Patents

Literature

197results about How to "Realize pick and place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive rehabilitation nursing bed for paralyzed patient

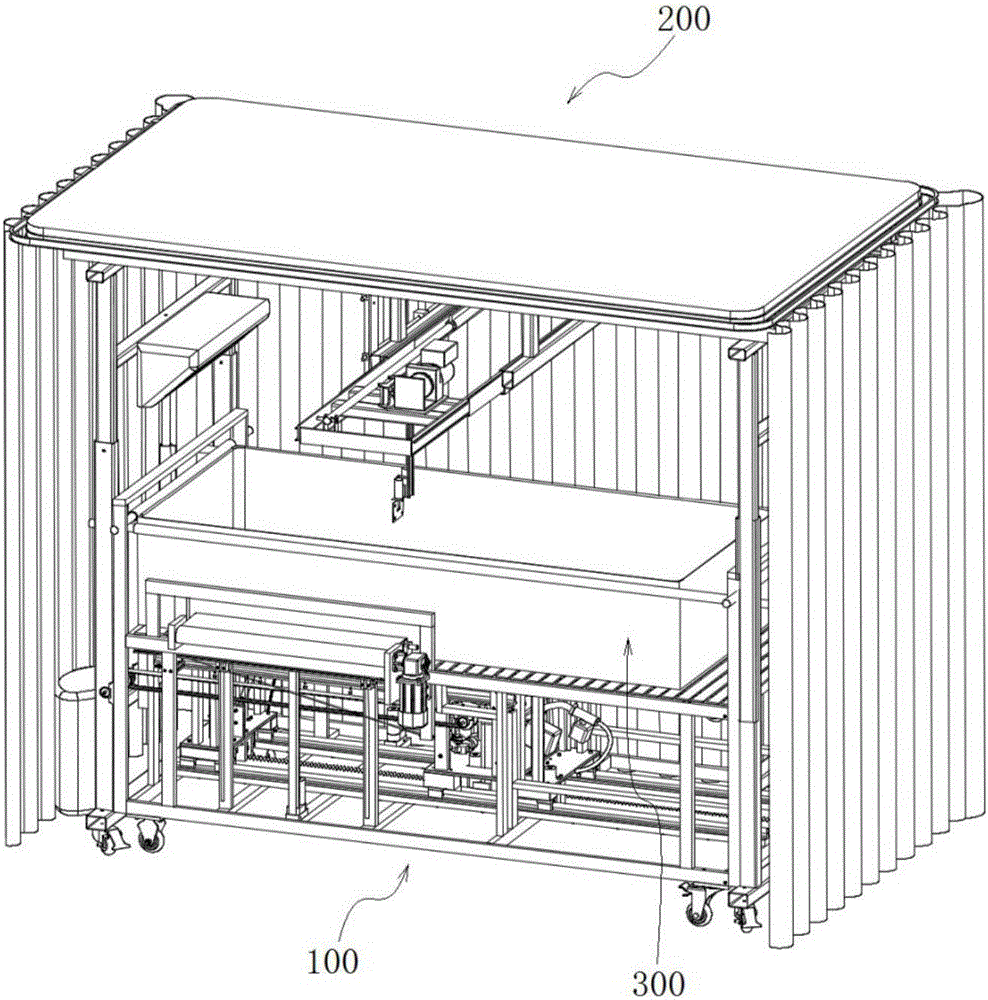

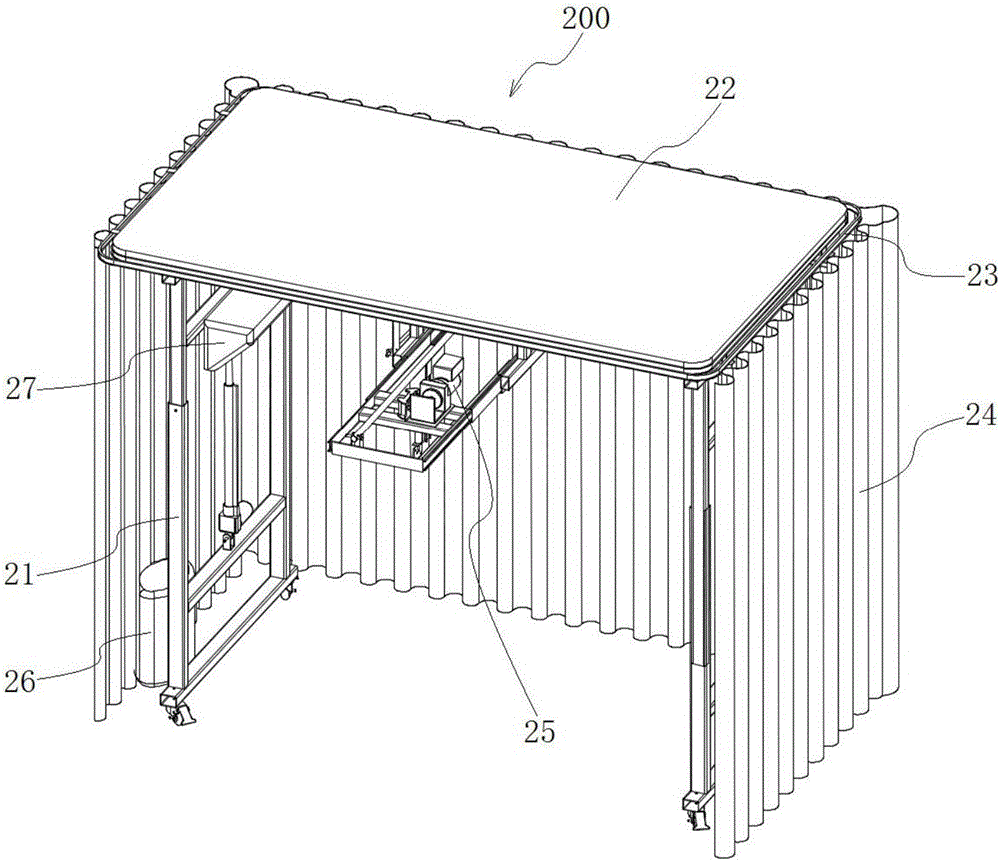

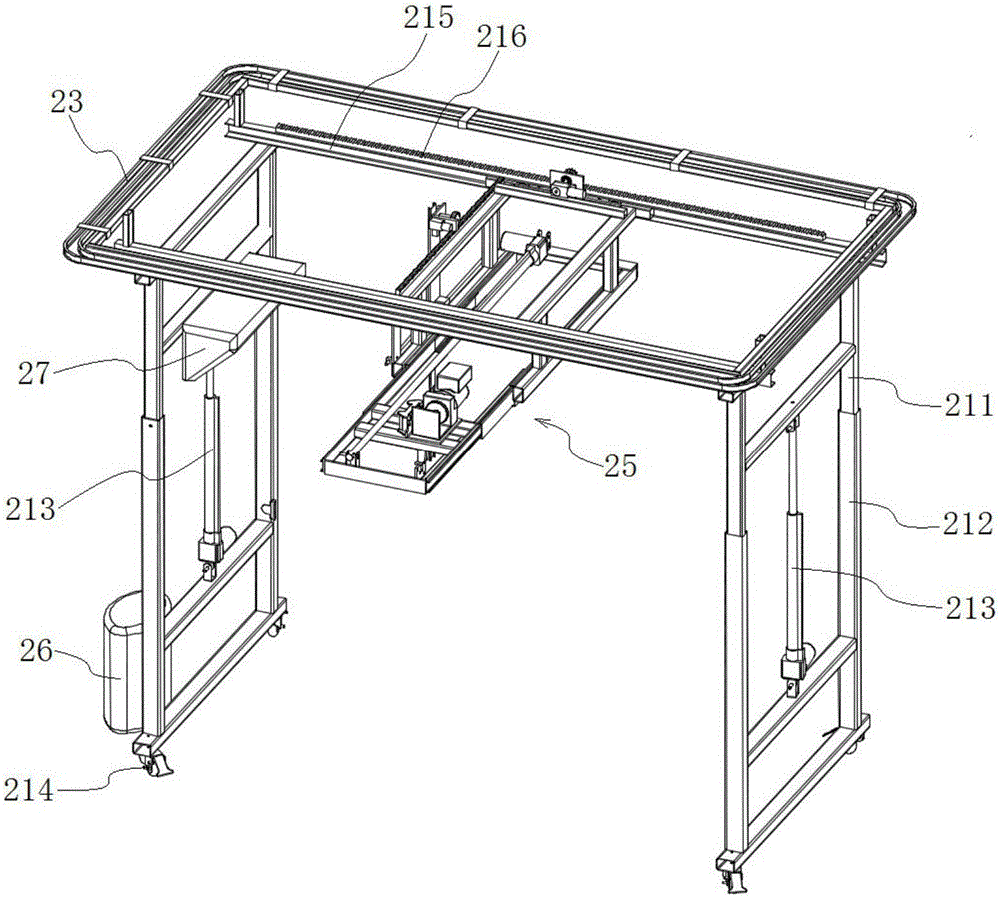

The invention discloses a comprehensive rehabilitation nursing bed for a paralyzed patient, and belongs to the field of nursing beds. The comprehensive rehabilitation nursing bed comprises a bed body and an outer frame arranged on the periphery of the bed body in an enclosing mode; the bed body comprises a bed body frame, a bed board and a defecation device arranged below the bed board; the outer frame comprises a frame body, an insulation roof, a curtain guide rail, a curtain and a hoisting and transfer device arranged on the frame body, the insulation roof is fixed on the top of the frame body, the curtain guide rail is fixed on the periphery of the insulation roof, and the curtain is installed on the curtain guide rail and used for enclosing the outer frame to form an independent space. According to the comprehensive rehabilitation nursing bed for the paralyzed patient, the nursing bed is arranged in a separate thermostatic chamber, back raising, knee bending, body turning, massage, automatic defecating and transferring to or out of the bed for the patient can be achieved, the functions of adjusting the temperature in the thermostatic chamber, bathing the patient on the nursing bed, having meals and providing entertainment exchange for the patient can be achieved, the functions do not interfere with each other in structure, the functions supplement each other, and a comfortable rehabilitation nursing environment with various functions is created for the patient.

Owner:上海稼多医疗器械有限公司

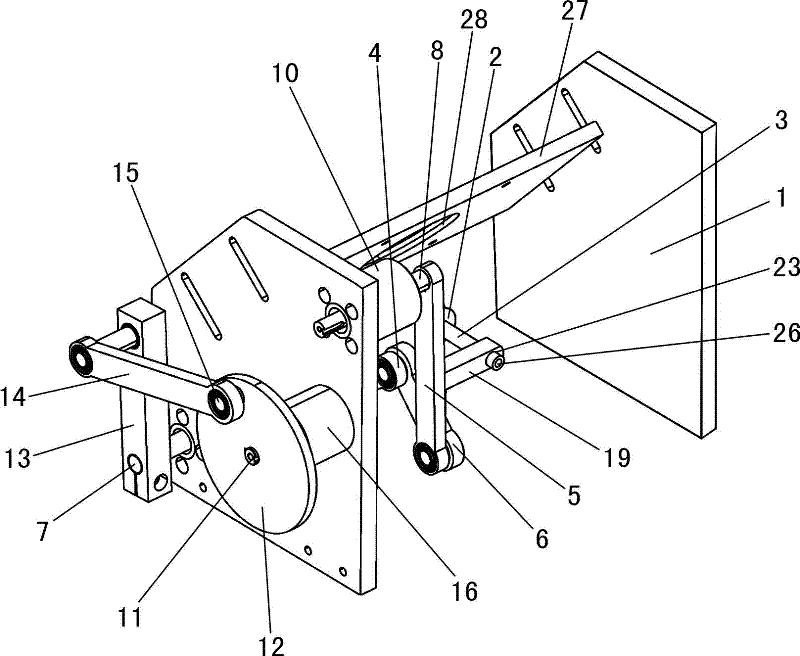

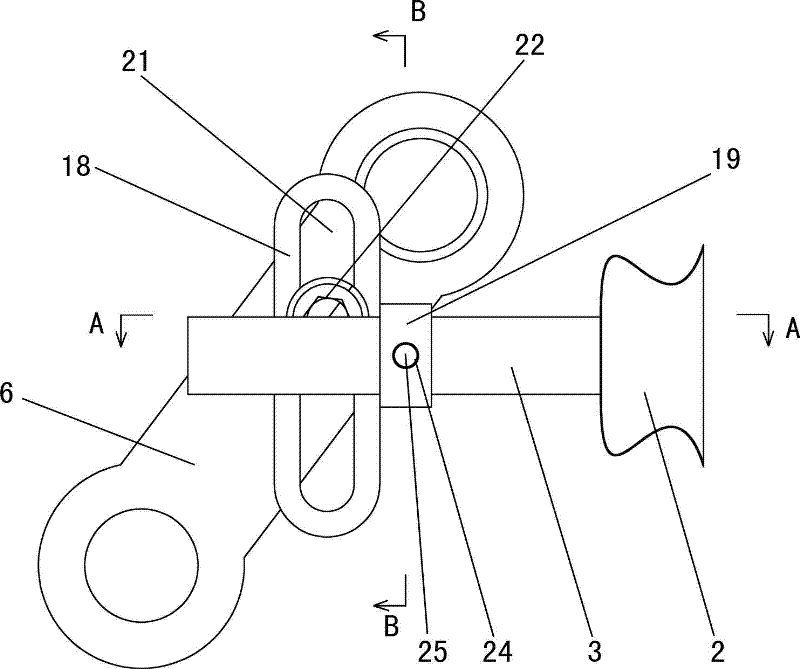

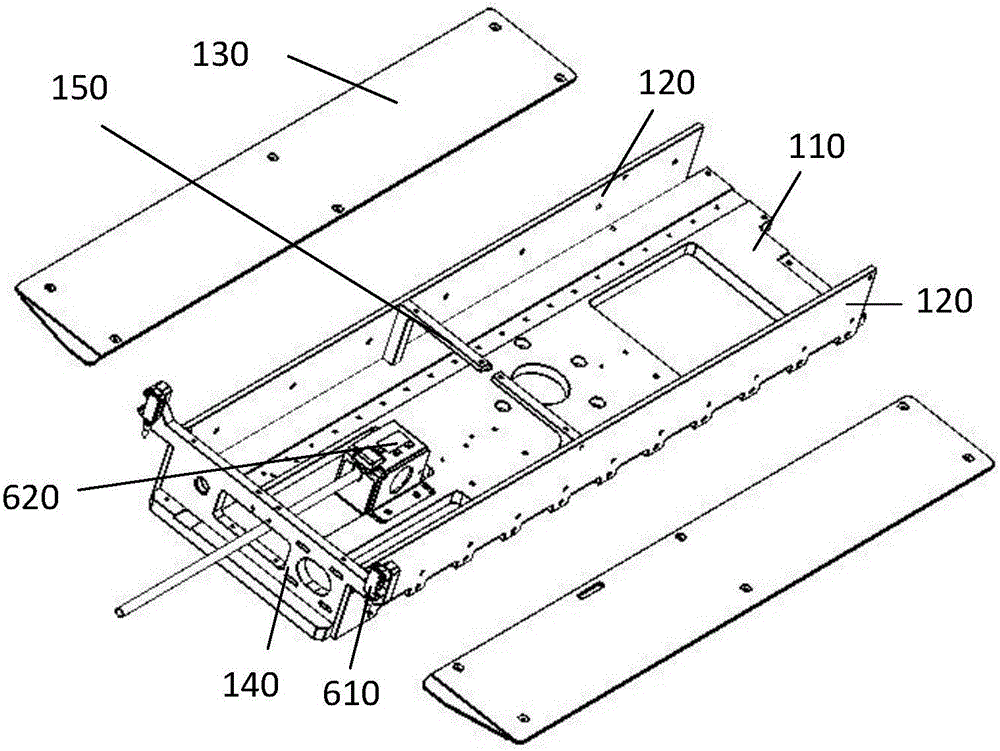

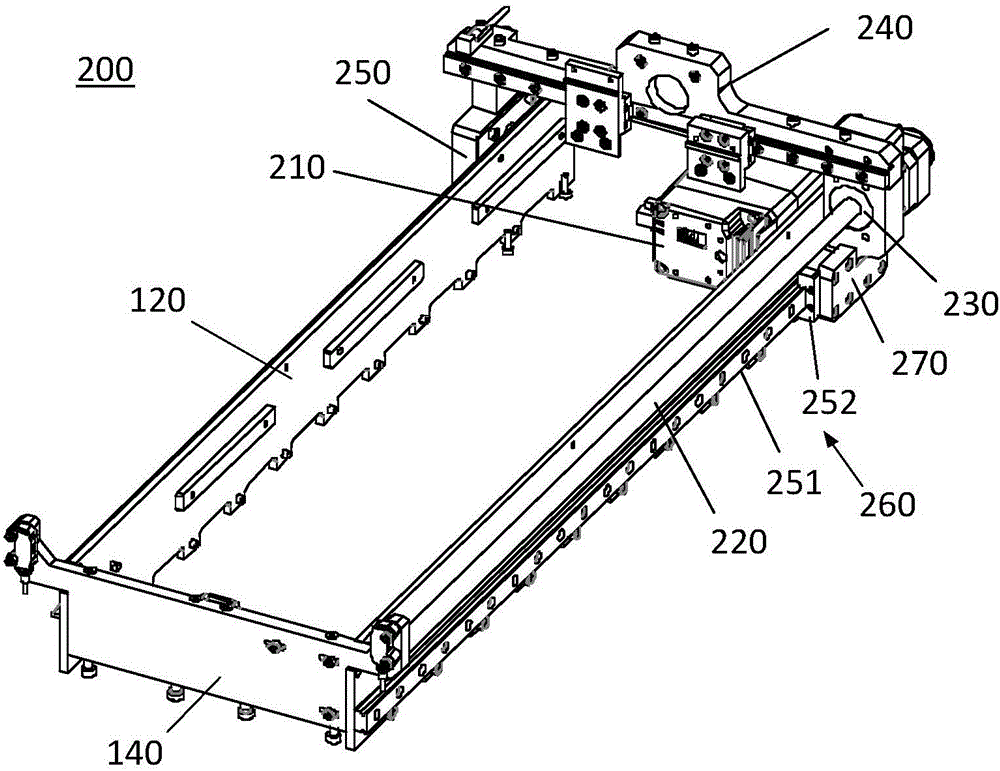

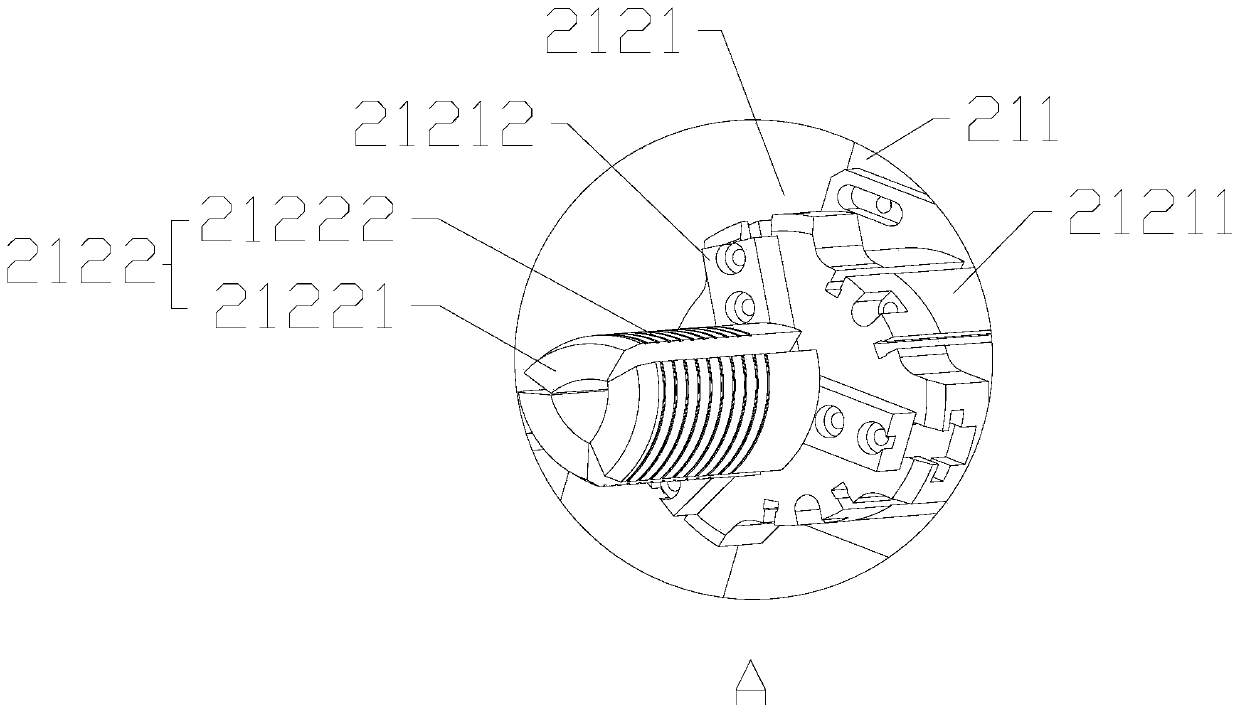

Item taking-placing device

ActiveCN102344041ARealize pick and placeHigh speedConveyor partsArticle separationEngineeringMechanical engineering

