Stacking and transferring device based on omni-directional mobile platform

A technology of omnidirectional movement and platform, applied in the direction of lifting device, etc., can solve the problems of inconvenient turnover, low stacking efficiency, and large working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

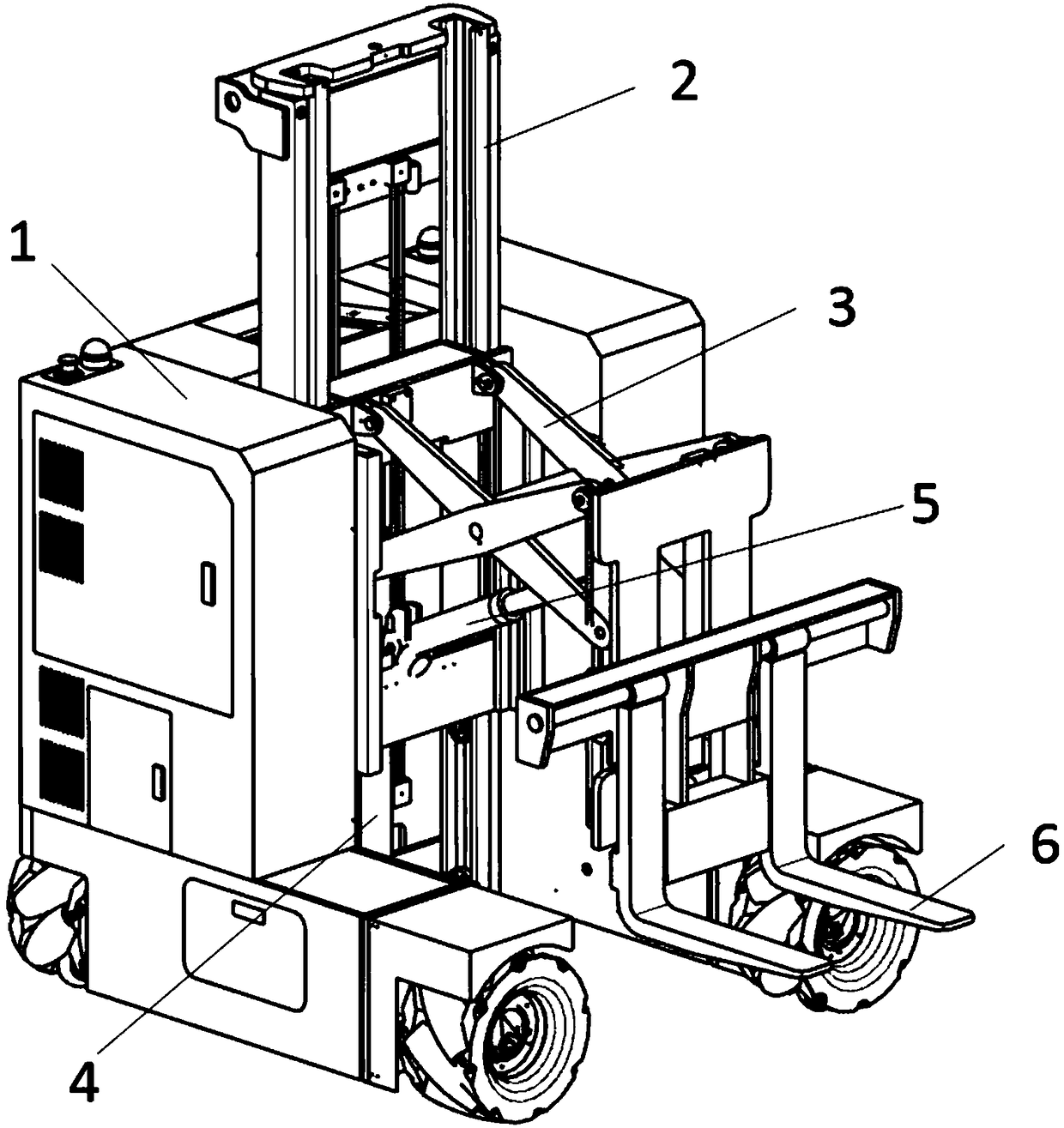

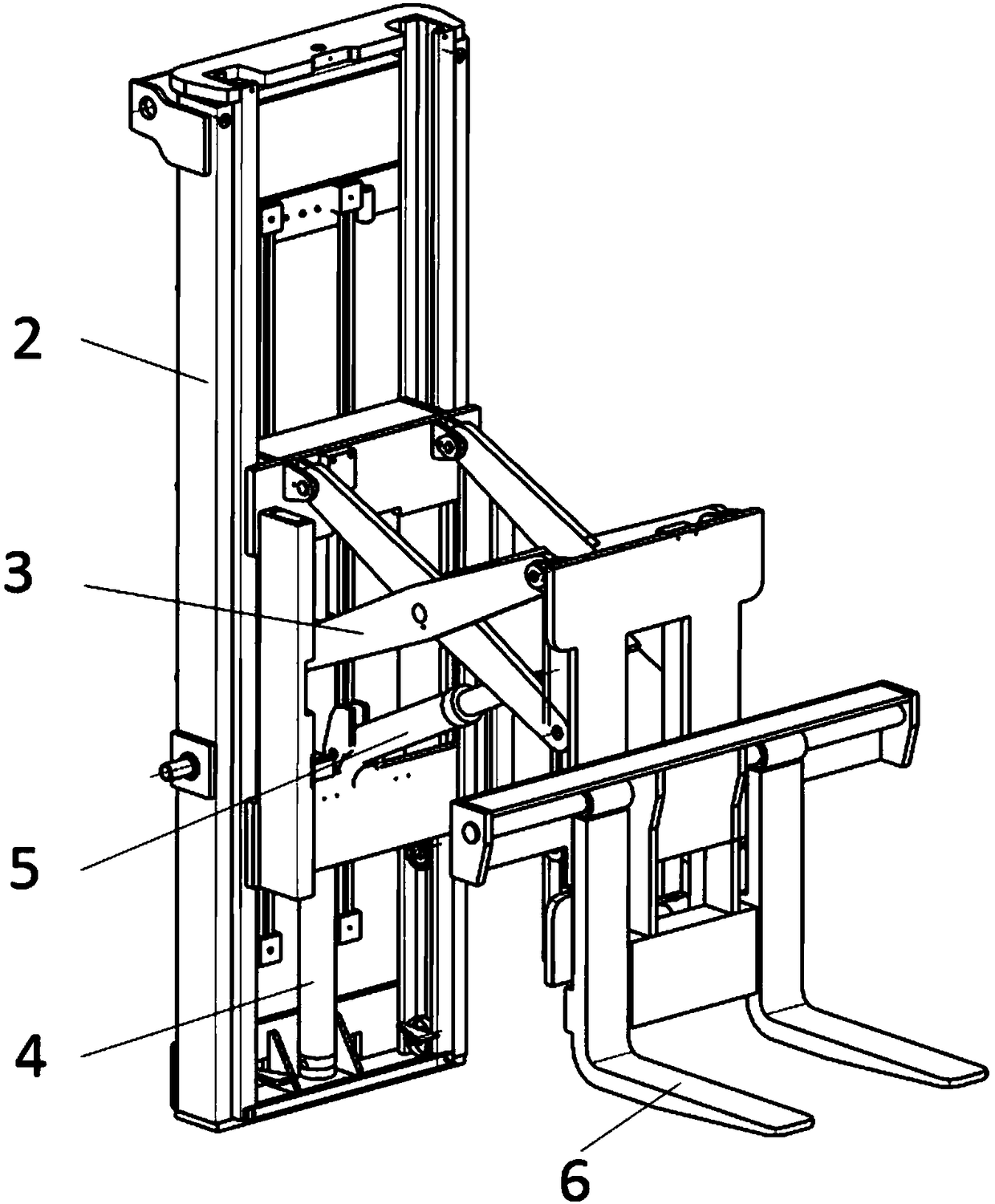

[0021] Such as figure 1 , figure 2 As shown, the stacking transfer equipment of the present invention includes an omnidirectional mobile platform 1 , a lifting frame 2 , a scissor mechanism 3 , a cargo fork 4 , a lifting cylinder 5 , and a forward cylinder 6 . The omnidirectional mobile platform 1 can move vertically, horizontally, obliquely, in situ turning and combined movements, so as to realize omnidirectional movement in all directions in the warehouse.

