Multifunctional thin film three-axis tensile testing machine and testing method

A tensile testing machine and tensile testing technology, applied in the direction of applying stable tension/compression to test material strength, etc., can solve the problem of rare membrane connector test and analysis research, three-dimensional membrane connector test technology and instruments Less problems, to achieve the effect of smooth operation

Active Publication Date: 2014-07-23

SHANGHAI JIAO TONG UNIV

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical engineering applications, in addition to the uniaxial and biaxial mechanical properties of membrane materials, the mechanical properties of membrane connectors are also very important propertie

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

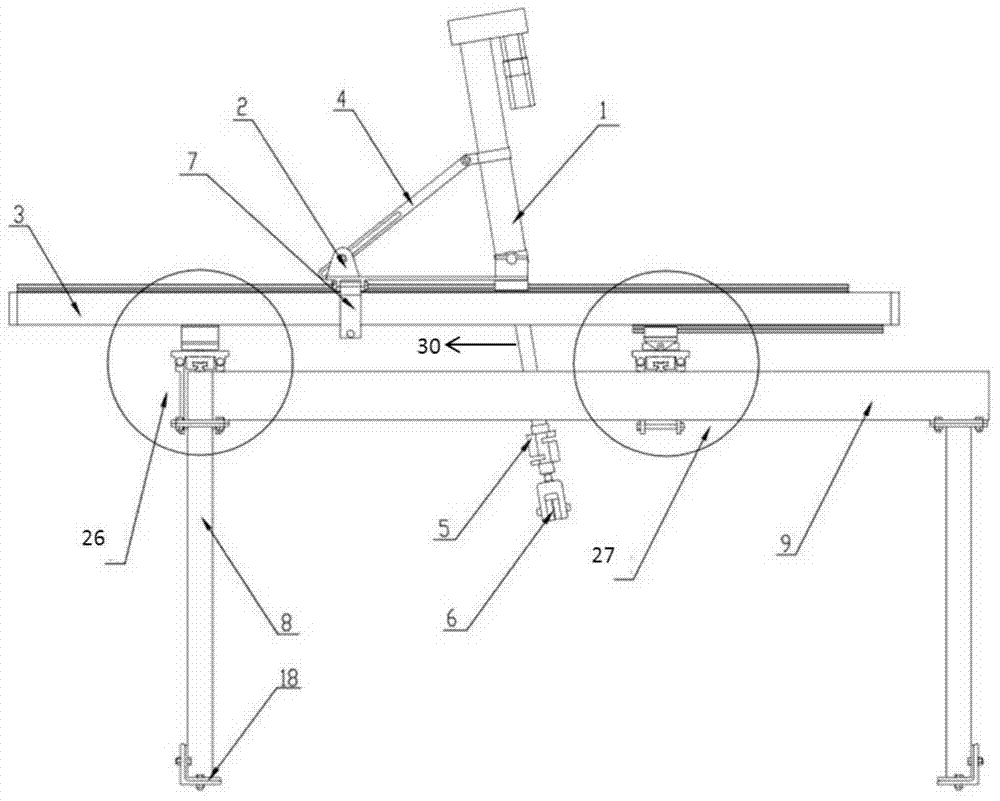

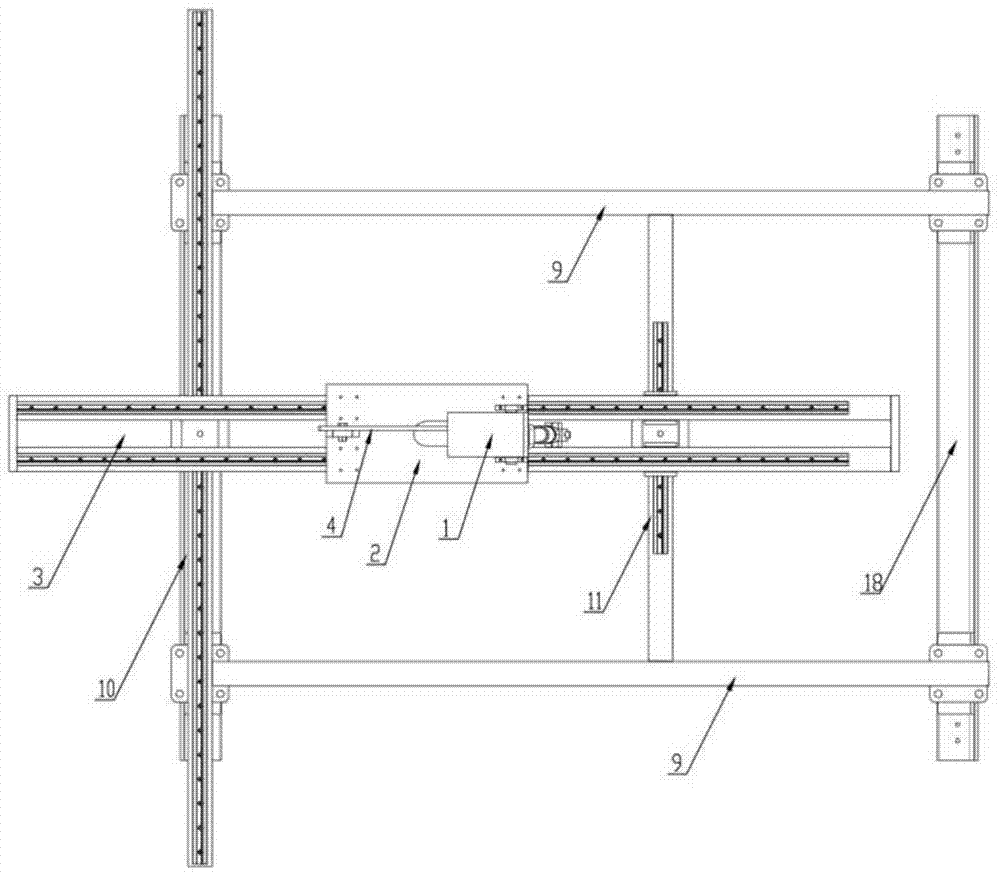

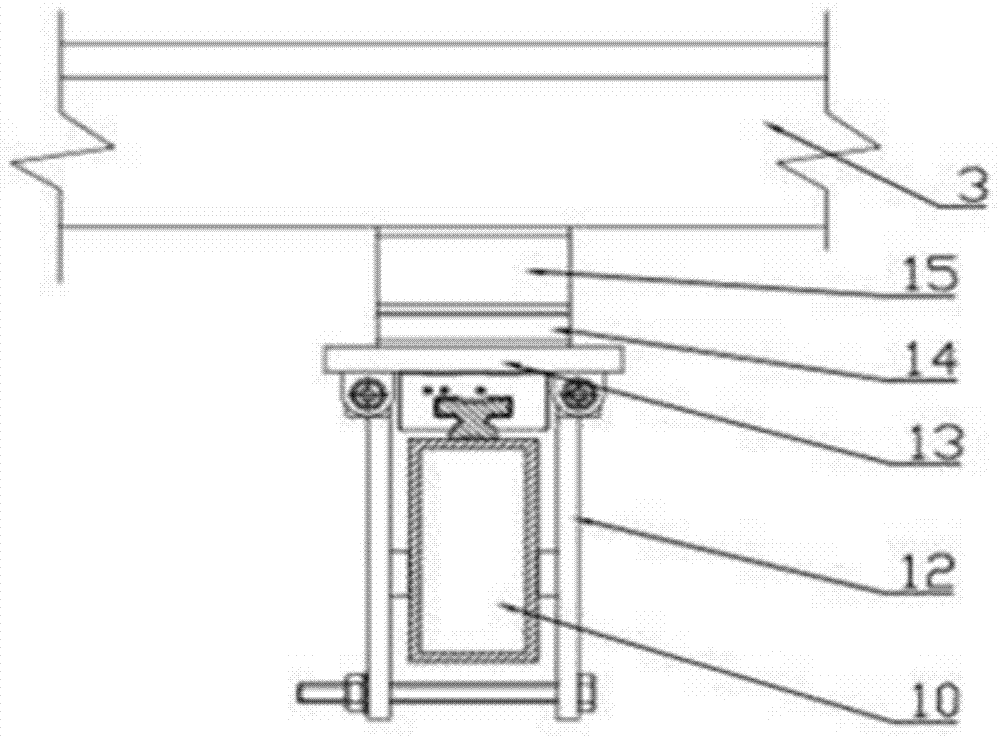

The invention discloses a multifunctional thin film three-axis tensile testing machine. The multifunctional thin film three-axis tensile testing machine comprises a horizontal double-axis testing device and a Z-axis tensile testing device, wherein the Z-axis tensile testing device is constructed above the horizontal double-axis testing device; the Z-axis tensile testing device comprises second stand columns, frameworks, a first fixed guide rail beam, a second fixed guide rail beam, a movable guide rail beam, a Z-axis platform, a first fixed plate, a movable rod, an electric cylinder, a second tension sensor and a second clamp. The invention further discloses a thin film three-axis tensile testing method which comprises a plurality of steps. The multifunctional thin film three-axis tensile testing machine and the testing method can realize