Owner:GUANGDONG HUASHENG PLASTIC

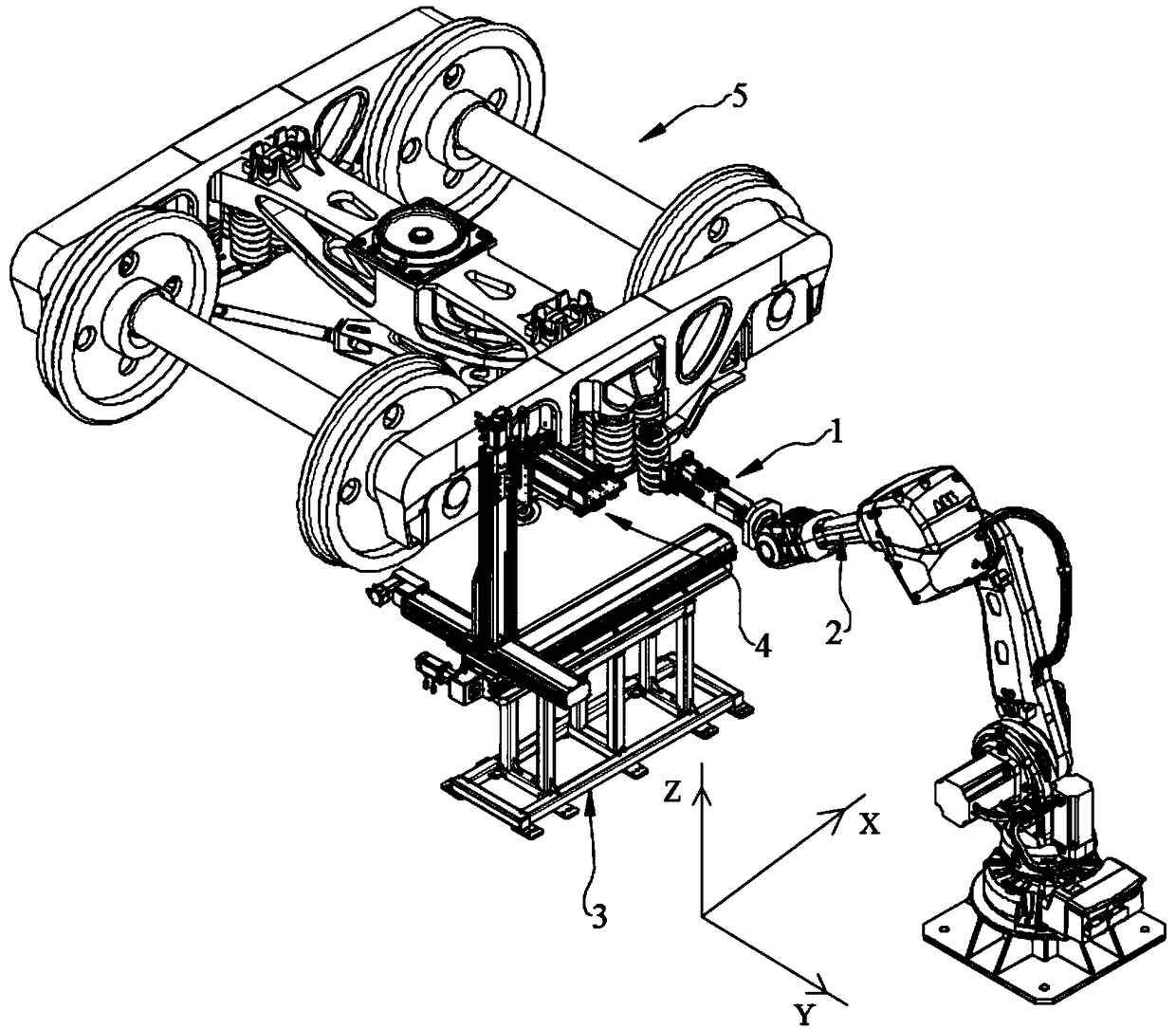

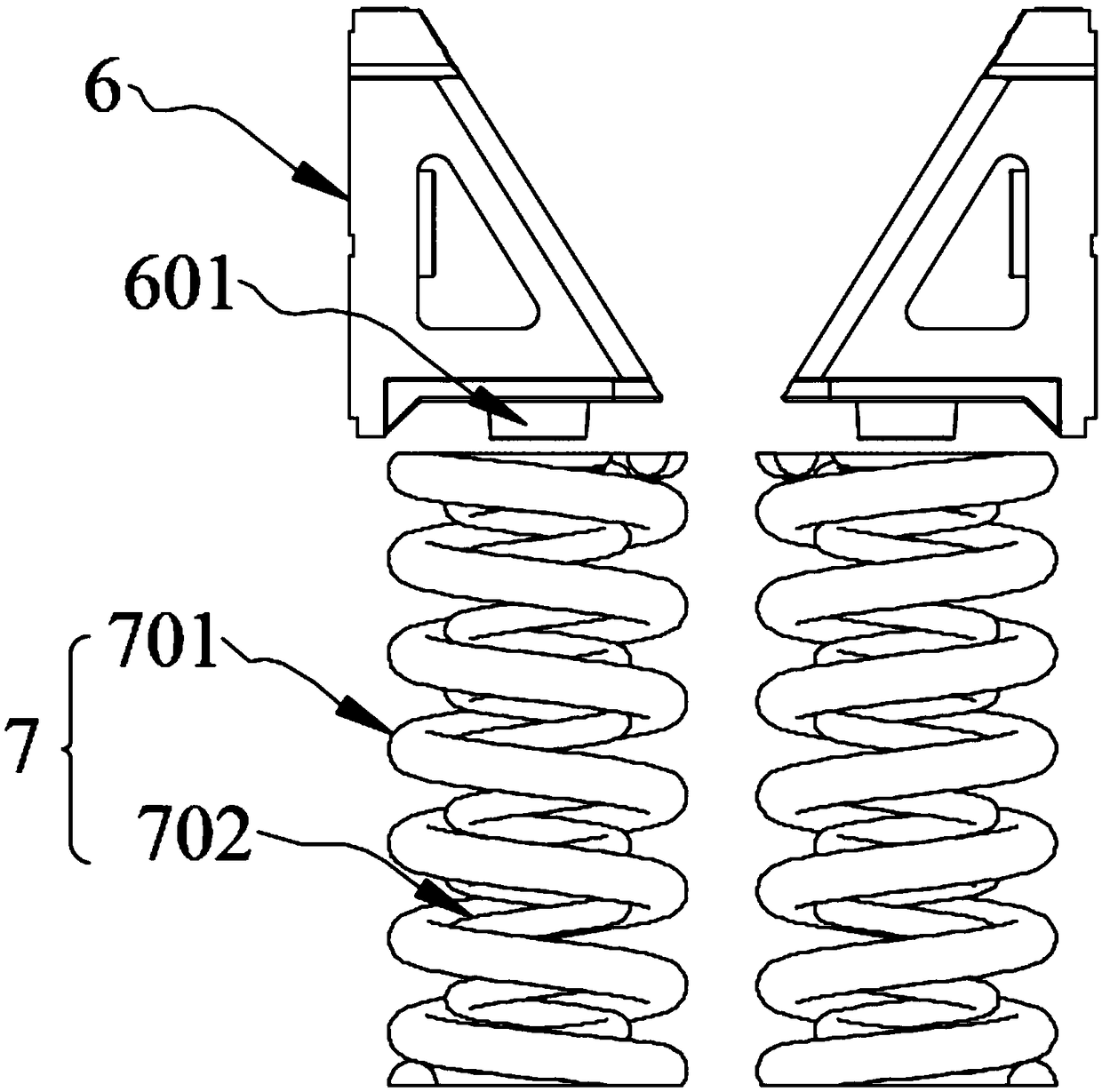

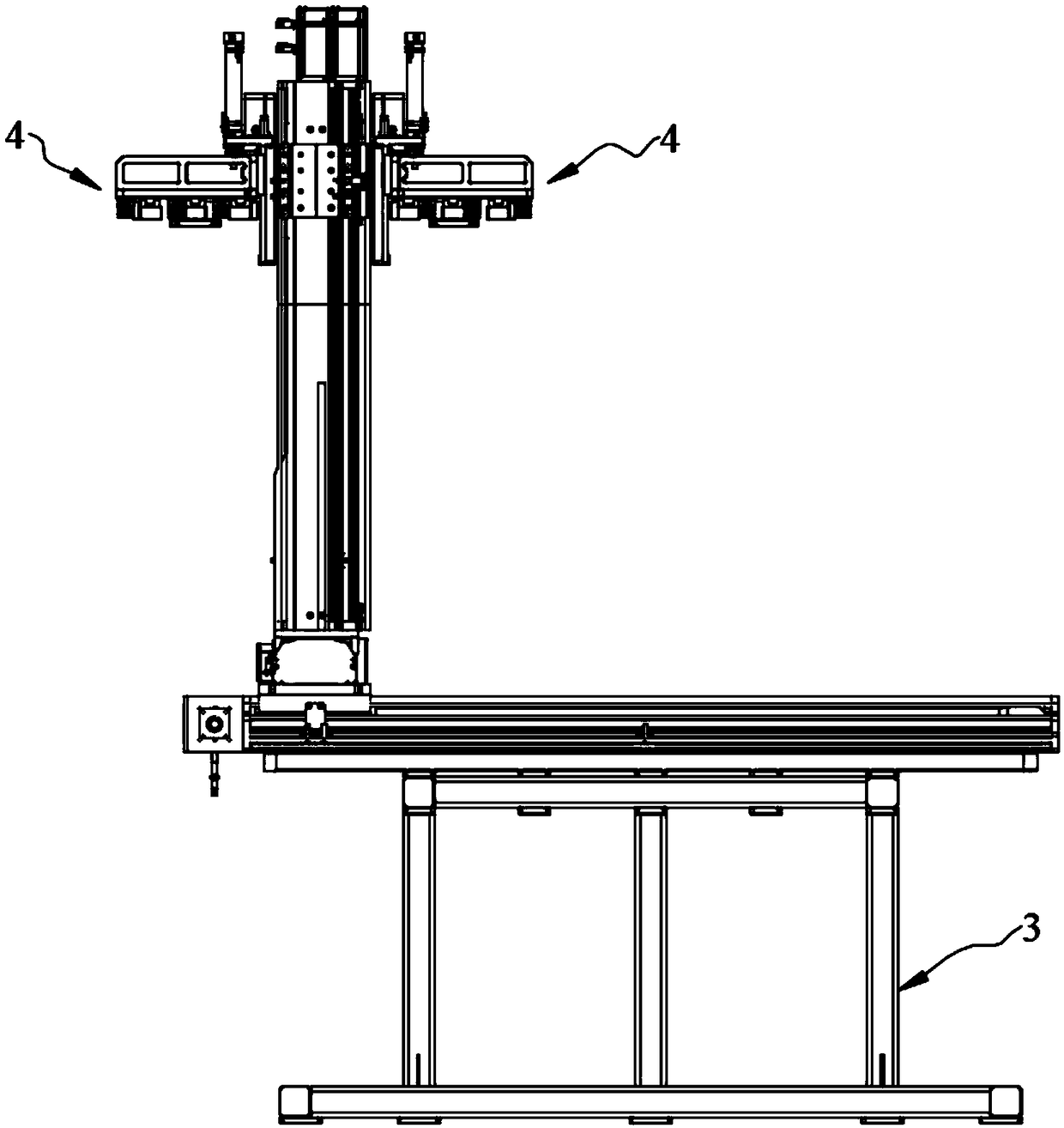

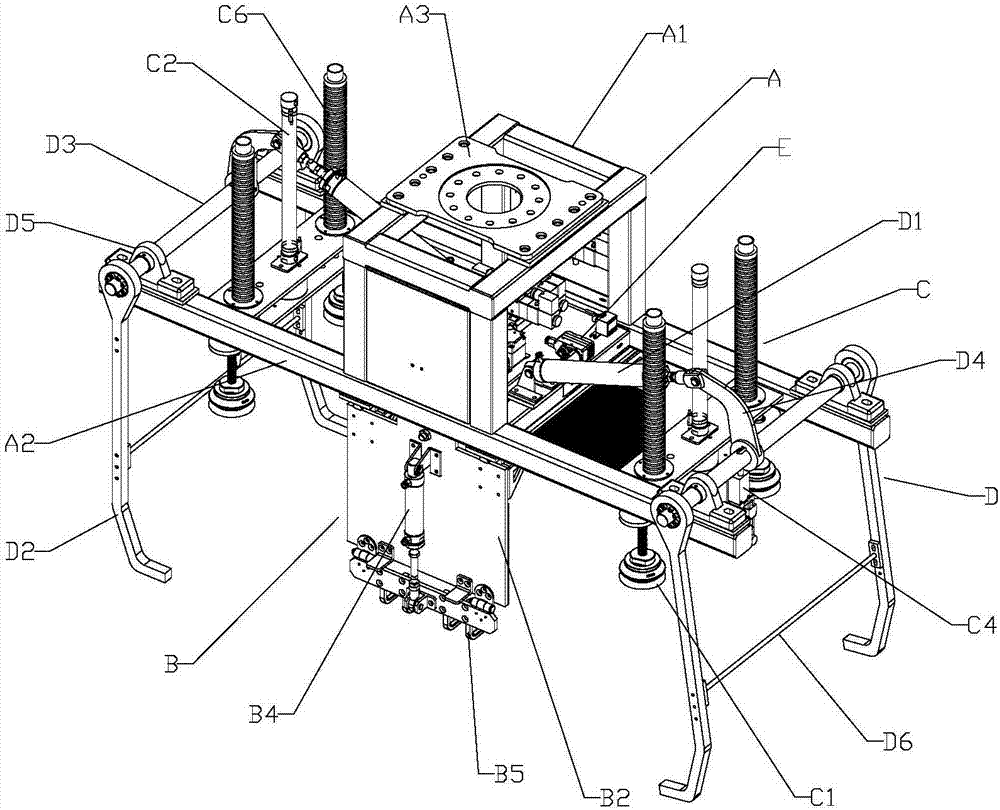

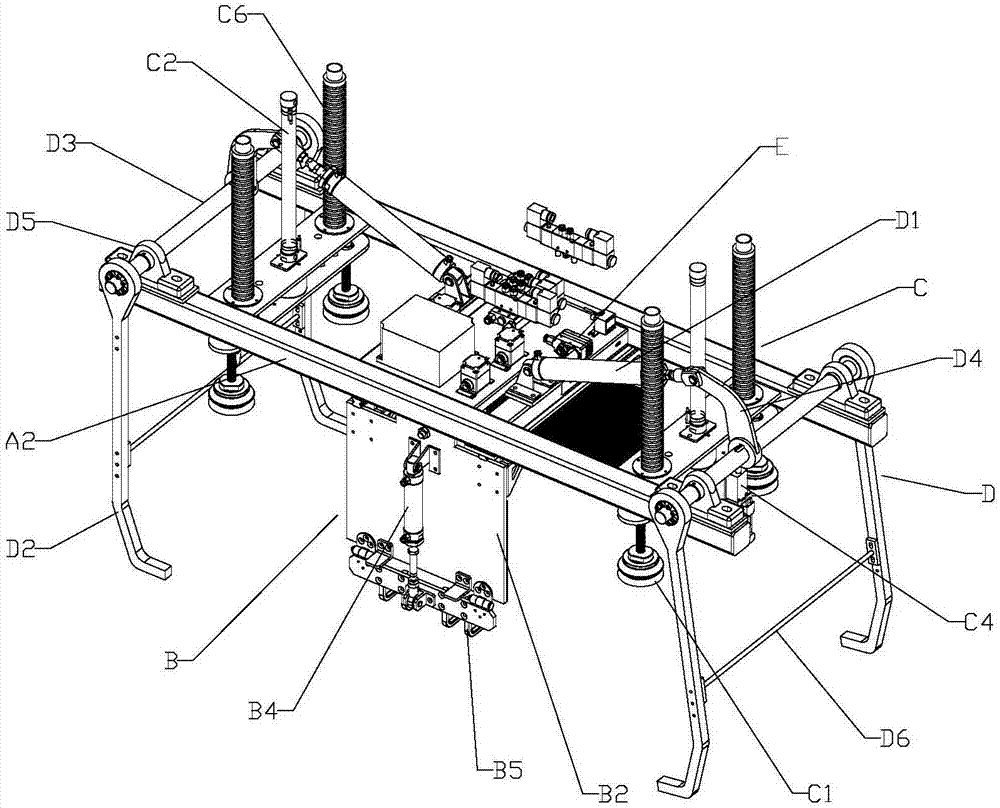

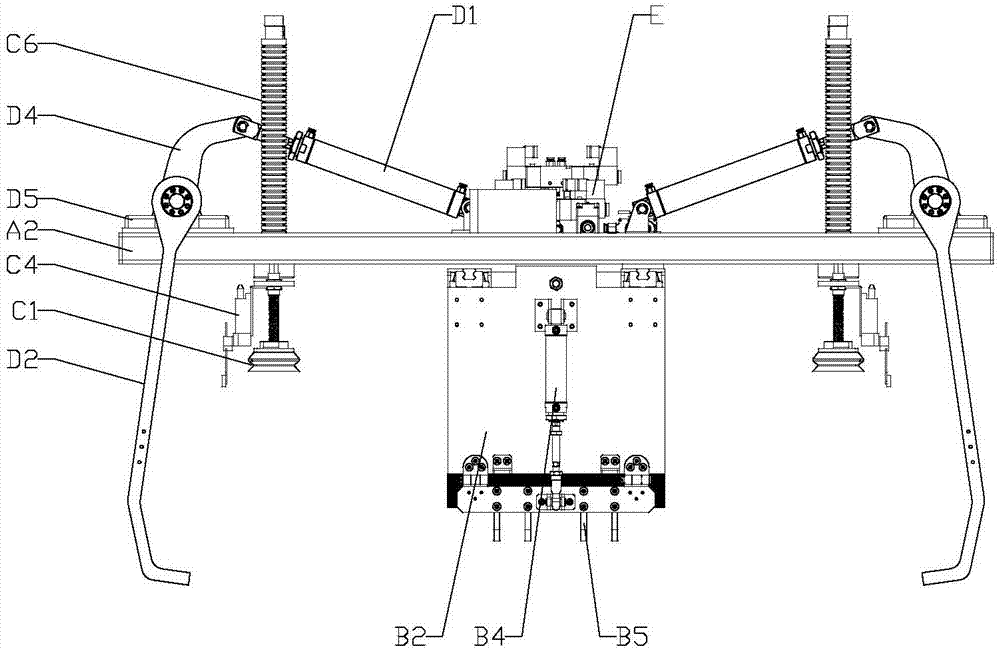

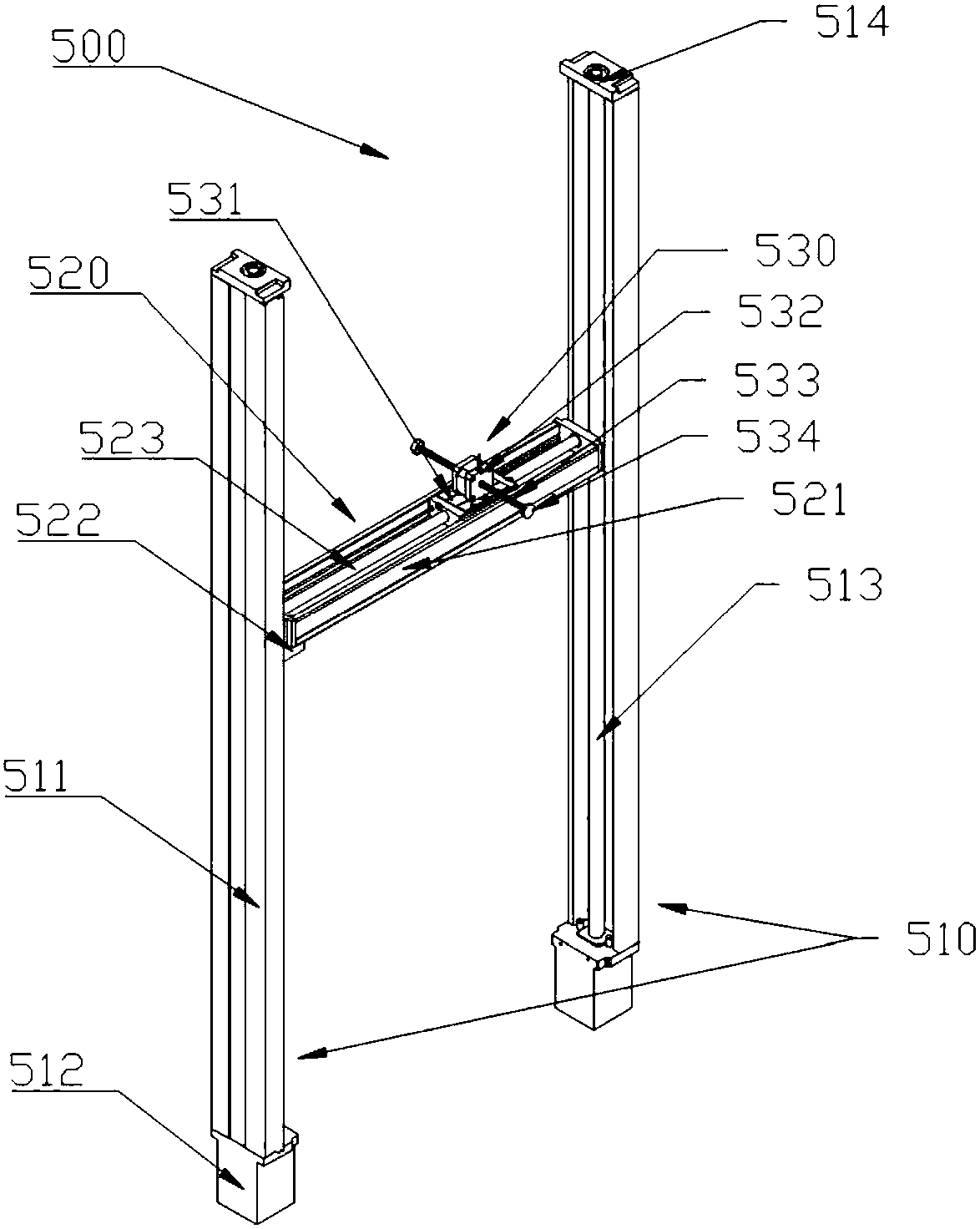

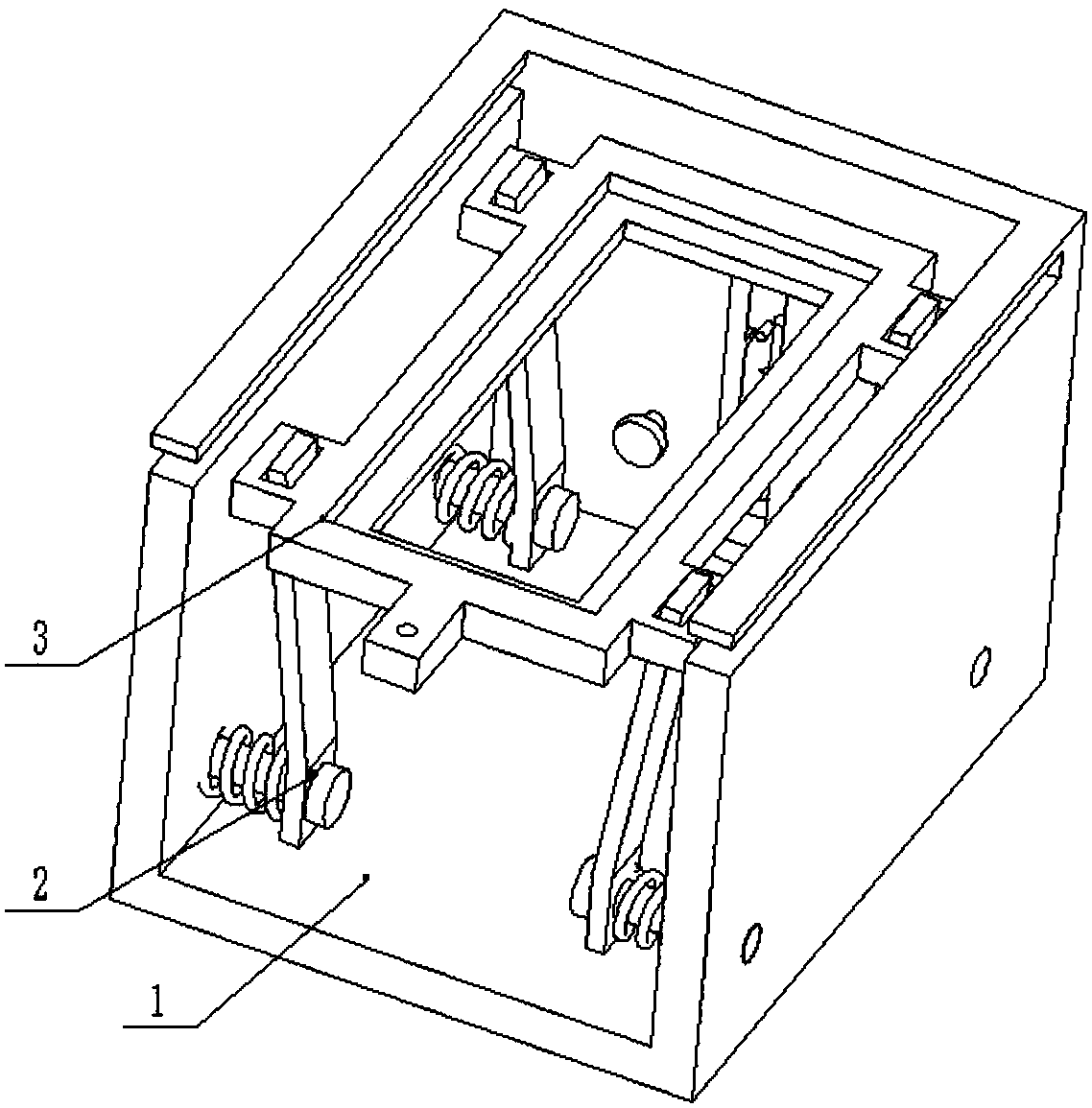

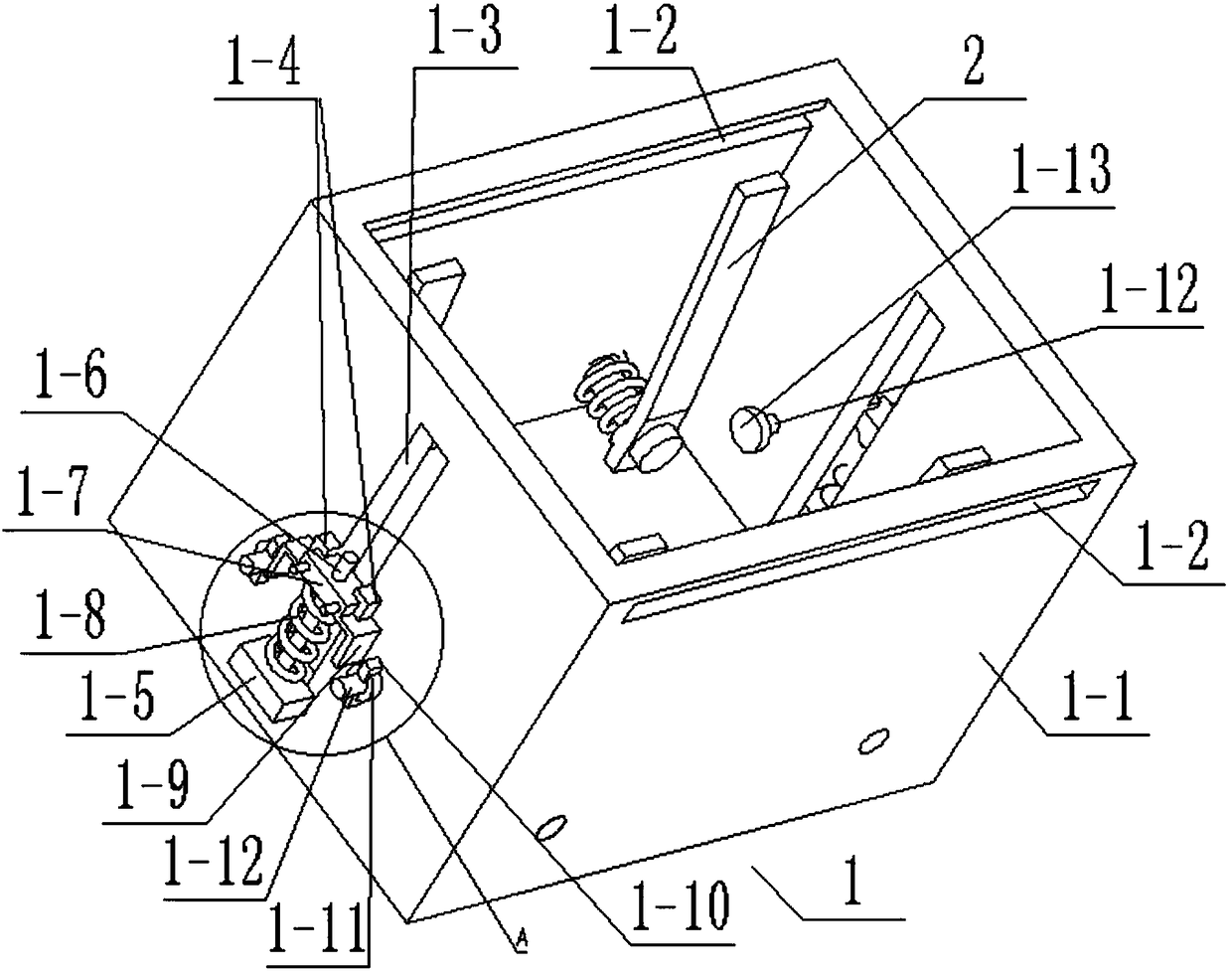

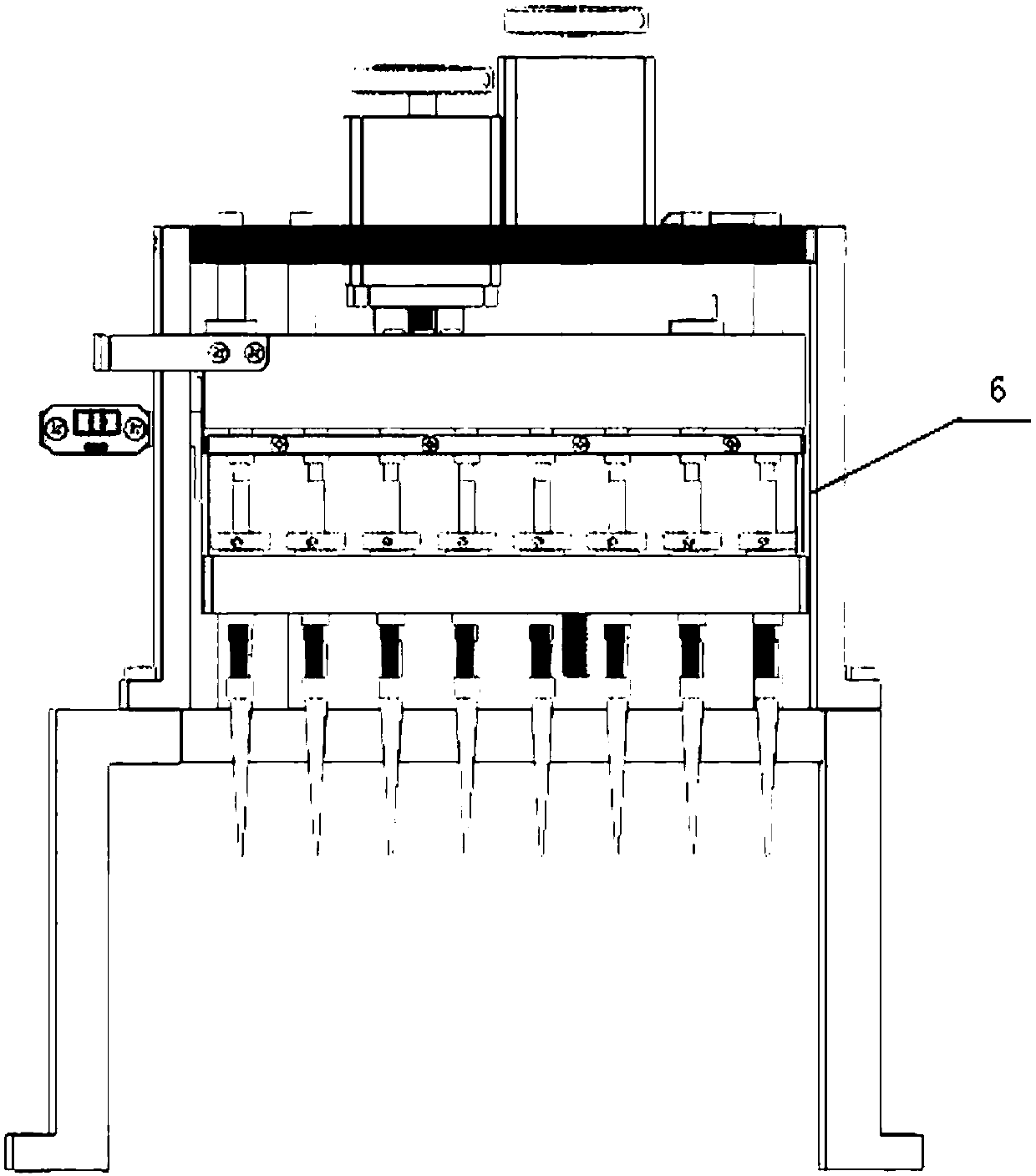

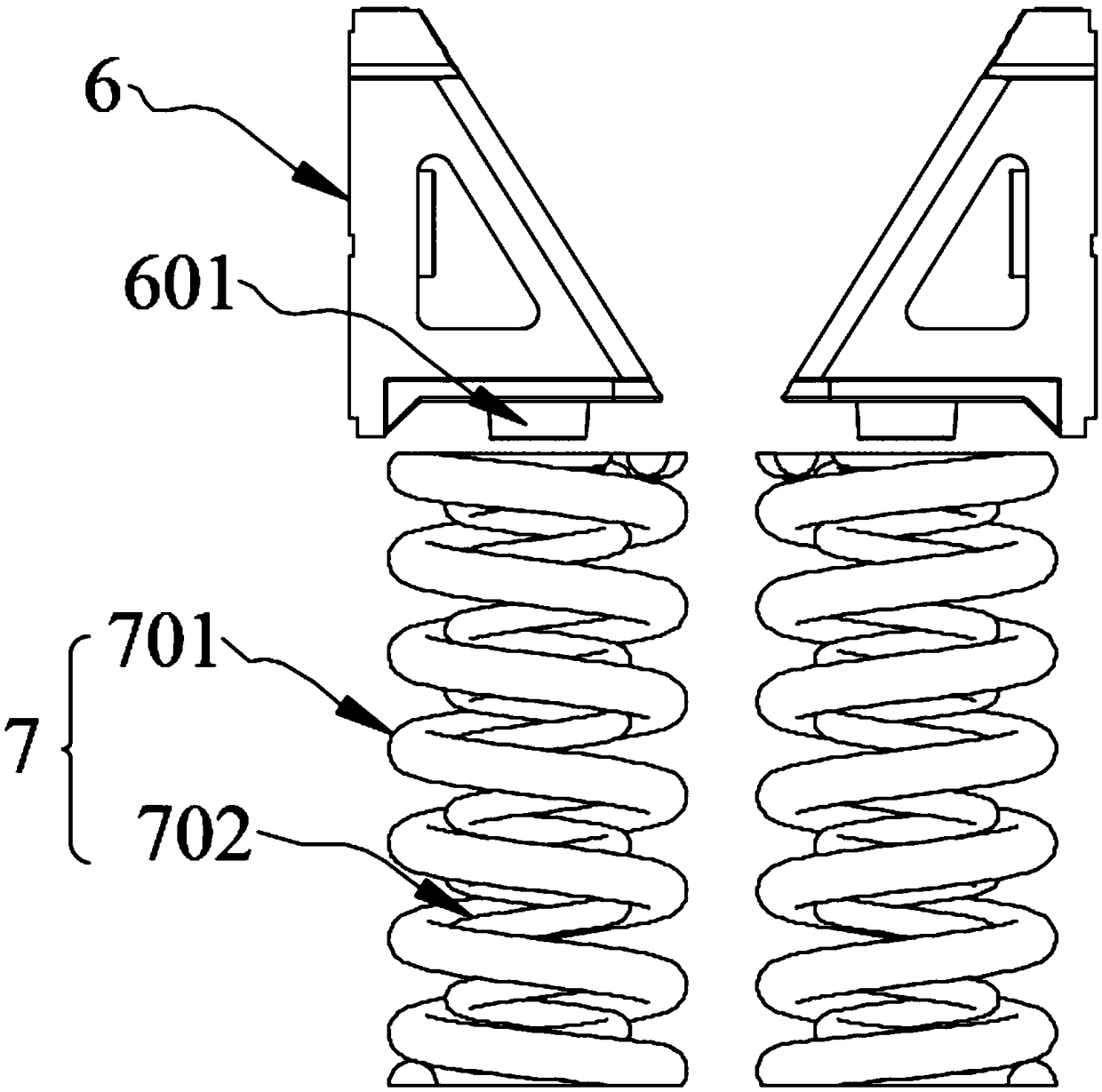

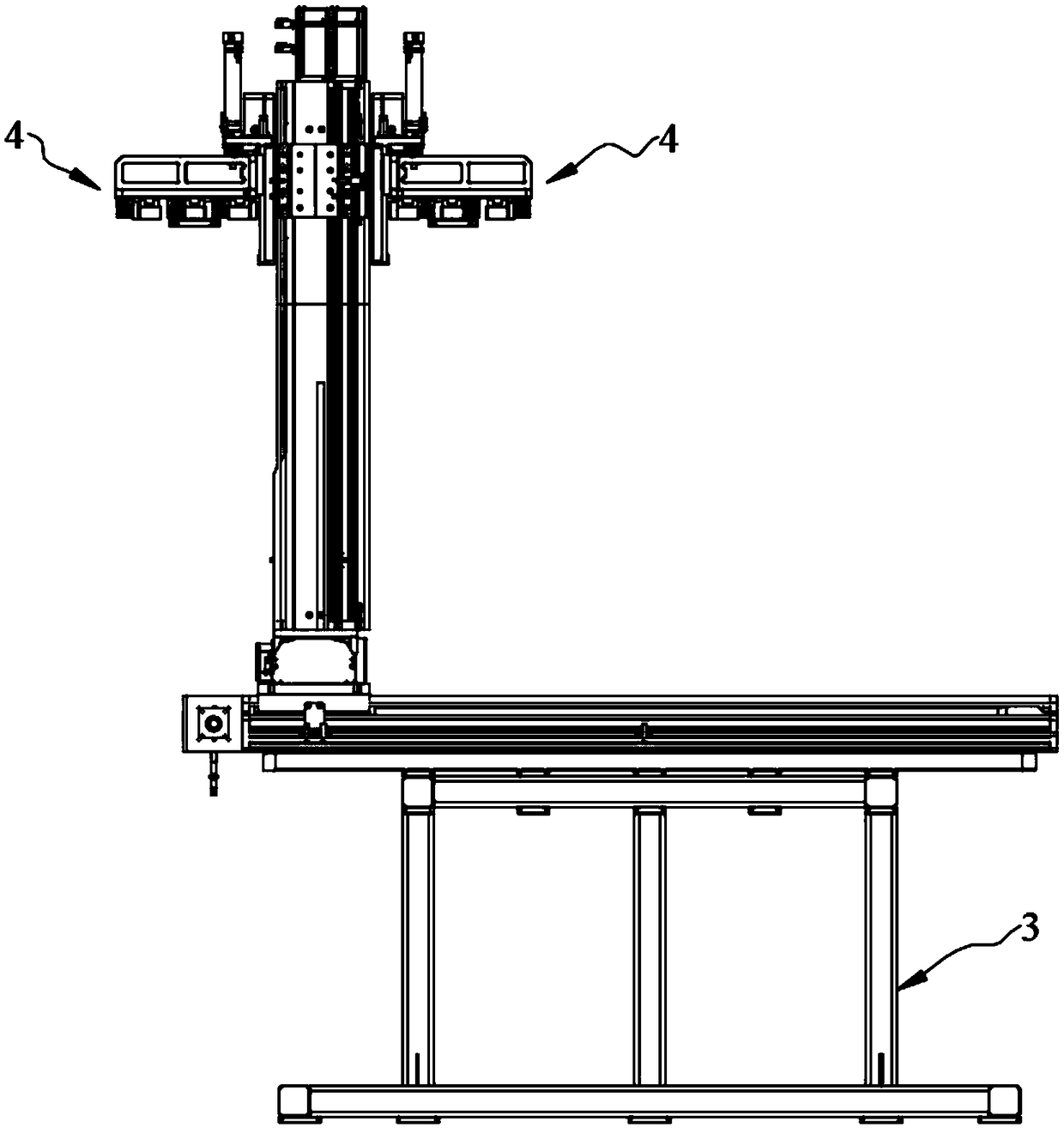

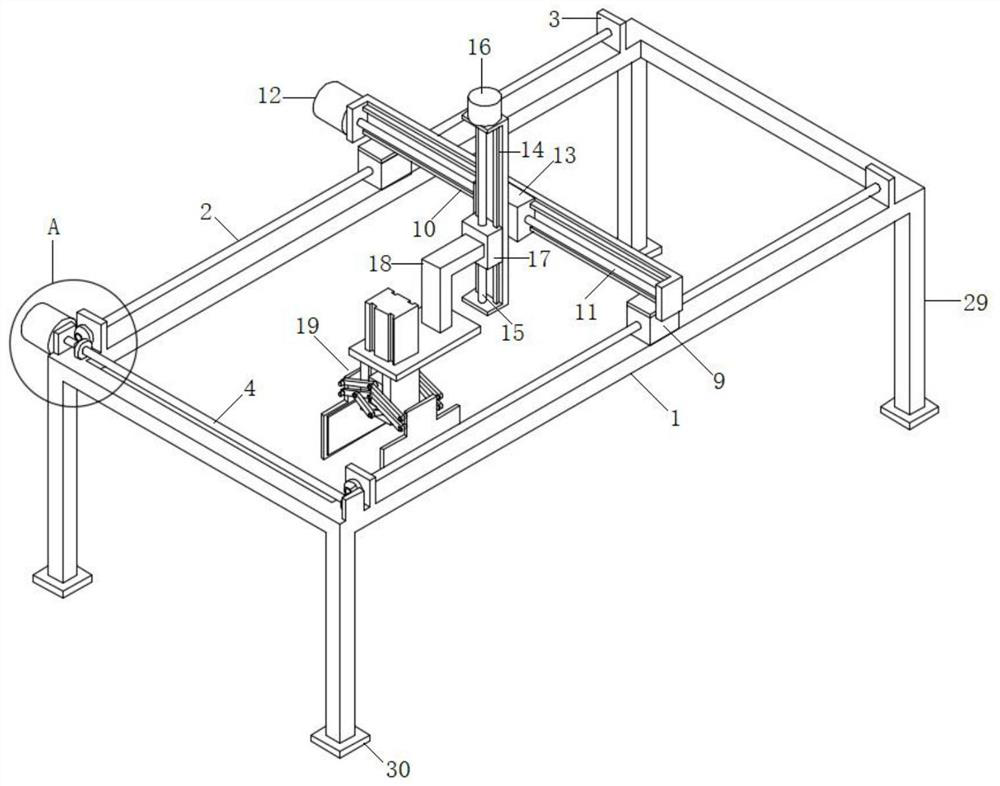

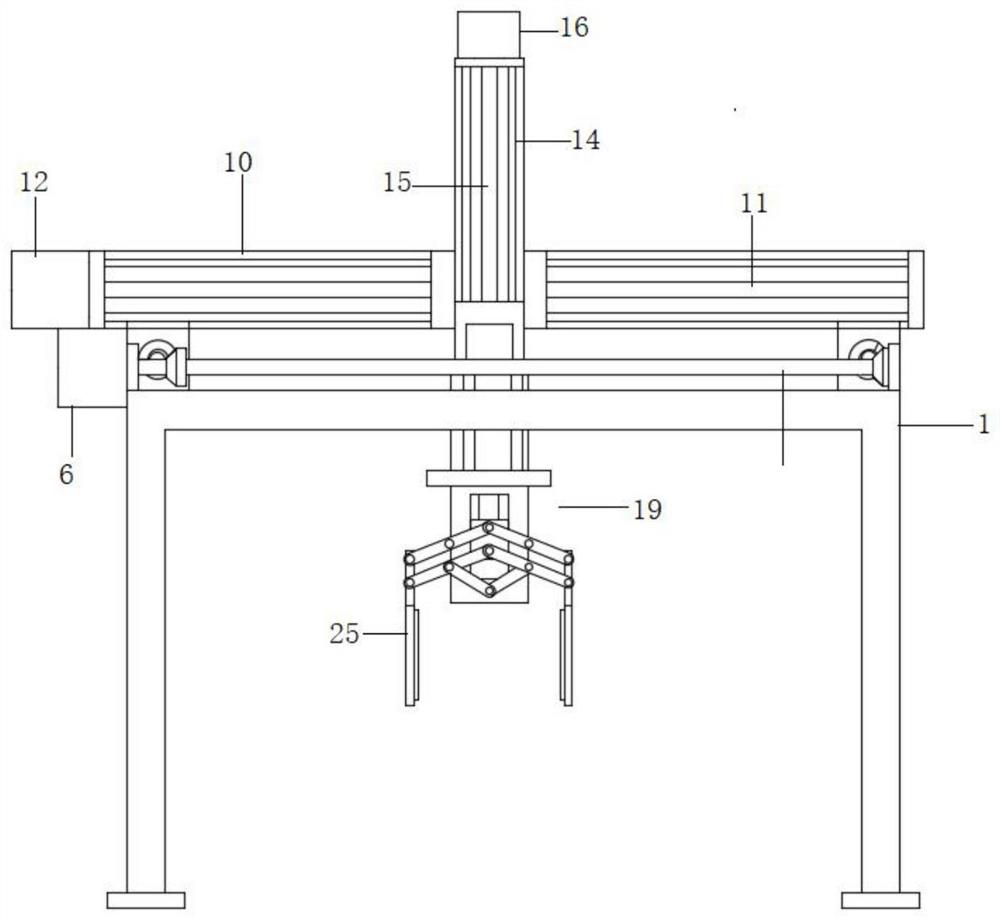

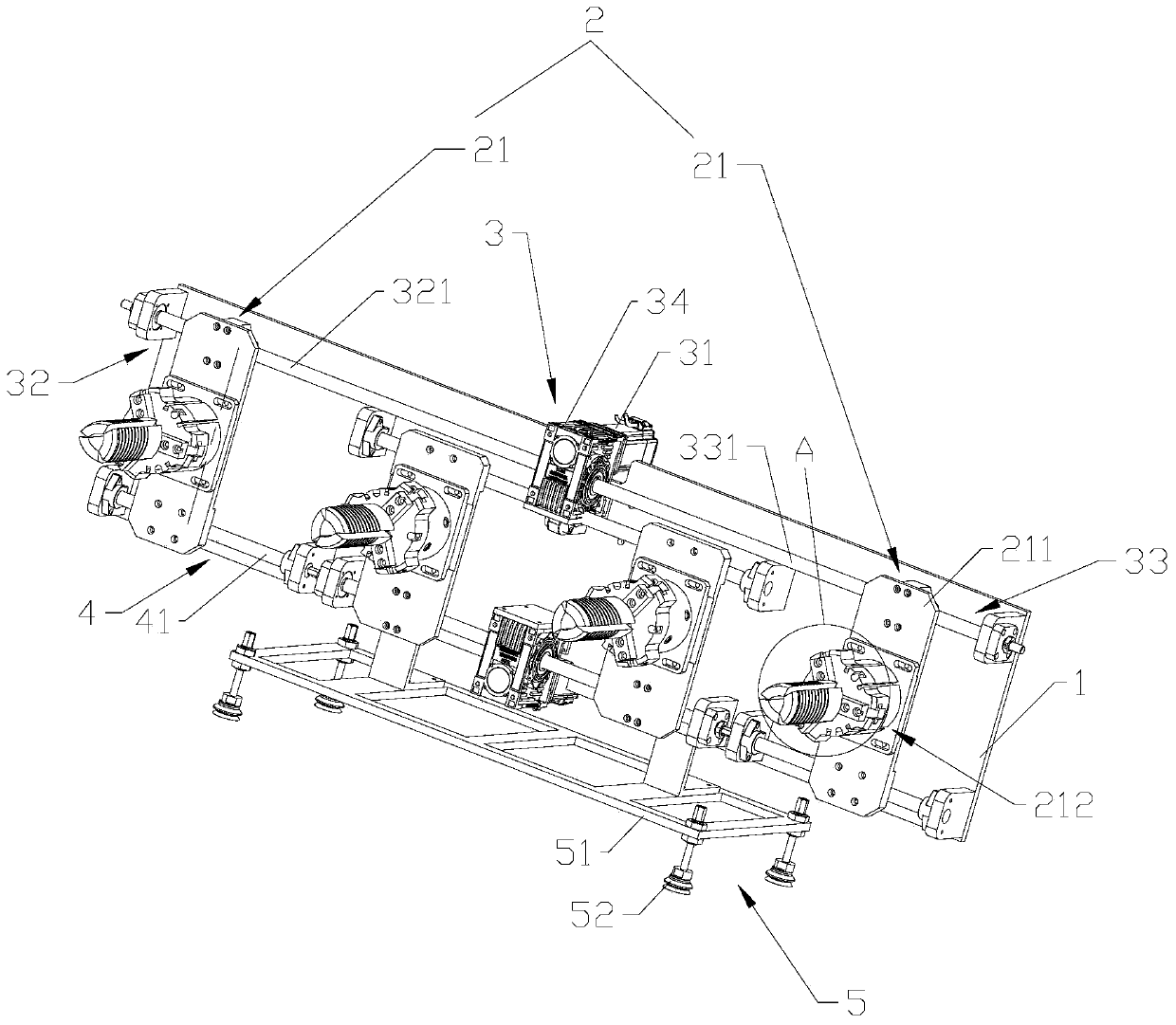

Automatic disassembling system for bogie bearing spring

ActiveCN108637634AAchieve precise positioningImprove disassembly efficiencyMetal working apparatusBogieEngineering

The invention discloses an automatic disassembling system for a bogie bearing spring and belongs to the technical field of bogie disassembling device. The problems that in the existing bogie disassembling process, both a bearing spring and an inclined wedge block need taken out in a manual carrying mode, thus, the labor intensity is high, and the working efficiency is low are solved. The automaticdisassembling system comprises a jacking device and a clamping device; the jacking device comprises a jacking unit used for taking an inclined wedge block out, and the jacking unit is connected witha three-axis cantilever; and the clamping device comprises a clamping head for clamping the bearing spring, and the clamping head is connected with a mechanical arm.

Owner:SOUTHWEST JIAOTONG UNIV

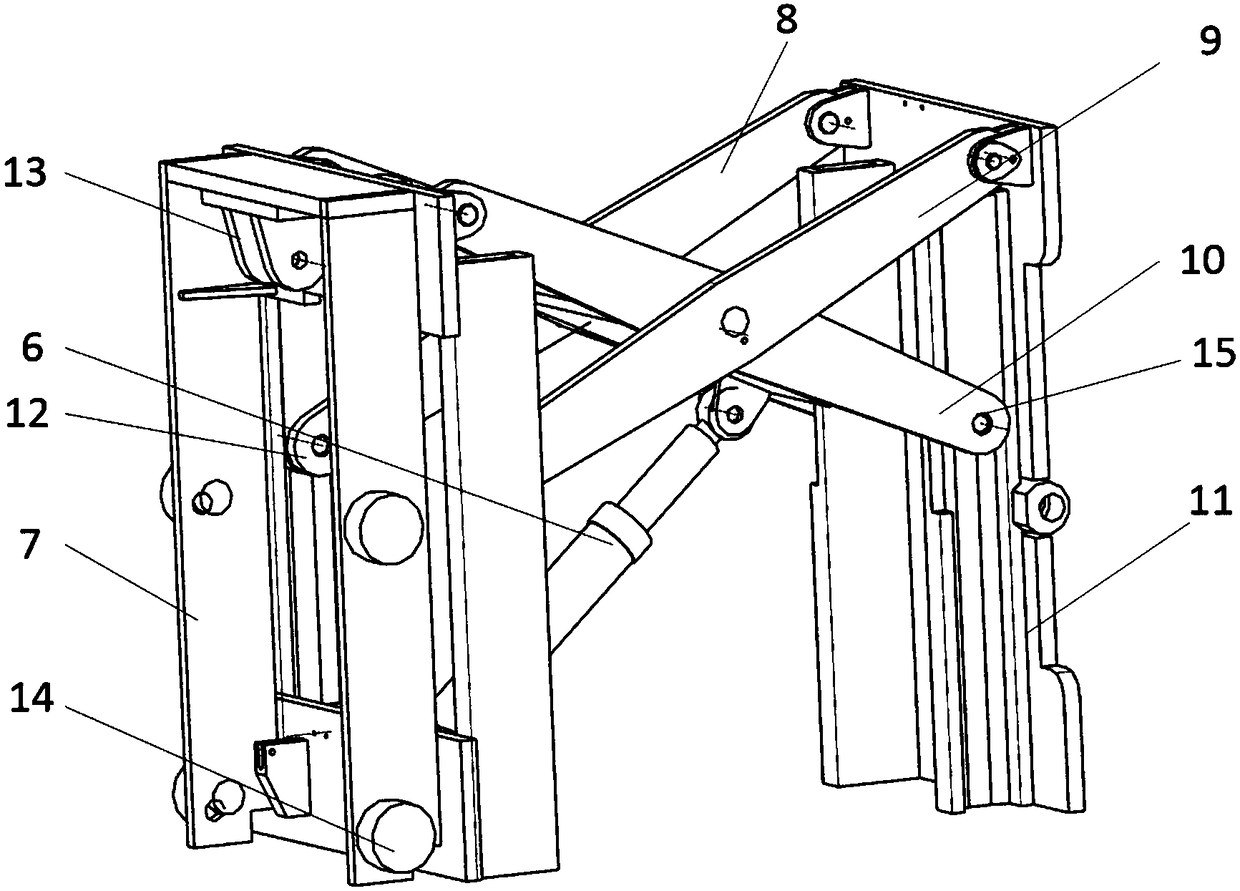

Combined clamp for palletizing and transferring robot

PendingCN107381078AImplement one-time fetchingImprove crawling efficiencyStacking articlesDe-stacking articlesControl engineeringCarton

Provided is a combined clamp for a palletizing and transferring robot. The combined clamp includes a clamp rack, and a carton extracting mechanism, a paperboard extracting mechanism, a cardboard extracting mechanism and a gas-path control module are arranged on the clamp rack; the carton extracting mechanism, the paperboard extracting mechanism and the cardboard extracting mechanism are all independently arranged and do not intervene in one another; the gas-path control module controls the carton extracting mechanism, the paperboard extracting mechanism and the cardboard extracting mechanism separately. According to the combined clamp for the palletizing and transferring robot, by integrating the carton extracting mechanism, the paperboard extracting mechanism and the cardboard extracting mechanism onto a clamp, the clamp is capable of synchronously clamping a carton, a paper board and a cardboard, one-time clamping is achieved, and the efficiency of clamping is greatly improved; the combined clamp works in a fully-automatic mode, the effect and efficiency of palletizing are greatly improved, the performance is reliable, the operation is convenient, and the labor amount is effectively reduced.

