Combined clamp for palletizing and transferring robot

A technology for handling robots and fixtures, which is applied in the directions of transportation and packaging, unstacking of objects, conveyor objects, etc. It can solve the problems that affect the production efficiency and effect, the stacking is easy to be inconsistent, and the labor intensity is high, so as to achieve stacking effect and efficiency improvement , reduce the amount of labor, and the effect of simple and reasonable institutional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

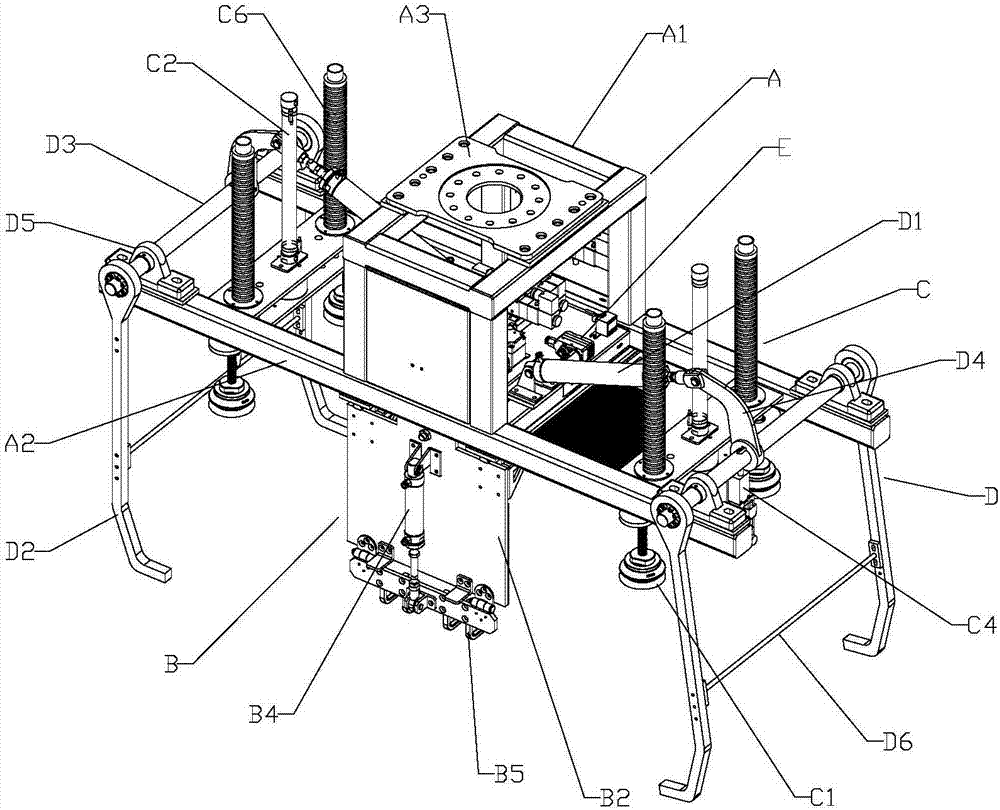

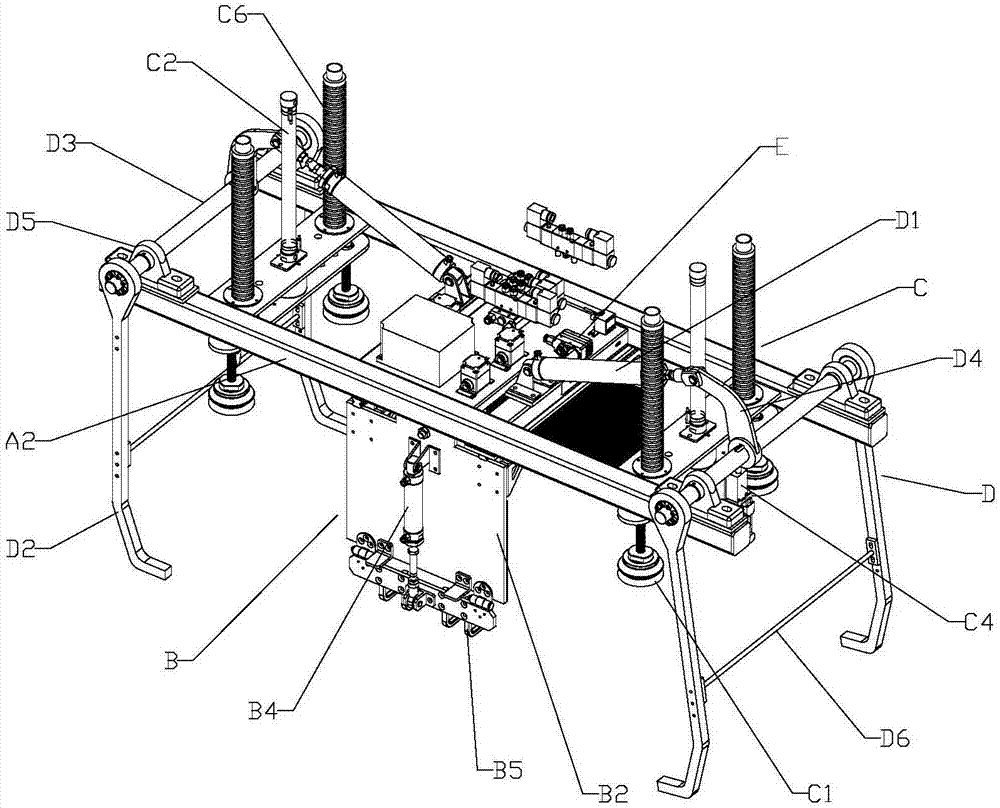

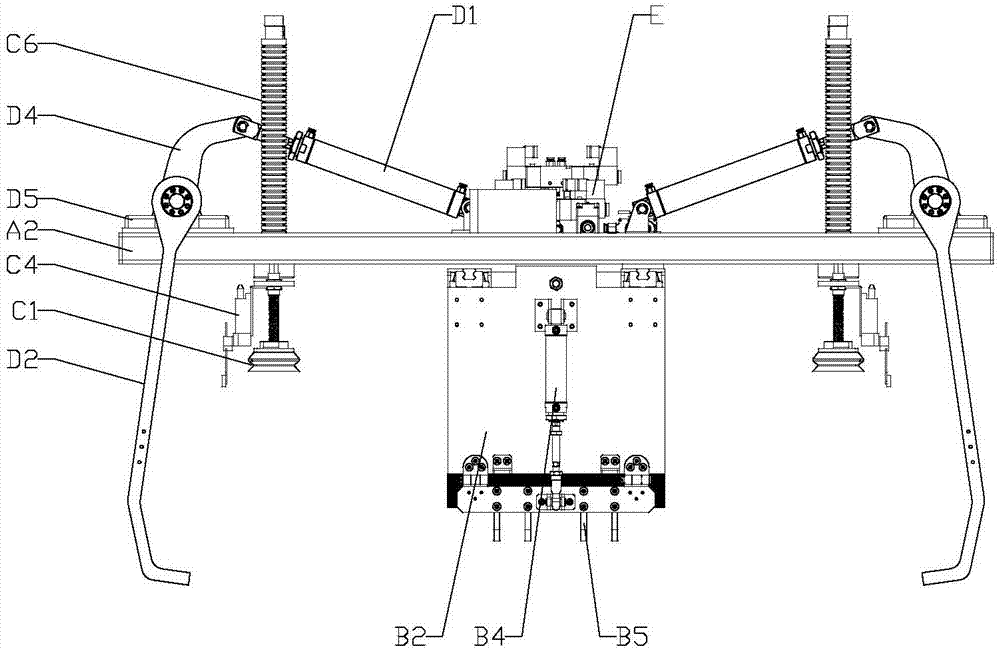

[0030] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1-Figure 10 As shown, the composite fixture for palletizing and handling robots of the present invention includes a fixture frame A, and the fixture frame A is provided with a carton extraction mechanism B, a cardboard extraction mechanism C, a cardboard extraction mechanism D and an air path control module E; The carton extraction mechanism B, the cardboard extraction mechanism C and the cardboard extraction mechanism D are set independently of each other without interfering with each other; the air circuit control module E controls the carton extraction mechanism B, the cardboard extraction mechanism C and the cardboard extraction mechanism D respectively; the fixture frame A It includes the electric control box A1 and the fixture horizontal frame A2. The electric control box A1 is set on the upper side of the middle part of the fixture horizontal frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com