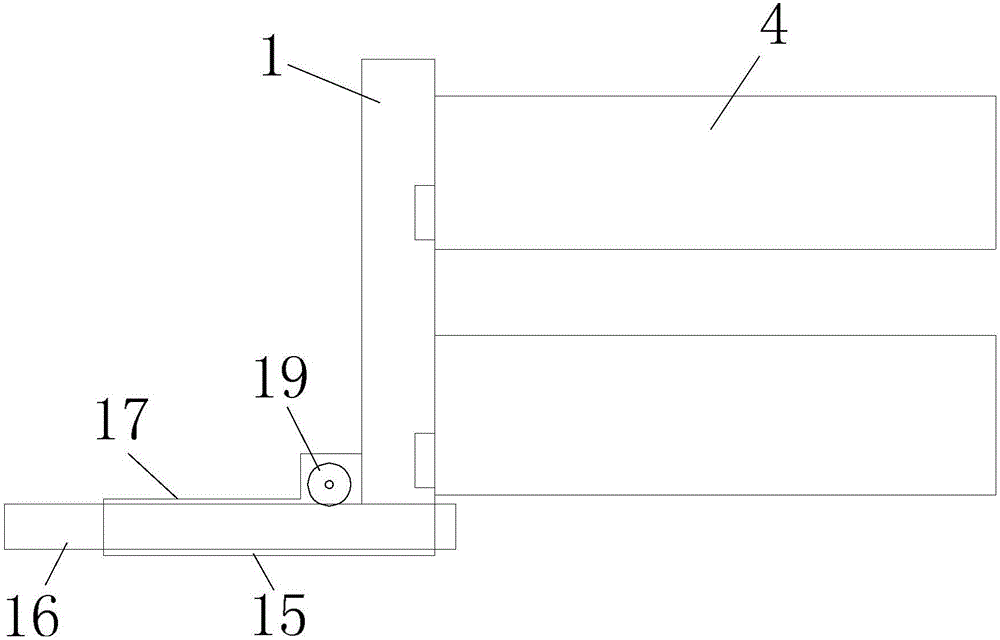

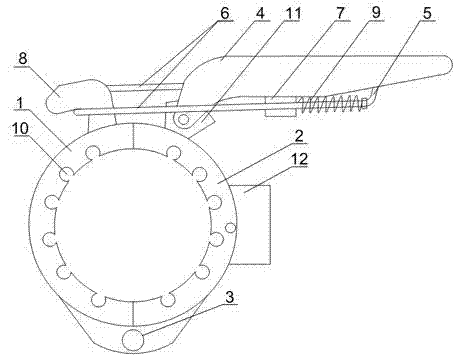

The invention relates to an improved hemostasis clamp for being used under an endoscope and a clamp part thereof. The clamp part comprises clamping pieces, a clamp tube, a stop pin, a connecting pin,a clamping piece fixing base and a connecting tube; the clamping piece fixing base is arranged inside the clamp tube and can move back and forth, an open deformation hole is formed in the tail of eachclamping piece, the connecting pin runs through the deformation holes in the two clamping pieces and then is fixedly connected with the front end of the clamping piece fixing base, and one side of each deformation hole in the tail of the clamping piece is provided with a protrusion turned outwards; an annular stop step is arranged at the tail of the inner wall of the clamp tube, when the two clamping pieces are clamped, the protrusions at the tails of the clamping pieces are clamped to the stop step, and the stop pin is fixed to the front portion of the clamp tube and therefore the clamping piece fixing base is limited from sliding out of the clamp tube. By adopting the technical scheme, the purposes that part breakage happens from beginning to end, and no fragment residue exists; the tails of the clamping pieces are connected with a release part, the maximum space utilization is obtained, after clamping is released, and the total length is the smallest.

Owner:ANREI MEDICAL HZ

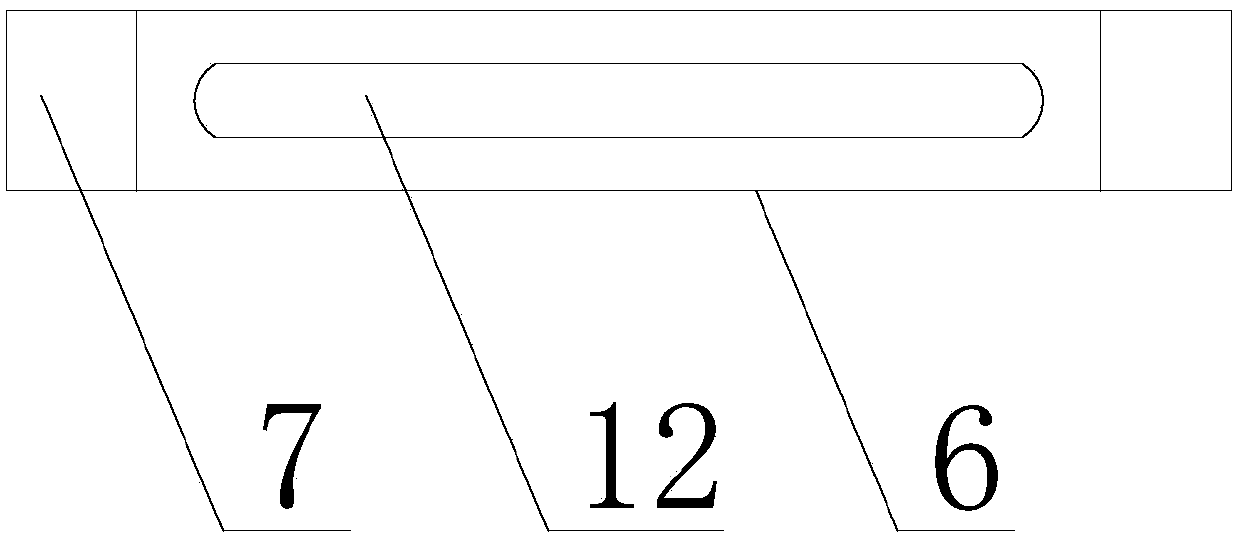

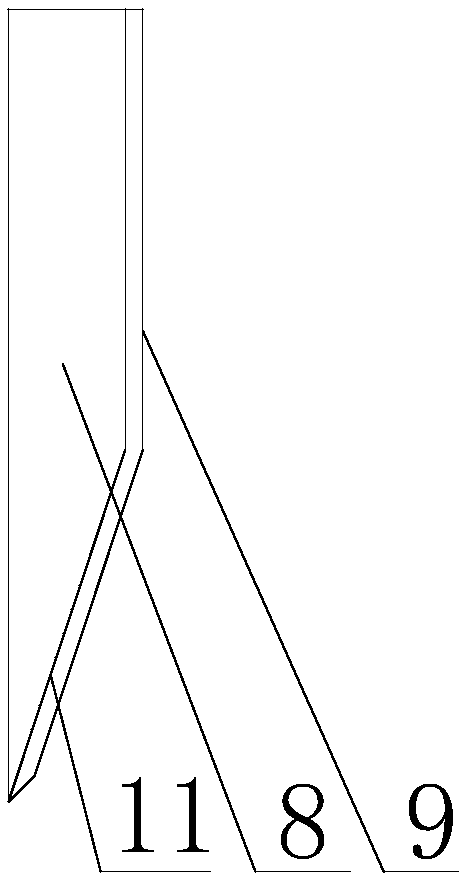

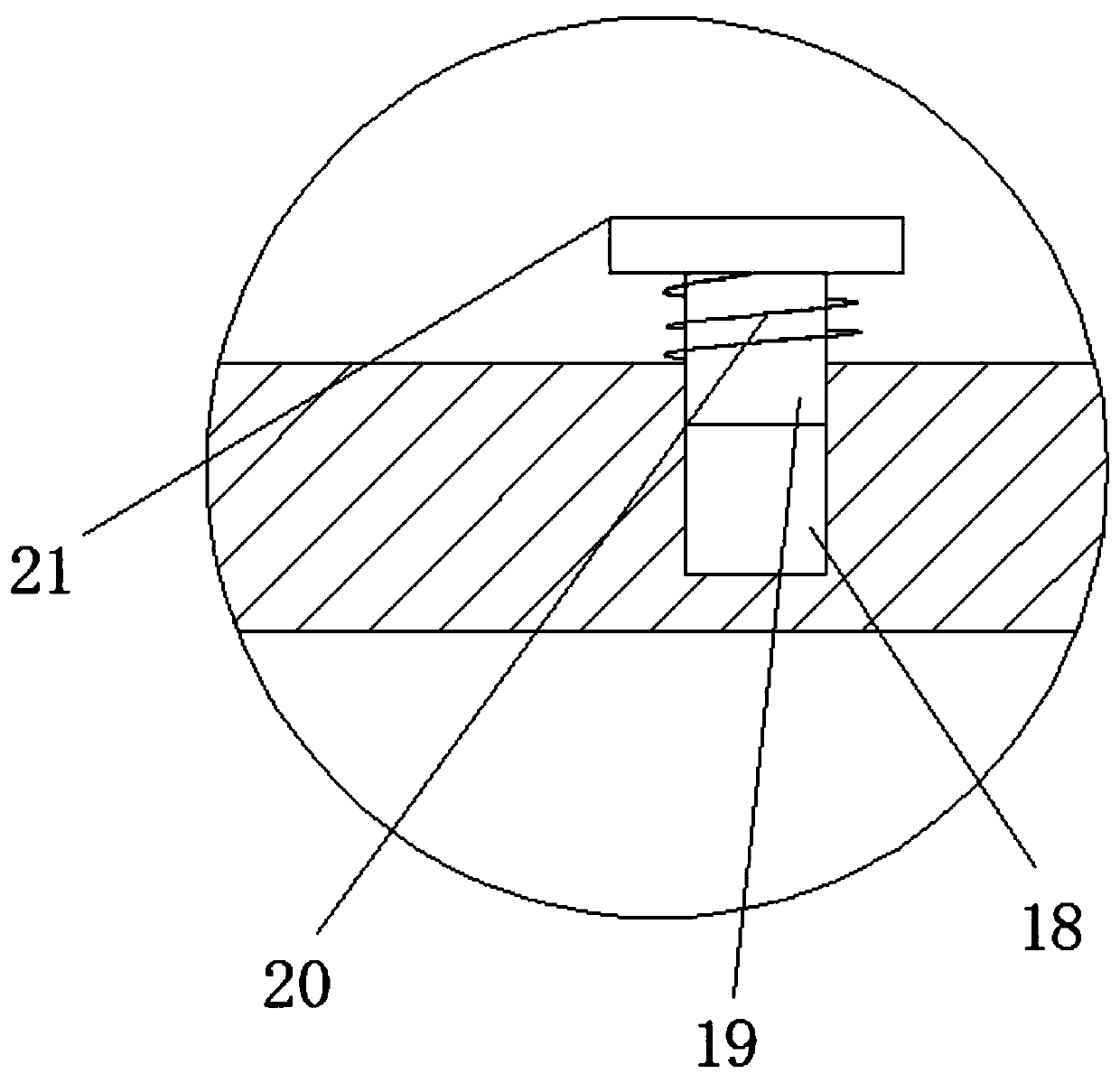

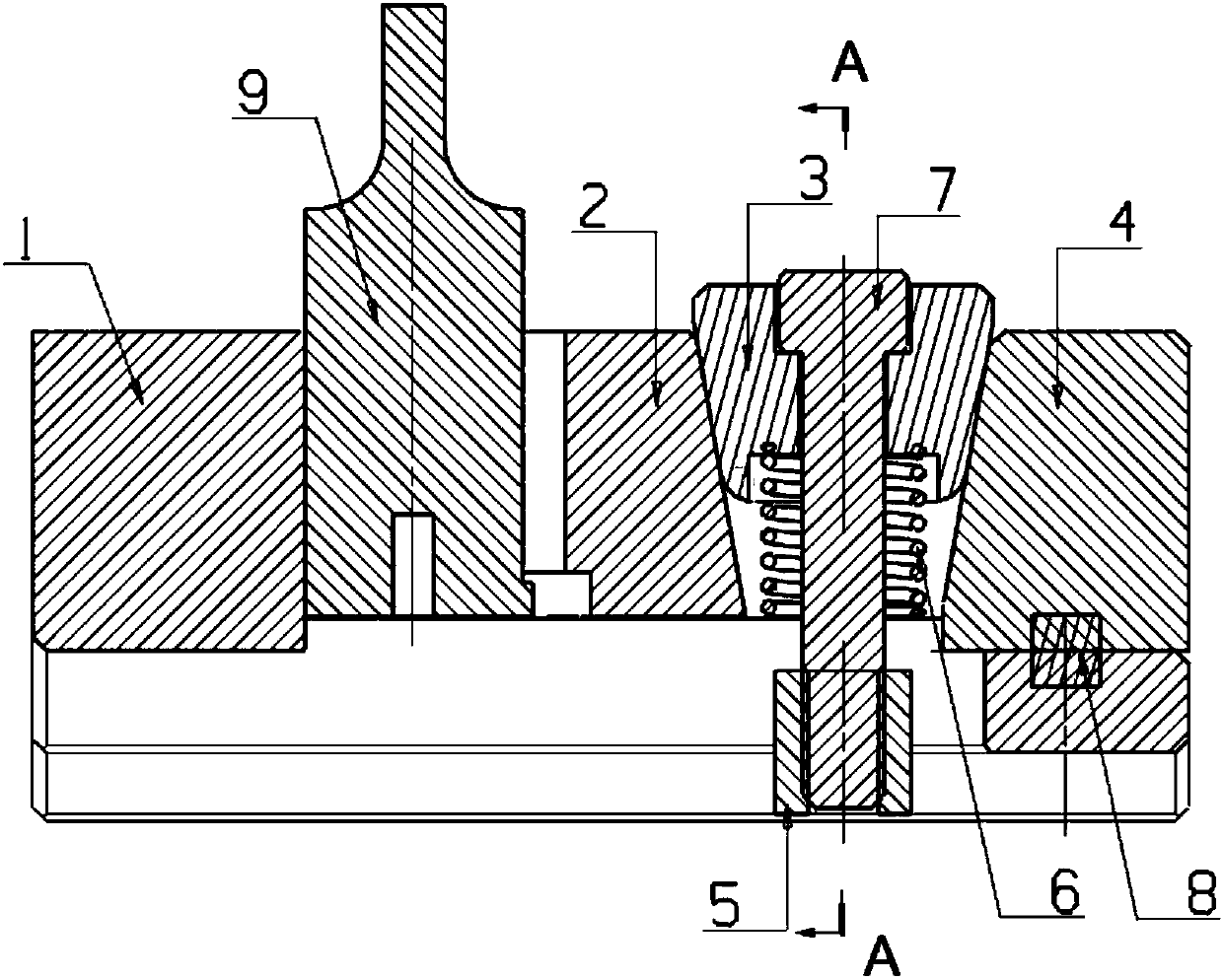

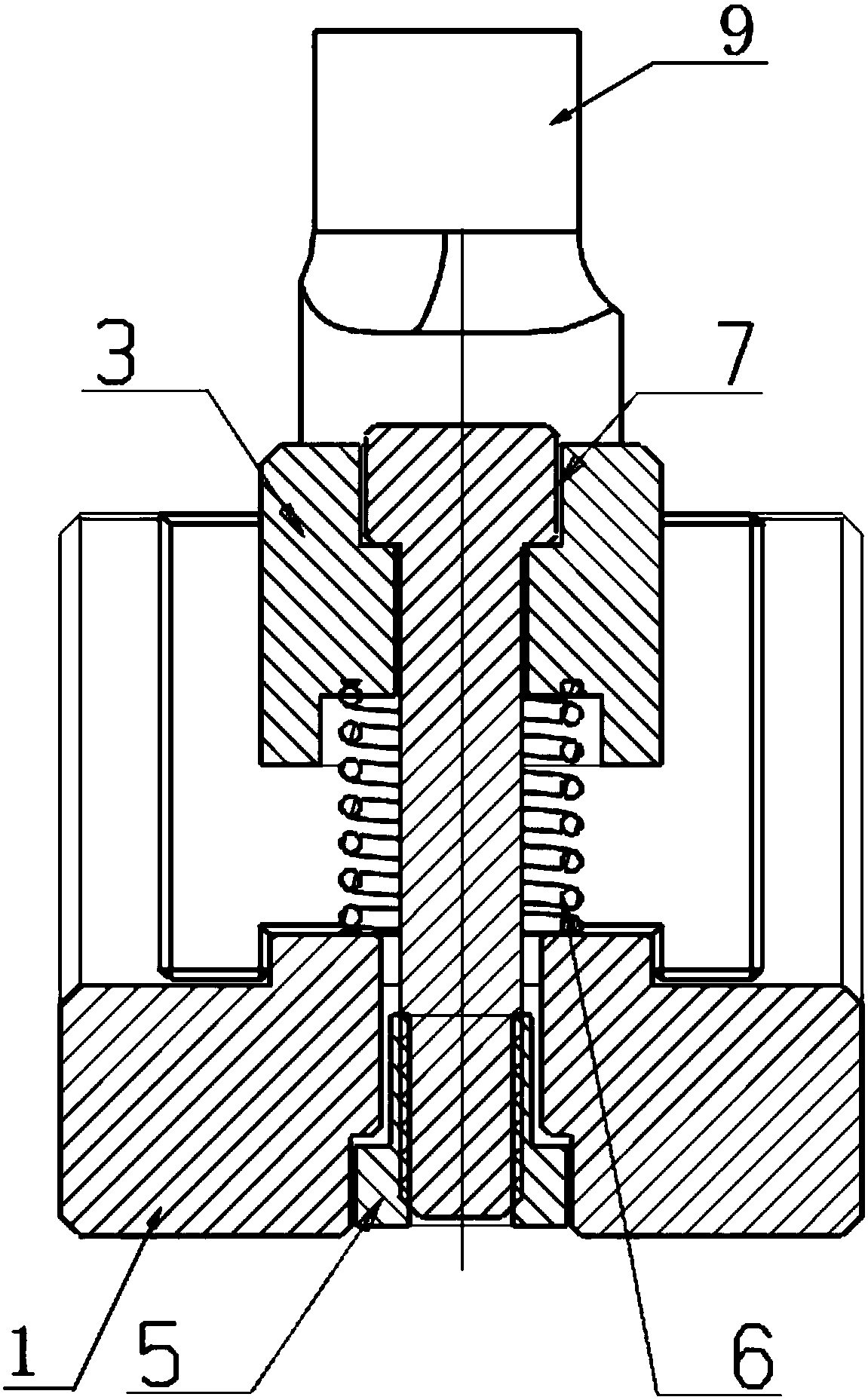

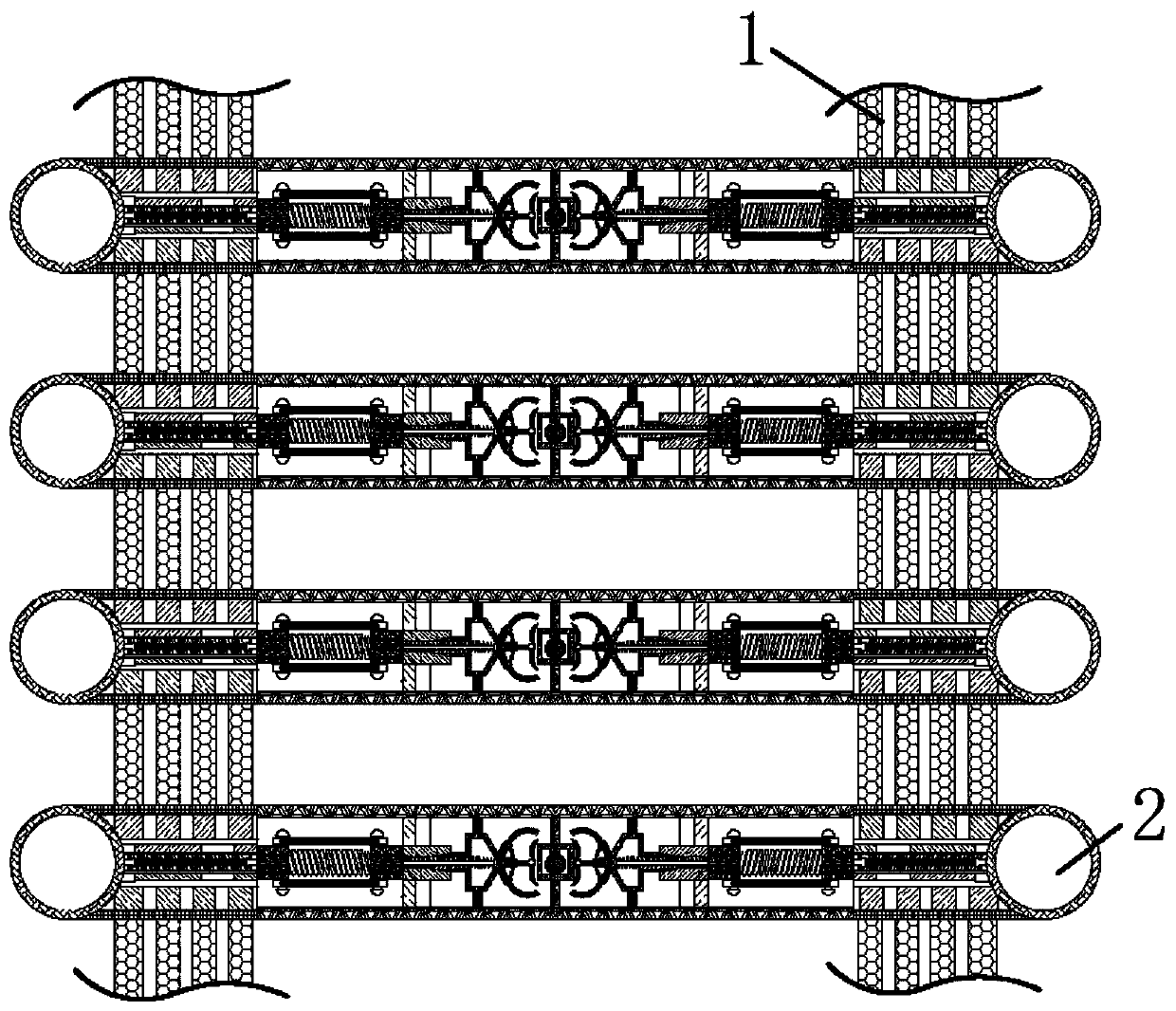

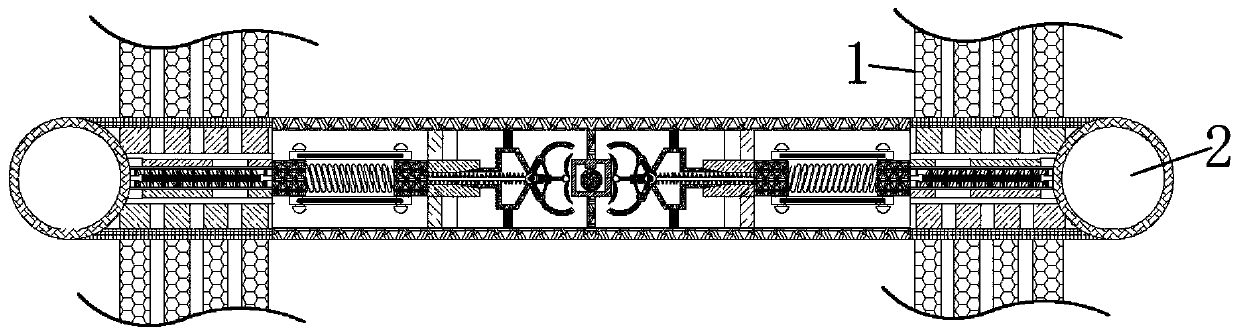

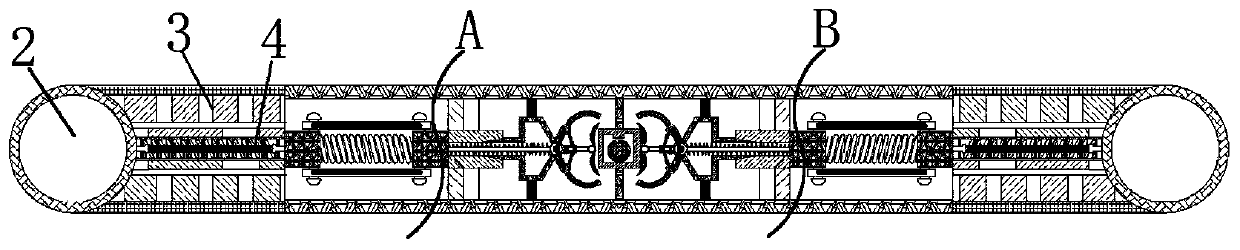

Clip device used in coordination with endoscope and clipping part of clip device

The invention relates to a clip device used in coordination with an endoscope, and the clipping part of the clip device comprises clips, a clip tube, a clip fixing base and a connecting tube. The chipfixing base is positioned in the clip tube and can move forward and backward, the connecting tube is fixed at the back end of the clip fixing base, the tail parts of the two clips are stored in the clip tube and are movably connected with the front end of the clip fixing base through a deformation hole, and the inner wall of the tail part of the clip tube is provided with a stop step. When the two clips are clamped, the protruding parts at the tail parts of the clips are blocked on the stop step, the front end of the clip fixing base extends forward to form a connecting part, the front part of the connecting part protrudes to the left and right sides respectively to form radial pin parts, and the tail parts of the two clips are respectively sleeved on the two radial pin parts through thedeformation hole to realize the movable connection between the clips and the clip fixing base. According to the present invention, the scheme has reliable structure, convenient release, fewer components and parts, easier manufacturing and lower cost.

Owner:ANREI MEDICAL HZ

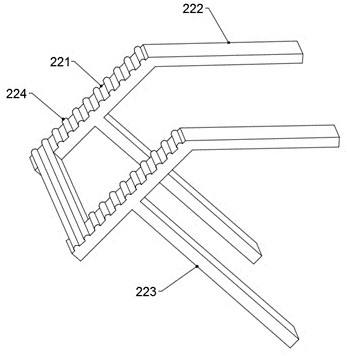

Bearing type cylindrical barrel carrying tool

The invention provides a bearing type cylindrical barrel carrying tool. The tool comprises a rear hanger, clamping arms and clamping oil cylinders. The clamping oil cylinders are arranged on the rear hanger. The clamping arms are arranged on the rear hanger in a sliding manner. Each clamping arm is connected with a piston rod of the corresponding clamping oil cylinder. Each clamping arm comprises an arm base and a clamping plate, wherein a fixed contact part is arranged on the inner side of the clamping plate. A first driving device is hinged to the position, on one side of each fixed contact part, of the corresponding clamping plate and is connected with a first contact part. A second driving device is hinged to the position, on the other side of each fixed contact part, of the corresponding clamping plate and is connected with a second contact part. A first elastic contact part is connected between each first contact part and the corresponding fixed contact part, and a second elastic contact part is arranged between each second contact part and the corresponding fixed contact part. The rear side of the rear hanger is provided with bearing sliding grooves and bearing rods, and driving teeth are arranged on the bearing rods. The bearing sliding grooves are provided with sliding groove baffles, and driving openings are formed in the sliding groove baffles. A driving gear of a bearing motor is engaged with the driving teeth of the bearing rods at the position of the driving openings. The bearing type cylindrical barrel carrying tool is suitable for barrels with different diameters, and the clamping intensity of the bearing type cylindrical barrel carrying tool on barrel cargoes is improved.

