Patents

Literature

164results about How to "Realize spacing adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

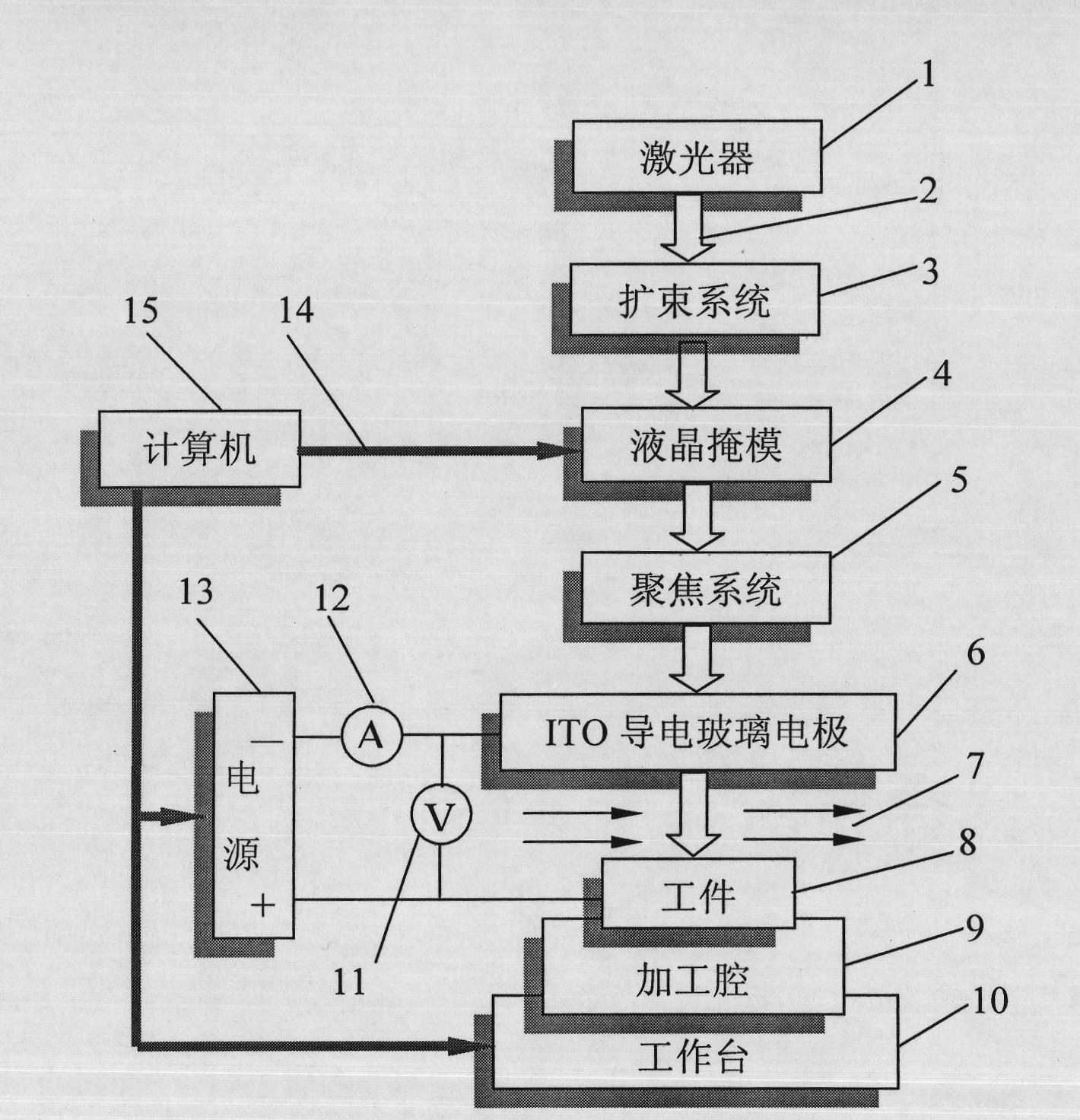

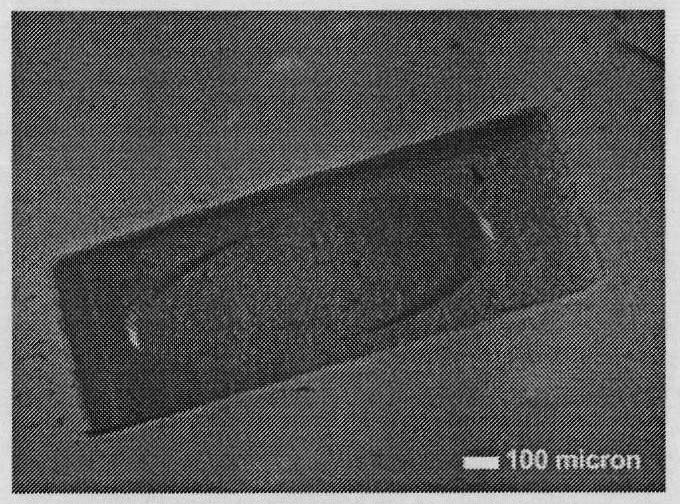

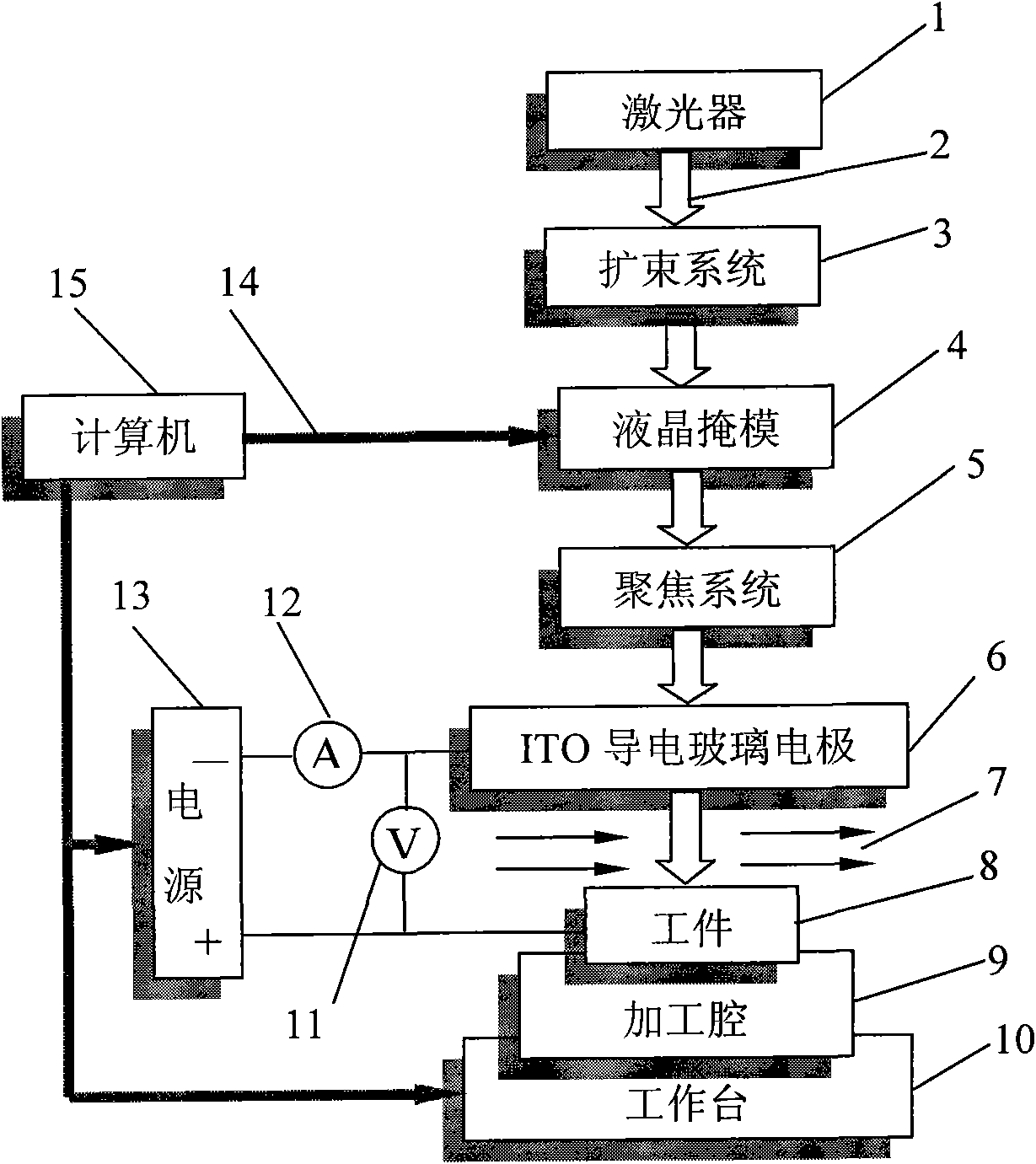

Photoelectrochemical three-dimensional processing method and device of laser bubble cavitation

InactiveCN101856753ALarge amount of erosionErosion is smallMachining electrodesElectrical-based machining electrodesElectrochemical responseManufacturing technology

The invention relates to a photoelectrochemical three-dimensional processing method and device of laser bubble cavitation, belonging to the non traditional combined machining field of the manufacturing technology. The method utilizes laser beam to irradiate the surface of workpieces in the solution and generate bubbles, as the bubble cavitation caused by bubble-collapsing combines with the electrochemical reaction so as to remove workpiece material under the action of photoelectrochemical reaction and realize etching and processing. In the device of the invention, a liquid crystal display of which the display of the grey level image is controlled by a computer is used as a mask plate, and when laser beam penetrates through the liquid crystal mask, an image with gray feature is generated to perform spatial modulation to the energy distribution in the laser spot. In the areas with higher laser radiation energy on the workpieces, the bubble cavitation is stronger, the speed of the photoelectrochemical reaction is higher and the etching removal rate is higher; in the areas with lower energy, the reverse happens, thus the processing of three-dimensional image can be realized. The device of the invention is applicable to the removal and processing of conductive metal material; and the display of the grey level image of the liquid crystal mask can be controlled by a computer, thus the processing efficiency of complex three-dimensional images can be increased greatly.