Owner:GUANGDONG LXD ROBOTICS CO LTD

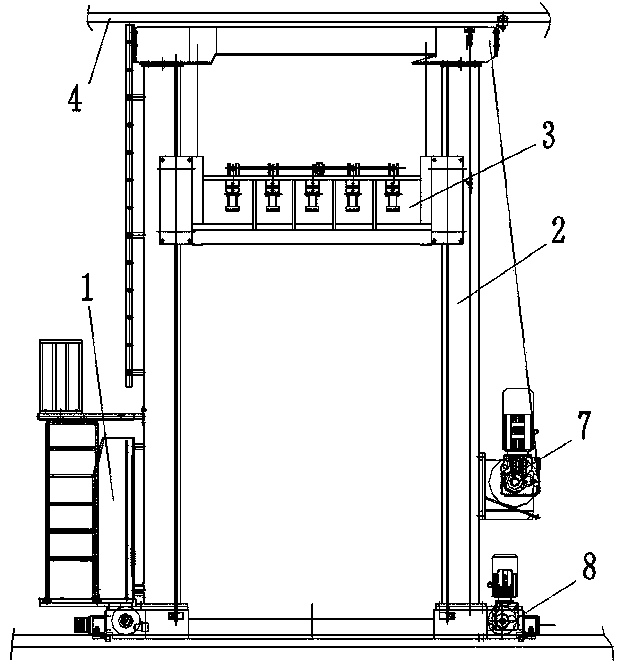

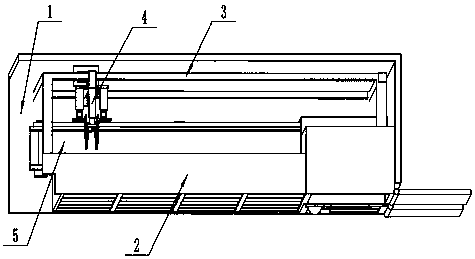

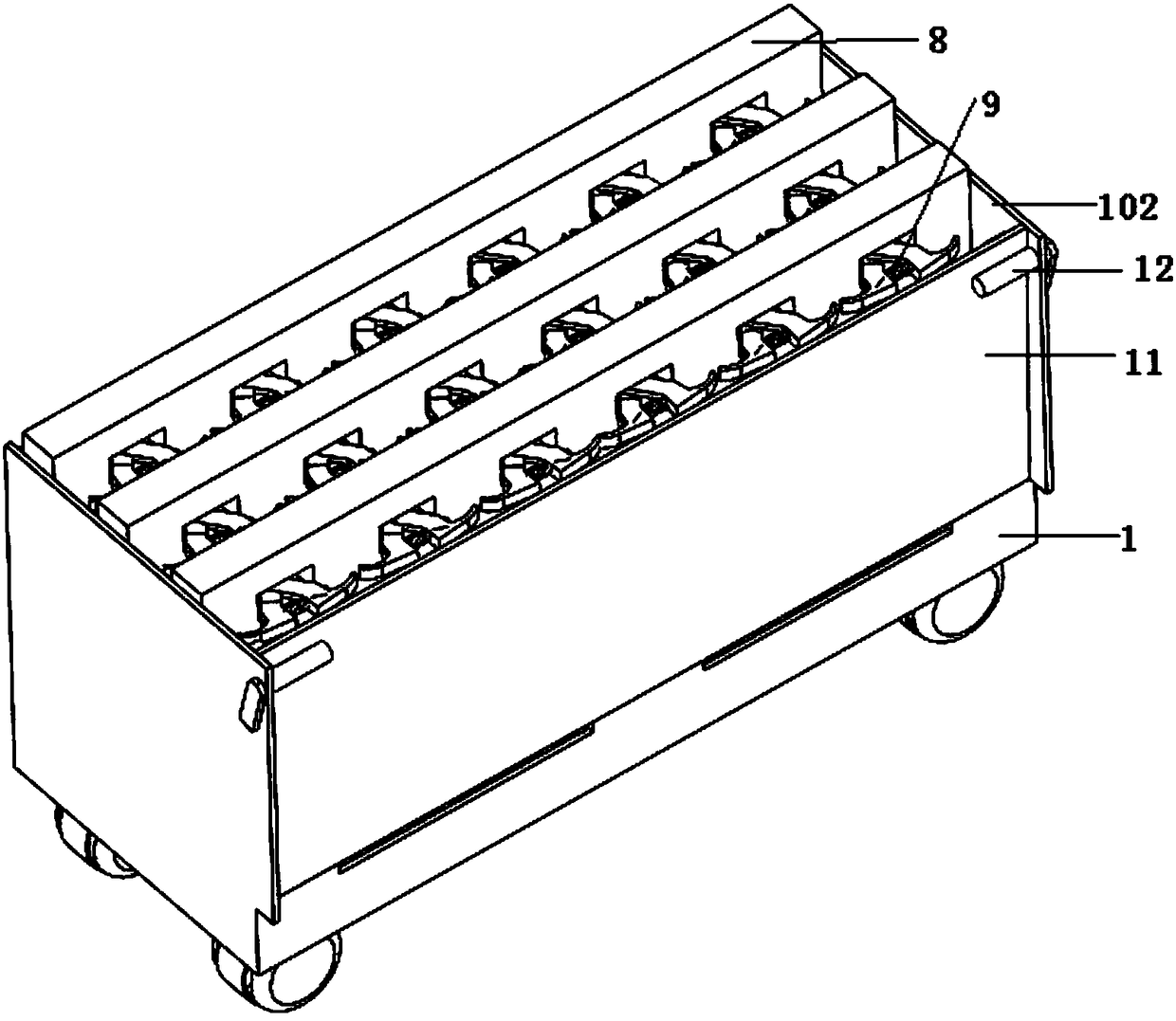

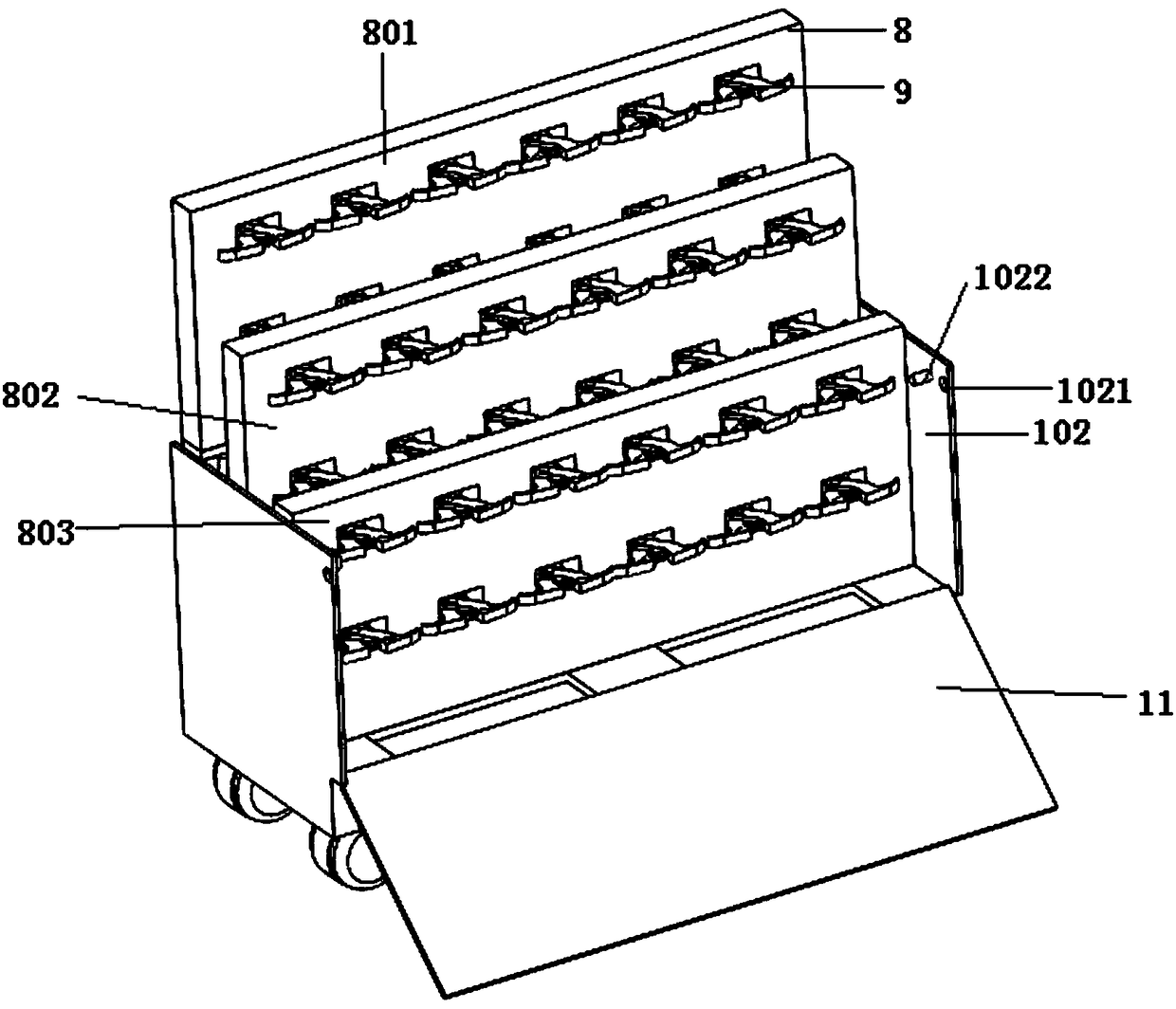

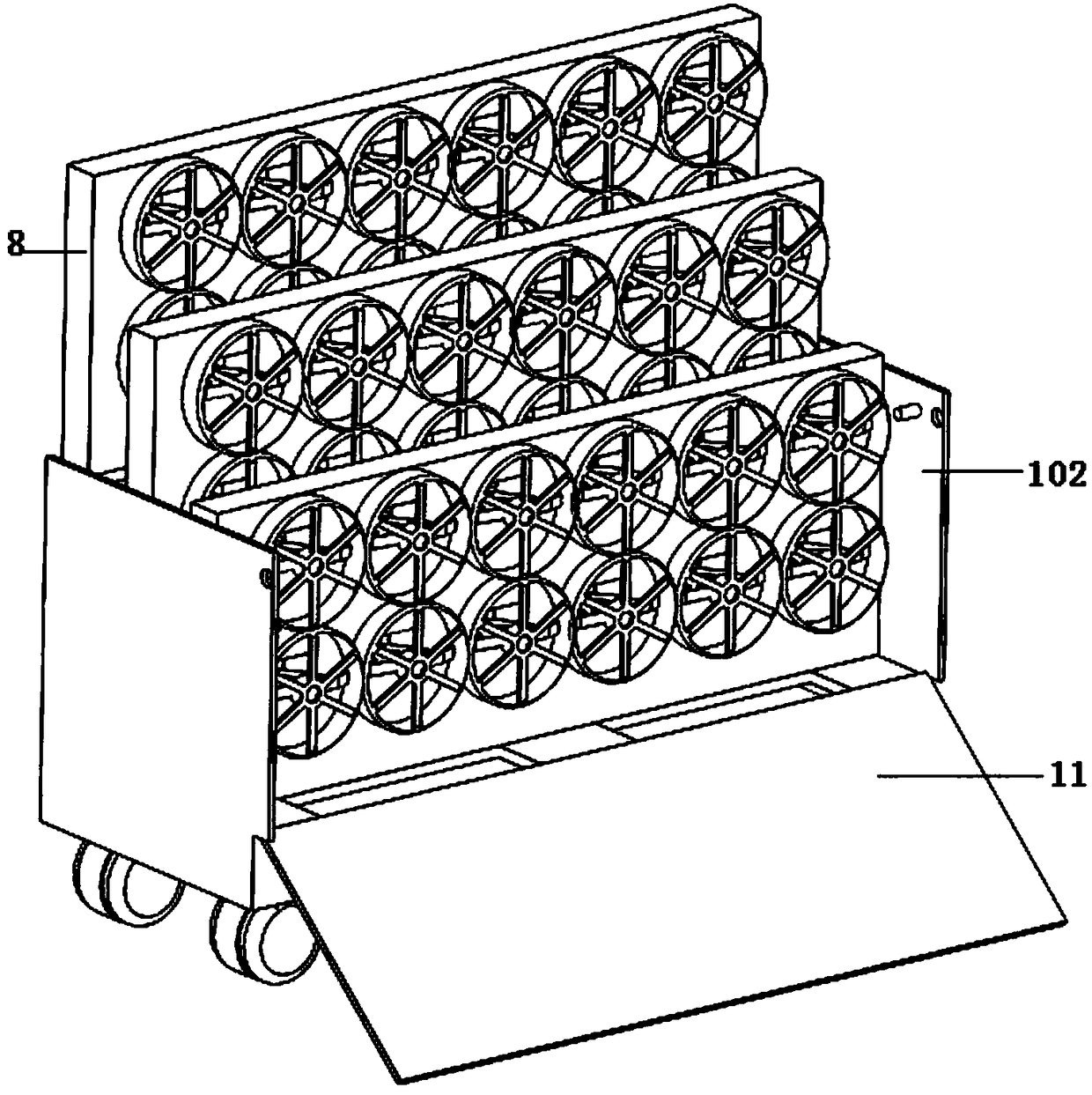

Piano type stacker device

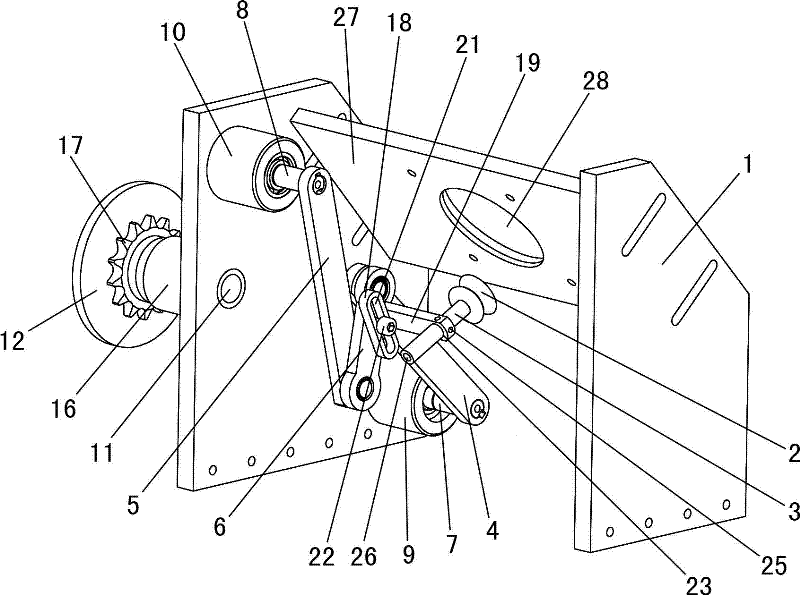

The invention relates to a piano type stacker device. A motor, an electromagnetic clutch drive system and a cantilever type hook are arranged on a cargo carrying table. A transmission shaft is connected with an output shaft of the motor. A driving part of an electromagnetic clutch is connected with the transmission shaft, and a driven part of the electromagnetic clutch is connected with a chain wheel. The chain wheel is connected with a chain and drives the chain to horizontally move back and forth. A connecting part is connected with the chain, and the chain drives the connecting part to horizontally move back and forth. The cantilever type hook is connected with the connecting part, and the connecting part drives the cantilever type hook to horizontally move back and forth. Hooks for hooking battery handles are arranged on the cantilever type hook. According to the piano type stacker device, a stacker quickly and accurately fetches and places batteries in a hooking mode, the multiple batteries in a battery compartment can be simultaneously fetched out at one time and a part of the batteries can be independently fetched out, the stacker device is convenient and flexible to use, and fetching and placing efficiency is greatly improved.

Owner:CHINA UNITED ENG +1

Box taking and placing mechanical arm

ActiveCN105858192ASolve installation difficultiesEasy to installConveyorsConveyor partsContact typeManipulator

The invention discloses a box taking and placing mechanical arm. The mechanical arm comprises a supporting frame, a mechanical claw device mounted on the supporting frame and an offset drive device driving the mechanical claw device to move; the mechanical claw device comprises a clamping mechanism fixedly connected with the offset drive device and two symmetrically-arranged clamping plates; one end of each clamping plate serves as a connecting part, and the other end of each clamping plate serves as a clamping part; the connecting parts are fixedly connected with the clamping mechanism, and the clamping parts incline towards the inner side relative to the connecting parts; and the box taking and placing mechanical arm can replace manpower, and take and place packaging boxes like a medicine box on a goods shelf, manpower is saved, meanwhile, work efficiency is improved, the clamping parts incline towards the inner side, fixed-point clamping of the boxes can be achieved, and compared with a full-contact type mechanical claw in the prior art, the box taking and placing mechanical arm has the beneficial effects that positioning and clamping are easier, and clamping missing cannot appear.

