Patents

Literature

45 results about "Static stretching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Static stretching is used to stretch muscles while the body is at rest. It is composed of various techniques that gradually lengthen a muscle to an elongated position and hold that position for 30 seconds to two minutes. 30 seconds is the minimum duration to get the benefits of stretching, whereas two minutes is the maximum. During this holding period or directly afterwards, participants may feel a mild discomfort or warm sensation in the muscles. Static stretching exercises involve specialized tension receptors in our muscles. When done properly, static stretching slightly lessens the sensitivity of tension receptors, which allows the muscle to relax and to be stretched to greater length. There is doubt over the effectiveness of static stretching, with some circles of sport strongly recommending against it, such as soccer, slamball and rugby league. Recently, there has been a controversy. over static stretching saying that it gets you ready but makes you weaker. Isometric Stretching/ Static Stretching is often advocated by many coaches and fitness experts as great way to stretch before an athletic event or exercise activity.

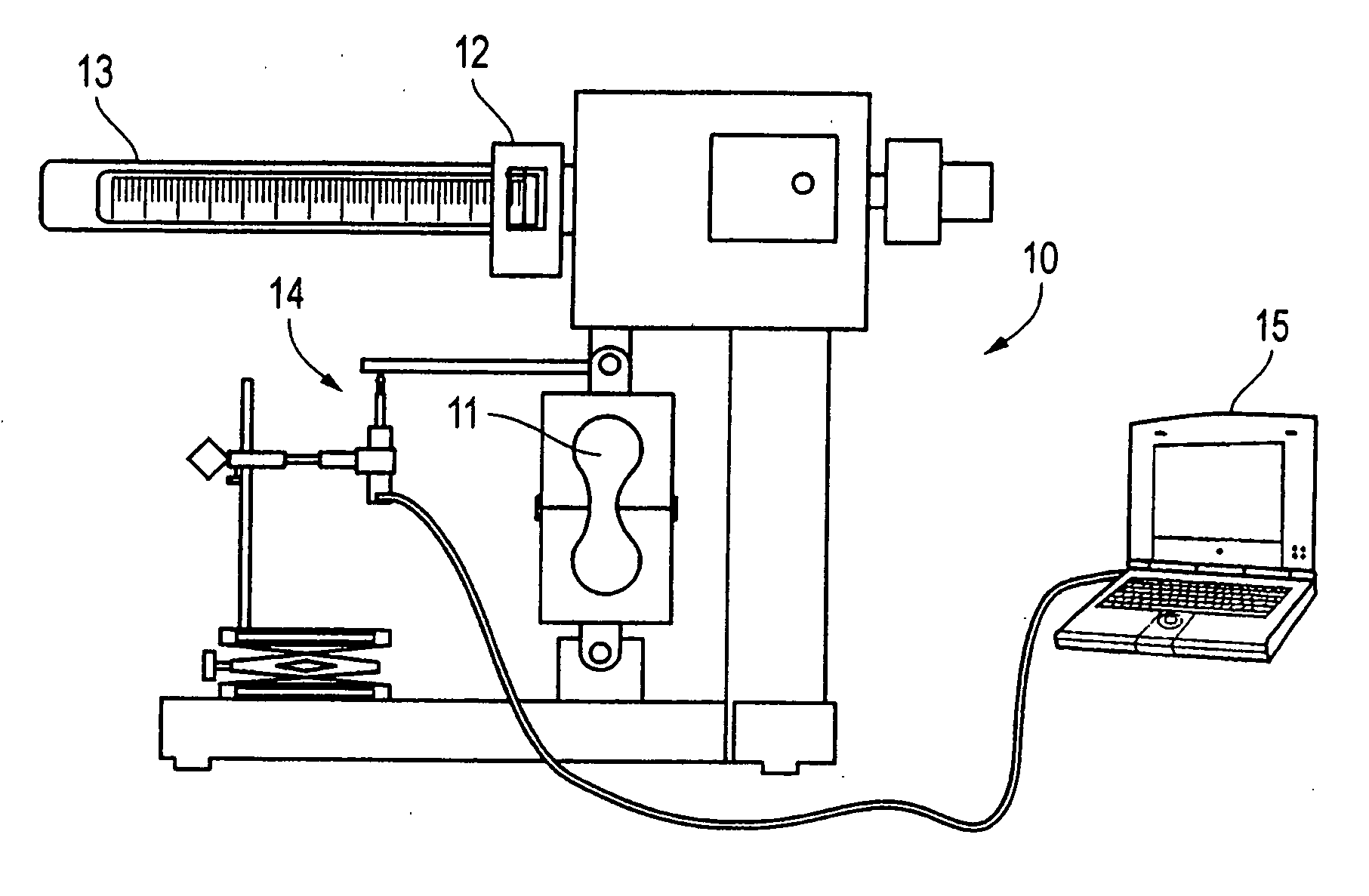

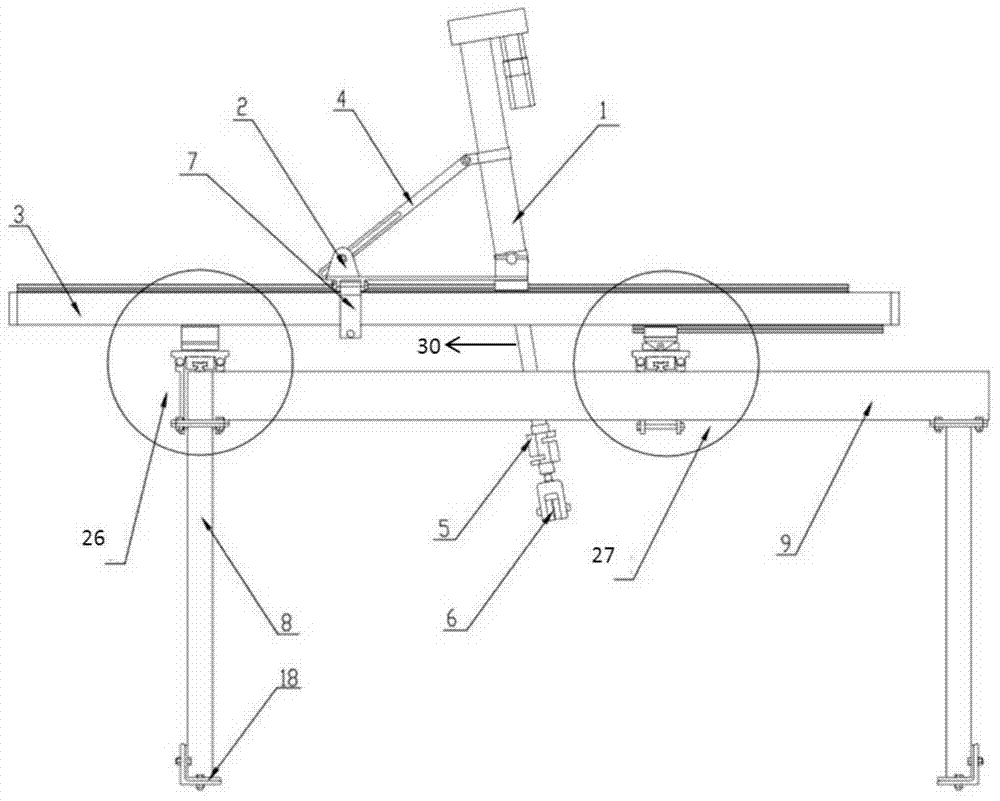

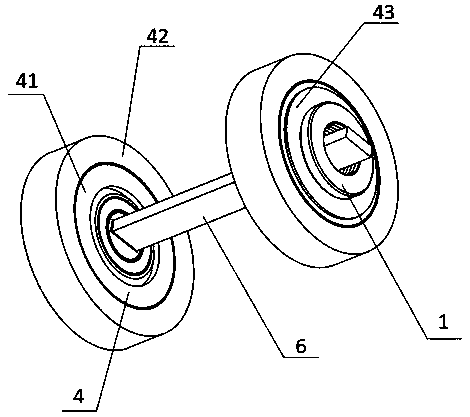

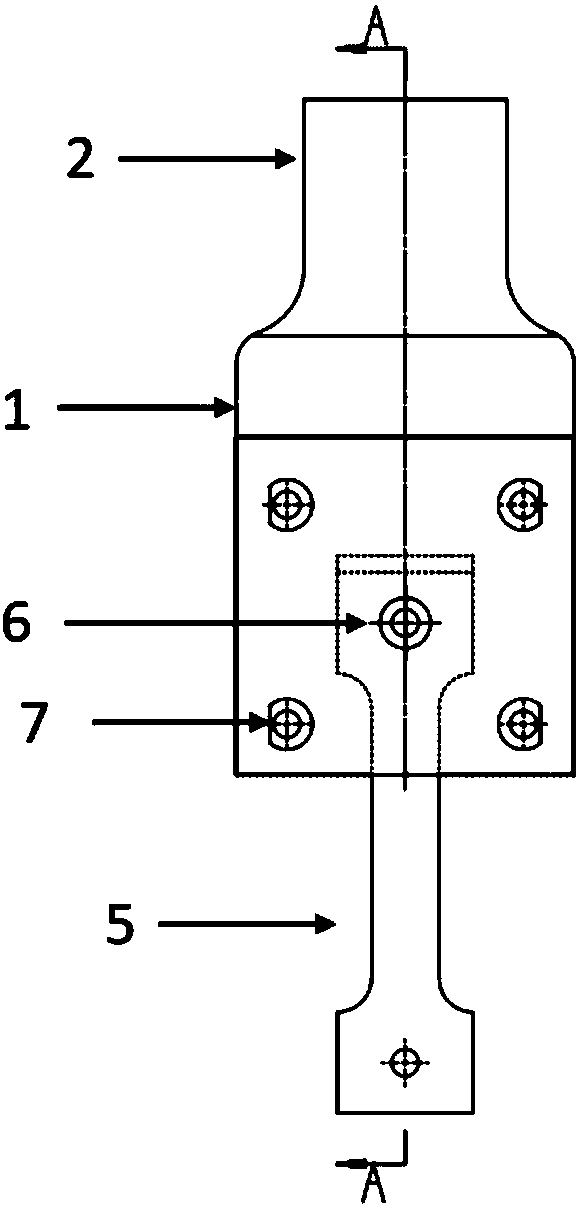

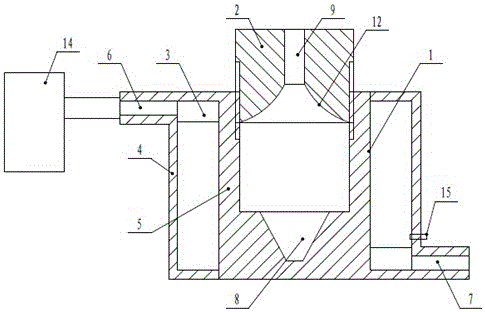

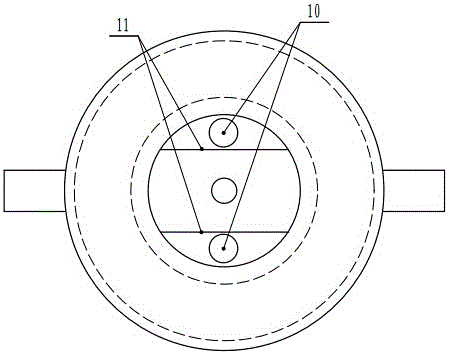

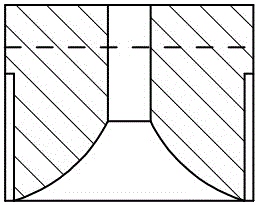

Biaxial extension test device

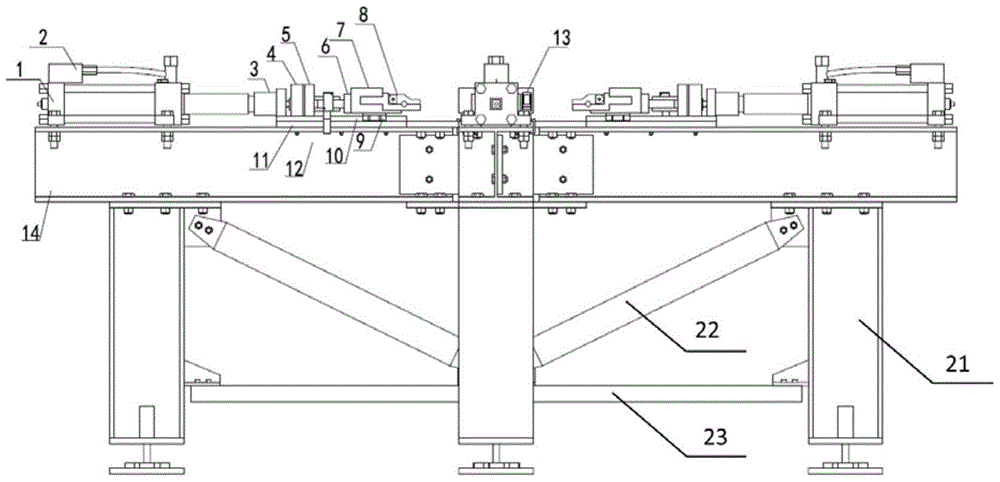

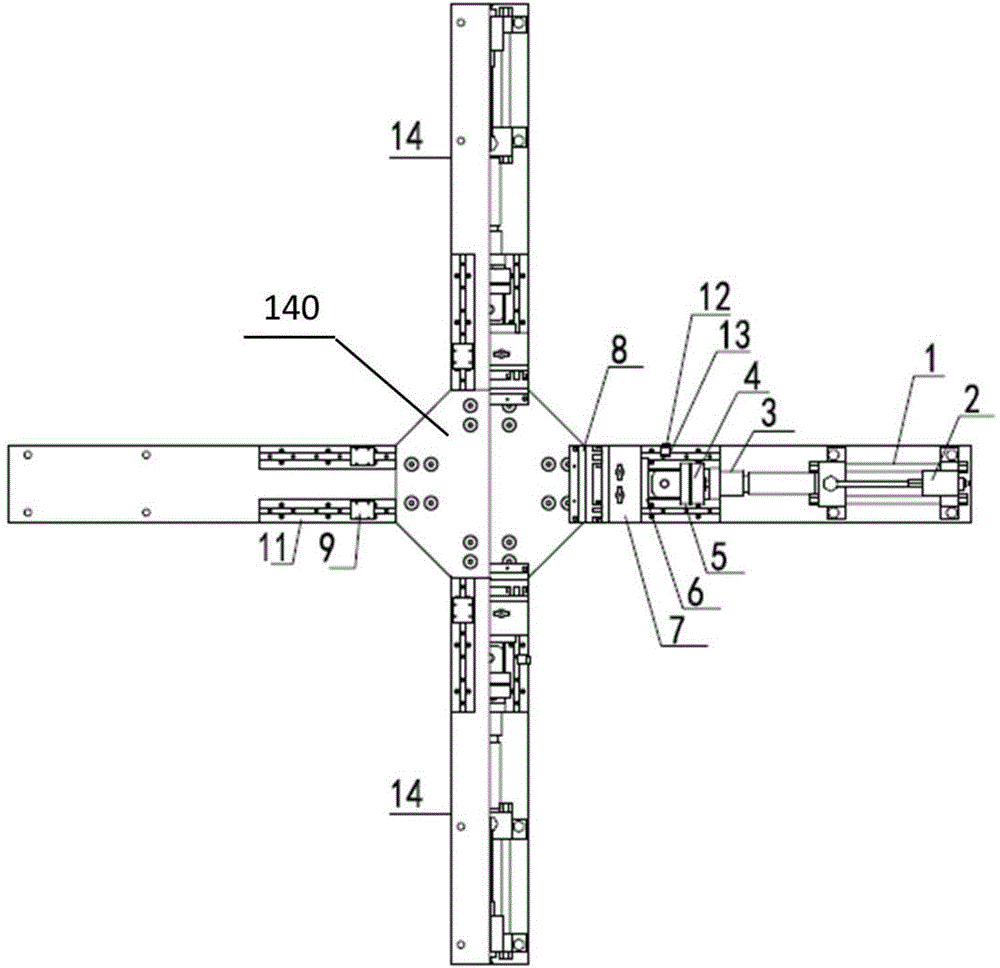

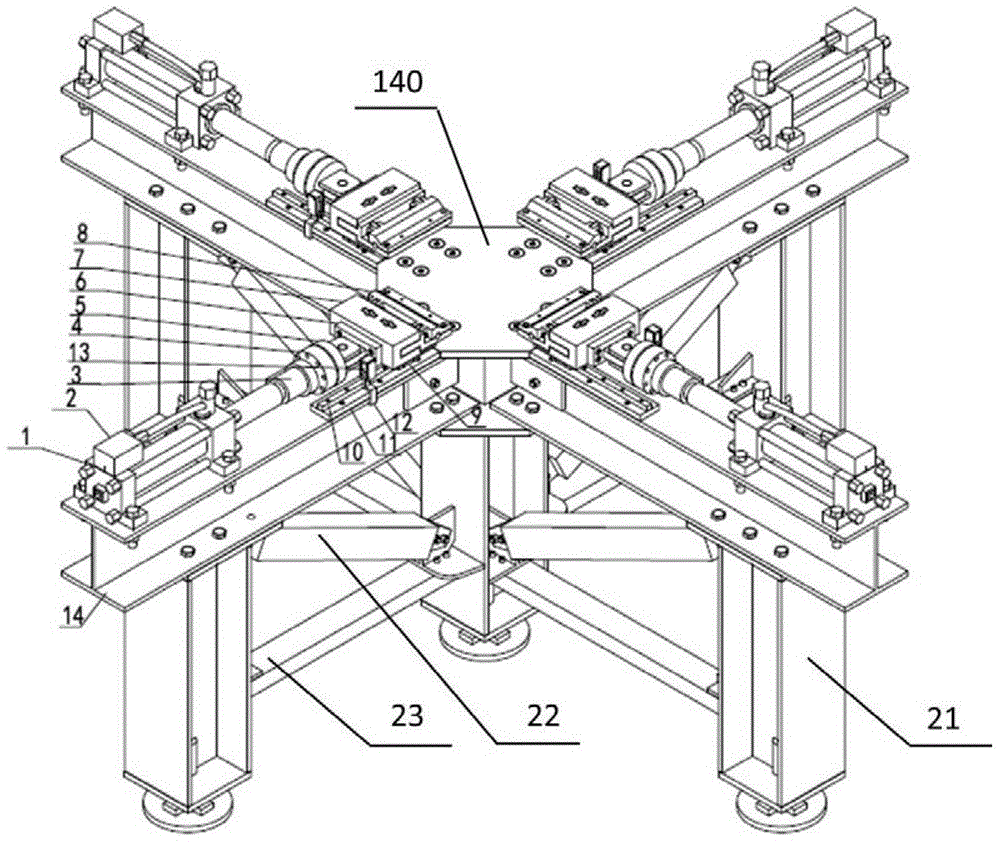

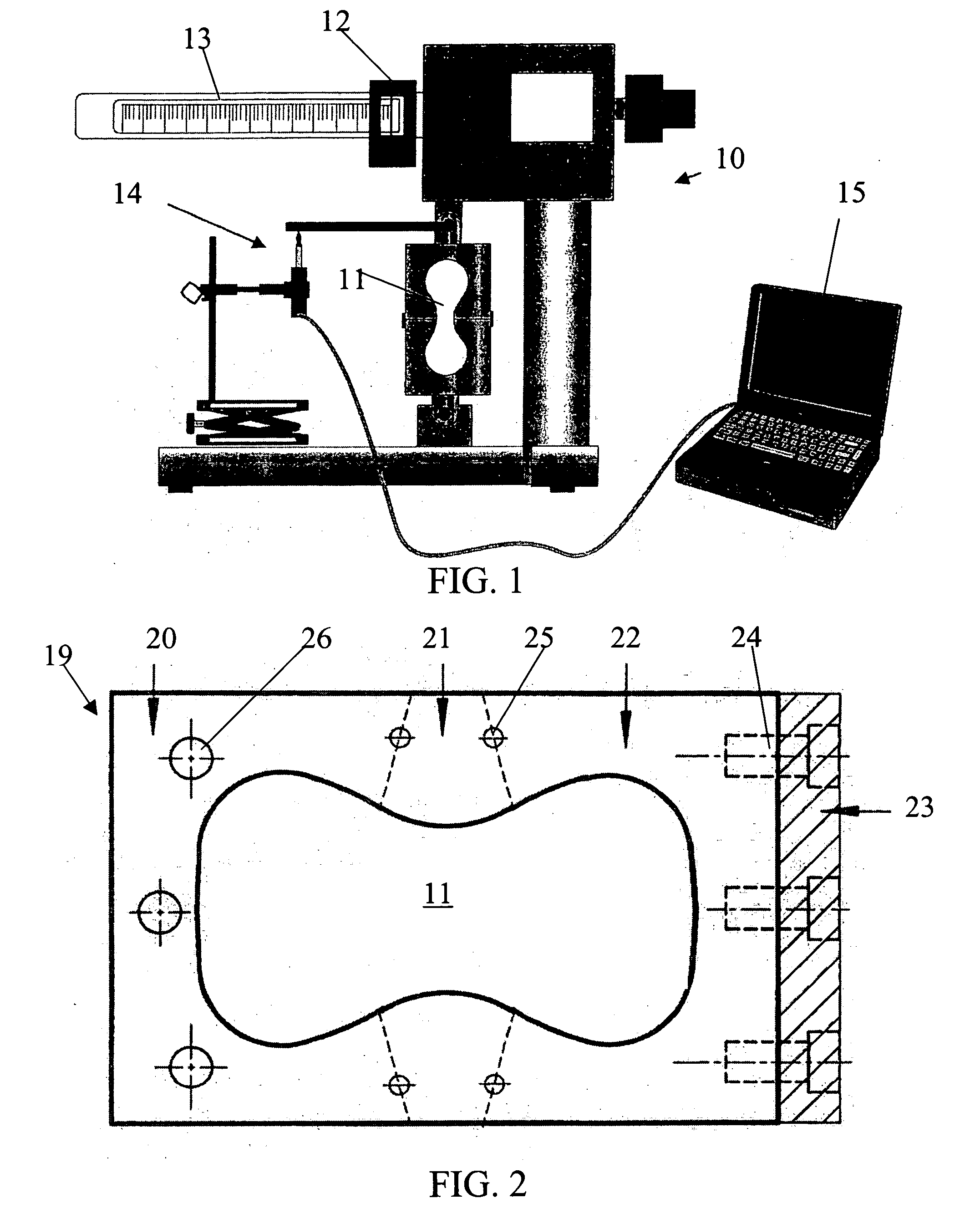

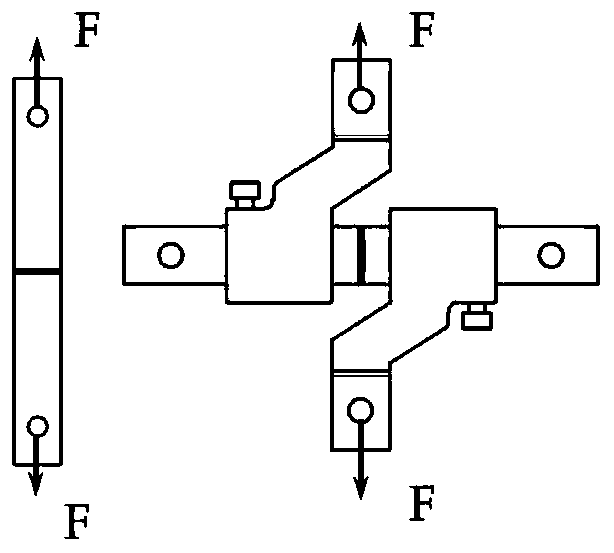

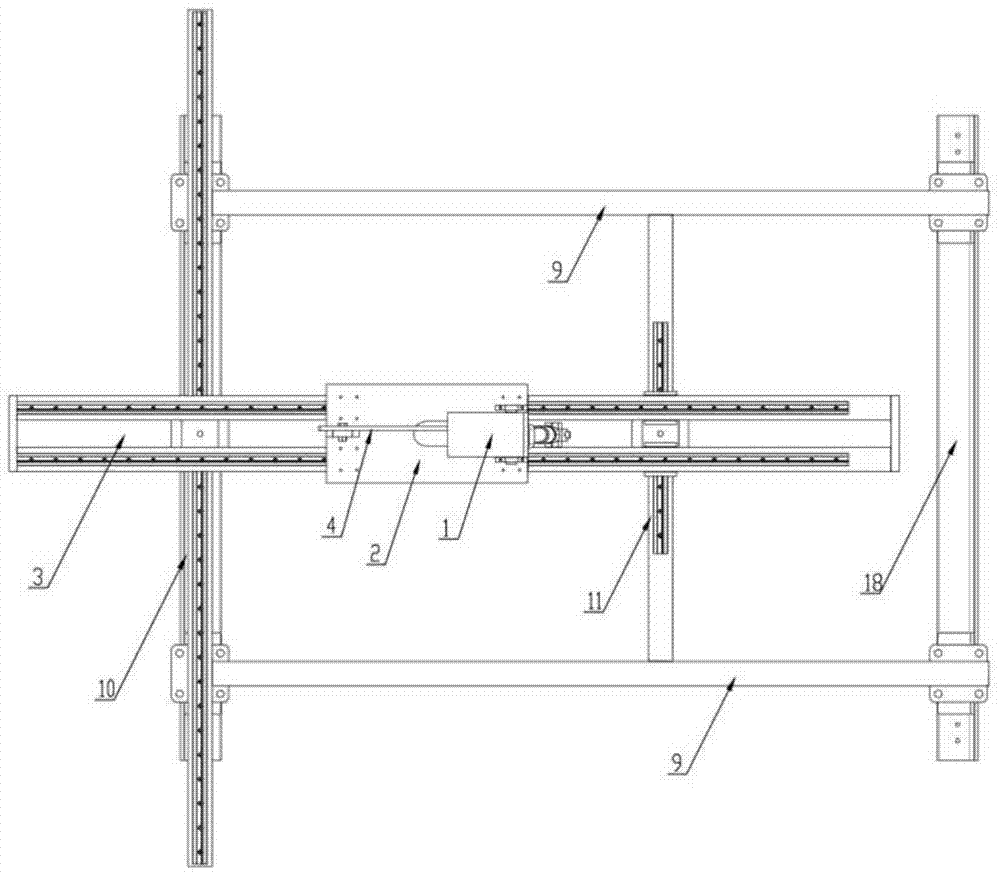

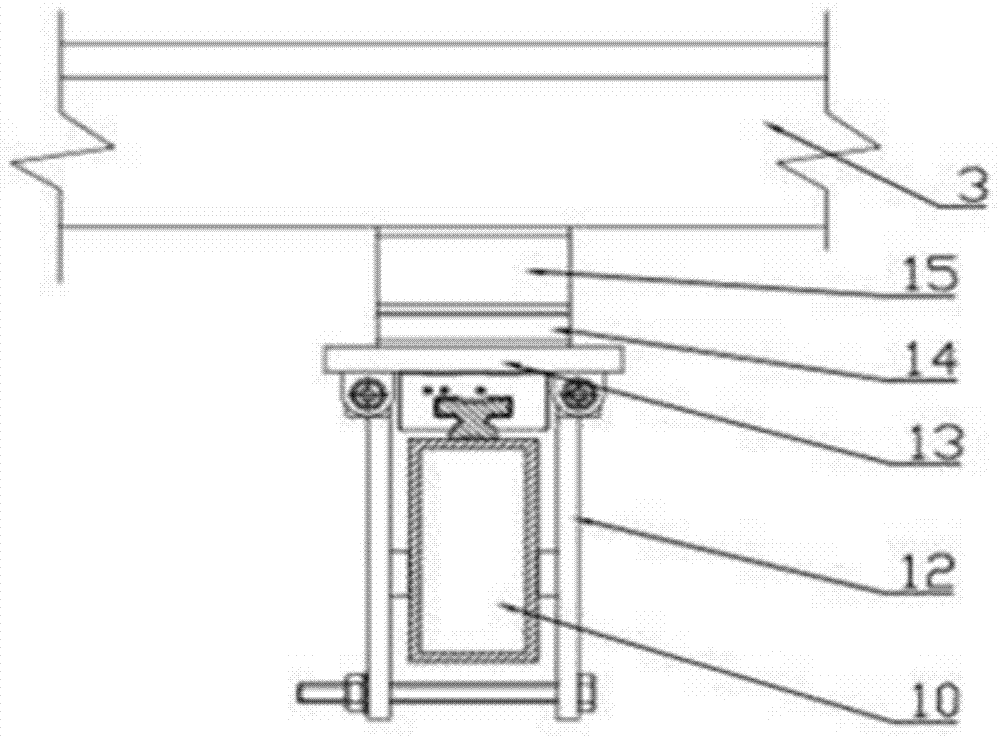

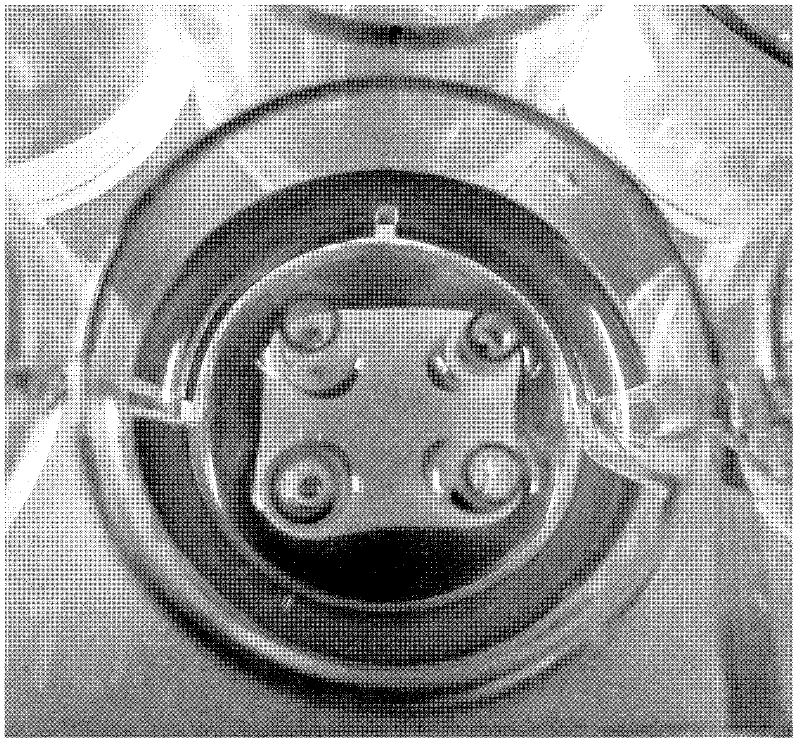

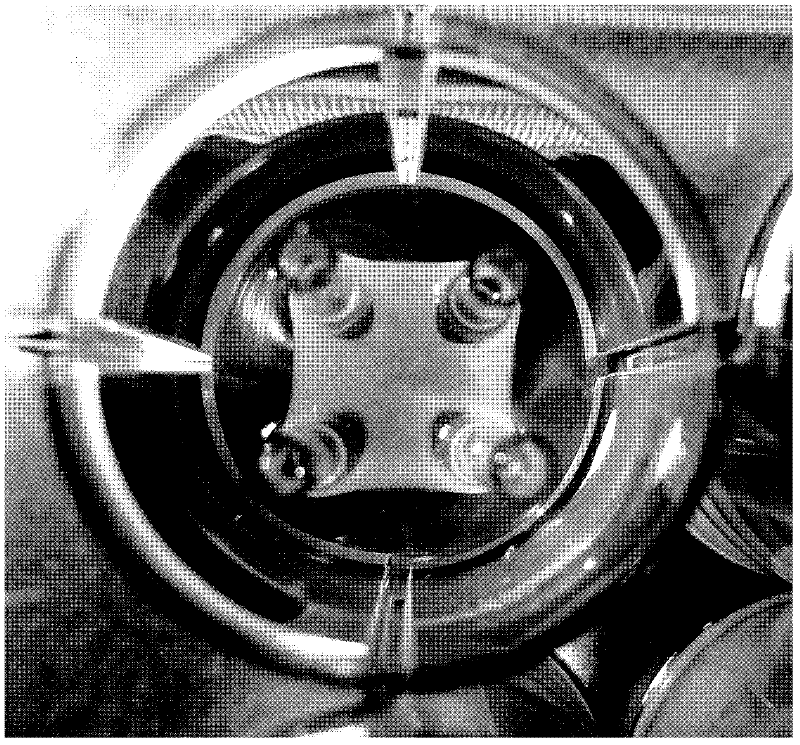

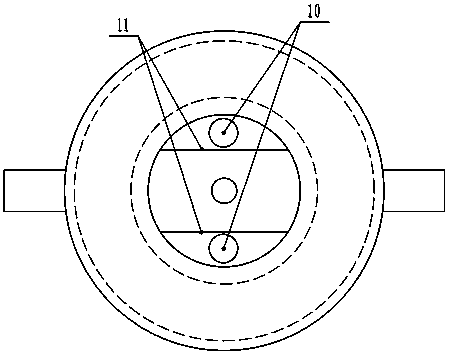

ActiveCN104568591ACompact structureWell formedMaterial strength using tensile/compressive forcesStress ratioEngineering