Owner:HEFEI HANDBAROW APPURTENANCES TECH

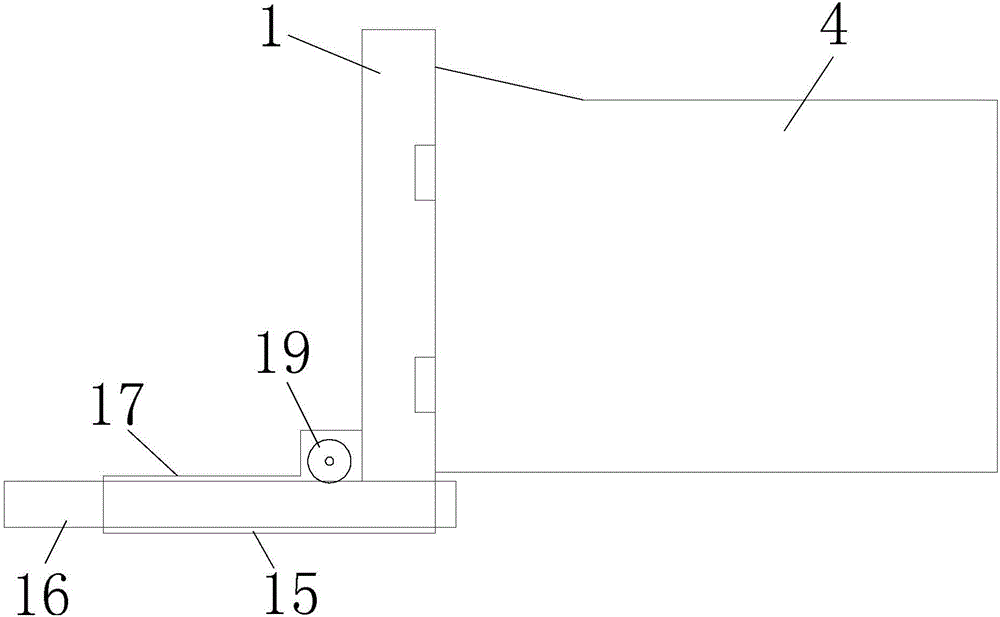

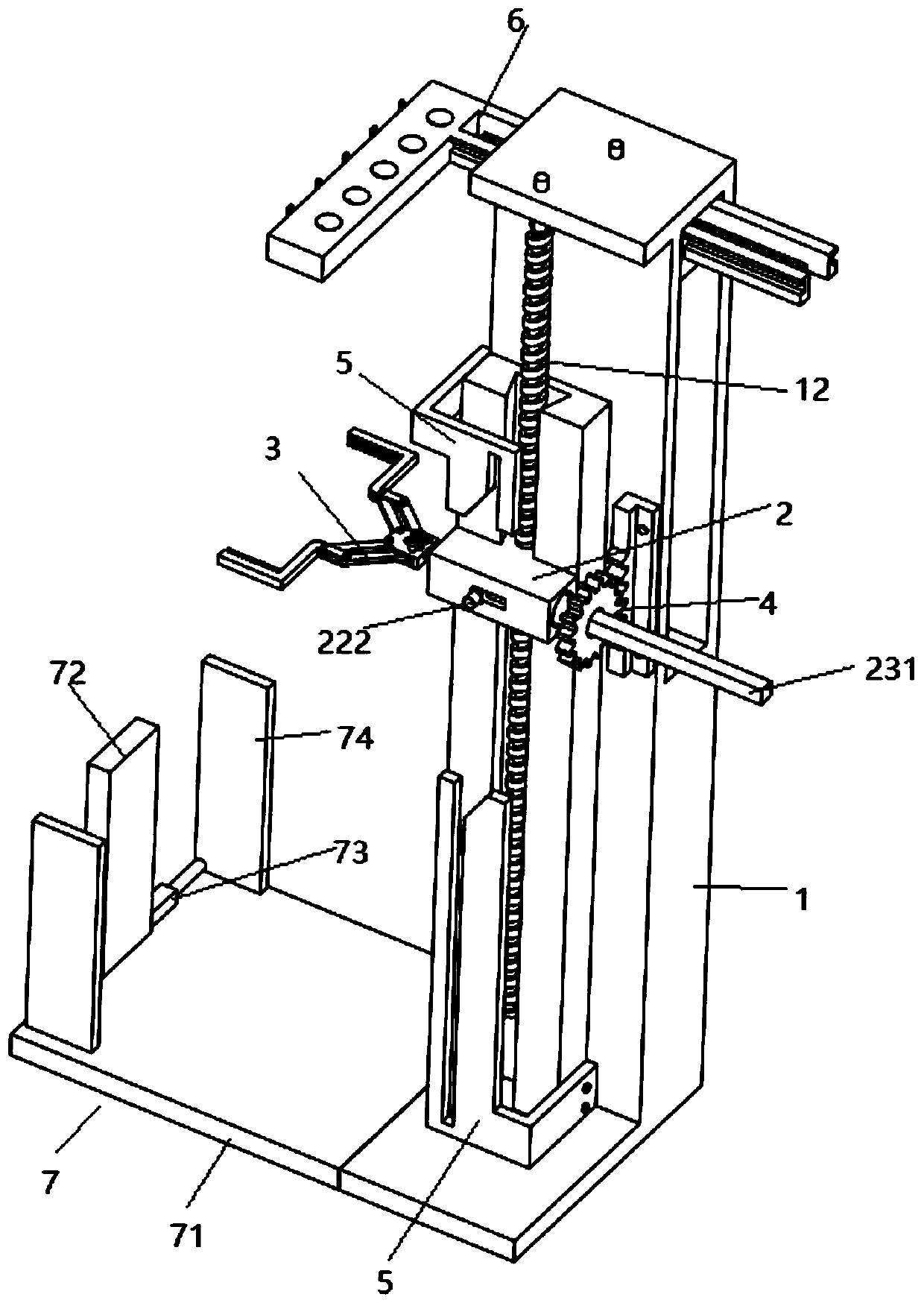

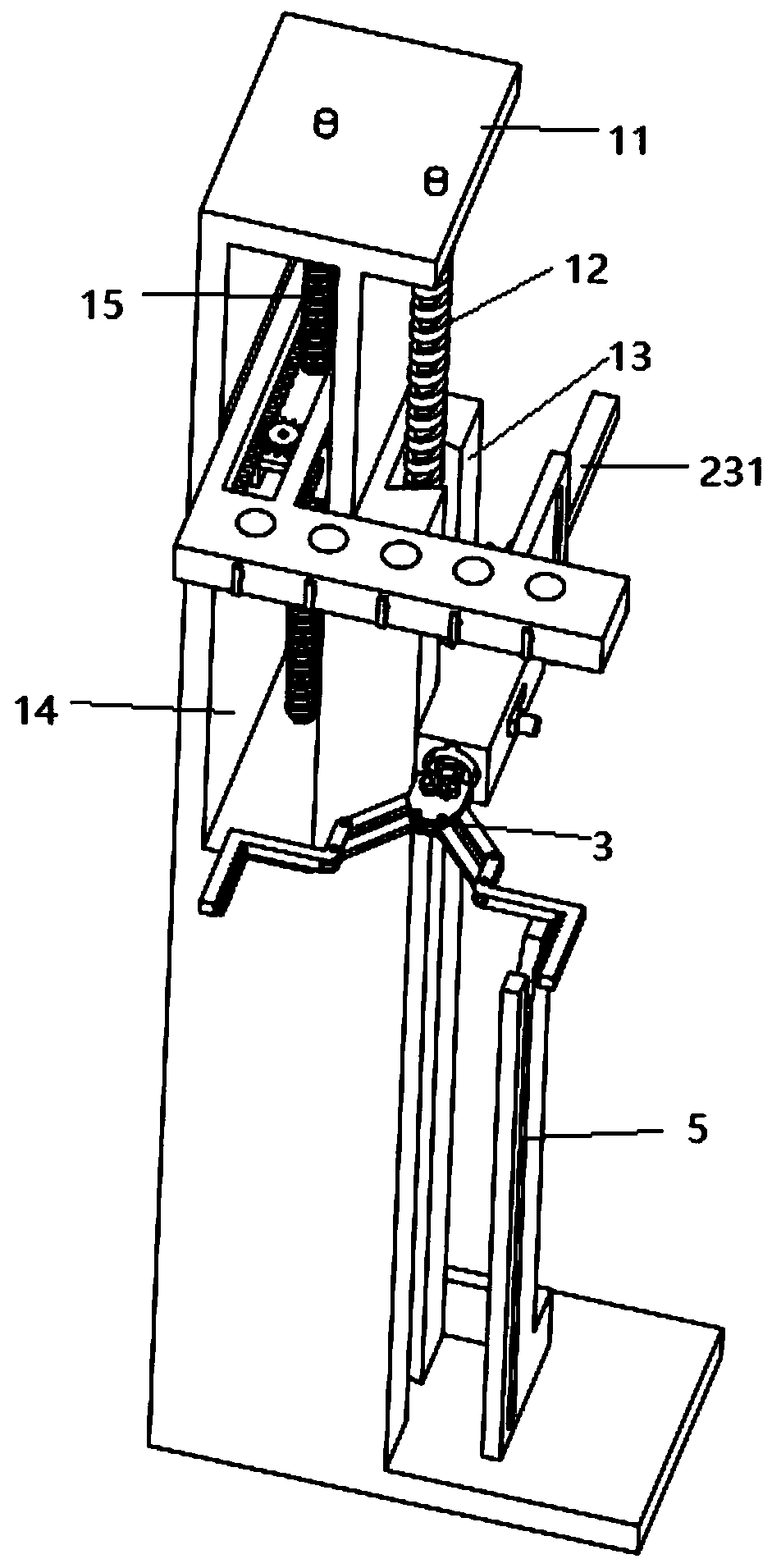

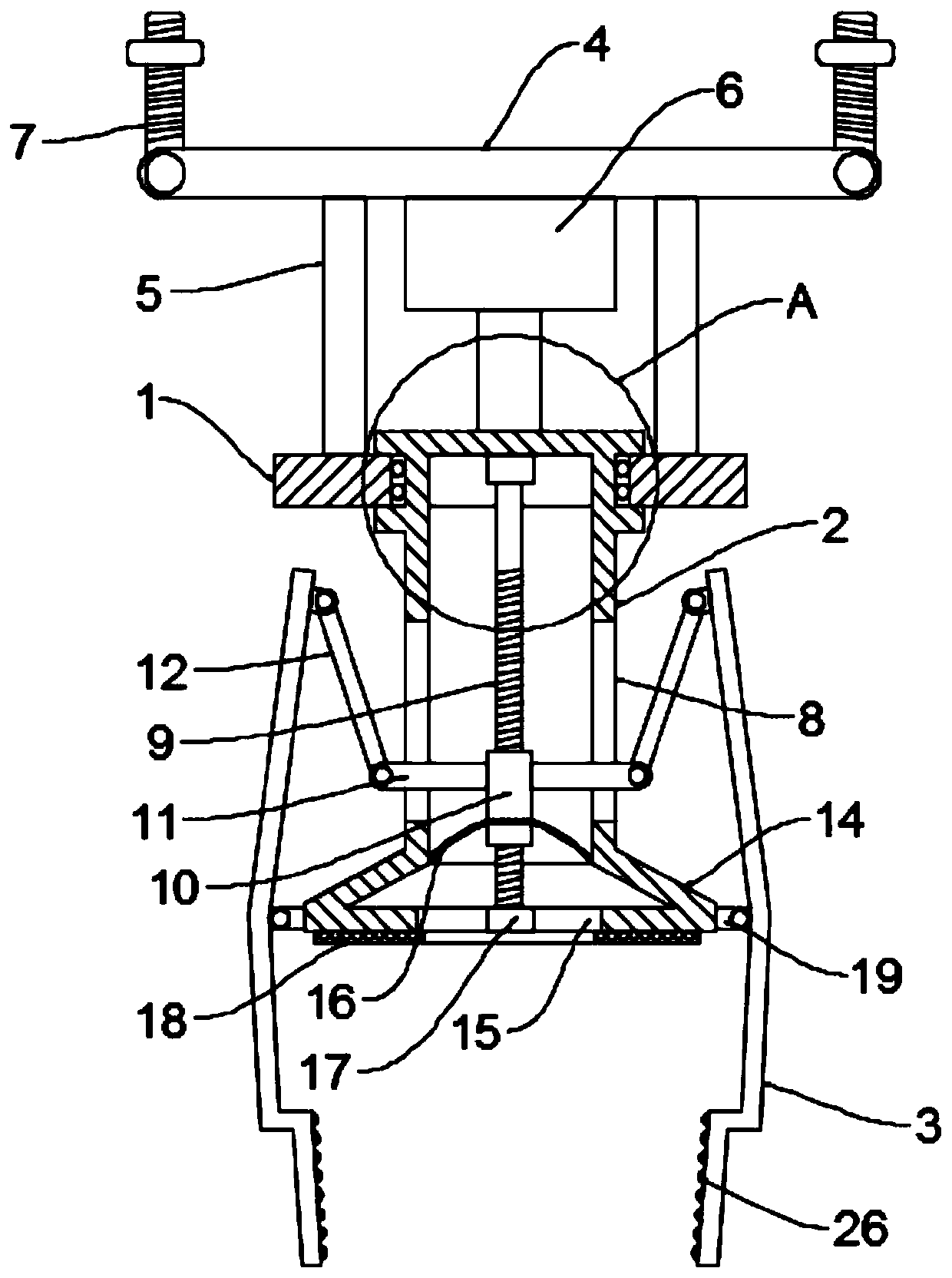

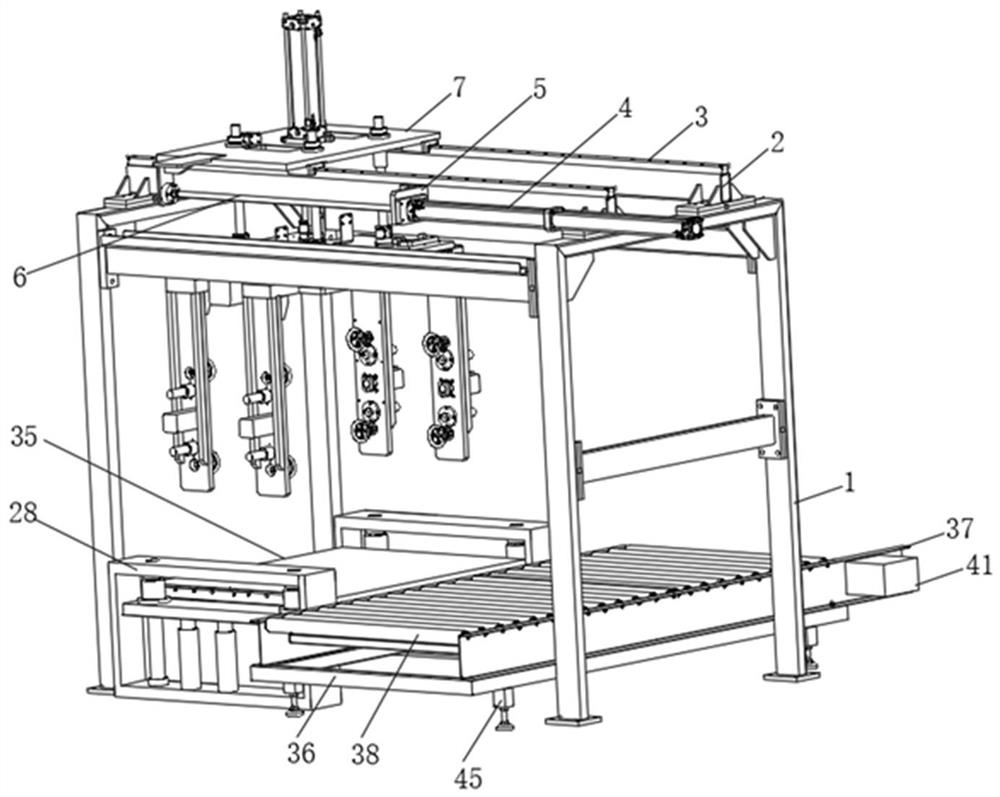

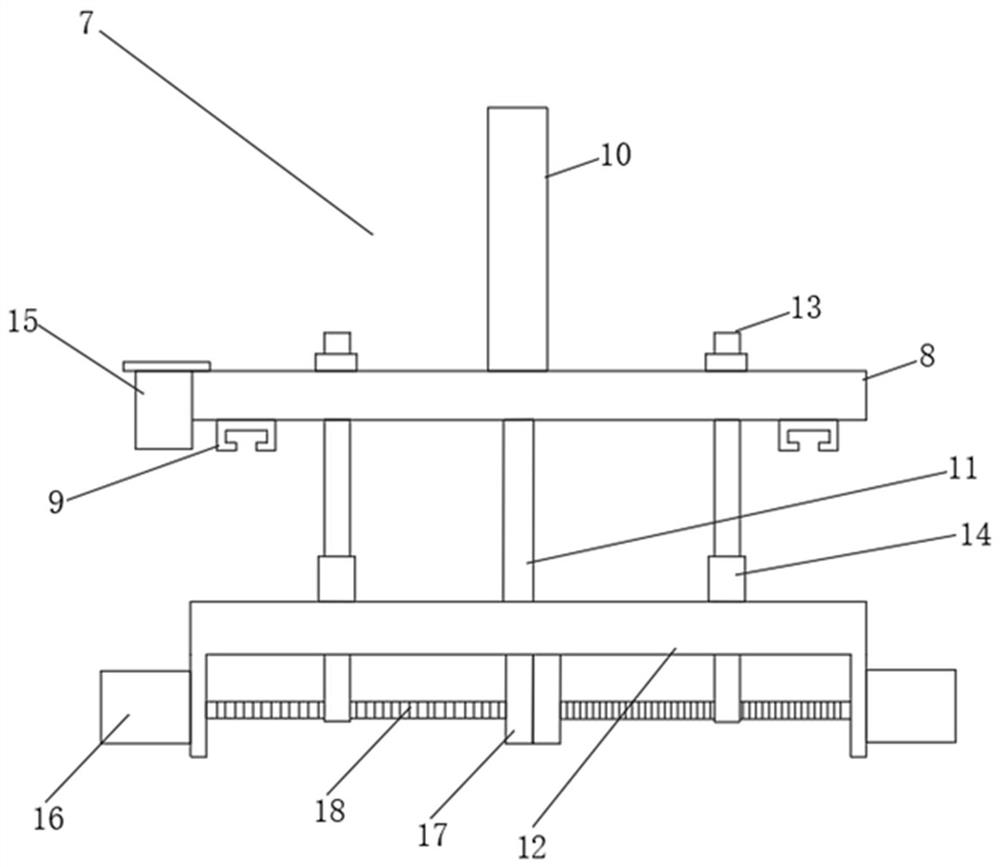

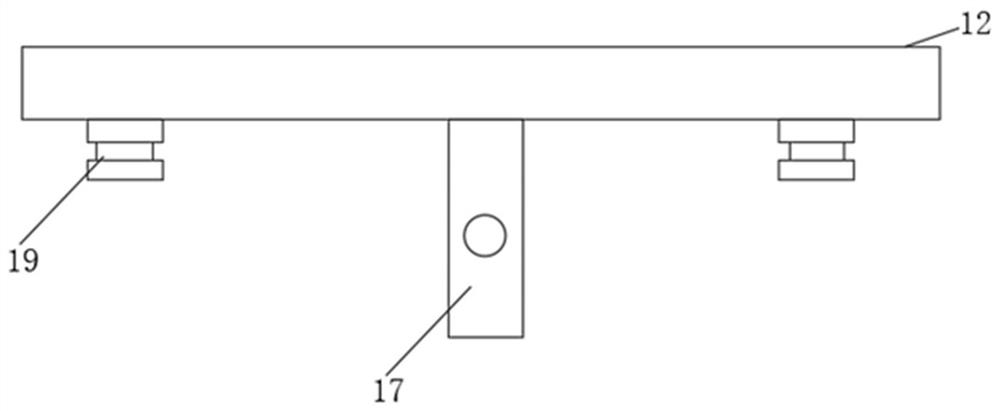

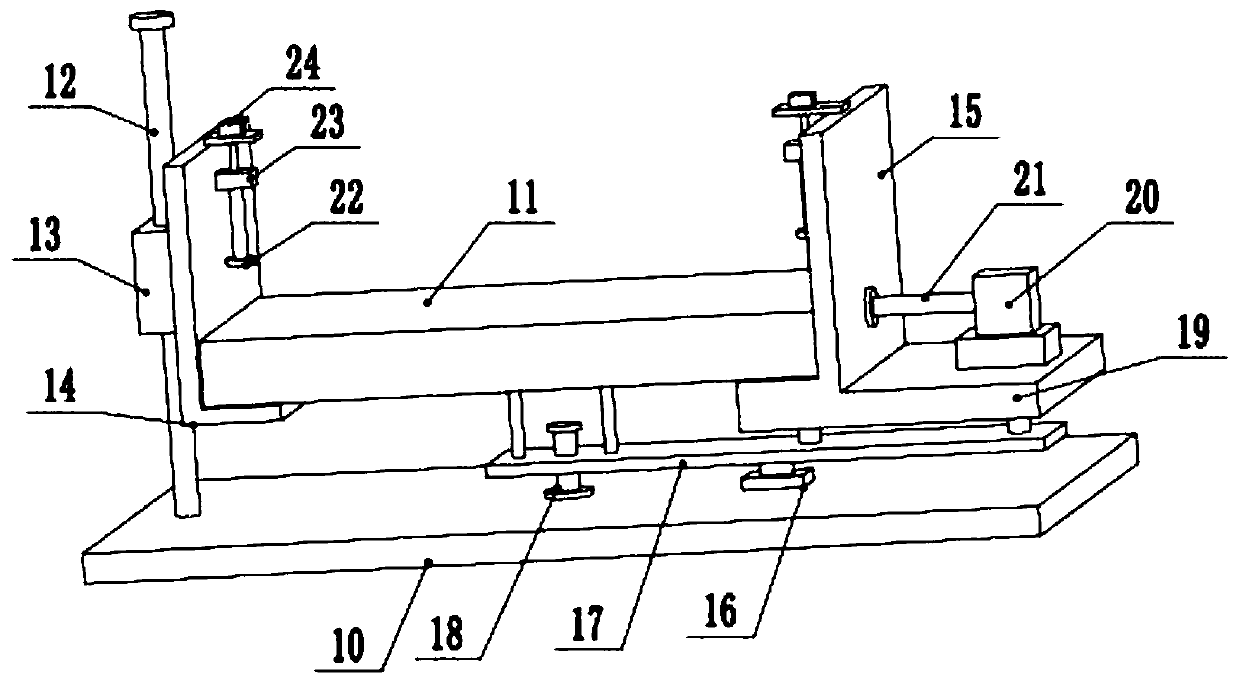

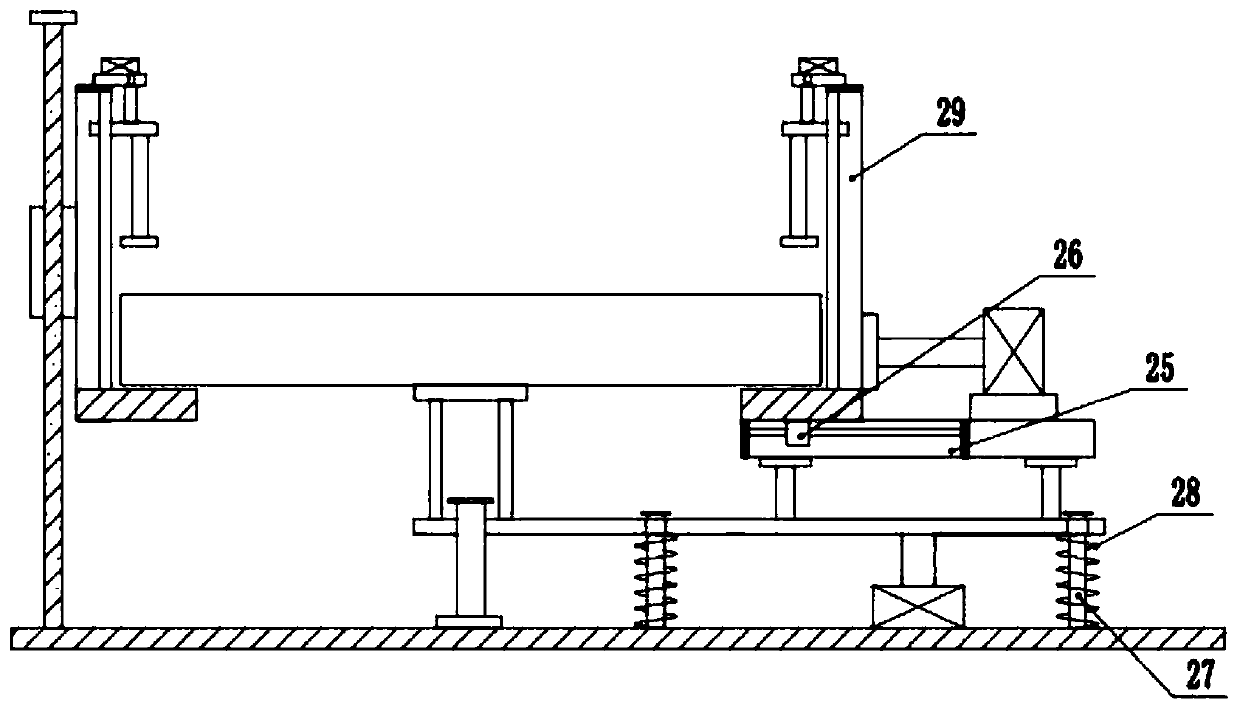

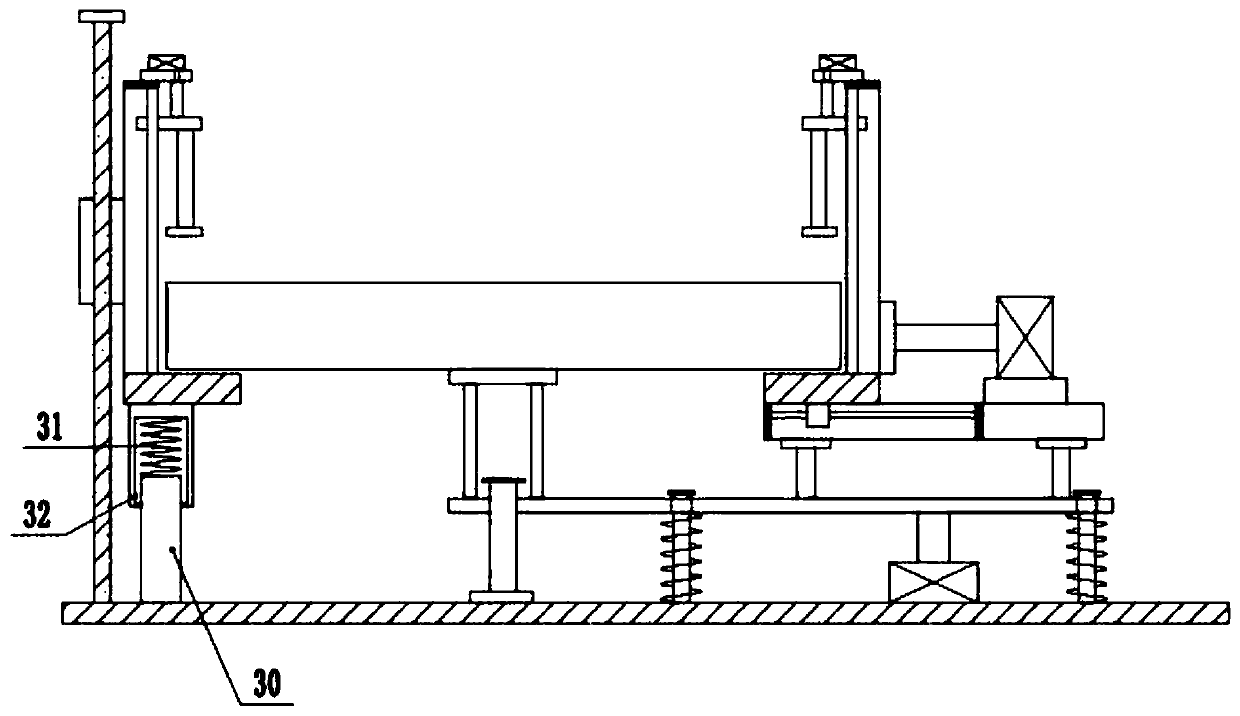

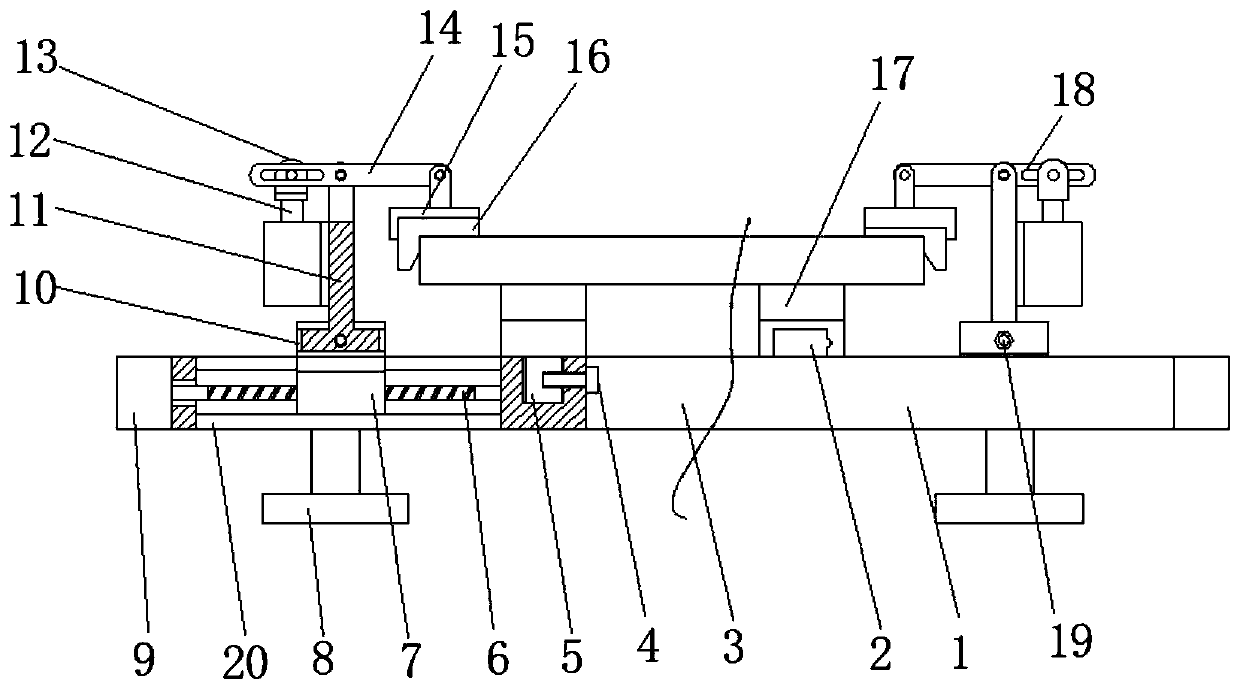

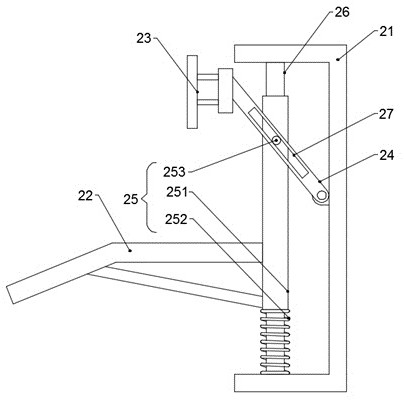

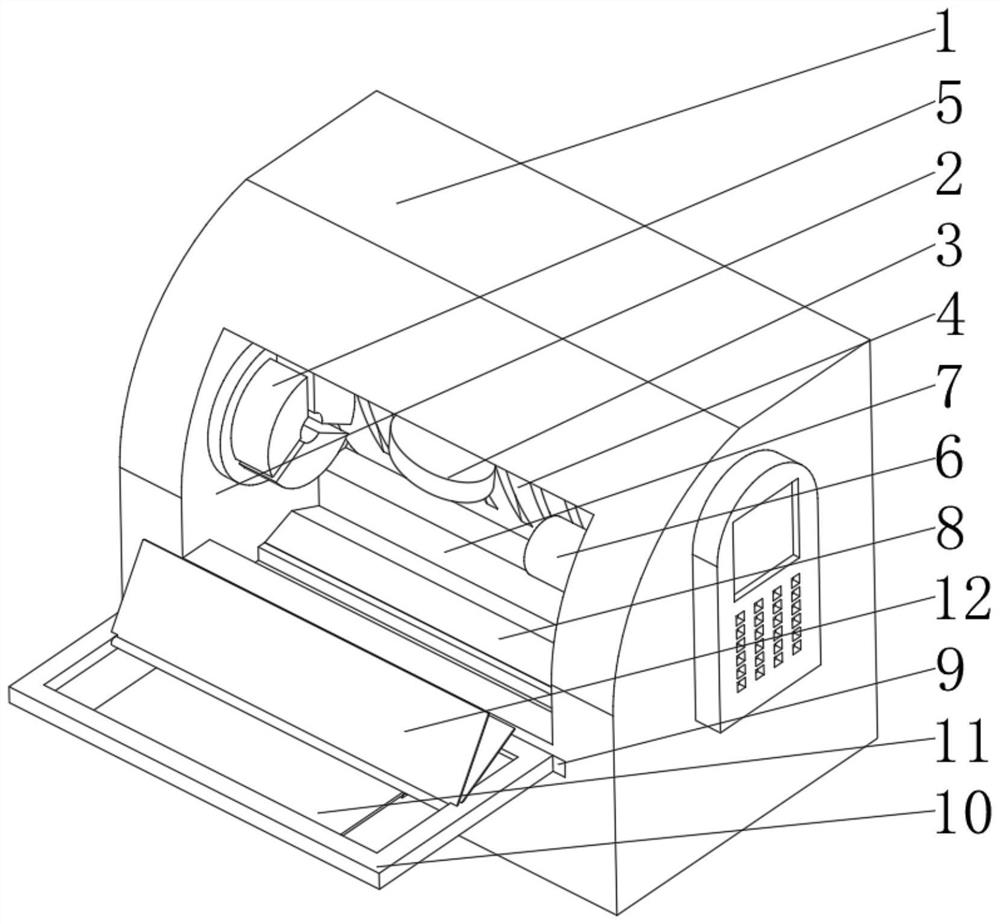

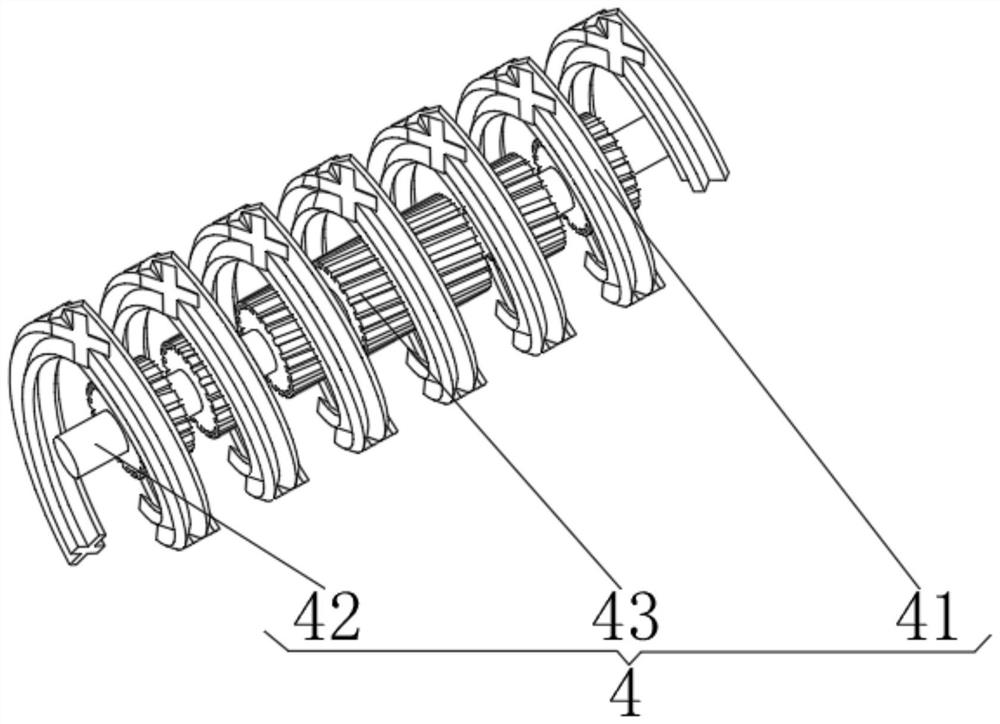

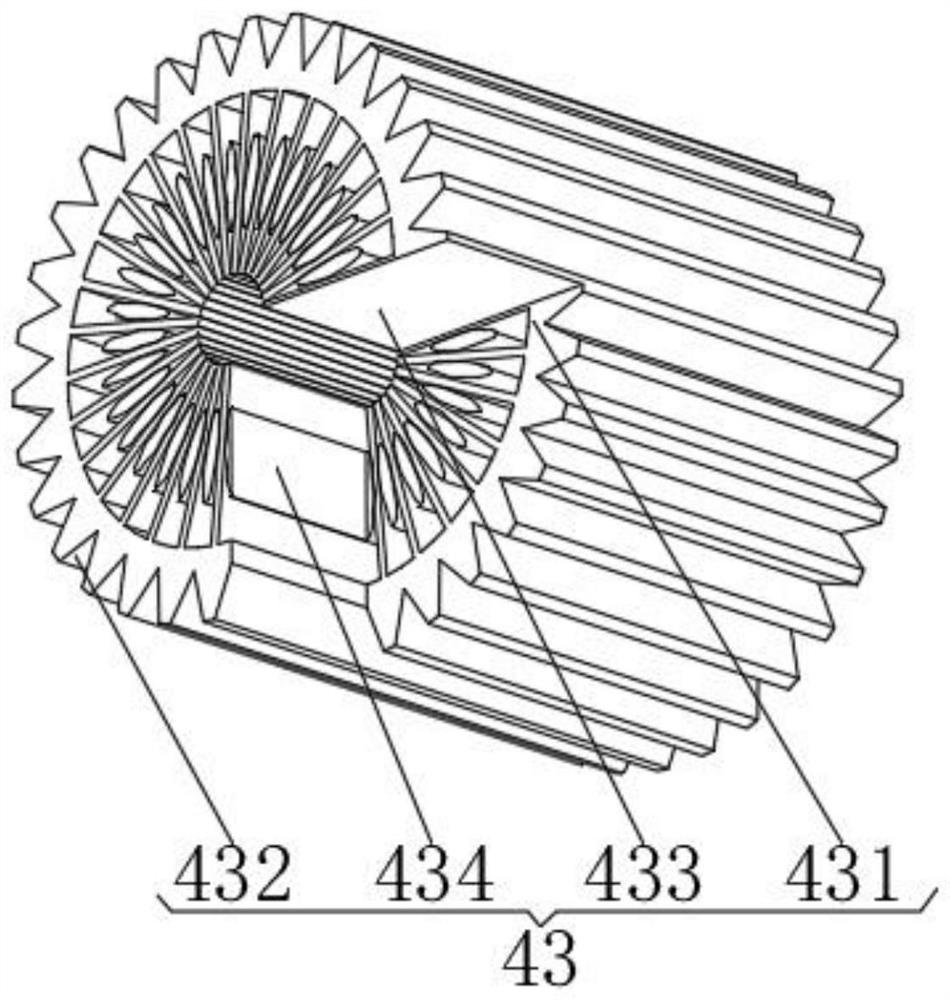

Sandwich type structure insulation board production facility

ActiveCN111545407APrevent fallingEasy to clamp and fixLiquid surface applicatorsCoatingsInsulation layerAdhesive

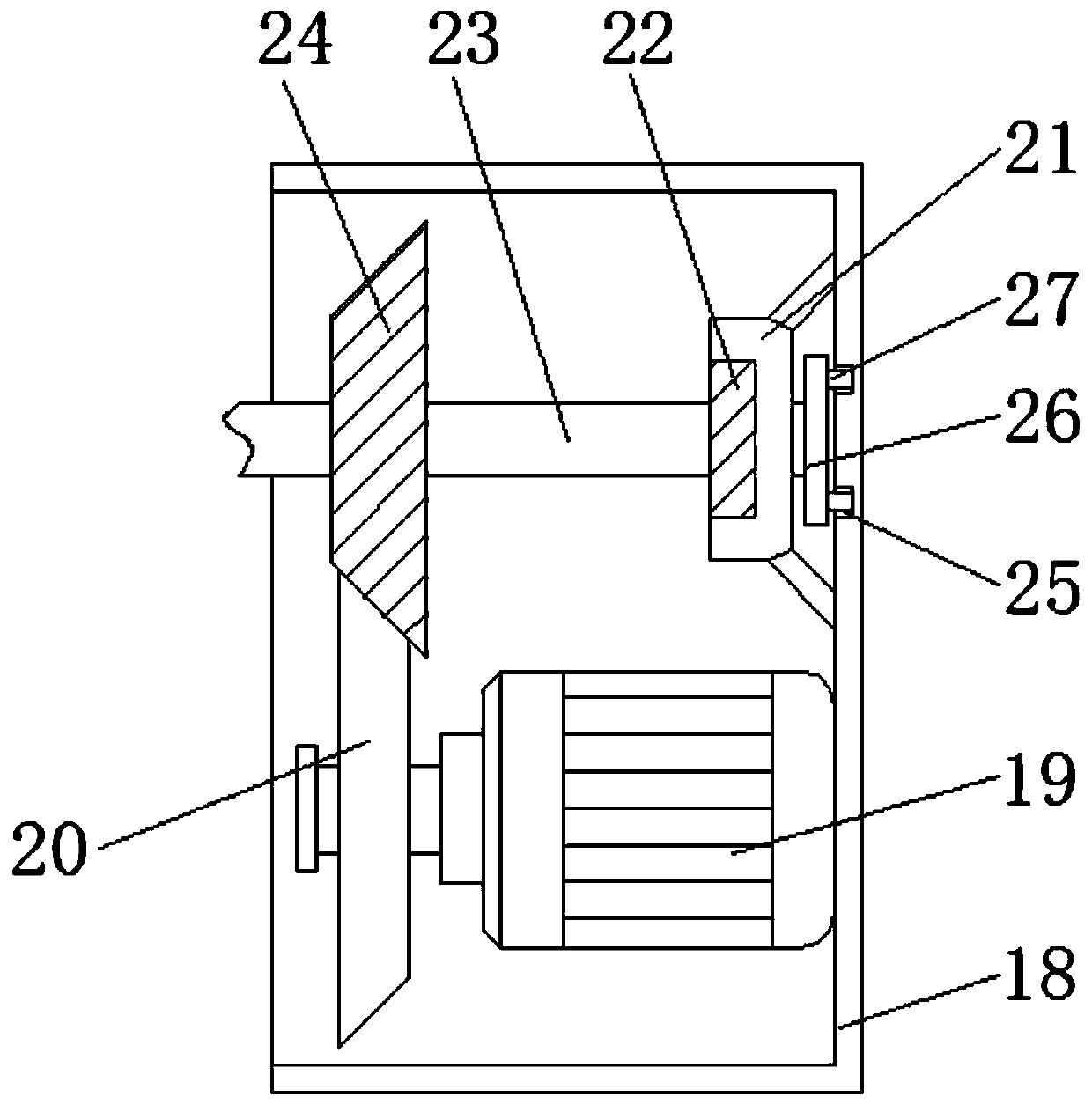

The invention discloses a sandwich type structure insulation board production facility. The sandwich type structure insulation board production facility comprises a locating supporting frame. A lifting locating mechanism which can move up and down is arranged on the front side of the locating supporting frame, a clamping mechanism which is used for clamping a middle insulation layer is fixedly arranged in the lifting locating mechanism, and a turnover mechanism which can control the clamping mechanism to be turned over is arranged on the lifting locating mechanism. Meanwhile, limiting lockingbases which cooperate with the lifting locating mechanism are arranged at the upper end and the lower end of the front side of the locating supporting frame, and an adhesive application mechanism which conducts adhesive application on the clamped middle insulation layer in the clamping mechanism is arranged on the rear side of the locating supporting frame. By means of the sandwich type structureinsulation board production facility, the process that after adhesive application operation is conducted on one side of the middle insulation layer, and a sheet of plywood adheres to the side of the middle insulation layer, the turnover of the middle insulation layer is achieved under the turnover action of the turnover mechanism, then adhesive application operation is conducted on the other sideof the middle insulation layer, and a sheet of plywood adheres to the side of the middle insulation layer is achieved, the automatic adhesive application and double-side adhesion adhesive applicationprocess of the middle insulation layer is achieved, and the combination manufacturing efficiency of an insulation board is improved.

