Fluffy soil compacting device

A compaction device and soil technology, applied in soil protection, roads, road repairs, etc., can solve problems such as difficult to adapt, uneven compacted road surface, and insufficient stability of vehicle movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

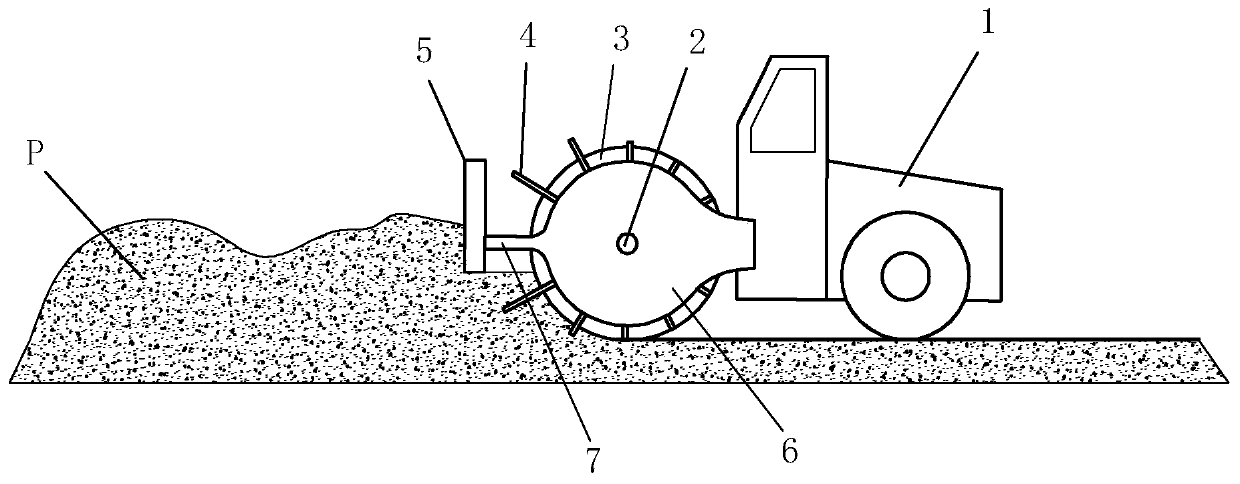

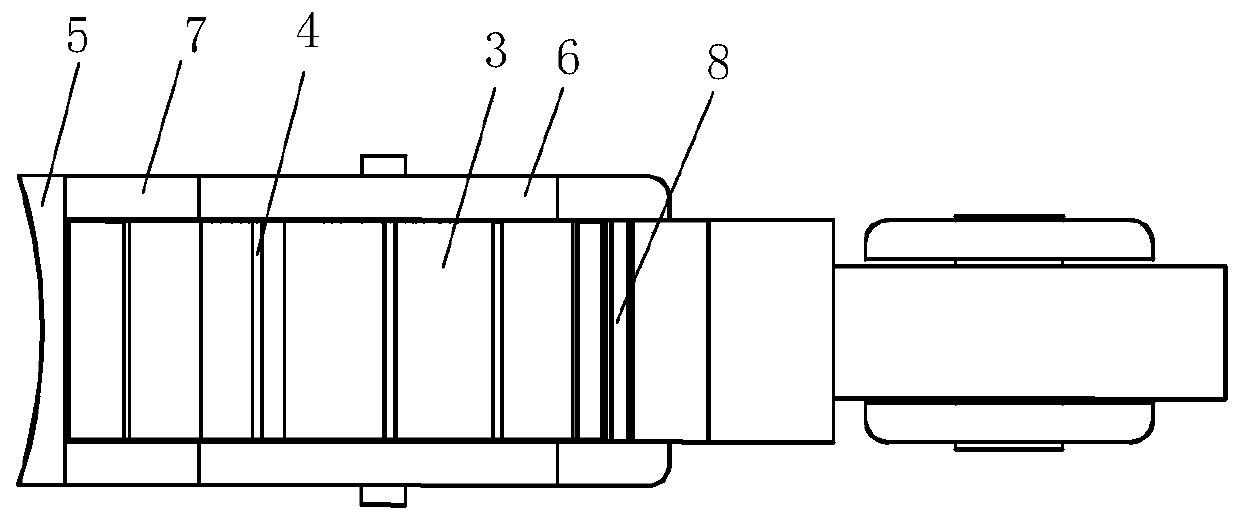

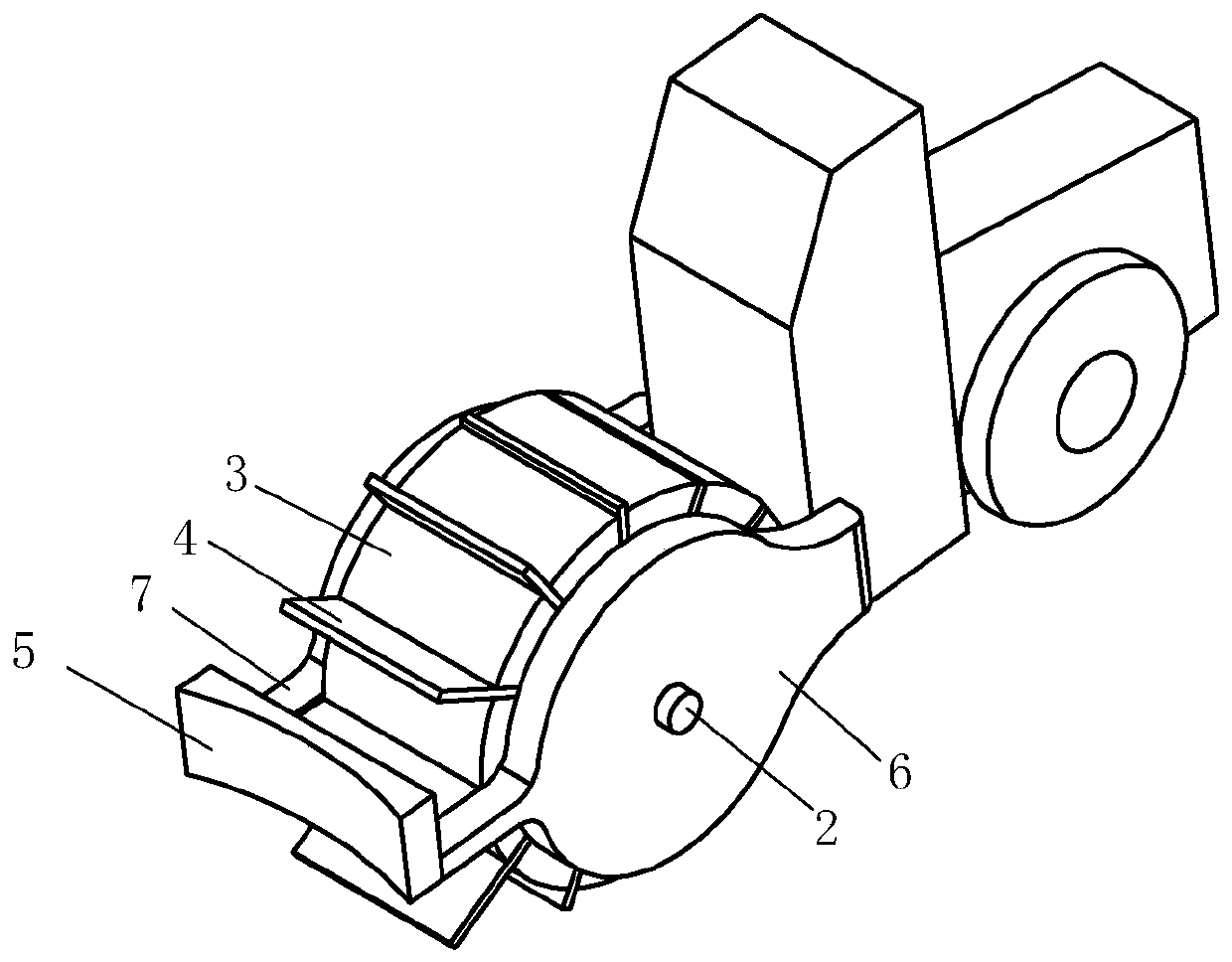

[0022] Embodiment 1: a kind of fluffy soil compaction device, as Figure 1-Figure 9 As shown, it includes a compacting wheel 3, and also includes a flat plate 5, two fixed side plates 6 and a plurality of blades 4, and guide rods 41 are respectively arranged on both sides of the bottom of the blade, and uniformly distributed on the compacting wheel. There are a plurality of blade slots 31 with the same number as the number of blades. The compacting wheel is installed between two fixed side plates through the rotating shaft 2 and bearings. The inner walls of the two fixed side plates are symmetrically opened to make the blades extend. out and retract the guide groove 61 of the compacting wheel, the blade is inserted into the blade slot 31 of the compacting wheel, the guide rod 41 of the blade is located in the guide groove, and the blade can slide freely in the blade slot; when the blade follows the pressure While the solid wheel is rotating, under the action of the guide groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com