The invention discloses a biaxial extension test device. The biaxial extension test device comprises a horizontal rack which is an orthogonal cross, wherein a servo-cylinder is mounted at the end part of each of four arms of the horizontal rack and sequentially connected with a tension sensor and a combined fixture; a linear guide rail is arranged on the surface of each of the four arms of the horizontal rack; and the combined clamps are arranged on the linear guide rails, can move along the linear guide rails and are used for clamping test pieces. The invention also provides a method for the biaxial extension test device to perform biaxial extension test, and the method comprises a plurality of steps. The biaxial extension test device is compact in structure, concise in format, stable in operation and high in precision, has various test functions (unidirectional static extension, low-cycle reciprocating extension, bidirectional static tensile strength and optional biaxial stress ratio low-cycle reciprocating extension), and can be applied to uniaxial tensile test machines, biaxial tensile test machines and the like.

Owner:SHANGHAI JIAO TONG UNIV

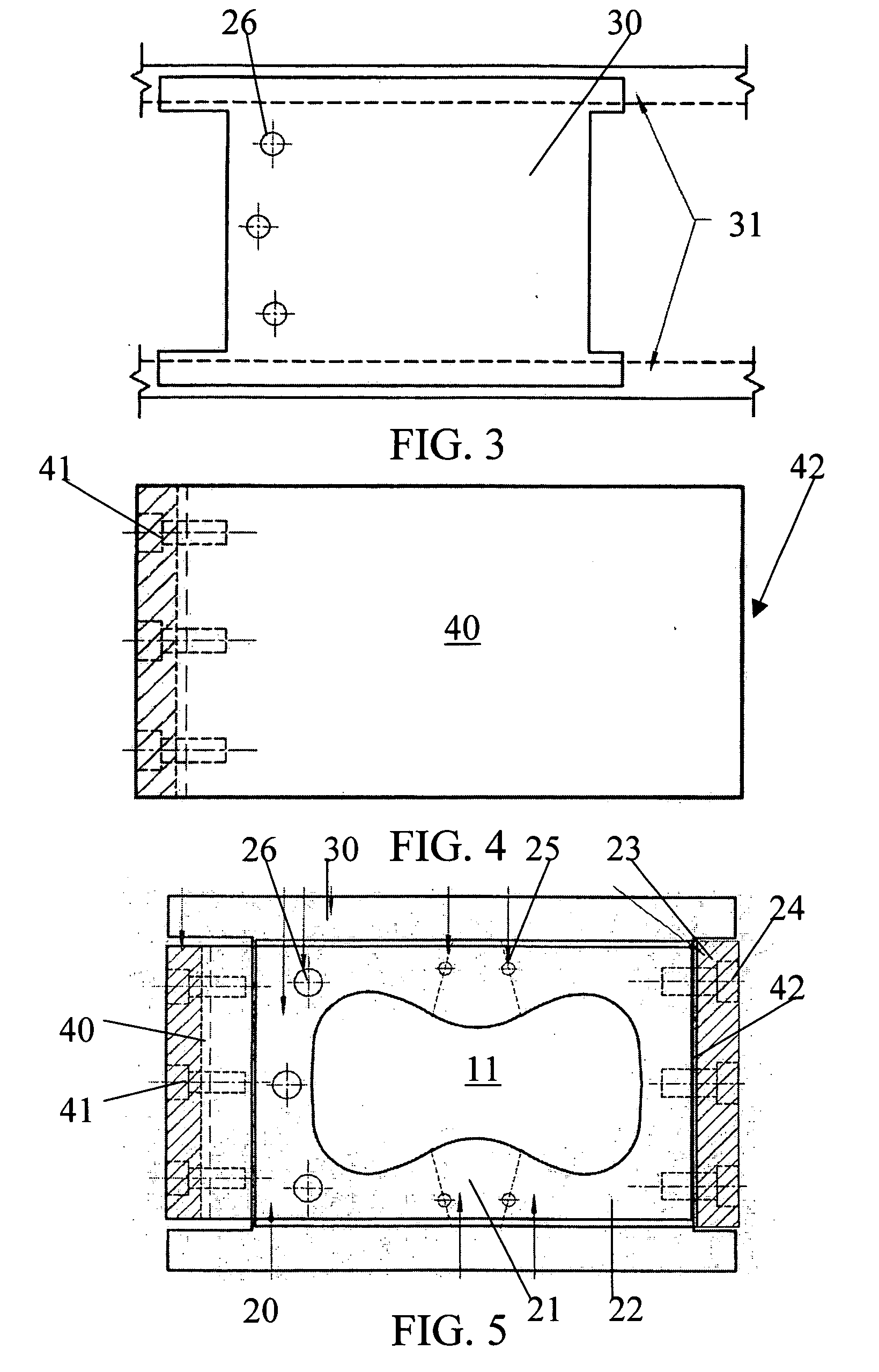

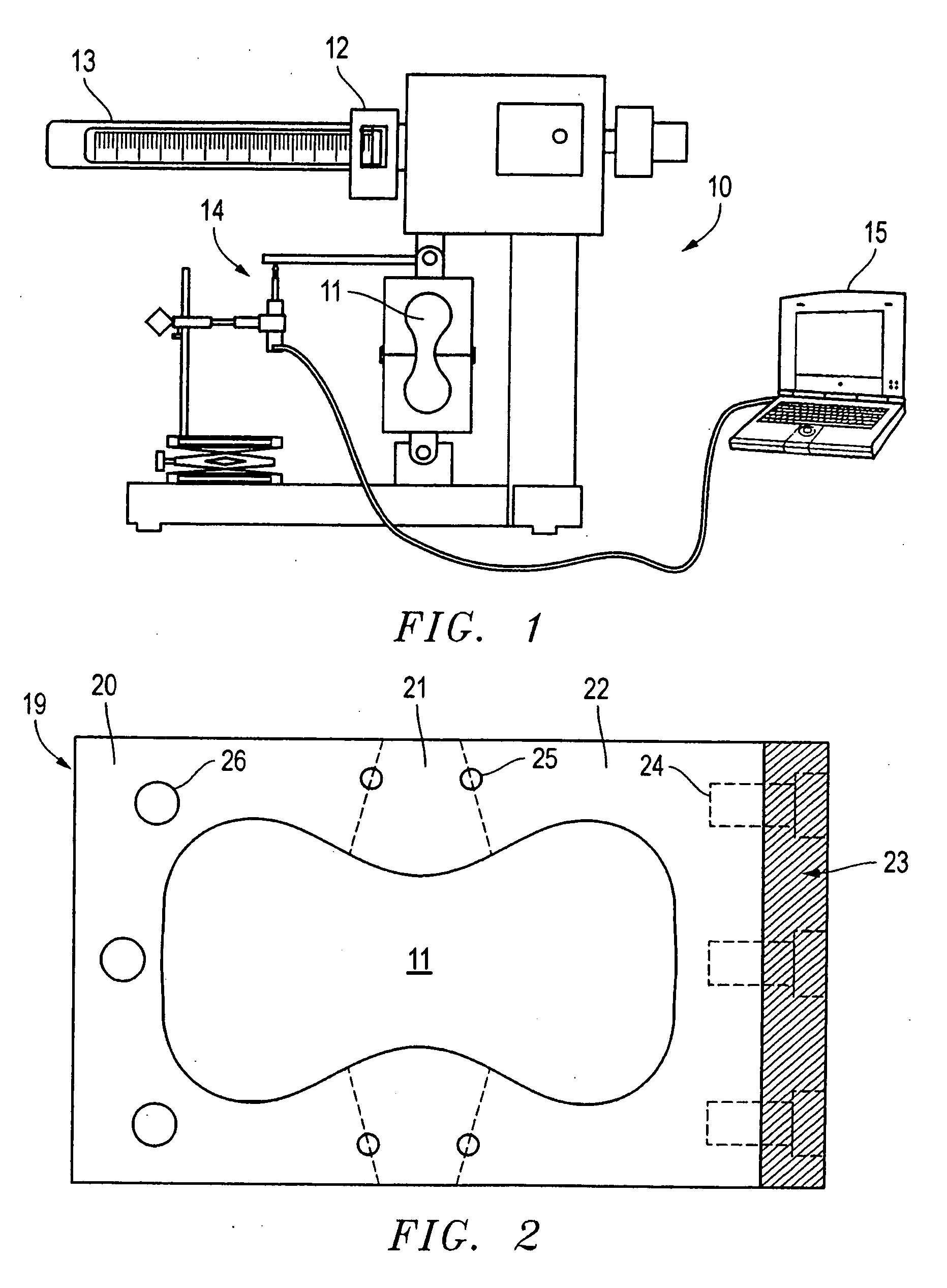

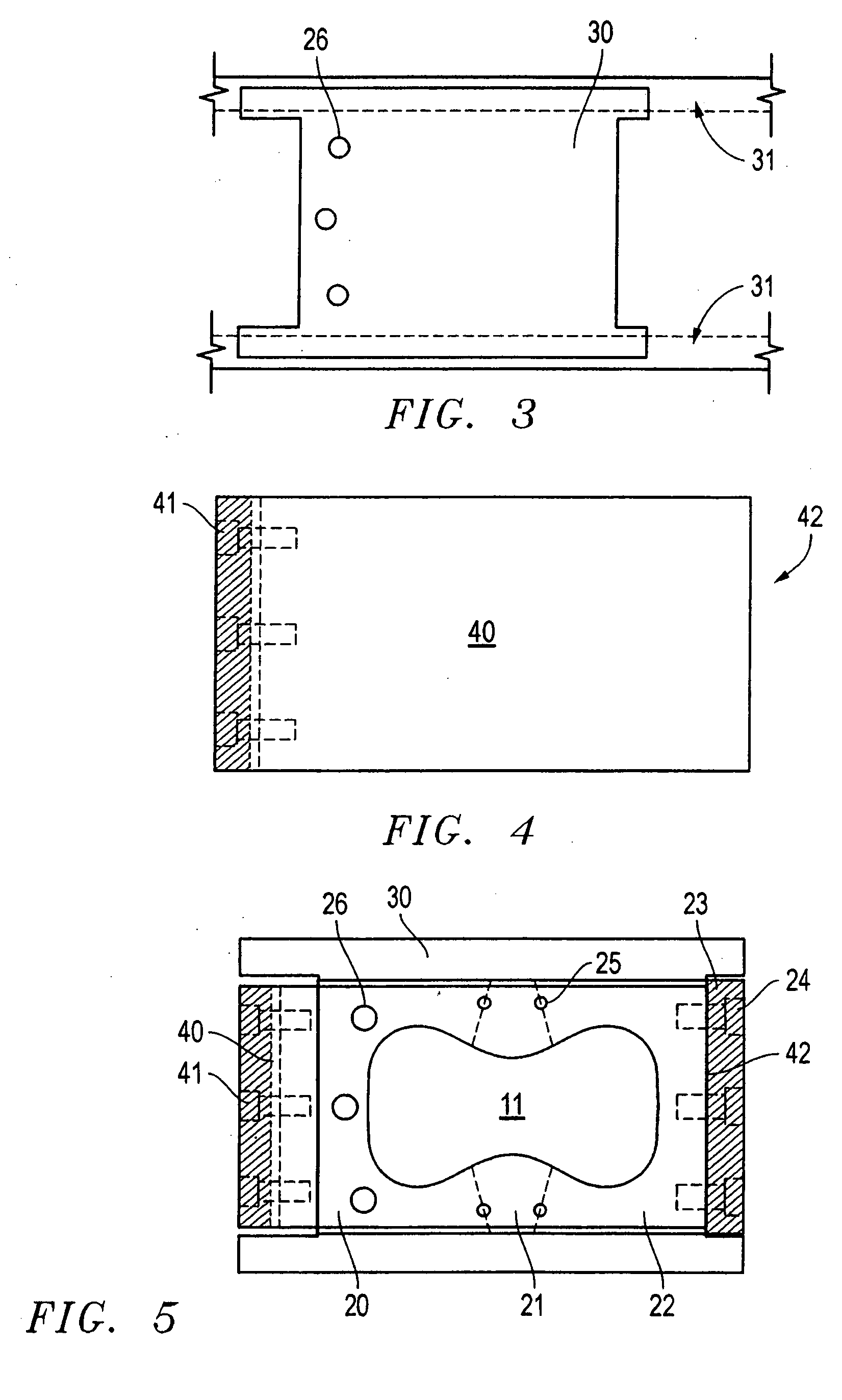

Testing apparatus and method of deriving Young's modulus from tensile stress/strain relationships

ActiveUS20050126300A1Better fit for purpose designsTest accurateMaterial strength using tensile/compressive forcesMaterial testing goodsYoung's modulusUltimate tensile strength

A method of testing and a tester apparatus to determine the axial stress and strain of cements under the temperature and pressures encountered by cement during use in wellbore environments. Using these stress and strain measurements, the Young's Modulus may be established for a material at the encountered temperature and pressure of the wellbore. By combining static tensile strength testing and elasticity measurements of cements, Young's Modulus values for different cement compositions under stresses that are similar to the conditions occurring in an actual wellbore are possible.