Owner:武汉鼎华源保温节能技术有限公司

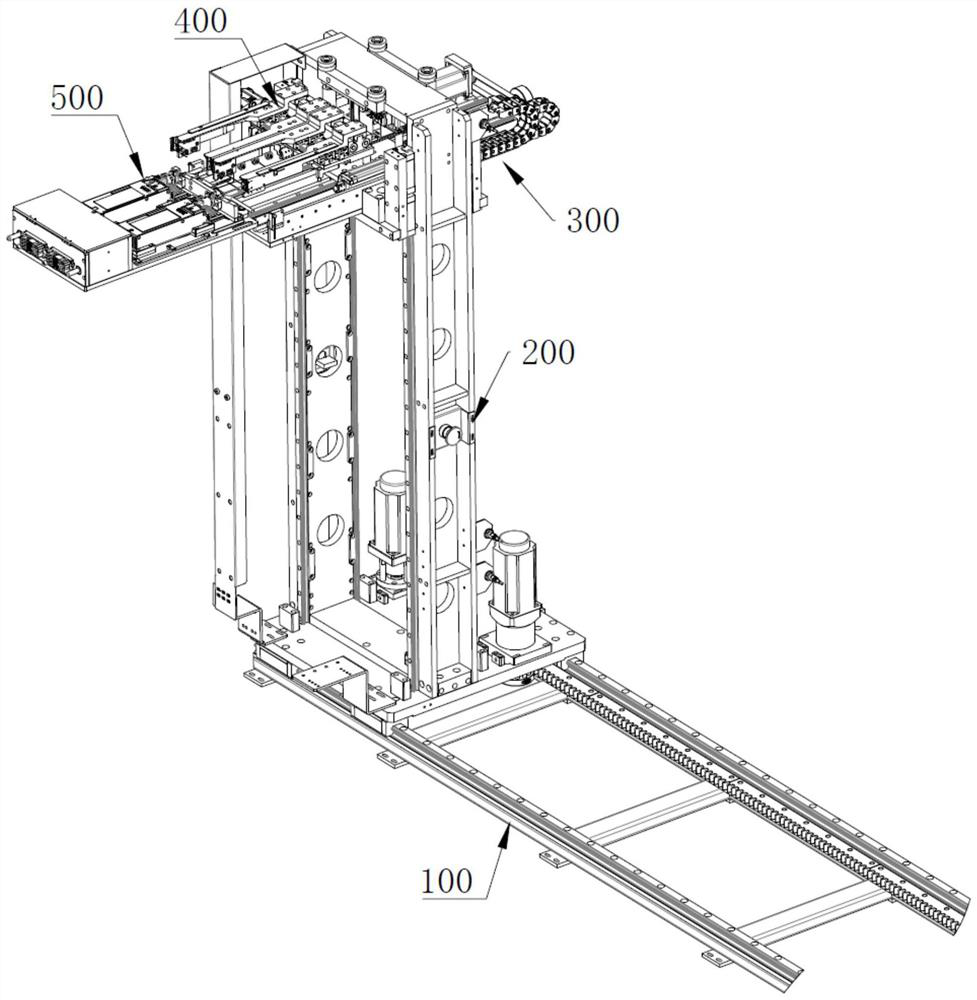

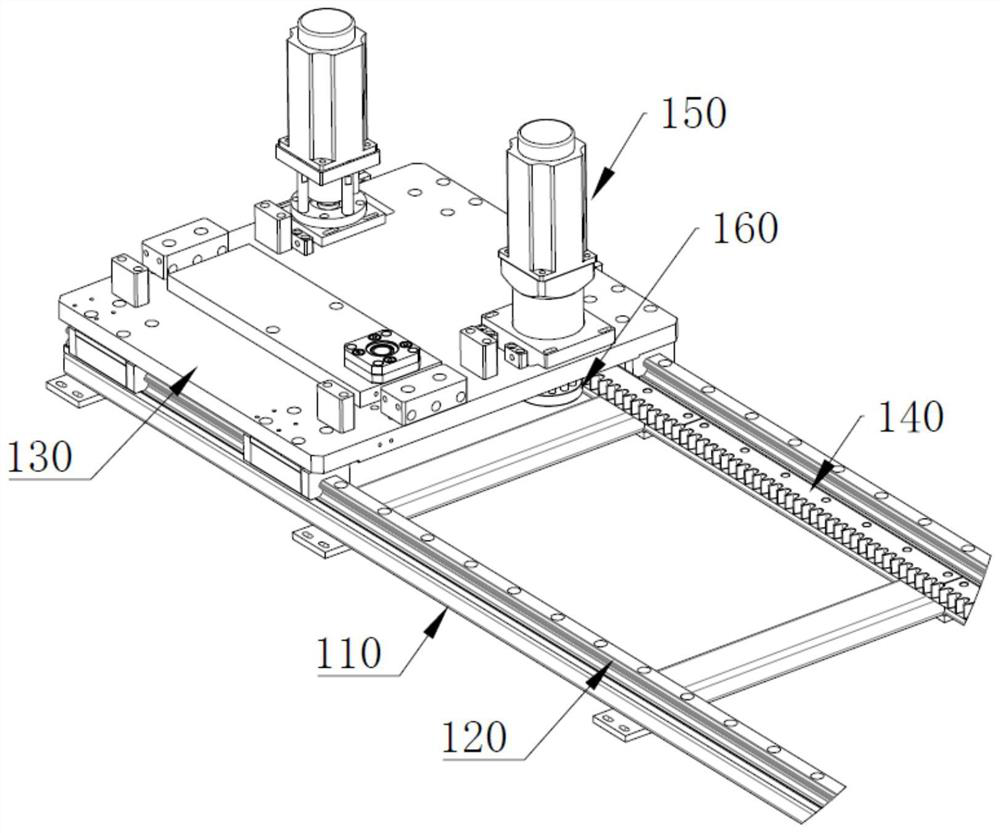

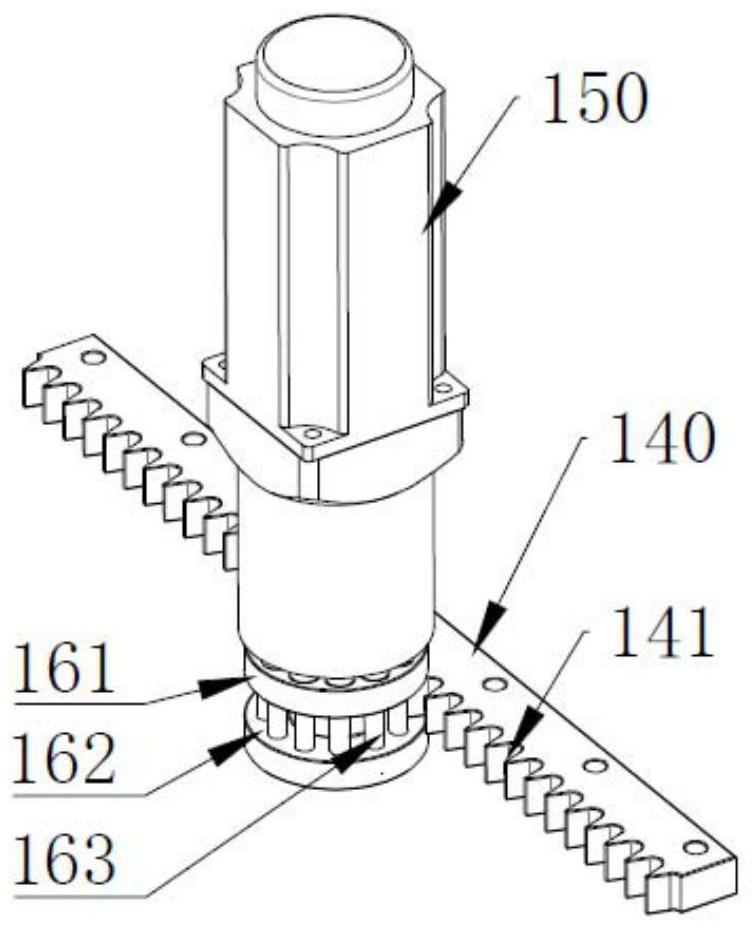

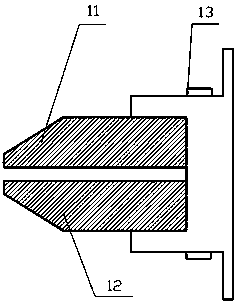

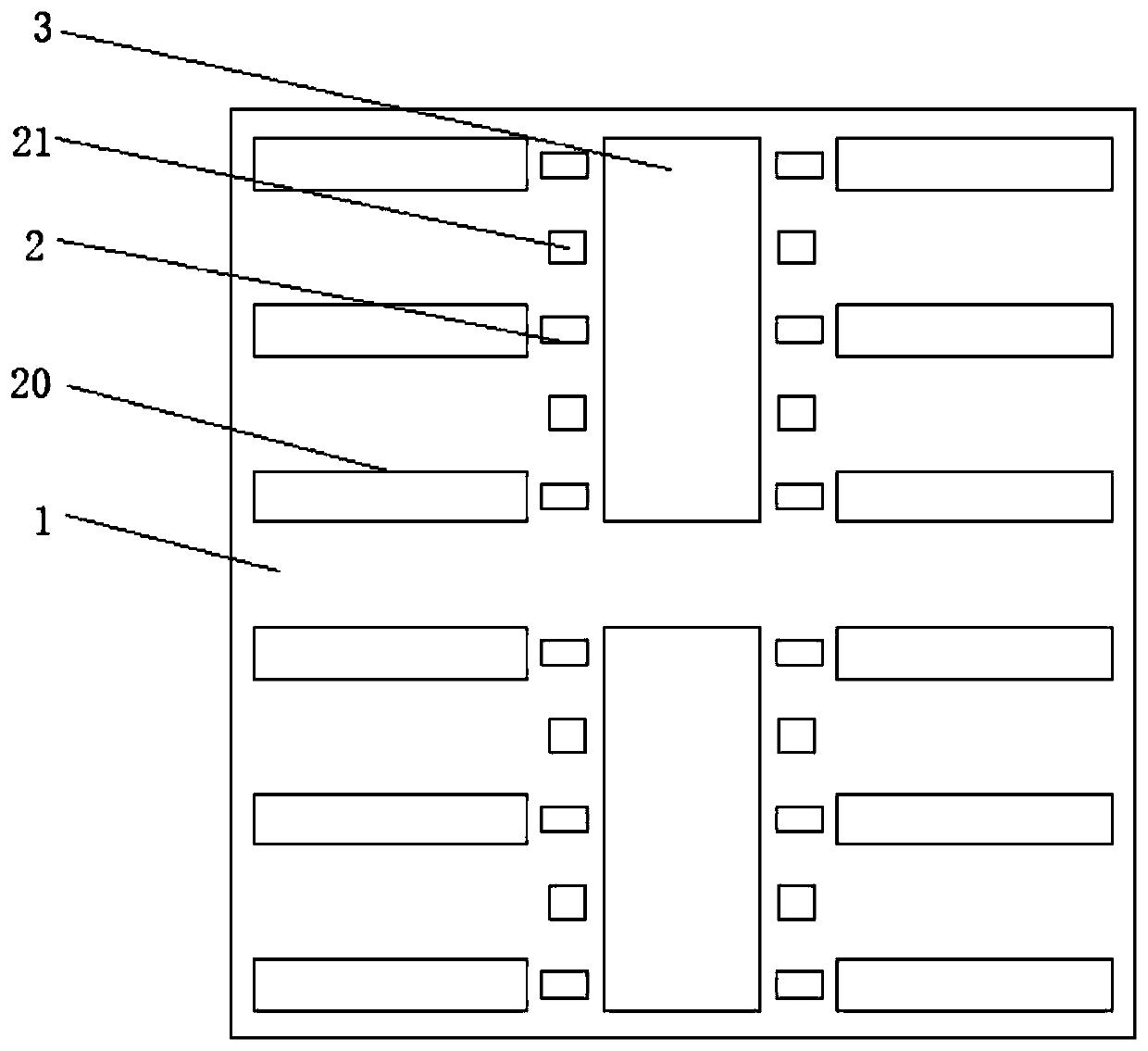

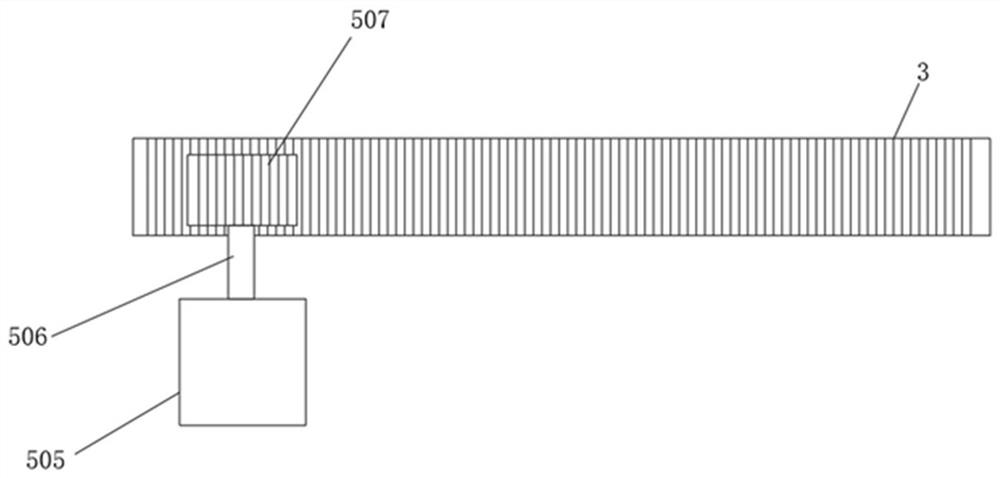

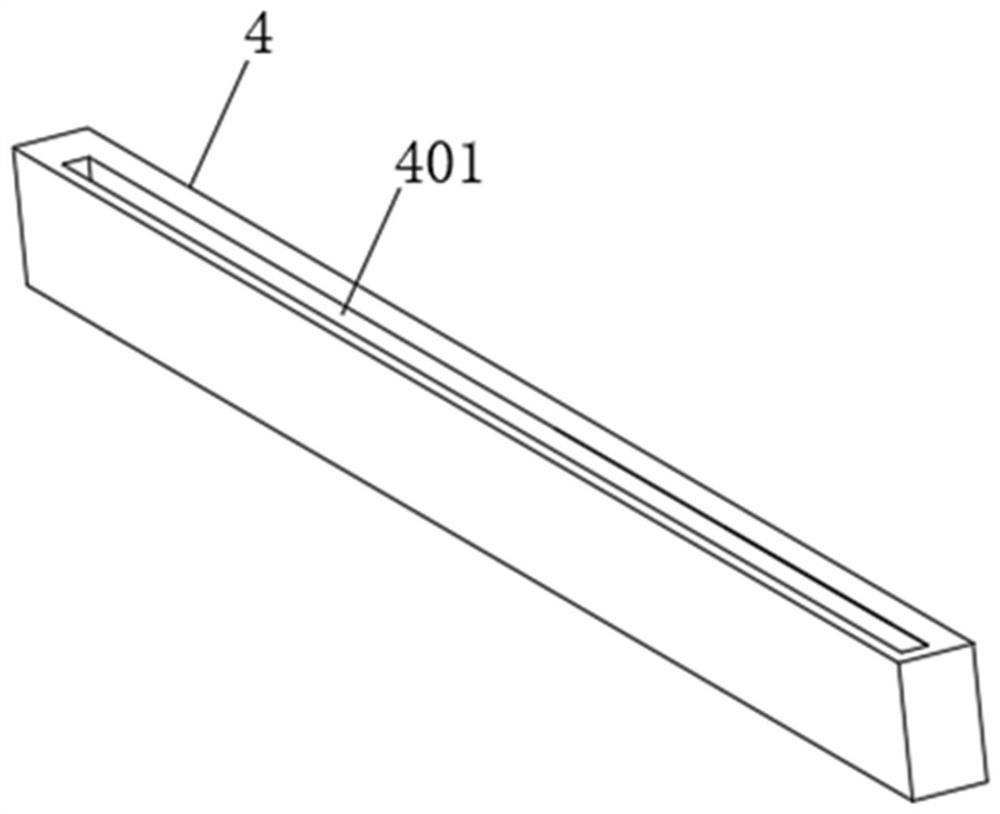

Aging product transportation mechanism

InactiveCN112173623ARealize intelligent workHigh degree of automationElectrical testingConveyor partsEngineeringTransportation technology

The invention relates to the technical field of aging automatic transportation, in particular to an aging product transportation mechanism. The aging product transportation mechanism comprises a linear transportation line, a lifting conveying device for conveying to the linear transportation line, a grabbing driving device for conveying to the lifting conveying device, a grabbing inserting and pulling device mounted on the grabbing driving device, and at least one group of test jigs. According to the aging product transportation mechanism, a full-automatic large-range transportation structureis adopted, in the using process, range transportation can be achieved through the linear transportation line, the automation degree is high, manpower and material resources are saved, meanwhile, lifting is adopted to adapt to positions with different heights for transportation and placement, the grabbing driving device is matched with the grabbing inserting and pulling device to be used for driving and inserting and pulling products after the products are transported, the overall automation degree is high, and the working efficiency is high.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

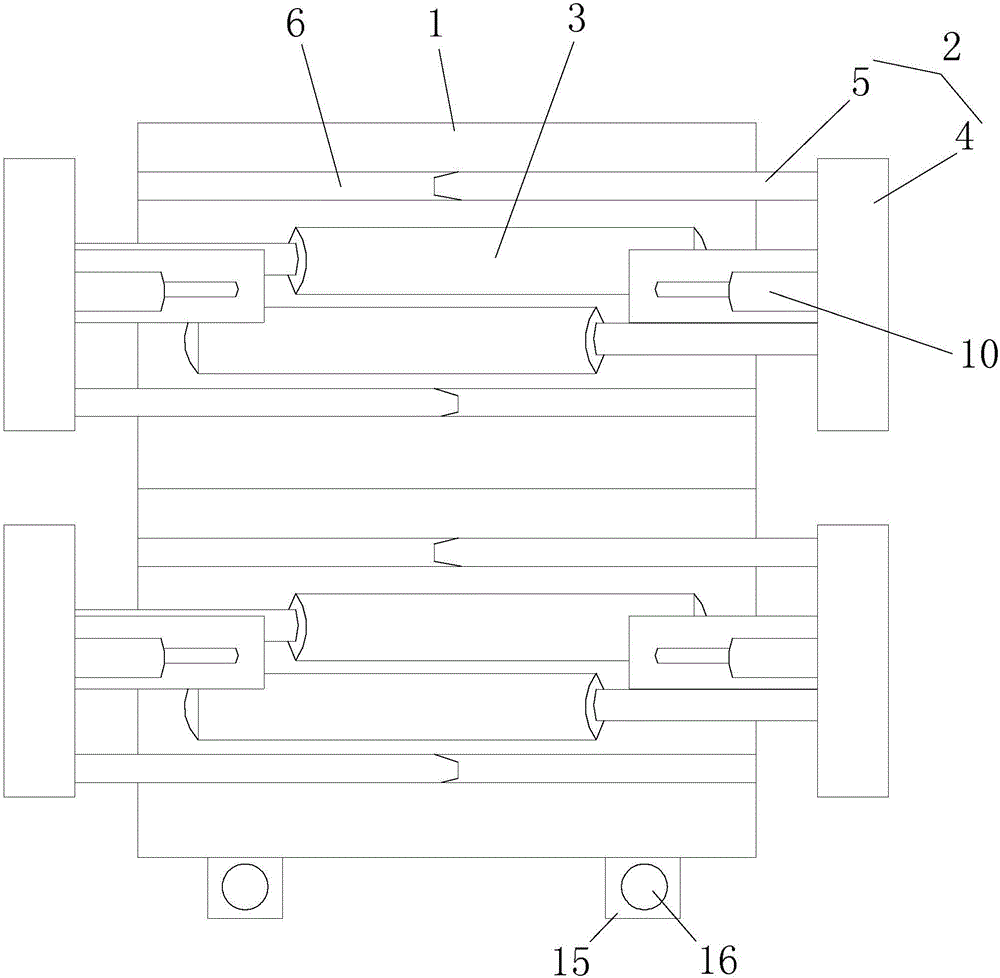

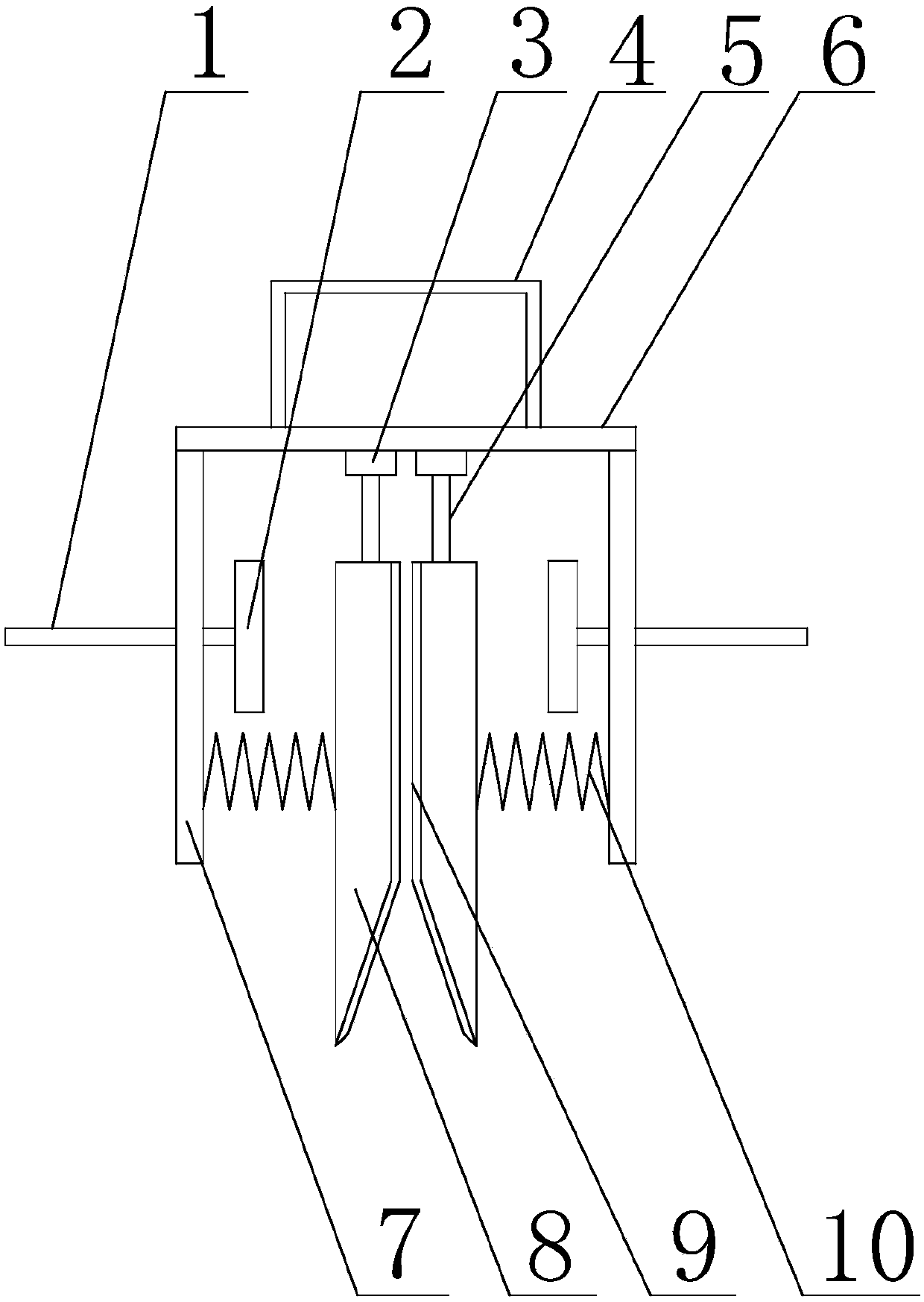

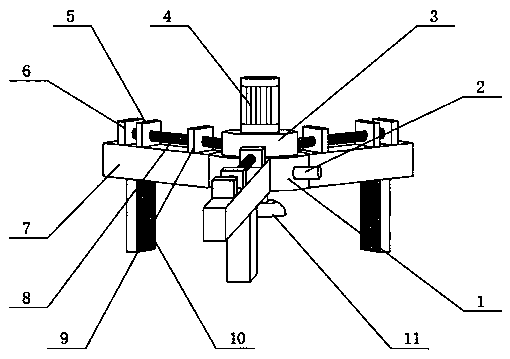

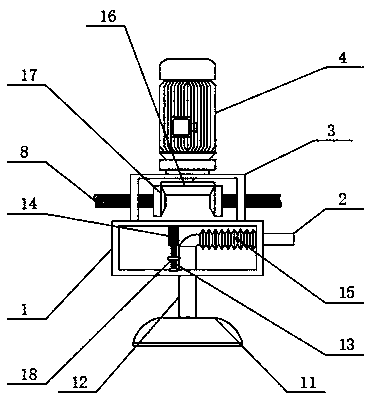

High-speed tensile test steel plate sample piece clamp

InactiveCN103674697AIncrease clamping strengthRealize flexible connectionStrength propertiesForcepsEngineering

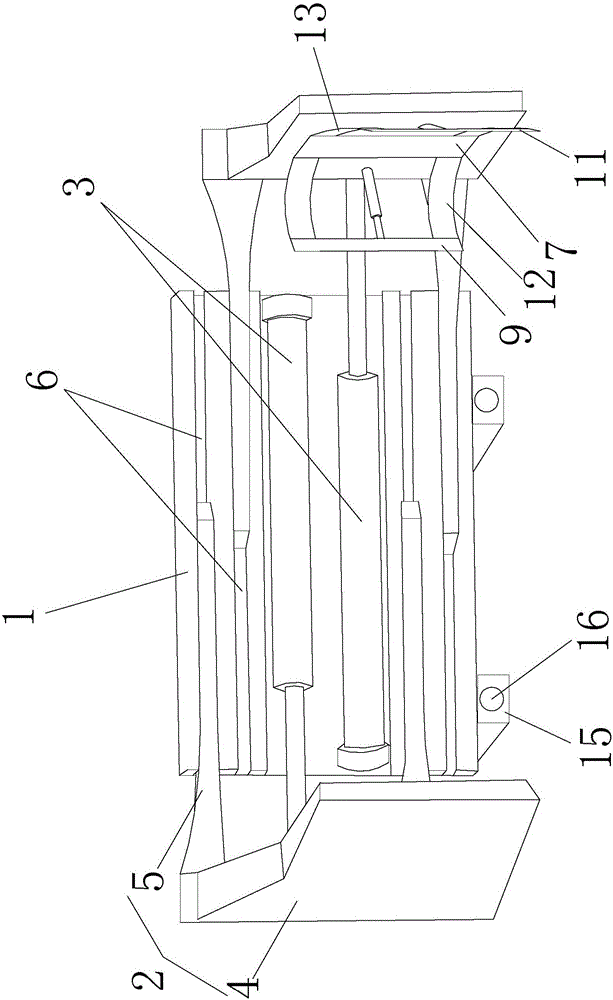

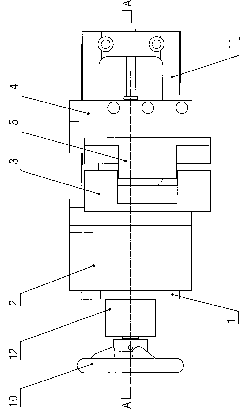

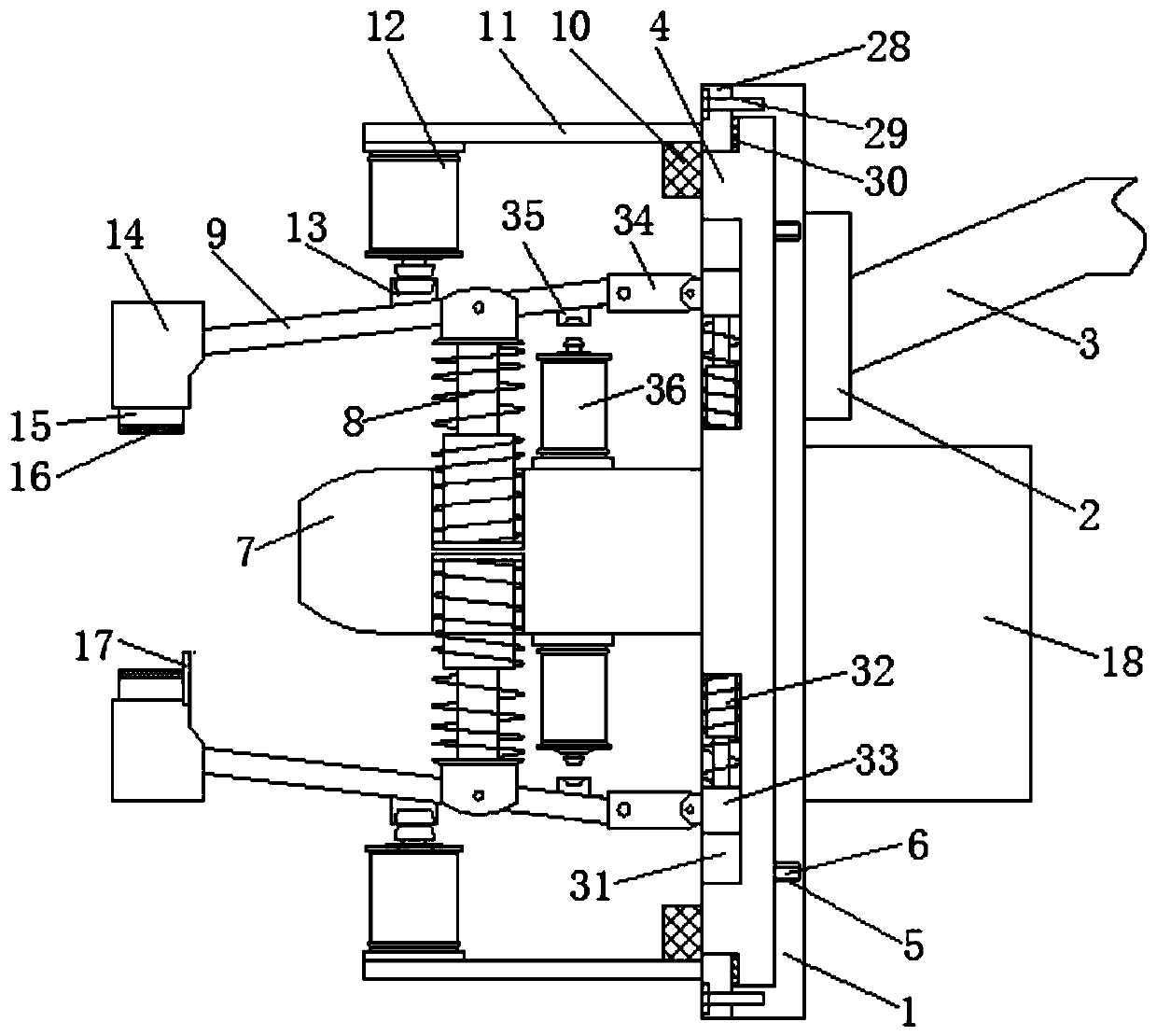

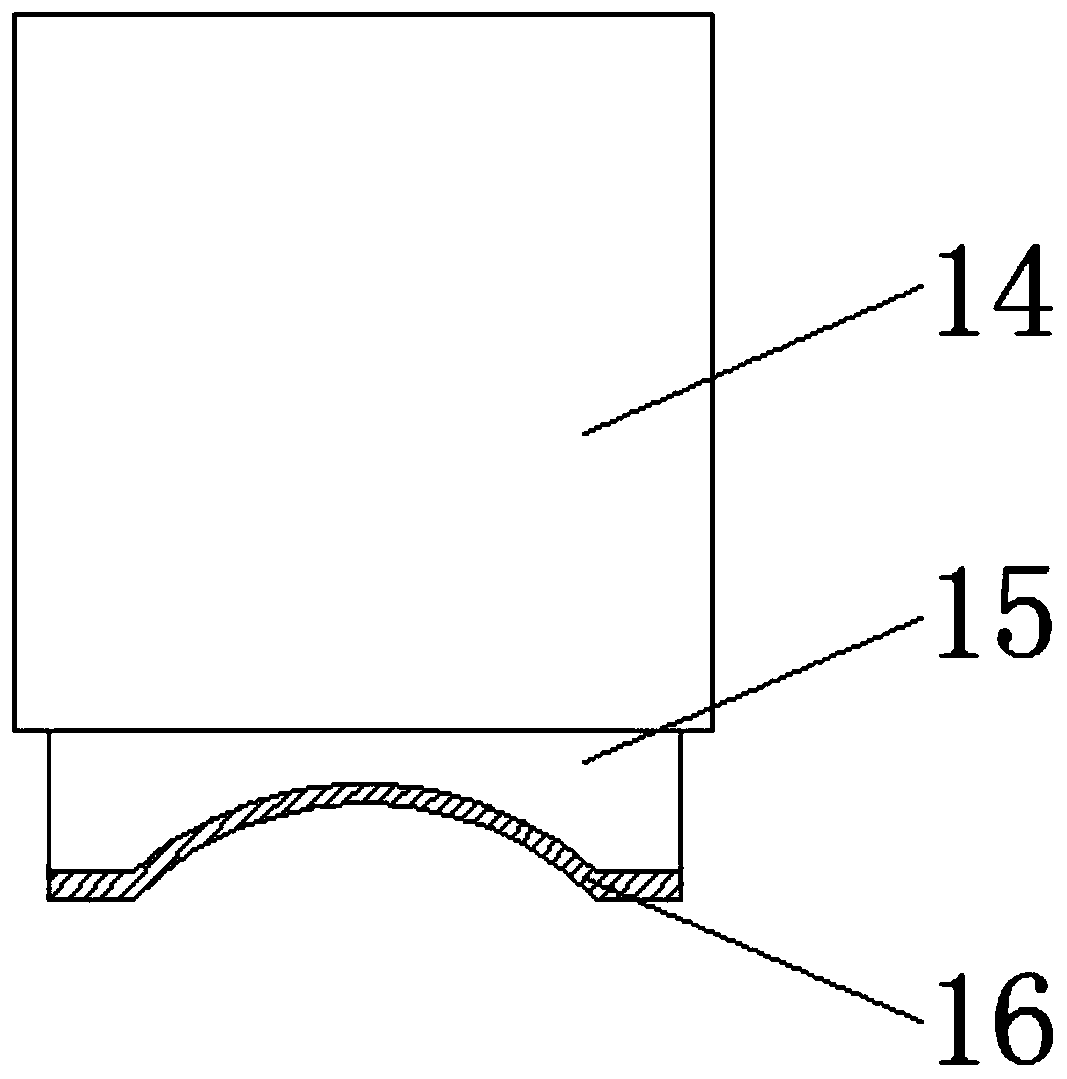

The invention provides a high-speed tensile test steel plate sample piece clamp. The high-speed tensile test steel plate sample piece clamp comprises an upper holding forcep, a lower holding forcep and a locking device, wherein a clamp forceps shape is formed by the upper holding forcep and the lower holding forcep which are symmetrical up and down; the rear ends of the upper holding forcep and the lower holding forcep are mounted in the locking device. Each of the upper holding forcep and the lower holding forcep is provided with a corresponding bolt hole and a locking bolt which penetrates through the two bolt holes is arranged to lock the upper holding forcep and the lower holding forcep; the rear end of the locking device is mounted on a base; an elastic device is arranged on the base and the base is provided with two seat plates which are arranged in parallel; a buffering spring is connected between the two seat plates. According to the clamp, on the basis of keeping the structure of a previous static stretching test clamp, the locking bolt structure is additionally arranged on the upper holding forcep and the lower holding forcep so that the clamping force on a steel plate sample piece is improved; the elastic connection device is arranged so as to realize the flexible connection of the clamp and stretching test equipment and the influences on testing data by stretching impacts are reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

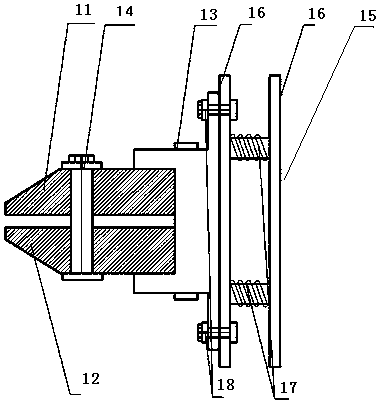

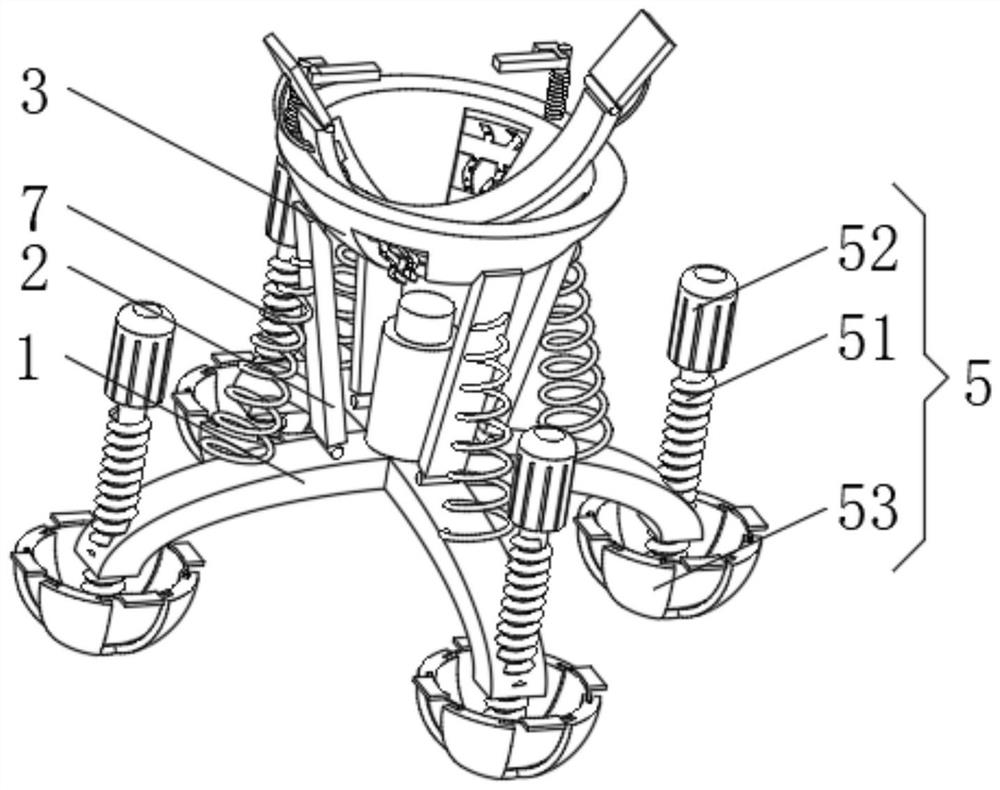

Clamping component structure of industrial robot

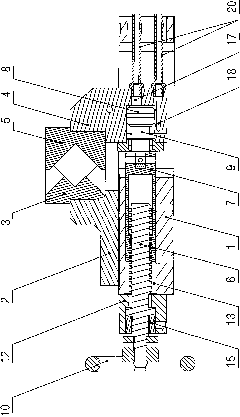

ActiveCN110497427AIncrease clamping strengthEasy to controlGripping headsMulti directionalFuture of robotics

The invention discloses a clamping component structure of an industrial robot, relates to the technical field of industrial robots and mainly aims to solve the problem that a clamping head of the industrial robot only implements lateral clamping and may cause shake of a clamped object on the clamping part. The clamping component structure comprises a fixed mounting plate, a fixed cylinder body anda plurality of clamping rod parts, wherein the fixed cylinder body is installed on the fixed mounting plate; the clamping rod parts are arranged on the outer wall of the fixed cylinder body; the bottom of the fixed cylinder body is provided with a sucking disc body, wherein the sucking disc body is of a conical structure and communicates with the inside of the fixed cylinder body; the sidewall ofthe sucking disc body is fixedly provided with hinging seats corresponding to the clamping rod parts one by one; the middle part of each clamping rod part is hinged to the corresponding hinging seat;and a push component capable pulling the clamping rod parts is arranged inside the fixed cylinder body. The clamping component structure disclosed by the invention is simple in structure, improves the clamping firmness by virtue of multi-directional clamping, adopts united control drive, is convenient to operate and is relatively high in practicability.