Owner:SUZHOU GICHEN S&T CO LTD

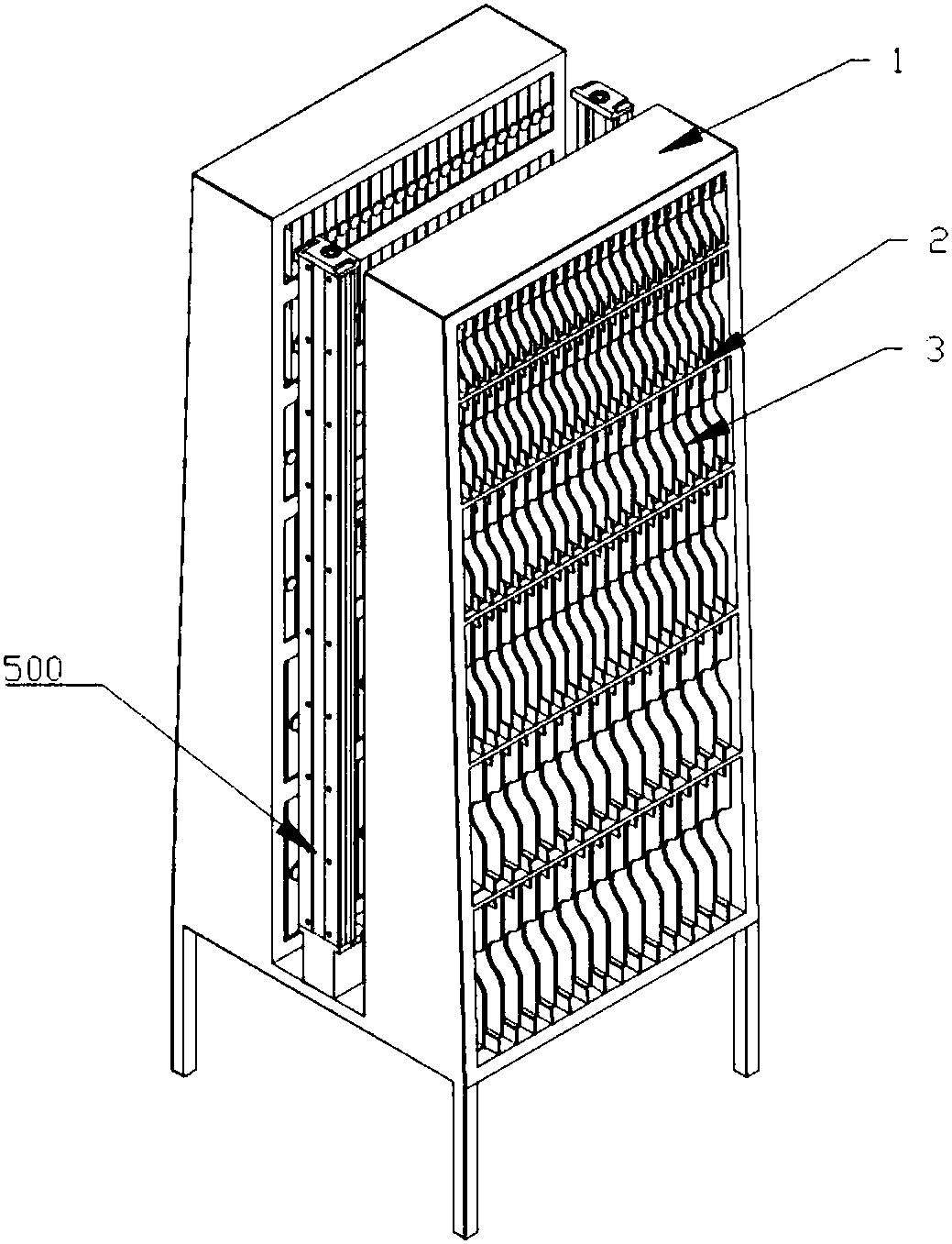

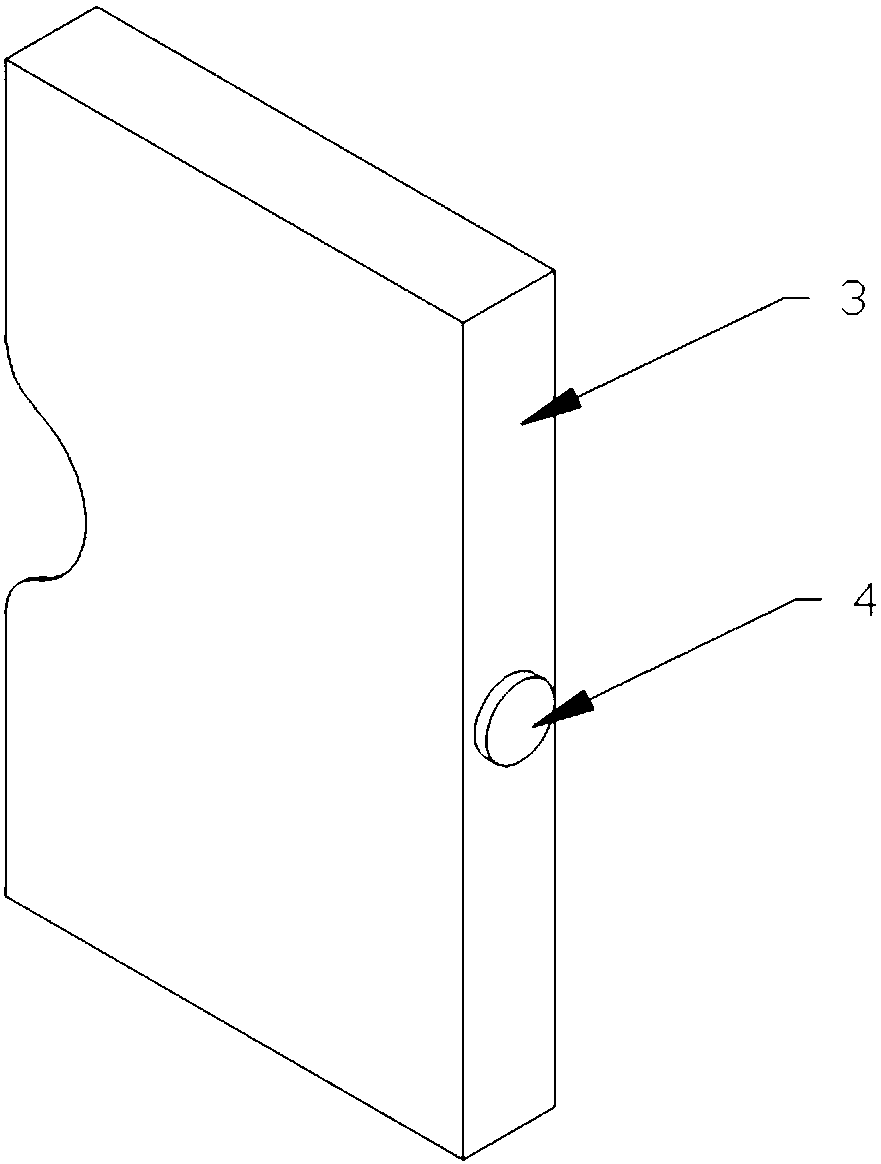

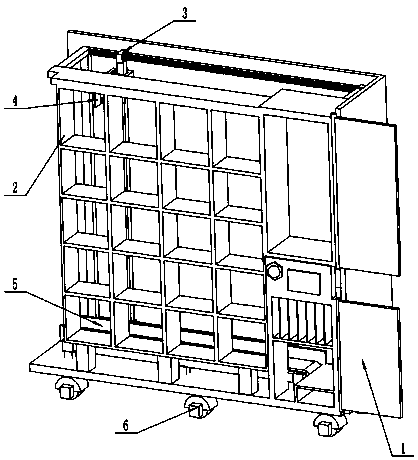

Intelligent article picking and placing mechanism

PendingCN108244848AImprove protectionRealize automatic pick and placeBook cabinetsFlexible MechanismsMotor drive

The invention discloses an intelligent article picking and placing mechanism, which comprises a bidirectional frame body with a base, several layers of grids arranged at the inner part of the bidirectional frame body, article boxes placed in the grids, electromagnet arranged at the back faces of the article boxes, and a movable flexible mechanism arranged in the middle of the bidirectional frame body; a vertical moving motor drives a first screw to rotate and realize the vertical lifting of a U-type cross rod as well as the picking and placing of articles at different grid layers; the horizontal moving motor drives the second screw to rotate and realize the horizontal movement of the moving slide block as well as pick and place articles at different grids; a flexible motor drives the screwto rotate in front and back directions, and the top block is pushed to move forwards and backwards, the article boxes are pushed out to suck with the electromagnets and then contracted; the mechanismsaves labor force, is convenient and intelligent; the design of the article boxes can well protect the articles; meanwhile, the bidirectional design of the frame body can store more articles and savespace.

Owner:深圳市三维通机器人系统有限公司

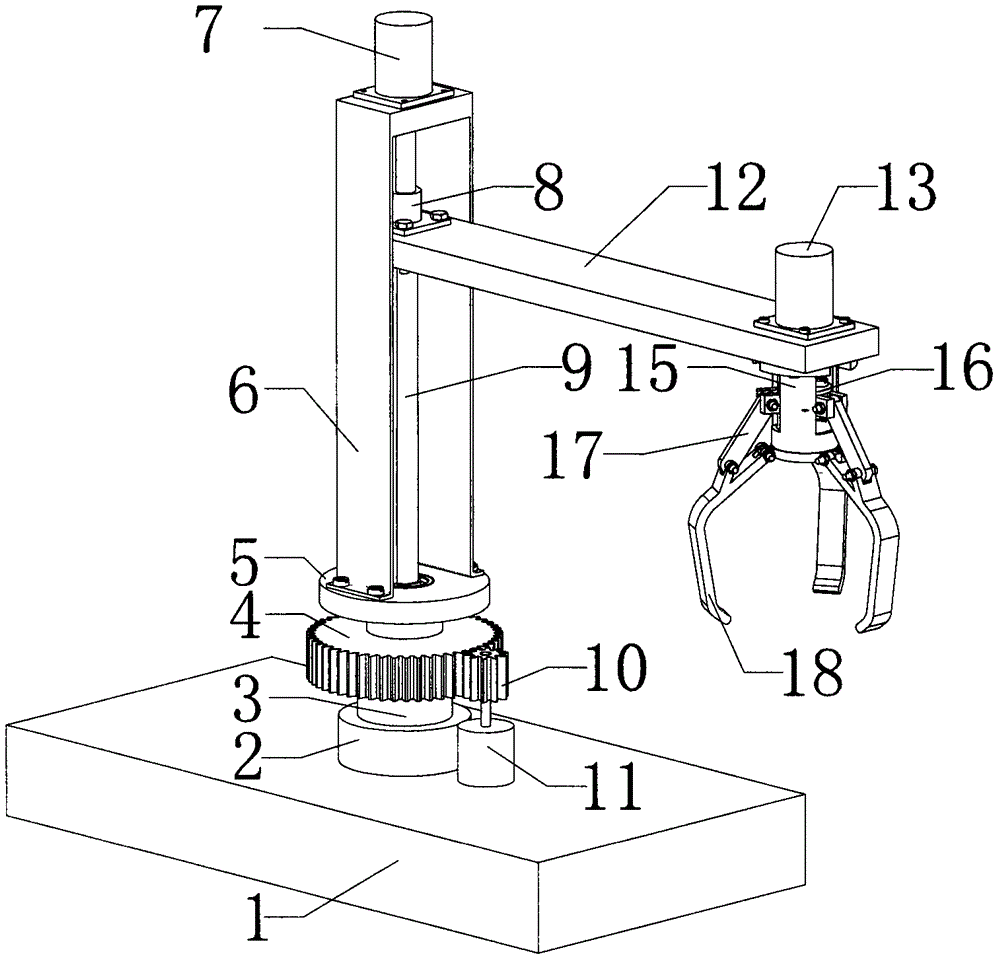

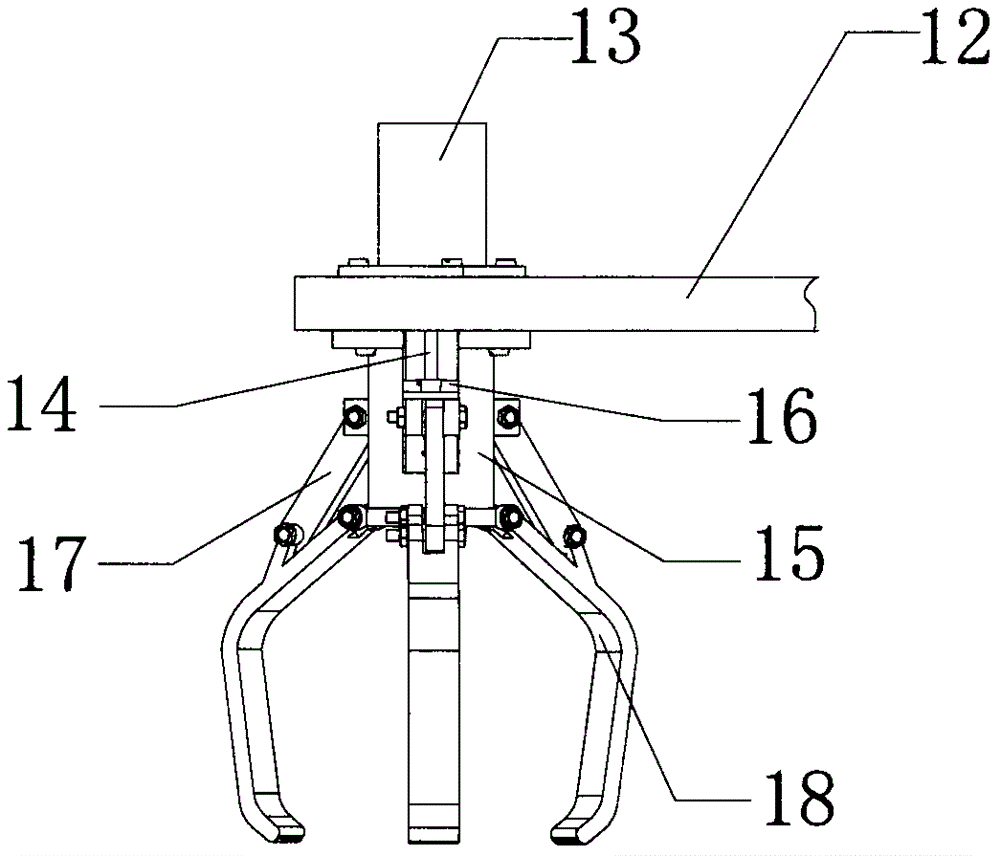

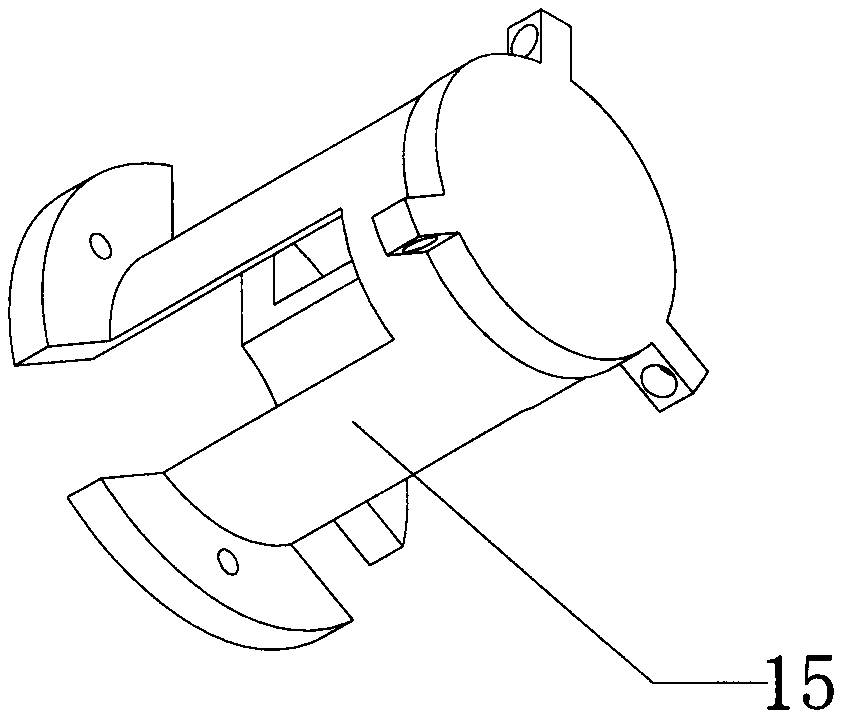

Electric object grabbing manipulator

InactiveCN105818142ARealize pick and placeImprove crawling efficiencyProgramme-controlled manipulatorGripping headsGear wheelElectric machinery

The invention discloses an electric grabbing manipulator. The base is fixedly connected to the mandrel through a shaft sleeve, the mandrel is fixedly connected to a large gear, and the large gear is fixedly connected to a vertical arm through a connecting piece. The middle part of the arm is provided with a large screw rod, which is fixedly connected to the lifting motor, and the large screw rod is connected to the rotating arm through a screw nut. The grasping motor is fixedly connected with the small screw rod, the small screw rod is provided with a connecting rod disk, the connecting rod disk is movably connected with the back of the claw through the connecting rod, and one end of the claw is movably connected with the sleeve. A rotating arm motor is arranged on one side of the bushing, and the rotating arm motor is fixedly connected with the pinion gear, and the large gear meshes with the pinion gear. The invention has the advantages of reasonable design, stable operation, high grasping efficiency, good reliability and high degree of automation, and is worthy of popularization.

Owner:XINCHANG COUNTY CHENGGUAN TOWN XINSHENG BEARING FACTORY

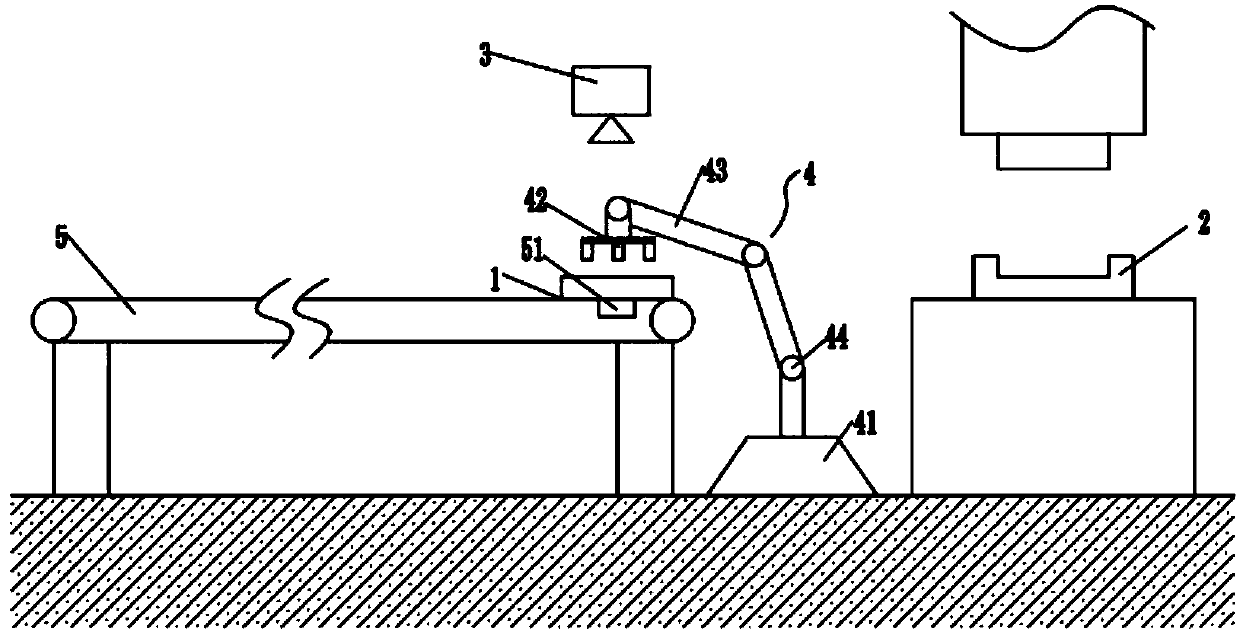

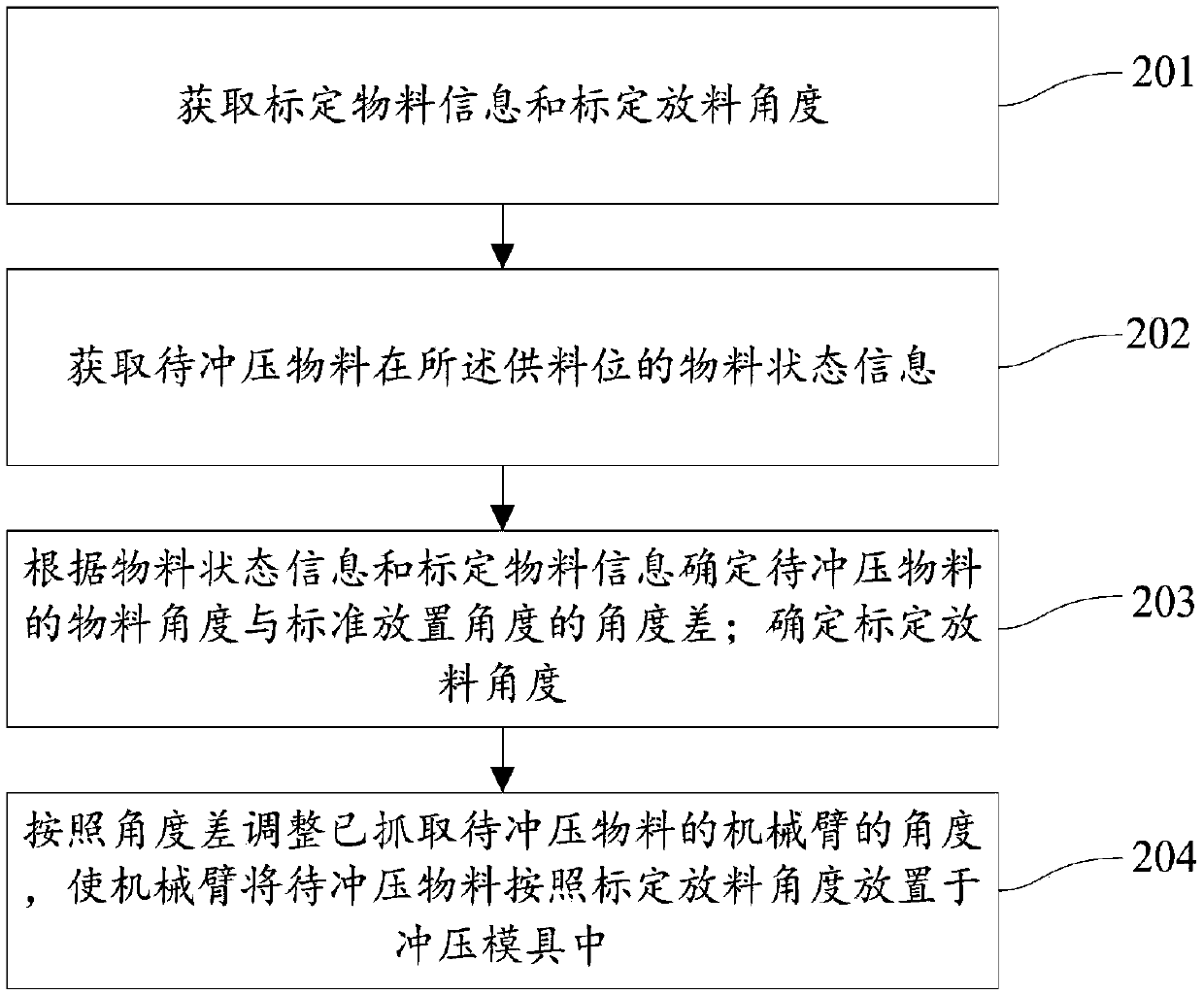

Stamping part feeding robot and method based on visual identity

ActiveCN109604466ARealize pick and placeMetal-working feeding devicesMetal working apparatusMaterial supplyVisual perception

The invention discloses a stamping part feeding robot and method based on visual identity. The robot comprises an image collection device, a controller and a mechanical arm, wherein the image collection device is arranged above a material supply station and used for collecting state information of a material; the controller is connected with the image collection device and used for acquiring the state information of the material, calculating the angle difference of the material according the state information of the material and calibration material state information, and sending a control command of conducting adjustment according to the angle difference; and the fixed end of the mechanical arm is arranged between the material supply station and a stamping die, the moving end of the mechanical arm is provided with a grabbing mechanism, the grabbing mechanism is used for grabbing the material from the material supply station, and the mechanical arm puts the material into the stamping die after adjusting the material to the datum angle according to the control command. The stamping part feeding robot and method based on visual identity can be suitable for angle and position change of any workpiece material, and material picking and placing at any material state are achieved.

Owner:岚士智能科技(上海)有限公司

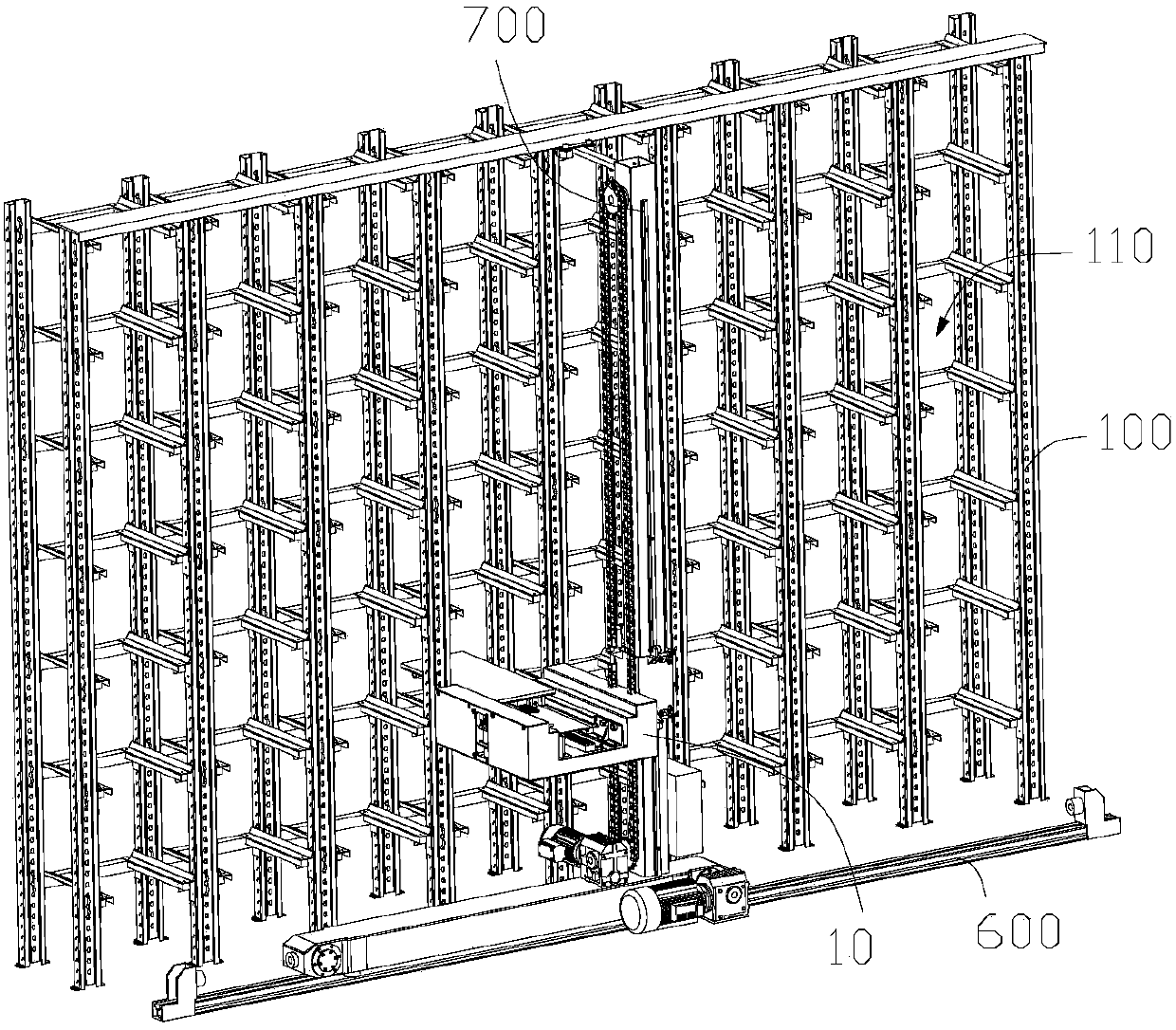

Goods carrying mechanism and stereoscopic warehouse

The invention provides a goods carrying mechanism and a stereoscopic warehouse, and belongs to the technical field of transportation of goods. The mechanism includes a goods frame, a bearing table, agoods carrying piece and a drive unit; the goods frame is provided with several goods storage cavities, the bearing table is arranged on the goods frame in a sliding mode, the goods carrying piece includes a bearing surface and an installation surface, the bearing surface is provided with skidproof stripes, and the drive unit is installed between the bearing table and the goods carrying piece andused for driving reciprocating motion, relative to the bearing table, of the goods carrying piece, so that the goods carrying piece selectively stretches into corresponding goods storage cavities or are taken out from the corresponding goods storage cavities. In the operational process, the goods carrying mechanism can conveniently and fast take the goods in the goods frame or place the goods on the goods frame, work is safe and stable and the efficiency is high.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