Owner:BAKER HUGHES INC

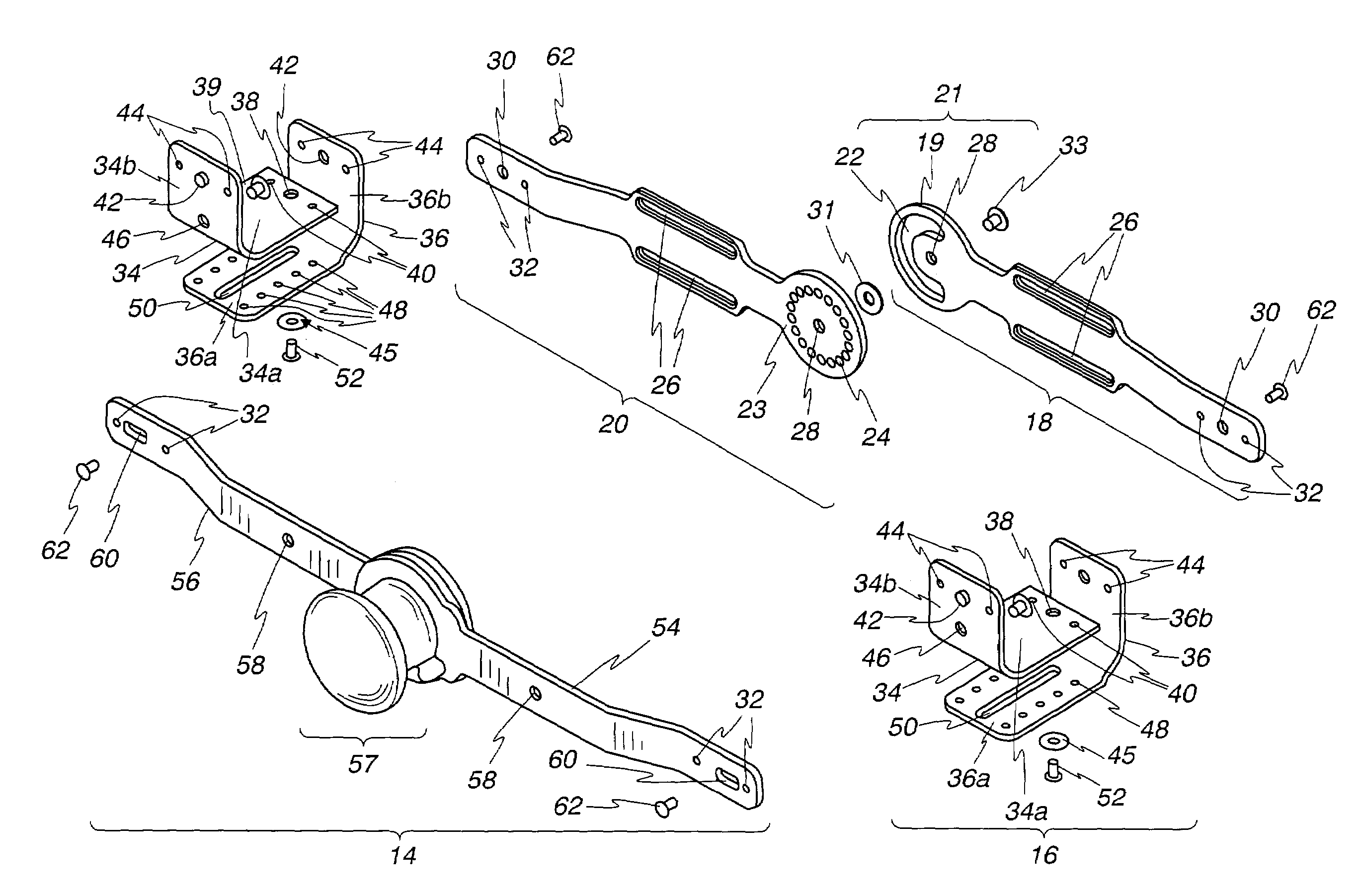

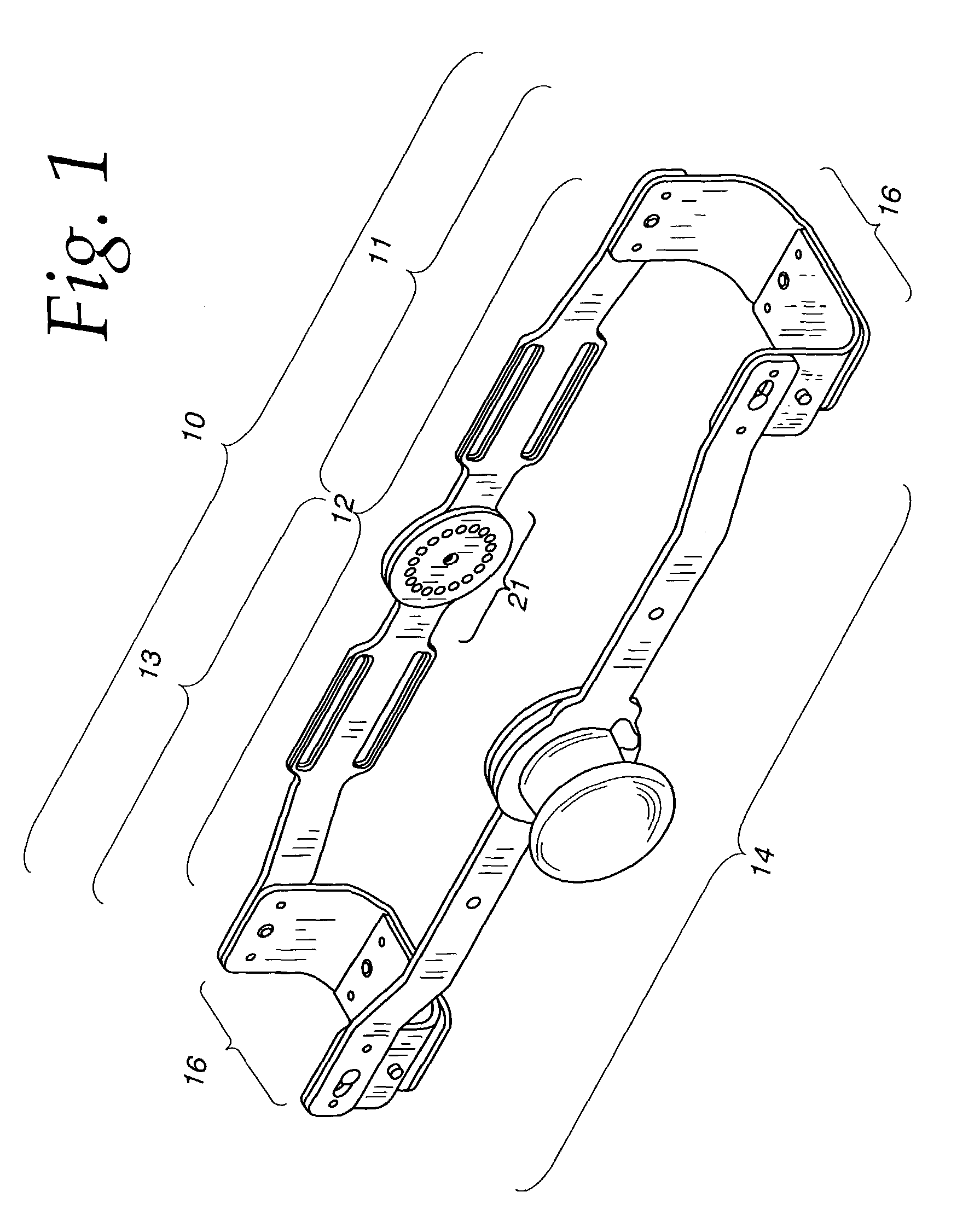

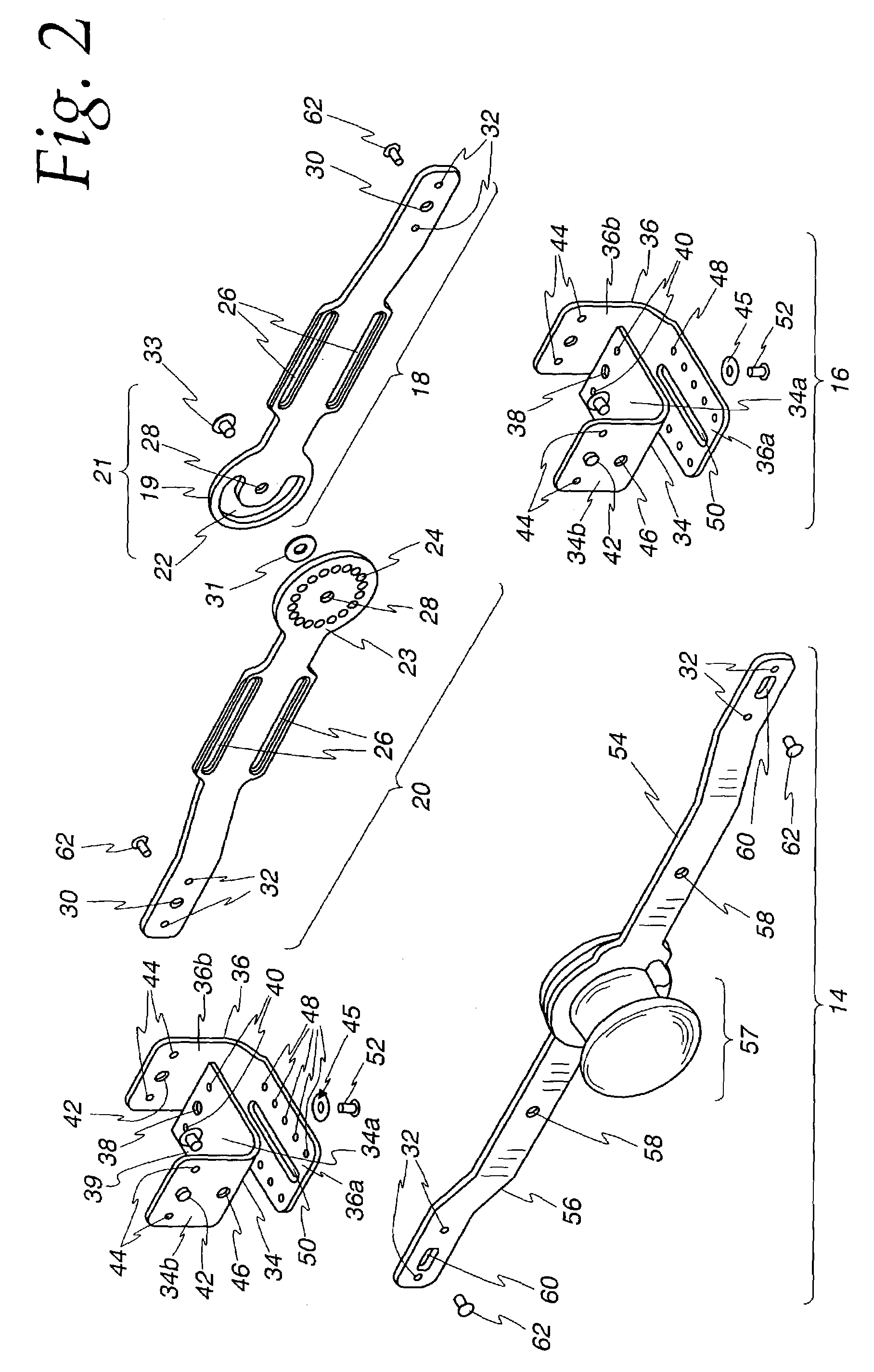

Multi-functional joint brace

InactiveUS7156818B2Provide stabilityAvoid injuryNon-surgical orthopedic devicesLocking mechanismRange of motion

A multi-functional brace for a joint includes a releasable locking mechanism that allows the brace to be set for static stretch of the joint in either flexion or extension, and a range of motion assembly that allows for free movement of the joint through its natural axis over a controlled range of motion when the locking mechanism is released.

Owner:DJO

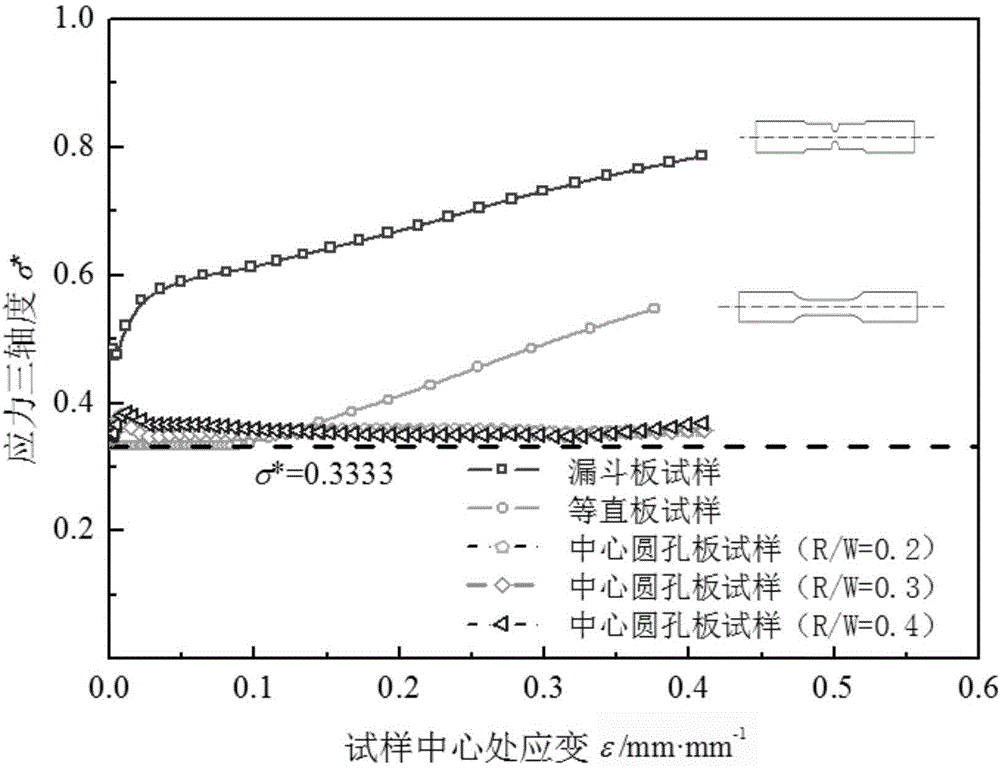

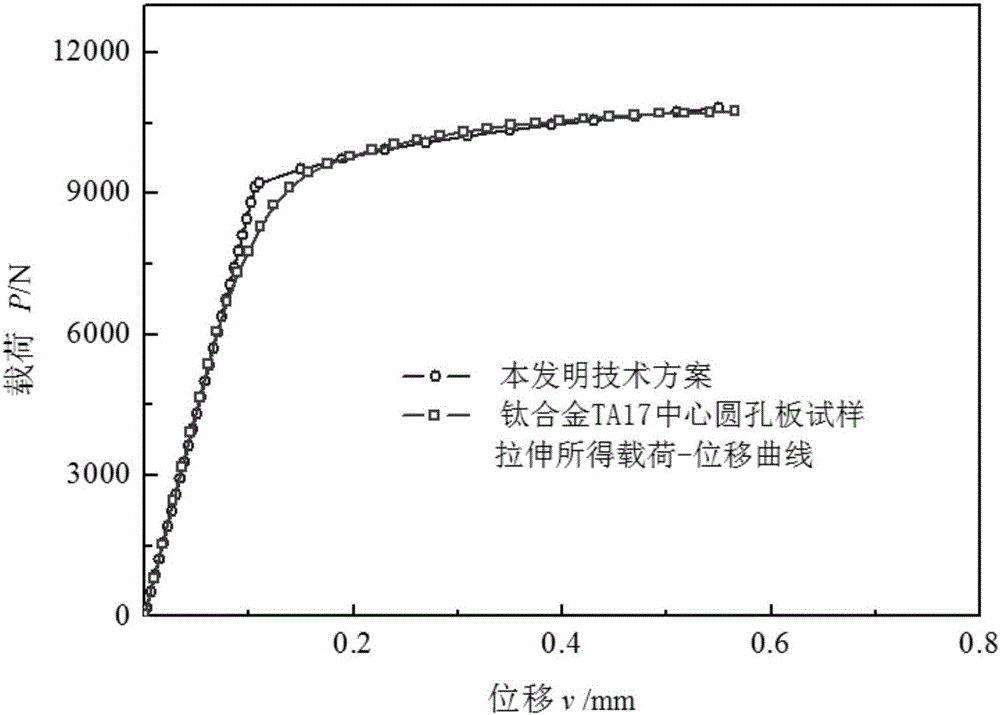

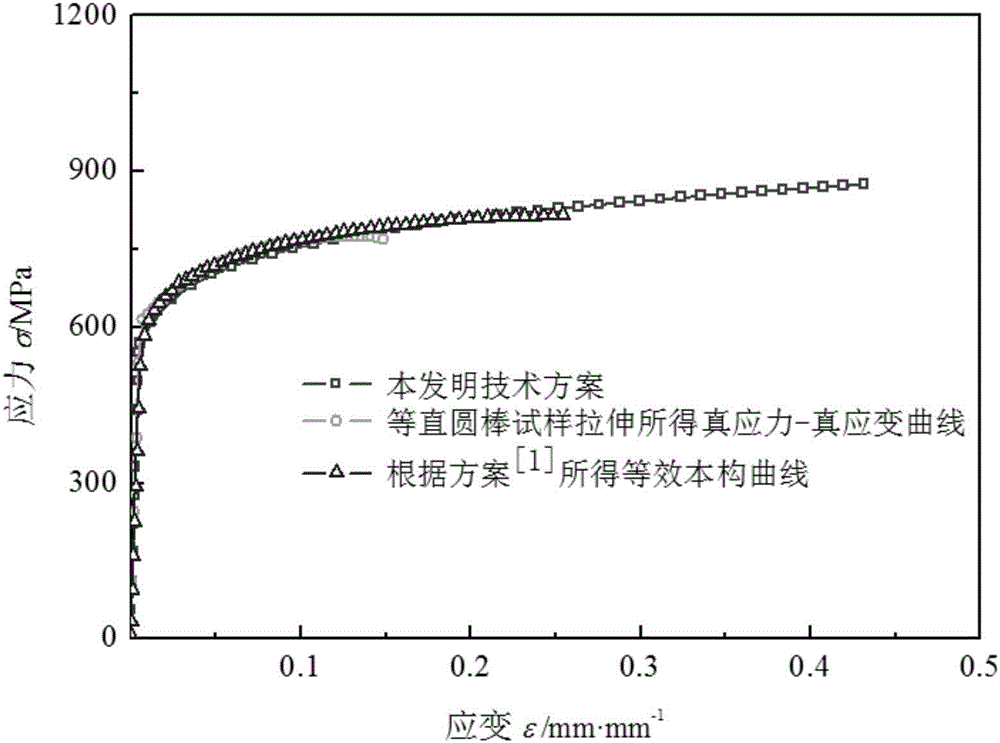

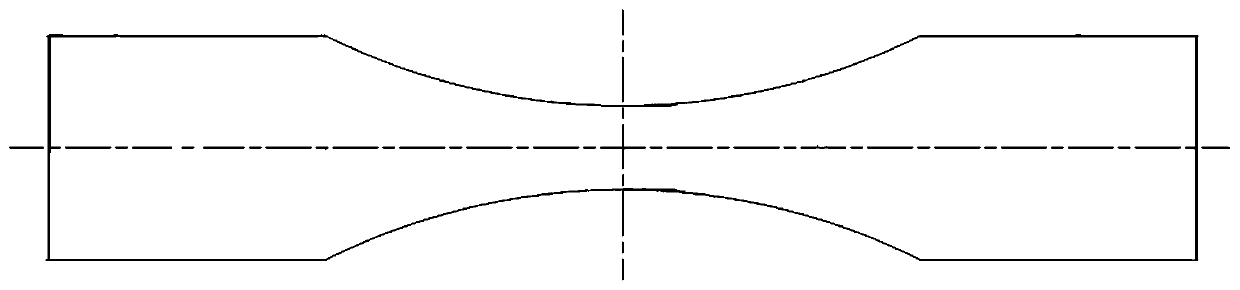

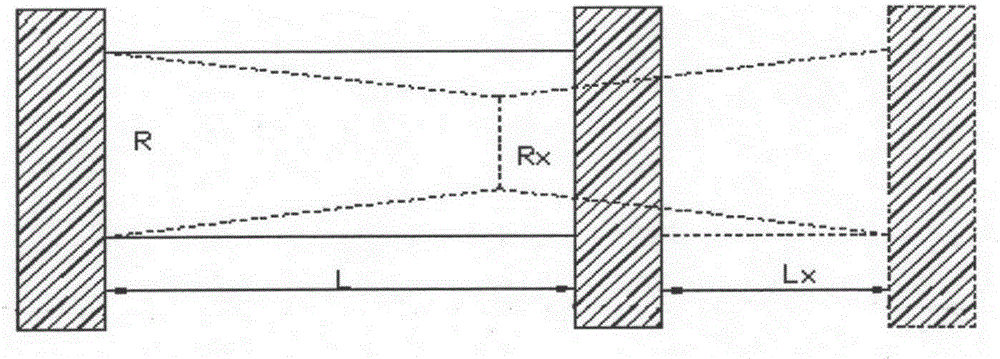

Test method for uniaxial constitutive relation of ductile material

ActiveCN106644711AThe method is simpleWide range of constitutive relationsMaterial strength using tensile/compressive forcesP v curveStressed state

The invention discloses a method for determining the large deformation uniaxial constitutive relation of a material based on the energy principle and a P-V curve obtained by stretching a central circular hole plate specimen. The method comprises the following steps: performing quasi-static tensile test on a central circular hole plate specimen to obtain a continuous P-V curve, and determining the elastic stiffness S, the feature load P* and the displacement index m by the curve so as to obtain the large deformation uniaxial constitutive relation of the material. The method disclosed by the invention is applicable to a ductile material with an isotropic strengthening and constitutive relation according with the power law, wherein the structure of the central circular hole plate specimen is special, namely during the tensile test, the circular hole edge center point material unit of the specimen is under uniaxial stress state before the occurrence of necking; compared with an equidistant specimen, the method disclosed by the invention is easier to implement, and the obtained uniaxial stress-strain relation is wider in range; the method has great significance on the engineering structure design and safety assessment work.

Owner:SOUTHWEST JIAOTONG UNIV

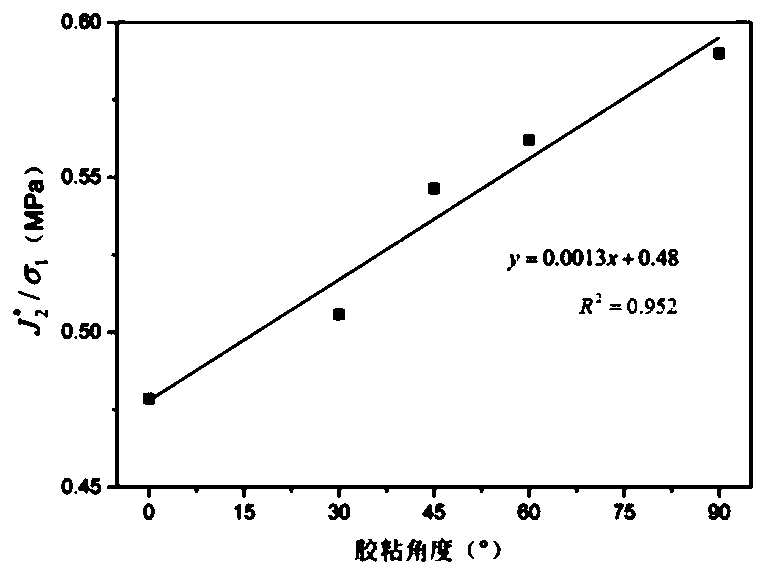

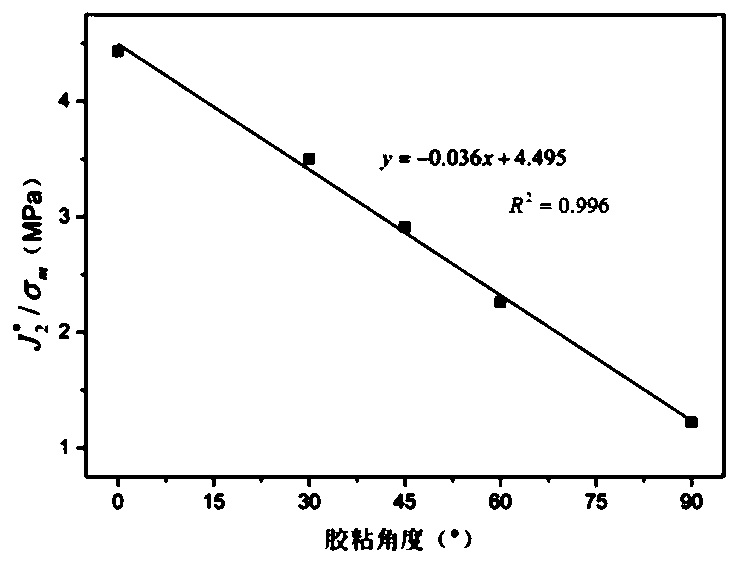

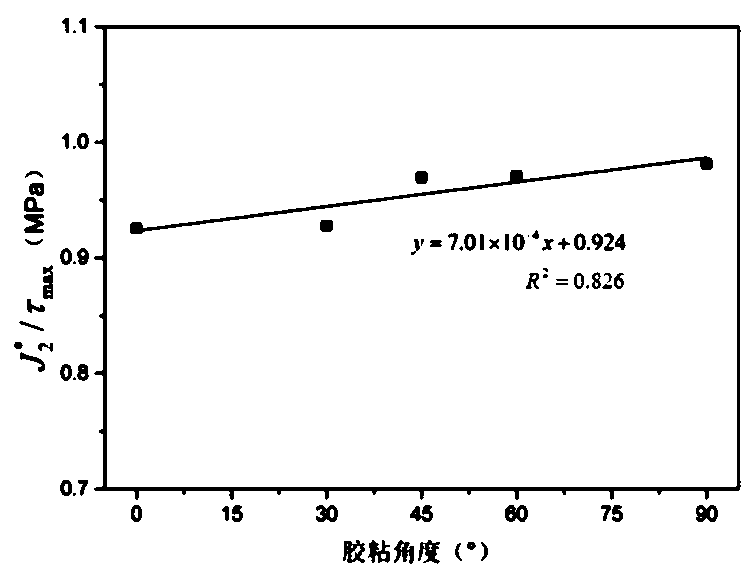

Uniform stress criterion-based bonding structure fracture failure analysis method

InactiveCN110175396AAchieving Strength PredictionSolve the problem that the real failure does not fit wellDesign optimisation/simulationSpecial data processing applicationsElement modelStressed state

The invention discloses a uniform stress criterion-based bonding structure fracture failure analysis method, which is characterized by comprising the following steps of 1, carrying out the quasi-static tensile tests on the bonding joints with different tension-shear ratios to obtain the initial failure loads and the initial failure areas of the bonding joints with different tension-shear ratios, 2, establishing a finite element model of a bonding joint with the same test size and different tension-shear ratios, and applying the initial failure load to a position, corresponding to the initial failure area, in the finite element model to obtain an initial failure point and initial failure stress, 3, obtaining the equivalent forces of the bonding joints with different tension-shear ratios ina complex stress state, and 4, establishing a finite element model of the bonding joint needing to be subjected to fracture failure analysis, applying the one-way stress, when the stress is greater than or equal to the maximum equivalent stress, starting to fail the glue layer of the bonding joint, determining a failure unit, deleting the failure unit, and recording the corresponding failure stress.