Owner:佛山市文杰智能机械有限公司

Rainproof sealing connection structure of outdoor power distribution box

InactiveCN105958336AHigh protection levelSimple structureSubstation/switching arrangement casingsEngineeringRabbet

The invention discloses a rainproof sealing connection structure of an outdoor power distribution box. A flange is arranged on the peripheral edge of a box door in a manner of vertically extending towards the inner side, wherein the inner side surface of the flange is provided with an half-cylinder boss along the length direction; a rabbet folded edge which is located at the inner side of the flange and is fastened to the flange is arranged on the peripheral edge of a rabbet of a door frame body in a manner of vertically extending towards the outer side; a water swelling rubber sealing strip comprises an air-tight clamping part and an air-tight leak-proof part; the front end of the air-tight clamping part is provided with a left clamping leg and a right clamping leg for clamping the rabbet folded edge; the front end surface of the air-tight leak-proof part is hermetically attached to the surface of the door frame body; a concave surface jogged with the boss is arranged on the outer side surface of the air-tight leak-proof part; and a plurality of sealing ribs are arranged on the concave surface at intervals. The connection structure of the box door and the door frame body is optimized, and the sealing strip with high rainproof performance is embedded between the box door and the door frame body, so that the rainproof sealing connection structure has the rainproof performance with a high protection grade.

Owner:JIAXING GANKUN IND DESIGN

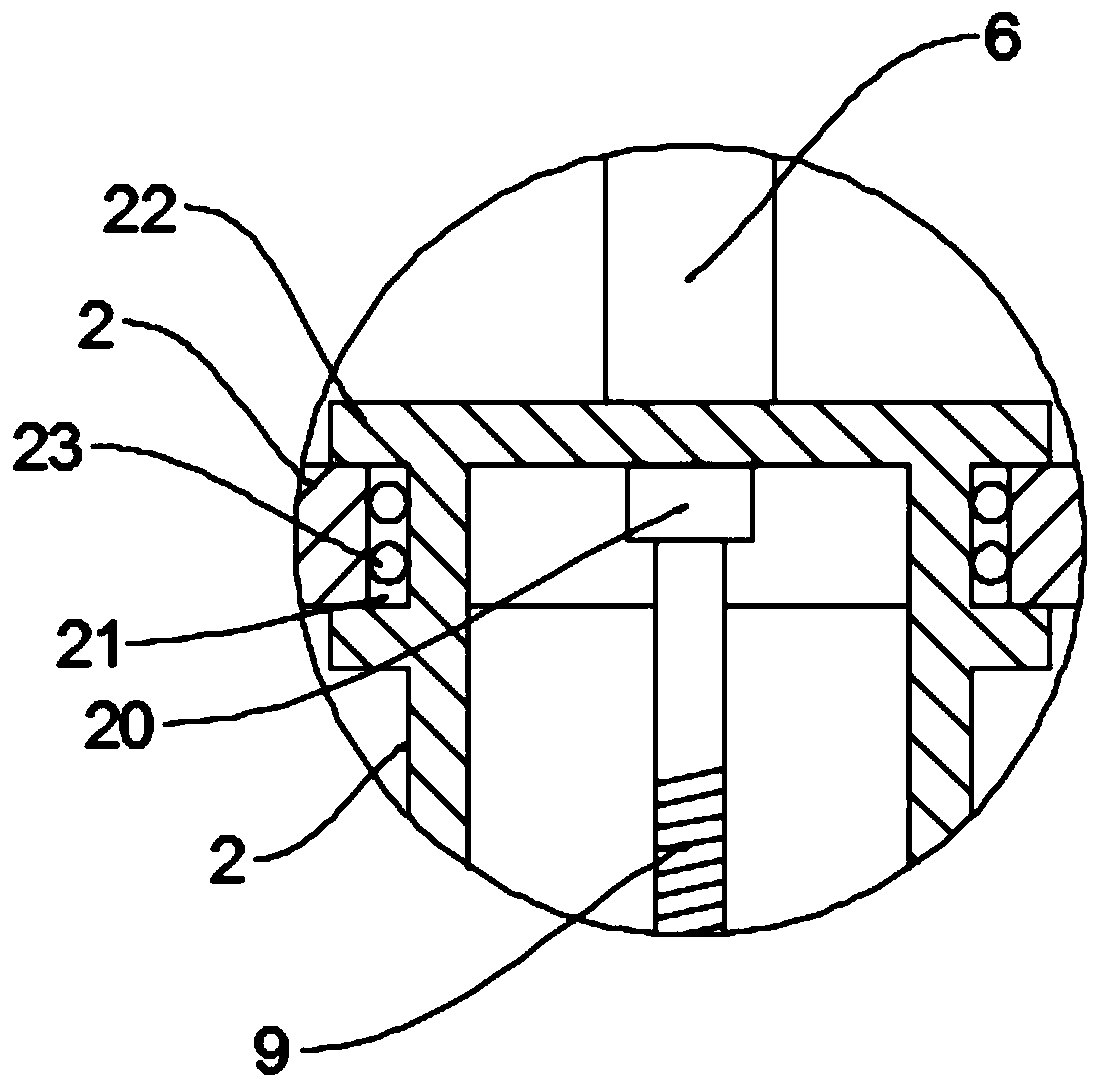

Clamp

ActiveCN101797730ACompact structureMove straight and stableWork holdersEngineeringMechanical engineering

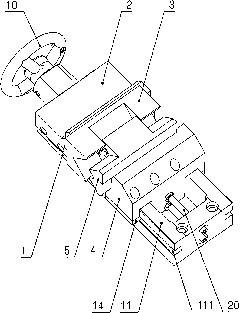

The invention discloses a clamp which has compact structure and high clamping strength and precision. The clamp comprises a pedestal, a fixed clamp jaw base and a movable clamp jaw base. The fixed clamp jaw base is fixed on the pedestal; the movable clamp jaw base is movably arranged on the pedestal; a fixed clamp jaw body is arranged on the fixed clamp jaw base; a movable clamp jaw body which matches with the fixed clamp jaw body is arranged on the movable clamp jaw base; a screw rod adjusting device is arranged in the pedestal; a piston cavity is arranged in the movable clamp jaw base; a piston is arranged in the piston cavity, and the piston cavity is divided into a front oil cavity and a rear oil cavity by the piston; two oil channels which are respectively communicated with the frontoil cavity and the rear oil cavity are arranged in the movable clamp jaw base; oil pipe joints are arranged at the oil channels; one side of the piston is provided with a piston rod; and the piston rod is connected with the screw rod adjusting device. The clamp adopts internally-mounted oil cylinder, thereby having very compact structure. In addition, the clamp can clamp the workpiece tightly without supporting the internally-mounted oil cylinder by adopting a long guiding rod. Moreover, the point of the application of the hydraulic force is close to the jaw of the clamp, thus the clamp has higher clamping strength and precision.

Owner:SUZHOU KINKALTECK MACHINERY TECH

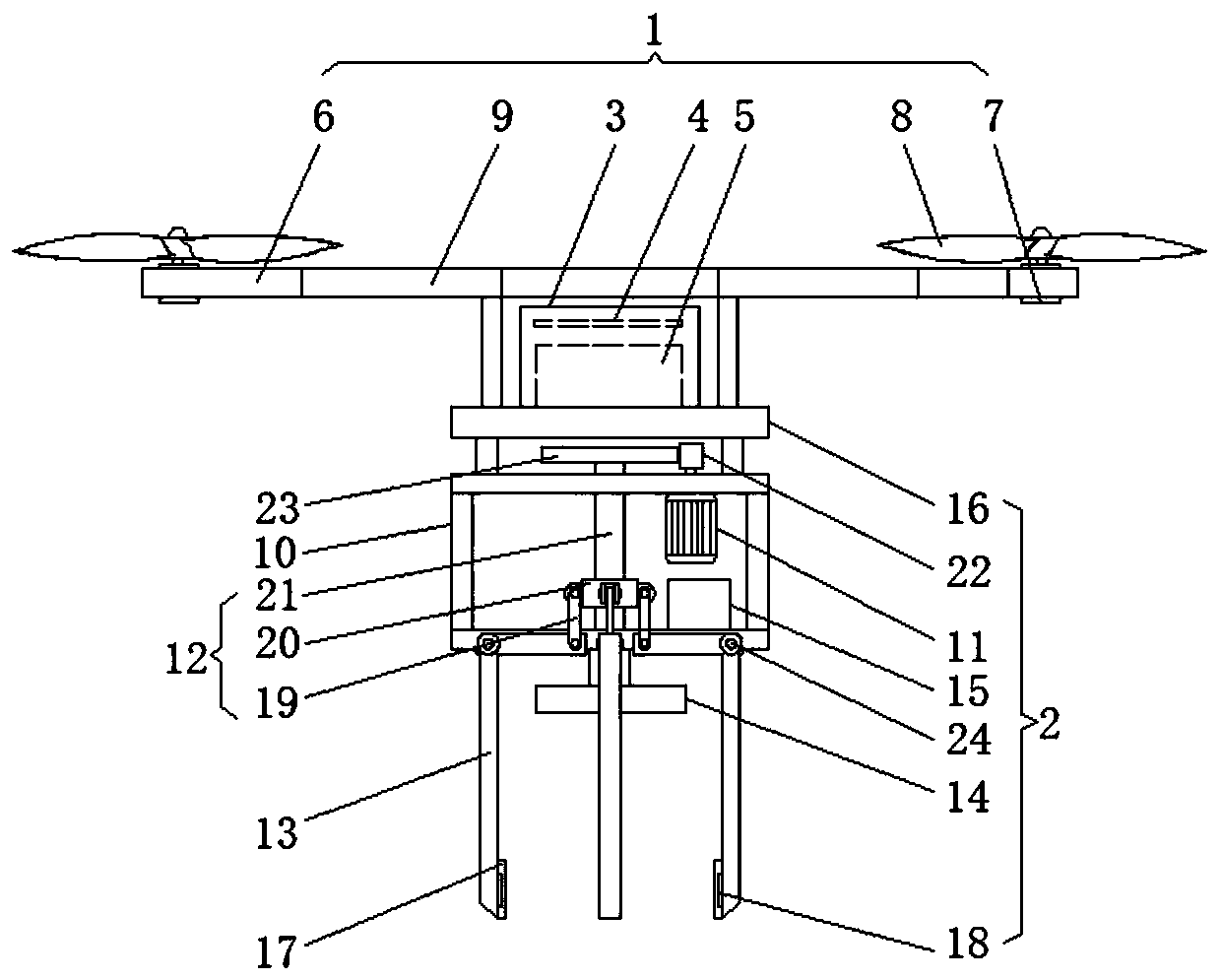

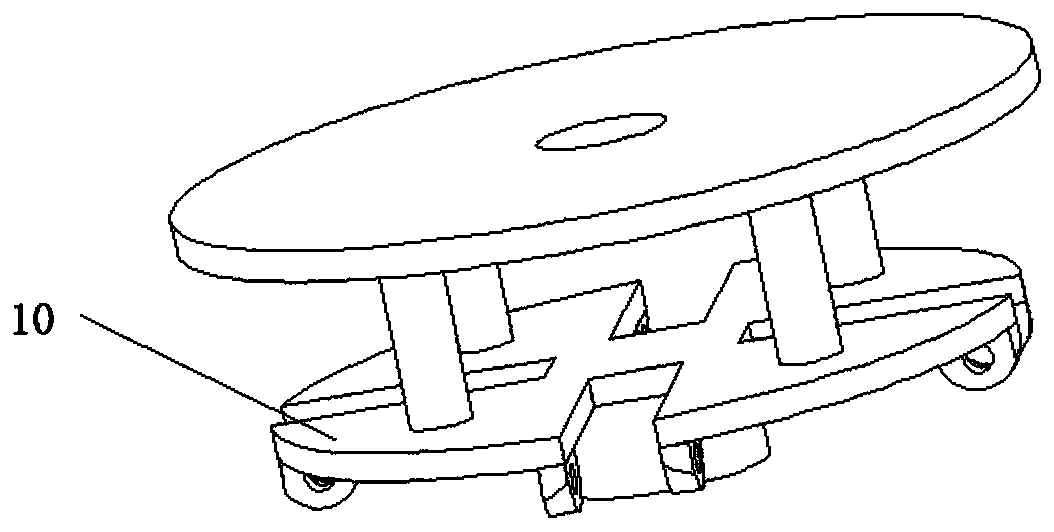

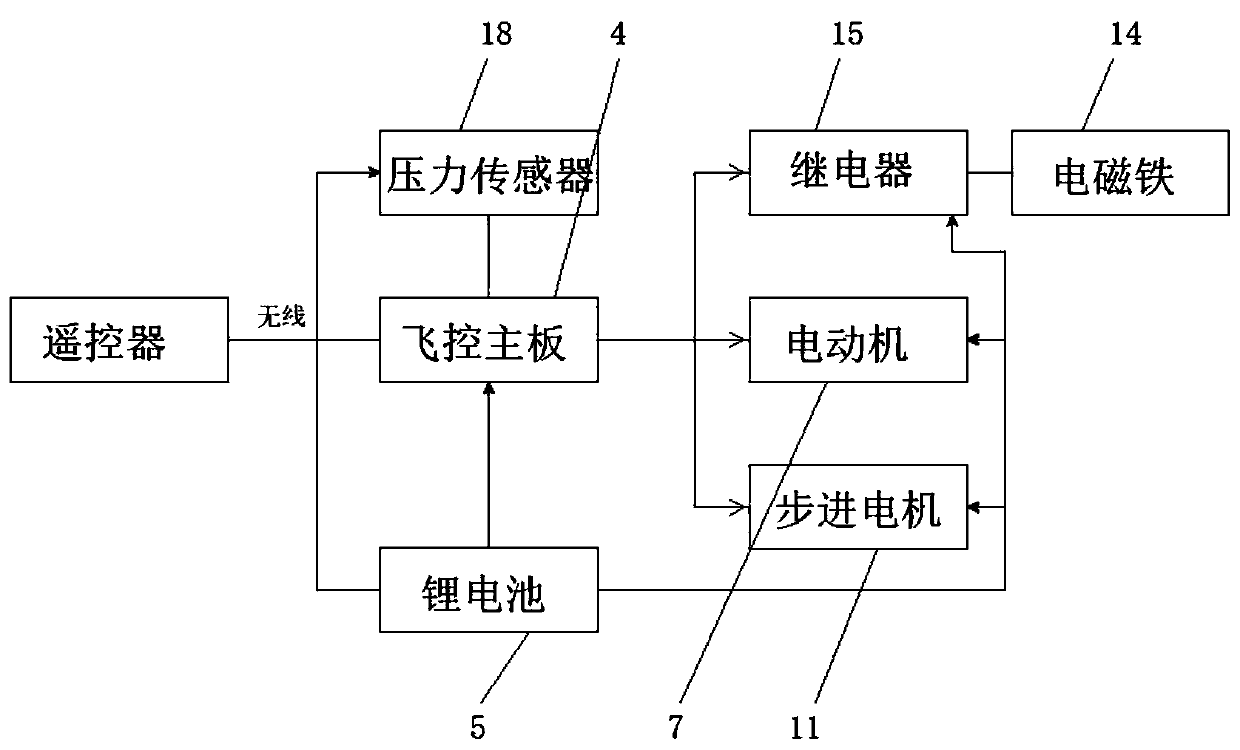

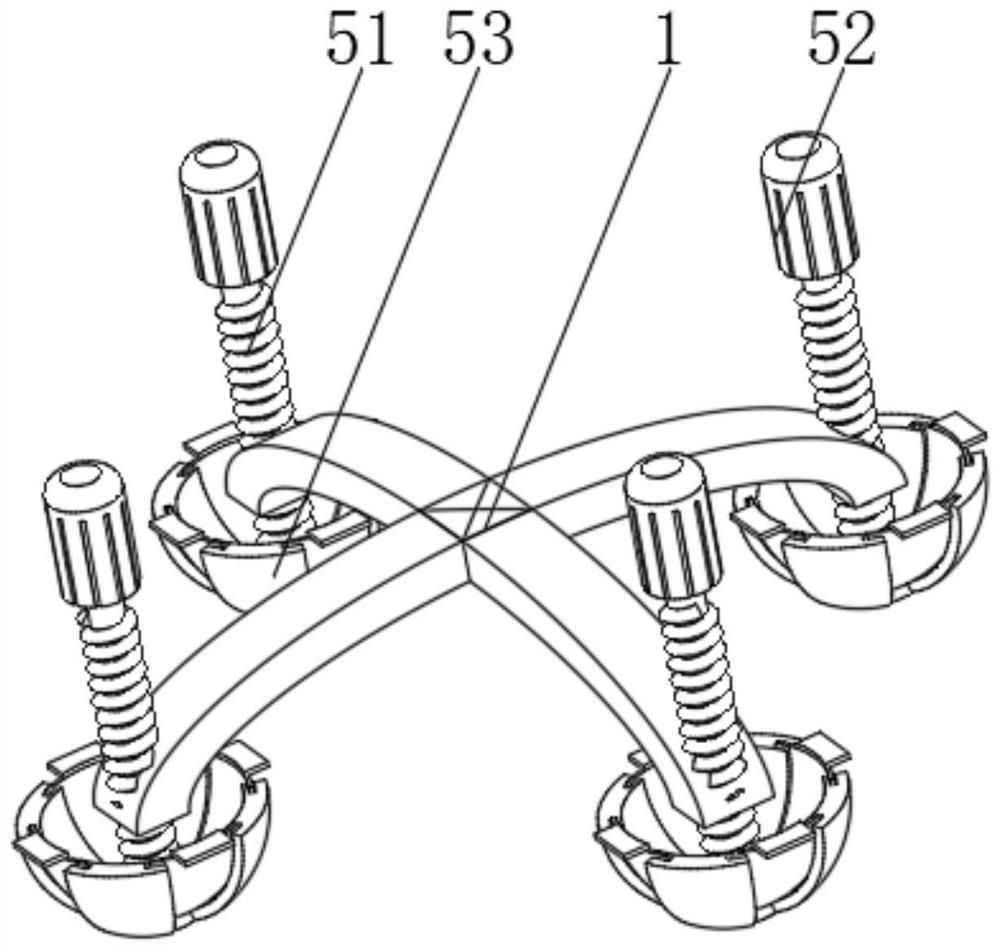

Unmanned aerial vehicle multifunctional fetching device and method

PendingCN110949669AImprove convenience and efficiencyIncrease clamping strengthGripping headsRemote controlled aircraftElectric machineryAutomotive engineering

The invention discloses an unmanned aerial vehicle multifunctional fetching device. The Unmanned aerial vehicle multifunctional fetching device comprises an unmanned aerial vehicle body and an objectfetching device fixedly connected below the unmanned aerial vehicle body. The unmanned aerial vehicle body comprises a main machine body, a flight control mainboard, a lithium battery, rotor wings, motors and blades. The flight control mainboard is connected with the lithium battery and is fixedly connected to the interior of the main machine body; a mounting frame is fixedly connected to the topof the main machine body, annularly distributed rotors are fixedly connected to the edge of the mounting frame, motors are fixedly connected to the ends of the rotors, blades are fixedly connected tothe output ends of the motors, and the fetching device comprises a fixing frame, a stepping motor, a connecting rod mechanism, a clamping jaw, an electromagnet and a relay. The object fetching deviceis fixedly connected to the bottom of the unmanned aerial vehicle, the stepping motor is used for controlling the clamping jaw to clamp non-iron objects, meanwhile, the electromagnet is matched to adsorb the iron objects, the unmanned aerial vehicle can be conveniently used for transporting, taking and placing the objects, and the object transporting convenience and efficiency are improved.

Owner:NANJING FOREST POLICE COLLEGE

Wooden cabinet transfer equipment

PendingCN112141873AEasy to moveReduce the adverse effects of inertiaConveyorsBase supporting structuresElectric machineryEngineering

The invention relates to the technical field of transfer equipment, in particular to wooden cabinet transfer equipment. The wooden cabinet transfer equipment comprises a support frame, a moving assembly, a lifting plate, a clamping assembly and a lifting assembly. Lead screws are driven by corresponding first motors to rotate, a nut moves on the lead screws, a connecting plate is driven by the nutto move in the direction of the lead screws, so as to drive two clamping plates to move, the clamping plates at two ends of the lifting plate are driven by the two first motors to correspondingly move, so as to clamp a wooden cabinet, and the two first motors are used for driving, so that accurate control for clamping operation of the wooden cabinet is increased, control for the clamping force can be improved, the wooden cabinet is clamped more firmly by the wooden cabinet transfer equipment, the safety of subsequent transfer operation is improved, and the wooden cabinet can be prevented frombeing extruded and damaged in the operation process.

Owner:萧县八宝畜禽养殖农民专业合作社

Bearing type barrel handling equipment

InactiveCN106348210AIncrease clamping strengthReduce stressLifting devicesEngineeringMechanical engineering

The present invention proposes a supporting type barrel transport attachment, two groups of transport devices are installed on the rear hanger; the transport device includes two clamping arms and two clamping oil cylinders; On the rear hanger, each clamp arm is connected with a piston rod clamping the oil cylinder; the clamp arm includes an arm base and a splint, and a fixed contact part is arranged on the inner side of the splint; the first drive device is hinged on the splint on one side of the fixed contact part, and the first drive The device is connected to the first contact part; the splint on the other side of the fixed contact part is hinged to the second driving device, and the second driving device is connected to the second contact part; the first elastic contact part is connected between the first contact part and the fixed contact part, and the second The second elastic contact part is connected between the contact part and the fixed contact part; a support chute and a support rod are arranged on the rear side of the rear hanger, and the support rod is provided with driving teeth; The board is provided with a driving port, and the driving gear of the supporting motor meshes with the driving teeth. The invention is suitable for barrels with different diameters, and improves the clamping strength for barrel-like goods.