Owner:JIANGSU UNIV

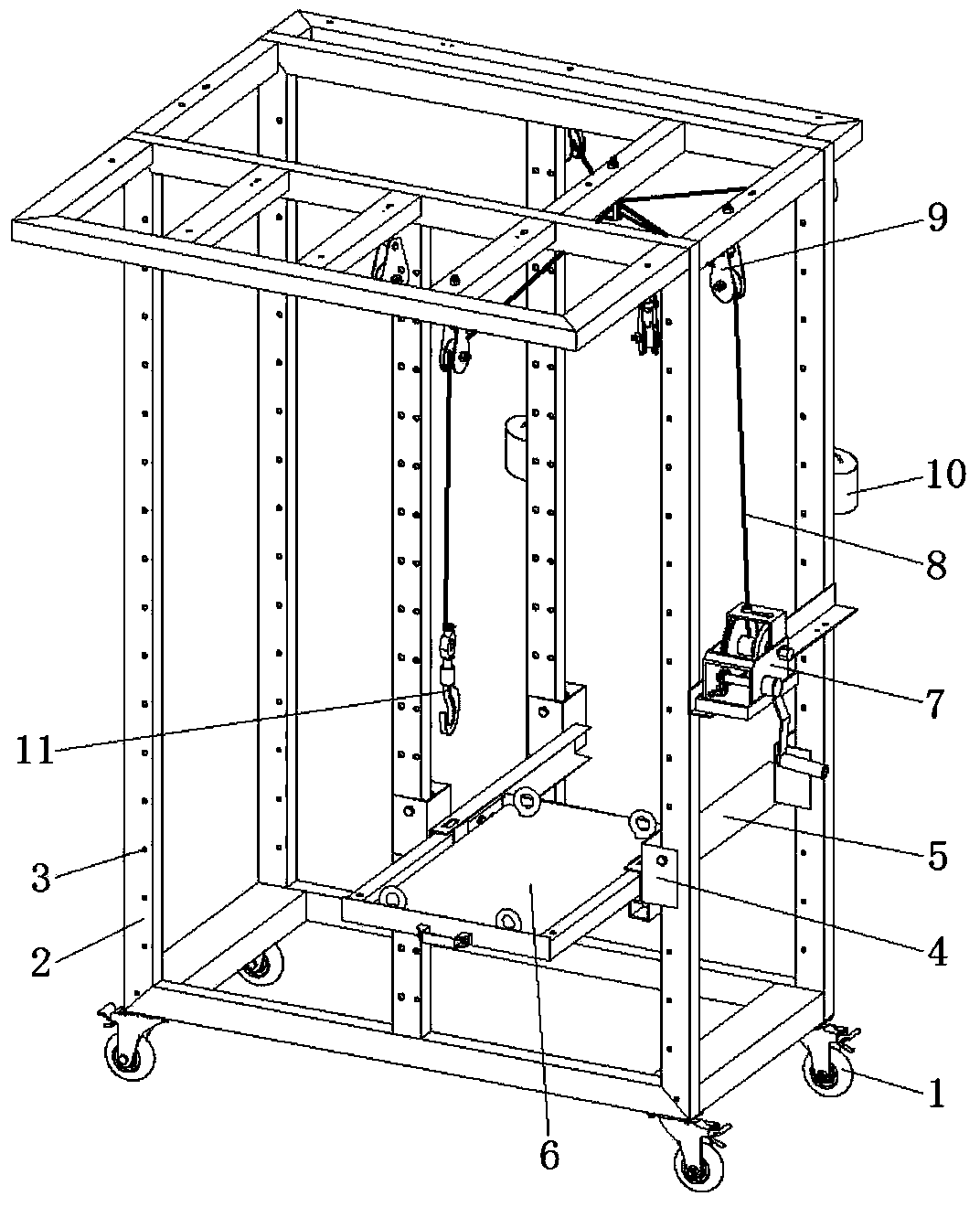

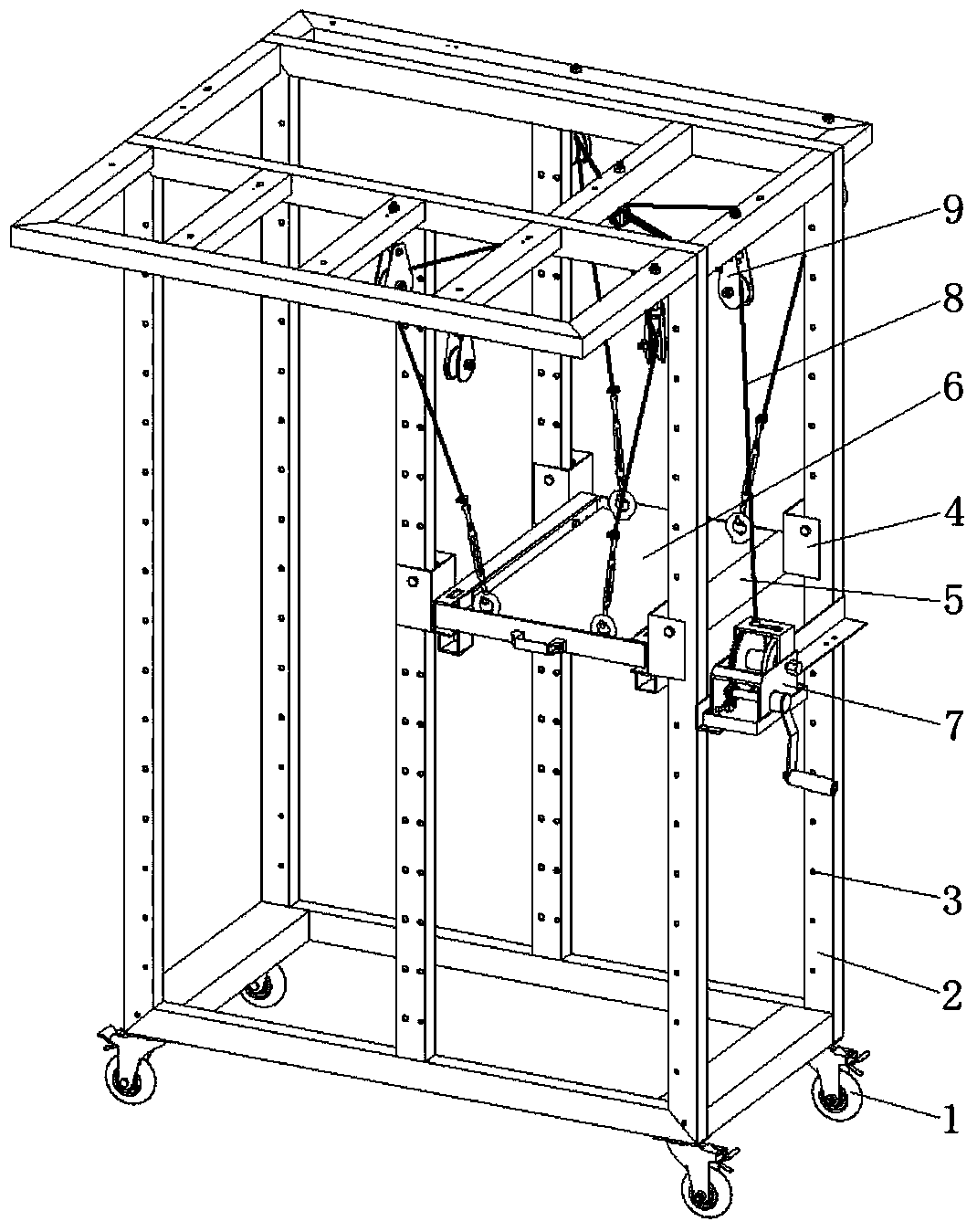

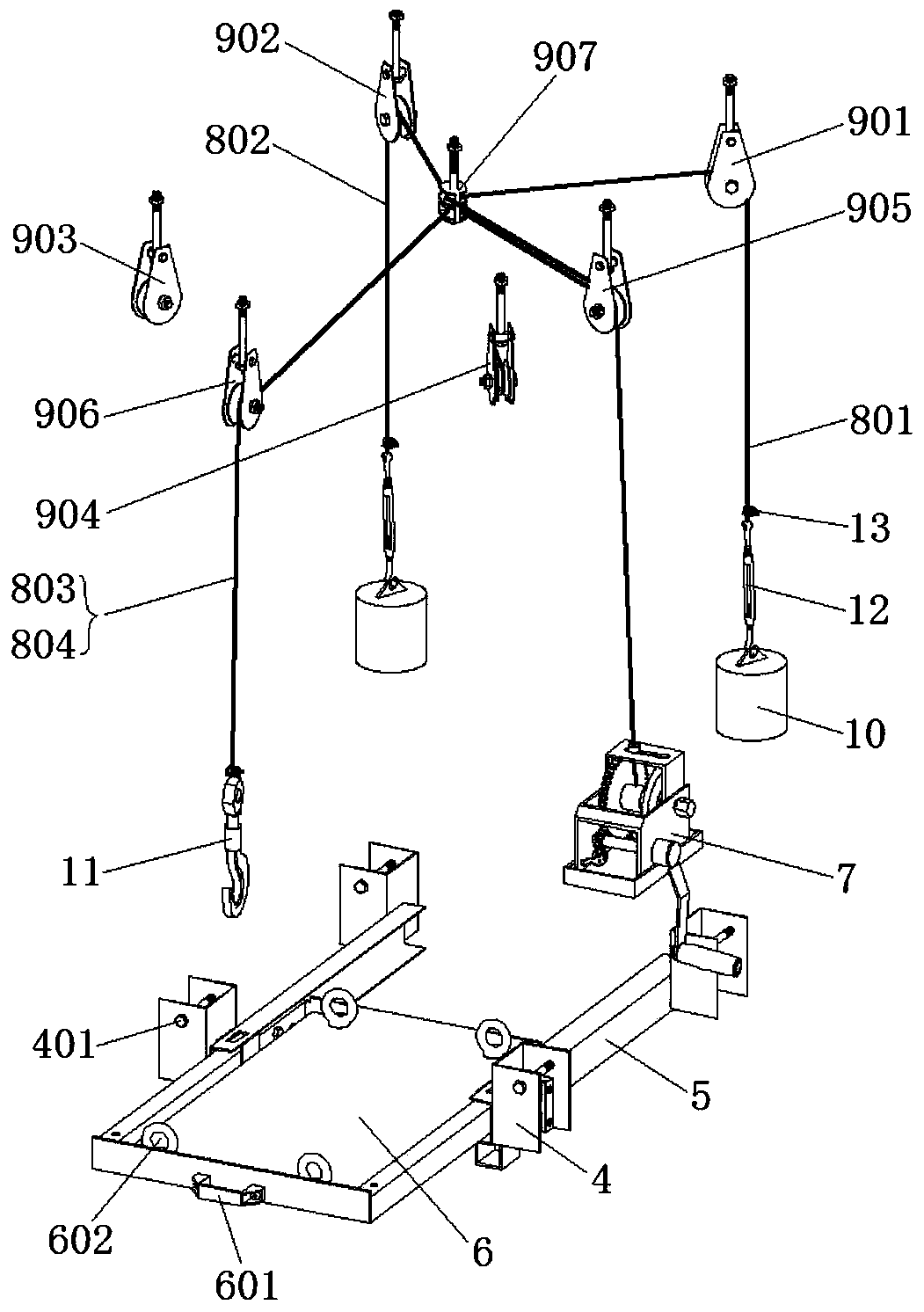

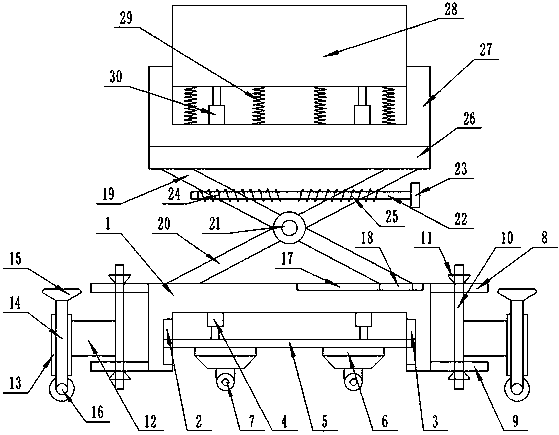

Self-loading and unloading heavy-load shelf with adjustable layer interval

ActiveCN104210796ARealize spacing adjustmentAchieve mechanical propertiesWinding mechanismsStorage devicesBlock and tackleWinch