[0022] The lifting frame 2 is installed on the omnidirectional mobile platform 1 through three hinged shafts, and the two inner sides of the lifting frame 2 are designed with slide grooves.

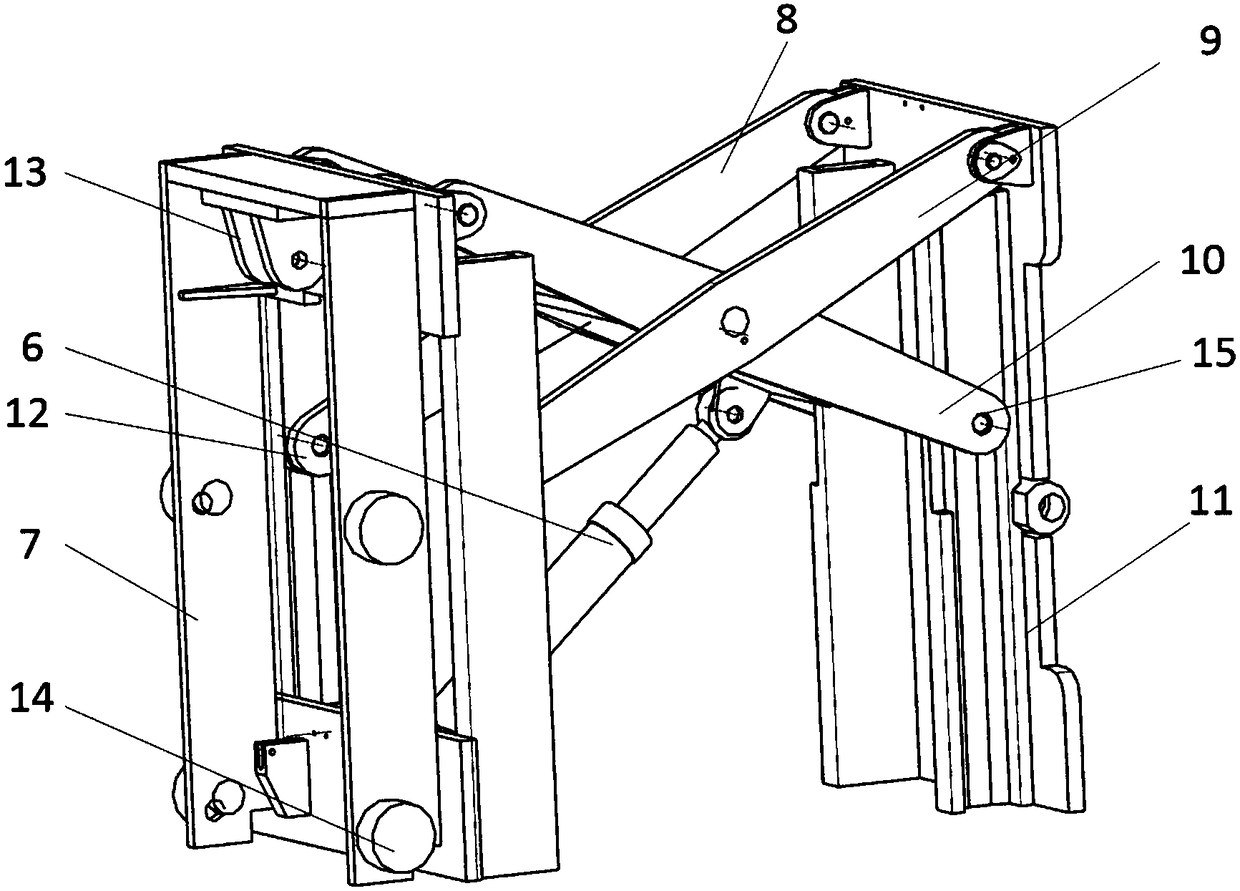

[0023] Such as image 3 As shown, the scissors mechanism 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com