Owner:HEFEI HANDBAROW APPURTENANCES TECH

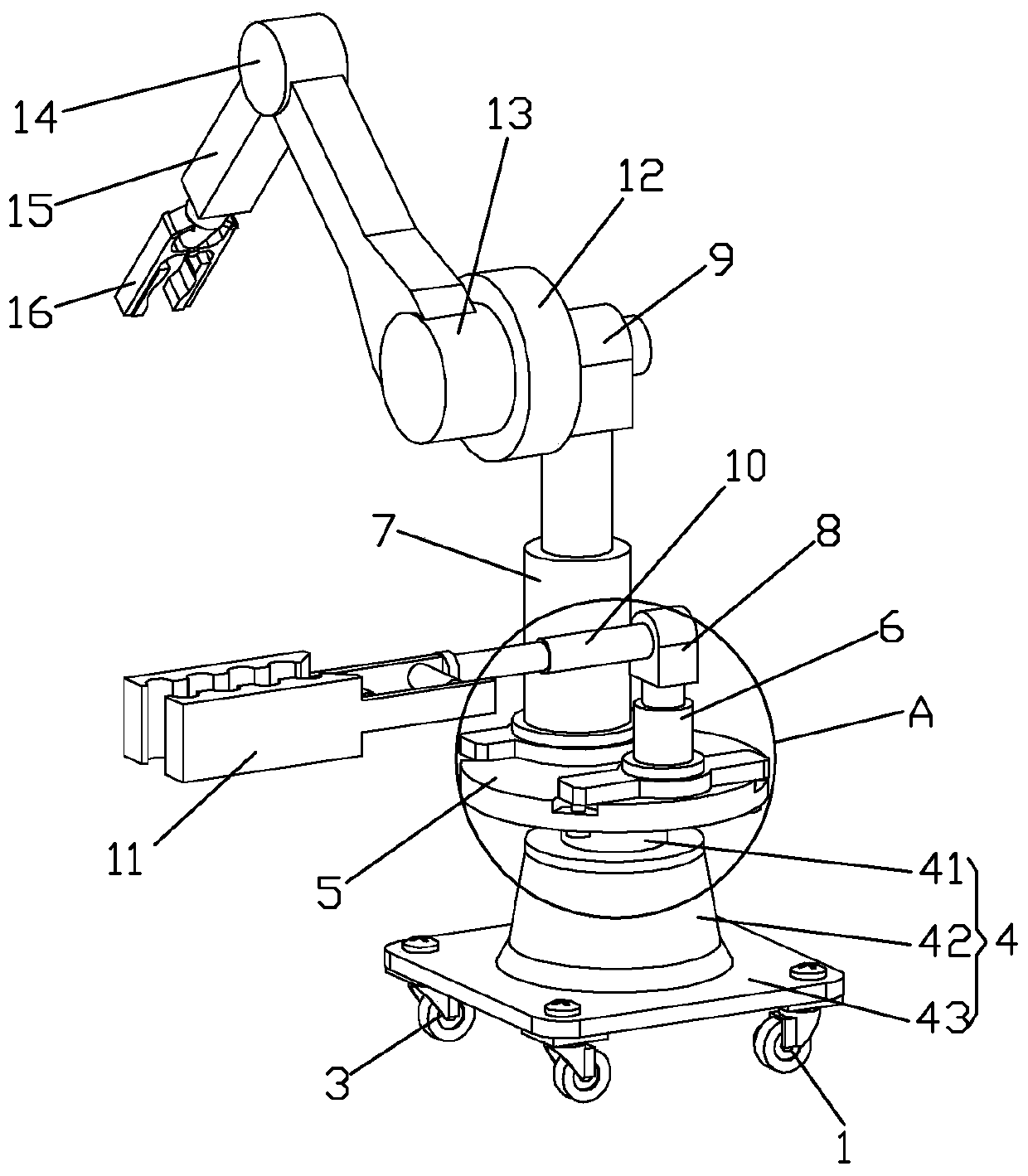

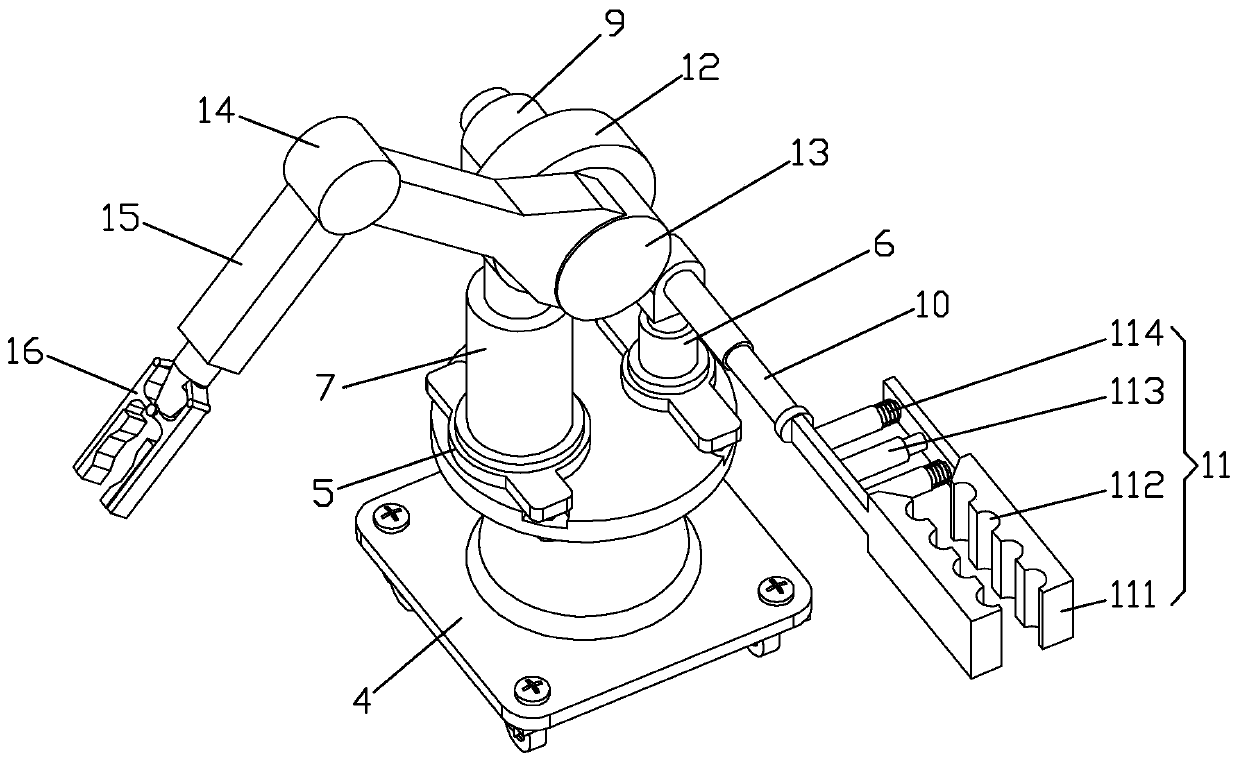

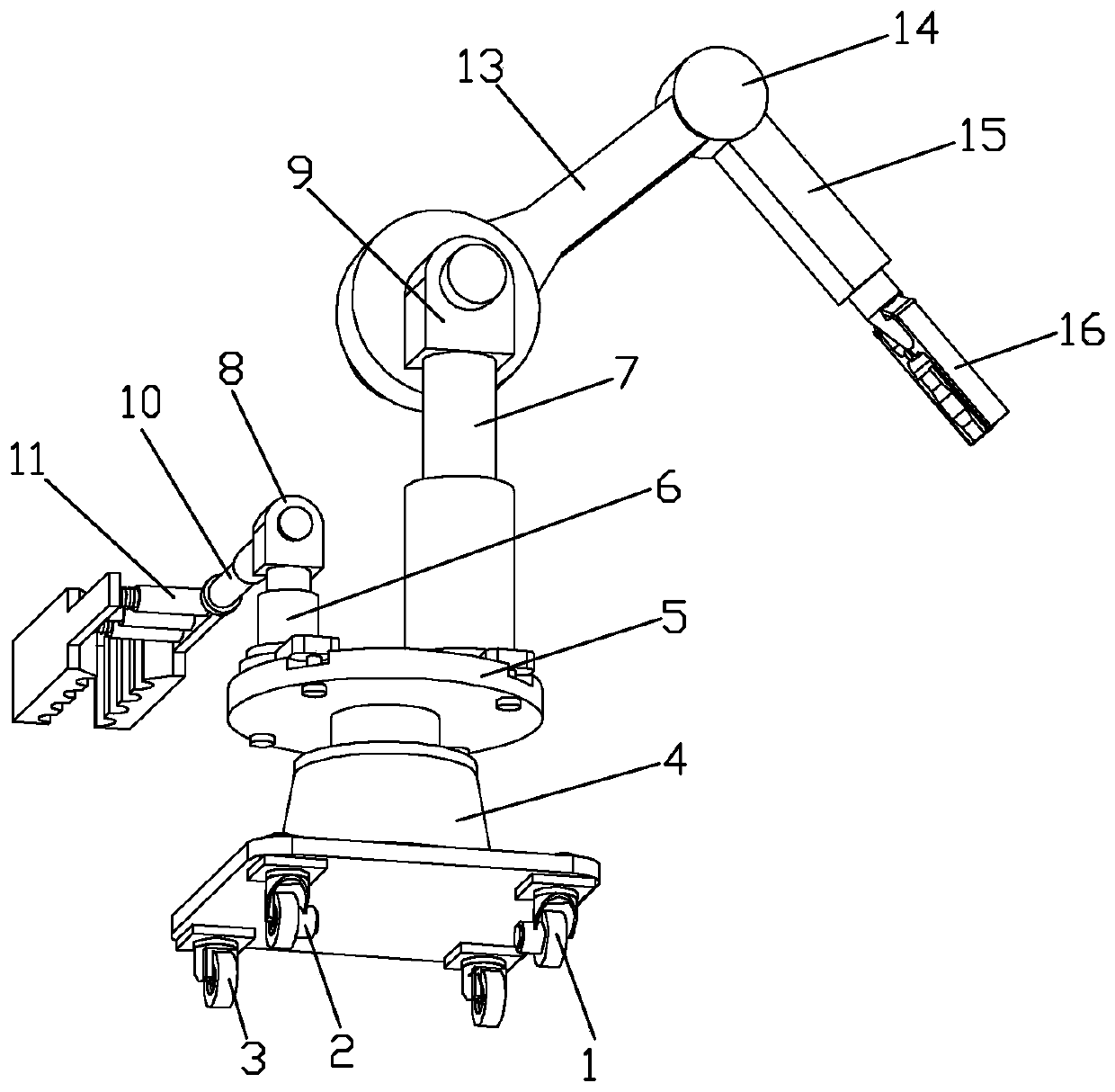

Intelligent industrial robot

InactiveCN110039522AImprove efficiencyExpand the scope of workProgramme-controlled manipulatorGripping headsSmall armsDrive wheel

The invention relates to the technical field of industrial robots, in particular to an intelligent industrial robot. The intelligent industrial robot comprises a base mechanism. A drive wheel and a driven wheel are fixedly arranged at the bottom of the base mechanism. A first electric telescopic oil cylinder and a second electric telescopic oil cylinder are fixedly arranged at the upper end of thebase mechanism through supporting mechanisms correspondingly. The control output end of the first electric telescopic oil cylinder is rotationally provided with a third electric telescopic oil cylinder through a first elastic coupler, and the control output end of the third electric telescopic oil cylinder is fixedly provided with a first clamping mechanism. The control output end of the second electric telescopic oil cylinder is rotationally provided with a fourth rotating shaft through a second elastic coupler, and a clamping large arm is fixedly arranged on the side, away from the second elastic coupler, of the fourth rotating shaft. The end portion, away from the fourth rotating shaft, of the clamping large arm is rotationally connected with a clamping small arm through a bearing. A second clamping mechanism is fixedly arranged at the end portion, away from the bearing, of the clamping small arm. By means of the intelligent industrial robot, clamping is convenient, and the intelligent industrial robot is worthy of being popularized.

Owner:WENZHOU LEKONG ENERGY SAVING TECH

Height-adjustable casting mold machining clamping mechanism

ActiveCN110877261ASave resourcesReduce complexityGrinding drivesGrinding machinesSlide plateCasting mold

The invention relates to the technical field of casting equipment and discloses a height-adjustable casting mold machining clamping mechanism comprising a bottom plate, fixed support plates and movable support plates. The set of movable support plates symmetrical with the fixed support plates are arranged in the position, on the right sides of the fixed support plates, above the bottom plate. Thetops of the fixed support plates and the movable support plates are each fixedly provided with a set of lifts. Lifting rods are connected to the lower side output ends of the lifts. Horizontal slidingplates are fixedly installed on the bottom inner sides of the lifting rods. Pressing plates are downwards installed at the bottoms of the sliding plates. Transverse piston rods are rightwards fixedlyinstalled on the lower portions of the right side faces of the movable support plates. Cylinders are arranged at the right ends of the piston rods. A transverse supporting plate is fixedly installedin the position, at the bottoms of two sets of struts, on the lower side of a fixed seat. The middle of the lower surface of the bottom of the supporting plate is downwards connected with a hydraulicrod. A strut fixed to the upper surface of the bottom plate is arranged at the bottom of the hydraulic rod. The height-adjustable casting mold machining clamping mechanism has the advantages that operation is easy, clamping force is high, stability is good, resources are saved, and use cost is low.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Fixing equipment used in production process of laminated glass

InactiveCN107584851AAvoid air bubblesIncrease clamping strengthLaminationLamination apparatusEquipment useLaminated glass

The invention discloses fixing equipment used in the production process of laminated glass. The fixing equipment comprises a connecting plate; both ends of the connecting plate are provided with a supporting plate; each supporting plate is provided with an elastic element; one end of each elastic element is connected with the corresponding supporting plate; the other end of each elastic element isprovided with a clamping plate; the clamping plates are located between the two supporting plates; a slope is arranged on the clamping surface of each clamping plate; a movable rod is arranged on each supporting plate; a pressing plate is arranged on each movable rod; each pressing plate is located between the corresponding clamping plate and supporting plate; a sliding groove is formed in the connecting plate; movable blocks are arranged in the sliding groove; the movable blocks can move in the sliding groove; a connecting rod is arranged on each movable block; one end of each connecting rodis connected with the corresponding movable block; and the other end of each connecting rod is connected with the corresponding clamping plate. The device provided by the invention can rapidly clamptwo pieces of glass, and the generation of bubbles between the two pieces of glass is avoided.

Owner:德阳市聚阳特种玻璃有限公司

Positioning mechanism for electromechanical equipment processing

InactiveCN110877222AEasy to handleImprove processing qualityWork clamping meansMeasurement/indication equipmentsEngineeringScrew thread

The invention belongs to the technical field of electromechanical equipment processing, and in particular relates to a positioning mechanism for electromechanical equipment processing. The invention provides the following solution in order to solve the problems that a conventional workpiece clamping positioning mechanism has poor precision and a complicated debugging process when a workpiece is fixed: the positioning mechanism includes a mounting frame, a plurality of strip-shaped holes are arranged in two sides of the top of the mounting frame, and two rectangular through grooves are arrangedin the middle of the top of the mounting frame; and the interior of each strip-shaped holes is rotatably connected with a threaded rod through a bearing, a movable block is in threaded connection with the outer side of each threaded rod, and the top end of each movable block is provided with an insertion seat. According to the positioning mechanism, a workpiece to be processed is clamped and fixed by using the clamping mechanism, so that workers can conveniently process the workpiece; and at the same time, the position of a clamping mechanism is detected and determined by a distance measuringsensor, so that the clamping position of the clamping mechanism is determined, and when the clamping mechanism clamps the workpiece, the workpiece is effectively positioned and fixed to improve the processing quality of the workpiece.

Owner:宝鸡市捷龙商贸有限公司

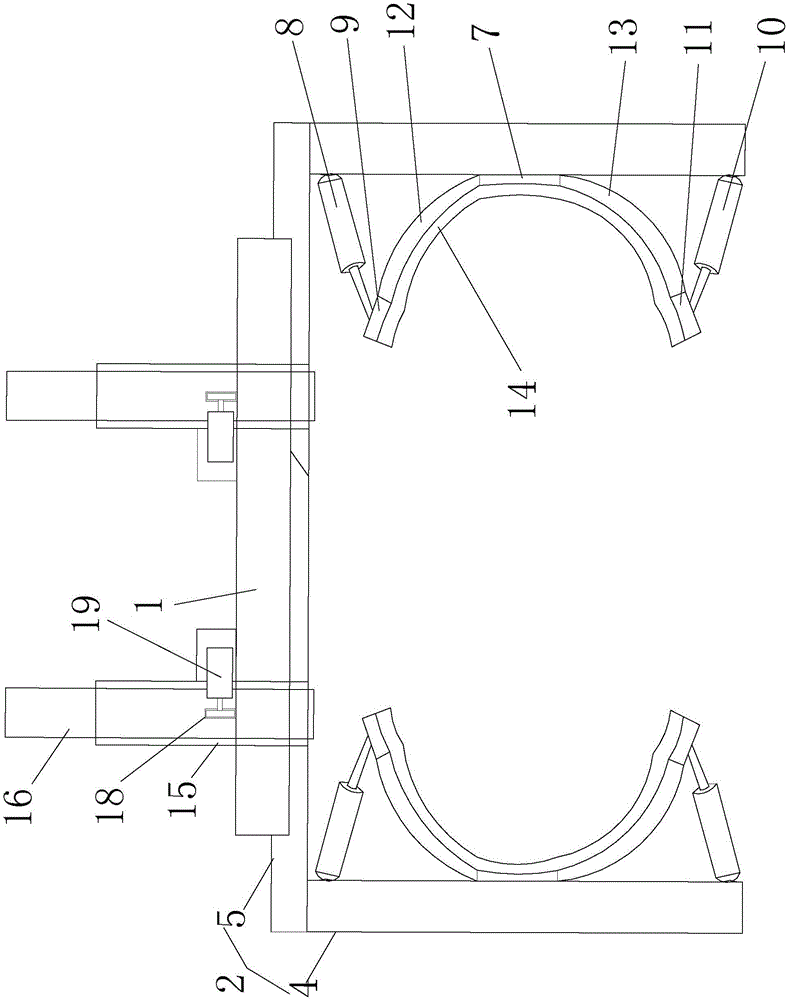

Ship lifting device

ActiveCN113415757AIncrease clamping strengthSimple structureLifting framesLoad-engaging elementsMarine engineeringLifting equipment

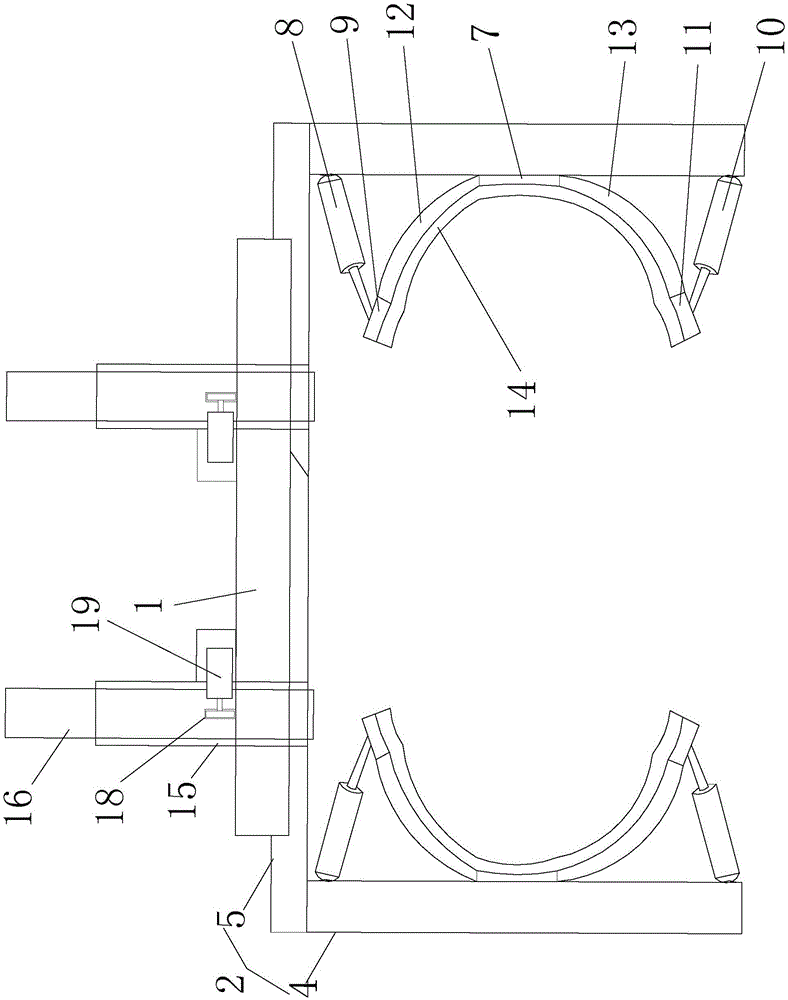

The invention discloses a ship lifting device, and relates to the technical field of ship lifting equipment. The ship lifting device comprises a top suspension frame and two side bearing frames fixed to a dam body, and each side bearing frame is provided with a ship bearing part capable of sliding on the side bearing frame; each ship bearing part comprises a lifting connecting frame, a bearing component, a side pressure clamping part, an elastic sliding part and a guide rod, the guide rod is vertically and fixedly arranged on the lifting connecting frame, and the bearing component is arranged on the elastic sliding part and used for bearing the bottom of a ship; the side portions of the side pressure clamping parts are connected with the lifting connecting frames through clamping supports, and the side pressure clamping parts are used for abutting against the side wall of the ship; and the elastic sliding parts drive the clamping supports to rotate around the connecting positions of the clamping supports and the lifting connecting frames when sliding relative to the guide rods. The ship lifting device is simple in structure, ship lifting connection is achieved by supporting the bottom of the ship and clamping the side of the ship, lifting stability is improved, operation is convenient, and use is convenient.

Owner:山东辛丁技术有限公司

Machining lathe

PendingCN112427663AAvoid scattered distributionEasy to cleanAuxillary equipmentMaintainance and safety accessoriesBalancing machineEngineering

The invention discloses a machining lathe which comprises a lathe body, a machining cavity is formed in the middle of the front face of the lathe body, a flow guide mechanism is fixedly connected to the back face of an inner cavity of the machining cavity, an auxiliary fixing mechanism is movably connected to the middle of the inner wall of the right side of the inner cavity of the machining cavity, an electromagnet is fixedly connected to the bottom of an inner cavity of a bottom groove, a cleaning groove is formed in the position, located above the electromagnet, of the front face of the inner cavity of the bottom groove, a waste disc is slidably connected to the inner surface of the cleaning groove, a balance mechanism is fixedly connected to the middle of the bottom of an inner cavityof the waste disc, and a collecting mechanism is fixedly connected to the top of the balance mechanism. The invention relates to the technical field of lathes. A rotating air screen is formed throughair flow generated by rotation of the equipment, so that splashing of sweeps is blocked, and the periphery is protected; and through wind power generation, electromagnetic force is generated to adsorbthe sweeps, so that he sweeps are cleaned in a centralized mode, the sweeps are prevented from being scattered and distributed in the equipment, and cleaning is convenient.

Owner:焦超锦

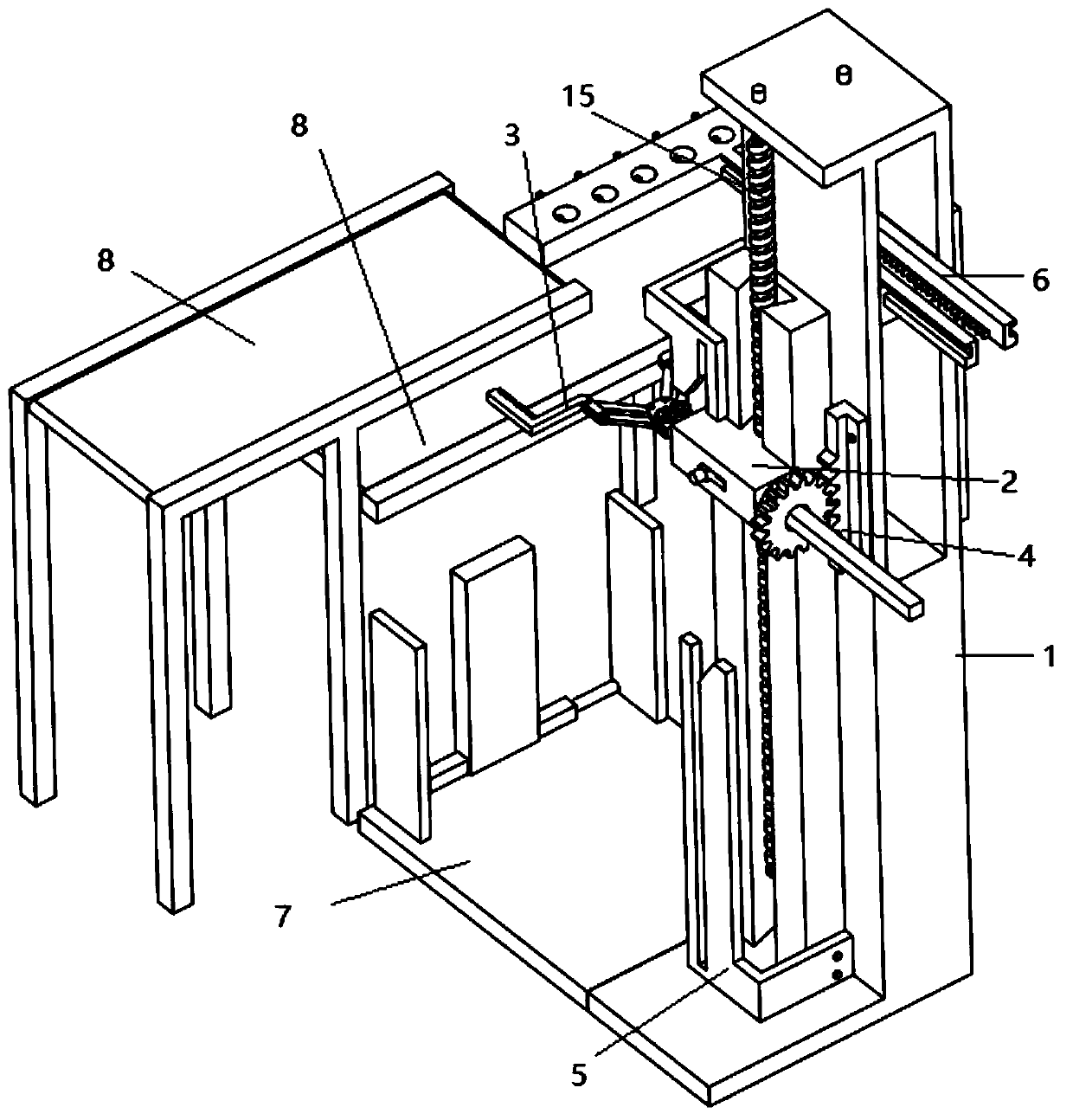

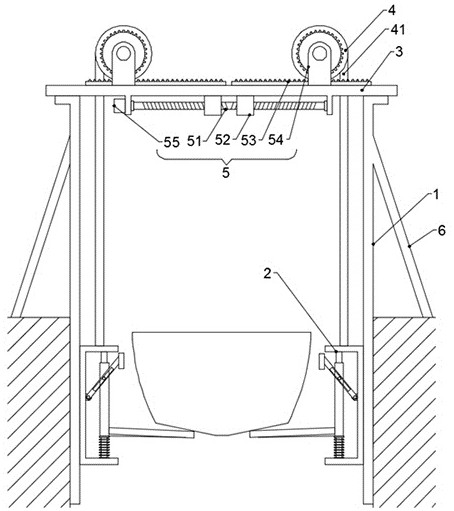

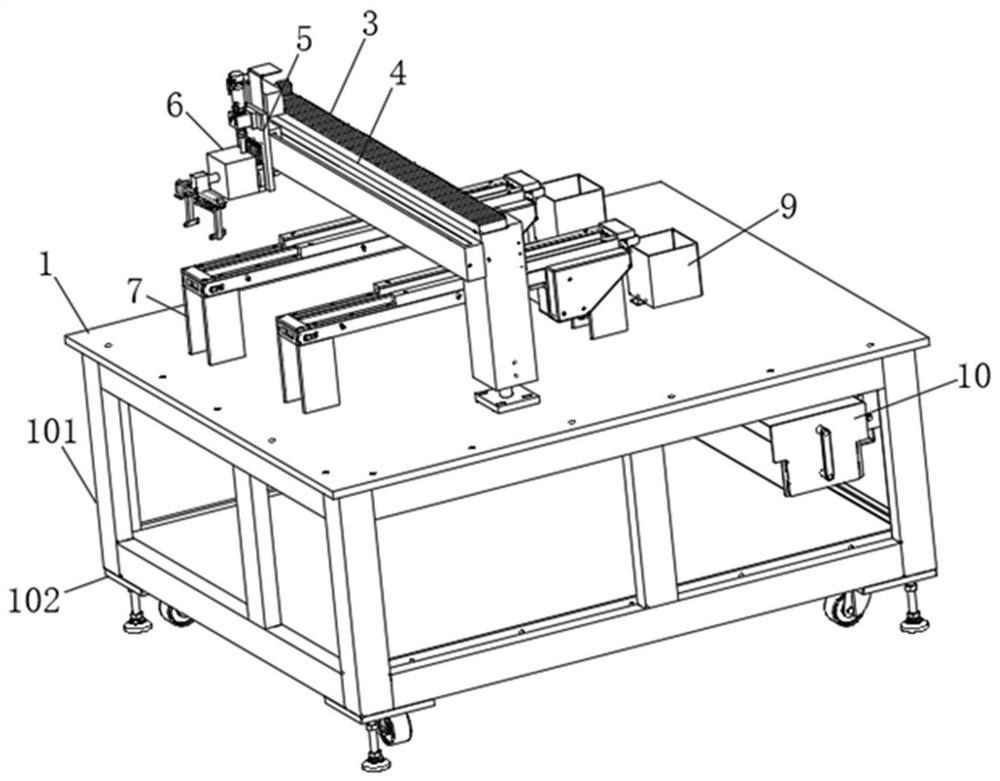

Grabbing and dumping equipment for tea leaf picking box

ActiveCN112020995ASave human effortHigh degree of automationPicking devicesElectric machineryAgricultural engineering

The invention relates to the technical field of tea leaf picking, in particular to grabbing and dumping equipment for a tea leaf picking box. The grabbing and dumping equipment for the tea leaf picking box comprises a base table, a moving assembly, a lifting assembly, a conveying assembly and a clamping assembly, wherein the conveying assembly is driven by a third motor to convey dumped tea leavesto a channel, and the dumped tea leaves enter a storage chamber of a collecting box through the channel, and the tea leaves in the picking box are dumped together in a mechanical mode and are conveyed together through the conveying assembly, so that a large amount of manpower is saved, the automation degree of tea leaf picking is improved, the operation convenience of picking personnel is also improved, the picking personnel only need to place the picking box in the hand at one end of the conveying assembly, meanwhile, the grabbing and dumping equipment is suitable for the situation that plenty of picking personnel exist, and disorder occurs in the process that plenty of picking personnel gather the tea leaves in respective picking box is avoided.