The invention discloses a self-loading and unloading heavy-load shelf with an adjustable layer interval, and belongs to the field of shelves. The self-loading and unloading heavy-load shelf comprises a main framework, a layered frame, a manual winch, steel wire ropes, a pulley block, a heavy object and a lifting hook, wherein the layered frame comprises rolling lifting sliding sleeves, heavy-load slide rails and a tray; the heavy-load slide rails are arranged on both sides of the tray, and are arranged on vertical columns of the main framework through the rolling lifting sliding sleeves arranged at the two ends of the heavy-load slide rails; the manual winch is fixed on one side of the main framework, and four steel wire ropes are led out of the manual winch; after the steel wire ropes pass through the pulley block on the top of the main framework, two of the steel wire ropes are combined together and are connected with the hoisting hook, and the other two steel wire ropes are connected with the heavy object; hoisting rings are arranged on the four corners of the tray respectively and are correspondingly connected with the four steel wire ropes, and the tray is lifted or lowered through the manual winch. By adopting the self-loading and unloading heavy-load shelf, the height of a laminate can be adjusted under the condition that the laminate is under load; moreover, loading and unloading of heavy goods can be realized, and the self-loading and unloading heavy-load shelf is particularly suitable for storing heavy goods.

Owner:常州东吉路国际贸易有限公司

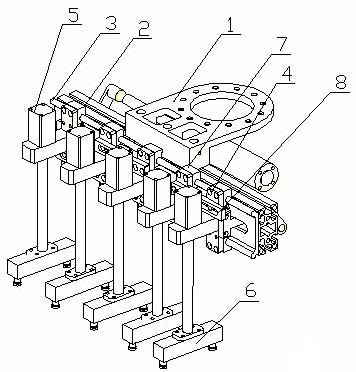

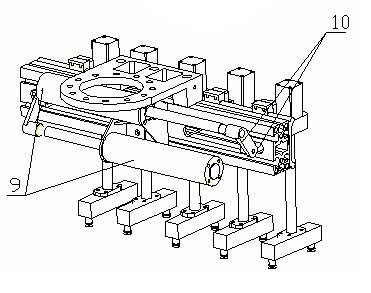

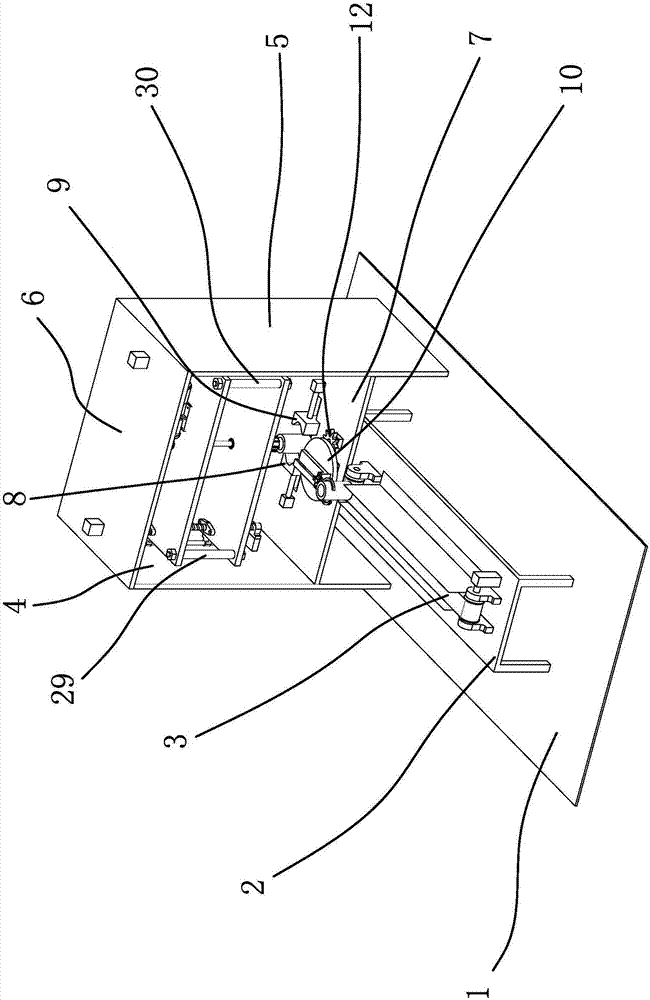

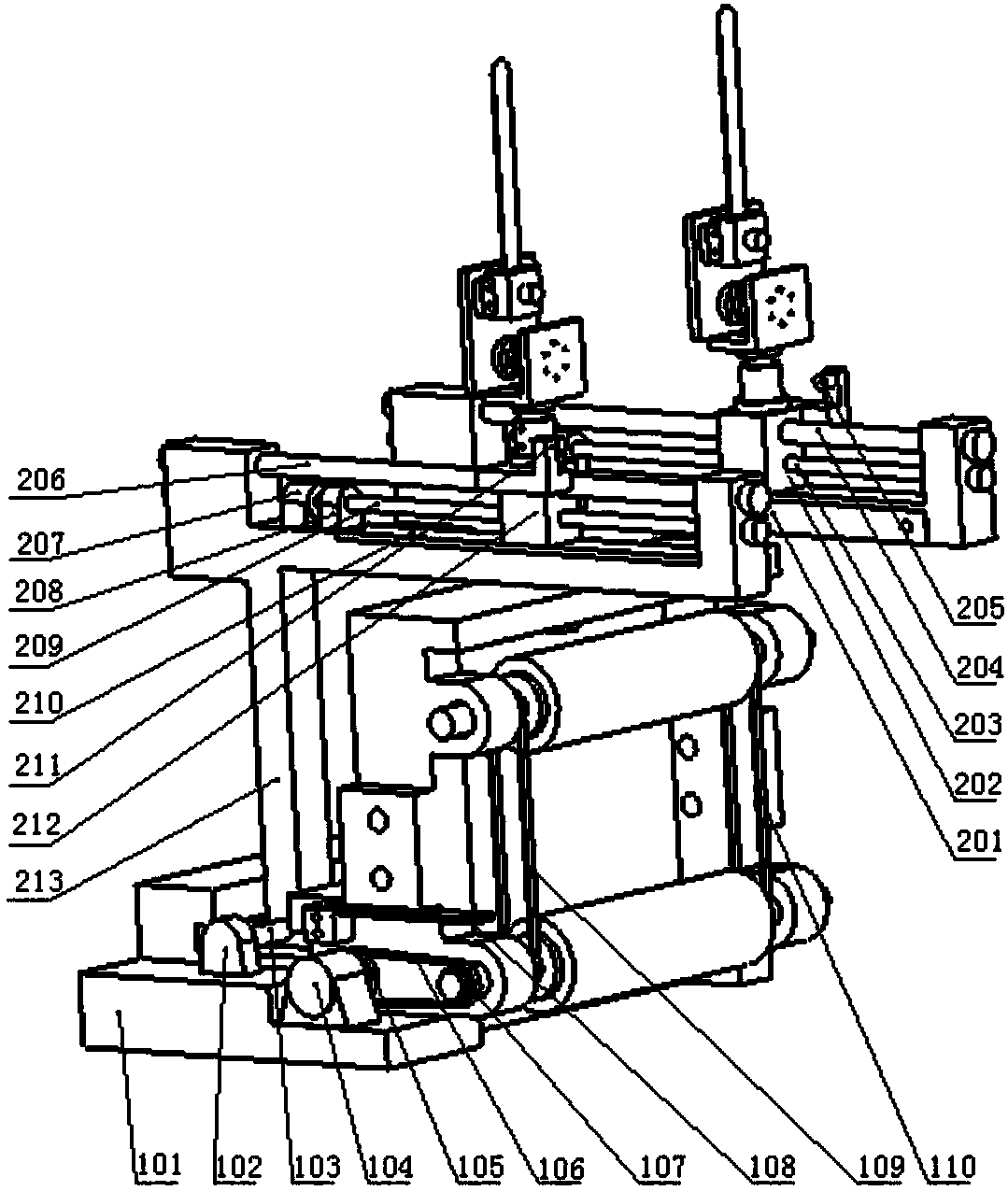

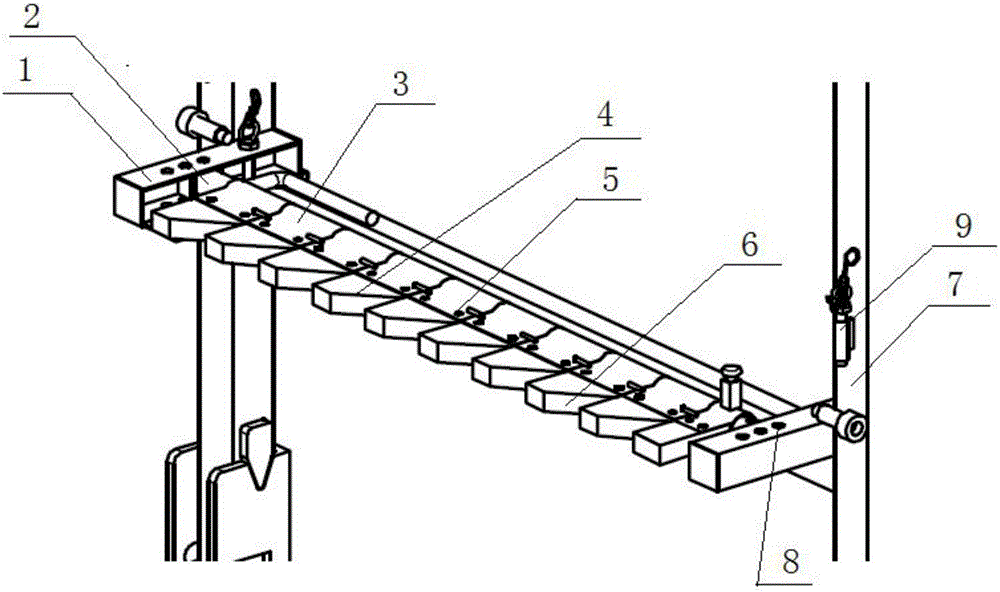

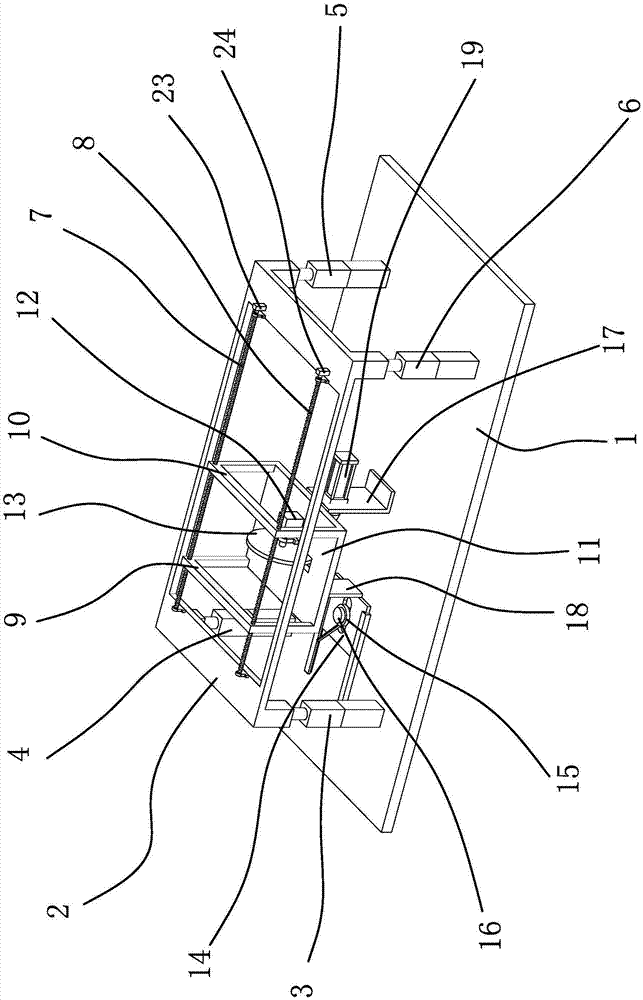

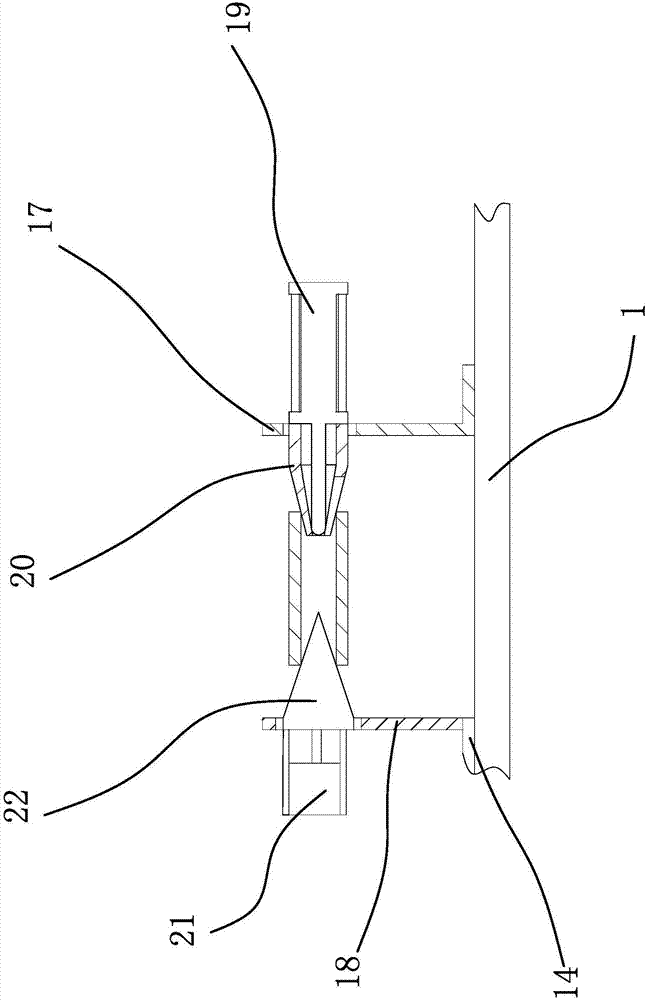

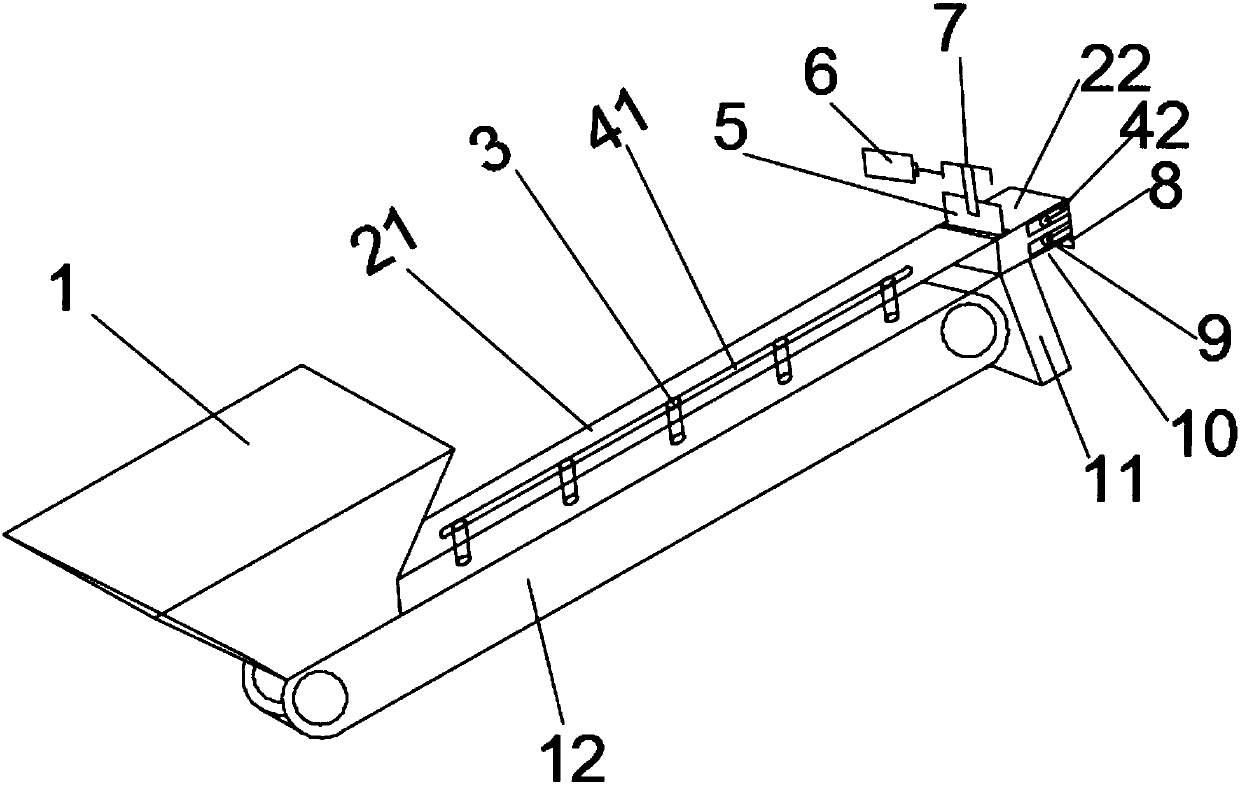

Robot hand grip for packaging and conveying dispersed materials

InactiveCN102249087AImplement one-time fetchingAdjustable spacingConveyor partsRobot handEngineering

The invention relates to a robot hand grip for packaging and conveying dispersed materials. The hand grip comprises a platform (1), a support frame (2), a sliding rail (3), N groups of fingers, a sliding block (7), a first connecting member (8) with a limit groove, air cylinders (9) and a second connecting member (10). The support frame (2) is fixed on the platform (1). The