Hydraulic engineering pipeline supporting system

A technology for pipeline support and water conservancy engineering. It is applied to pipeline supports, pipe components, pipes/pipe joints/fittings, etc. It can solve problems such as poor buffering effect, and achieve the effect of improving buffering capacity, ensuring efficiency and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

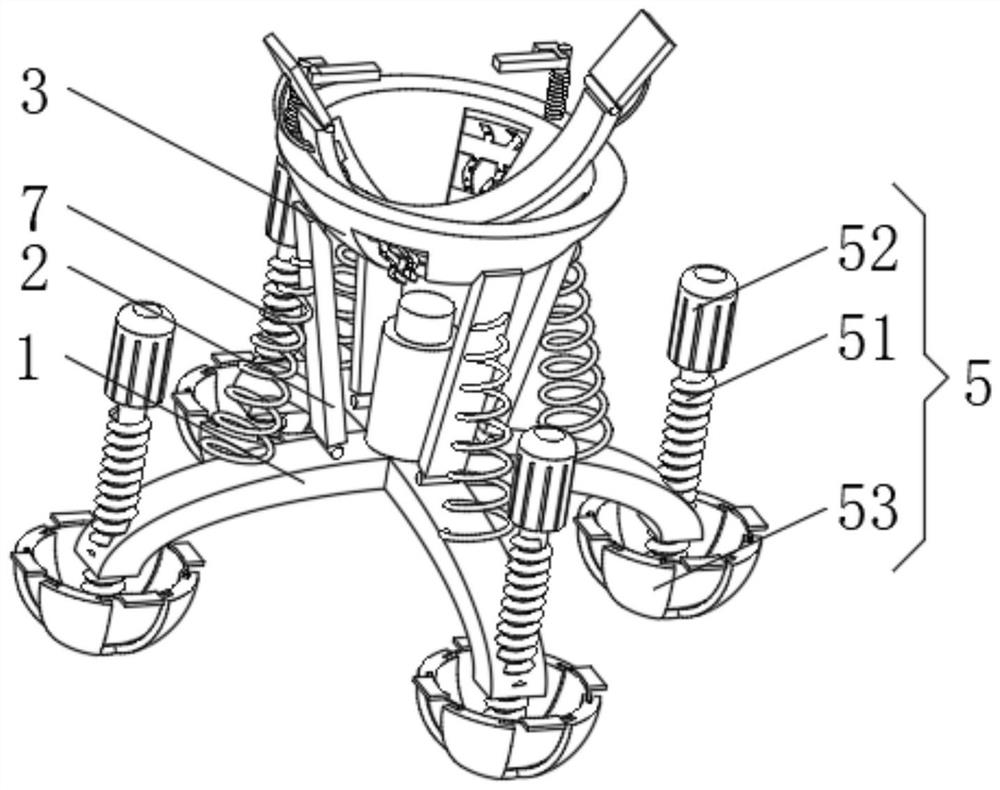

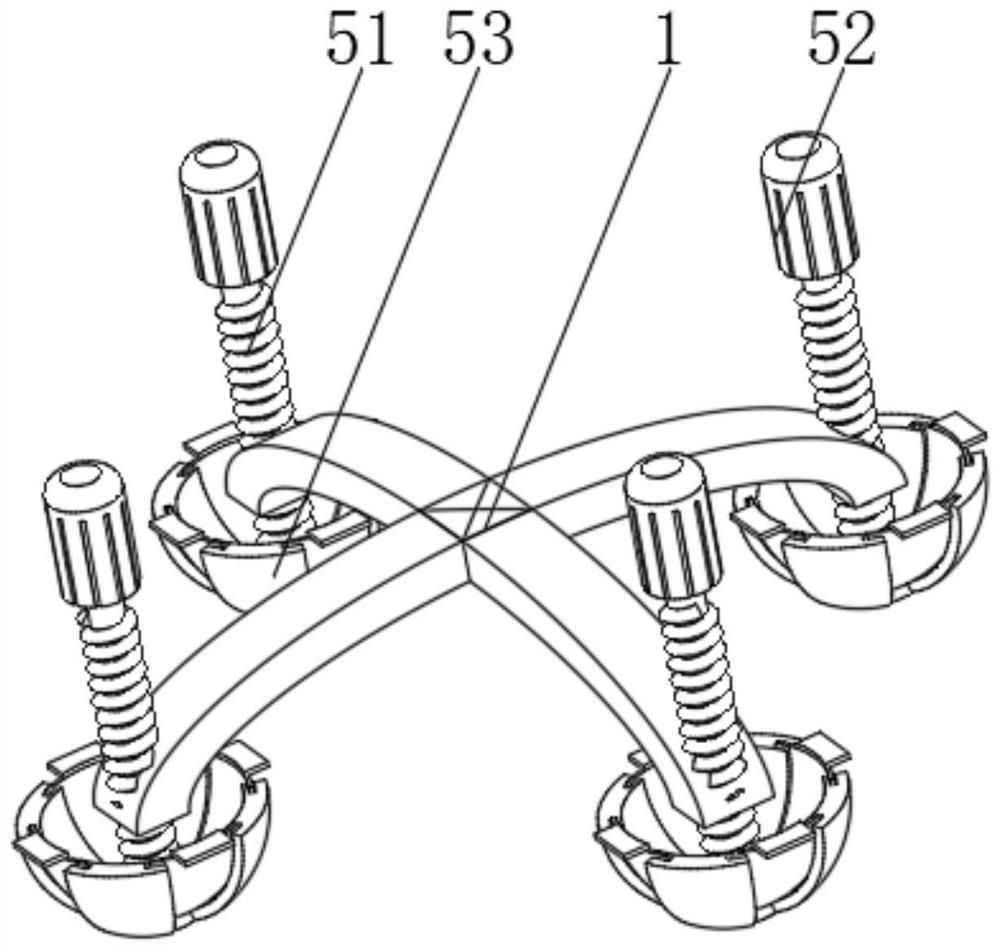

[0035] see Figure 1-3 , the present invention provides a technical solution: a hydraulic engineering pipeline support system, including a base 1, a support plate 2 is symmetrically installed on the top of the base 1, a support plate 3 is slidably connected to the top of the support plate 2, the base 1 and the support plate 3 An adjustment device 5 is provided on the outside, and the adjustment device 5 has a threaded column 51, which runs through the base 1 and extends to the outside of the base 1, and the top end of the threaded column 51 is fixedly connected with a handle 52, and the outer side of the handle 52 is uniformly provided with Anti-skid groove, the bottom of threaded column 51 is equipped with half disk 53.