Owner:JILIN UNIV

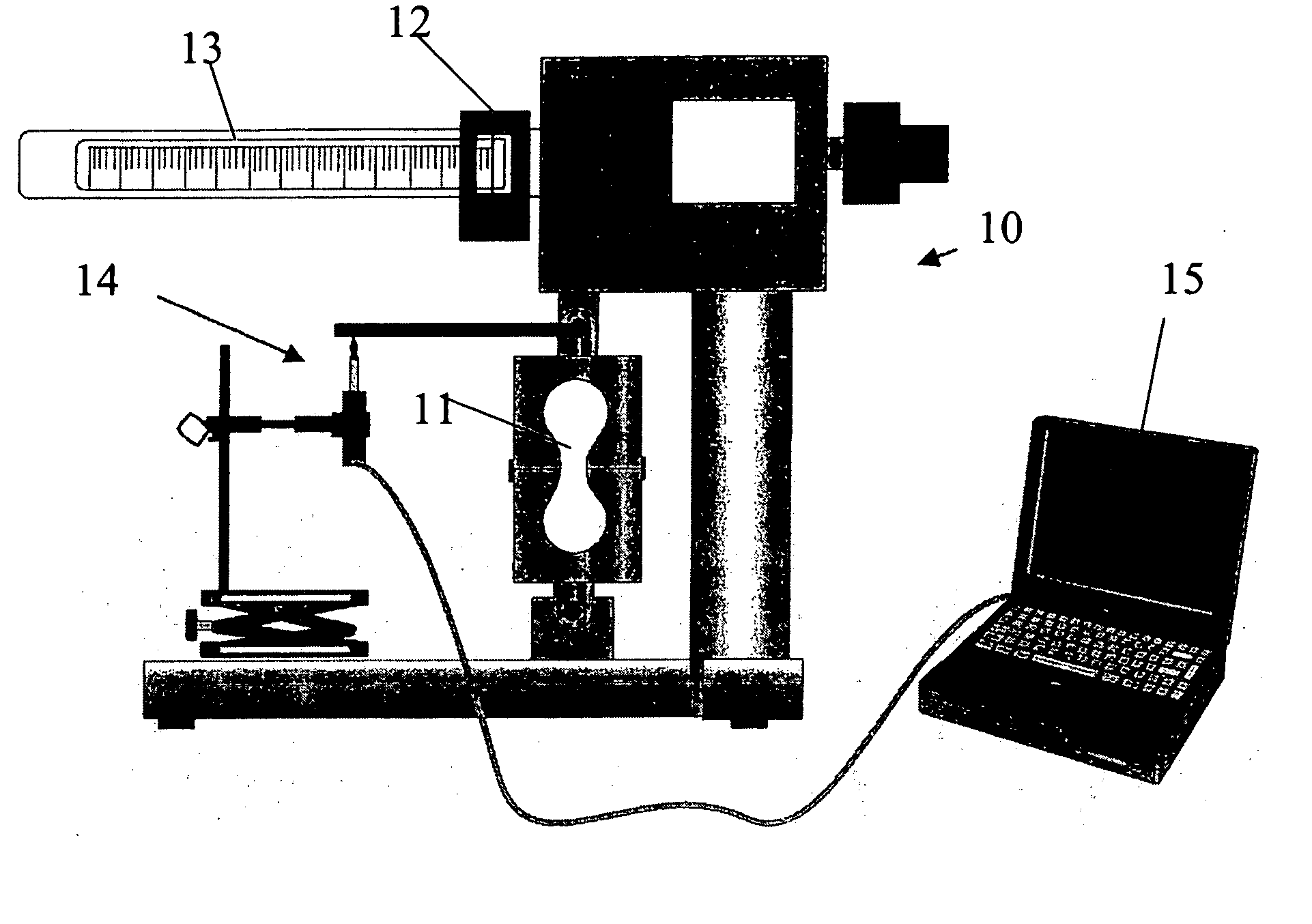

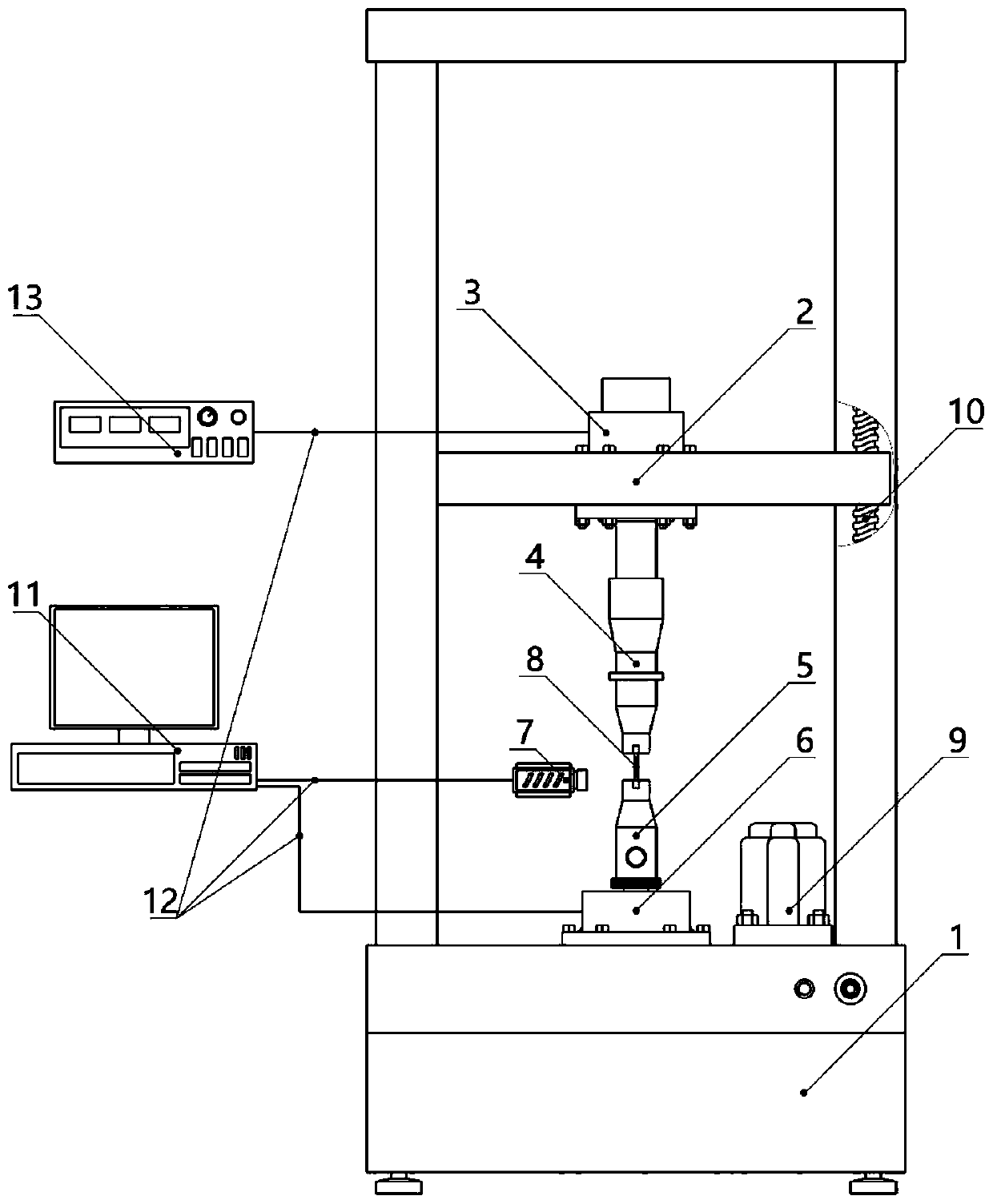

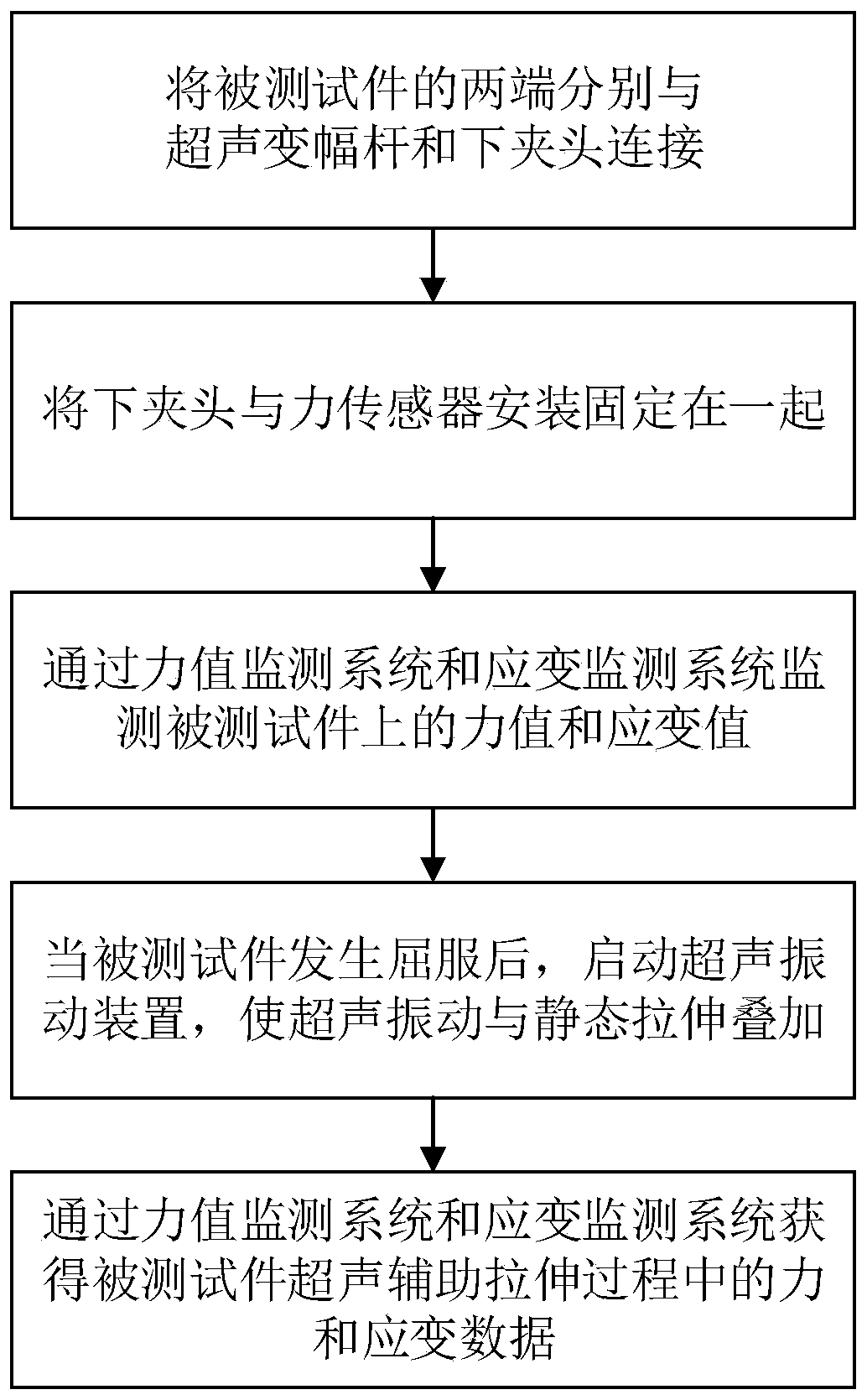

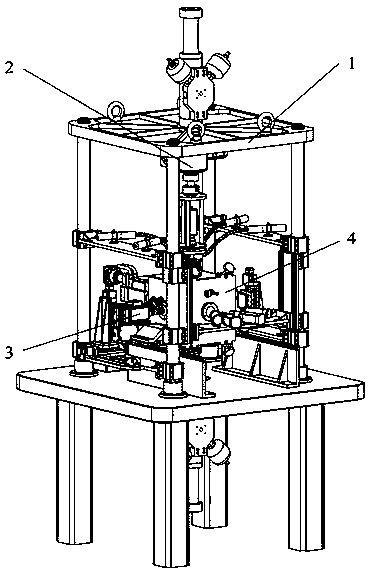

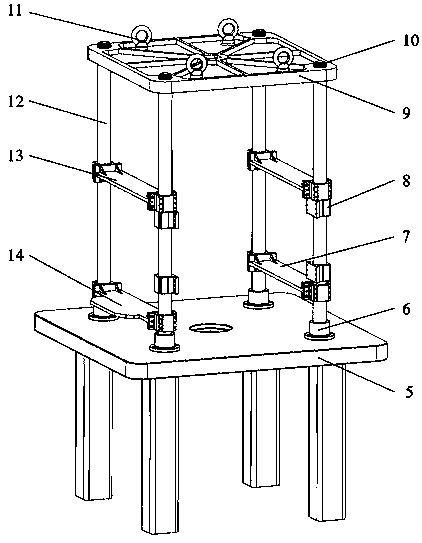

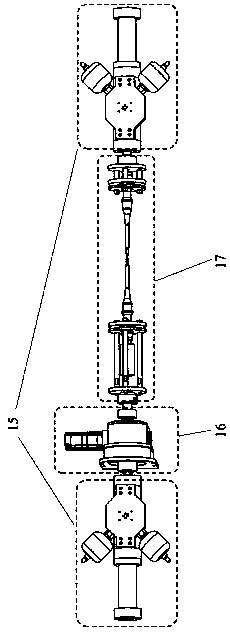

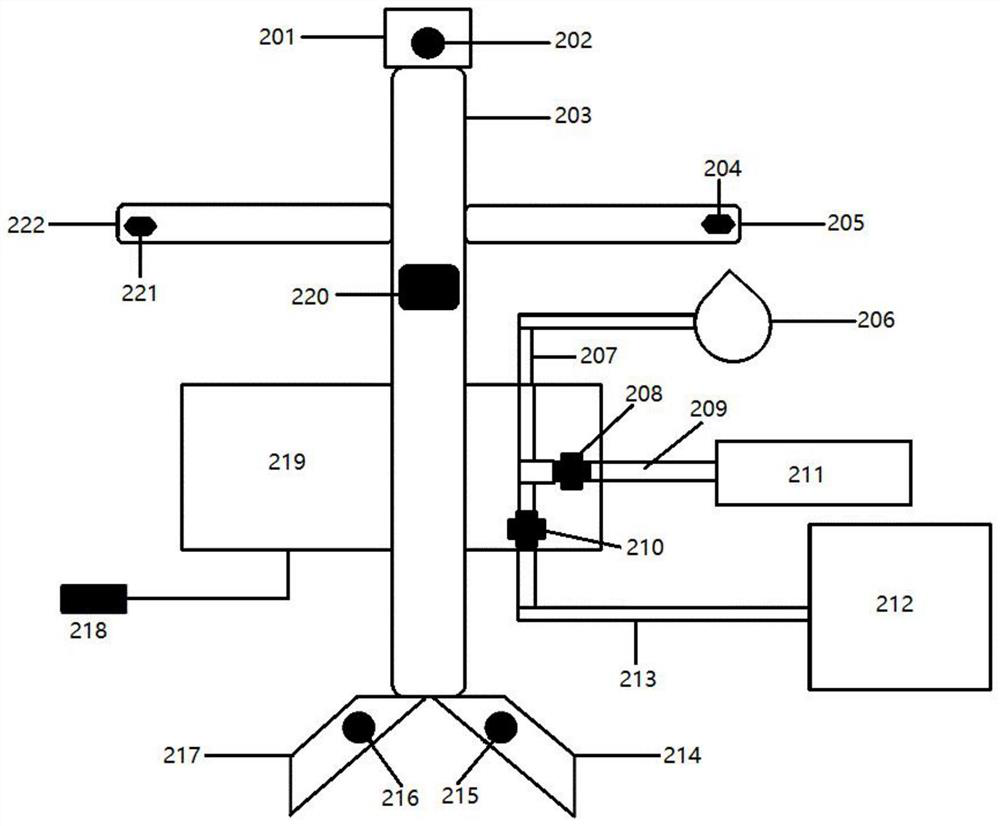

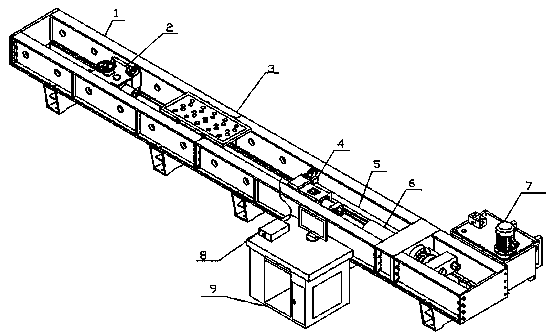

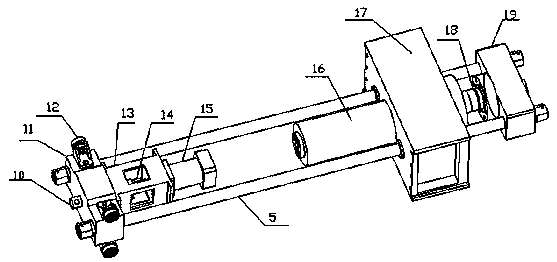

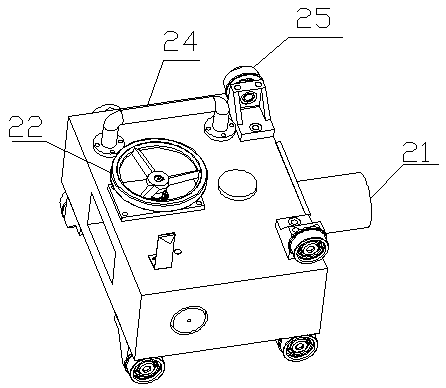

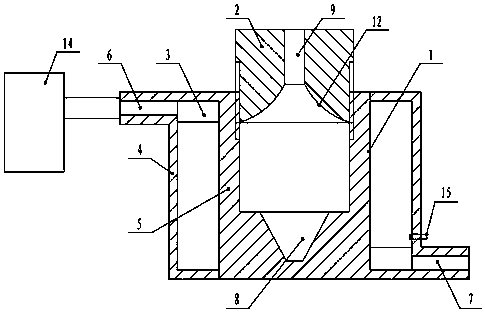

Ultrasound-assisted tensile test machine and test method

InactiveCN109738285AImprove test accuracySimple structureMaterial strength using tensile/compressive forcesEngineeringHandling system

The invention provides an ultrasound-assisted tensile test machine and a test method. The test machine comprises a base; a force value monitoring system with a force sensor; a lower clamp head fixed on the force sensor; a lifting device mounted on the base; an ultrasonic vibration system which comprises an ultrasonic controller and an ultrasonic vibration device, wherein the ultrasonic vibration device is mounted on the lifting device, the ultrasonic vibration device comprises an ultrasonic vibration generator and an ultrasonic horn, the ultrasonic horn is connected with the ultrasonic vibration generator, and a tested piece is connected and fixed between the ultrasonic horn and the lower clamp head; a strain monitoring system with an industrial camera; and a signal collection and processing system which is connected with the force value monitoring system, the lifting device, the ultrasonic vibration system and the strain monitoring system. According to the test machine and the test method, high frequency controllable vibration is provided through utilization of the ultrasonic vibration generator and a vibration direction is consistent with a static stretching direction of the tested piece, so an ultrasonic vibration load and static stretching load overlapped tensile test is realized.

Owner:SHANGHAI JIAO TONG UNIV

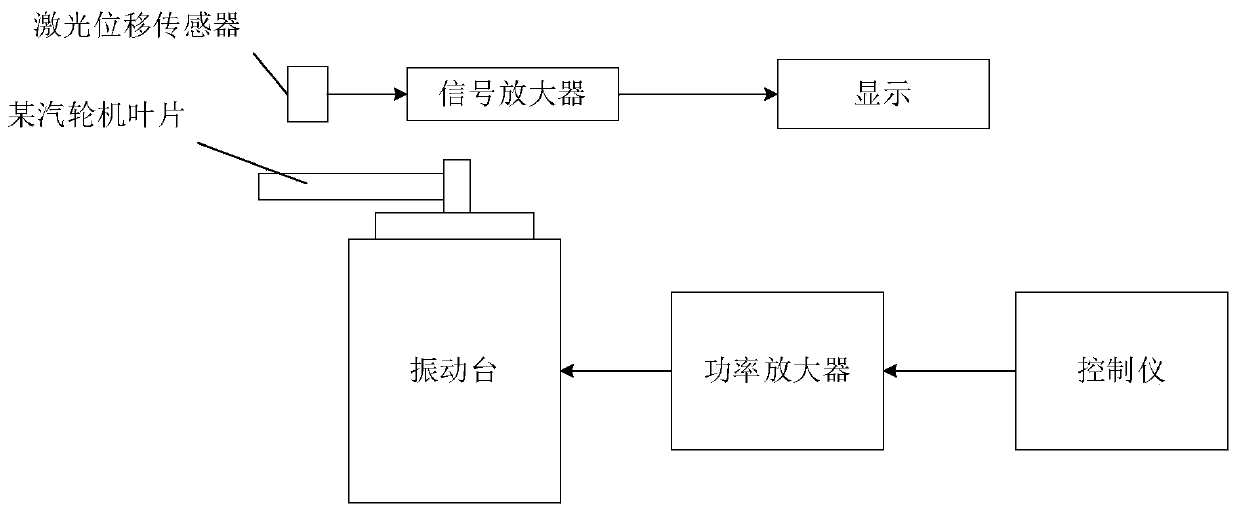

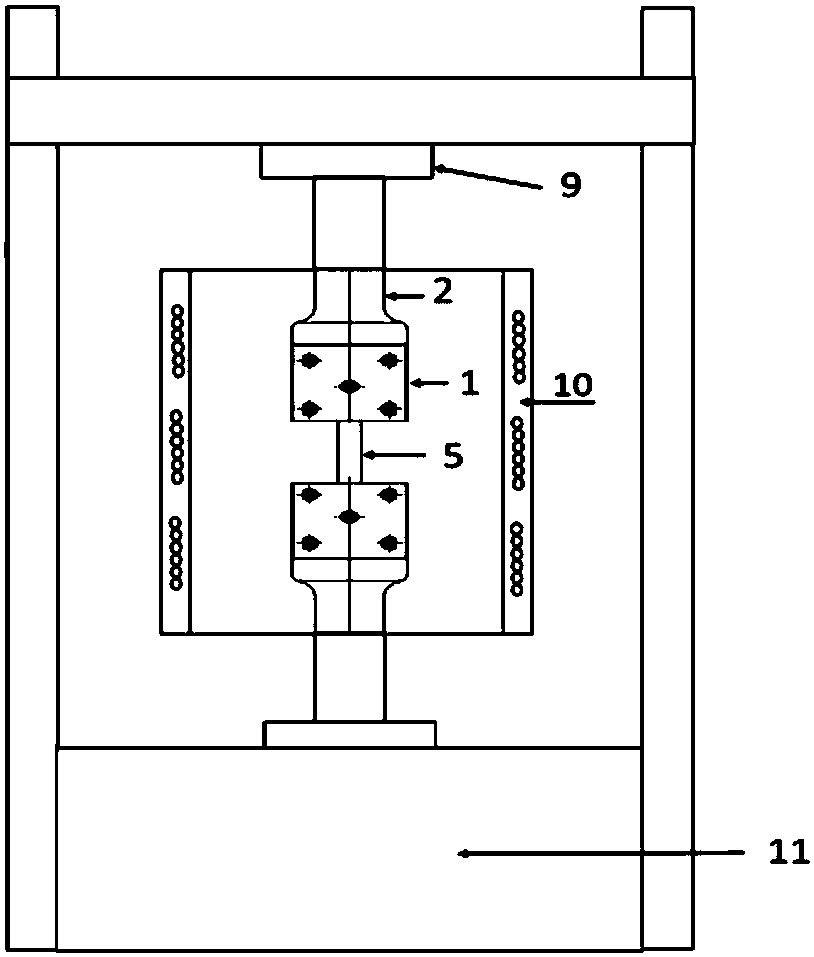

High-temperature ultrasonic fatigue in-situ test instrument and test method

ActiveCN110441163AEasy maintenancePrevent surface oxidationMaterial strength using tensile/compressive forcesScientific instrumentEngineering

The invention relates to a high-temperature ultrasonic fatigue in-situ test instrument and a test method, and belongs to the field of a precise scientific instrument. The instrument consists of an integrated frame module, a mechanical loading module, a high temperature loading module and an in-situ monitoring module, wherein the integrated frame module is used for accurately positioning each functional module and simultaneously providing stable support and effective vibration isolation; the mechanical loading module is used for synchronously exerting static stretching or compression load on two ends of a tested sample and exerting an ultrasonic fatigue load according to test needs and is capable of realizing axial precise positioning; the high temperature loading module is used for exerting a high temperature load on the tested sample; and the in-situ monitoring module is used for performing in-situ monitoring on the surface deformation damage and the internal damage defect of the tested sample. The synchronous representation and three-dimensional reconstruction for the defect information of the tested sample can be implemented from inside to outside and from the exterior to the interior. The high-temperature ultrasonic fatigue in-situ test instrument has the characteristics that the load environment is complex, the test precision is high and meanwhile the material mechanical behavior and deformation damage mechanism can be dynamically monitored.

