Double-working-station stacking machine with temporary storage area and working method of butt joint area of double-working-station stacking machine

A buffer area and double-working technology, which is applied in the field of stackers, can solve the problems of no stacker, only one cache position, and low efficiency of picking up goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the embodiments, and the X and Y directions below are subject to the directions indicated in the drawings.

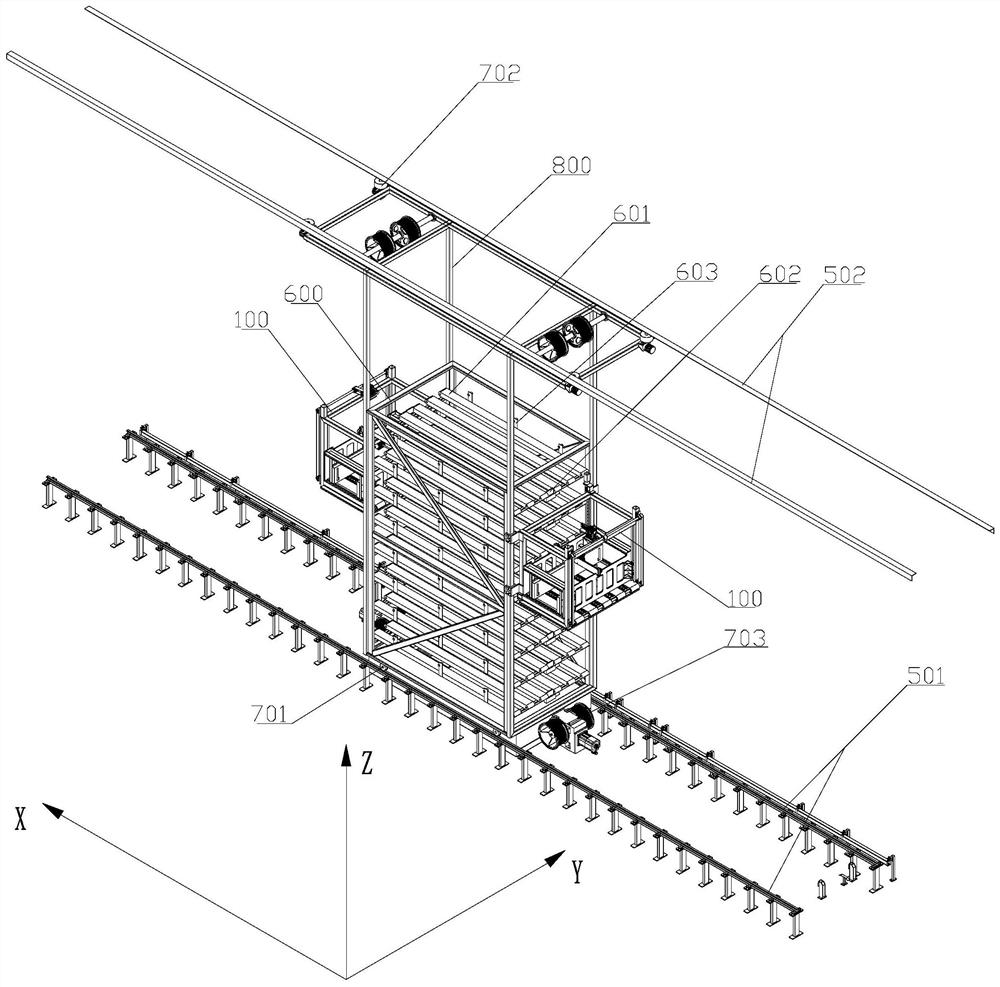

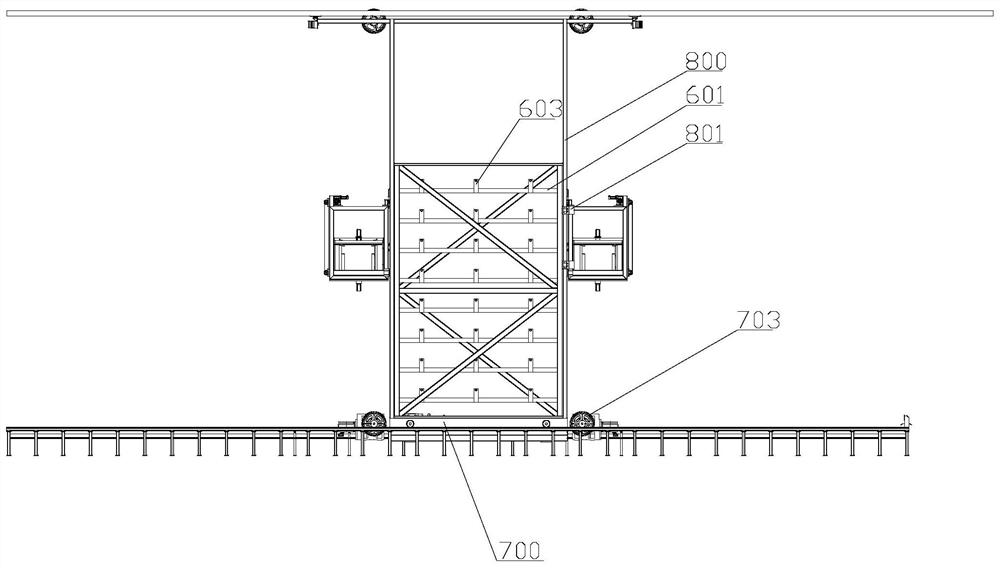

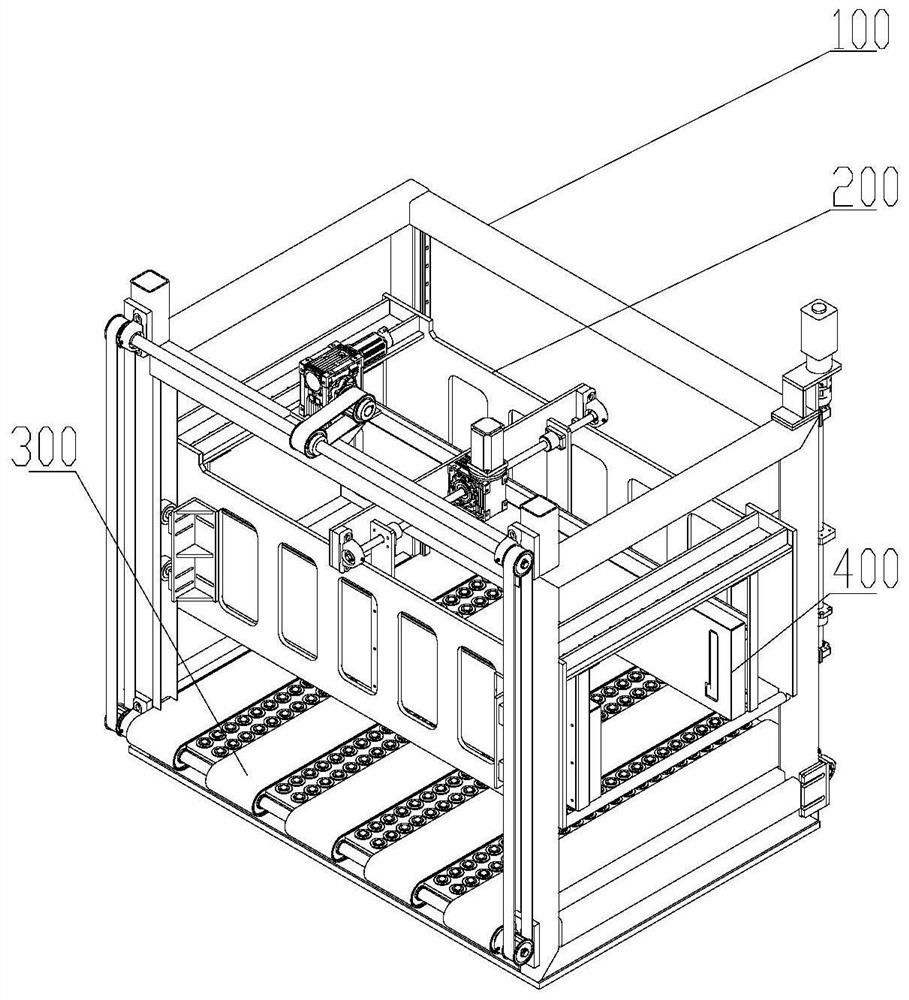

[0046] like figure 1 and 2 As shown, this embodiment proposes a dual-station stacker with its own buffer area, including a stacker seat 700 , a translation mechanism, a loading platform lifting mechanism 703 , a loading platform and a buffer area 600 . The stacker vehicle seat 700 is a plate structure, and the translation mechanism is installed on the stacker vehicle seat 700, including a bottom traveling wheel 701, a top traveling wheel 702 and a reduction motor driving the bottom traveling wheel 701 to operate. The buffer area 600 is fixed above the middle part of the stacker seat 700. Because the stacker has added a buffer area 600, it is heavier than the traditional stacker. It is necessary to set up and down a total of four tracks in the warehouse, namely figure 1 The doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com