Sample pretreatment mechanism and full-automatic analysis system for direct-reading spectrometer

A technology of sample pretreatment and direct-reading spectrometer, which is applied in the field of automatic analysis system, can solve the problems of reducing detection efficiency, operating errors, overtime and other problems, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

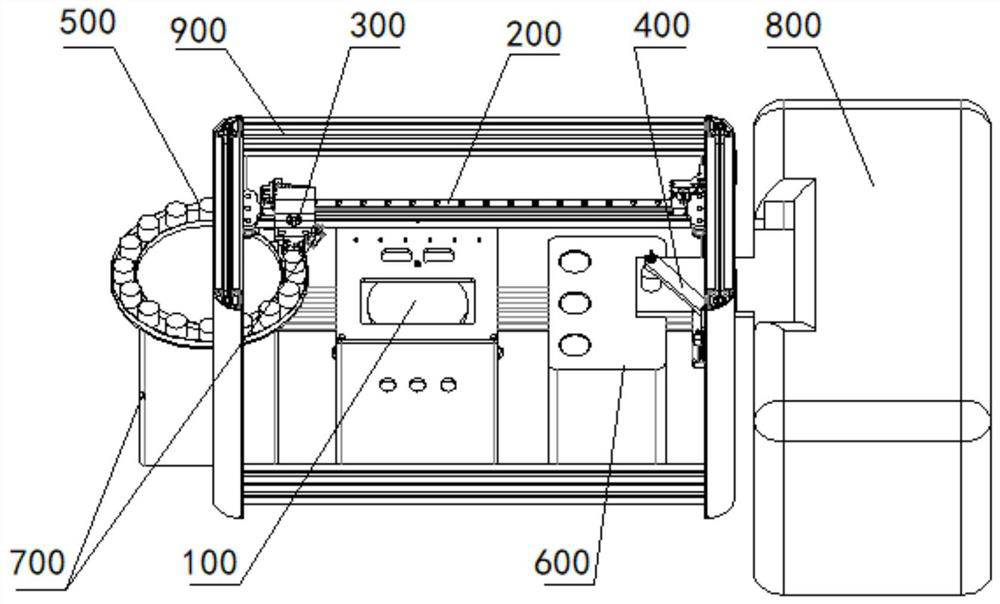

[0053] A sample pretreatment mechanism provided by an embodiment of the present invention includes:

[0054] A sample introduction assembly 500; the sample introduction assembly 500 includes a sample tray 501 and a first drive member for driving the sample tray 501 to rotate; the sample tray 501 has a plurality of sample positions arranged in a circle;