multi-angle tension and have a multi-test function; the multi-angle tension comprises unidirectional static tension, low-cycle circulation back-and-forth tension, bidirectional static tension, low-cycle circulation back-and-forth tension with any double-axis stress ratio, three-dimensional connection part tension and low-cycle circulation back-and-forth tension with any three-axis stress ratio; the multifunctional thin film three-axis tensile testing machine is stable in operation, and the multifunctional thin film three-axis tensile testing machine and the testing method can be used for building membrane tests, airship skin tests and the like.

Description

technical field [0001] The invention relates to a tensile testing machine and a testing method, in particular to a multifunctional film triaxial tensile testing machine and a testing method. Background technique [0002] Polymer composite fabric film has the advantages of light weight, high strength, chemical resistance, durability, etc. It is widely used in modern architectural structures, aerospace and other industrial fields, such as architectural membrane structures, aviation airships, aerospace parachutes or soft landing systems. Fabric film materials have complex mechanical behavior characteristics, mainly manifested in nonlinearity, inelasticity, anisotropy, viscoelasticity, bidirectionality, etc. of the material. In recent years, researchers have continuously carried out experimental and analytical studies on the bidirectional mechanical behavior of membrane materials, and have achieved important research progress and results. However, in practical engineering appli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08

Inventor 陈务军王利钢施光林

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com