Owner:JILIN UNIV

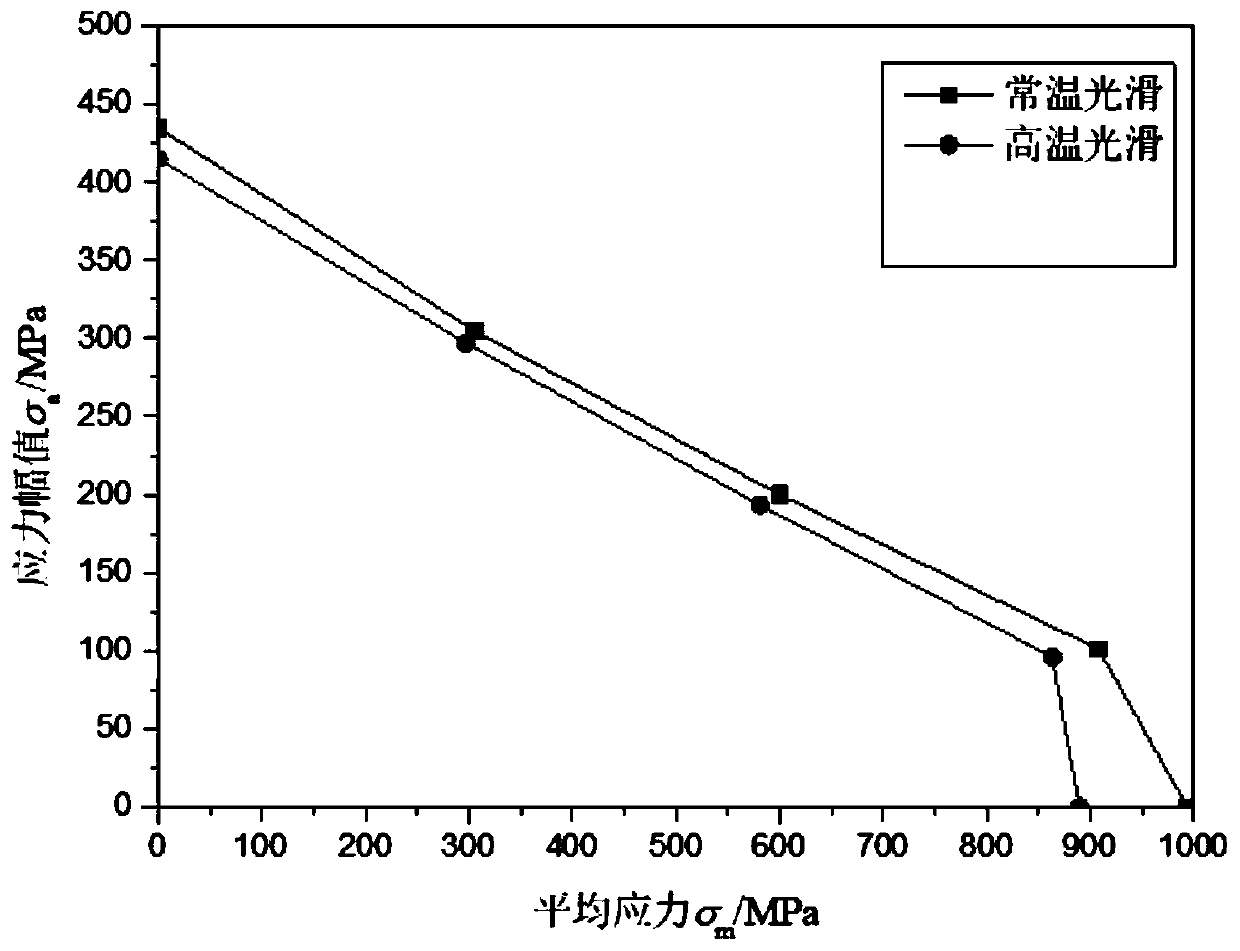

Method for determining allowable amplitude of turbine engine blade

ActiveCN110595709AIn line with the actual service situationEasy to understandMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringTurbine

The invention discloses a method for determining allowable amplitude of a turbine engine blade. The method comprises the following steps: correspondingly carrying out a normal-temperature quasi-statictensile test on a standard smooth test piece of the material for the blade and a high-temperature quasi-static tensile test on the standard smooth test piece of the material for the blade so as to obtain the attribute of the basic material of the material for the blade of the turbine engine; correspondingly carrying out a normal-temperature high-cycle fatigue test on a standard smooth test pieceof the material for the blade and a normal-temperature high-cycle fatigue test on the standard smooth test piece of the material for the blade to obtain an equal life curve of the material for the blade; carrying out an actual blade high cycle fatigue device to determine the blade fatigue limit at normal temperature; and introducing a relation between the fatigue life reserve coefficient and the amplitude of the monitoring point, and determining the allowable amplitude of the actual blade. The method is simple in design experiment and low in cost; the determined allowable amplitude result is more accurate, and the accuracy of the result is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

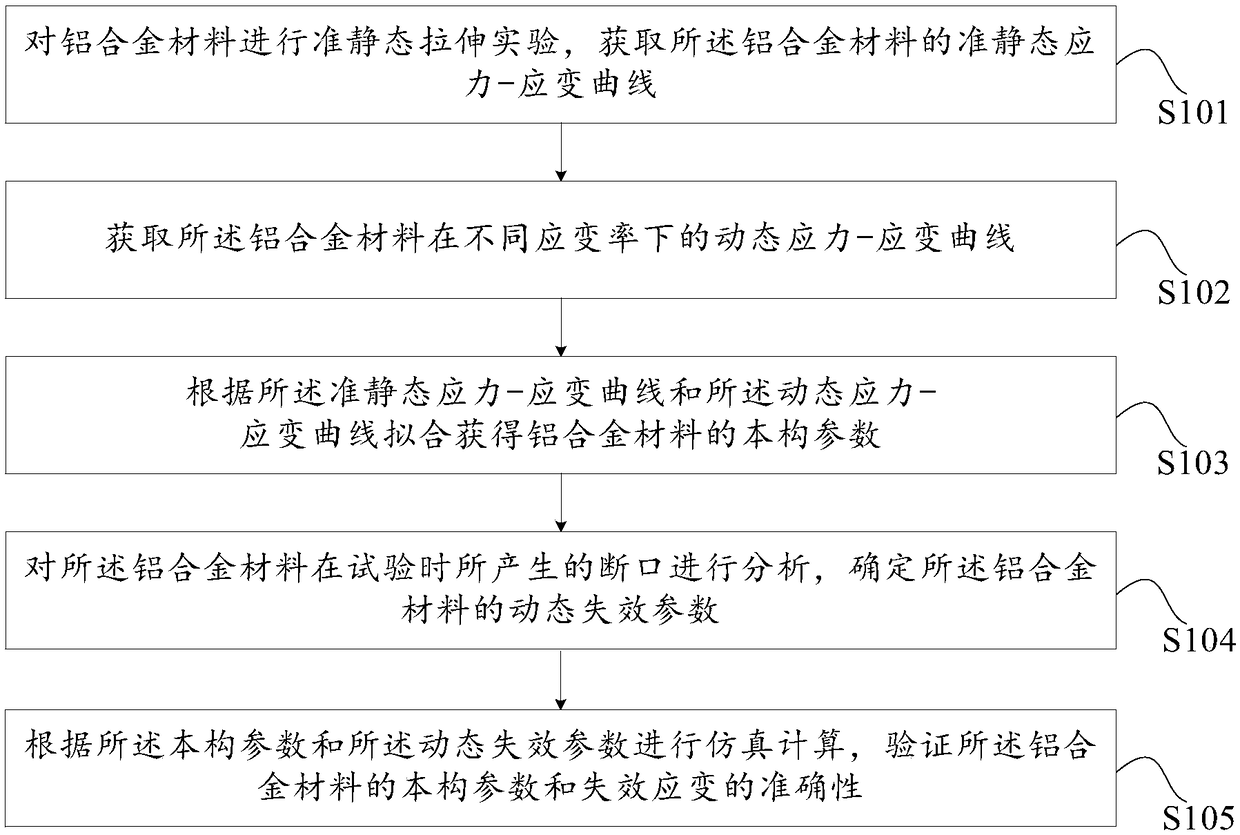

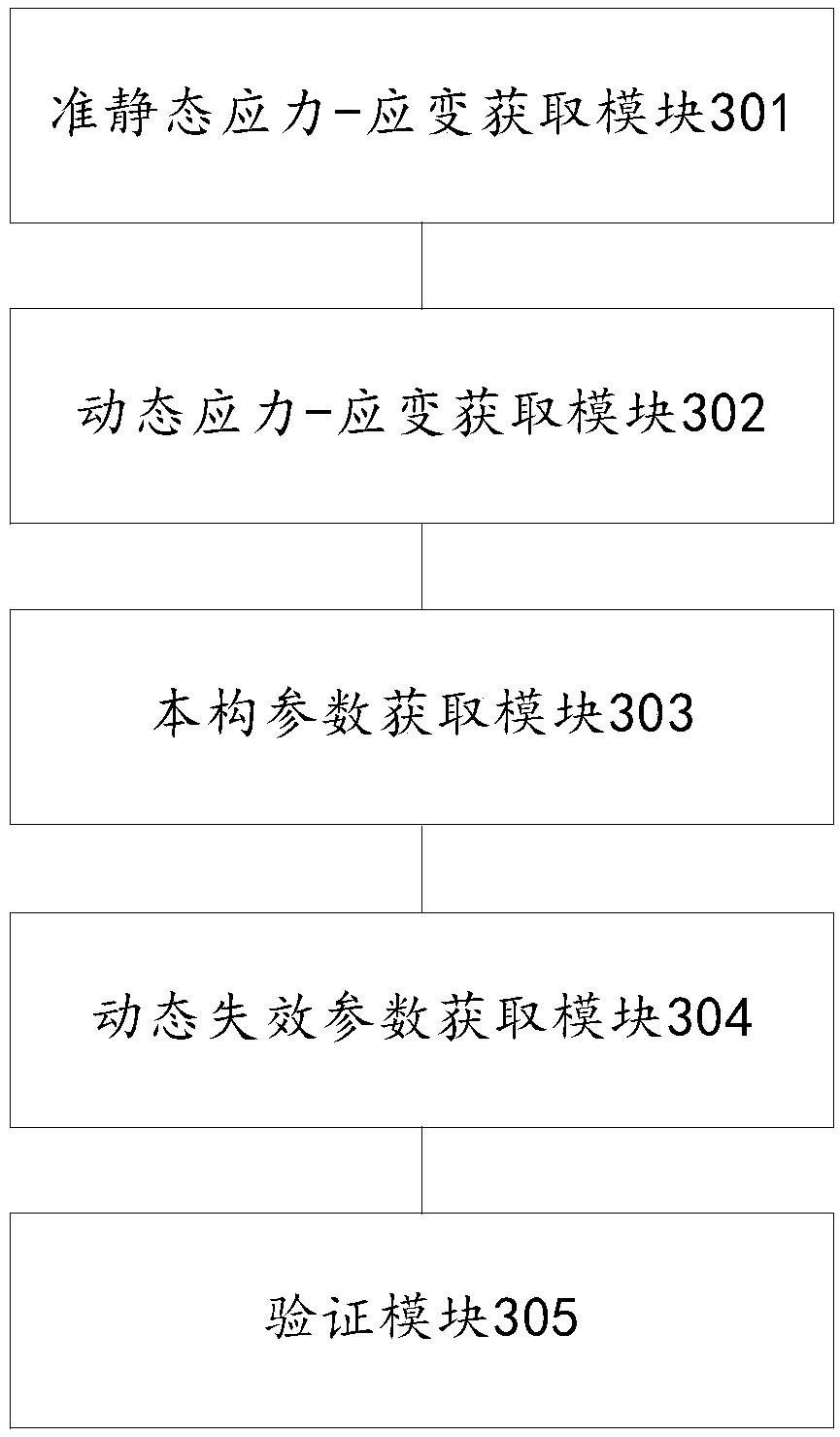

Method and device for obtaining and verifying constitutive parameters and dynamic failure parameters

InactiveCN109238855AVerify accuracyMaterial strength using tensile/compressive forcesMetallurgyFailure strain

The embodiment of the invention relates to a method and device for obtaining and verifying constitutive parameters and dynamic failure parameters. The method comprises the steps of: performing a quasi-static tensile experiment of an aluminium alloy material, and obtaining the quasi-static stress-strain curve of the aluminium alloy material; obtaining the dynamic stress-strain curve of the aluminium alloy material in different strain rates; obtaining the constitutive parameters of the aluminium alloy material by fitting according to the quasi-static stress-strain curve and the dynamic stress-strain curve; analyzing the fracture generated when the aluminium alloy material is tested, and determining the dynamic failure parameters of the aluminium alloy material; and, performing simulation calculation according to the constitutive parameters and the dynamic failure parameters, verifying the accuracy of the constitutive parameters and failure strain of the aluminium alloy material, simulating quasi-static stress-strain and dynamic stress-strain of the aluminium alloy material, then, obtaining the constitutive parameters and the dynamic failure parameters of the aluminium alloy material,and finally, verifying the constitutive parameters and the dynamic failure parameters.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI +1

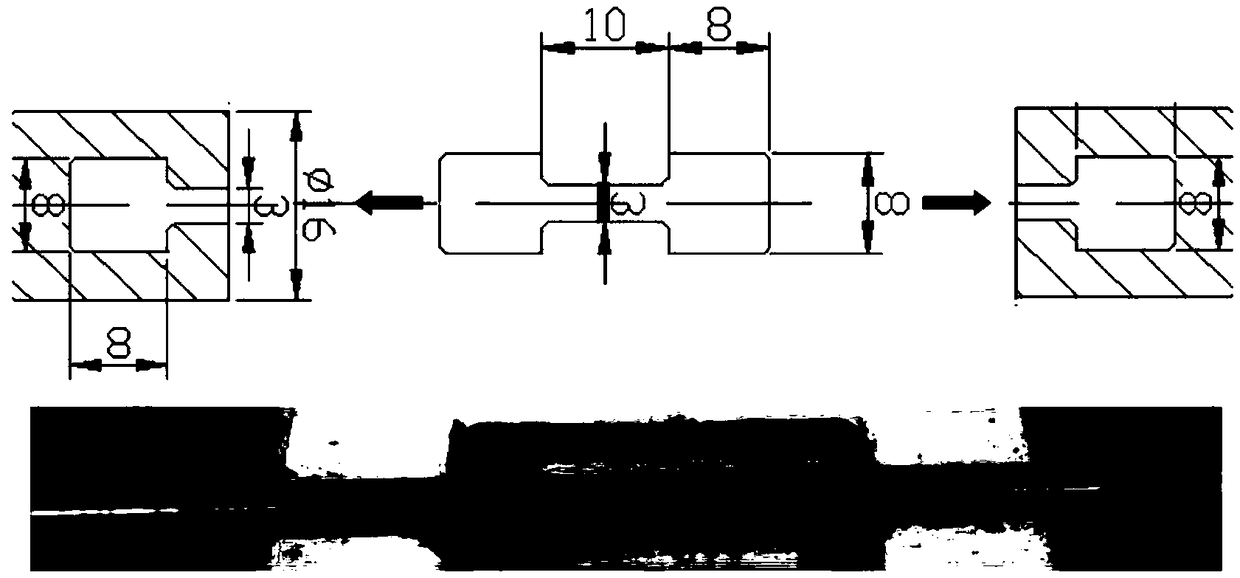

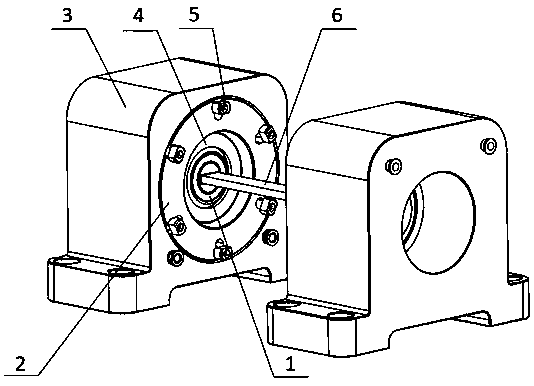

High-speed tensile test steel plate sample piece clamp

InactiveCN103674697AIncrease clamping strengthRealize flexible connectionStrength propertiesForcepsEngineering

The invention provides a high-speed tensile test steel plate sample piece clamp. The high-speed tensile test steel plate sample piece clamp comprises an upper holding forcep, a lower holding forcep and a locking device, wherein a clamp forceps shape is formed by the upper holding forcep and the lower holding forcep which are symmetrical up and down; the rear ends of the upper holding forcep and the lower holding forcep are mounted in the locking device. Each of the upper holding forcep and the lower holding forcep is provided with a corresponding bolt hole and a locking bolt which penetrates through the two bolt holes is arranged to lock the upper holding forcep and the lower holding forcep; the rear end of the locking device is mounted on a base; an elastic device is arranged on the base and the base is provided with two seat plates which are arranged in parallel; a buffering spring is connected between the two seat plates. According to the clamp, on the basis of keeping the structure of a previous static stretching test clamp, the locking bolt structure is additionally arranged on the upper holding forcep and the lower holding forcep so that the clamping force on a steel plate sample piece is improved; the elastic connection device is arranged so as to realize the flexible connection of the clamp and stretching test equipment and the influences on testing data by stretching impacts are reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Simulation method for three-dimensional network silicon carbide based ceramic

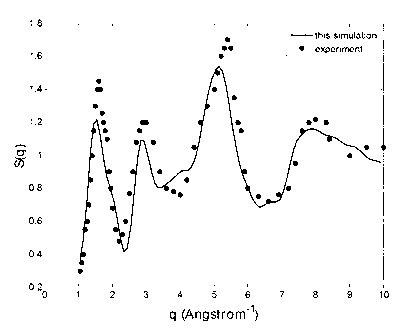

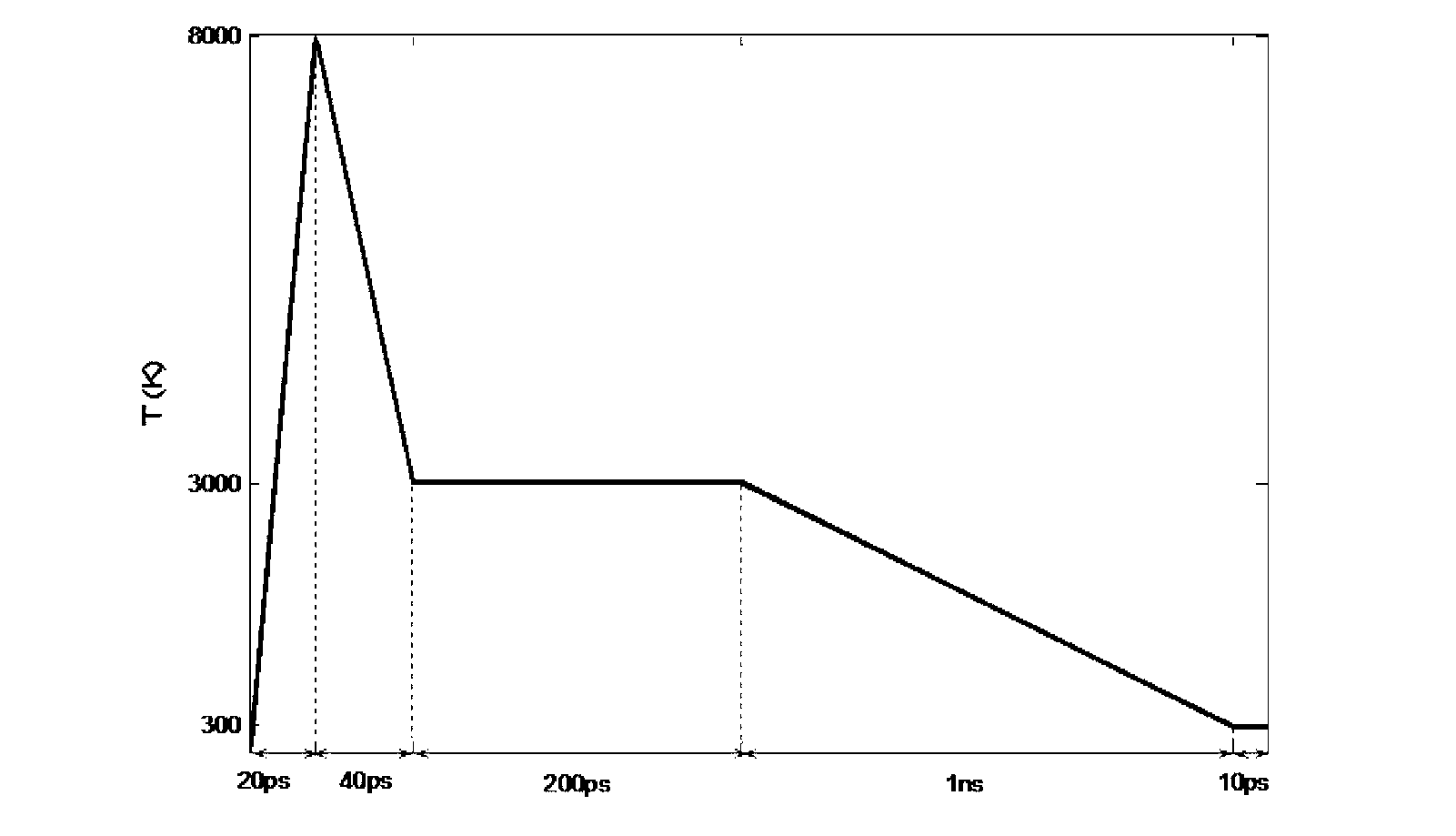

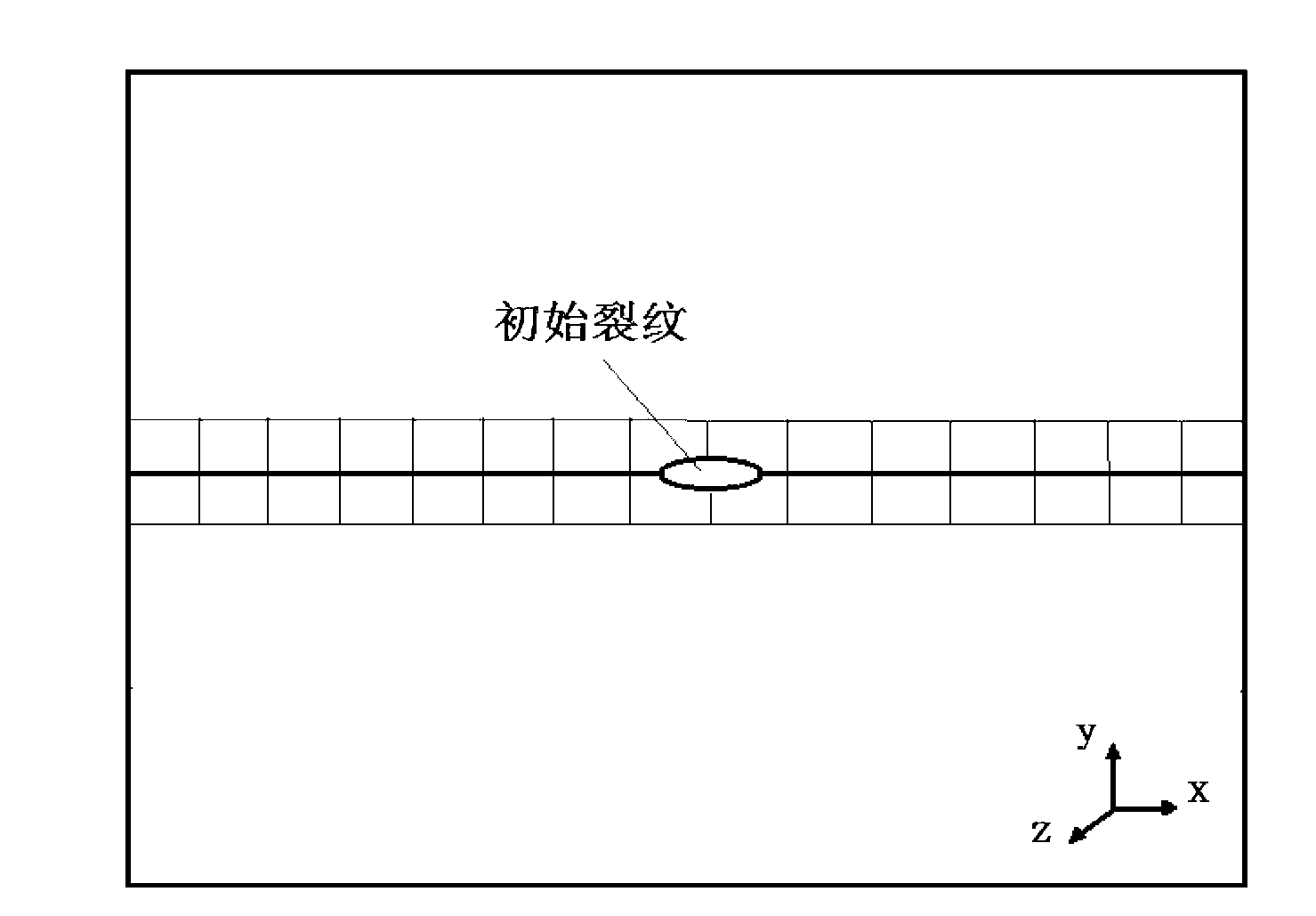

InactiveCN103235840AAccurate Mechanical PropertiesEfficient analysisSpecial data processing applicationsMaterial DesignStrength of materials

The invention discloses a simulation method for a three-dimensional network silicon carbide based ceramic, which comprises the following steps: step 1, establishing an initial model of the three-dimensional network silicon carbide based ceramic; step 2, determining a potential energy function and parameters; step 3, using a melt-quench method to generate a structure model of the three-dimensional network silicon carbide based ceramic; and step 4, adopting a quasi-static stretching method to determine mechanical characteristics of the three-dimensional network silicon carbide based ceramic. According to the method, a three-dimensional model meeting an experiment result can be generated by a completely random initial structure, and accurate material mechanical characteristics can be obtained through analysis, so that various characteristics of the material can be demonstrated truly. The method can be used for effectively analyzing and designing materials, improve the material design efficiency and reduce the design cost greatly.

Owner:WENZHOU UNIVERSITY

Testing apparatus and method of deriving young's modulus from tensile stress/strain relationships

InactiveUS20060278024A1Better fit for purpose designsTest accurateMaterial strength using tensile/compressive forcesMaterial testing goodsYoung's modulusUltimate tensile strength

A method of testing and a tester apparatus to determine the axial stress and strain of cements under the temperature and pressures encountered by cement during use in wellbore environments. Using these stress and strain measurements, the Young's Modulus may be established for a material at the encountered temperature and pressure of the wellbore. By combining static tensile strength testing and elasticity measurements of cements, Young's Modulus values for different cement compositions under stresses that are similar to the conditions occurring in an actual wellbore are possible.