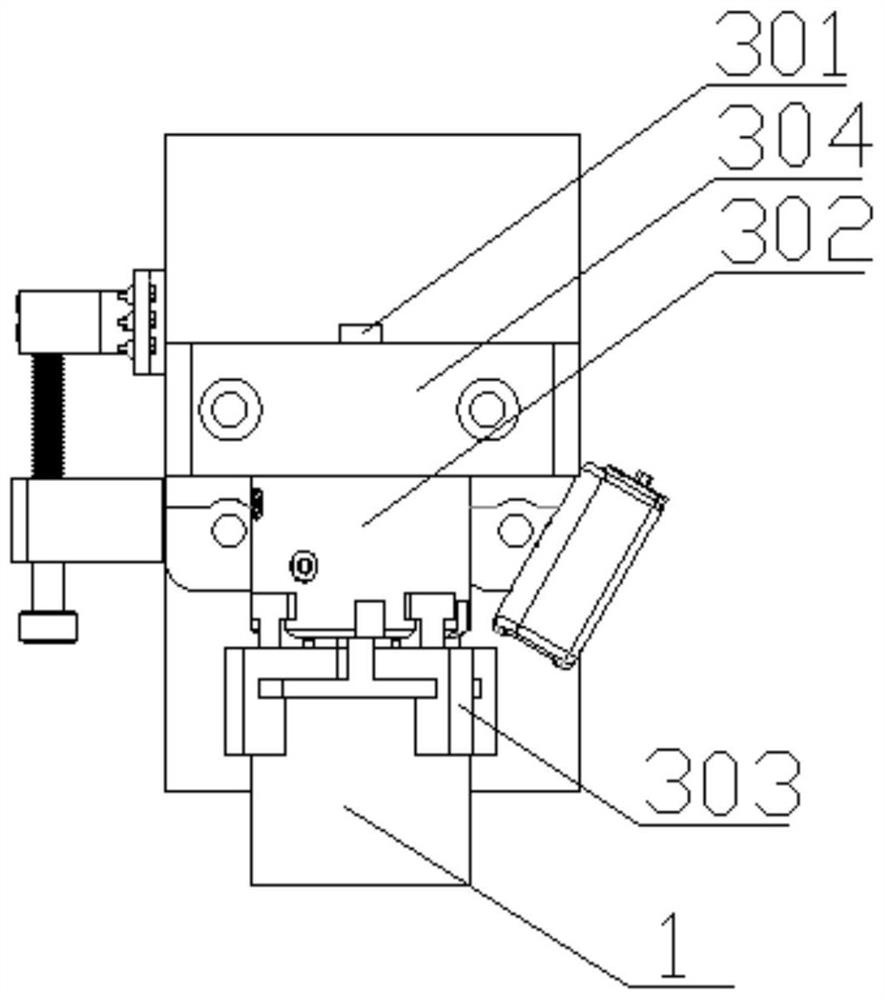

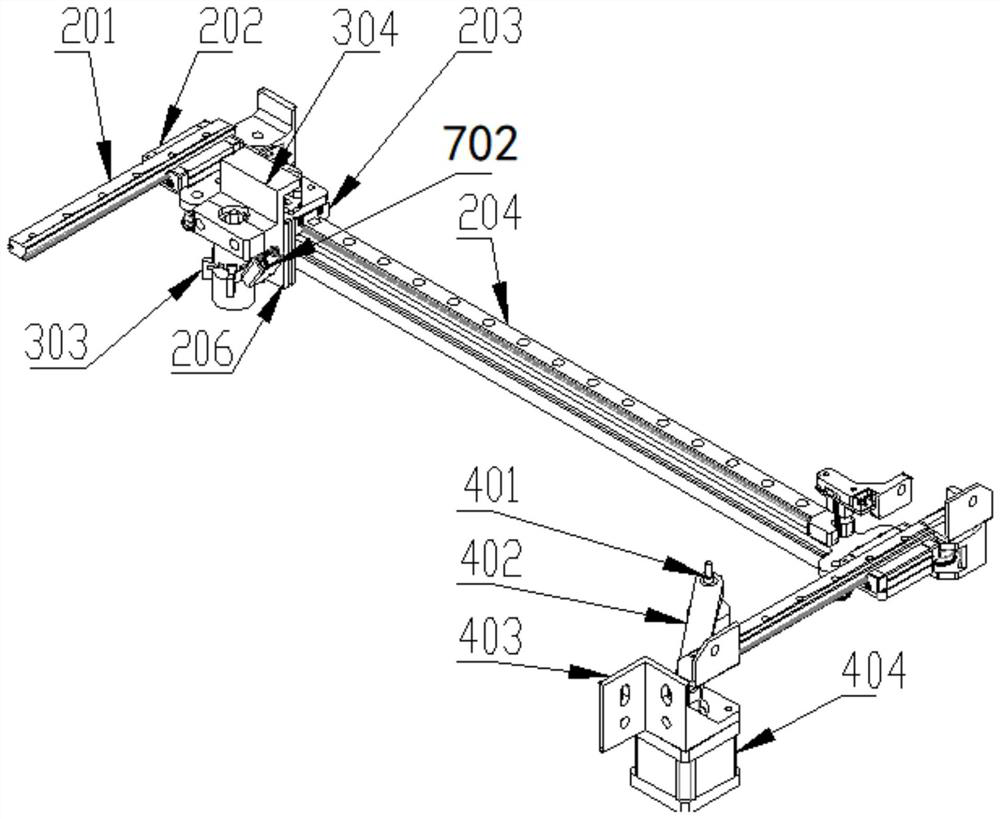

[0055] A sampling component 300, configured to grab a sample 1 from the sample position;

[0056] Sample grinding assembly 100, used for grinding sample 1;

[0057]The transfer assembly 200 is used to drive the sampling assembly 300 to reciprocate along the x-axis, y-axis and z-axis direction, so that the sampling assembly 300 grabs the sample 1 from the sample position, and transfers the grabbed sample 1 to the grinding sample assembly 100 to perform grinding, and transfer the polished sample 1 to a designated position; or realize that the sampling component 300 directly transfers the sample 1 grasped from the sample positio...

Embodiment 2

[0099] as attached figure 1 As shown, an embodiment of the present invention also provides a kind of automatic analysis system for direct-reading spectrometer, comprising:

[0100] Direct reading spectrometer 800, used to analyze the element content of sample 1;

[0101] The sample pretreatment mechanism described in any one of Embodiment 1; the transfer assembly 200 in the sample pretreatment mechanism drives the sampling assembly 300 to transfer the polished sample 1 to the direct-reading spectrometer 800, or drives the sampling assembly 300 to directly transfer the sample 1 from The sample 1 grabbed by the sample position is transferred to the direct reading spectrometer 800 .

[0102] In this embodiment, the direct-reading spectrometer 800 is connected with the sample pretreatment mechanism in Embodiment 1 through a frame 900 to form a whole.

[0103] The working principle of the embodiment of the present invention is as follows:

[0104]The mechanical claw 303 transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com