sliding rail (3) is fixed at the front side of the support frame (2). Each group of fingers comprises a small air cylinder base (4) with columnar embossments, a small air cylinder (5) and an executing part (6). The sliding block (7) is connected to the sliding rail (3) in a sliding manner. The adjacent N groups of fingers are connected by means of the first connecting member (8) with the limit groove. Columnar embossments on the small air cylinder base (4) having the columnar embossments of the N groups of fingers are spliced and matched with the limit groove of the first connecting member (8) having the limit groove. Two air cylinders (9) are fixed at the back side of the support frame (2) reversely. The invention can meet the need of grasping a plurality of dispersed materials once and can be used for adjusting space between the materials.

Owner:江阴纳尔捷机器人有限公司

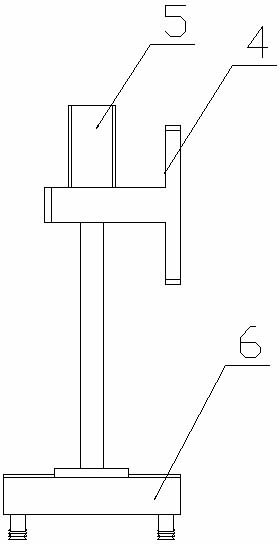

Transfer device for emergency medical device

InactiveCN108033391ASimple and reasonable structureReduce manufacturing costLifting framesEngineeringMedical treatment

The invention discloses a transfer device for an emergency medical device. The transfer device comprises a base, a left groove, a right groove, a pneumatic rod, a slide rod, slide wheel bases, slide wheels, an upper installation rod, a lower installation rod, a rotating shaft, a rotary handle, an installation plate and the like. The emergency medical device can be effectively and stably transferred; the height of the whole device can be adjusted by rotating the rotary handle and adjusting the folding angle of a first folding rod and a second folding rod; movement is conducted by releasing theslide wheels through the pneumatic rod during transferring; the height of universal wheels is adjusted by rotating a handle; guiding is conducted through the universal wheels; the fine adjustment of the height is realized through a hydraulic cylinder on the lower side of a fixed base; the whole device is buffered through springs; distance adjustment is realized by a left extension plate and a right extension plate under the effect of connecting lead screws, so the transfer device is suitable for medical devices of different sizes; by arranging a gradienter, the levelness can be observed, and the damage caused by inclination is prevented; a gear drives a rack, a pressing base presses the device, and the device is prevented from sliding when transferred.