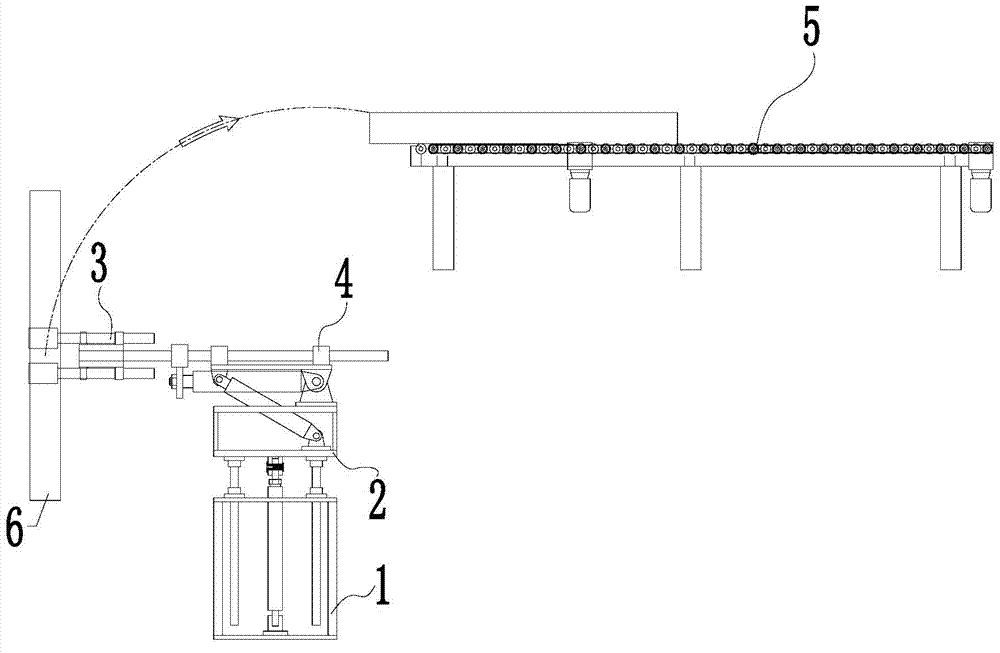

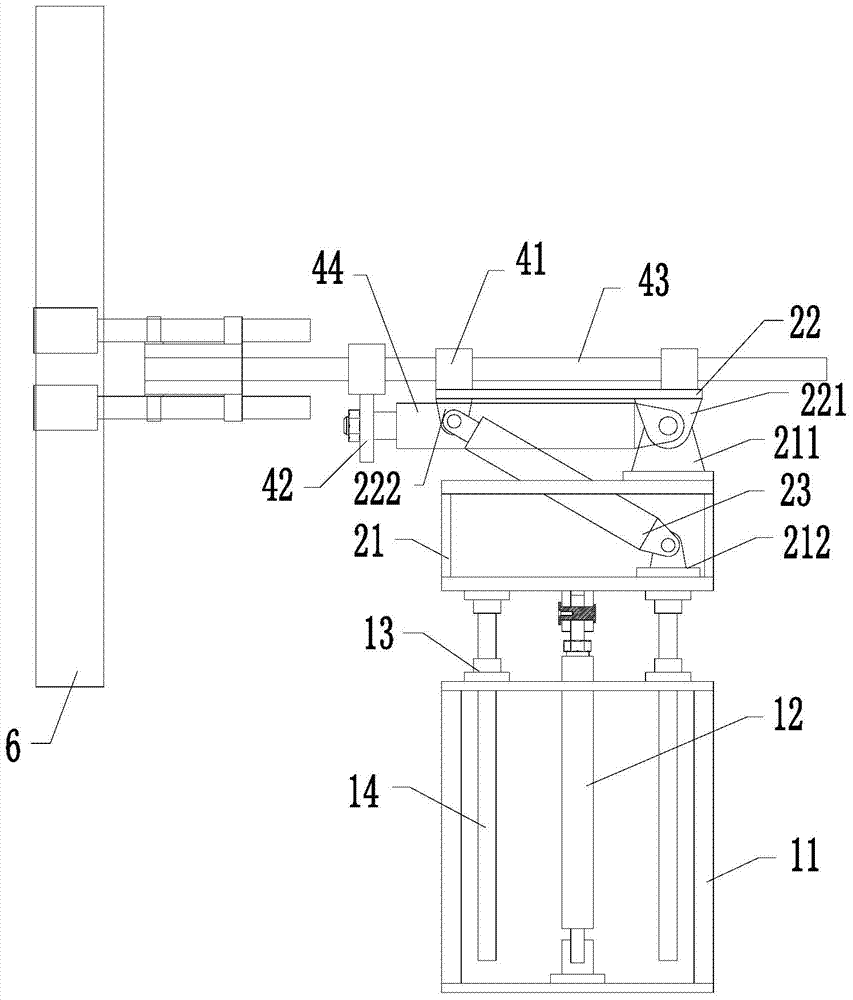

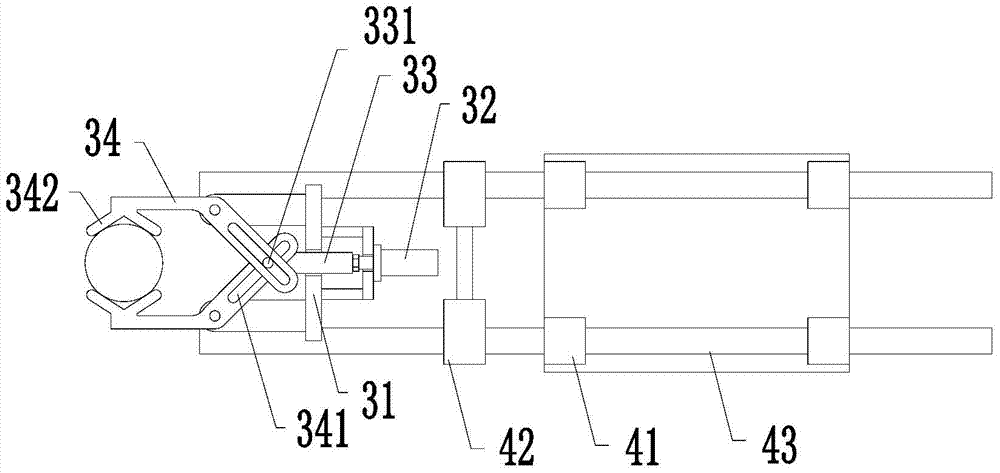

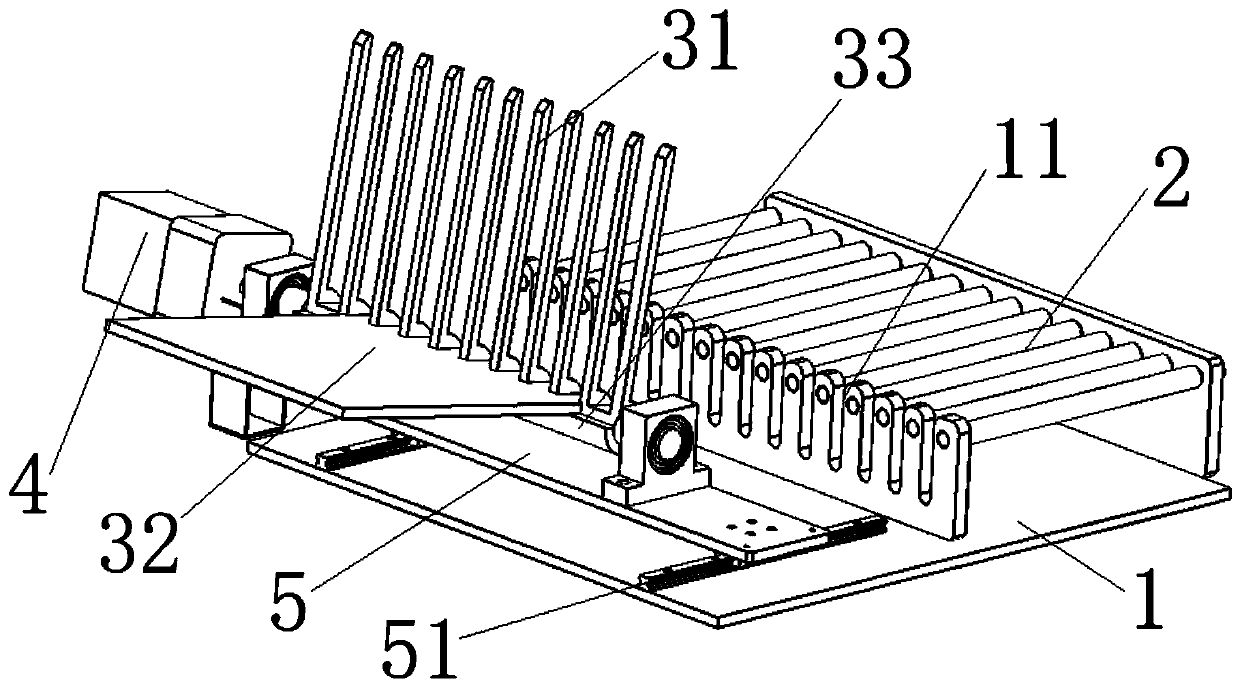

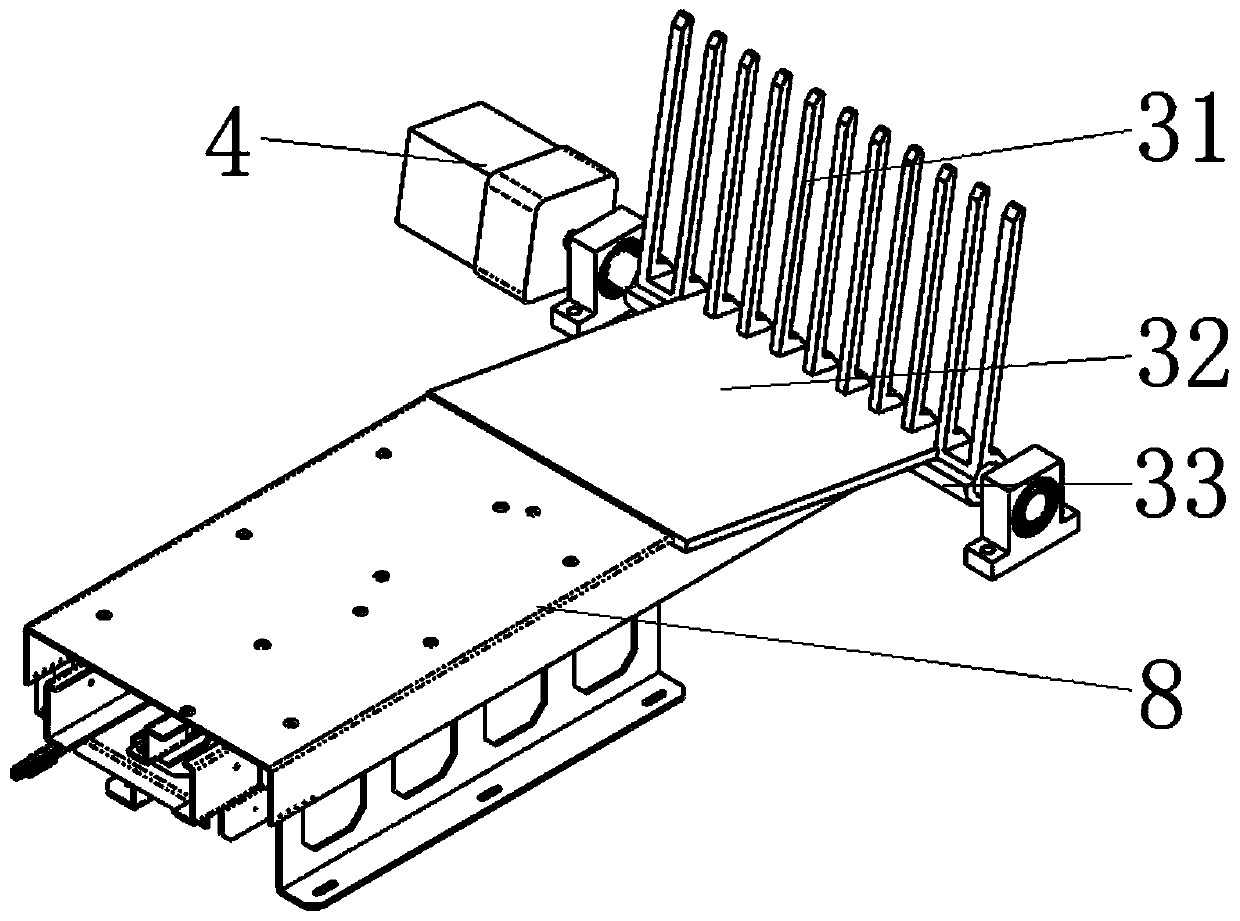

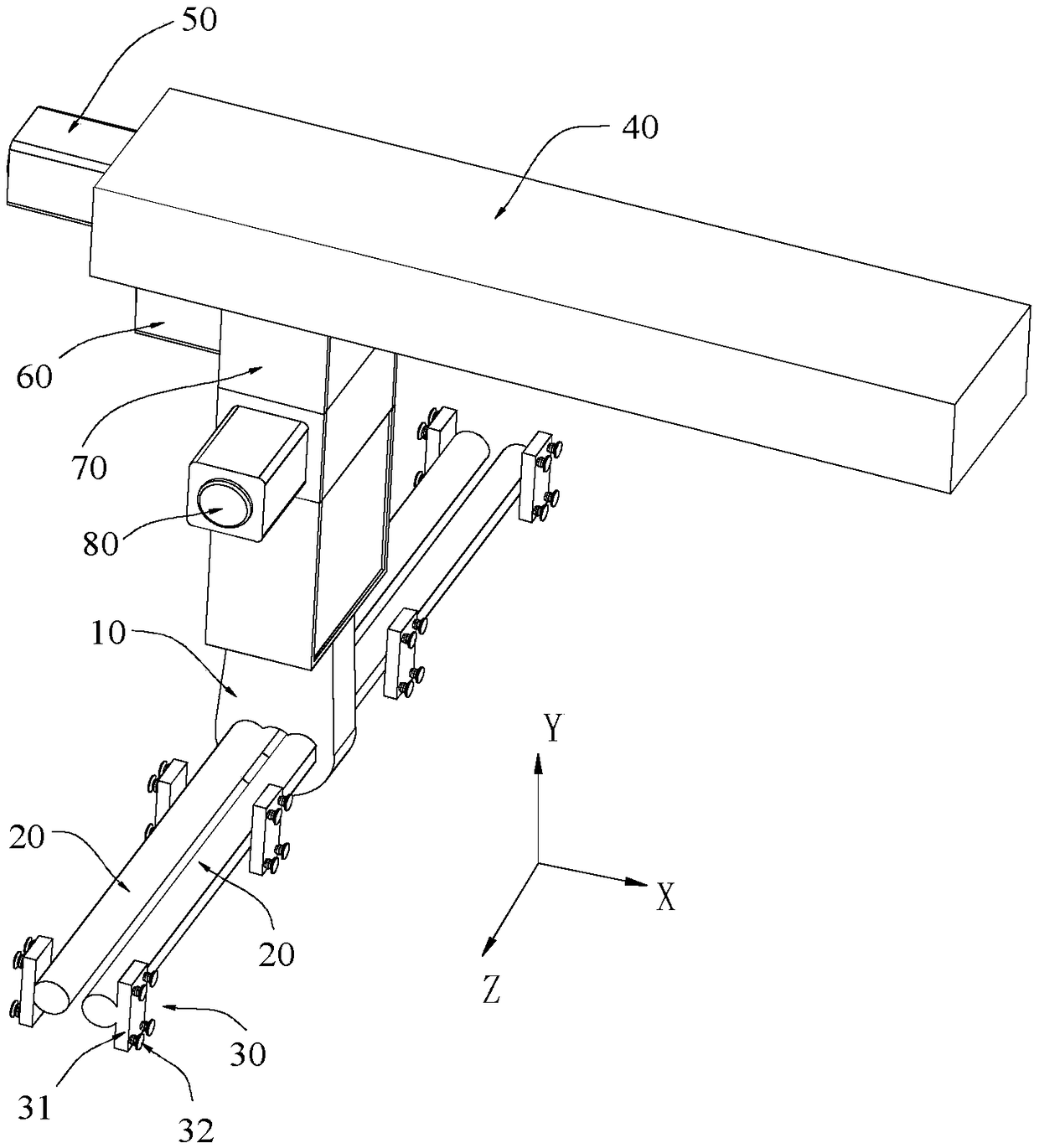

Alloy casting rod conveying device

InactiveCN103787058ARealize fully automatic pick and placeRealize deliveryConveyor partsRoller-waysEngineeringMechanical equipment

The invention discloses an alloy casting rod conveying device. The alloy casting rod conveying device is frequently used for conveying magnesium alloy casting rods and comprises a lifting mechanism, a turnover mechanism, a clamping mechanism, a walking mechanism and a conveying mechanism, the lifting mechanism drives an alloy casting rod to ascend and descend, the turnover mechanism turns over the alloy casting rod, the clamping mechanism clamps the alloy casting rod, the walking mechanism drives the clamping mechanism to move, and the conveying mechanism conveys the alloy casting rod. The turnover mechanism is arranged on the lifting mechanism, the walking mechanism is arranged on the turnover mechanism, the clamping mechanism is connected with the walking mechanism, the conveying mechanism is arranged above the turnover mechanism, the clamping mechanism comprises a support, and a heavy load cylinder is arranged on the support and connected with clamping hands used for clamping the alloy casting rod. Under the cooperation of the mechanisms, the alloy casting rod is taken, placed and conveyed completely through mechanical equipment, and production efficiency is greatly improved.

Owner:CHINA MAGNESIUM IND

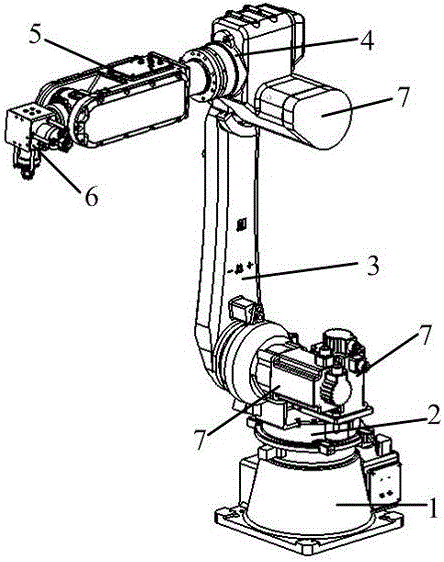

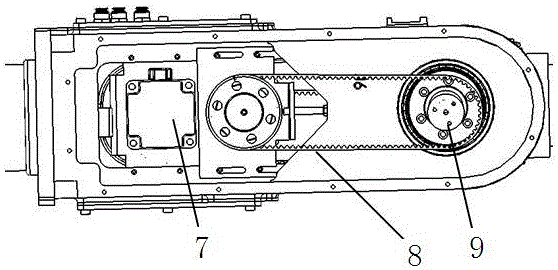

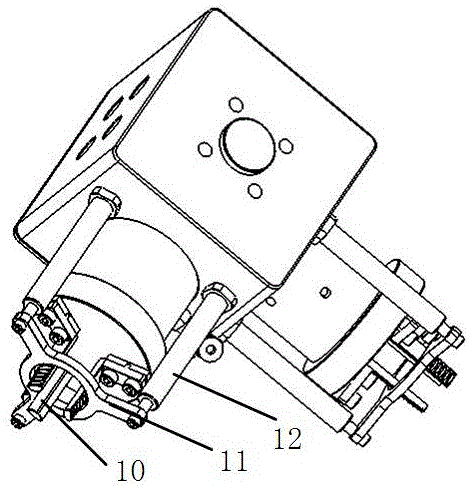

Mechanical arm

InactiveCN106625764ASave human effortShorten the timeGripping headsMetal working apparatusElectric machineryEngineering

The invention discloses a mechanical arm, which comprises a base, a rotary waist, a big arm, a small arm, a cantilever and an executive component. The rotary waist is arranged on the base; a motor in the base drives the rotary waist to rotate on the base through a transmission mechanism; two ends of the big arm are axially connected with the side end of the rotary waist and the small arm; a motor on the end part of the big arm drives the big arm to rotate by adopting a connecting shaft of the rotary waist as an axis through a transmission gear; a motor on the end part of the small arm drives the small arm to rotate by adopting a connecting shaft of the big arm as an axis through a transmission gear; two ends of the cantilever are axially connected with the front end of the small arm and the executive component; a motor built in the cantilever rotates the cantilever through a rotary shaft connected with the small arm; and a belt wheel transmission mechanism connected with the motor rotates the executive component. The mechanical arm provided by the invention is applicable for loading and unloading digital controlled lathe processing pipe type workpieces, and can be used for loading and unloading workpieces with different diameters, so that the manpower is greatly saved, the time is saved, and the production efficiency is improved.

Owner:HOHAI UNIV CHANGZHOU

Computer mainframe box transportation and placing protection device

ActiveCN108557229AAchieve clampingPrevent dumpingDamagable goods packagingInternal fittingsEngineeringFront cover

The invention relates to the technical field of computer transportation application, in particular to a computer mainframe box transportation and placing protection device. When a mainframe box is taken out of or placed into a protection case, automatic splitting and integrating of a rear cover plate and a front cover plate can be achieved, so that the purpose of conveniently taking and placing the mainframe box is achieved, people can use the mainframe box conveniently, the working efficiency is improved, and the working time is shortened; in the process of automatically splitting and integrating the rear cover plate and the front cover plate, the mainframe box can be clamped, the phenomenon that the mainframe box topples or is damaged due to unfirm fixing, caused by shaking, of the mainframe box in the transportation process is prevented, and economic losses are avoided. The front end and the rear end of the box are each provided with a cover plate sliding groove, and the left end and the right end of the box are each provided with a sliding-frame sliding groove; and four L-shaped retaining parts are arranged, the front end and the rear end of the left end face of the box are each fixedly connected with one L-shaped retaining part, the front end and the rear end of the right end face of the box are each fixedly connected with one L-shaped retaining part, the two L-shaped retaining parts on the left end face and the two L-shaped retaining parts on the right end face are symmetrically arranged, and the lower end of the left end and the lower end of the right end of the boxare each provided with a spring seat.

Owner:优备科技股份有限公司

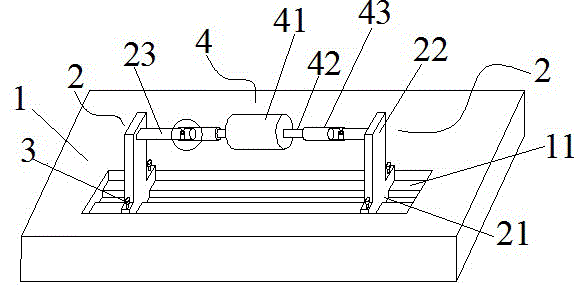

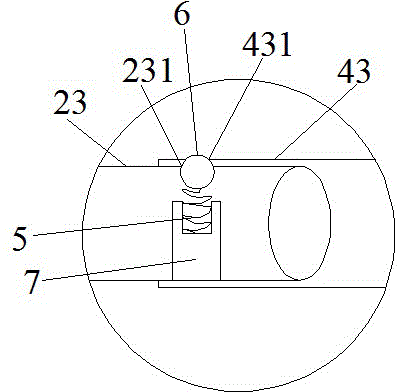

Wire wrapping device capable of winding and unwinding wires quickly

The invention discloses a wire wrapping device capable of winding and unwinding wires quickly. The wire wrapping device comprises a base, a pair of sliding seats and a wire wrapper, wherein chutes are formed in the base; the bottoms of the sliding seats are arranged in the chutes; each sliding seat comprises a sliding portion, a mounting portion and a mounting shaft; each mounting portion is integrally formed above the corresponding sliding portion; each mounting shaft is fixedly connected with the corresponding mounting portion; a fastener structure is arranged in a cavity in one end, which is far away from the corresponding mounting portion, of each mounting shaft; the wire wrapper comprises a wire wrapping portion, a rotating shaft and two connecting rods; the rotating shaft penetrates in the wire wrapping portion and drives the wire wrapping portion to rotate; the connecting rods sleeve the mounting shafts, and are respectively connected with two ends of the rotating shaft rotatably; and a clamping hole which is matched with the fastener structure is formed in one end, which is far away from the rotating shaft, of each connecting rod. The positions of the sliding seats can be adjusted, so that the sliding seats are suitable for wire wrappers with various specifications and sizes, and the universality is high; and moreover, the wire wrapper can be mounted and can wind and unwind wires without the aid of tools, and by the flexible design of the fastener structure, the wires can be wound and unwound quickly.

Owner:SUZHOU GUJI ELECTRONICS TECH

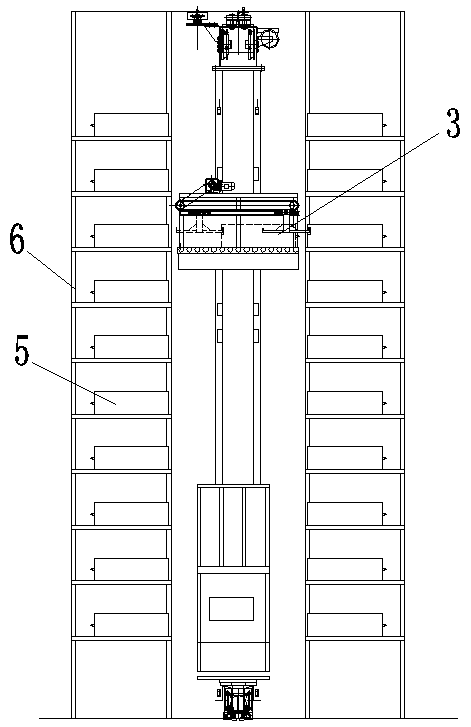

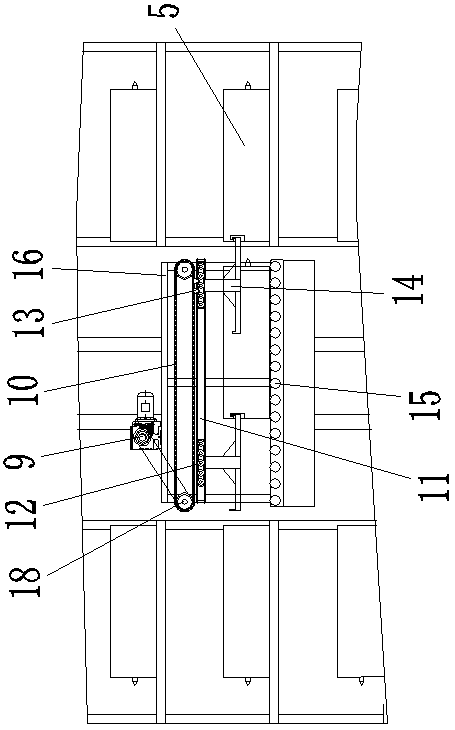

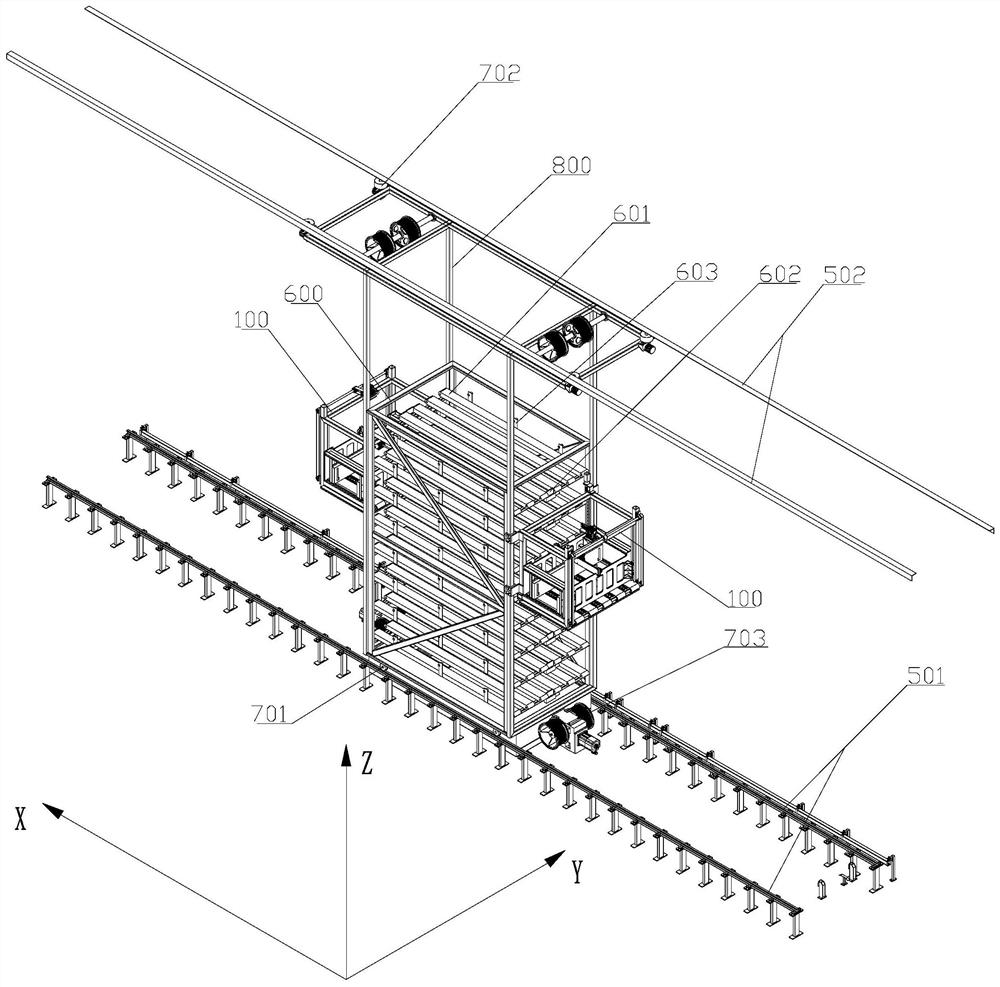

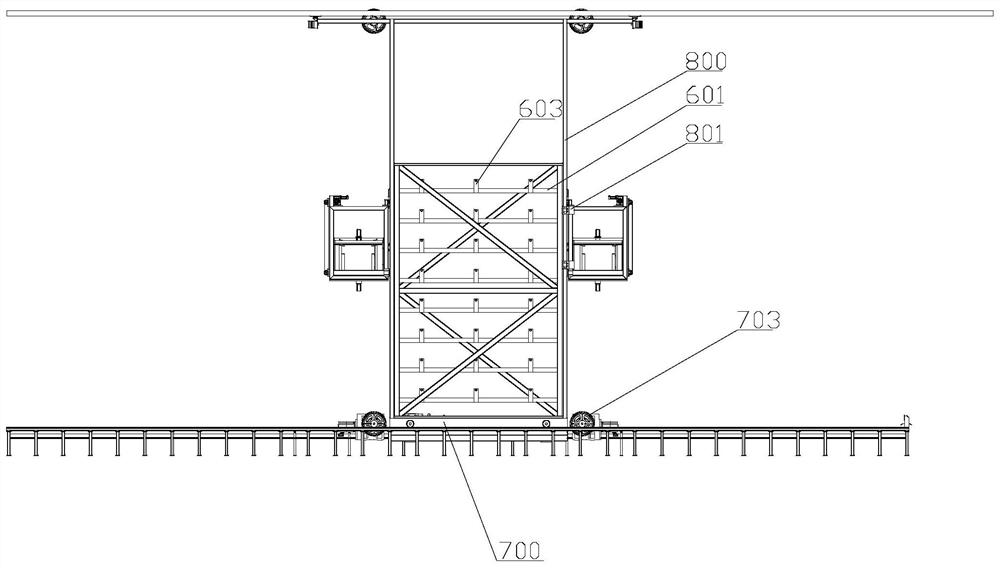

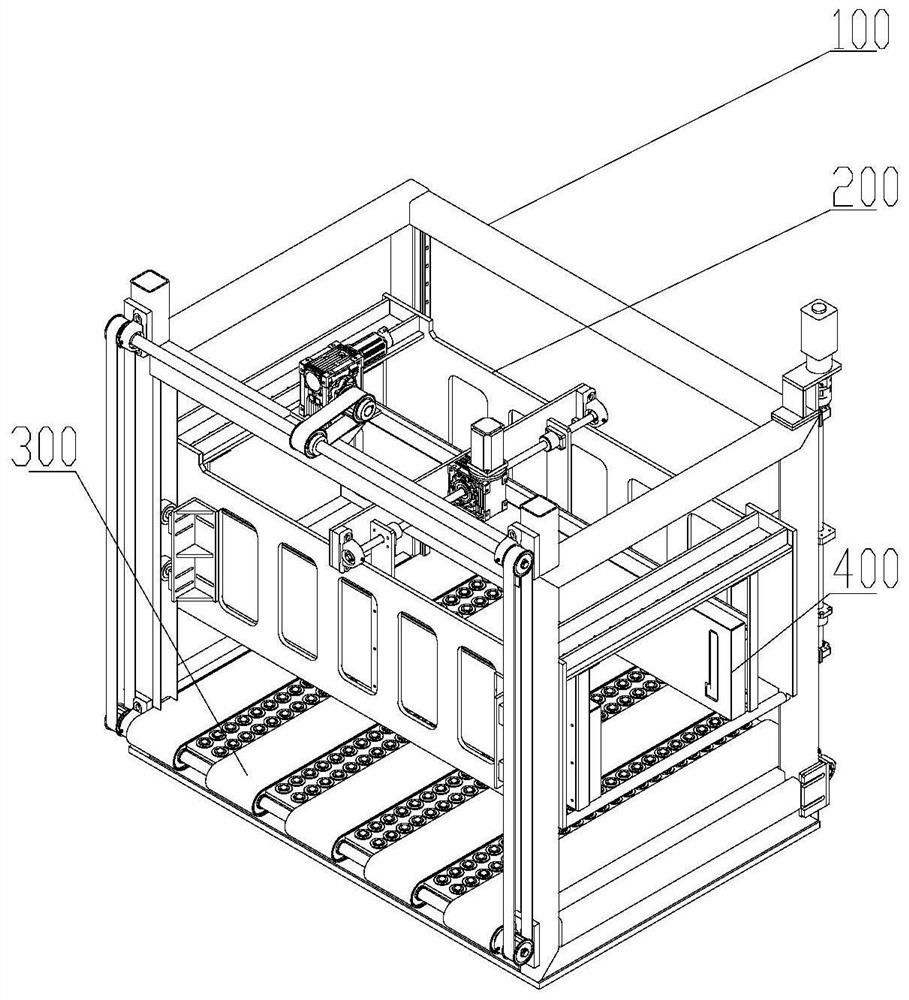

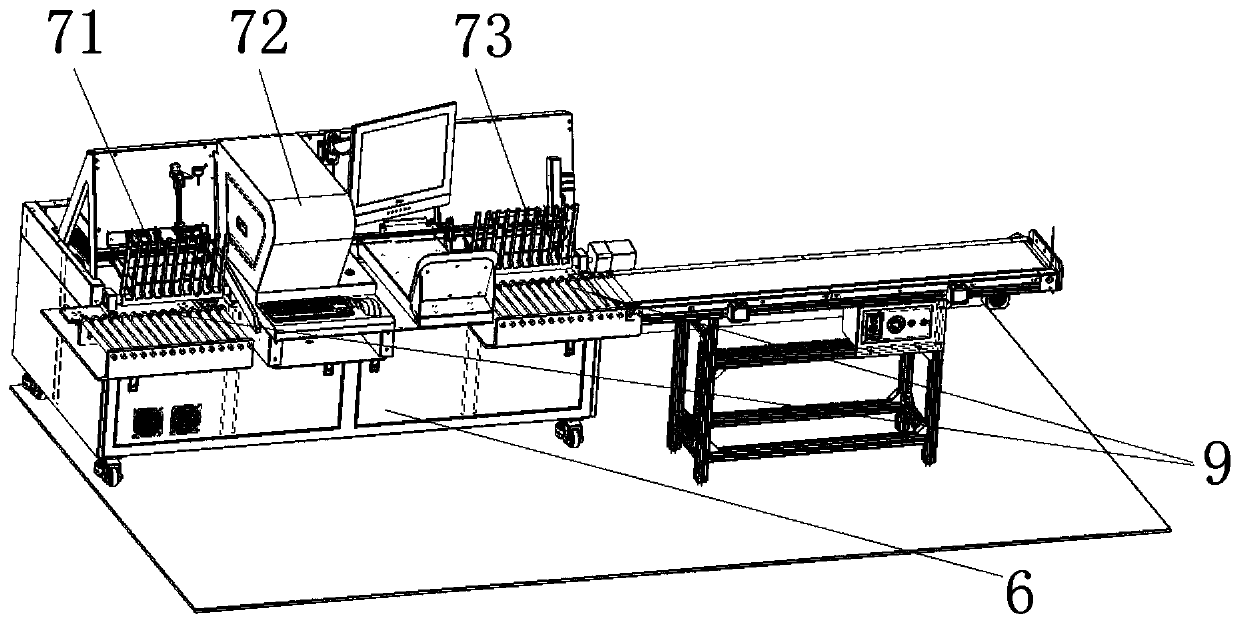

Double-working-station stacking machine with temporary storage area and working method of butt joint area of double-working-station stacking machine

The invention relates to a double-working-station stacking machine with a temporary storage area and a working method of a butt joint area of the double-working-station stacking machine. The double-working-station stacking machine comprises a stacking machine seat and a lifting mechanism, wherein the temporary storage area is arranged on the stacking machine seat, the temporary storage area comprises multiple layers of temporary storage conveying belts, the two ends, located in the conveying direction of the temporary storage conveying belt, of the temporary storage area are open, each layer of temporary storage conveying belt can be independently driven in a two-way mode, goods carrying tables are arranged at the two ends, located in the conveying direction of the temporary storage conveying belt, of the stacking machine seat, the lifting mechanism is used for driving the goods carrying tables to ascend and descend, the maximum ascending height of the goods carrying tables is not smaller than the sum of the height of the goods carrying tables and the height of the temporary storage area, a lower-layer conveying mechanism and a liftable upper-layer holding and clamping mechanism are arranged on the goods carrying tables, and the lower-layer conveying mechanism comprises a transportation conveying belt capable of being bidirectionally driven. The double-working-station stacking machine with the temporary storage area and the working method of the butt joint area of the double-working-station stacking machine have the advantages that the stacking machine is provided with a plurality of temporary storage positions, storage and taking integration can be achieved for a particularly long roadway, goods are stored and taken at the same time in the process of travelling from one end of the roadway to the other end of the roadway, the travelling time of the stacking machine is saved, and efficiency is improved.