Owner:BJ SERVICES CO

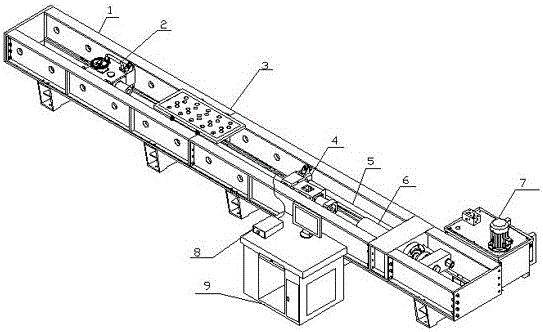

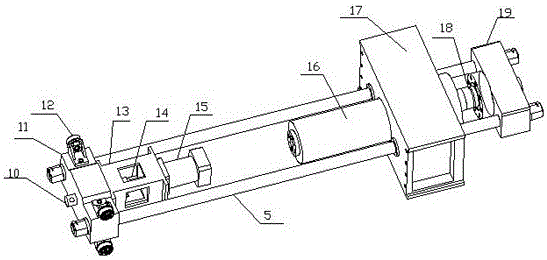

System and method for detecting crimping quality of end fitting of composite insulator

ActiveCN106018099ATensile load adjustableSensitive deformation damage detectionMaterial strength using tensile/compressive forcesComposite insulatorsEngineering

The invention provides a system and a method for detecting the crimping quality of an end fitting of a composite insulator. The system comprises a horizontal lathe and a pull rod arranged in the horizontal lathe, wherein a tensile load device used for providing pull force for a to-be-detected composite insulator and a torsion load device for providing torsional force for the to-be-detected composite insulator are sequentially arranged on the pull rod in a sleeving manner; a sample end of the torsion load device is connected with one end of the to-be-detected composite insulator, and the other end of the to-be-detected composite insulator is connected with a mobile locking device; a testing device used for acquiring the deformation condition generated when a material of the to-be-detected composite insulator is damaged is further arranged at the sample end of the torsion load device; the output end of the testing device is connected with a computer. The system and the method are used for analyzing the crimping condition of the end fitting of the composite insulator by simulating the static tensile load and the dynamic torsional load borne by the composite insulator in the actual on-line operation process and by comprehensively utilizing the detecting device.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +4

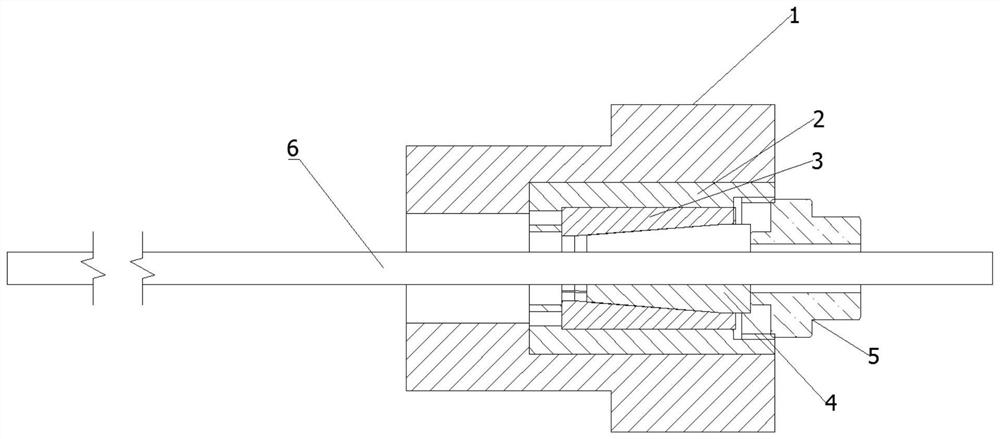

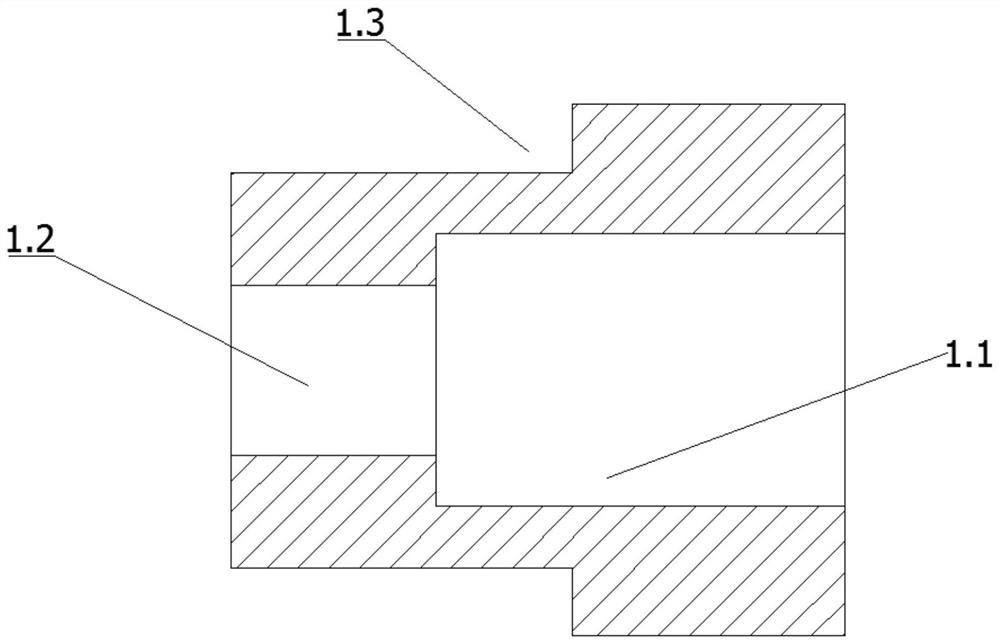

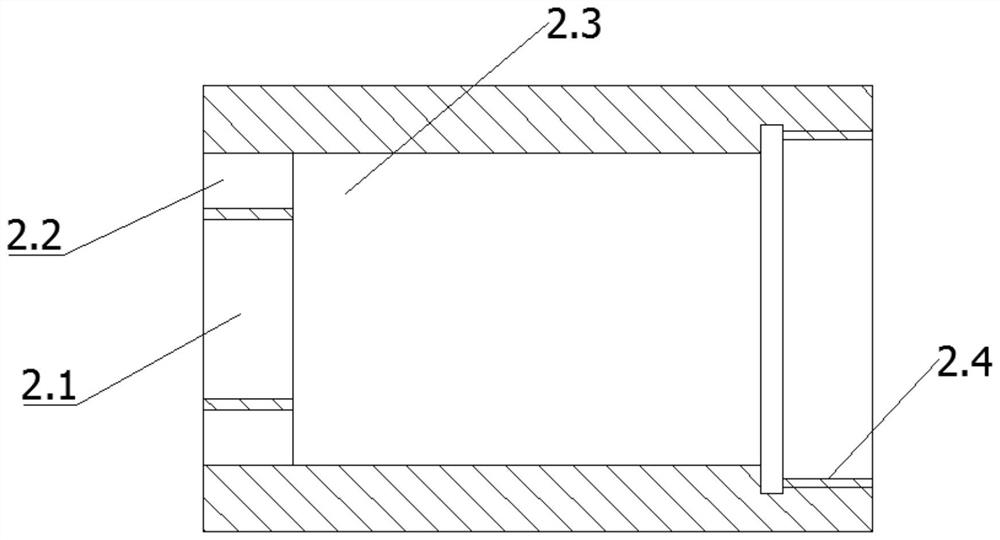

Clamping piece type small-diameter steel bar stretching clamp and clamping structure

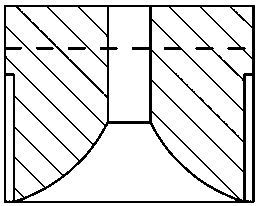

PendingCN112255089AIncrease squeezeEasy to slipMaterial strength using tensile/compressive forcesMetallic materialsEngineering

The invention provides a clamping piece type small-diameter steel bar stretching clamp and the clamping structure; after an existing stretching experiment is studied, the stretching clamp is improved,a clamp capable of meeting the requirement of a large stretching testing machine for conducting a small-diameter rod body metal material static stretching test is developed, multiple clamping piecesare arranged to clamp a to-be-tested rod body; when an adjusting nut rotates to extrude the clamping piece, the conical surface of the outer wall of the clamping piece and the conical surface of the inner wall of the outer clamping sleeve interact with each other to extrude the to-be-tested rod body in the radial direction in the process that the clamping piece extrudes towards the outer clampingsleeve along with the adjusting nut, and the to-be-tested rod body is pressed tightly along with screwing of the adjusting nut. Therefore, a problem that in the existing static stretching test, the to-be-tested rod body is easy to slip or cannot be clamped is solved; and a propelling effect is achieved on the characteristic research of the microscopic NPR anchor rod; an alignment sleeve is arranged to guarantee the coaxiality of the to-be-tested rod body and the first clamping groove, the clamping piece of the multi-petal structure presses the to-be-tested rod body to guarantee that the to-be-tested rod body is stressed in a balanced mode, and the test precision is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

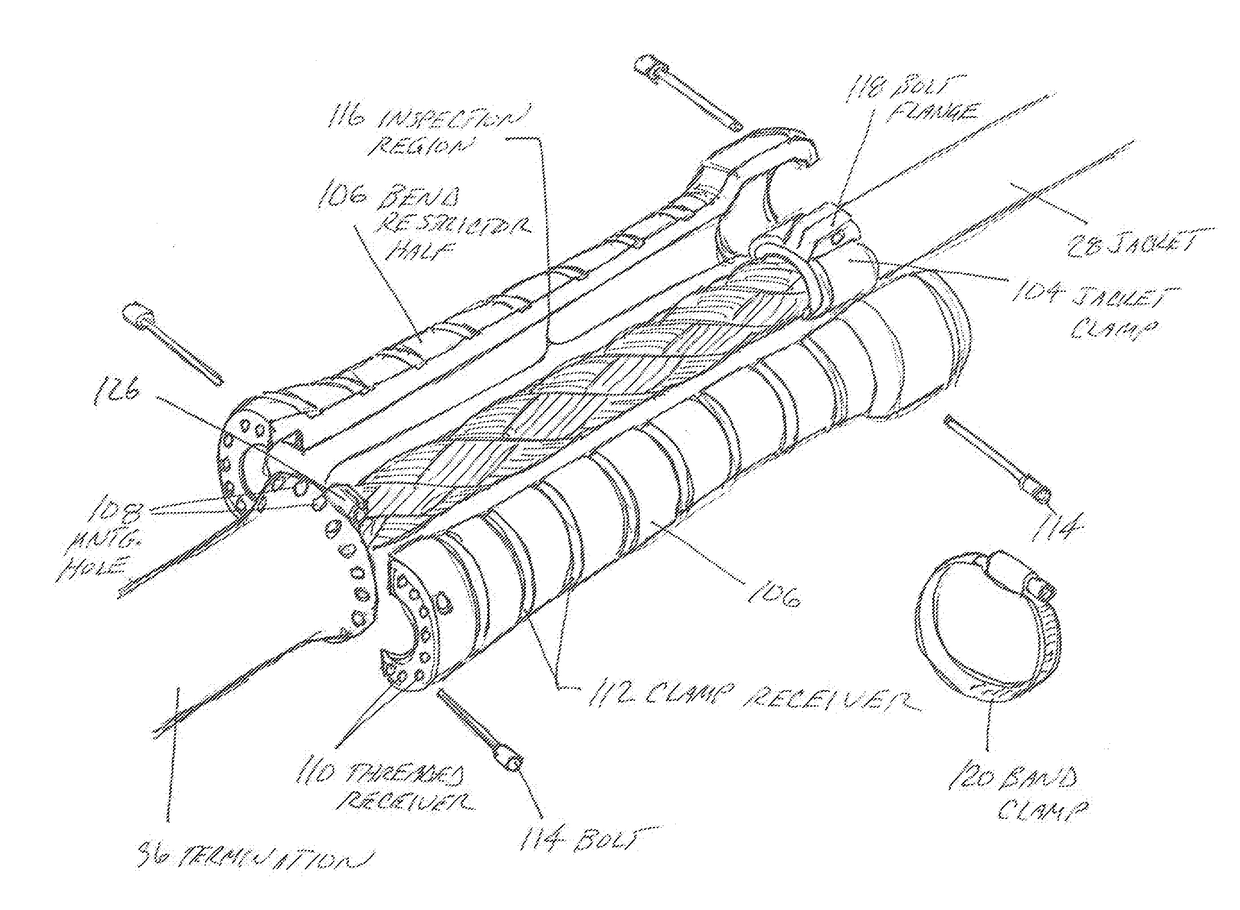

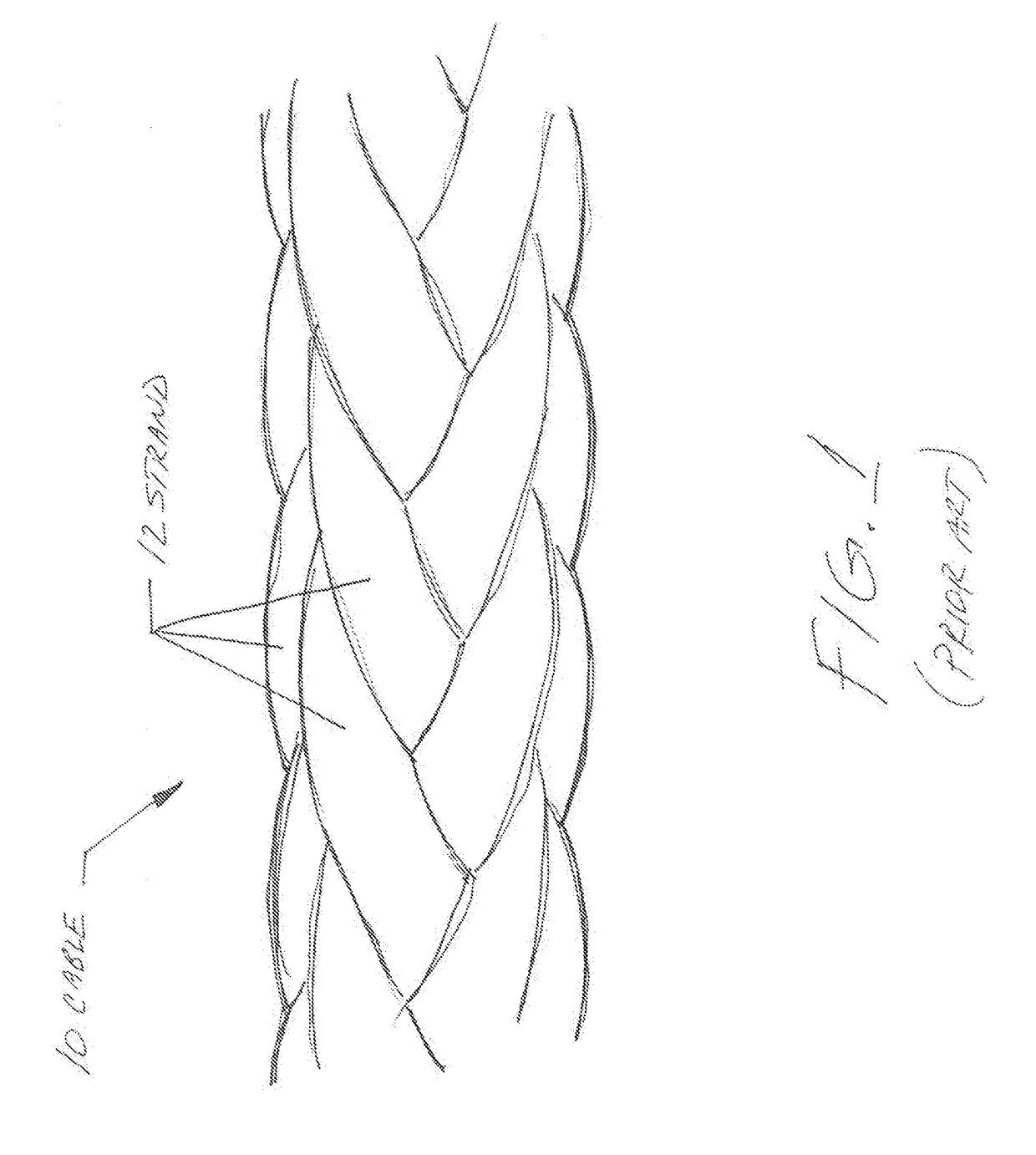

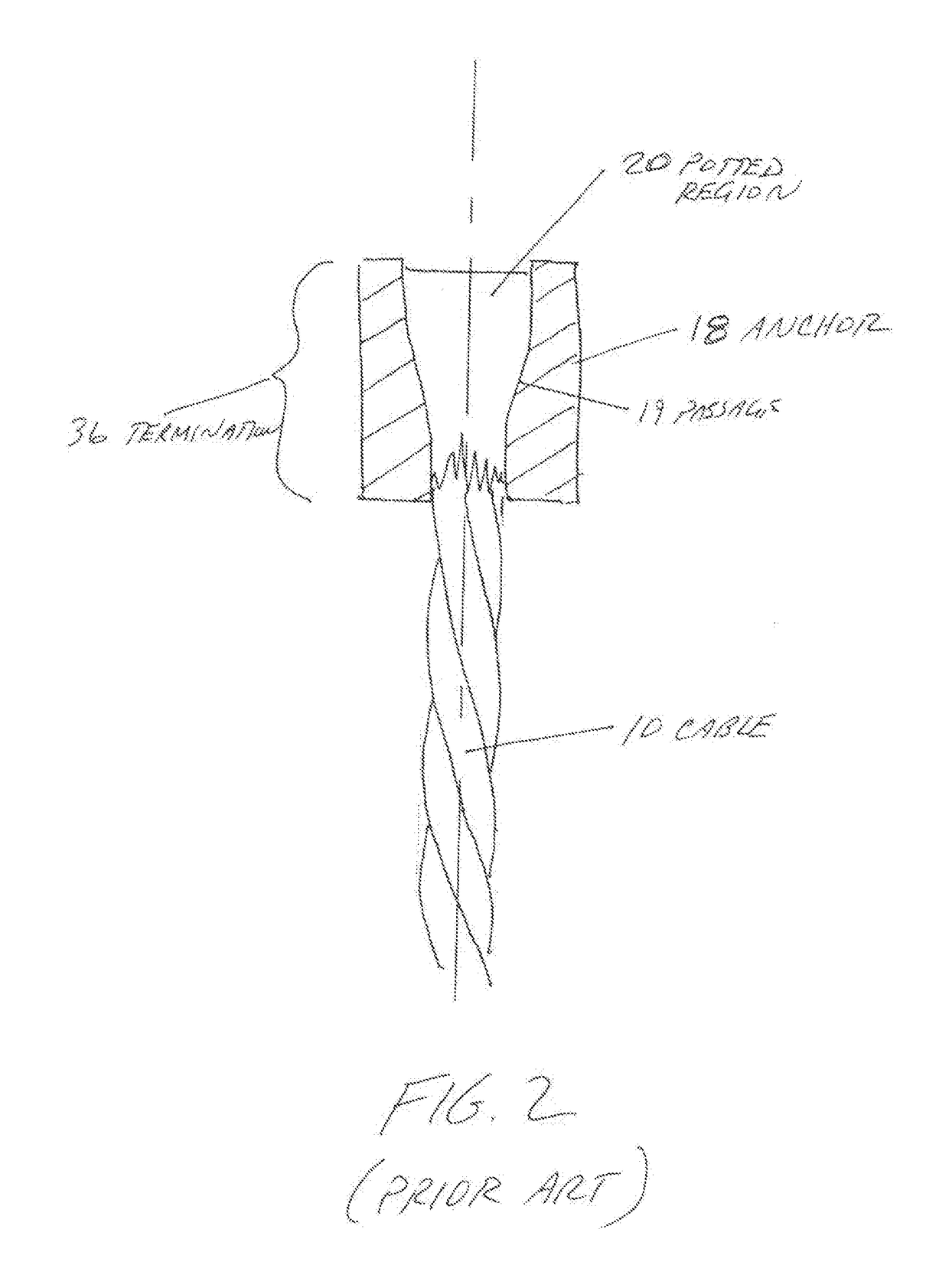

Method and Apparatus for Producing a Synthetic Semi-Static Tensile Member

InactiveUS20170356481A1Ropes and cables for vehicles/pulleyRod connectionsEngineeringMechanical engineering

A structure for a semi-static tensile member and a method for producing the semi-static tensile member. A tensile member is prepared by attaching terminations to an assembly of synthetic filaments. The tensile member is then attached to a loading apparatus that subjects the tensile member to a pre-defined loading process. The tensile member is thereby conditioned to a stable length. A bend restricting device is attached to the cable assembly proximate the point where the synthetic strands exit the termination and enter the freely-flexing portion of the cable. The bend restricting device is configured to permit periodic inspection of the cable in the region it covers.

Owner:CAMPBELL RICHARD V

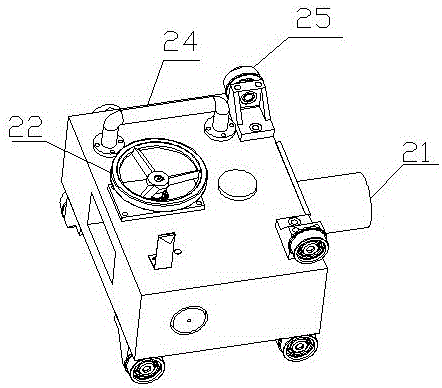

Multifunctional thin film three-axis tensile testing machine and testing method

ActiveCN103940667AAchieve translationAchieve rotationMaterial strength using tensile/compressive forcesPull forceStress ratio

Owner:SHANGHAI JIAO TONG UNIV

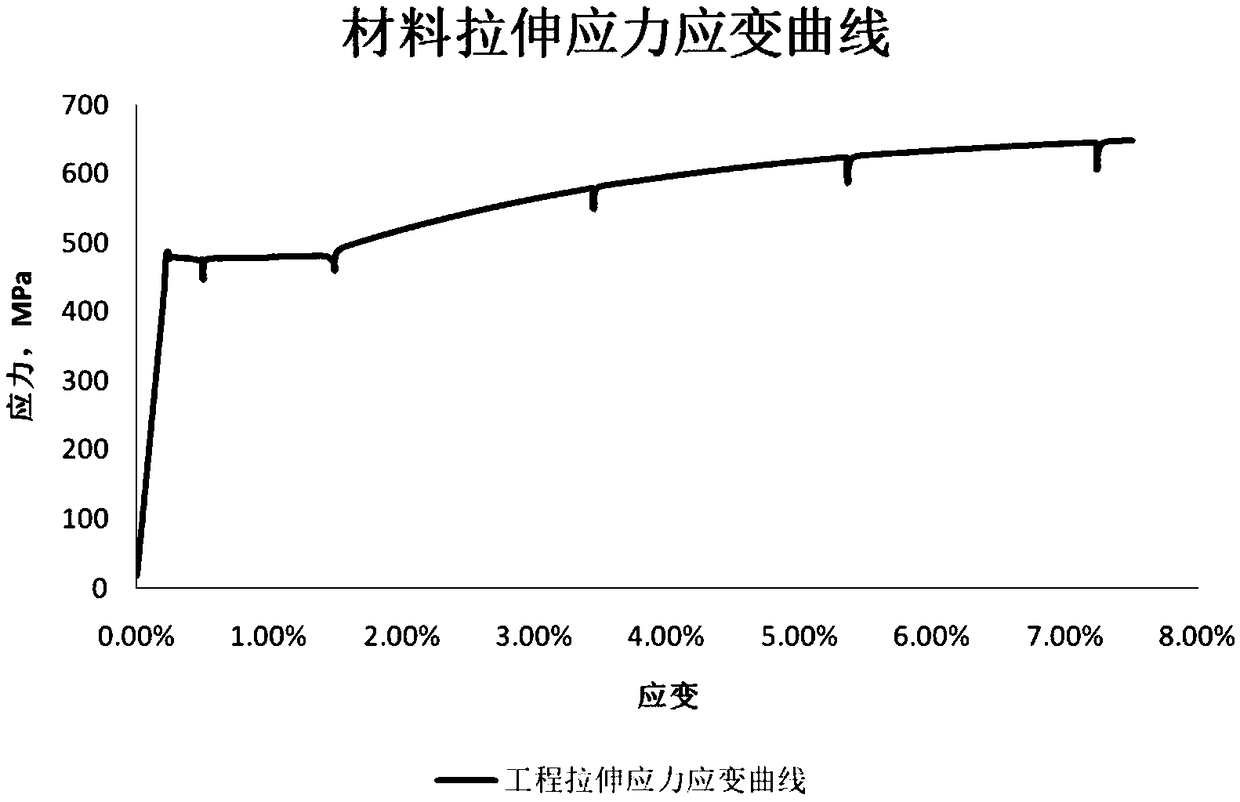

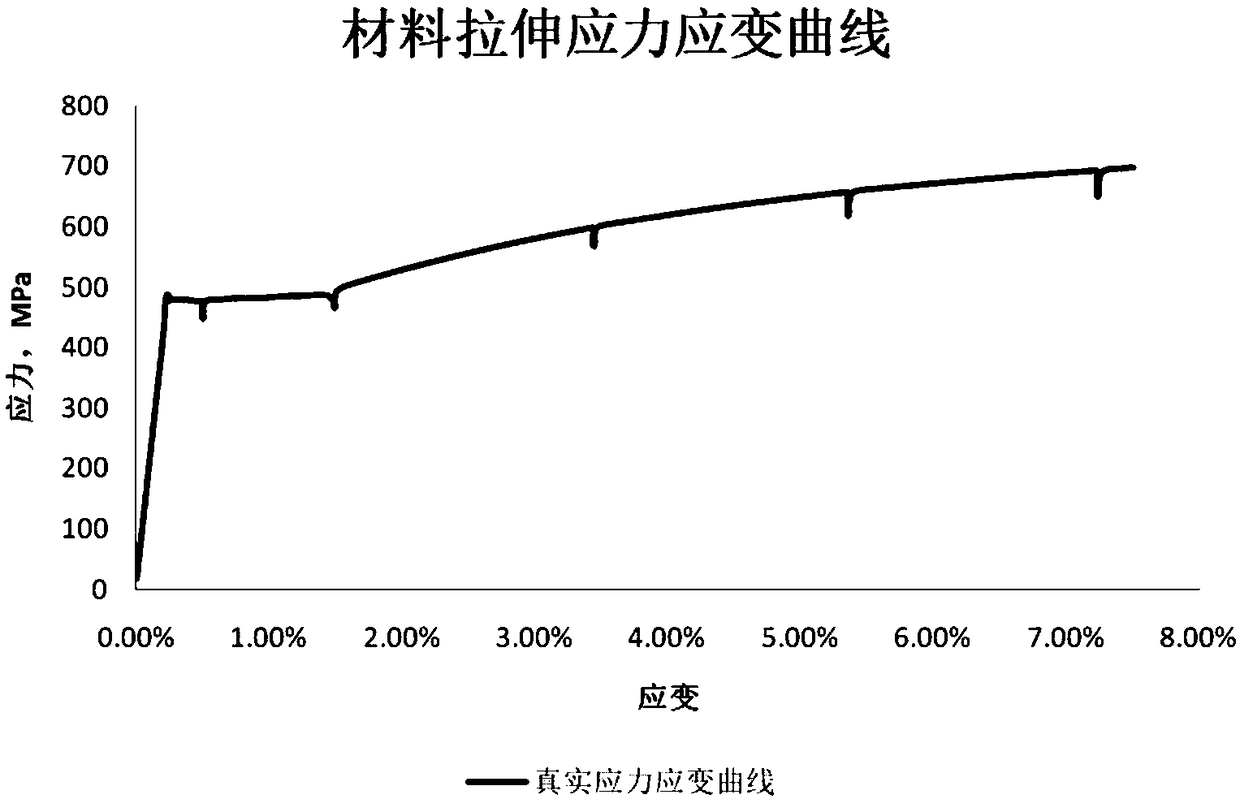

Method used for obtaining stress-strain curve of metal materials at static tensile states

ActiveCN109115603AMaterial strength using tensile/compressive forcesStress–strain curveMetallic materials

The invention provides a method used for obtaining stress-strain curve of metal materials at static tensile states. The method is invented through improvement of tensile experiment and experiment dataprocessing analysis based on strain control or displacement control states, and mainly comprises two steps: firstly, experiment data is obtained through improved tensile experiment, and then the experiment data is adopted in processing of the real stress-strain curve of an obtained material at limit slow tensile, i.e. static tensile states. According to the method, the real stress-strain curve ofa material at long period stretching process is obtained through experiments, so that effective evaluation of material real using performance is realized, and important guiding meaning on the metal material at long term stretching states is achieved.

