High-speed tensile test steel plate sample piece clamp

A technology of high-speed stretching and steel plates, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as test failure, sample falling off, affecting the accuracy of test data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, further illustrate the structure of the present invention namely using method:

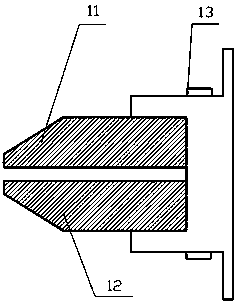

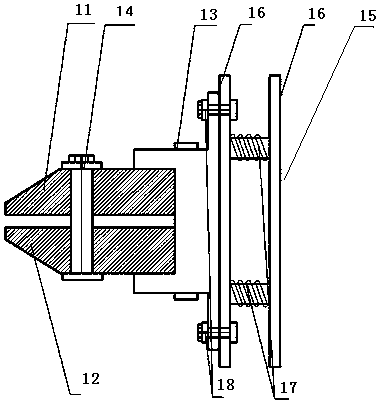

[0014] see figure 2 , the high-speed tensile test steel plate sample fixture has the same upper clamping clamp 11, lower clamping clamp 12 and locking device 13 as the existing clamps, the upper clamping clamp and the lower clamping clamp form a clamp shape symmetrically up and down, and the front end For the jaw, the rear end is installed in the locking device. Its improvement lies in:

[0015] Each of the upper clamping pliers 11 and the lower clamping clamp 12 has a corresponding bolt hole for loading a locking bolt 14 . After the locking device 13, a base 15 loaded with an elastic connecting device is added. The base 15 has two seat plates 16 arranged in parallel, and the two seat plates 16 are welded together by two buffer springs 17 , and the locking device 13 is connected to one of the seat plates 16 by a pair of bolts 18 .

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com