Owner:SANLUX

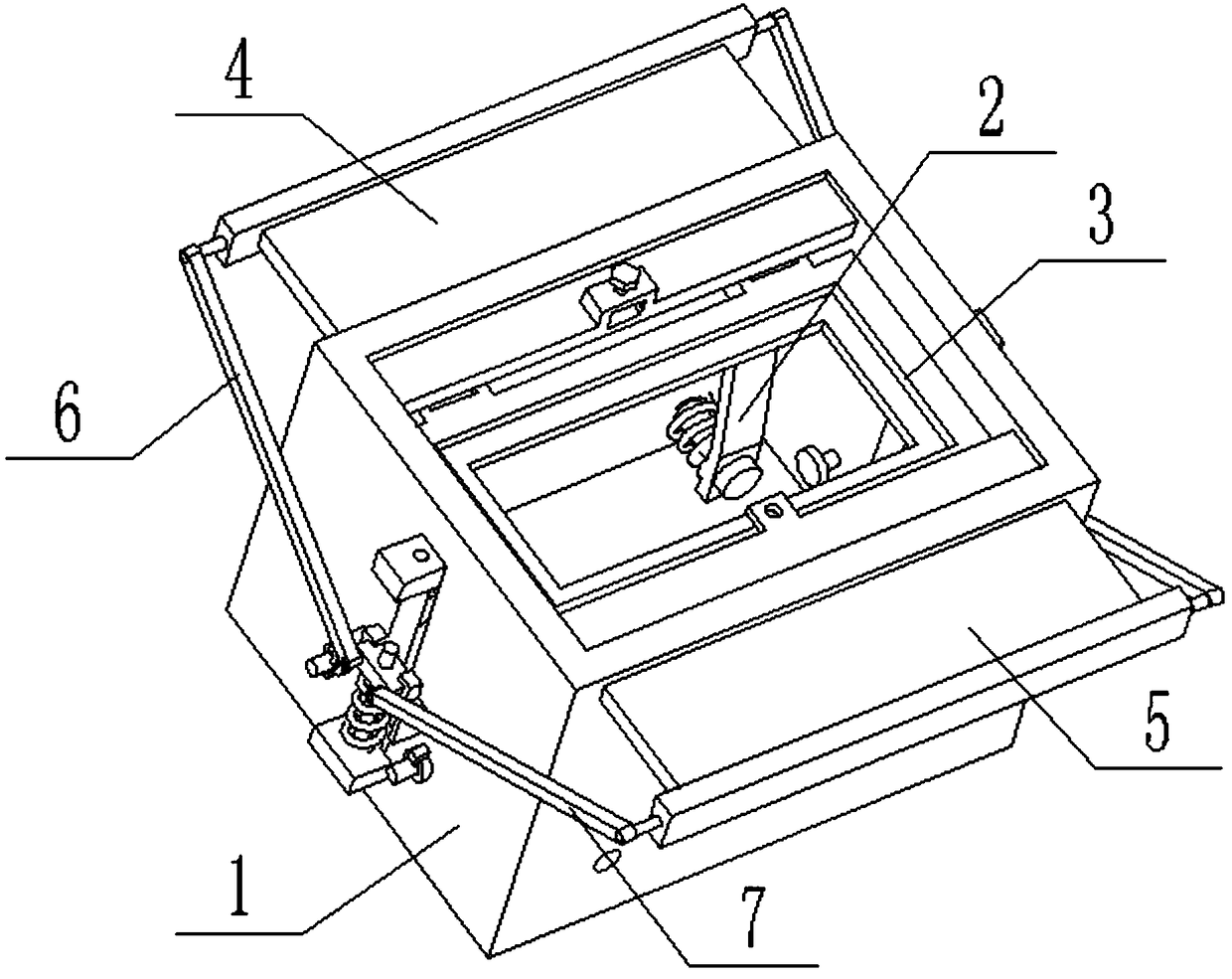

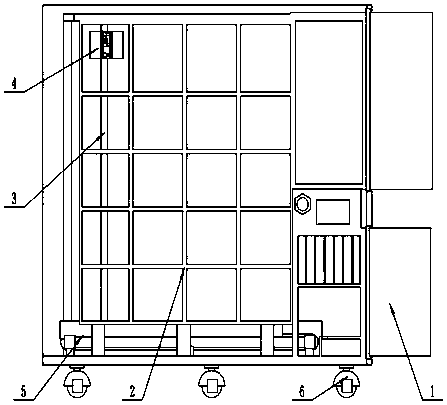

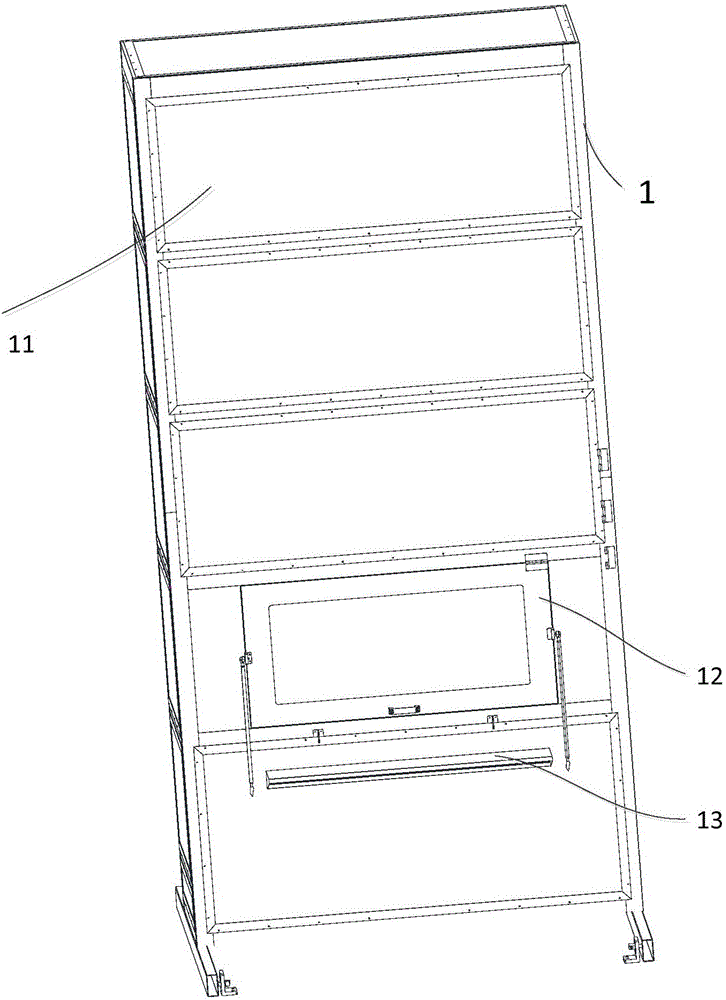

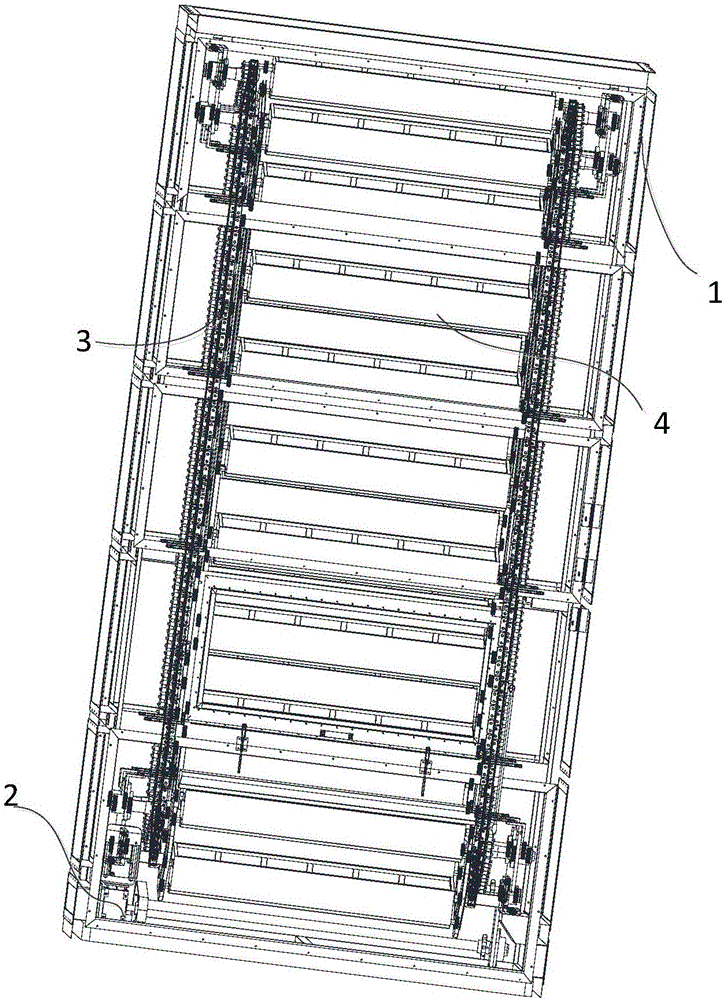

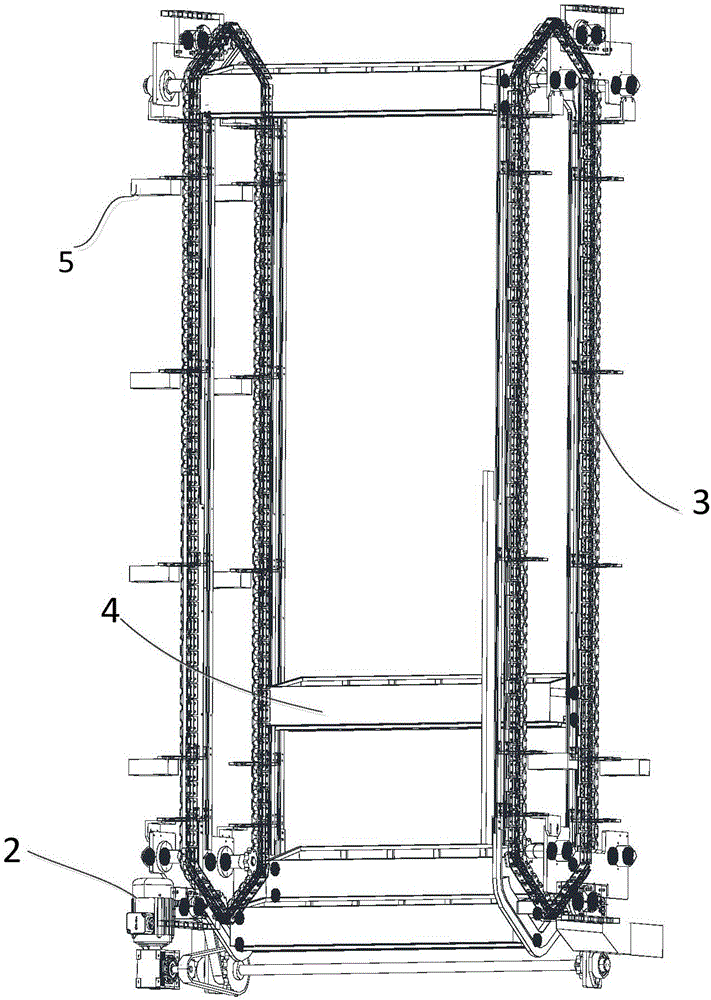

File cabinet with functions of automatic classification, storage and extraction

ActiveCN109820350AEasy and quick to getImprove work efficiencyBook cabinetsFurniture partsMoving partsFile storage

The invention discloses a file cabinet with functions of automatic classification, storage and extraction. The file cabinet comprises a base, a file bracket part, a sliding bracket part, a file extraction and storage part, a file transport part and a moving part, and is characterized in that when the file cabinet is in use, firstly the moving part moves the whole file cabinet to a designated position, positions of all file folders are stored in a control computer, when extraction is needed, the sliding bracket part drives the file extraction and storage part to move to the position where the file folders are placed, takes out the file folders, places the file folders on the file transport part, and transports the file folders to a file extraction box, and the file folders are manually taken out, when the file folders need to be placed, the sliding bracket part drives the file extraction and storage part to the rear of a file storage box, takes out the file folders, and then places thefile folders to the designated positions, thereby more conveniently and rapidly helping people getting the required files, saving the time and energy wasted by manual searching and file placement, improving the working efficiency of people, and achieving the automatic classification, storage and extraction.

Owner:济宁市公共卫生医疗中心(济宁市第四人民医院)

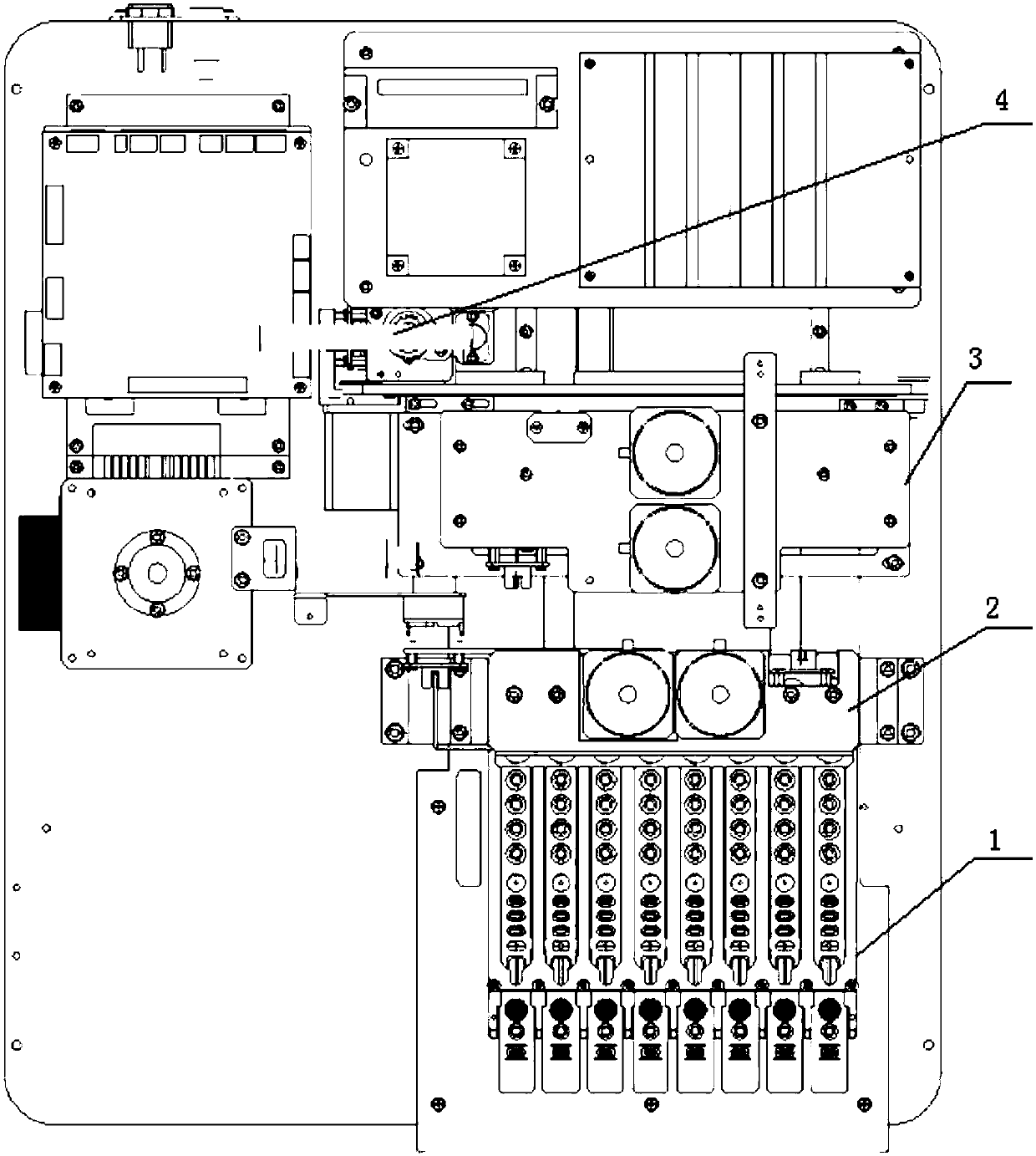

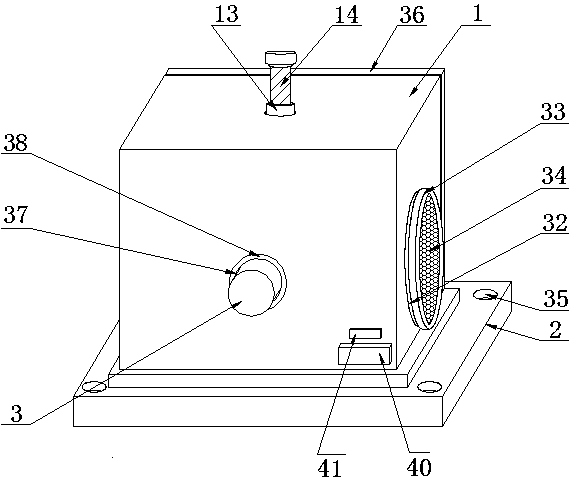

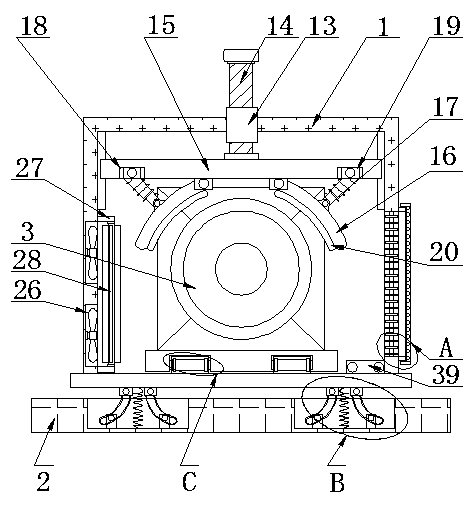

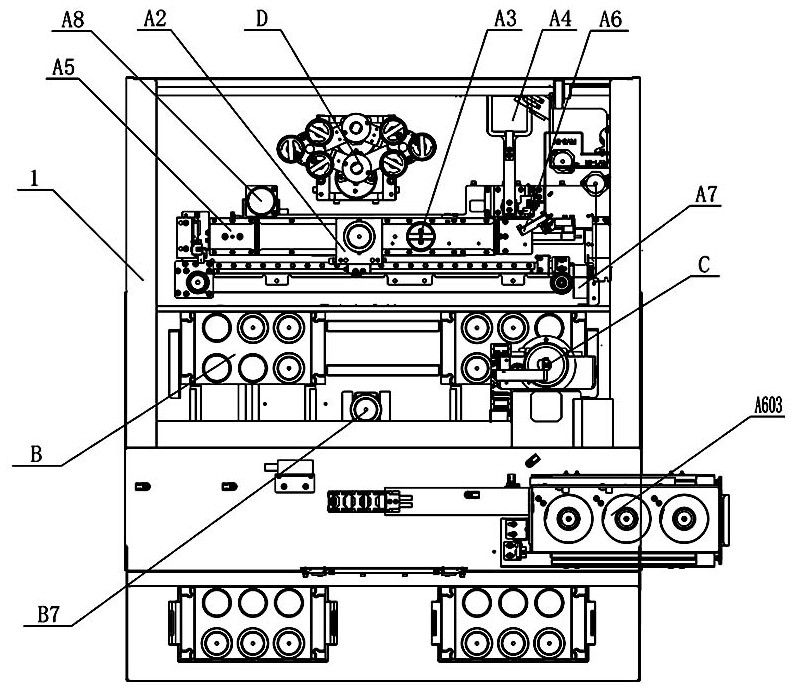

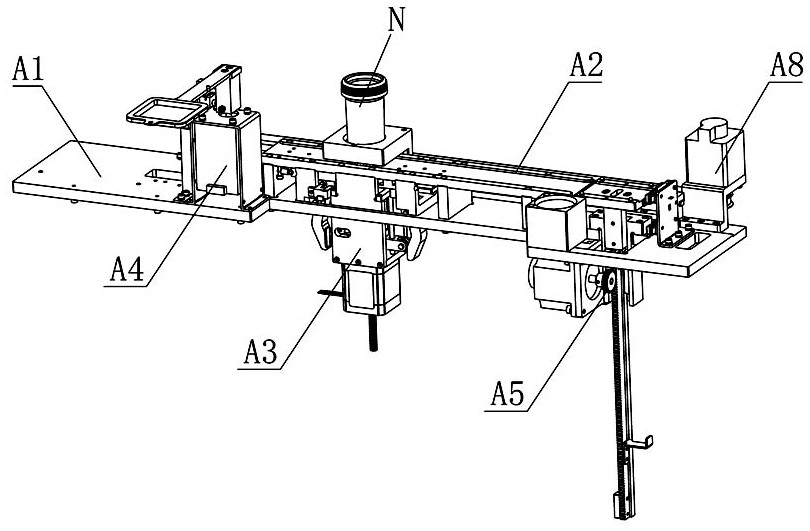

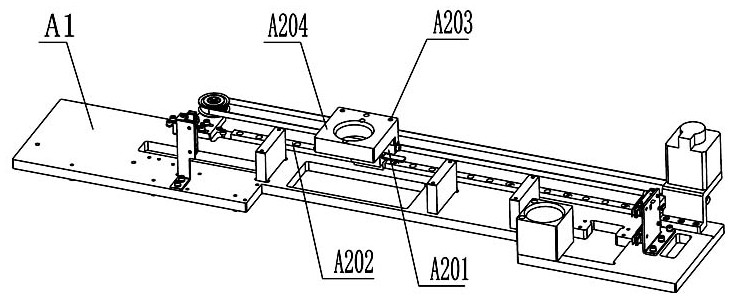

Small full-automatic chemiluminescent analyzer

The invention discloses a small full-automatic chemiluminescent analyzer and belongs to the technical field of chemiluminescence immune assay. The small full-automatic chemiluminescent analyzer disclosed by the invention comprises a sample reagent rack, a liquid transfer device, a magnetic bead adsorption and extraction device and a measuring and reading device which are mutually independently tiled from the front to rear. The small full-automatic chemiluminescent analyzer is favorable for installation and maintenance of instruments and is convenient to use and easy to popularize.

Owner:NANTONG EGENS BIOTECH

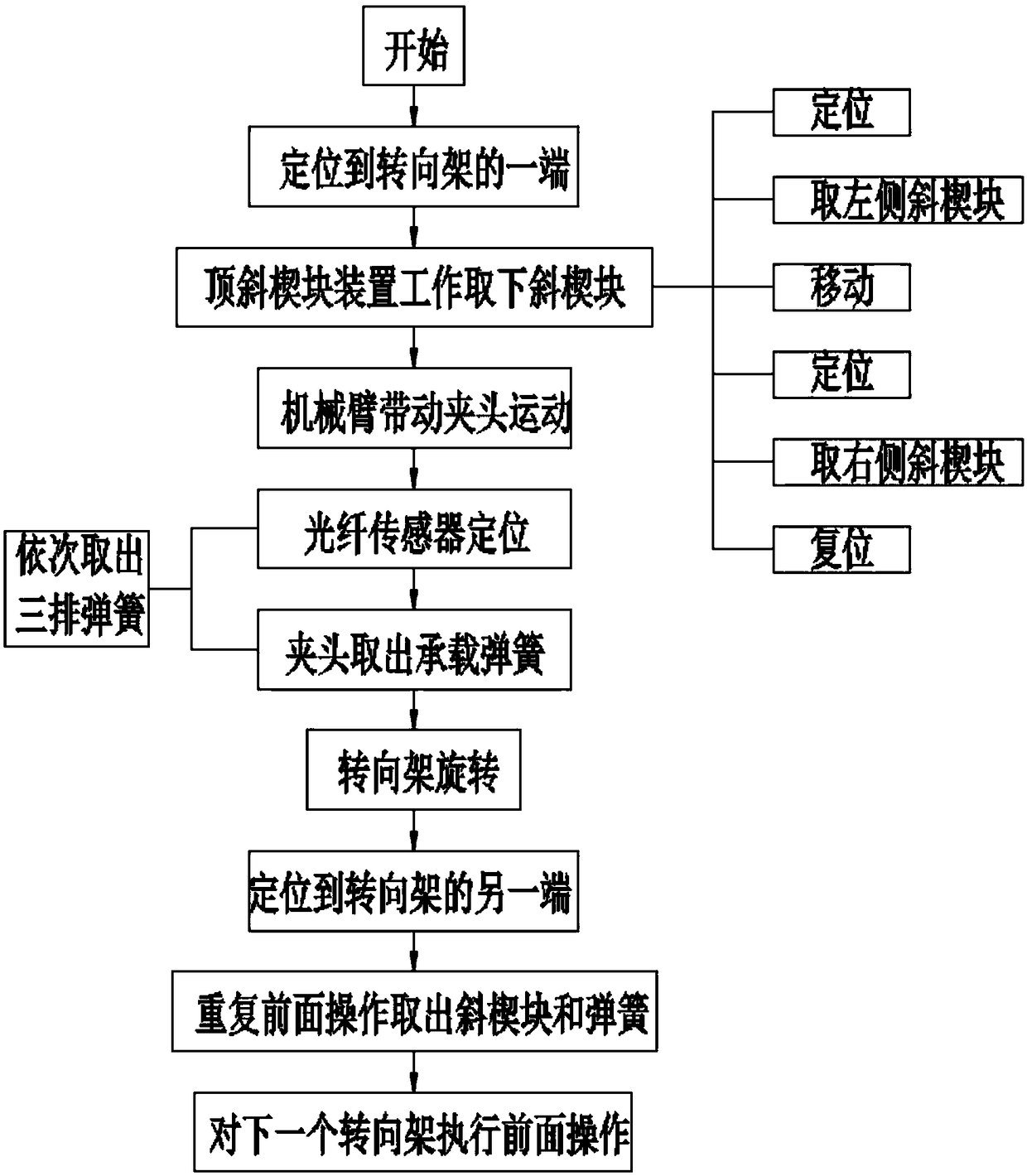

Bogie bearing spring disassembling process

ActiveCN108857312AImprove pick-and-place efficiencyReduce labor intensityMetal working apparatusBogieEngineering

The invention discloses a bogie bearing spring disassembling process, and belongs to the technical field of disassembly of bogie bearing springs. The process is used for solving the problems that in the existing bogie disassembling process, by adopting the mode of manually carrying bearing springs, the labor intensity is large, hidden safety hazards exist in the carrying process, and the work efficiency is low. The process comprises the following steps that S1, one end of a bogie is located; S2, a jacking device works to remove tapered wedges; S3, a mechanical arm drives a chuck to move; S4, alocating device locates bearing springs, and a bijective optical fiber sensor locates outer spring bodies of the bearing springs; S5, the chuck takes out the bearing springs, and three rows of bearing springs are sequentially taken out, the out-taken bearing springs are placed on a transfer frame, and the outer spring bodies and inner spring bodies of the bearing springs are separated; S6, the bogie rotates, and the other end of the bogie is located; S7, the operation of S1 to S5 is repeated, and the tapered wedges and the bearing springs are taken out; S8, the operation of S1 to S7 is repeated for a next bogie.