Owner:TIANJIN PIPE GROUP CORP

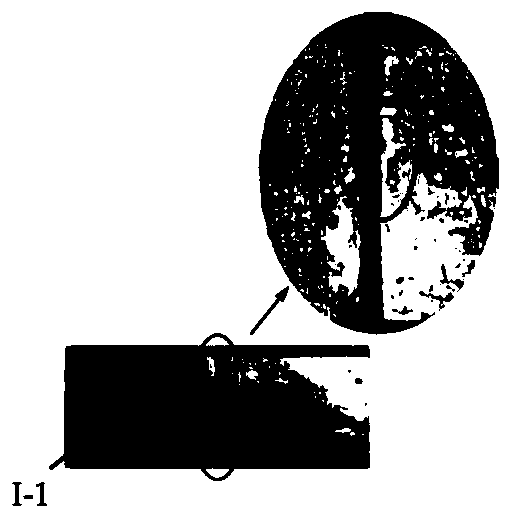

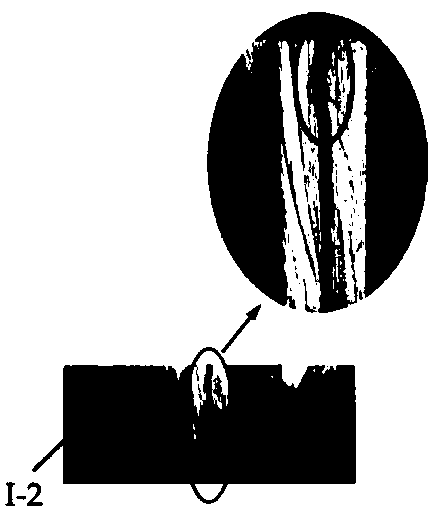

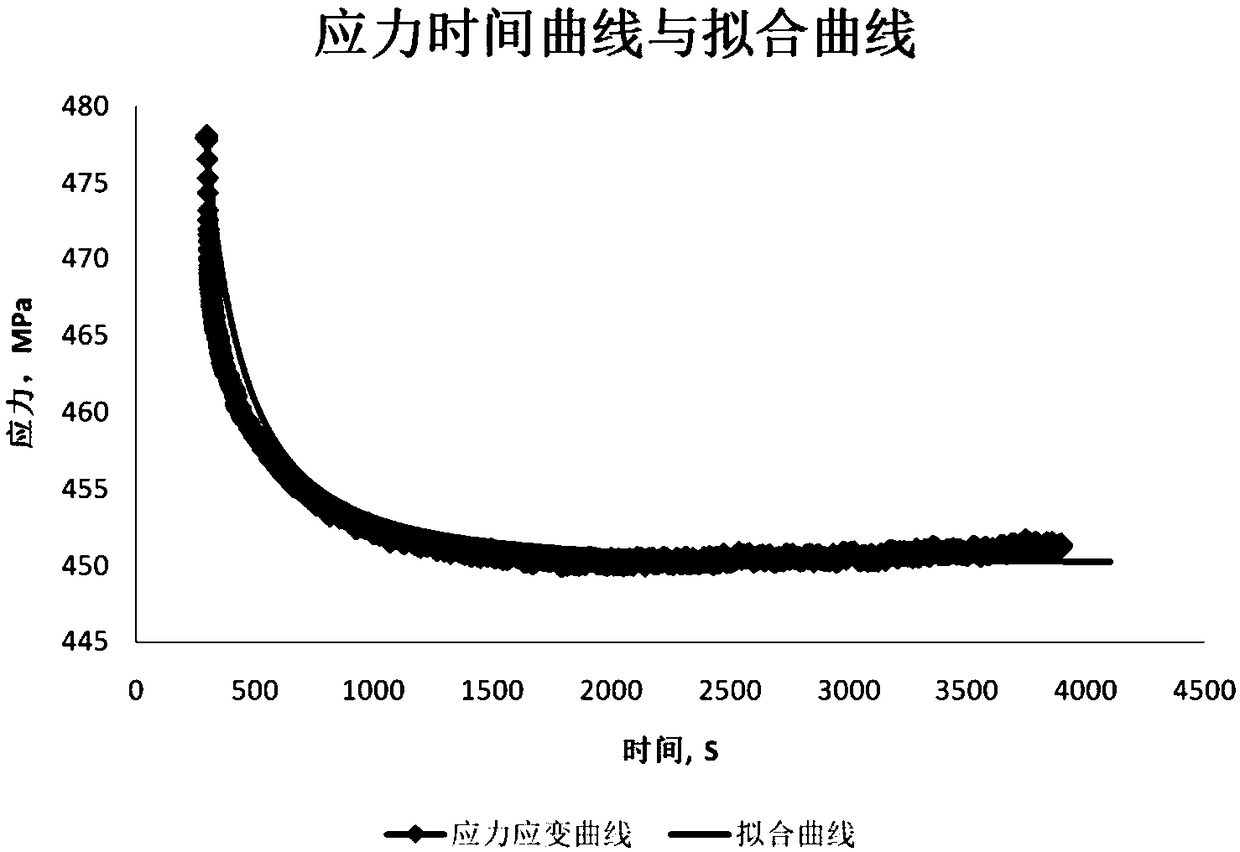

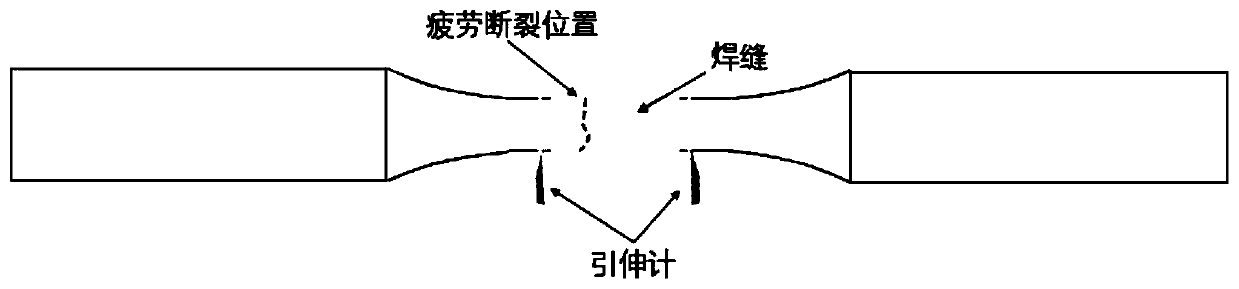

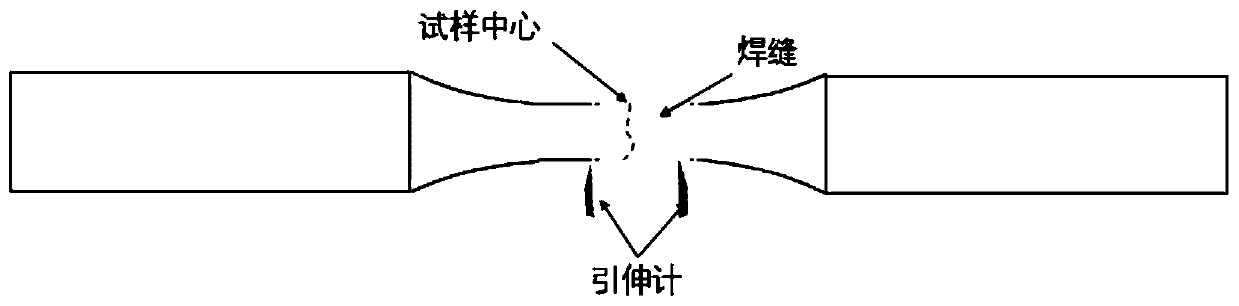

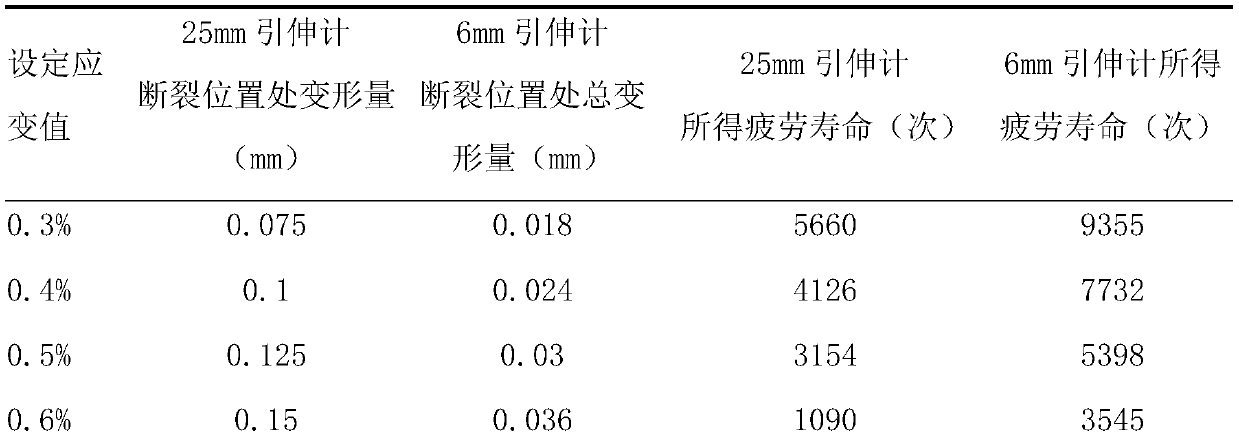

Non-uniform structure thick plate welding joint low-cycle fatigue performance testing method

ActiveCN109883826AImproving accuracy of lifetime assessmentRevised strainMaterial strength using tensile/compressive forcesInvestigating material hardnessThick plateHardness

The invention provides a non-uniform structure thick plate welding joint low-cycle fatigue performance testing method. The non-uniform structure thick plate welding joint low-cycle fatigue performancetesting method comprises the following steps: under the set strain amplitude, a sample is subjected to low-cycle fatigue testing, and the fracture position is observed; the sample is subjected to static stretching testing in a static stretching machine, and the fracture position is observed; a metallographic sample of a welding joint is selected, and the non-uniform structure hardness distribution law of the welding joint is calibrated through a hardness meter; the fracture positions of a low-cycle fatigue test fracture sample and a static stretching test fracture sample are compared and analyzed, and the non-uniform structure hardness distribution law of the welding joint is combined to judge the low-cycle fatigue failure fracture position of the sample; the low-cycle fatigue failure fracture position is taken as a machining center of the low-cycle fatigue sample to remachine the sample, and the scale distance of the remachined low-cycle fatigue sample contains a fracture area; and the remachined sample is subjected to low-cycle fatigue testing again, low-cycle fatigue test results are analyzed, and the strain life equation of the fracture area of the welding joint is obtained.

Owner:SHANGHAI JIAO TONG UNIV

Tissue engineering lymph node model and construction method thereof

The invention discloses a tissue engineering lymph node model and a construction method thereof and belongs to the technical field of tissue engineering and regenerative medicine. The tissue engineering lymph node model comprises lymphocytes separated from lymphoid tissues and a collagen-Matrigel scaffold. The construction method for the tissue engineering lymph node model comprises the following steps of: preparing lymphocyte suspension and primary generation mouse fibroblast cell suspension; and compounding mixed cell suspension and the collagen-Matrigel scaffold, and culturing in a mold subjected to static stretching to obtain the tissue engineering lymph node model. The scaffold system subjected to static stretching can better simulate in-vivo environment and support the growth and proliferation of the lymphocytes, secretion of cell factors and the expression of surface markers, and has important significance for applying the tissue engineering lymph node model to immunotoxicity evaluation of biological materials, immune medicine screening and the like. The construction method has the advantages of simple operating process and mild implementation conditions.

Owner:INST OF BASIC MEDICAL SCI ACAD OF MILITARY MEDICAL SCI OF PLA

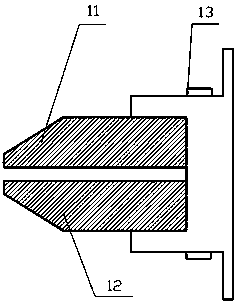

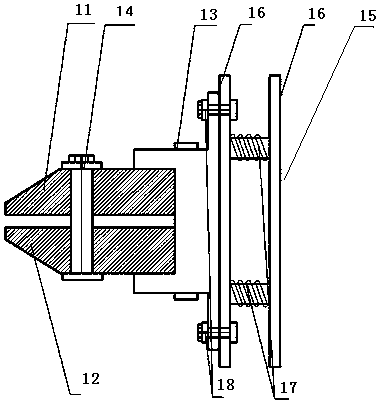

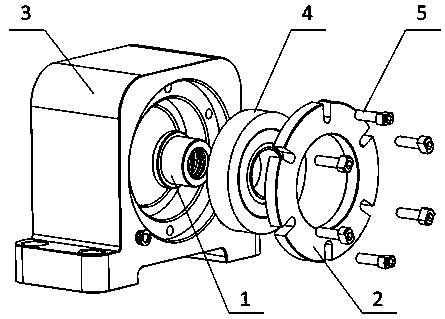

Sample clamping device for high-temperature high-frequency complicated load loading test

PendingCN109883820ANovel ideaFunction increaseMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesAviationEngineering

The invention relates to a sample clamping device for a high-temperature high-frequency complicated load loading test, and belongs to the technical field of material testing. The sample clamping device is composed of a left clamp and a right clamp which are same in structure; in the left clamp or the right clamp, an outer ring of a sleeve is matched with an inner ring of a knuckle bearing or a clamping part of a standard plate-shaped sample, is fixed through a quick-change baffle ring and is mounted on a supporting seat; an inner ring of the sleeve is provided with a thread, and is screwed with an outer thread section of a high-temperature high-frequency complicated load sample to realize the fixation of the high-temperature high-frequency complicated load sample; the bottom of the supporting seat is provided with four through holes, and is mounted on a tensile bending composite fatigue testing machine through bolts; and a tensile loading device on the testing machine is connected withthe supporting seat through bolts to realize the static tensile loading of the high-temperature high-frequency complicated load sample. The sample clamping device has the advantages as follows: the sample clamping device can be applicable to a material testing machine with loading functions of high temperature, tension, bending, ultrasonic vibration and the like; the sample clamping device is simple in structure and convenient in operation; and a powerful guarantee is provided for testing the mechanical properties of key structure materials in the fields of aviation, spaceflight and the like.

Owner:JILIN UNIV

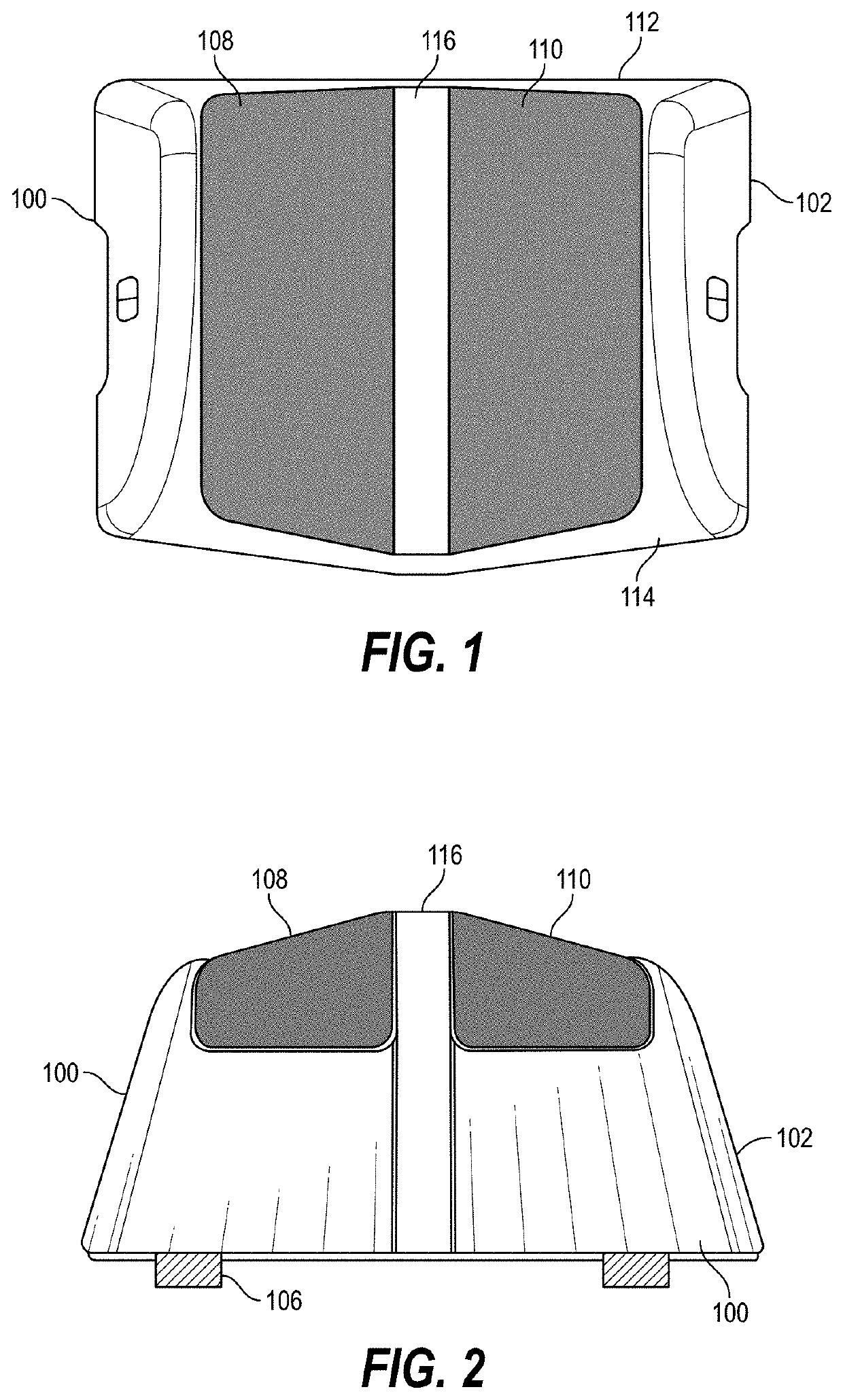

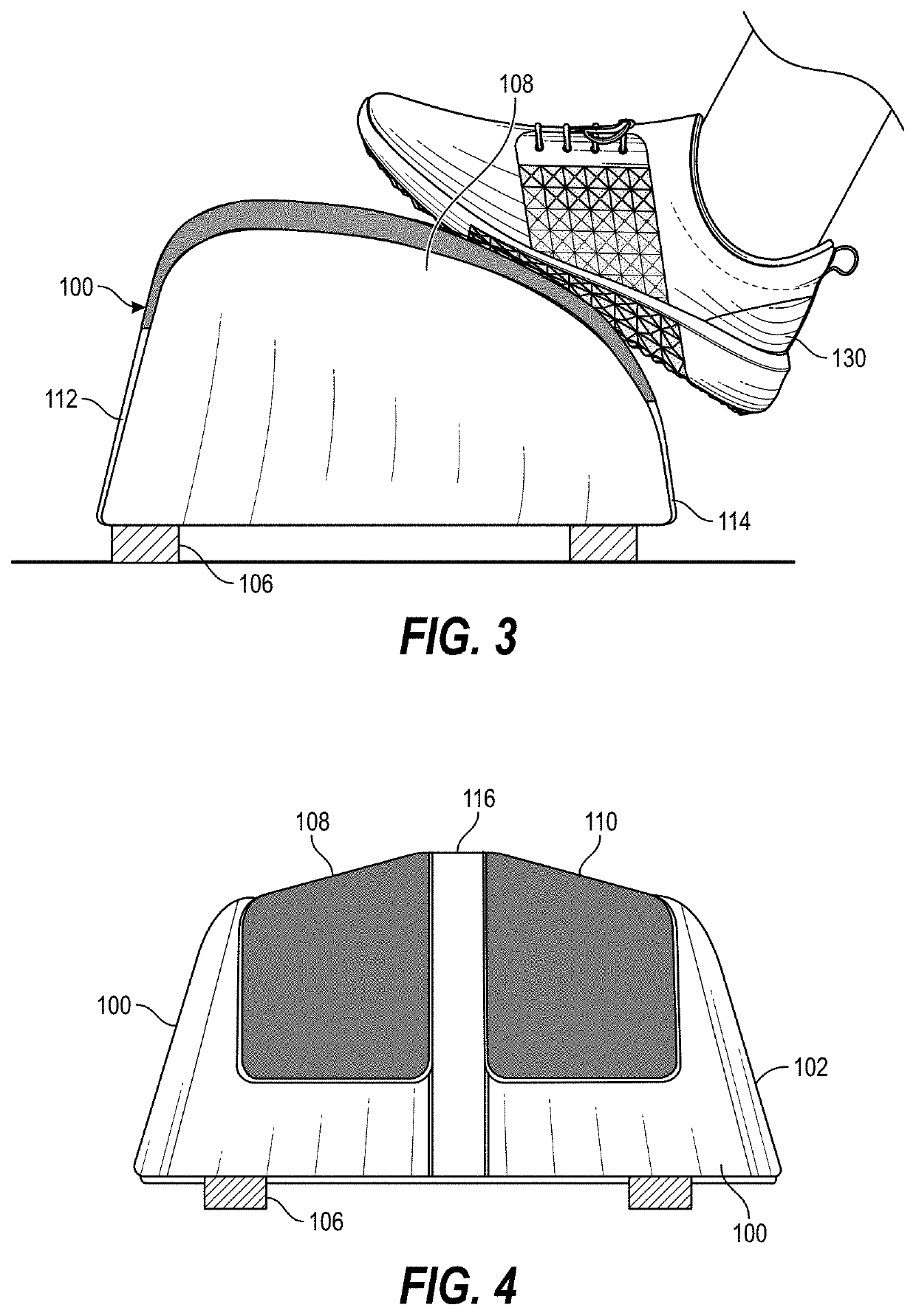

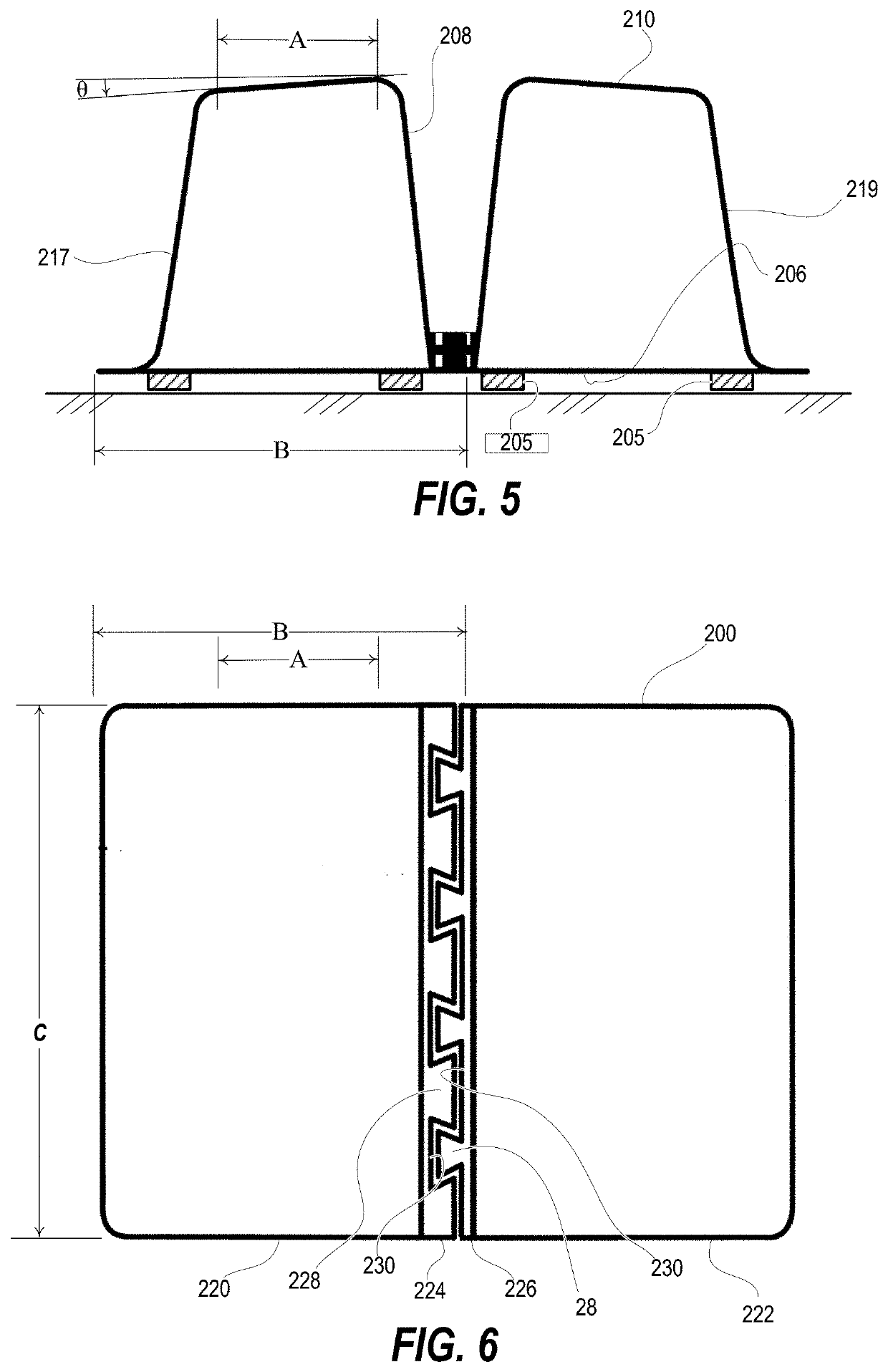

Device for isolated static stretching of the gastrocnemius (CALF) muscle

A calf-stretching device enables a user to conduct stretching exercises of the gastrocnemius muscles of the leg. The calf-stretching device includes a support base positionable on a floor surface and left and right surfaces immovably attached to the support base. Each of the left and right surfaces present a convex curved surface from a front side to a back side to receive respective feet of the user, the convex curved surface having a greater radial dimension on an inner portion than an outer portion to correspond to a foot arch of the user.