Owner:淮北醴恒净水科技有限公司

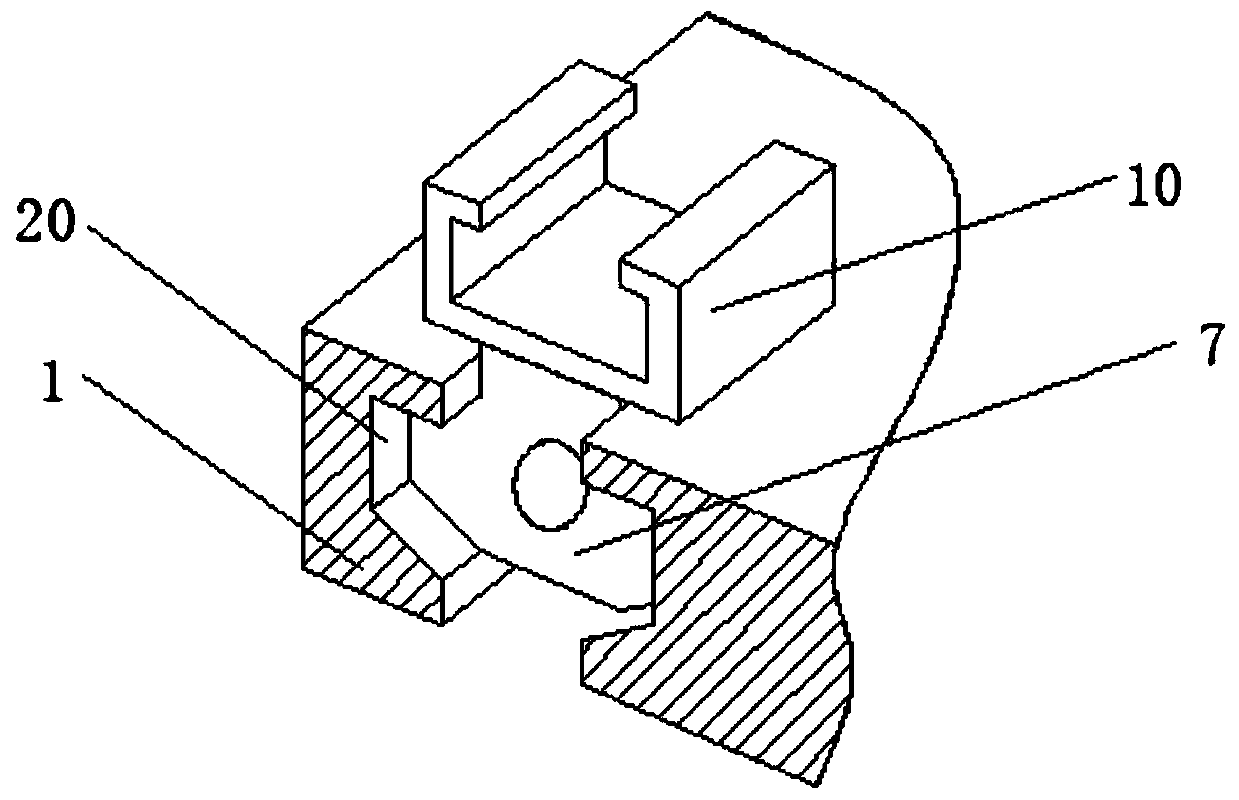

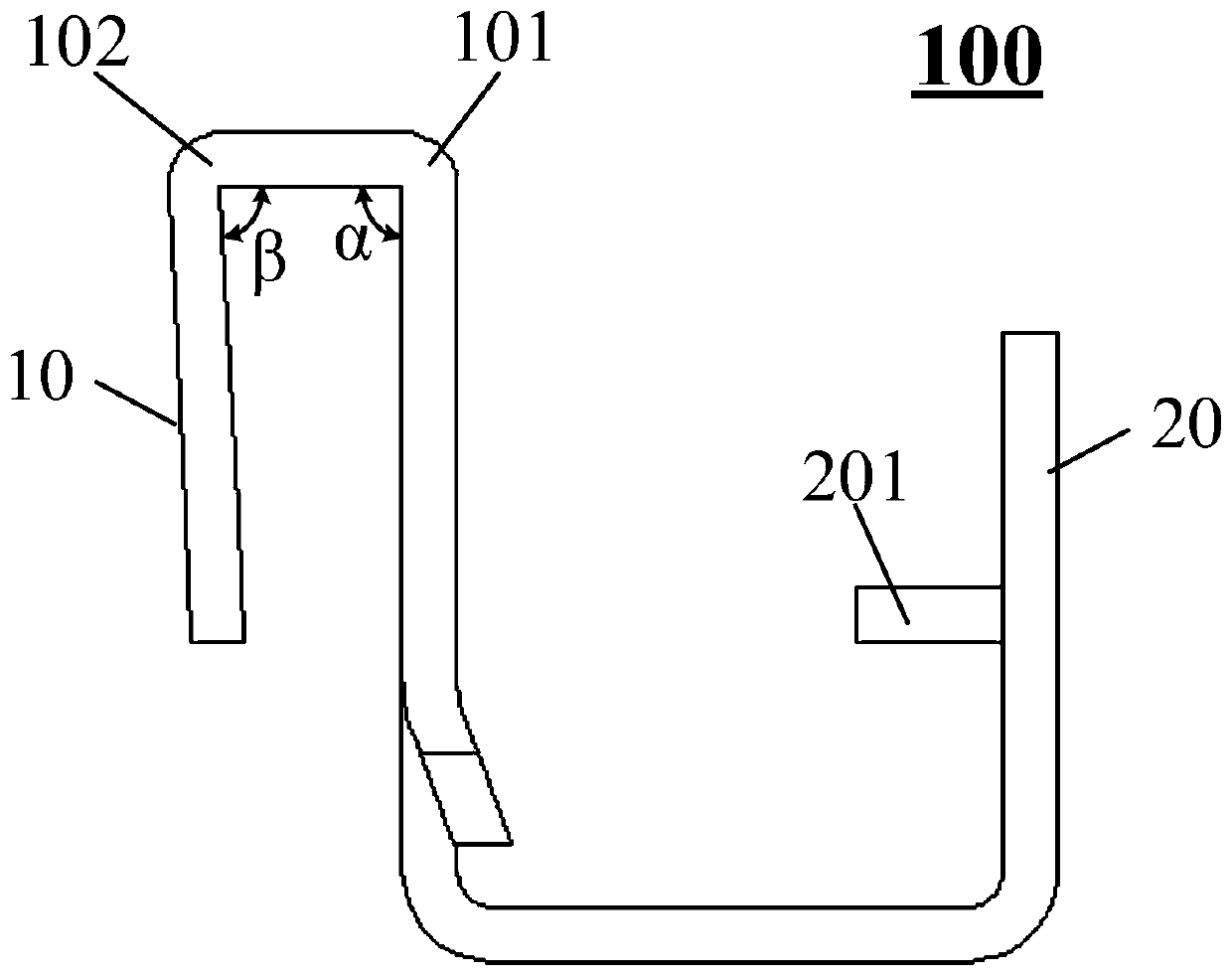

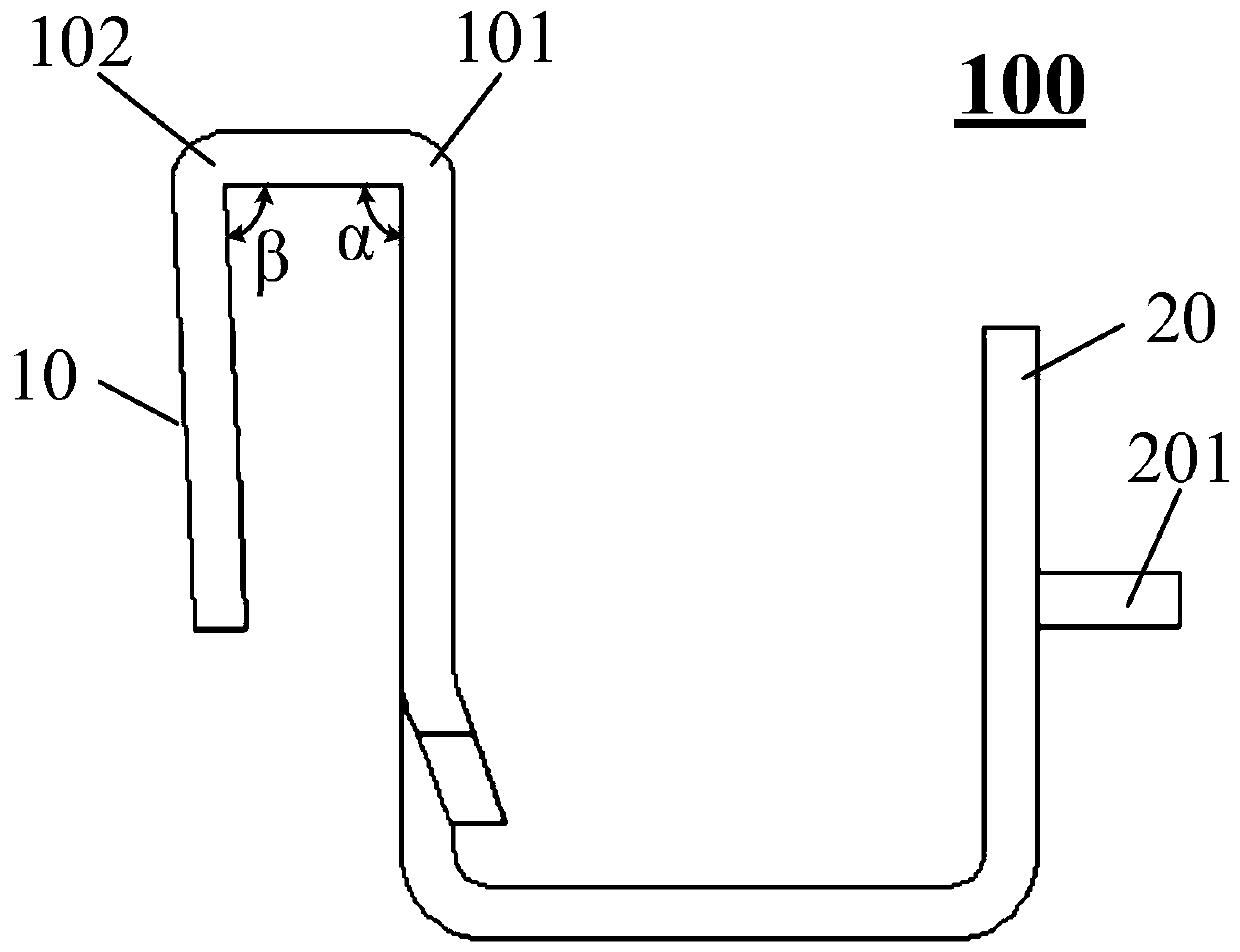

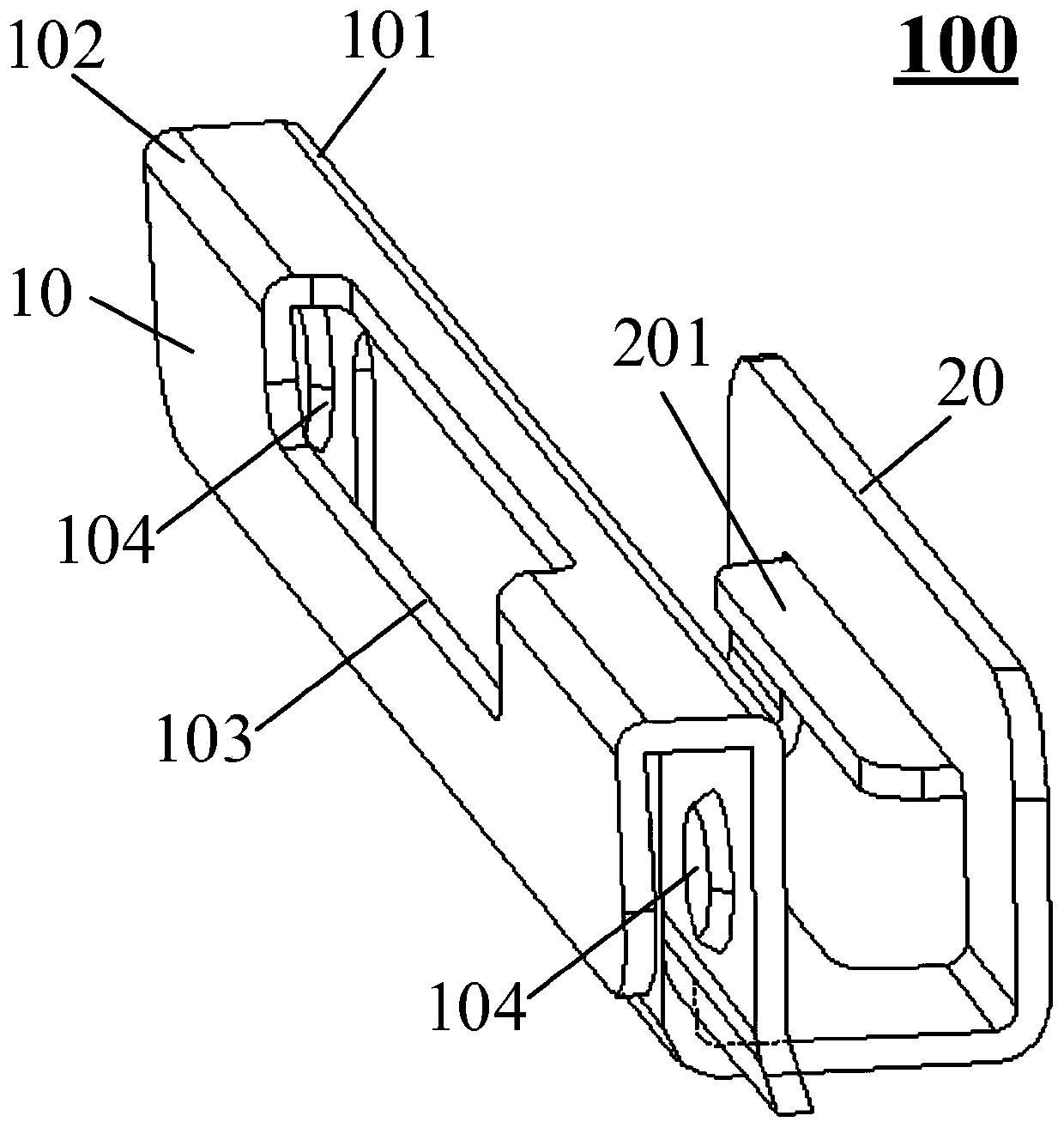

Hanging lug, backlight module and display device

PendingCN111508348AIncrease clamping strengthImprove assembly reliabilityIdentification meansAcute angleDisplay device

The invention provides a hanging lug, a backlight module and a display device, and relates to the technical field of display. The hanging lug comprises a first fixing structure used for clamping the backboard and a second fixing structure used for fixing the optical film, the first fixing structure and the second fixing structure are both U-shaped, one end of the first fixing structure is connected with one end of the second fixing structure, and the opening directions of the two fixing structures are opposite; the first fixing structure comprises a first bent part close to the second fixing structure and a second bent part connected with the first bent part, and the bent angle of the first bent part and / or the bent angle of the second bent part are / is an acute angle. And a limiting structure is arranged on the second fixing structure. According to the invention, the bending angle of at least one bending part of the first fixing structure is set to be the acute angle, so that the clamping force of the hanging lug on the backboard can be improved, the hanging lug is not easy to separate from the backboard, and the assembly reliability is improved. Besides, when the optical film is fixed by the second fixing structure, the optical film can be limited by the limiting structure, so that the optical film is not easy to separate from the suspension loop, and the assembly reliabilityis improved.

Owner:BOE TECH GRP CO LTD +1

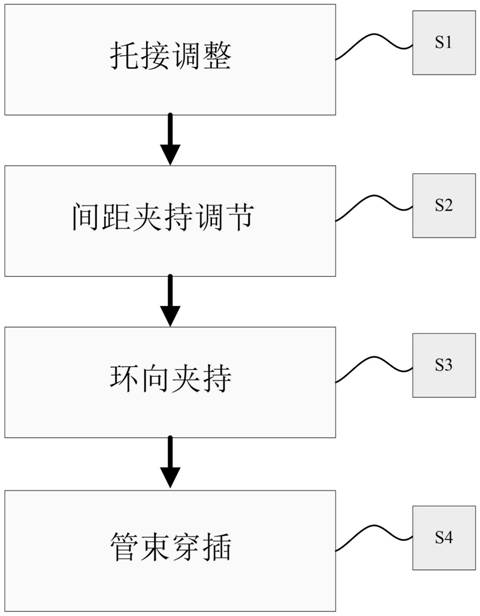

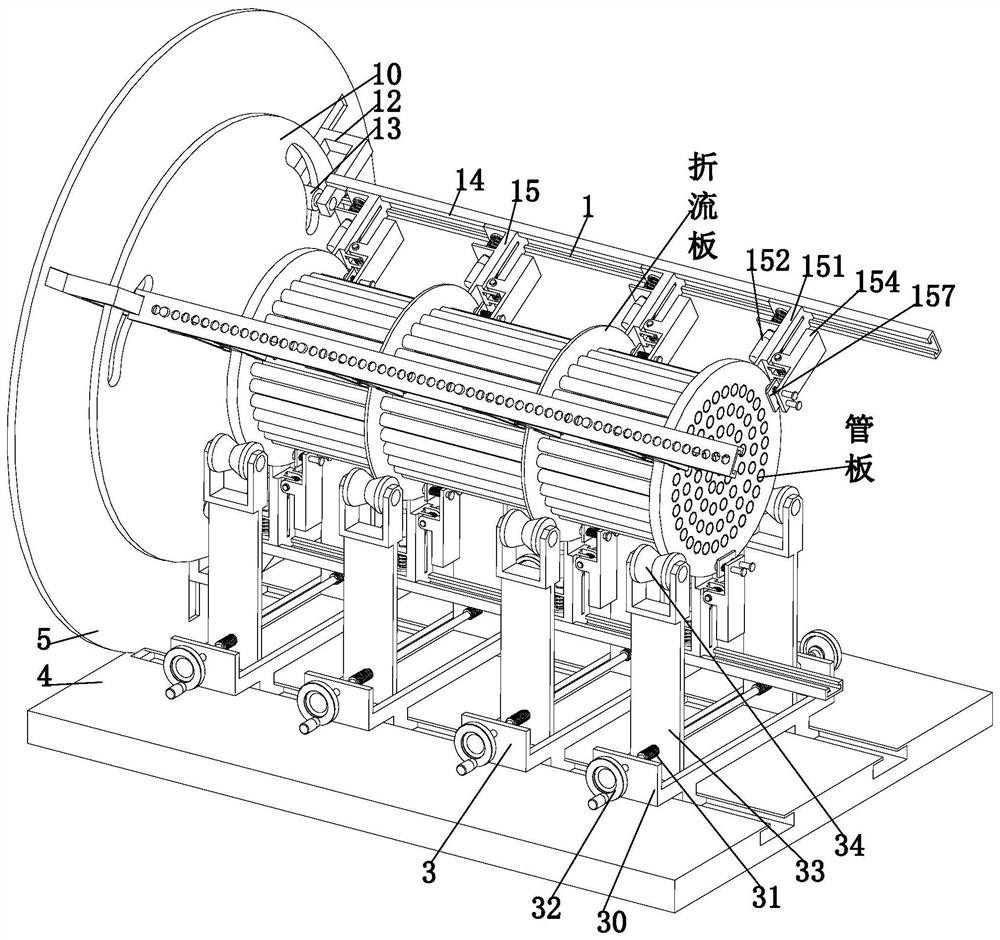

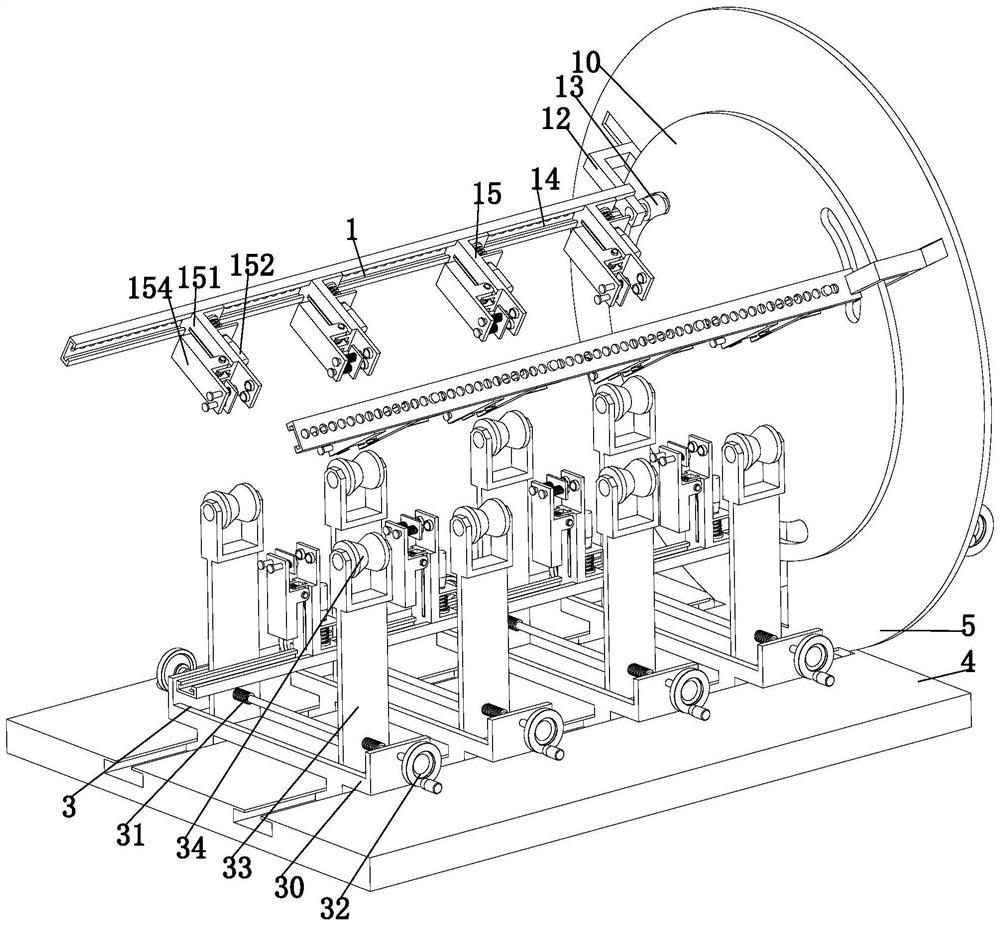

Shell-and-tube heat exchanger manufacturing and machining method

InactiveCN113146198AExpand the clamping rangeSatisfy the requirement of hoop clampingPositioning apparatusMetal working apparatusEngineeringManual handling

The invention provides a shell-and-tube heat exchanger manufacturing and machining method which involves a clamping mechanism, a regulation and control mechanism, bottom support mechanisms, a bottom plate and a ring stand vertical plate. The method solves the problems that when a heat transfer tube bundle is installed at present, tube plates at the two ends are clamped and fixed through clamps, then the spacing position of baffle plates is moved and fixed, and finally, the heat transfer tube bundle is inserted into the tube plates and the baffle plates; in the mode, manual operation is tedious, flexible and adjustable fixing clamps are not arranged to assist in the insertion process of the heat transfer tube bundle, the efficiency of the whole operation process is reduced, and large-scale production operation cannot be achieved; and the clamps can only clamp and fix the tube plates and the baffle plates with specified sizes, flexible adjustment cannot be achieved, and market requirements cannot be met.

Owner:韩洵

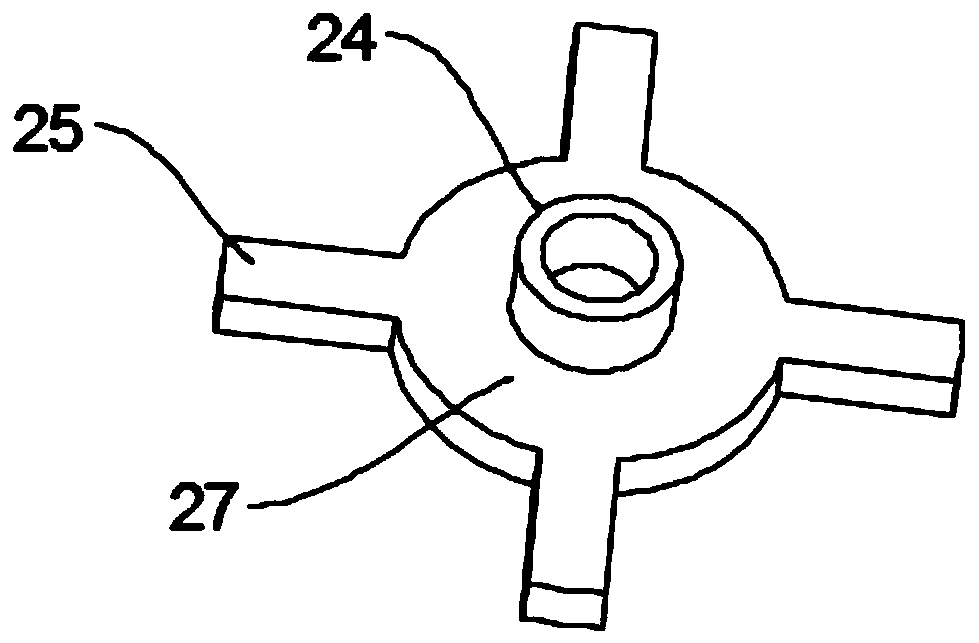

Clamping mechanism of electrical pipeline lift

InactiveCN103879930AGuaranteed clamping forcePrevent slippageSafety devices for lifting equipmentsRod connectionsPipe fittingIndustrial engineering

The invention discloses a clamping mechanism of an electrical pipeline lift. The clamping mechanism comprises a left clamping ring and a right clamping ring, and the left clamping ring is connected with the right clamping ring through a hinge pin. A handle is arranged on the upper portion of the right clamping ring, protrusions are arranged on the two sides of the handle, the handle is further provided with a pressing rod, the two ends of the pressing rod are connected with hanging rods, the upper portion of the left clamping ring is provided with hanging lugs, the hanging rods penetrate through the protrusions and are matched with the hanging lugs to enable the left clamping ring and the right clamping ring to be fixedly connected, and the hanging rods are further provided with a spring located between the protrusions and the pressing rod. In the clamping process, connection between the left clamping ring and the right clamping ring is adjusted through the spring. When a lifting portion swings obviously, the compressed spring keeps acting force between the pressing rod and the protrusions at any time, the clamping strength on a pipe fitting is guaranteed, and the pipe fitting is prevented from slipping downwards in the swinging process; meanwhile, relative sliding friction between the pipe fitting and the left clamping ring and relative sliding friction between the pipe fitting and the right clamping ring are avoided, and the damage degree of the pipe fitting is reduced.

Owner:SHOUGUANG JUNENG ELECTRIC

Clamping mechanism for mechanical deformation machining

ActiveCN109941735AStrong clamping forceImprove the stable clamping effectConveyor partsEngineeringBlock match

The invention relates to the technical field of mechanical clamping, in particular to a clamping mechanism for mechanical deformation machining. The clamping mechanism for mechanical deformation machining comprises a mounting plate, wherein the right side of the mounting plate is connected with a supporting rod through a first fixing block; the left side of the mounting plate is provided with a turntable; the left side of the mounting plate is provided with a first annular groove; the right side of the turntable is symmetrically provided with first sliding blocks matched with the turntable; the left side of the turntable is connected with a first fixing plate; the two ends of the first fixing plate are provided with grooves; a first spring rod is arranged in the inner cavity of each groove; and one ends, away from the first spring rods, of the groovesare movably connected with clamping arms through connecting pieces.The clamping mechanism is novel in structural design, the clamping force of the clamping mechanism is effectively enhanced, the stable clamping effect of the clamping mechanism is favorably improved, machines of different forms are conveniently machined, the working time is effectively reduced, the working efficiency is conveniently improved, and moreover, a clamped mechanical part is conveniently overturned and adjusted, and is convenient to use.

Owner:JILIN TEACHERS INST OF ENG & TECH

Two-jaw clamp

The invention discloses a two-jaw clamp capable of enabling fixed jaw body seats and a movable jaw body seats to be close to the center position of a saw blade, which comprises a base, a left fixed jaw seat, a right fixed jaw seat, a pair of guide rails, sliding seats and sliding seat translation locking devices, wherein the left fixed jaw seat and the right fixed jaw seat are fixed on the base; the guide rails are fixed on the base; the sliding seats are arranged on the guide rails in a sliding way; the sliding seat translation locking devices are fixed on the guide rails; a left fixed jaw body capable of translating and a right fixed jaw body capable of translating are respectively arranged on the left fixed jaw seat and the right fixed jaw seat; a left movable jaw seat is arranged at the left side of each sliding seat, and a left movable jaw body capable of translating is arranged on the left movable jaw seat; and a right movable jaw seat capable of translating is arranged at the right side of each sliding seat, and a right movable jaw body capable of translating is arranged on the right movable jaw seat. By adopting the asymmetric jaw arrangement, the invention ensures that in the process of horizontal sawing at 45 degrees, the saw blade can not saw the left fixed jaw seat and the right movable jaw seat, so that the base can be close to the center of the jaw as much as possible, thereby improving the clamping force of the jaws, improving the processing stability and prolonging the service life of the saw blade.