Owner:崔林

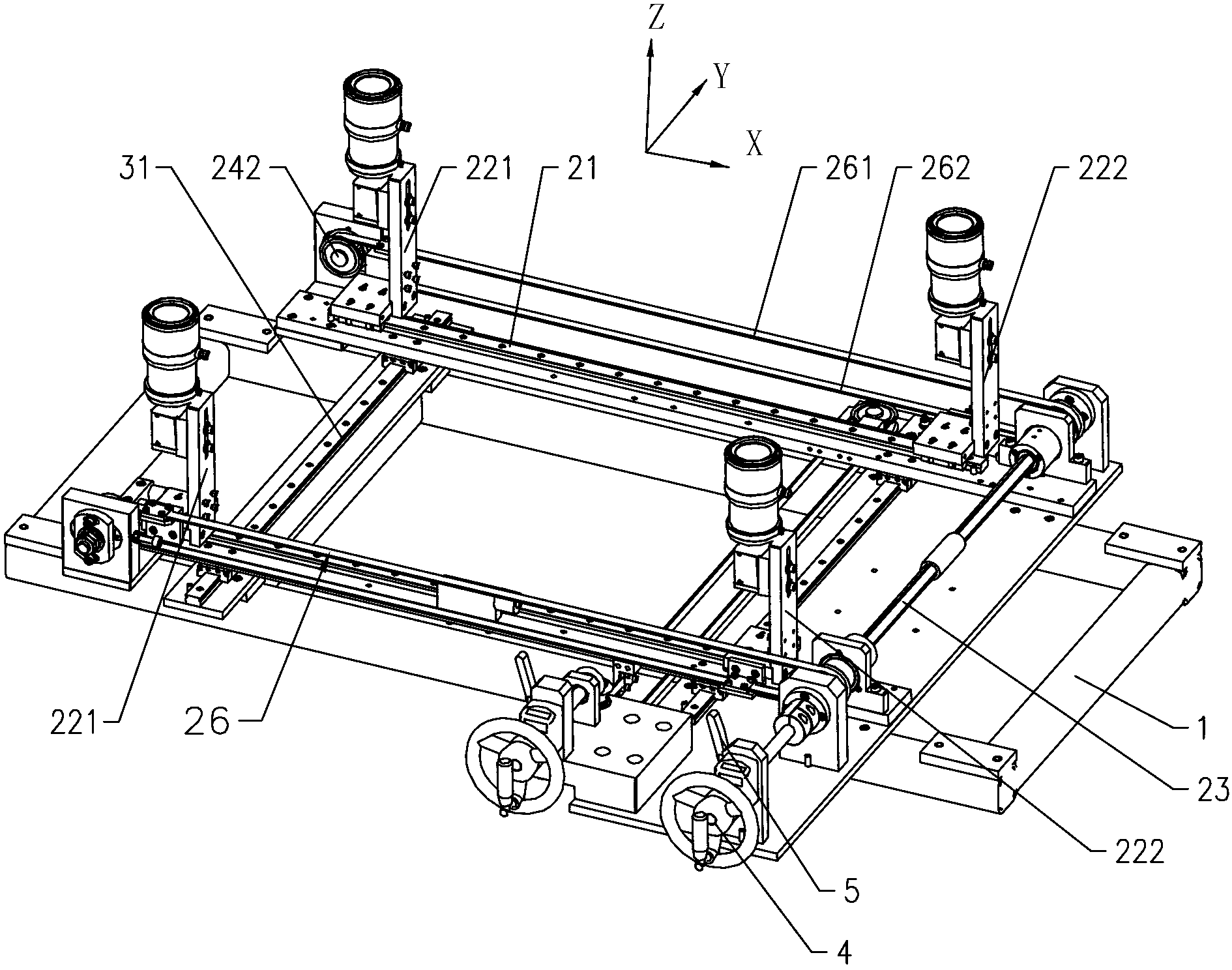

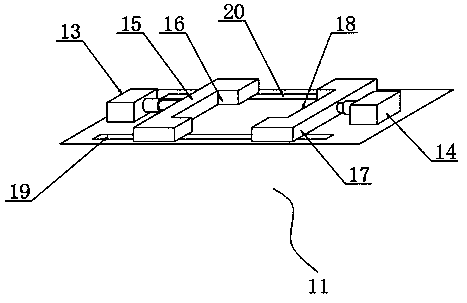

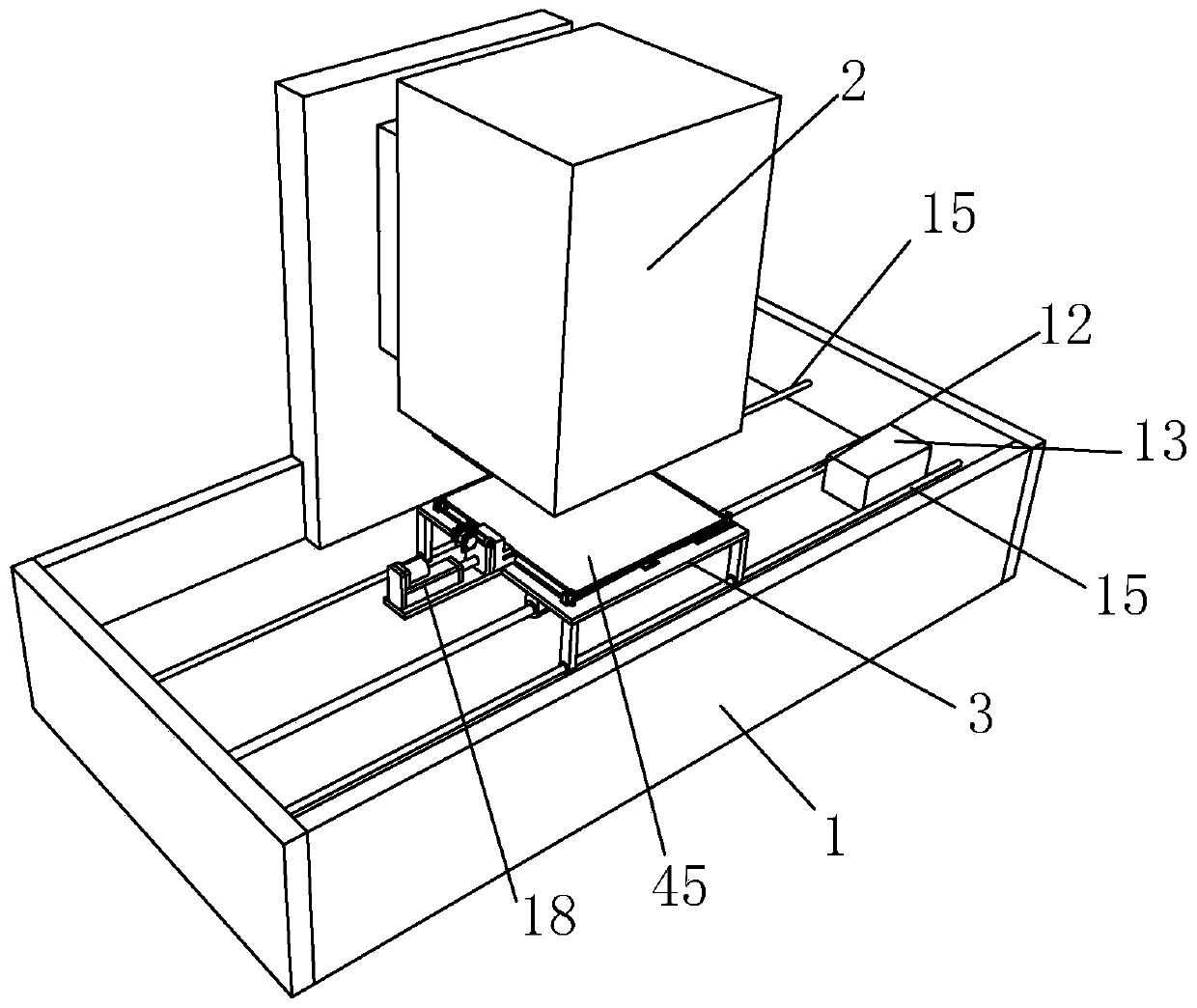

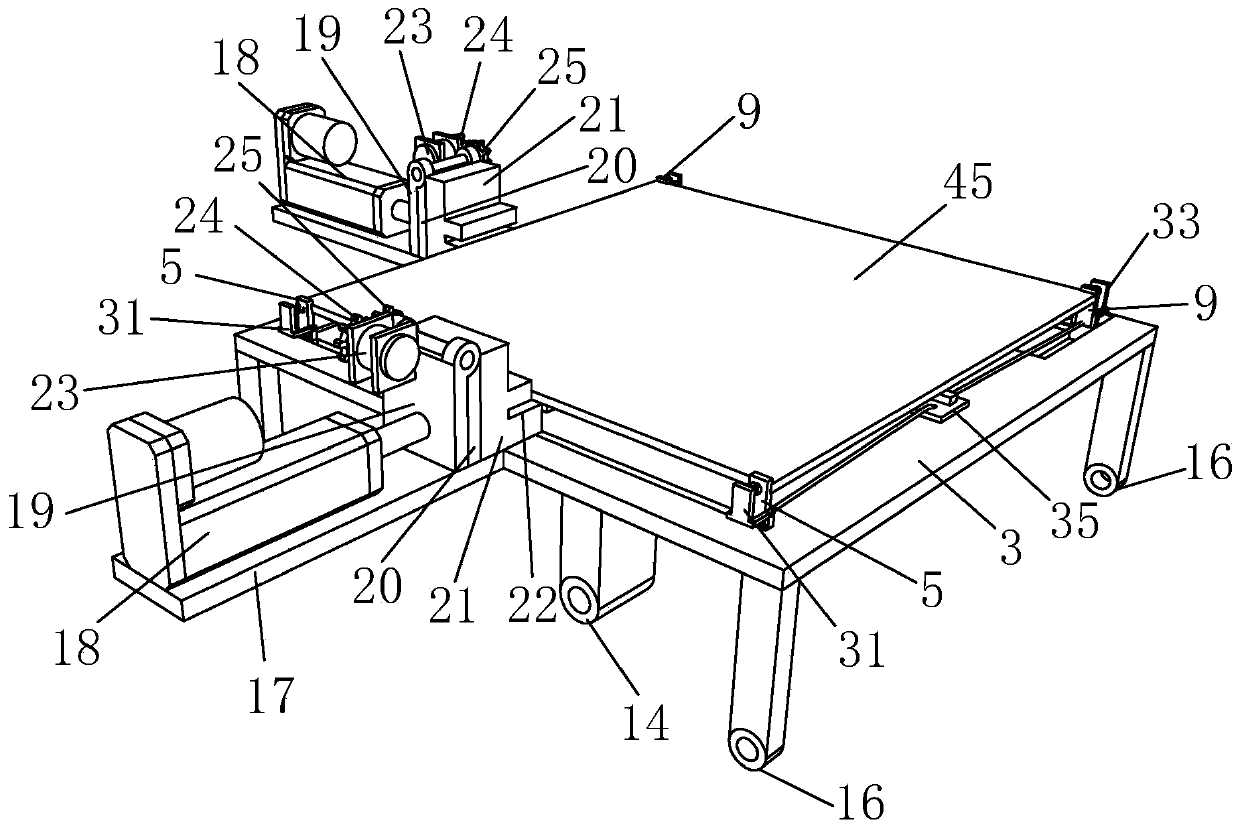

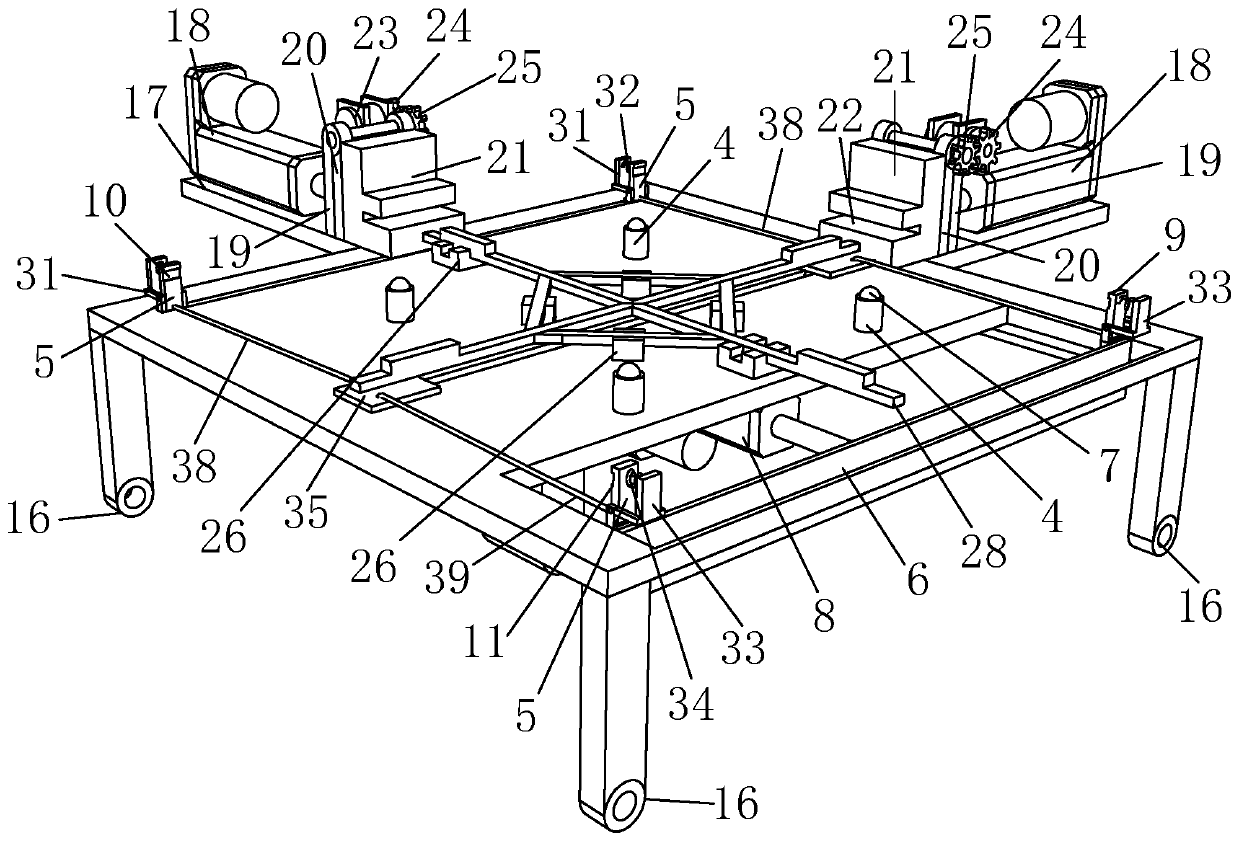

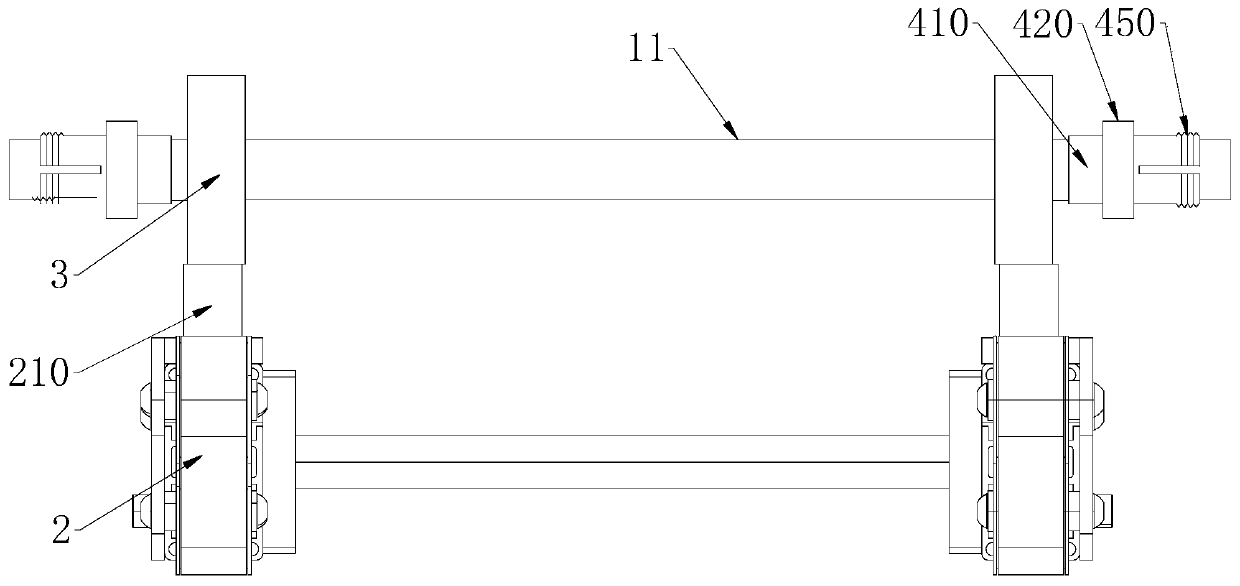

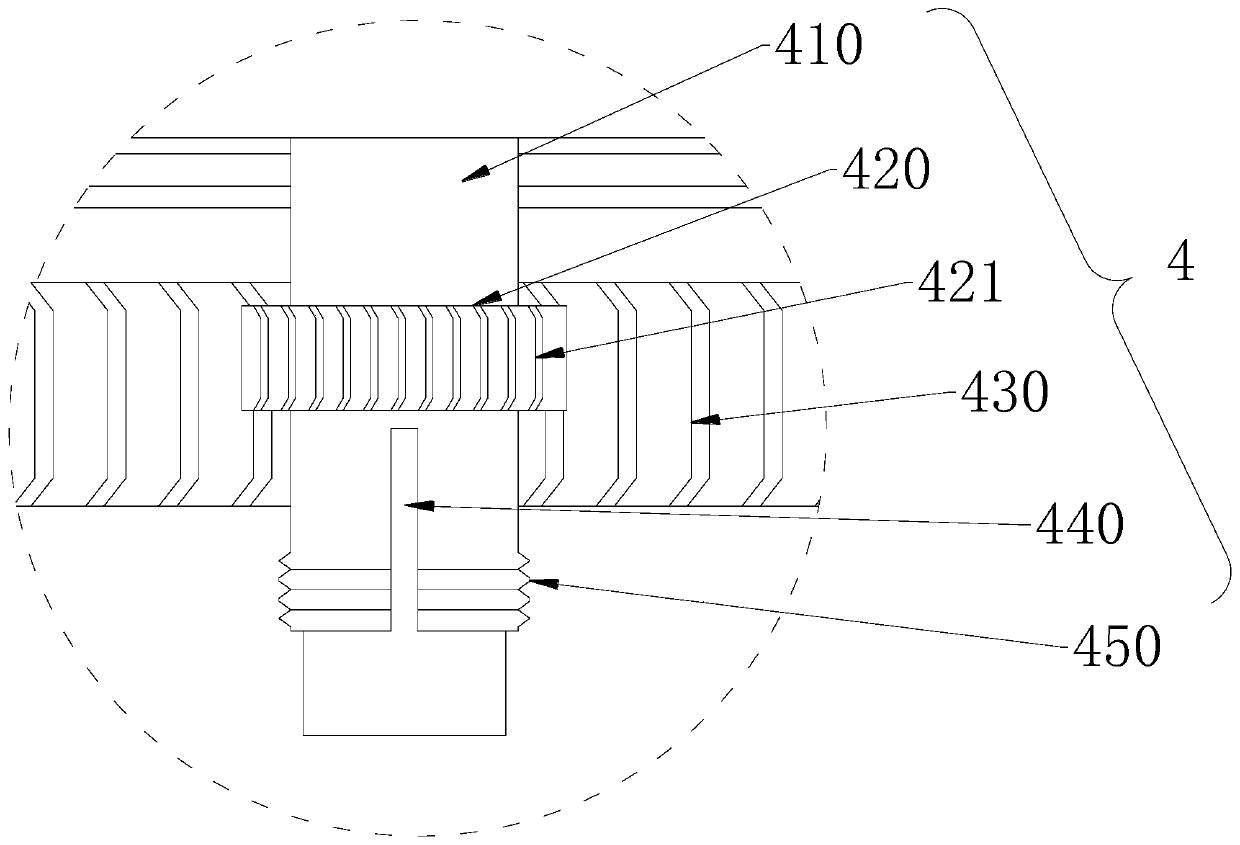

Space adjusting device for four objects arranged in rectangular form

ActiveCN103231906ARealize spacing adjustmentMovement in perfect harmonyConveyor partsDrive shaftEngineering

Owner:GOERTEK INC

Dust removal air duct polishing method

PendingCN107414613AAchieve circumferential polishingAchieve clampingEdge grinding machinesRevolution surface grinding machinesPolishingDust control

The invention provides a dust removal air duct polishing method, and belongs to the technical field of machinery. The dust removal air duct polishing method is characterized by comprising the following steps that firstly, a prepared dust removal air duct is clamped to an outer wall polishing machine, a polishing disc is started, the outer wall of the dust removal air duct is polished to remove burrs, and outer wall polishing lasts for 8-12 min; secondly, the dust removal air duct obtained after the outer wall is polished is placed in a conveying device; thirdly, the dust removal air duct is conveyed to a transfer mechanism through a conveying belt on the conveying device and transferred to the position between a first clamping block and a second clamping block through a mechanical arm on the transferring mechanism to be clamped; fourthly, an inner wall polishing machine is started, a polishing brush is rotated, the position relation between the polishing brush and the dust removal air duct is adjusted, the inner wall of the dust removal air duct is polished, and inner wall polishing lasts for 3-5 min; fifthly, inner wall polishing of the dust removal air duct is completed, and the dust removal air duct is conveyed out. The method has the advantage of being capable of polishing the dust removal air duct more conveniently.

