Automated sample pretreatment system

A sample and sample rack technology, applied in the field of automatic testing equipment, can solve the problems of cross-contamination of samples, great influence of addition amount, difficulty in grasping uniformity and standardization, etc., so as to improve efficiency and consistency, increase operational flexibility, and facilitate Effects of adjustments and optimizations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific working processes are provided, but the protection scope of the present invention is not limited to the following Described embodiment.

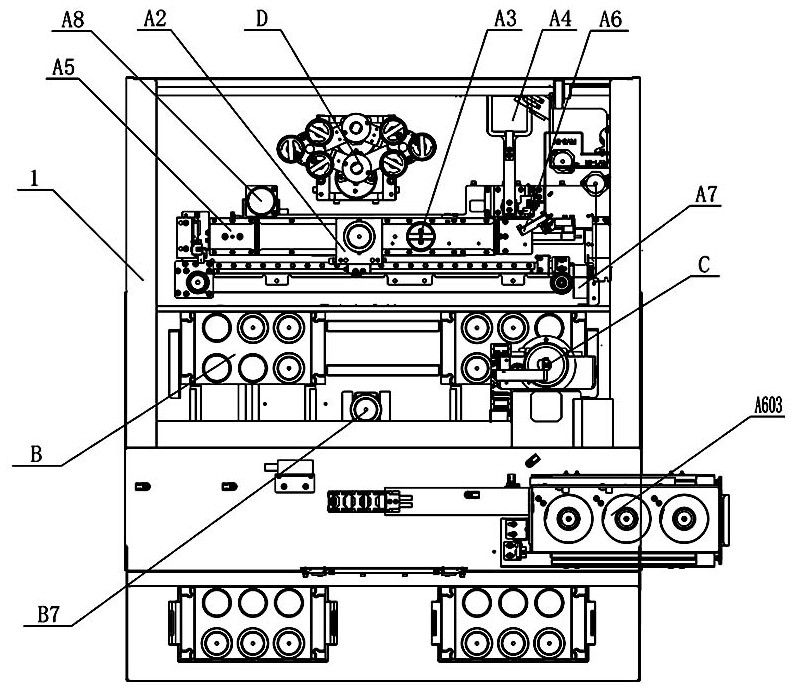

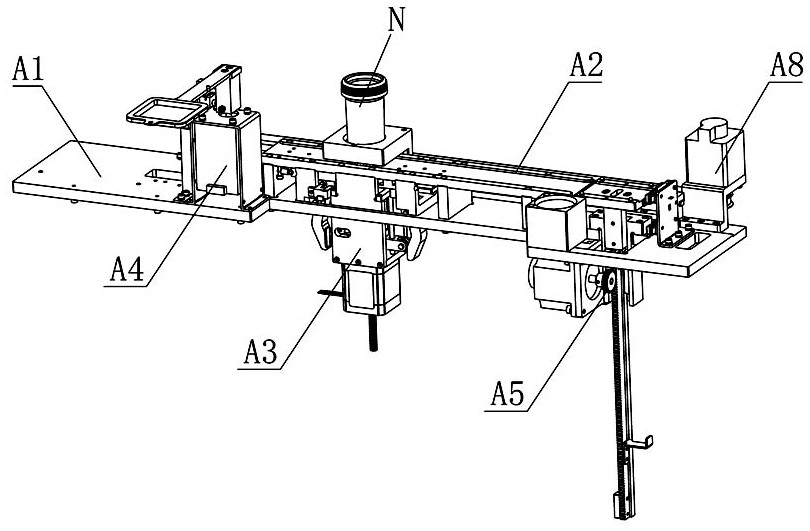

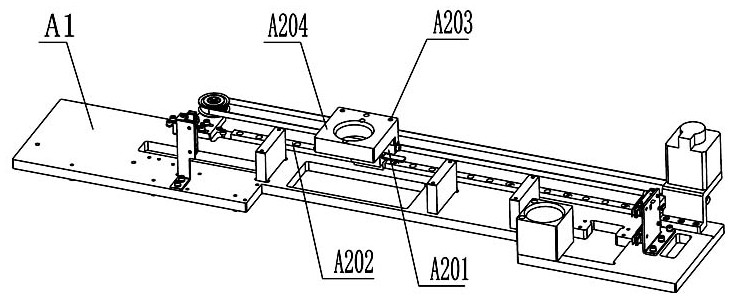

[0088] like figure 1 As shown, the automated sample pretreatment system of the present invention includes an installation frame 1 on which a horizontal conveying mechanism A2, a clamping mechanism A3, a safety protection mechanism A4, a vertical lifting mechanism A5, and a weighing and filling mechanism are installed. A6, sample rack transmission device B, mixing device D, automatic opening and closing cover transfer mechanism C, barcode scanner A7, abnormal sample temporary storage tank A8 and abnormal sample storage B7, etc., used to realize the whole tray or single tray o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com