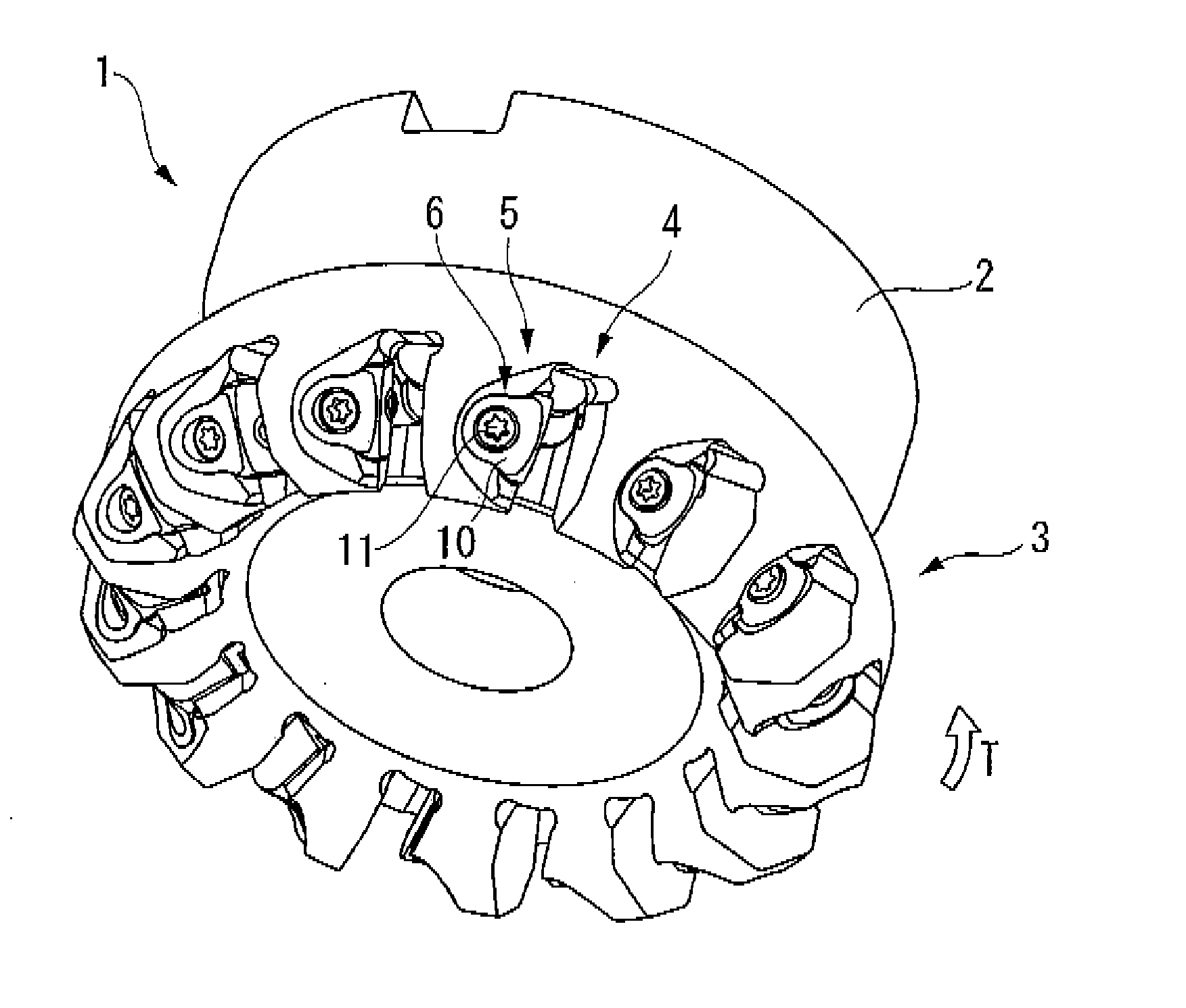

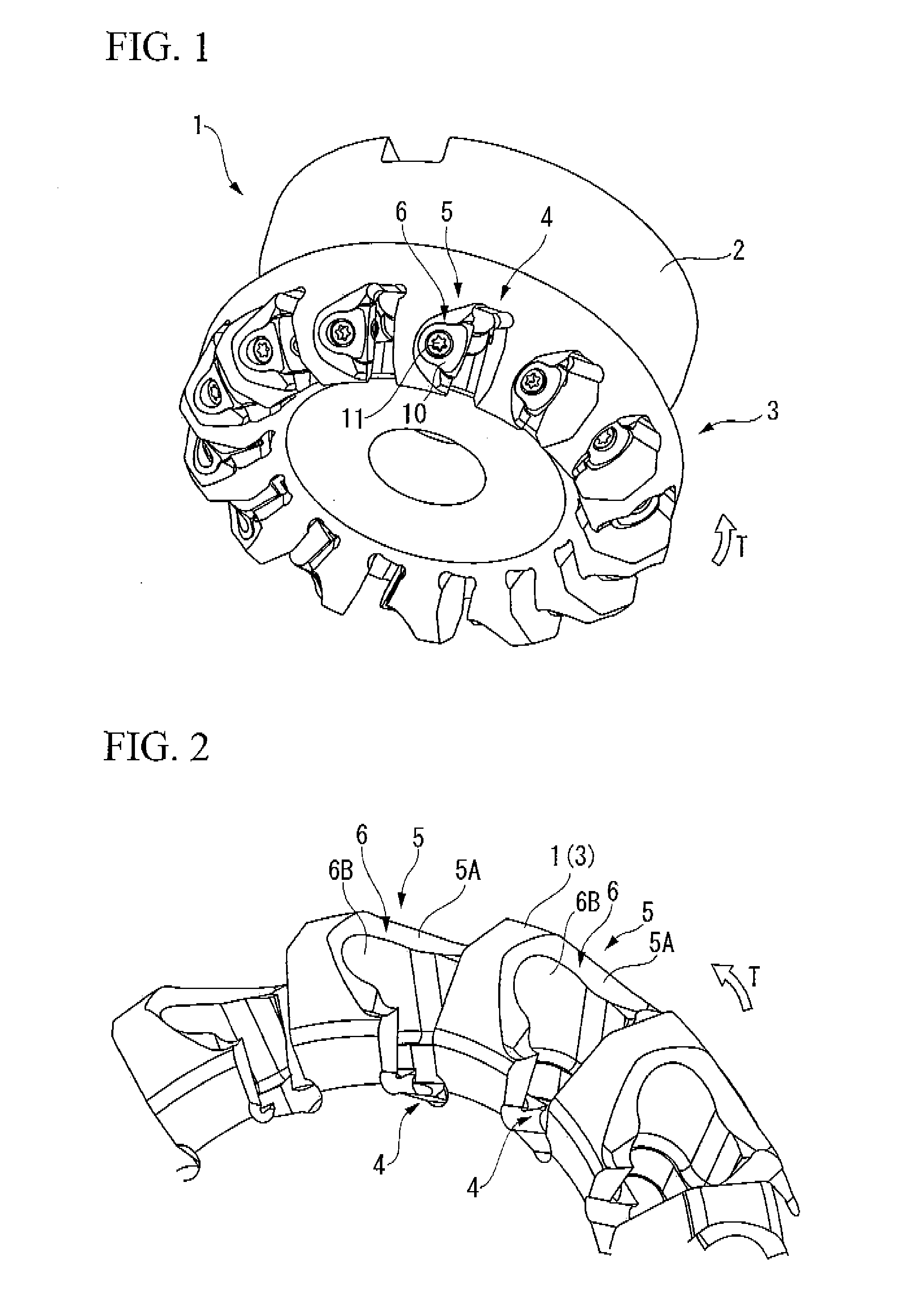

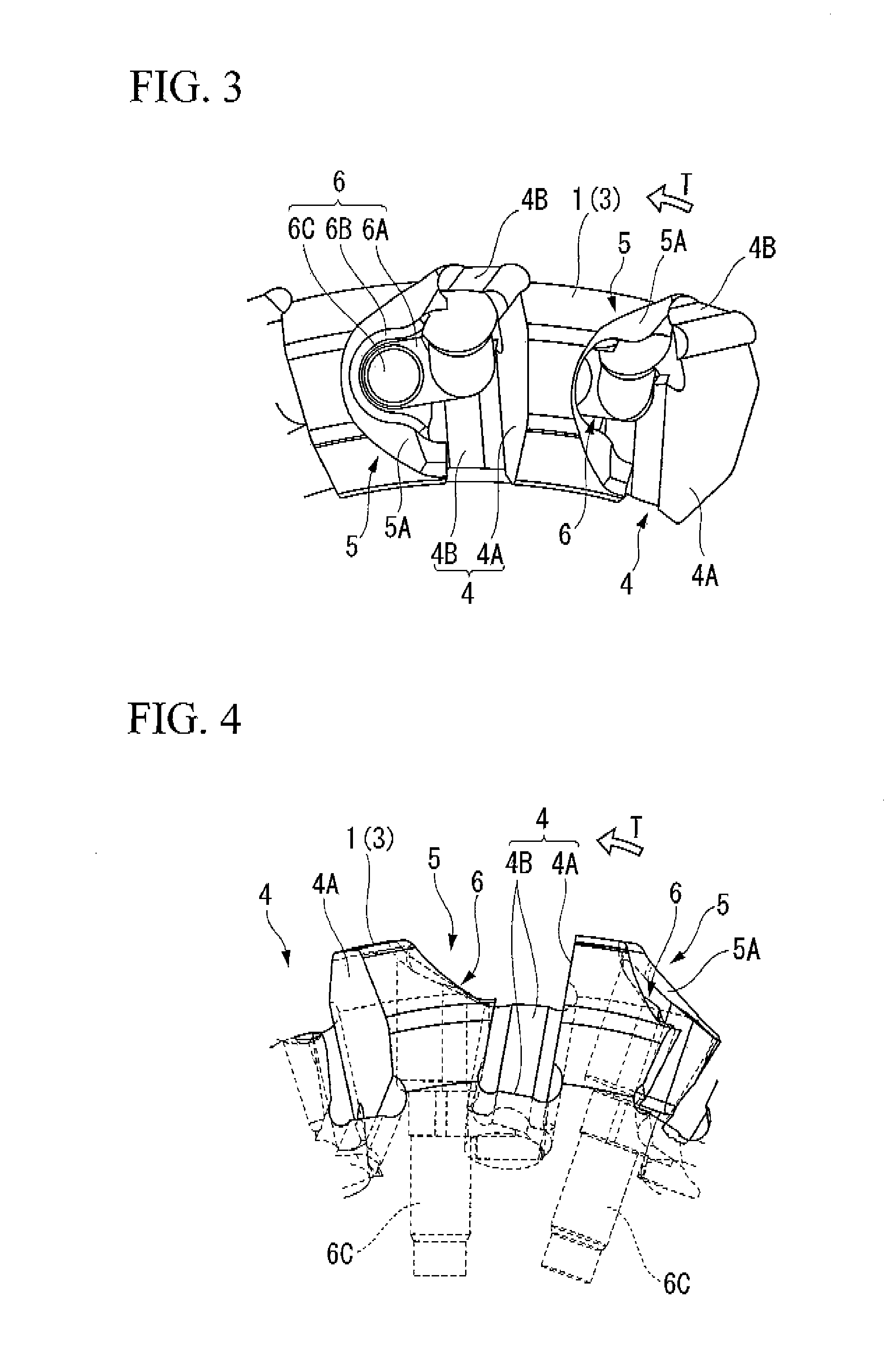

Insert clamping wedge and insert-detachable type cutter

ActiveUS20090245951A1Increase the number ofAvoid damageMilling cuttersShaping cuttersEngineeringMechanical engineering

An insert clamping wedge for clamp-fixing a cutting insert, seated in an insert attachment seat formed in a cutter body, to a recessed portion formed in the insert attachment seat is provided, the insert clamping wedge including: a wedge body, wherein the insert clamping wedge is pressed into the cutter body, wherein the wedge body includes a clamp surface which comes into close contact with the cutting insert and a wedge surface of which a gap between itself and the clamp surface becomes smaller in a press-insertion direction of the wedge body, and wherein the section perpendicular to the press-insertion direction of the wedge body from the wedge surface to the clamp surface being formed in a bell shape.

Owner:MITSUBISHI MATERIALS CORP

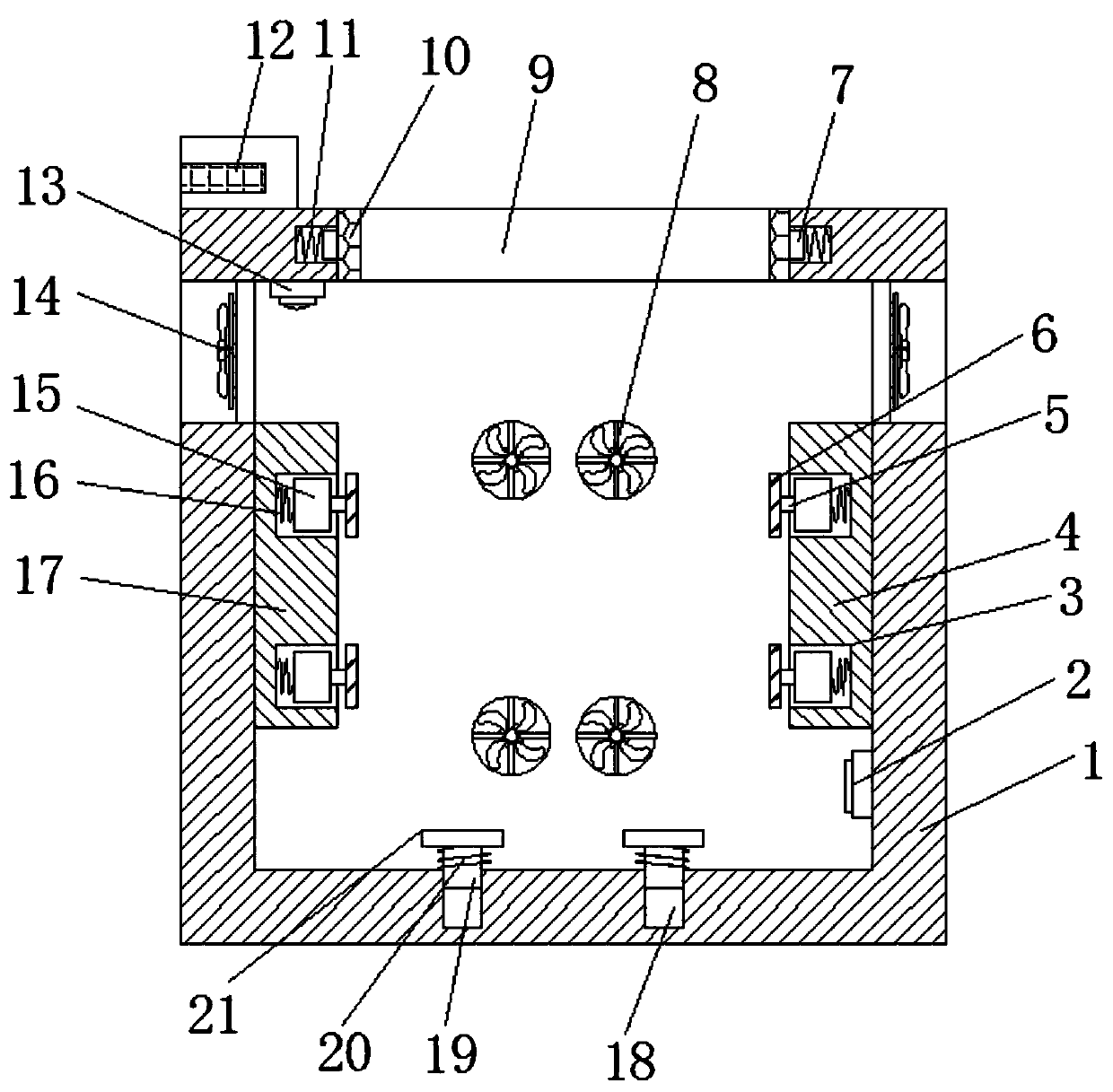

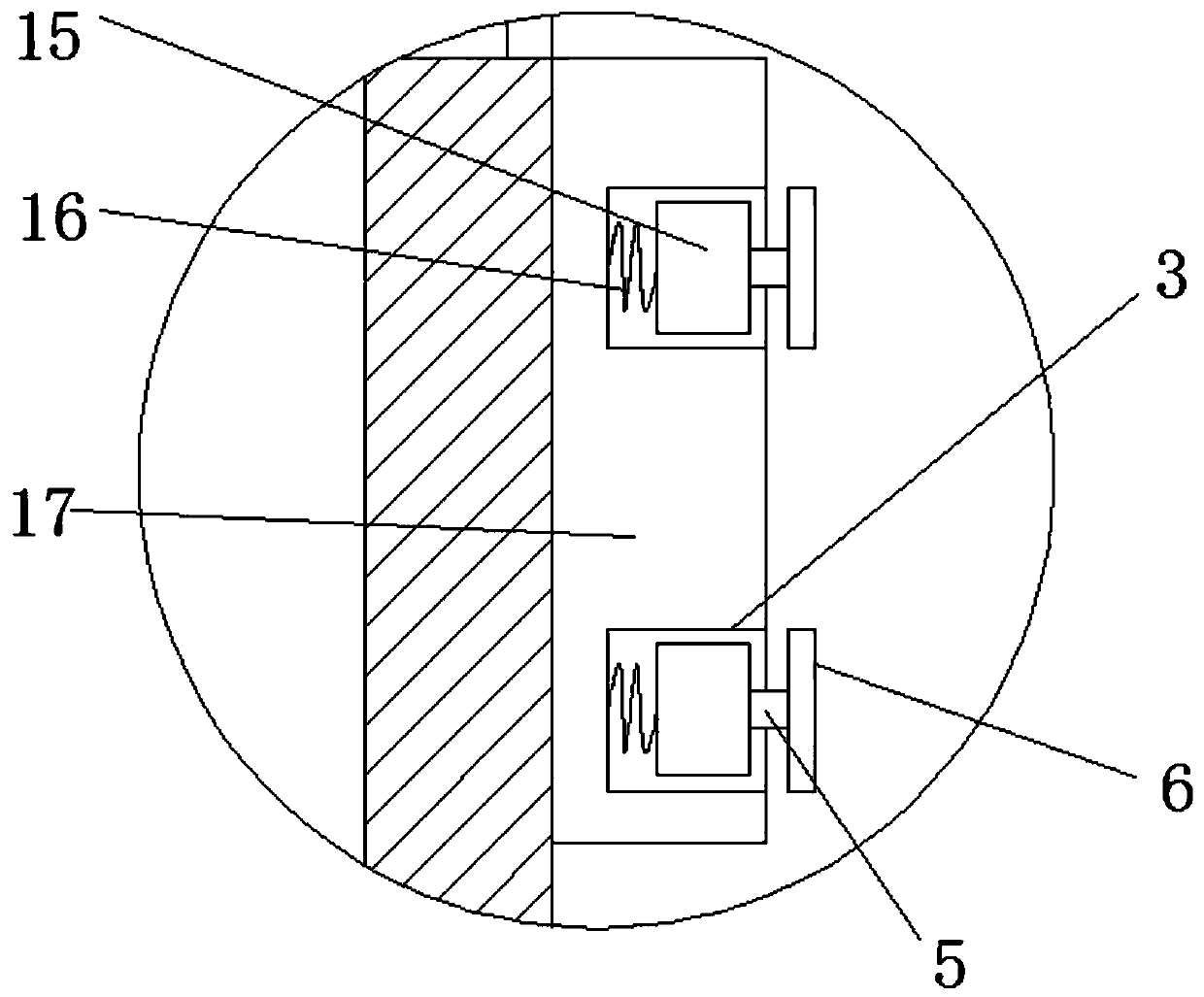

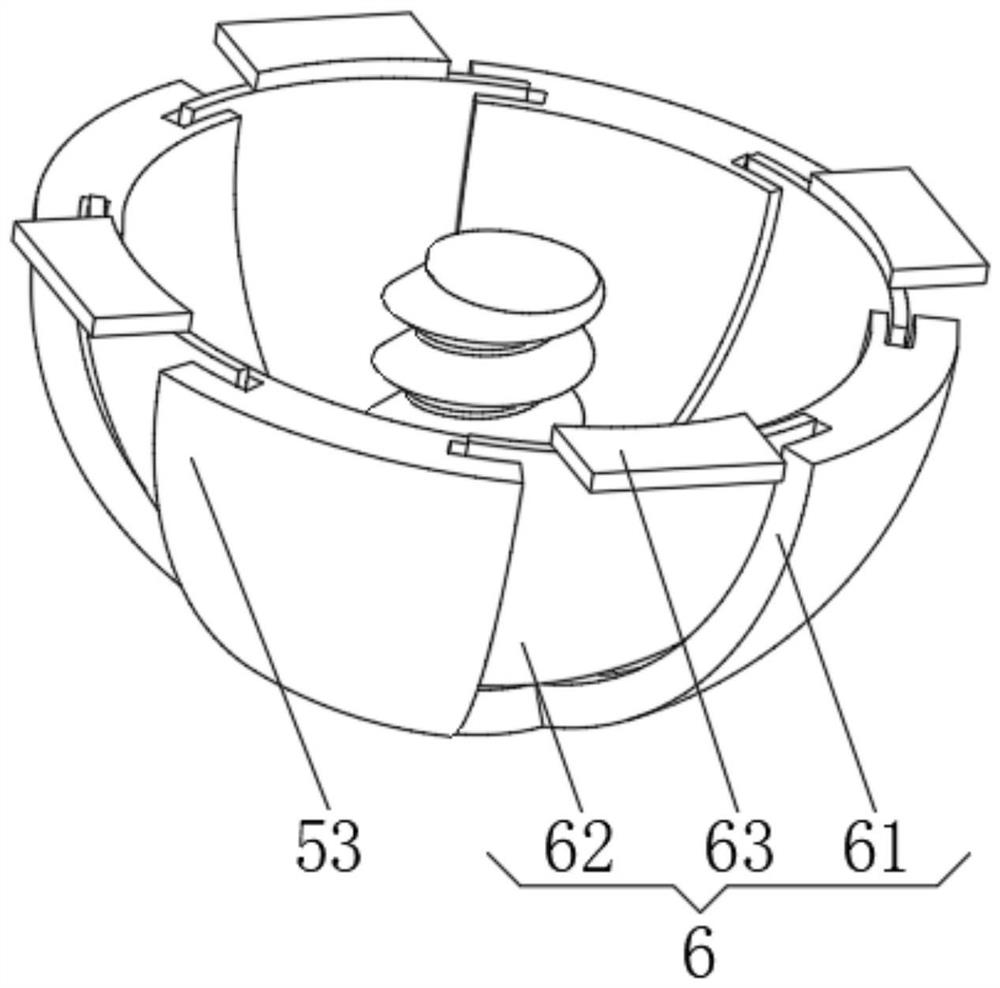

Battery protection device with good shock absorption effect

InactiveCN108682769AIncrease clamping strengthImprove stabilitySecondary cellsCell component detailsAbsorption effectEngineering

The invention discloses a battery protection device with a good shock absorption effect. The battery protection device comprises a box body, wherein the outer wall of the top of the box body is provided with a placement hole; the inner walls of two opposite sides of the placement hole are each provided with a first installation groove; the inner wall of one side of each first installation groove is in sliding connection with a sliding block; the outer wall of one side of each sliding block and the inner wall of one side of the first installation groove are welded with the same reset spring; the outer wall of one side of each sliding block is welded with a clamping plate; the inner walls of two opposite sides of the box body are respectively welded with a first installation plate and a second installation plate; the outer walls of two opposite sides of the first installation plate and the second installation plate are respectively provided with a plurality of second installation grooves. According to the battery protection device, battery clamping strength is improved, the stability of the battery is improved, in addition, the battery can be prevented from shaking, the shock adsorption ability of the device for the battery is effectively improved, the inner side of the device is subjected to dehumidification and radiating, and the protection ability of the device for the batteryis improved.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

Machining jig of circular nonstandard punch for automobile punching die

The invention discloses a processing jig for circular non-standard punches of automobile stamping dies, which consists of a jig body, a V-shaped slider, a V-shaped pressing block, a backer and a punch, and the jig body is connected to the backer ; The V-shaped pressing block is matched with the V-shaped slider and the slope of the backing; the punch is placed between the jig body and the V-shaped slider. The backing and the jig body are fixed with positioning keys and locked with bolts. A spring is arranged under the V-shaped pressing block, and the spring and the V-shaped pressing block are connected to the jig body through the cooperation of the bolt and the T-shaped nut. In the present invention, the horizontal pushing type clamping is converted into oblique downward pressing, and when the screw locks the pressing block, a forward and downward force is provided to the pushing block, and the backing is stable. Through the conversion of the force direction, the accuracy and stability of the circular non-standard punch clamping are greatly improved. It can effectively increase the clamping force and stability, reduce processing tremor, improve clamping accuracy and processing accuracy, simplify operation and improve efficiency.

Owner:十堰兴企信息科技有限公司

Clamping device for lithium battery processing

InactiveCN110695884AStable clampingIncrease clamping strengthAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a clamping device for lithium battery processing. The clamping device comprises a support, the lower part of the support is glidingly connected with a lifting air pipe, and thelower end of the lifting air pipe communicates with a sucking disc. A second motor is arranged in the support, and an output shaft of the second motor is connected with a second threaded rod in a transmitting mode. The side face of the lifting air pipe is fixedly connected with a third fixed block. When the clamping device is used, a lithium battery needing to be clamped is placed among three clamping plates, the lithium battery is clamped by the three clamping plates, and force bearing points are increased. When the lithium battery is clamped, the lifting air pipe moves downward. At the moment, the sucking disc contacts the clamped lithium battery and inhales through a connecting air pipe at the same time, so that the sucking disc absorbs the lithium battery, and the lithium battery canbe clamped more stably. Compared with the existing clamping device, the novel clamping device for lithium battery processing improves the clamping force for the lithium battery by increasing the forcebearing points and increasing adsorption force, so that the lithium battery is not easy to fall off.

Owner:天津鼎鑫缘新型材料科技有限公司

Hydraulic engineering pipeline supporting system

PendingCN114370550APrevent getting stuckImprove fitnessPipe supportsPipe elementsSupporting systemCircular disc

The invention discloses a hydraulic engineering pipeline supporting system which comprises a base, supporting plates are symmetrically installed at the top of the base, a supporting disc is slidably connected to the tops of the supporting plates, a clamping device is arranged outside the base and the supporting disc, the clamping device is provided with a supporting arc plate, and a clamping plate is rotatably connected to the top of the supporting arc plate; the adjusting device is provided with a threaded column, and the threaded column penetrates through the base and extends to the outside of the base; and the cleaning device is provided with sewage discharge grooves, and the sewage discharge grooves are evenly formed in the top of the semicircular disc. According to the hydraulic engineering pipeline supporting system, the purpose of improving the buffering capacity is achieved, damage caused by collision between the pipeline and the supporting device is reduced, the height of the pipeline at the fixed position can be adjusted according to needs, impurities deposited in the pipeline are discharged in time, the water conveying efficiency of the pipeline is guaranteed, and the adaptive capacity to the environment is improved.

Owner:白梦云

Computer network demultiplexer capable of preventing network cable from being dragged and damaged

InactiveCN111509479AIncrease clamping strengthAvoid drag damageRelieving strain on wire connectionCoupling parts mountingStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of computer networks. The invention discloses a computer network demultiplexer capable of preventing a network cable from being dragged and damaged. The demultiplexer comprises a device body, a dragging lantern ring is arranged in the equipment main body; the outer side of the dragging lantern ring is movably connected with a connecting assembly; a bearing spring is movably connected to the end, away from a mounting block, of a connecting spring; the outer side of the bearing spring is movably connected with an installation support, a supporting bearing is movably clamped inside the installation support, the outer side of the supporting bearing is movably connected with a supporting spring, the outer side of the supporting spring is movably connected with a connecting ring, the outer side of the connecting ring is movably connected with abutting clamping teeth, and the inner side of the connecting ring is movably connected with a shaft rod.Through abutting of an abutting block and abutting wrapping of the abutting clamping teeth, the problem that the network cable is directly acted on a connection part of the network cable and a cable branching port when being dragged by an external force, and further the network cable is pulled apart or the network cable and the cable branching port are broken and damaged is overcome.

Owner:杭州柯宏网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com