Method for determining allowable amplitude of turbine engine blade

An engine blade and determination method technology, which is applied in the application of stable tension/pressure to test material strength, vibration test, machine/structural component test, etc. Different degrees of problems, to achieve the effect of helping understanding and engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings.

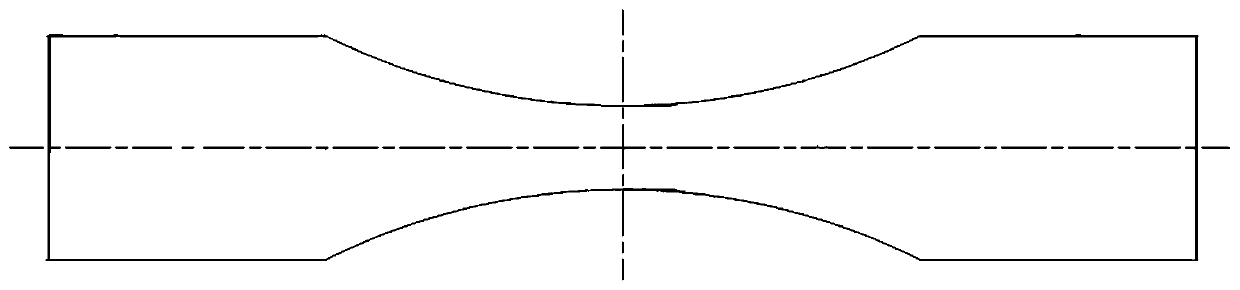

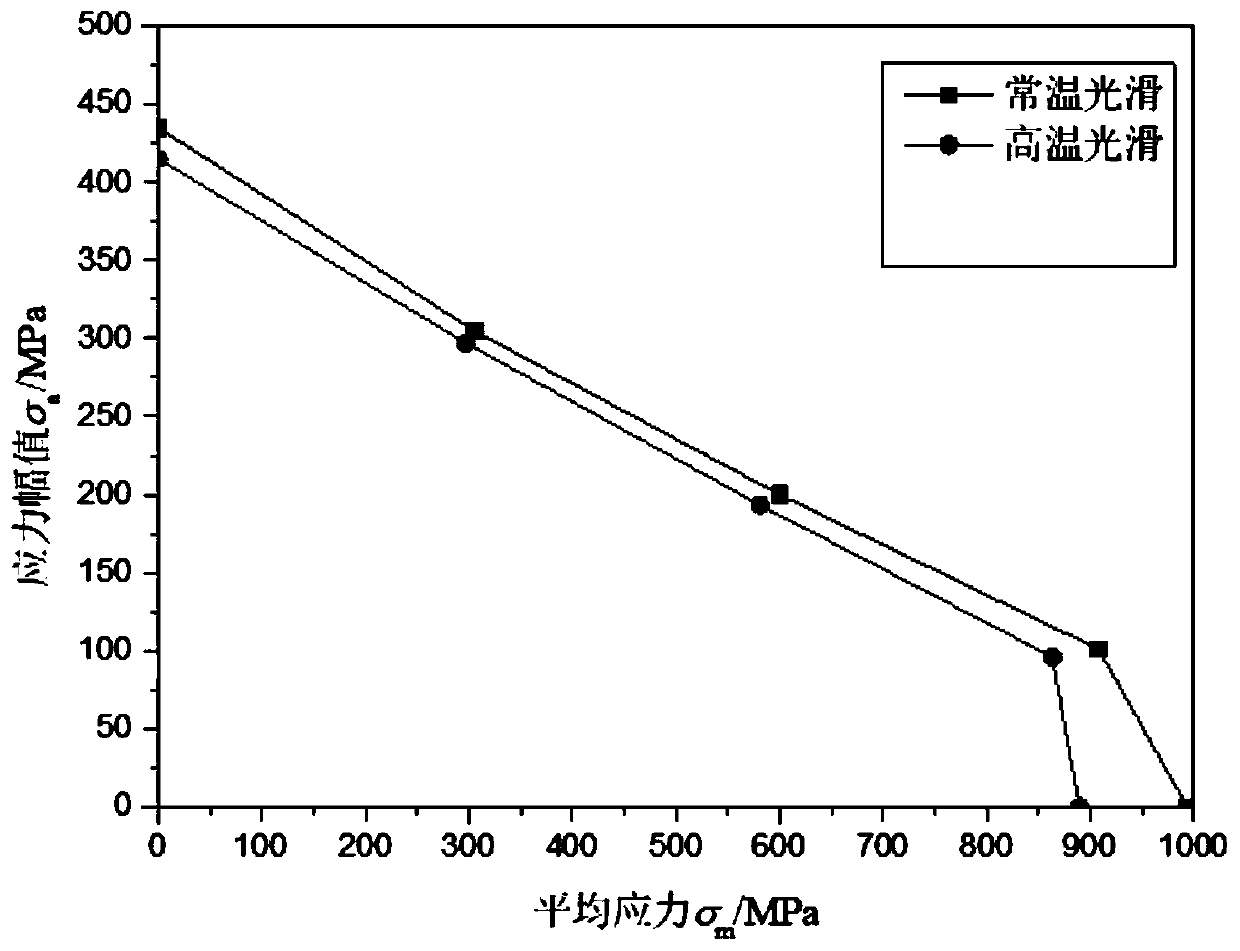

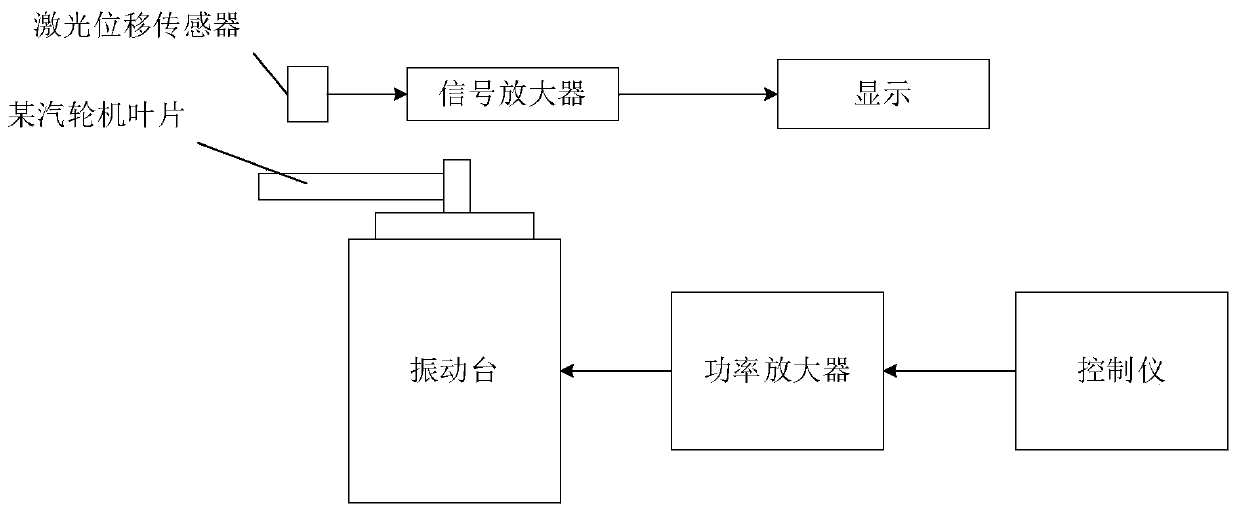

[0037] A method for determining the allowable vibration amplitude of a turbine engine blade of the present invention comprises: normal temperature quasi-static tensile test of a standard smooth test piece of material for the blade, high-temperature quasi-static tensile test of a standard smooth test piece of material for the blade, standard smoothness of the material for the blade Normal temperature high cycle fatigue test of the test piece, high temperature high cycle fatigue test of the blade material standard smooth test piece, high cycle fatigue test of the actual blade, and determination of the allowable amplitude of the actual blade. The test equipment used includes electro-hydraulic servo fatigue testing machine, electro-hydraulic servo tension-torsion fatigue testing machine with high temperature furnace, and electromagnetic exciter. The normal temperature desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com