Owner:ZHEJIANG JIEYU ENVIRONMENTAL PROTECTION EQUIPCO

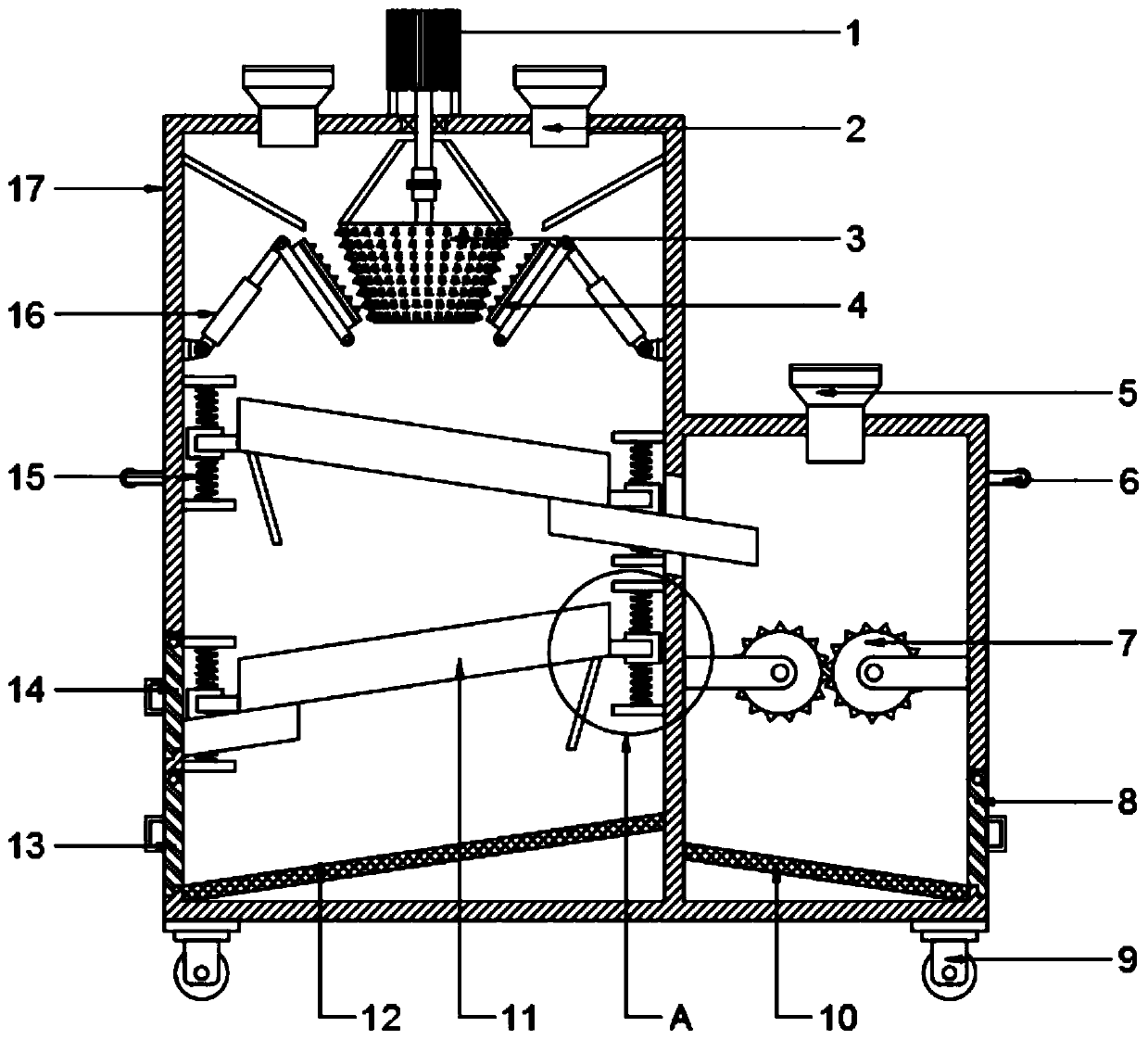

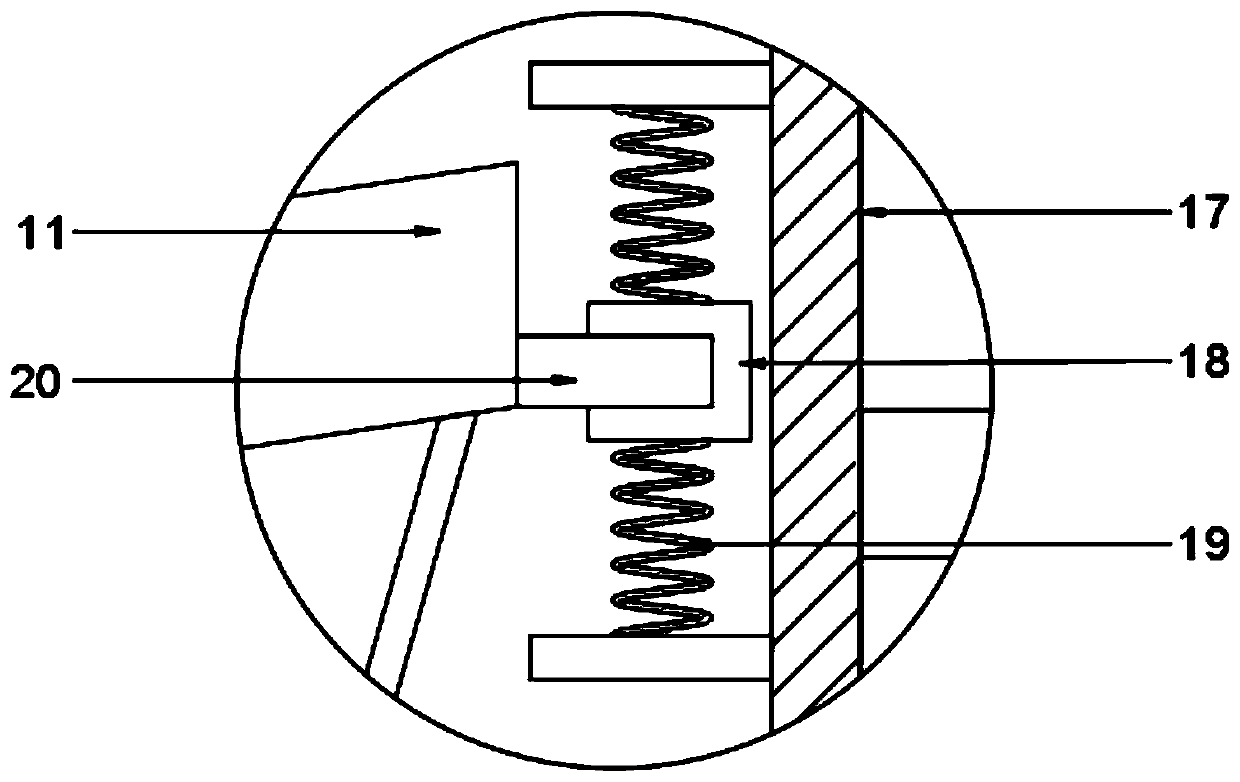

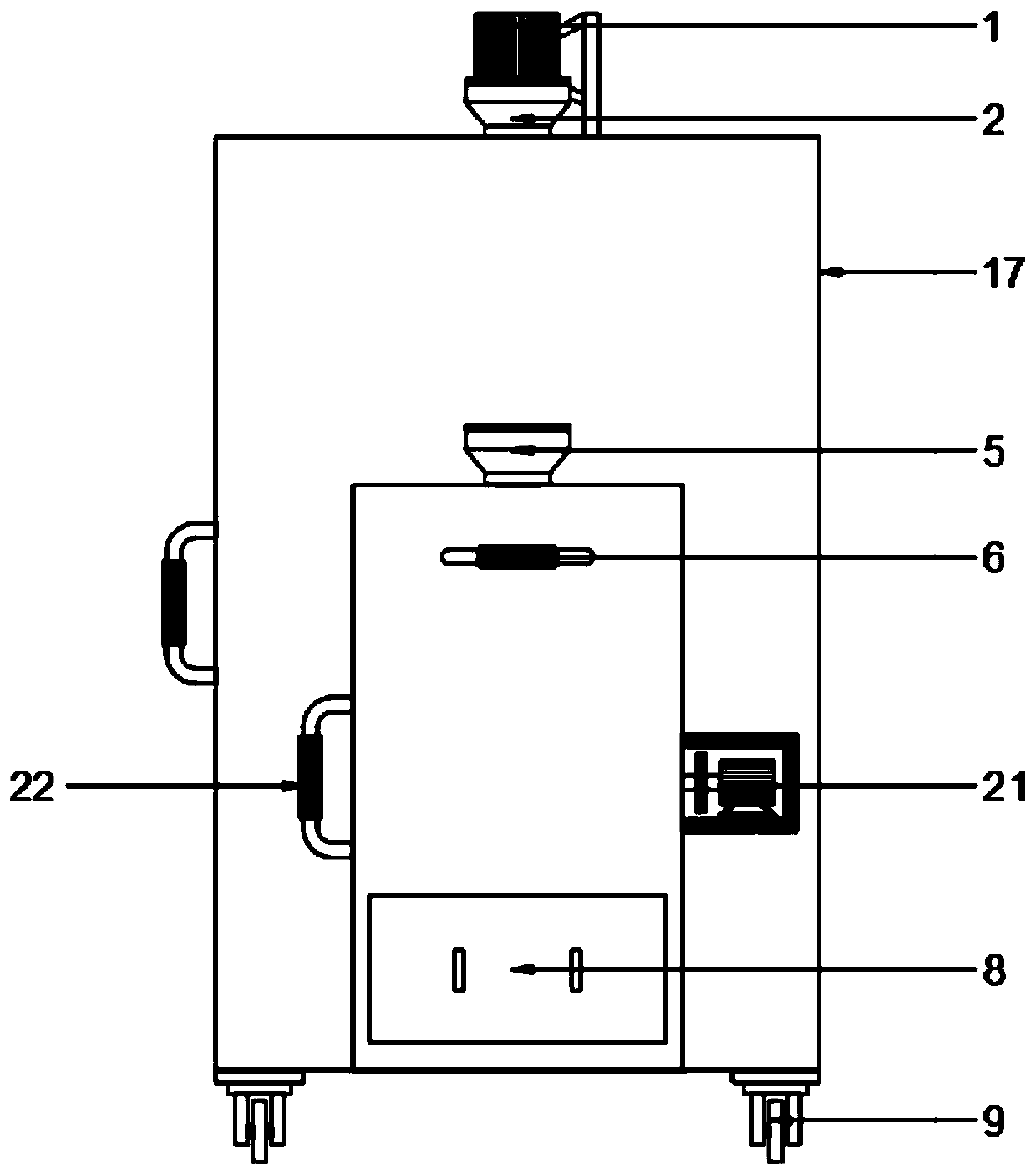

Raw material crushing device for machining

ActiveCN111437978AIncrease contact areaIncrease frictionGrain treatmentsStructural engineeringManufacturing engineering