Owner:AMIS JAMES

High-temperature and low-temperature fatigue test apparatus suitable for thin fatigue specimen plate

InactiveCN108387457ASimple structureImprove operational reliabilityMaterial strength using tensile/compressive forcesInterference fitTensile fatigue

The invention discloses a high-temperature and low-temperature fatigue test apparatus suitable for a thin fatigue specimen plate, and belongs to the technical field of fatigue detection for a material. The apparatus includes a thin fatigue specimen plate, a contact head, shaft connecting rods, necks, clampers, a heating furnace and a fatigue testing machine. The shaft connecting rods are connectedto the fatigue testing machine via the clampers; the necks are in interference fit to the holding ends of the thin fatigue specimen plate; the whole holding ends of the thin fatigue specimen plate are inlaid in the necks for efficiently holding and fixing a specimen; and after the thin fatigue specimen plate is put in the necks, a cover cooperates with a fixing pin and bolts to fix and clamp thethin fatigue specimen plate in the necks and to prevent the specimen from loosing and sliding in a high-cycle fatigue process. The apparatus is simple in structure, the specimen is easy to be installed and held, and high-temperature and low-temperature tensile-tensile fatigue tests and static tensile tests can be carried out. The problems that a test clamper cannot efficiently hold a thin fatiguespecimen plate with the thickness in a range of 1-3 mm at a high temperature and a fatigue specimen is easy to loose at a high temperature in the prior art are solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

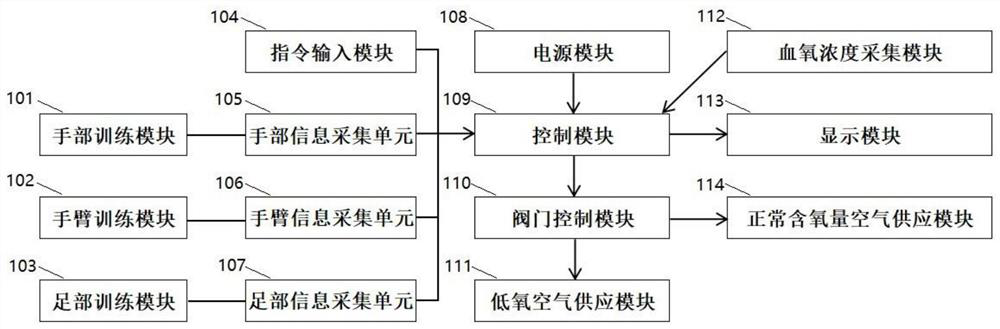

Intermittent hypoxia training device and control method thereof

ActiveCN112245876AQuality improvementImprove tensile propertiesGymnastic exercisingTherapy exerciseEngineeringRespiratory disease

The invention provides an intermittent hypoxia training device. The intermittent hypoxia training device comprises a hypoxia training system, a muscle stretching training instrument and a control module, the hypoxia training system is used for providing hypoxia air and normal oxygen content air required by intermittent hypoxia training, a valve control module arranged in the hypoxia training system is connected with the control module, and the muscle stretching training instrument is used for enabling a trainee to keep a training posture to carry out intermittent hypoxia training. An instruction input module arranged on the muscle stretching training instrument is connected with the control module. The invention further provides a control method of the intermittent hypoxia training device.By combining muscle static stretching training and intermittent hypoxia training, the auxiliary treatment of allergic respiratory diseases, the improvement of cardiovascular functions, the preventionof sudden cardiac death, the improvement of endogenous testosterone level and the improvement of whole-body microcirculation ability are facilitated, the training intensity is low, and the device andmethod are suitable for common trainees to use.

Owner:张良

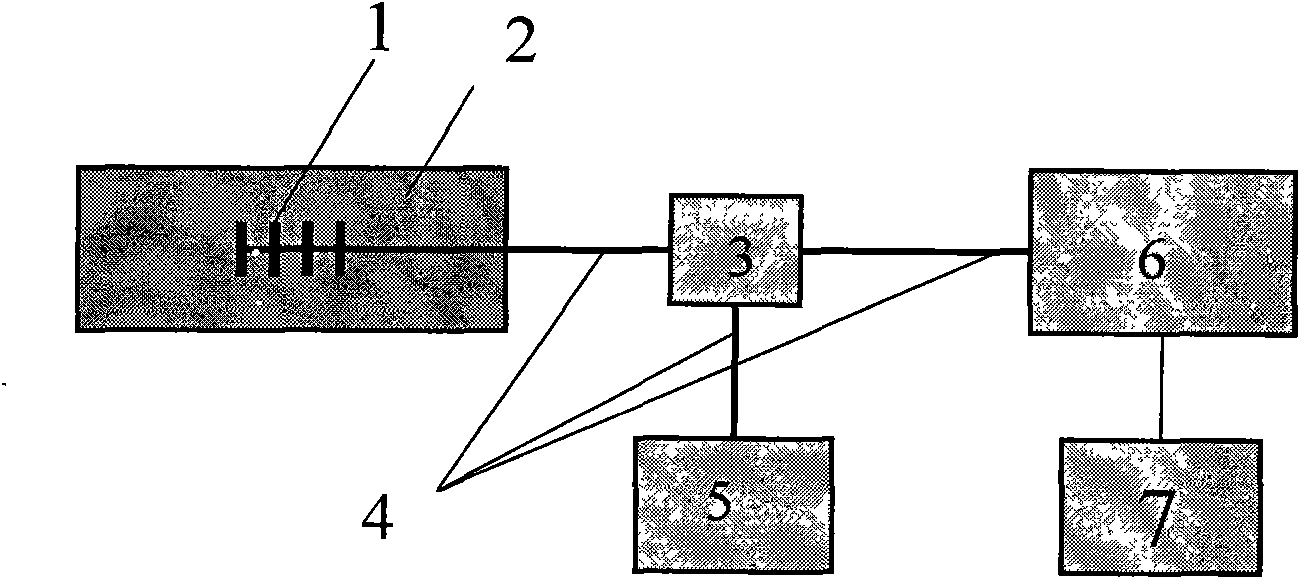

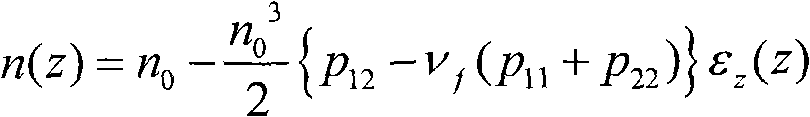

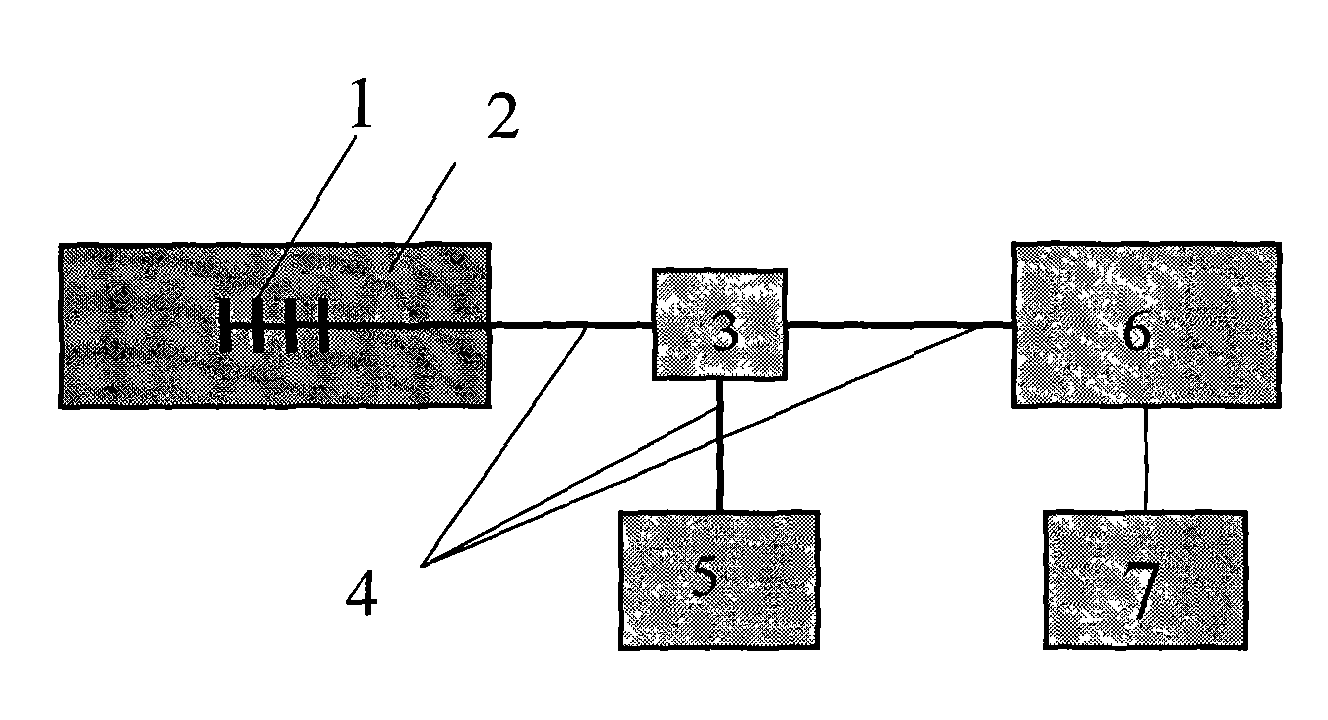

Method for positioning transverse cracks of carbon fiber composite material by using chirp grating

InactiveCN101819160AReal-time detection of transverse cracksSimple methodScattering properties measurementsOptically investigating flaws/contaminationGratingLength wave

The invention discloses a method for positioning transverse cracks of a carbon fiber composite material by using a chirp grating, which comprises the following steps of: (1) manufacturing a carbon fiber composite material cross-ply laminate with the stacking sequence of [0-degree 2 / 90-degree 4 / 0-degree 2], and embedding a chirp grating sensor into a 0-degree layer the carbon fiber composite material cross-ply laminate, wherein the chirp grating sensor is adjacent to a 90-degree layer; (2) under a condition with a constant temperature, using an optical fiber sensing analyzer to monitor a chirp grating reflection spectrum of a carbon fiber composite material test piece in a quasistatic tensile test; and (3) adjusting the length of the chirp grating to be accordant with a bandwidth phase of the chirp grating reflection spectrum before embedding in a coordinate system to ensure that a wavelength position corresponding to a point with decreased light intensity and a grating position corresponding to the wavelength in the chirp grating reflection spectrum are the positions where the transverse cracks are generated in the 90-degre layer of the composite material at that time. The method is simple, has a low cost, and can detect the transverse cracks in the carbon fiber composite material in real time.

Owner:SHENYANG INST OF AERONAUTICAL ENG

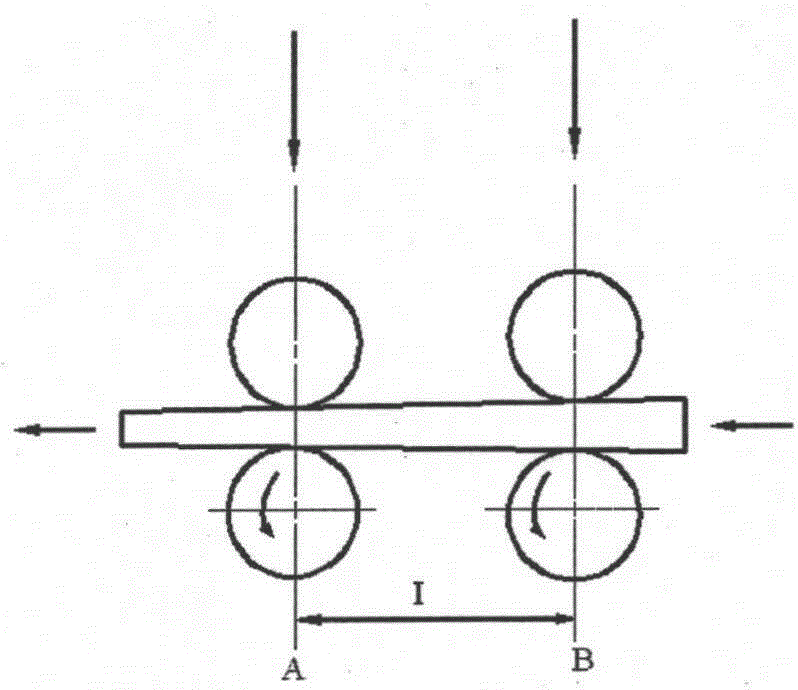

Method for designing optimal back zone draft ratio of drawing frame

InactiveCN105277438ASimple methodSave raw materialsMaterial strength using tensile/compressive forcesFiberEngineering

The invention provides a method for designing the optimal back zone draft ratio of a drawing frame. The method comprises the steps that an upper chuck and a lower chuck of a drawing tester clamp the two ends of a fiber fringe to conduct drawing, the fringe between the upper chuck and the lower chuck is drafted and drawn to be thin and long till the middle of the fringe is completely separated along with the process of drawing, and when the drawing force is the largest, the corresponding draft ratio is the optimal back zone draft ratio of the drawing frame. According to the method for designing the optimal back zone draft ratio of the drawing frame, static drawing of the drawing tester is adopted to simulate dynamic drawing, according to a relation curve of simulated drawing force and extension, the extension is converted into the draft ratio through a formula, the extension corresponding to the maximum value of the drawing force can have the maximum drawing force, evenness of sliver is minimum at this time, and therefore the draft ratio corresponding to the maximum value of the drawing force is the optimal draft ratio of a back draft zone. The method for designing the optimal back zone draft ratio of the drawing frame is simple, practical and capable of saving time, labor and raw materials, and the simple, effective and accurate method is provided for design of the back zone draft ratio of the drawing process.

Owner:DONGHUA UNIV

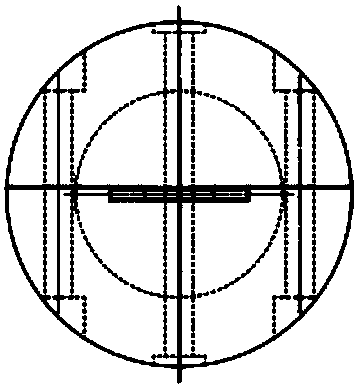

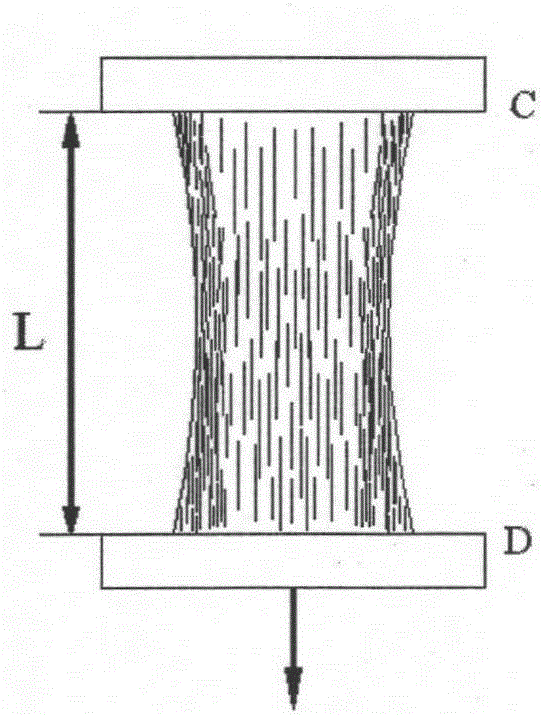

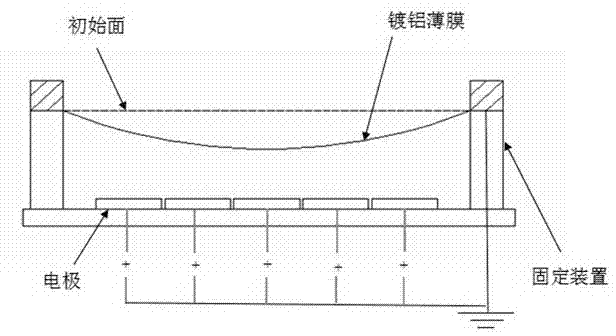

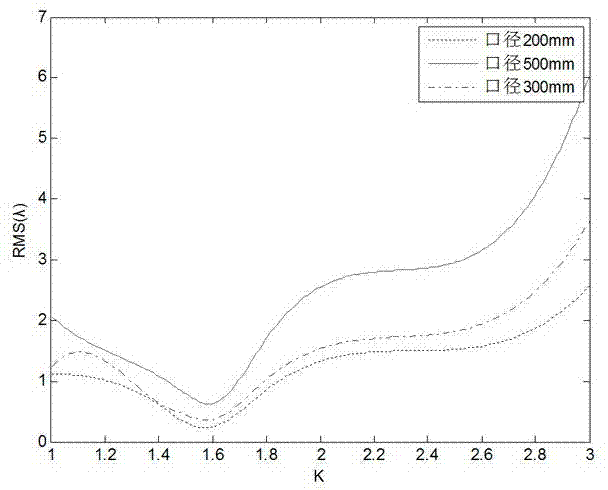

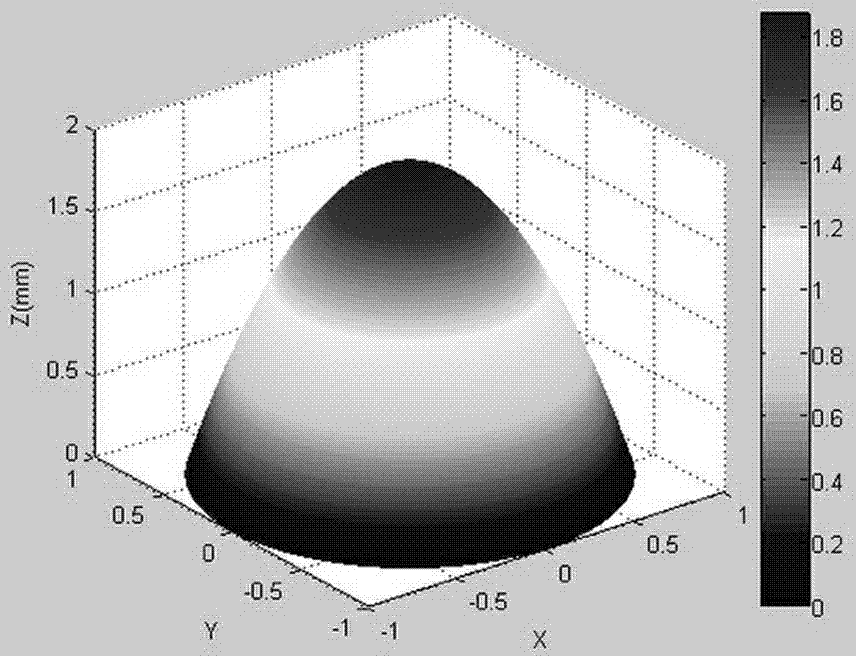

Method for manufacturing static stretching thin film reflecting mirror

The invention relates to a method for manufacturing a static stretching thin film reflecting mirror. The periphery of a thin film in the thin film reflecting mirror is fixed on a circular ring fixing device. Electrodes are arranged under the thin film. The electrodes comprise a central circular electrode and annular electrodes with the equal radial width, wherein the annular electrodes are distributed in a concentric-circle mode. The radius of the central circular electrode is 1.5-1.7 time the radial width of the annular electrodes. The number of the annular electrodes is 3-10. The pressure of the central position of the radius of the central electrode is used as the pressure of the central electrode area. The pressures of radial central points of the annular electrodes are used as the pressure of the annular electrode area. The pressures are converted into voltage signals to be input to the corresponding electrodes. The static stretching thin film reflecting mirror can be obtained through machine-shaping. Compared with a standard paraboloid, the three-dimensional surface shape of the thin film reflecting mirror obtained by adopting the static shaping control method is small in error. Compared with the prior art, the static stretching thin film reflecting mirror has the advantage that the surface shape precision is remarkably improved.

Owner:SUZHOU UNIV

Improved type breakage failure stress testing method of adhesion test piece

InactiveCN110220841AFracture Failure Stress TrueSolve the problem that the fracture failure stress of the bonded specimen cannot be truly reflectedUsing mechanical meansMaterial analysisElement modelStressed state

The invention discloses an improved type breakage failure stress testing method of an adhesion test piece. The improved type breakage failure stress testing method comprises the following steps: 1, performing quasi-tensile test on n adhesion abutting joints with different adhesive layer thicknesses to acquire initial breakage failure loads and initial breakage failure points of the n adhesion abutting joints; 2, building finite element models of the adhesion abutting joints of which the test sizes are identical and the adhesive layer thicknesses are different, applying the initial failure loads into the finite element models to ensure that an application position corresponds to the quasi-tensile test to acquire the breakage failure stresses of the unit corresponding to the initial breakagefailure points, wherein the failure stress comprises components, including sigma 1, sigma 2 and sigma 3, of three main stresses; and 3, acquiring the breakage equivalent stresses of the adhesion abutting joints with different adhesive layer thicknesses under complicated stress states. According to the improved type breakage failure stress testing method disclosed by the invention, the initial failure stresses of the adhesion abutting joints can be determined, the breakage equivalent stresses is determined, a real failure process is approached relatively, and the correctness of a breakage failure analysis process of an adhesion structure is improved.

Owner:JILIN UNIV

A method for testing the crimping quality of fittings at the end of composite insulators

ActiveCN106018099BTensile load adjustableSensitive deformation damage detectionMaterial strength using tensile/compressive forcesPull forceComposite insulators

The invention provides a system and a method for detecting the crimping quality of an end fitting of a composite insulator. The system comprises a horizontal lathe and a pull rod arranged in the horizontal lathe, wherein a tensile load device used for providing pull force for a to-be-detected composite insulator and a torsion load device for providing torsional force for the to-be-detected composite insulator are sequentially arranged on the pull rod in a sleeving manner; a sample end of the torsion load device is connected with one end of the to-be-detected composite insulator, and the other end of the to-be-detected composite insulator is connected with a mobile locking device; a testing device used for acquiring the deformation condition generated when a material of the to-be-detected composite insulator is damaged is further arranged at the sample end of the torsion load device; the output end of the testing device is connected with a computer. The system and the method are used for analyzing the crimping condition of the end fitting of the composite insulator by simulating the static tensile load and the dynamic torsional load borne by the composite insulator in the actual on-line operation process and by comprehensively utilizing the detecting device.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +4

Device and method for preparing static stretching sample of steel wire with section diameter being 2-10mm

InactiveCN105699151ASmall sizeGuaranteed thickness uniformityPreparing sample for investigationMetallic materialsEngineering

The invention discloses a device and a method for preparing a static stretching sample of a steel wire with a section diameter being 2-10mm. The device comprises a drum and a drum cover, the middle of the inner bottom of the drum is provided with a blind taper hole, the drum cover is arranged at the upper end of the drum wall which forms a cavity, the middle of the drum cover is provided with a through hole and a sprue, the lower side of the drum cover is provided with an arc transition surface protruding downwards, and the outer wall of the cavity is provided with a water inlet and a water outlet. One end of the stretching sample is vertically put into the device, and cooling water is fed into the cavity to solidify poured molten metal Sn. The device and the method for preparing the static stretching sample of the steel wire with the section diameter being 2-10mm have universality; by cooling outside the drum, solidification time of metal Sn solution can be shortened, and influences of overhigh temperature of molten metal Sn solution on textures of metal materials are avoided; due to self-positioning of the metal materials by the blind taper hole of the drum, positioning accuracy is realized while thickness uniformity of surrounding solidified metal Sn is guaranteed; in addition, the device has the advantages of structural simplicity, light weight, convenience, small size, convenience in assembly and disassembly, low manufacturing cost, time saving, labor saving and the like.

Owner:GUIZHOU UNIV

A method and device for preparing static tensile samples of steel wires with a cross-sectional diameter of 2-10mm

InactiveCN105699151BSmall sizeGuaranteed thickness uniformityPreparing sample for investigationMetallic materialsEngineering

The invention discloses a device and a method for preparing a static stretching sample of a steel wire with a section diameter being 2-10mm. The device comprises a drum and a drum cover, the middle of the inner bottom of the drum is provided with a blind taper hole, the drum cover is arranged at the upper end of the drum wall which forms a cavity, the middle of the drum cover is provided with a through hole and a sprue, the lower side of the drum cover is provided with an arc transition surface protruding downwards, and the outer wall of the cavity is provided with a water inlet and a water outlet. One end of the stretching sample is vertically put into the device, and cooling water is fed into the cavity to solidify poured molten metal Sn. The device and the method for preparing the static stretching sample of the steel wire with the section diameter being 2-10mm have universality; by cooling outside the drum, solidification time of metal Sn solution can be shortened, and influences of overhigh temperature of molten metal Sn solution on textures of metal materials are avoided; due to self-positioning of the metal materials by the blind taper hole of the drum, positioning accuracy is realized while thickness uniformity of surrounding solidified metal Sn is guaranteed; in addition, the device has the advantages of structural simplicity, light weight, convenience, small size, convenience in assembly and disassembly, low manufacturing cost, time saving, labor saving and the like.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com