Sulfur scraping device applied to operation of well testing steel wire for ultradeep high-sulfur gas well

A high-sulfur well-testing technology, which is applied in wellbore/well components, earthwork drilling, cleaning equipment, etc., can solve the problem of steel wire getting stuck, and achieve the effects of preventing stuck, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

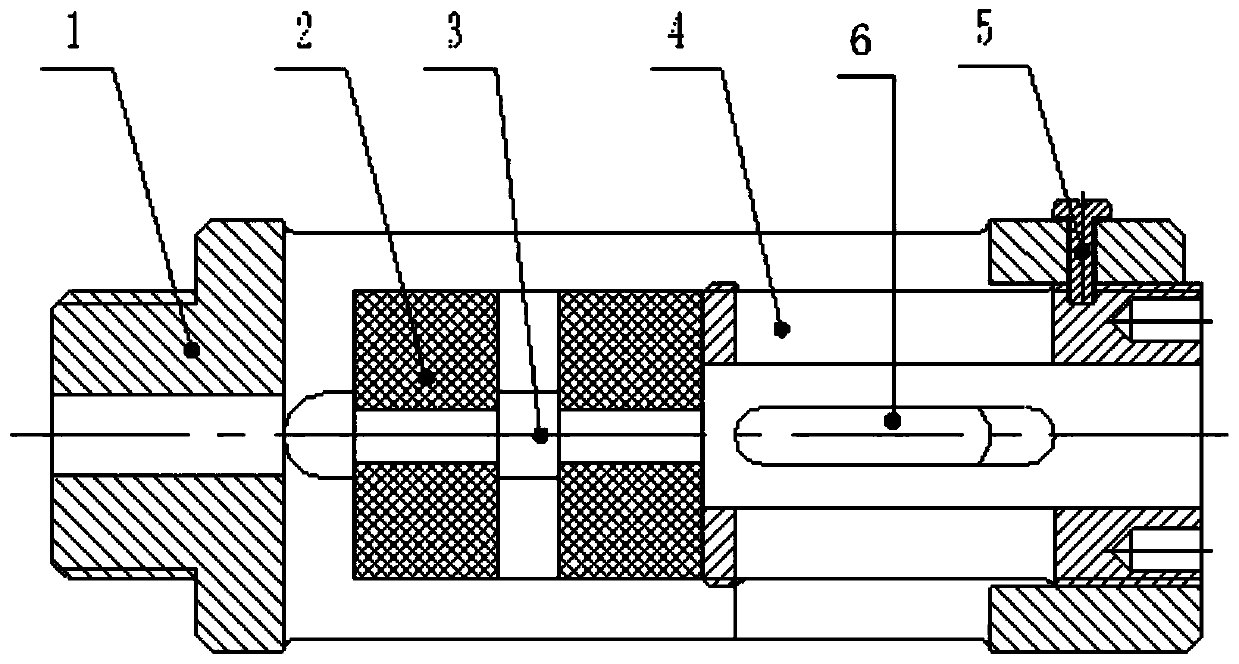

[0021] Such as figure 1 As shown, a sulfur scraping device for ultra-deep high-sulfur gas well testing steel wire operation, the sulfur scraping device is fixedly installed at the lower end of the sealing control head of the well testing steel wire, the sulfur scraping device mainly includes: a casing, a sulfur scraping part, a sulfur scraping groove and Discharge tray; the sulfur scraper is arranged inside the shell, and an internal thread is provided on the inner surface of one end of the shell, and the discharge tray is threadedly connected with the end of the shell provided with an internal thread, so that the sulfur scraper is inside the shell fixed to prevent the sulfur scraping parts from moving up and down along with the well test steel wire during well test steel wire operation, and the effect of scraping impurities cannot be achieved; Sealed control head connection; after the sulfur scraping device has been used for a period of time, it needs to be cleaned to prevent...

Embodiment 2

[0026] Preferably, the locating member is a positioning jack screw, and by opening a screw hole on the shell, screwing the jack screw in to complete the fixing of the discharge tray in the circumferential direction.

Embodiment 3

[0028] Preferably, the material of the sulfur scraper is preferably rubber, because the rubber sulfur scraper is not easy to chemically react with the substances in the sulfur gas well, and the rubber sulfur scraper is light and convenient, easy to install and take out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com