Owner:成都岁生科技有限责任公司

Feeding and discharging device and detection equipment

PendingCN111115269AReduce manufacturing costSmall footprintControl devices for conveyorsCharge manipulationRobot handTransfer line

Owner:JOINT STARS TECH

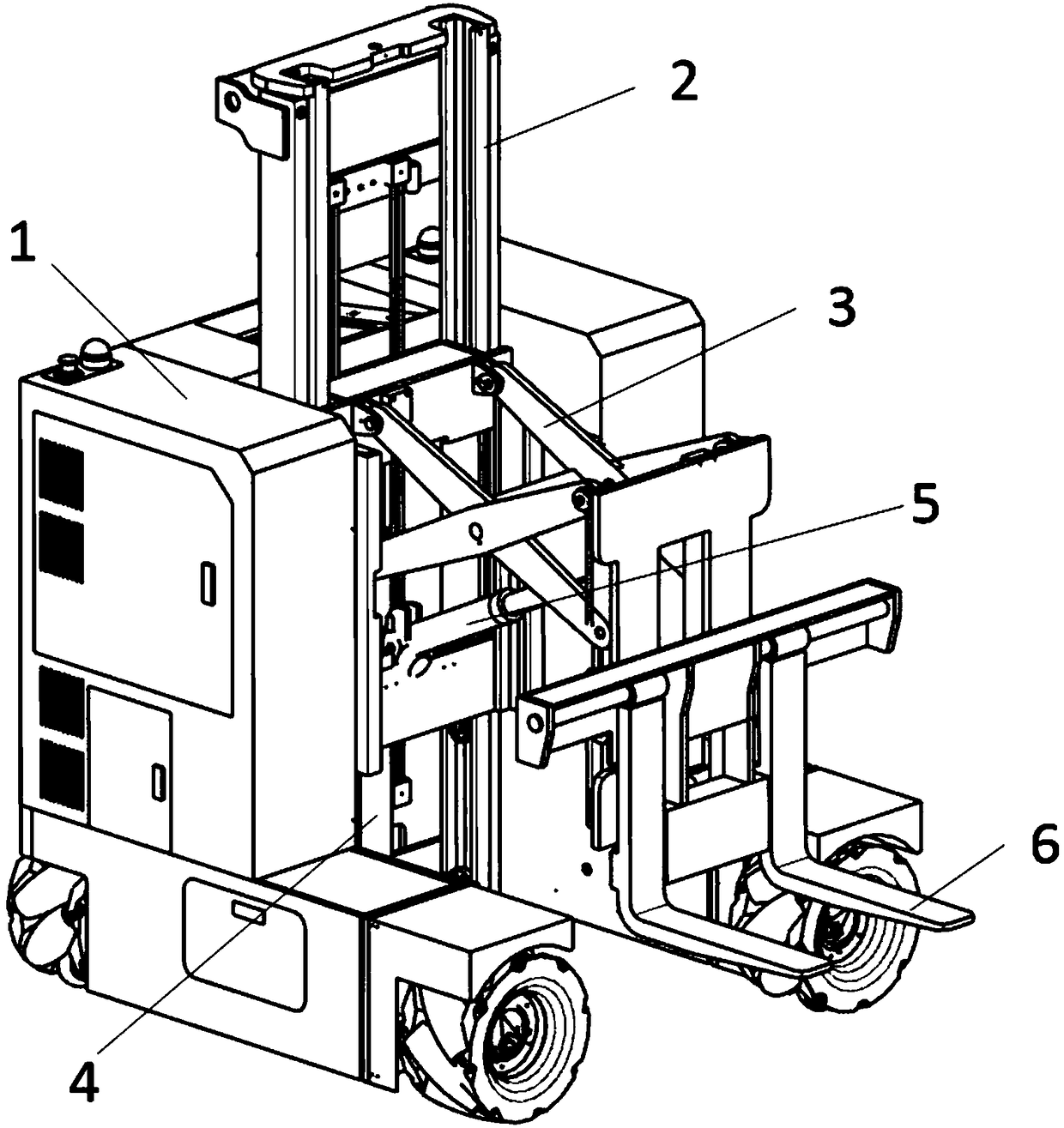

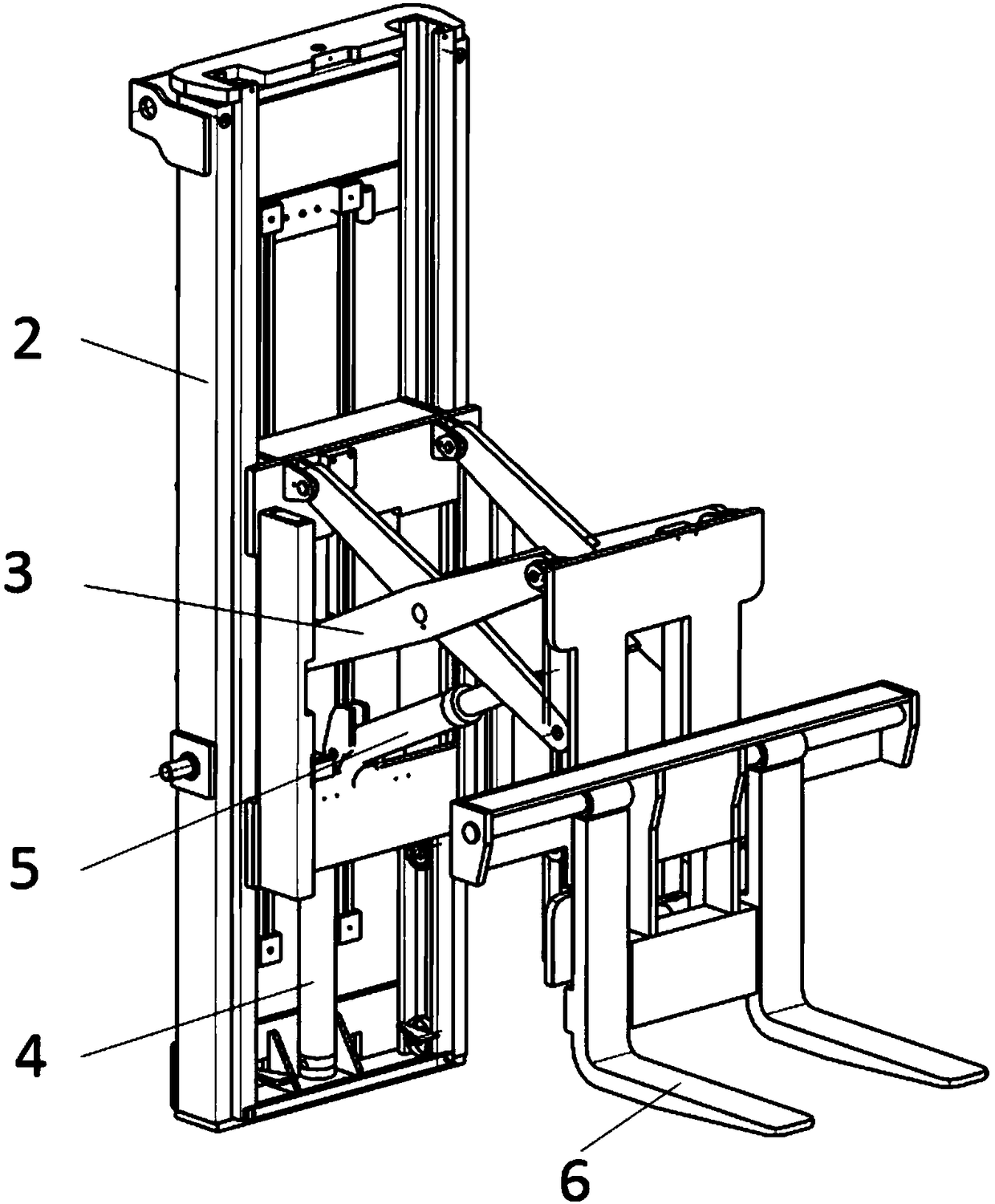

Stacking and transferring device based on omni-directional mobile platform

The invention relates to a stacking and transferring device based on an omni-directional mobile platform, and relates to the technical field of storage operation. The stacking and transferring devicebased on the omni-directional mobile platform can freely move in a warehouse in all directions, flexible transferring in the warehouse is achieved, and the operation efficiency is improved; the functions of obtaining, placing, stacking and transferring cargos in the warehouse can be achieved; the storage density can be increased, and the utilization rate of the warehouse can be effectively increased.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

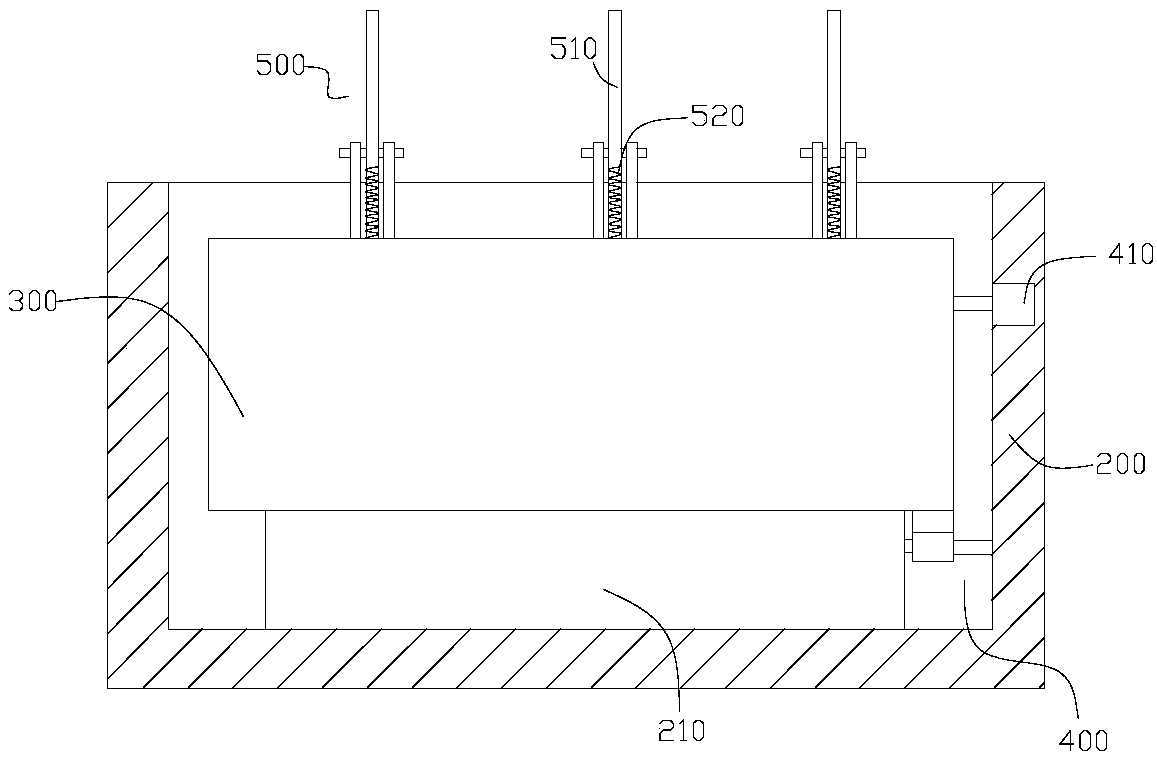

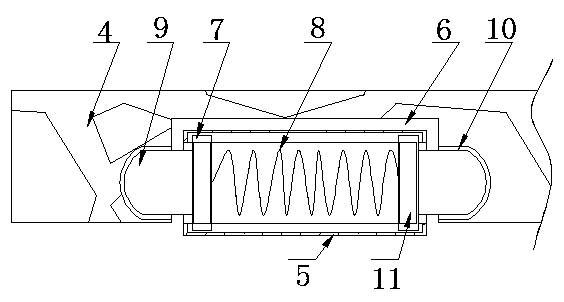

Mounting base for new energy automobile motor

ActiveCN110912328AAvoid damageImprove shock resistance and cushioning performanceStructural associationSupports/enclosures/casingsNew energyElectric machinery

The invention discloses a mounting base for a new energy automobile motor. The mounting base comprises a protective cover, a base and a motor body. The bottom of the motor body is fixedly connected with a bottom plate. Fixing frames are fixedly connected to the two sides of the bottom of the inner wall of the protective cover. Sliding grooves matched with the fixing frames are formed in the two sides of the bottom of the bottom plate. Sliding plates are slidably connected between the two opposite sides of the top and the bottom of the inner wall of the fixing frame, a buffer spring is fixedlyconnected between the opposite sides of the two sliding plates, and clamping blocks are fixedly connected to the sides, deviating from each other, of the two sliding plates. According to the mountingbase for the new energy automobile motor, motors of different sizes can be limited and fixed, the mounting base is stably mounted in a protective cover under the condition that normal work of the motors is not affected. Meanwhile, the vibration resistance and the buffering performance of the automobile motor are improved. The problem that the motor is damaged due to automobile jolt is solved, andthe actual use requirement is met.

Owner:爱浩博精密机械(淮安)有限公司

Novel storage box

InactiveCN106144379ARealize pick and placeTo achieve the purpose of picking and placing itemsStorage devicesEngineering

Owner:东莞市佰强实业投资有限公司

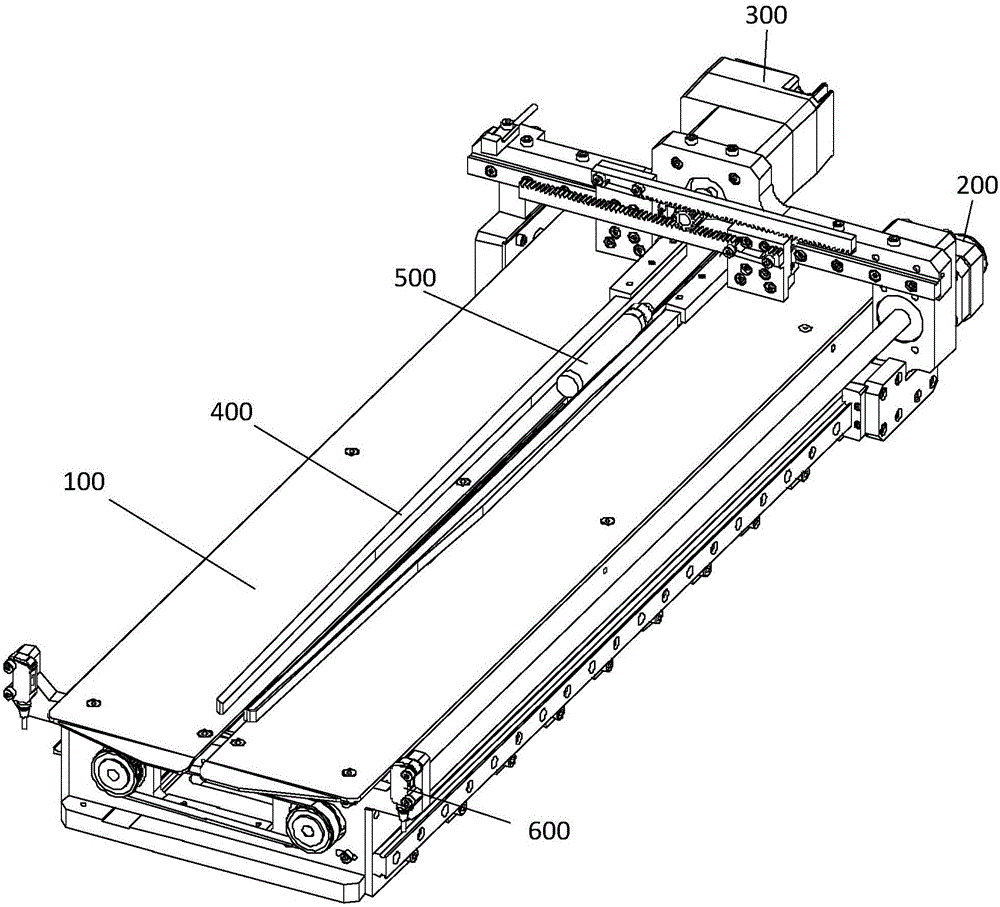

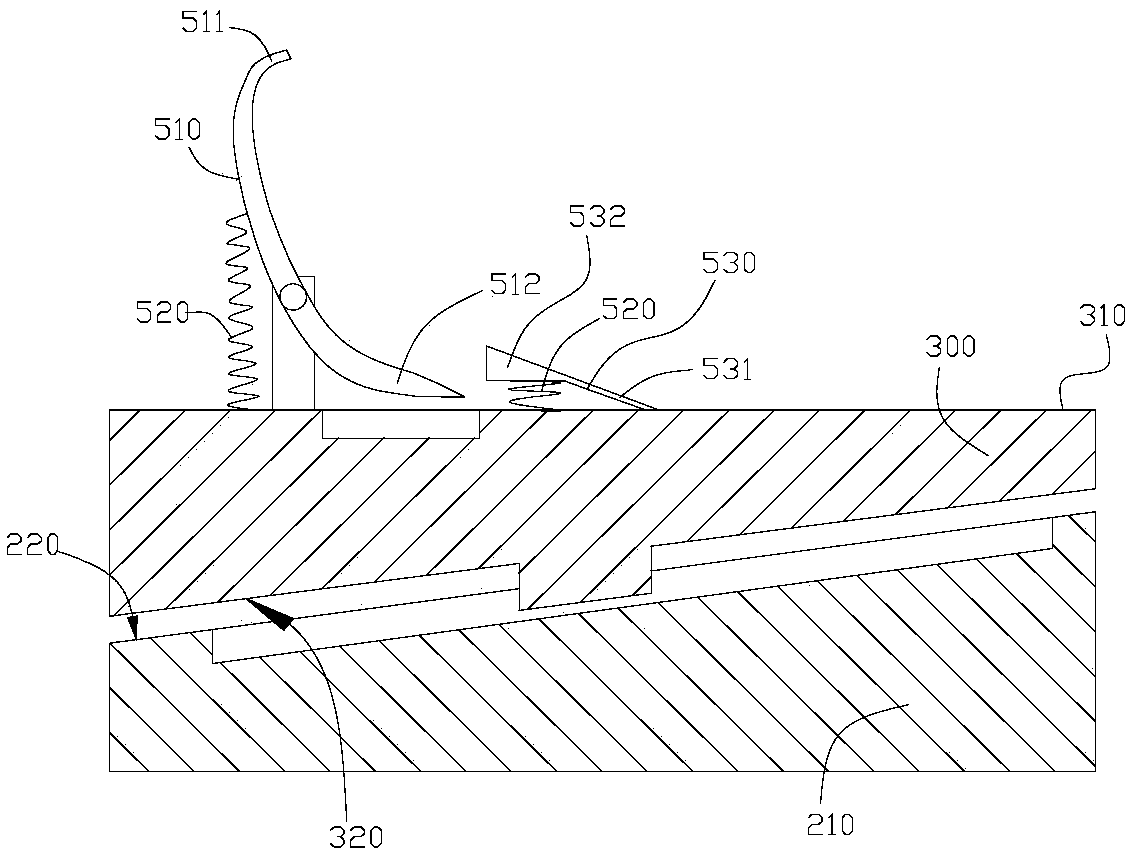

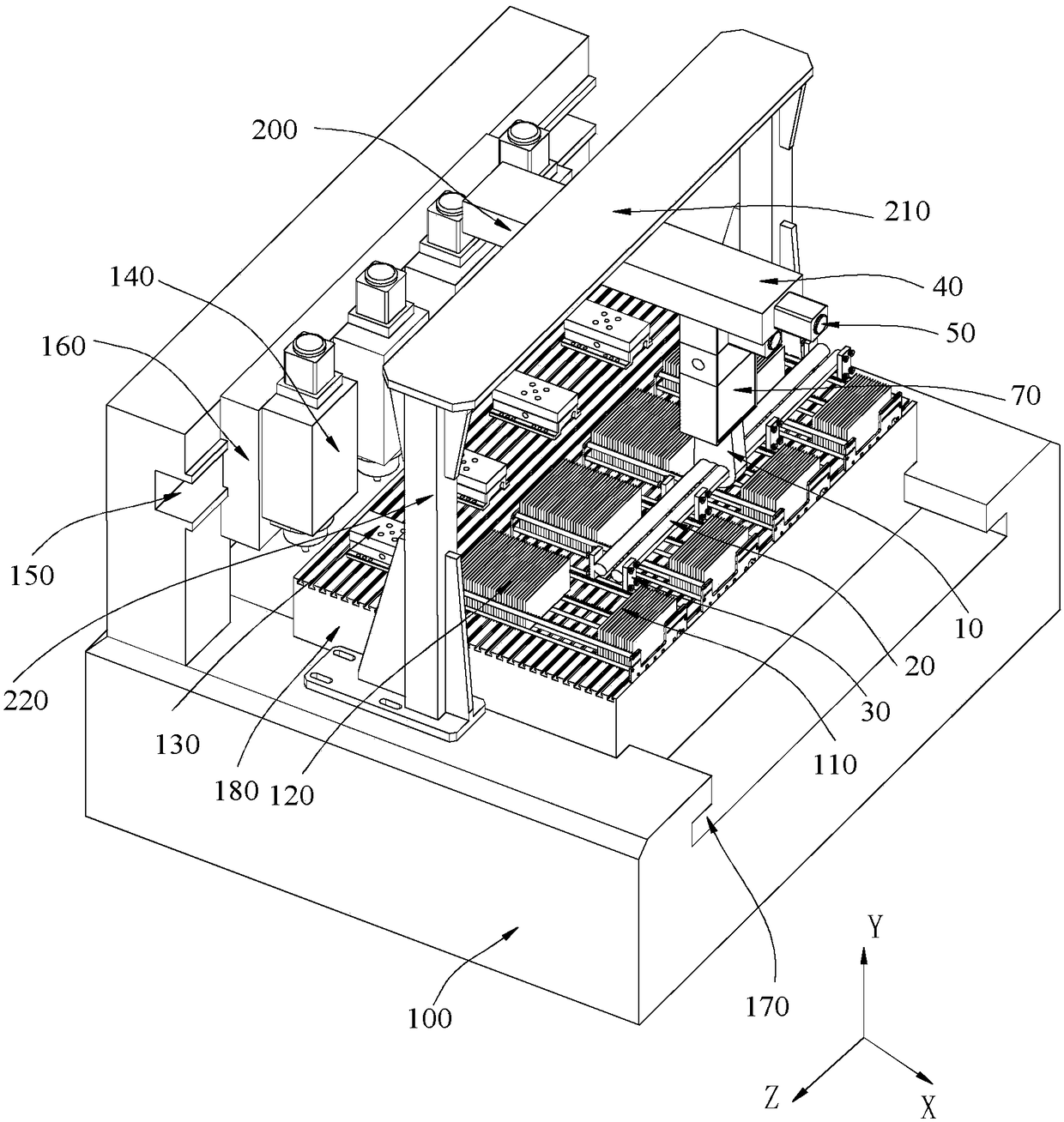

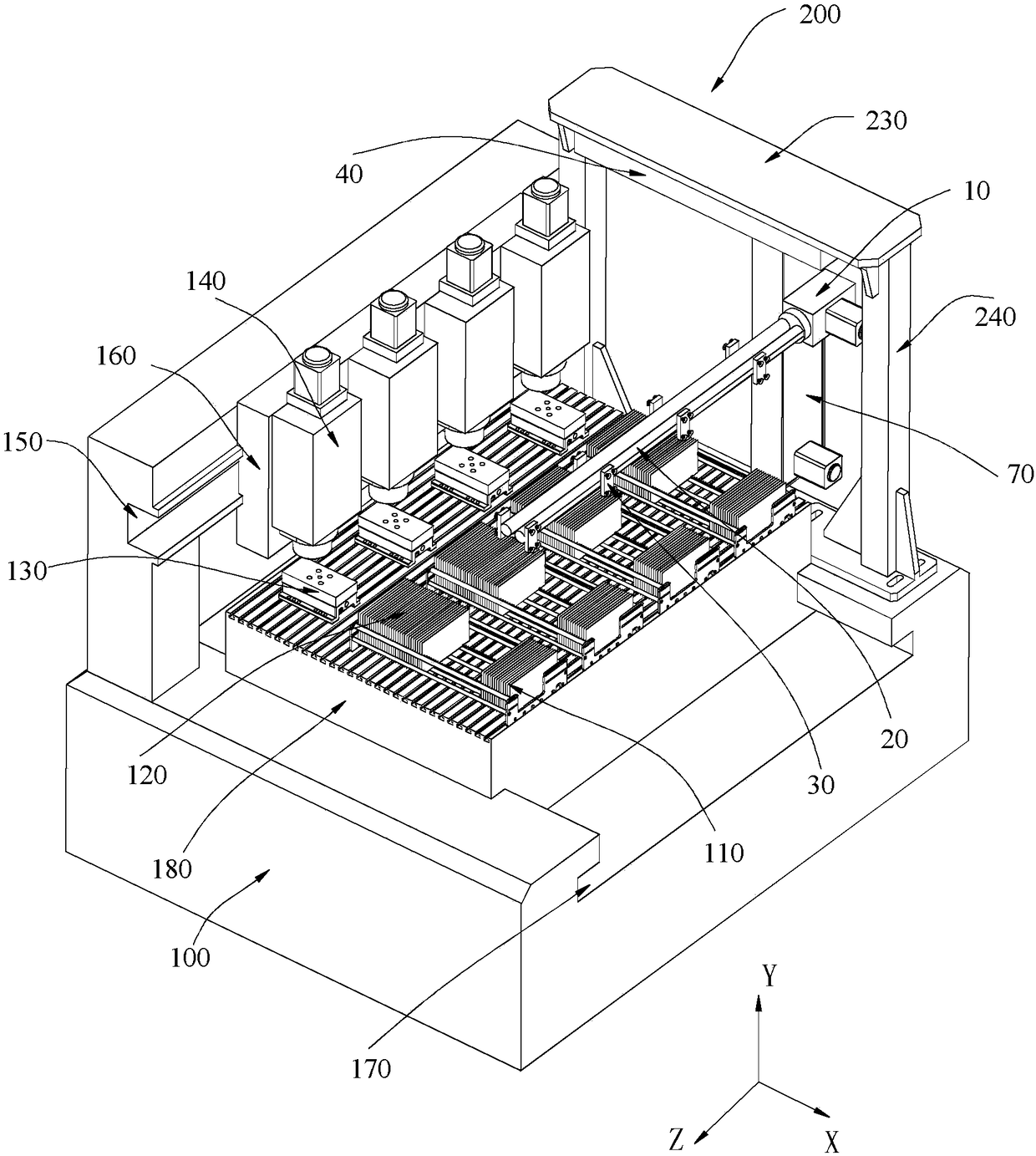

Plate picking-up and placing mechanism, and glass processing machine and method

PendingCN108408397ADoes not affect workImprove approachConveyor partsEngineeringMechanical engineering

The invention discloses a plate picking-up and placing mechanism, a glass processing machine and a glass processing method. The plate picking-up and placing mechanism comprises a mounting seat, two rotating rods and a first driving mechanism; the ends of the two rotating rods are both pivoted on the mounting seat; picking-up and placing pieces are arranged on the two rotating rods correspondingly;and the first driving mechanism is arranged on the upper portion of the mounting seat and used for driving the mounting seat to move in the X-axis direction and the Y-axis direction. The glass processing machine comprises the plate picking-up and placing mechanism, a processing platform, a processing machine head, a material frame and a second driving mechanism; the two rotating rods of the platepicking-up and placing mechanism are both arranged on the upper portion of the material frame; the processing platform is arranged at the end, close to a discharging area, in the X-axis direction andcan move in the X-axis direction; the processing machine head is arranged on the upper portion of the processing platform; and the second driving mechanism is used for driving the processing machinehead to move in the Y-axis direction and the Z-axis direction. The glass processing method comprises the following steps of picking up, processing and placing. Feeding, discharging and independent picking-up and placing before and after glass processing can be achieved.