[0036] The support plate 2 is rotatably connected to the base 1 , a buffer spring 7 is fixedly connected to one side of the support plate 2 , and the end of the buffer spring 7 away from the support plate 2 is fixedly connected to the base 1 .

[0037] The ...

Embodiment 2

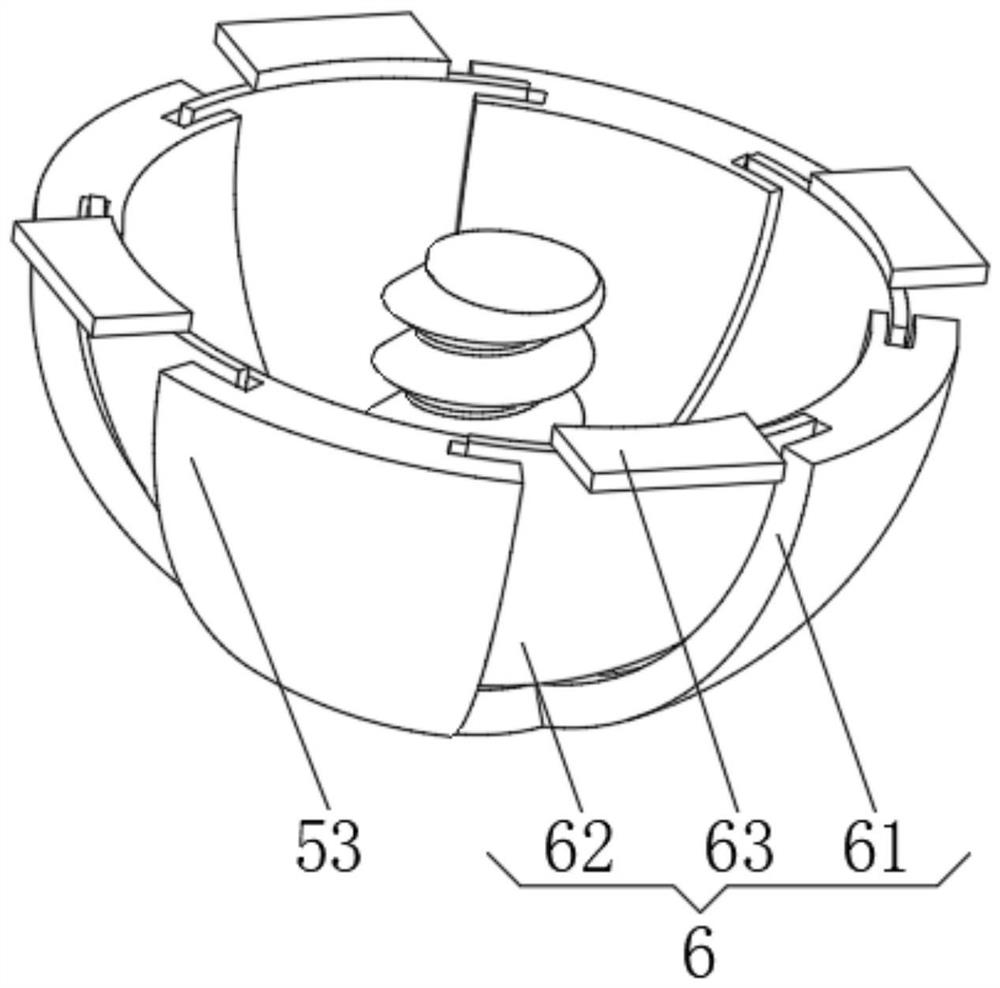

[0043] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a clamping device 4 is provided on the outside of the base 1 and the support plate 3, the clamping device 4 has a supporting arc plate 41, and the top of the supporting arc plate 41 rotates A clamping plate 42 is connected, and an elastic plate 43 is fixedly connected to one side of the clamping plate 42 , and an end of the elastic plate 43 away from the clamping plate 42 is fixedly connected to the support arc plate 41 .

[0044] The bottom of the support plate 3 is fixedly connected with a counterweight 10 , the counterweight 10 penetrates the support plate 3 and extends to the inside of the support plate 3 , and the support arc plate 41 is slidably connected with the counterweight 10 .

[0045] The top of the support plate 3 is equipped with an externally threaded column 11 near the clamping plate 42 , the externally threaded column 11 runs through the support plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com