Container truck-mounted crane type angle adjusting device

An angle adjustment device, a technology of automobile crane, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of time-consuming and laborious replacement, reducing work efficiency, cumbersome adjustment methods, etc., to ensure life safety, save labor costs, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

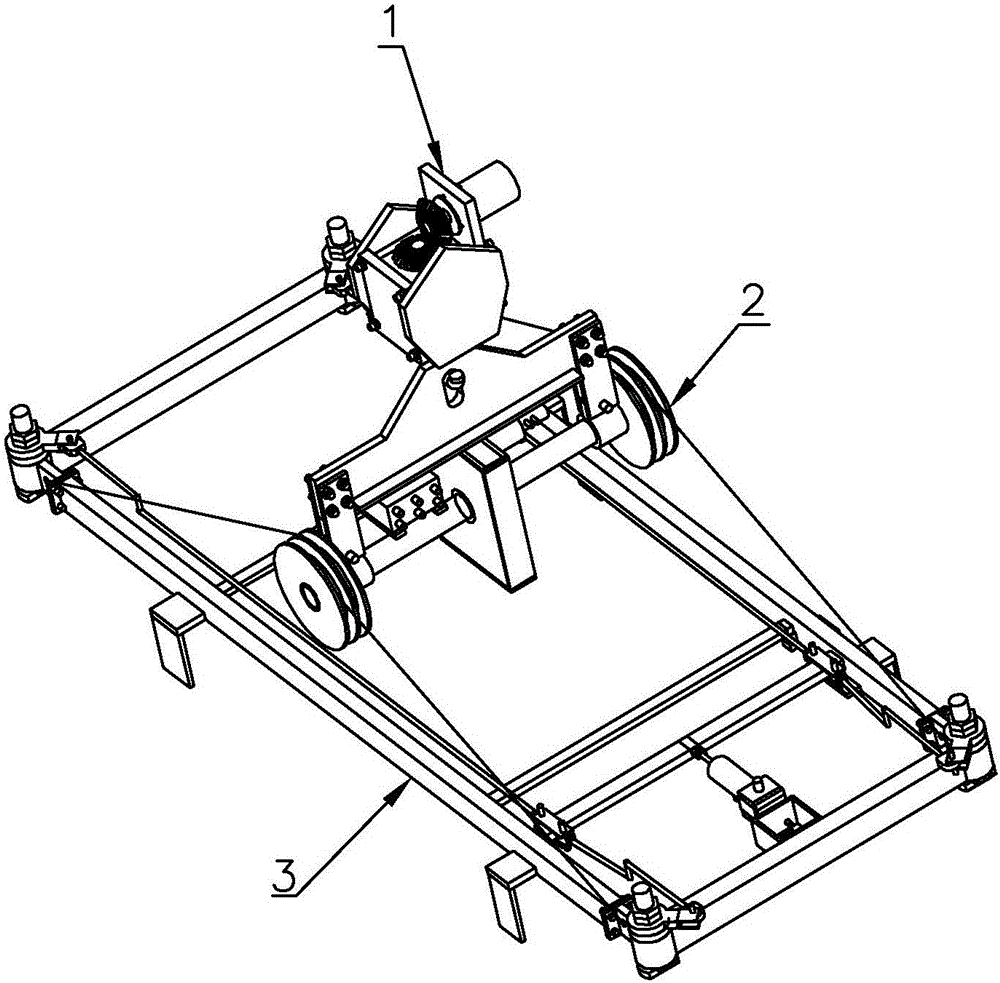

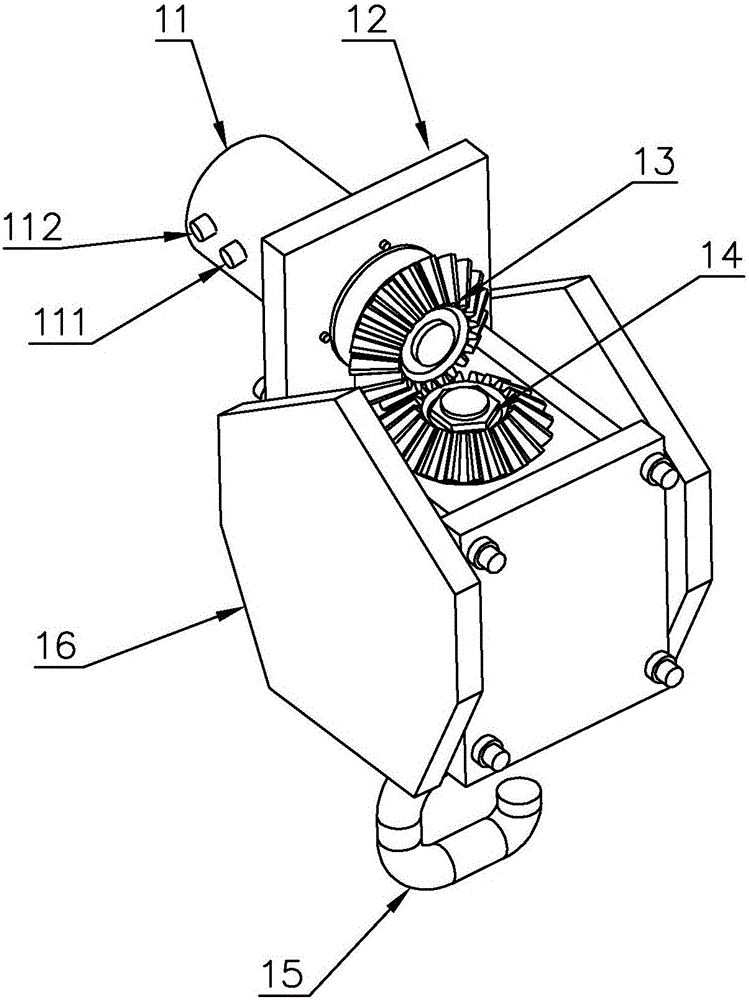

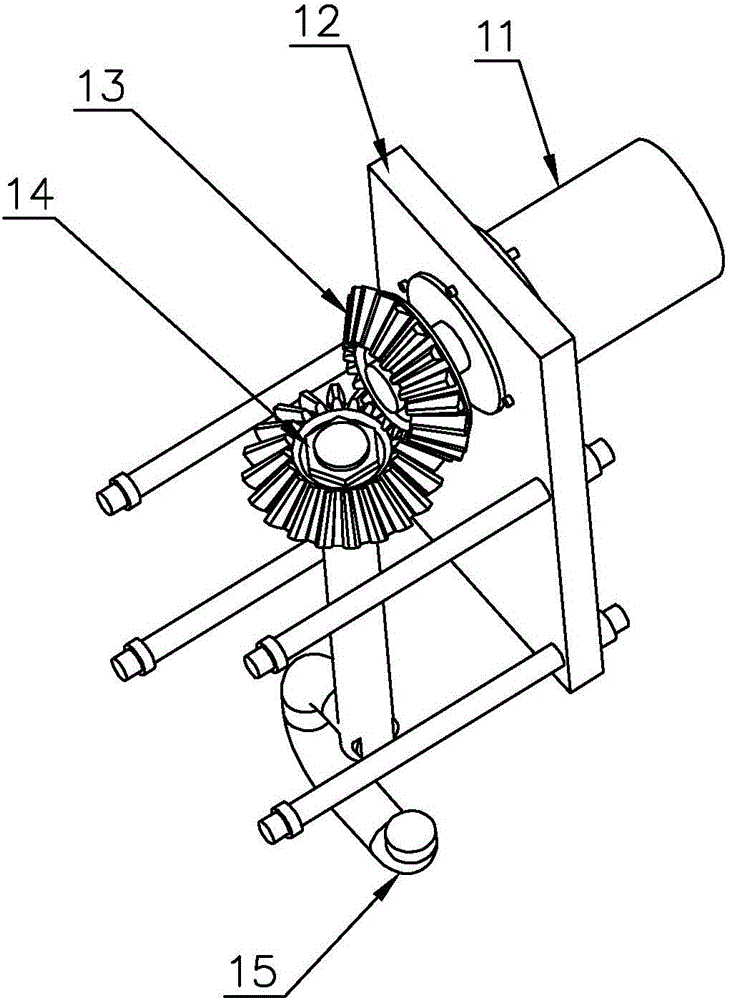

[0036] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-9 , to further specifically describe the technical solution of the present invention.

[0037] A container car crane type angle adjustment device, comprising a self-locking control frame 3, a lifting adjustment mechanism 2, a hook mechanism 1, the hook mechanism 1 is located on a crane, and the hook mechanism 1 includes a hook 15, a hook bracket 16, a hydraulic pressure Motor II11, fixed plate 12, helical gear 13, the hydraulic motor II11 is provided with an oil outlet VII111 and an oil inlet VII112, the shaft end of the hydraulic motor II11 is provided with a helical gear 13, and the helical gear 13 is meshed by gears Link to each other with the helical gear 13 at the top of the leading screw section of the hook 15, the helical gear 13 is provided with a nut 14, the nut 14 is fixed on the leading screw section of the hook 15, and the hook 15 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com