Owner:SHENZHEN DAYUCNC TECH

Quakeproof hammer replacement device, robot with same and quakeproof hammer replacement method

ActiveCN105896370ARealize pick and placeAchieve placementApparatus for overhead lines/cablesEngineeringReplacement method

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD MAINTENANCE CO +2

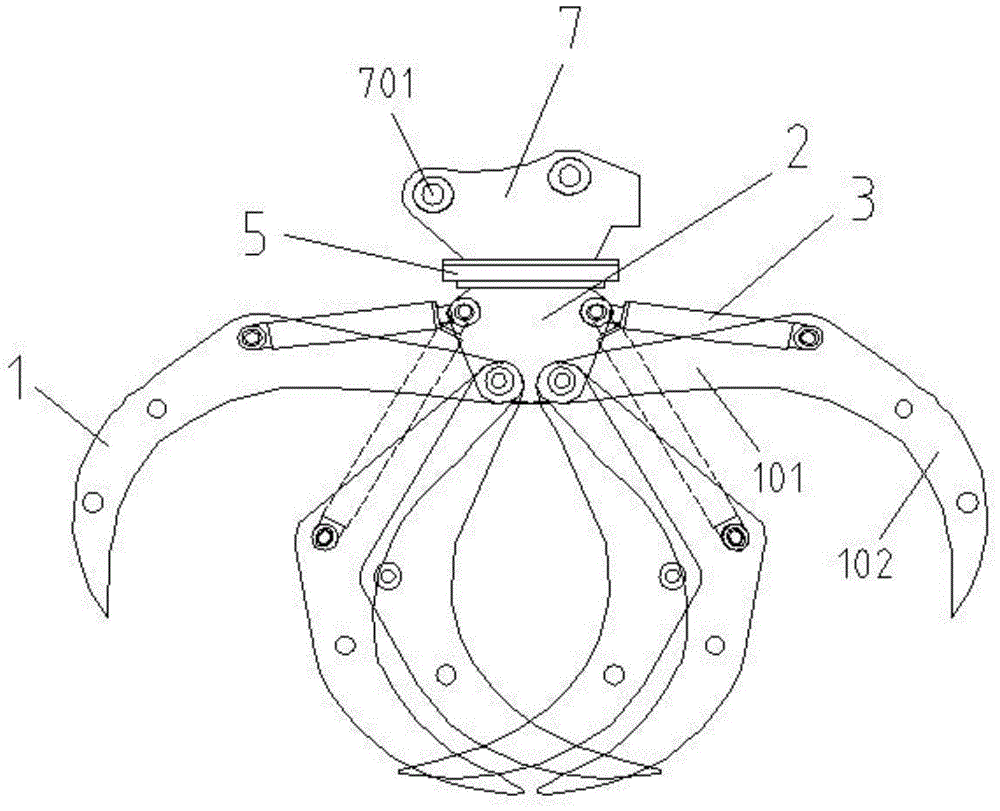

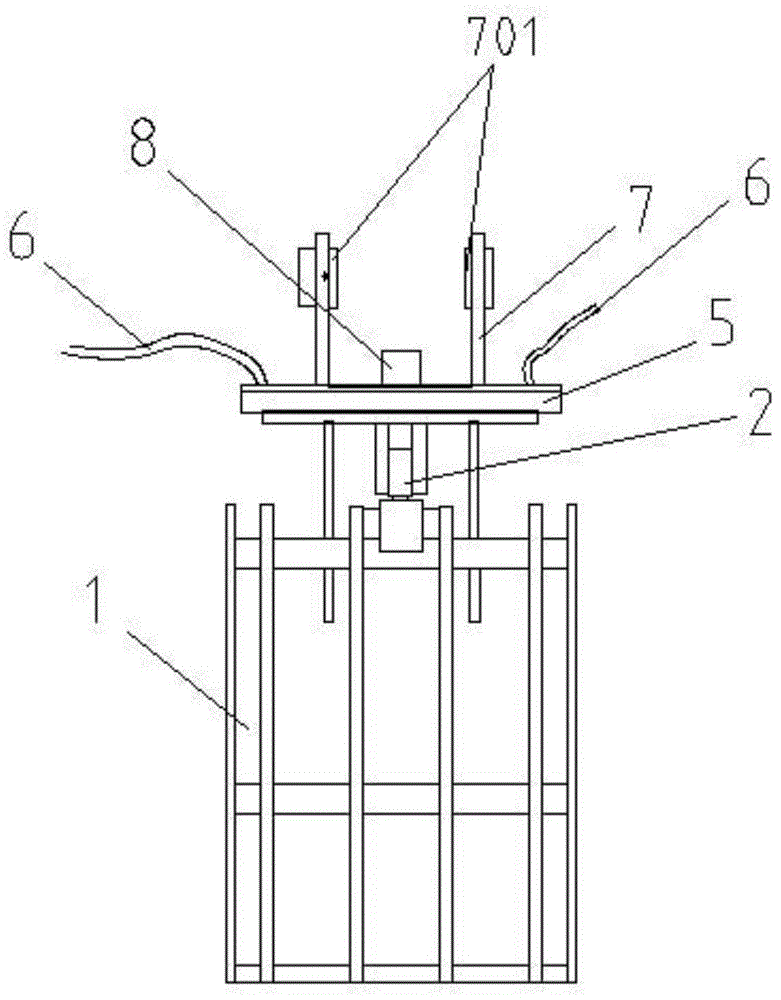

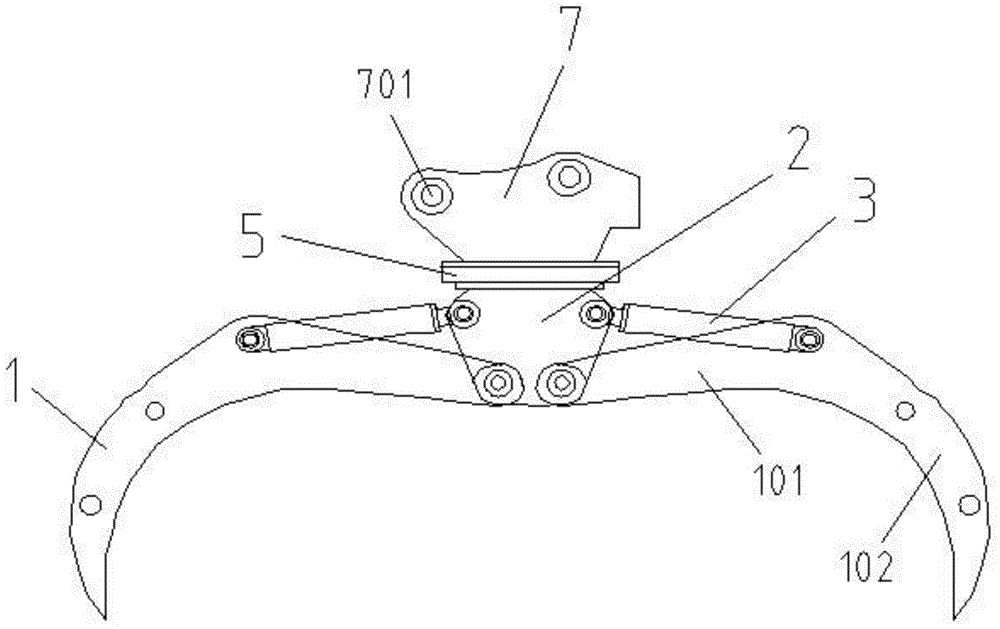

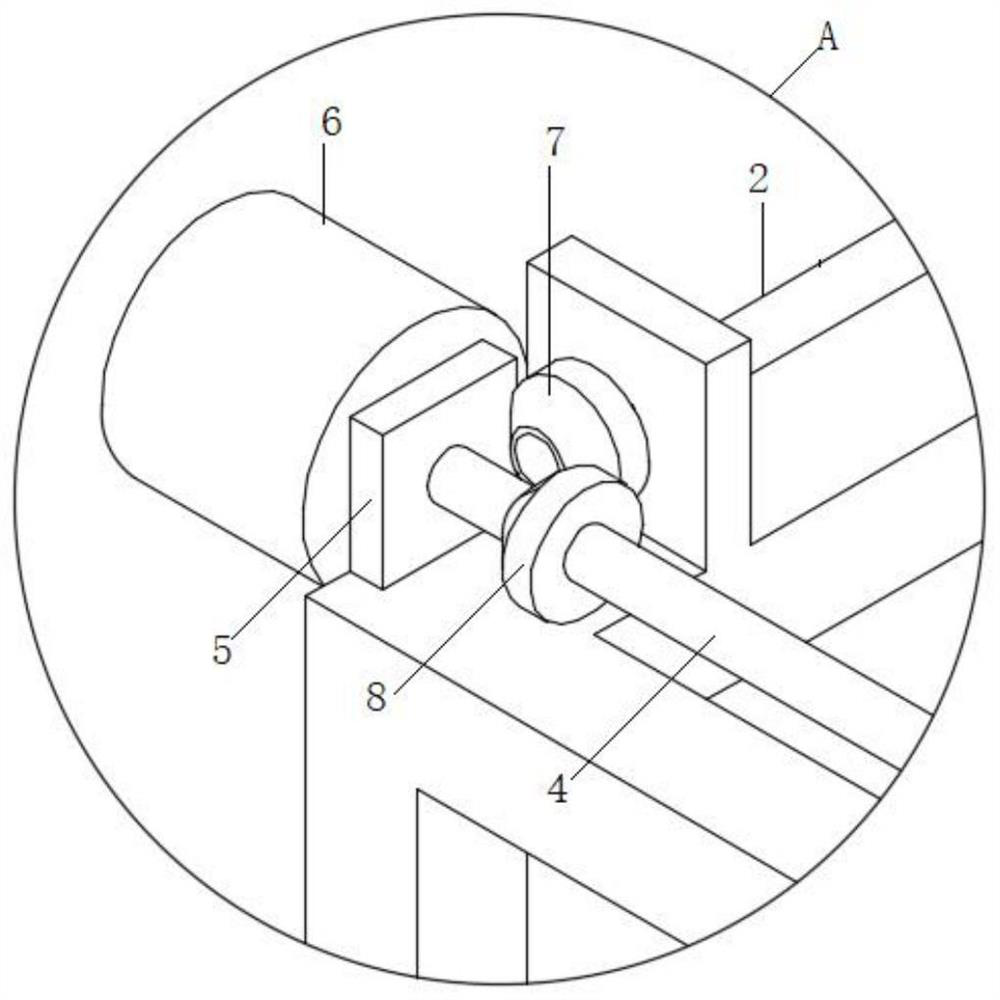

Hydraulic rotary clamp metal structural element

InactiveCN105317060ARealize pick and placeAddress flexibilitySoil-shifting machines/dredgersEngineeringOmni directional

The invention relates to an excavator, in particular to a replacement of a bucket of the excavator. A hydraulic rotary clamp metal structural element comprises an oil cylinder (2) and a hydraulic control system and is further provided with an oil cylinder rod (3), a rotary support (5) and a motor (8). The oil cylinder (2) is fixed to the inner circle of the rotary support (5), the motor (8) is fixed to the outer circle of the rotary support (5), a rotary shaft of the motor (8) is fixedly connected with the oil cylinder (2), at least two rows of opposite arm clamps (1) are hinged to the oil cylinder (2), each arm clamp (1) is composed of a straight line section (101) and a bent section (102), the arm clamps (1) are hinged to the oil cylinder through the straight line sections (101), one end of the oil cylinder rod (3) is hinged to the arm clamps (1), and the other end of the oil cylinder rod (3) is hinged to the oil cylinder. The structural element can achieve omni-directional mechanization and intelligent actions of multi-dimensional material grasping, material placing, material moving, stacking and a series of work.

Owner:SHENZHEN WANGANG LOGISTICS DEV

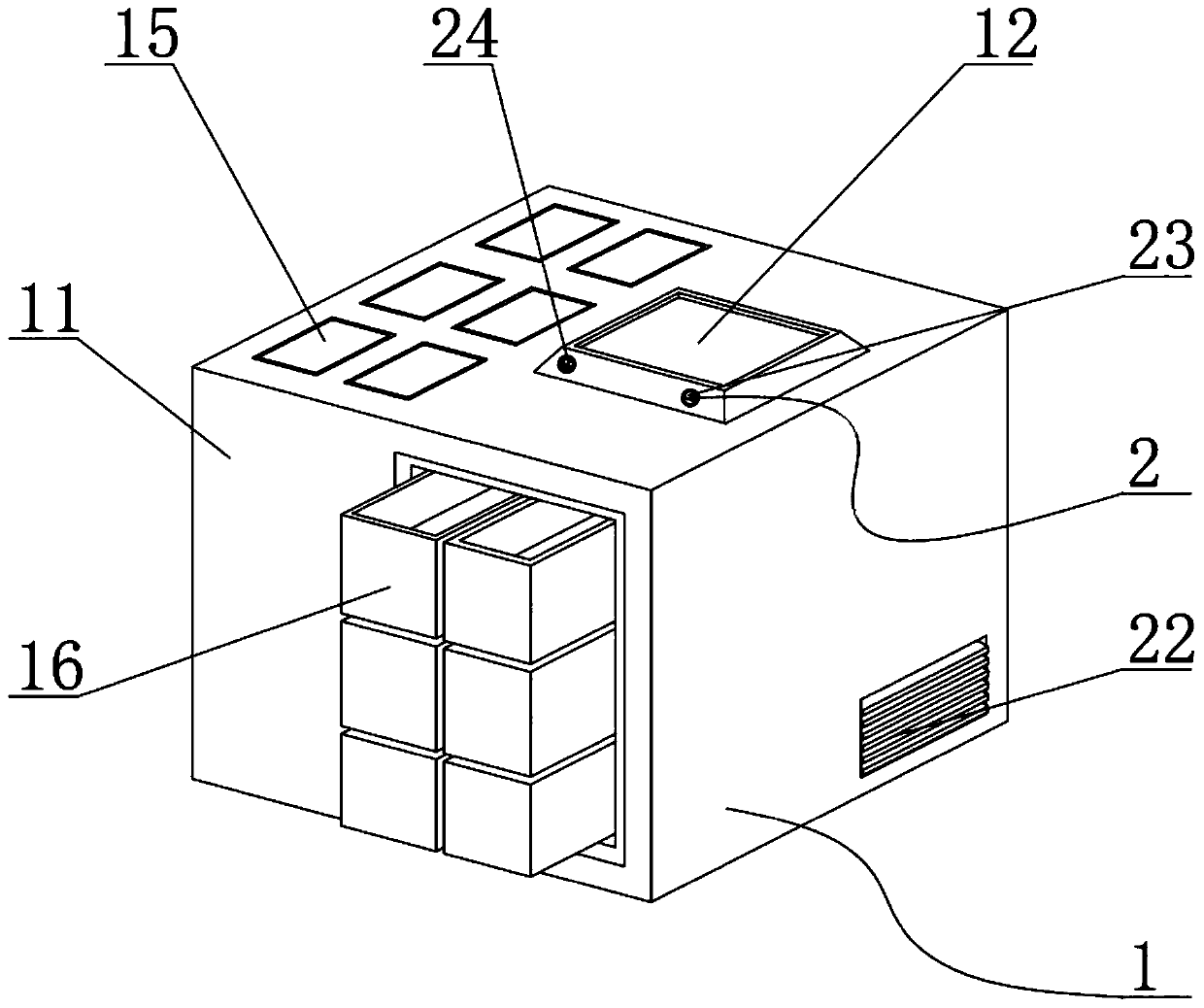

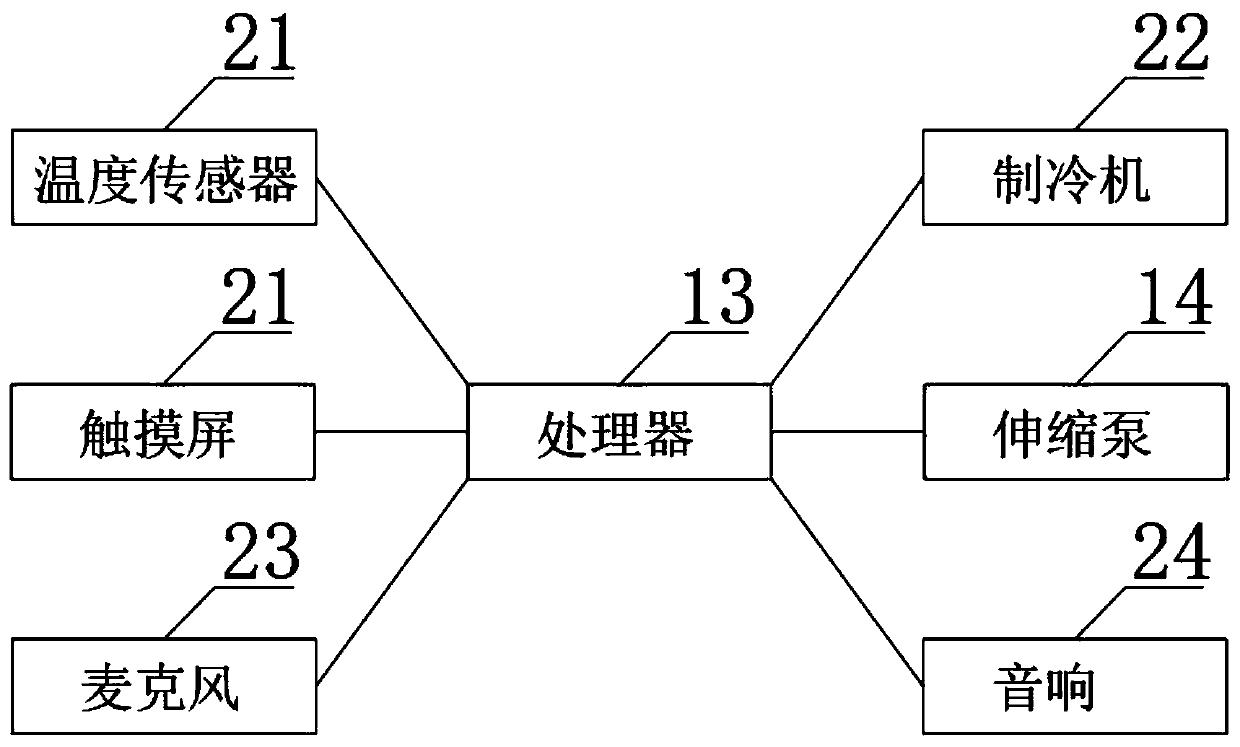

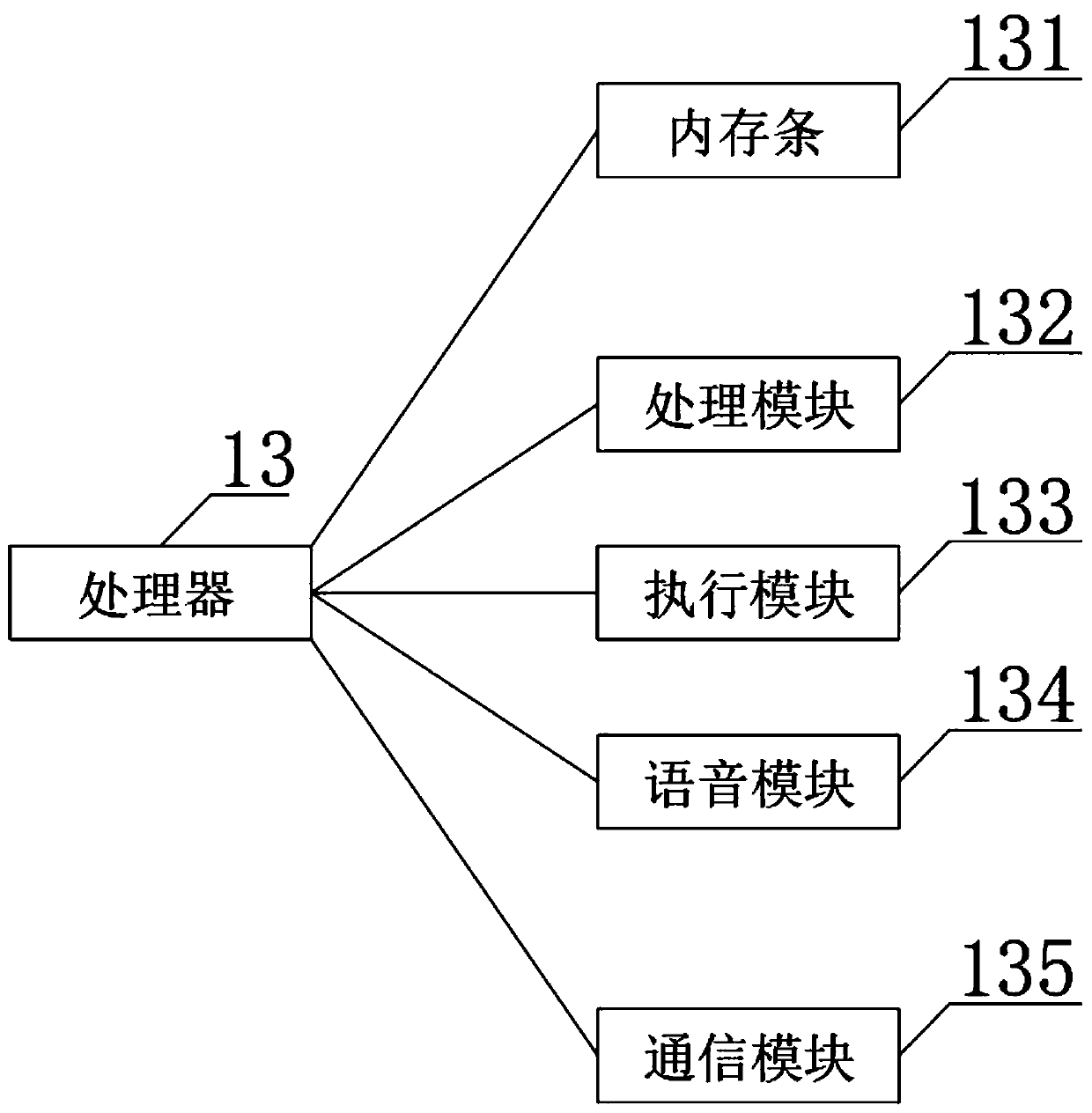

Intelligent limit first-aid kit

InactiveCN110507053AEasy to grab medicineRealize pick and placeMedical communicationPursesIntelligent lightingNetwork termination

The invention is suitable for the technical field of medical kits, and provides an intelligent limit first-aid kit. The intelligent limit first-aid kit comprises a kit assembly; the kit assembly comprises a kit body used for automatically adjusting the temperature; a touch screen used for human-computer interaction is installed on the surface of the kit body; the touch screen is electrically connected with a processor used for processing data and connected with a network terminal; and the processor comprises a database memory bank which stores real-time types and quantities of medicines in thekit and daily common disease recipes. The processor is controlled by voice input or touch screen operation; the processor is controlled to perform disease pairing diagnosis in a database of the memory bank and open corresponding drawers and containing boxes according to prescriptions corresponding to diseases; the processor can be controlled to access the internet to perform video diagnosis, prescription making and medicine taking with experts of a network terminal under the condition that the diseases cannot be judged; and the diagnosis function is added on the basis of an original kit, so that the whole kit is more intelligent and practical.

Owner:冯翔伟

Automatic stacking machine based on storage battery production

InactiveCN113335919ARealize palletizingImprove palletizing efficiencyStacking articlesConveyor partsElectric machineGear wheel

The invention discloses an automatic stacking machine based on storage battery production, and relates to the technical field of automatic equipment. The automatic stacking machine comprises a rack, wherein a pair of first lead screws is symmetrically and fixedly connected to the rack; a rotating shaft is fixedly connected to one end of the rack; a first motor is connected to one end of the rotating shaft; a first gear is fixedly connected to one end of each first lead screw; a second gear is fixedly connected to the rotating shaft; first sliding blocks are connected to the first lead screws in a threaded mode; a first driving mechanism is fixedly connected between the two first sliding blocks; a vertical second driving mechanism is fixedly connected to the first driving mechanism; and a grabbing assembly is fixedly connected to the second driving mechanism. According to the automatic stacking machine, through cooperation of the first driving mechanism and the second driving mechanism, the grabbing assembly can move in the transverse direction, the longitudinal direction and the vertical direction, so that stacking of storage batteries is achieved, and the stacking efficiency of the storage batteries is improved.

Owner:ANHUI HONGDA ELECTRICAL SOURCE

Automated sample pretreatment system

PendingCN113466480ARealize automatic sample injectionAchieve mixingMaterial analysisProcess engineeringTherapeutic effect

The invention discloses an automatic sample pretreatment system which comprises a mounting frame, and a horizontal conveying mechanism, a clamping mechanism, a safety protection mechanism, a vertical lifting mechanism, a weighing and filling mechanism, a sample frame transmission device, a mixing device, an automatic cover opening and closing transfer mechanism and a bar code scanner are arranged on the mounting frame. According to the invention, the whole-support or single-support automatic sample injection of a sample can be realized, and the sample can be added at any time in the sample injection process, so that the operation flexibility of medical personnel is improved; transferring, weighing, filling, uniform mixing and sample adding of samples can be achieved, and the pretreatment efficiency and consistency are improved; in the filling process, standardized addition can be performed according to a weighing result, so that errors caused by manual sample size evaluation are effectively solved, and the sample digestion effect is improved; and by adopting the uniform mixing device capable of improving the homogenization treatment effect of the non-liquid sample, the uniform mixing effect is enhanced.

Owner:AUTOBIO LABTEC INSTR CO LTD

Automobile hub conveying device and conveying method thereof

ActiveCN108423284AEasy accessRealize pick and placeContainers for annular articlesExternal fittingsSurface mountingGear wheel

The invention discloses an automobile hub conveying device. The automobile hub conveying device comprises a supporting box body; a first supporting plate and a second supporting plate are perpendicularly fixed to the top end surfaces of the side walls of the supporting box body; a first rotating shaft is fixed to the rear side wall of the supporting box body; a driving bevel gear is fixed to one end of the first rotating shaft; a second rotating shaft is installed and fixed to the surface of the first supporting plate; a driven bevel gear matched with the driving bevel gear is fixed to the bottom end of the second rotating shaft, and a first driven gear is fixed to the top end of the second rotating shaft; a first screw rod is fixed to the end face of the first driven gear; a first fixingshaft and a second fixing shaft are fixed to the surface of the first supporting plate; a second driven gear engaged with the first driven gear is fixed to the first fixing shaft; and a second screw rod is fixed to the end face of the second driven gear. The automobile hub conveying device is provided with a plurality of bearing plates, when the bearing plates are used, the bearing plates are madeto be in stair-shaped distribution due to transmission of the gears and the screw rods, the adjacent bearing plates are not affected by each other during hub taking and placing, and hubs on the upperlayer and the lower layer of the bearing plates can be directly taken and placed conveniently.

Owner:ANHUI SANLIAN UNIV

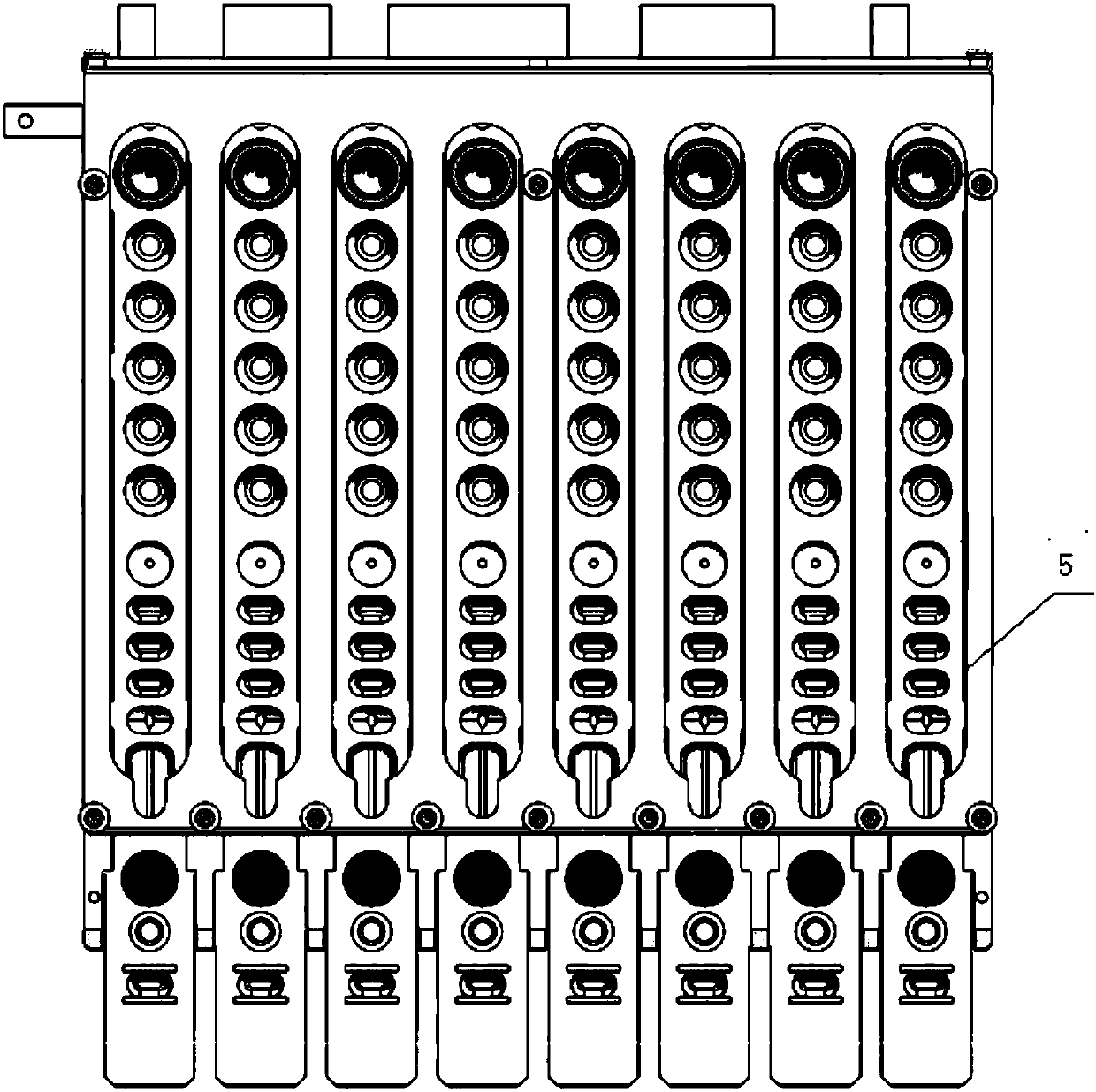

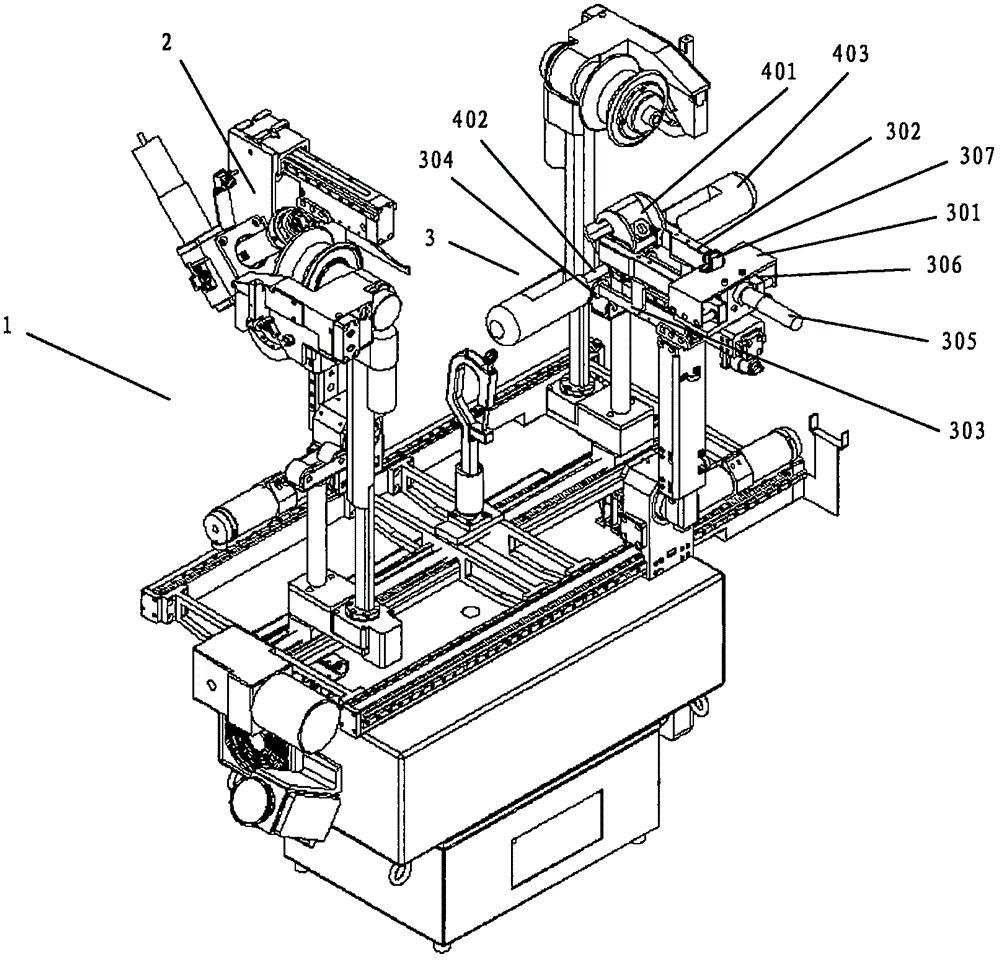

Fiber cake grabbing fixture and automatic fiber cake stacking system and method

InactiveCN109850585AHigh positioning accuracyExtended service lifeStacking articlesDe-stacking articlesFiberMechanical engineering

The invention discloses a fiber cake grabbing fixture and an automatic fiber cake stacking system. The grabbing fixture comprises a fixture base plate; at least one clamping jaw set is arranged on thefixture base plate; each clamping jaw set comprises two fixture modules arranged at intervals; each fixture module comprises a fixture base and a fiber taking module; each fiber taking module is arranged on each fixture base; the fixture base plate is provided with driving modules corresponding to the clamping jaw sets; the driving modules drive two fixture modules in the same clamping jaw set toapproach or leave from each other; the grabbing fixture is provided with the driving modules corresponding to the clamping jaw sets; the driving module can synchronously drive the two fixture modulesin the same clamping jaw set to approach or leave from each other, so that a gap between the fixture modules is conveniently adjusted to meet the gap change demands of fiber cakes in the fiber cake taking and placing process, and the fiber cake stacking efficiency is improved; and the invention provides the automatic fiber cake stacking system and stacking method to achieve effective improvementof the stacking efficiency, high reliability and reduction of the labor intensity.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com