The invention discloses a raw material crushing device for machining. The raw material crushing device comprises a box body as well as a crushing assembly and a screening assembly which are arranged in the box body, wherein the crushing assembly comprises a crushing hammer, crushing plates and electronic telescopic rods, and the screening assembly is clamped in the position below the crushing assembly through elastic assemblies fixedly mounted on the inner wall of a crushing chamber; and a smashing chamber communicating with the crushing chamber is further formed in the box body and a smashingassembly is arranged in the smashing chamber. With the adoption of the crushing hammer and the crushing plates with multiple groups of crushing teeth, friction force is increased, the crushing effectis improved, and by cooperation with the electronic telescopic rods, the spacing between the crushing hammer and the crushing plates is adjusted and practicability is high; vibrating screens are matched with the smashing assembly, so that the refining effect of raw materials is improved; the vibrating screens are matched with the elastic assemblies, disassembly and assembly are convenient, and flexibility is high; with the adoption of universal wheels provided with brake devices as well as hand rails, the raw material crushing device not only can move, but also can be fixed and has high flexibility; and with the adoption of access doors, replacement of the vibrating screens and overhauling of parts are convenient.

Owner:山东蓬莱电力设备制造有限公司

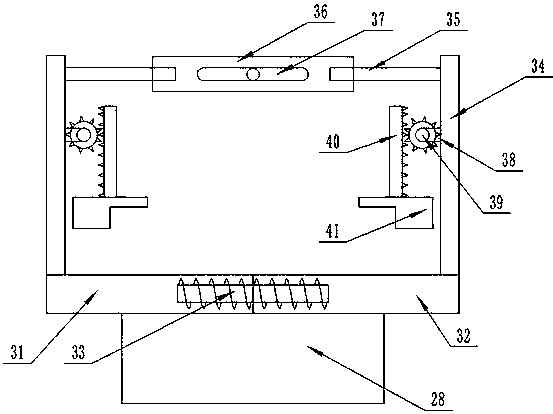

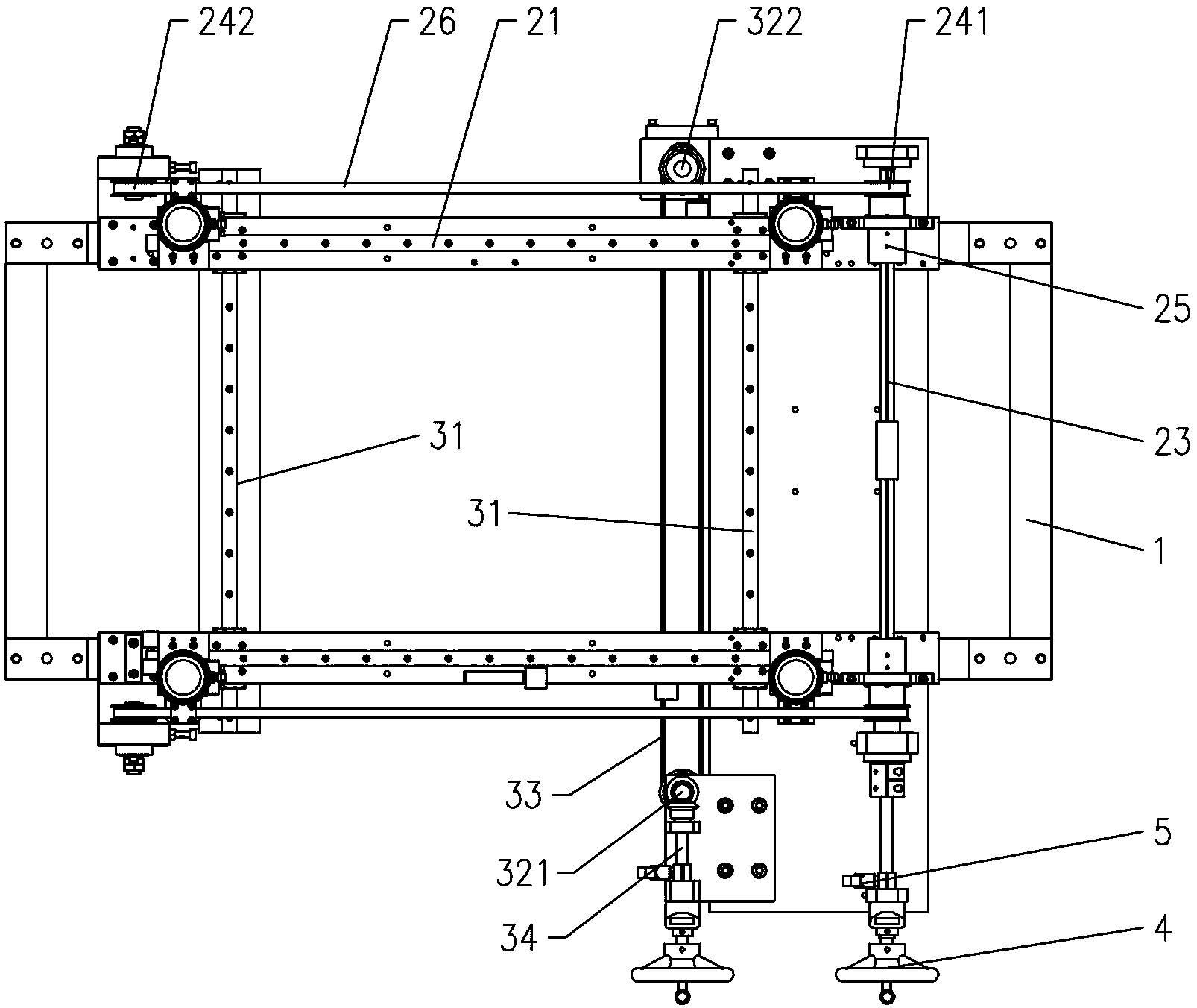

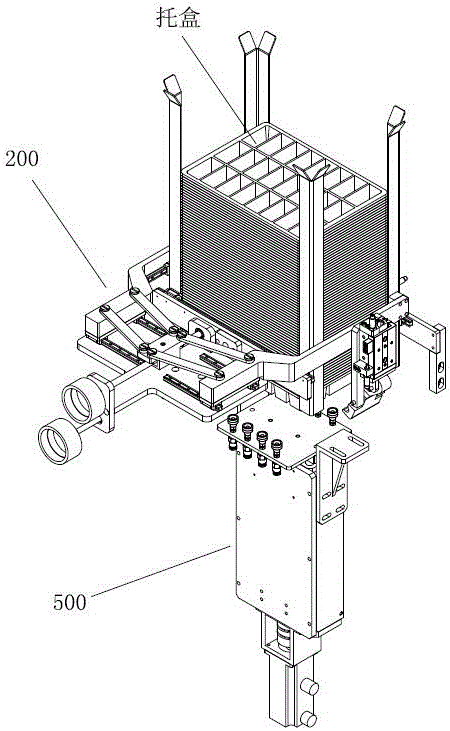

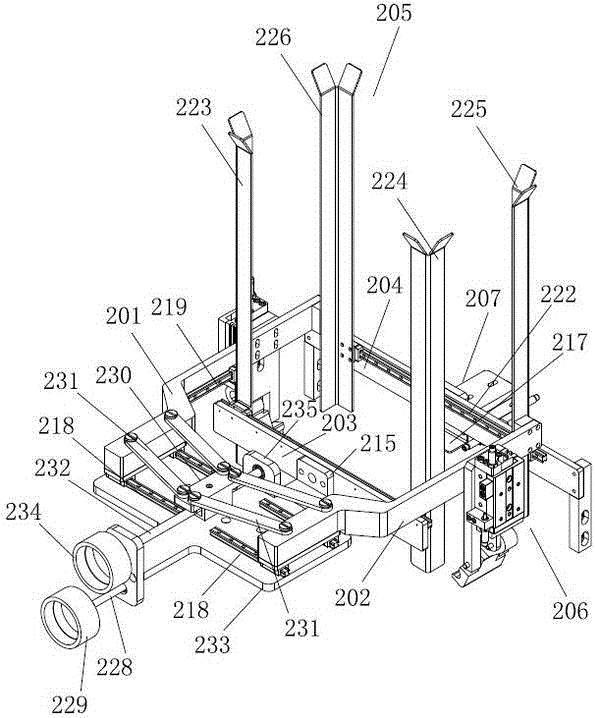

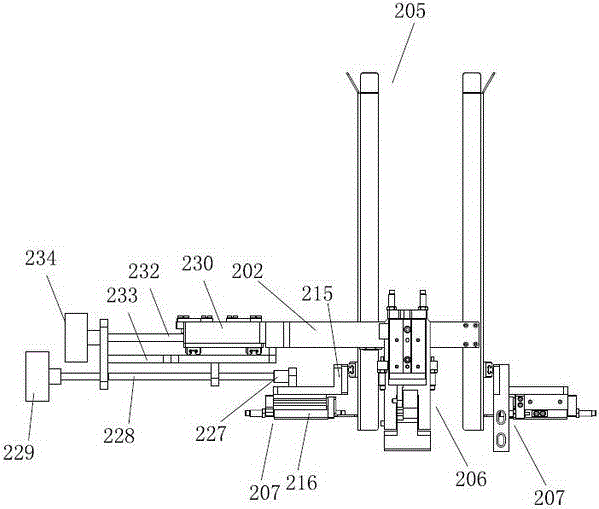

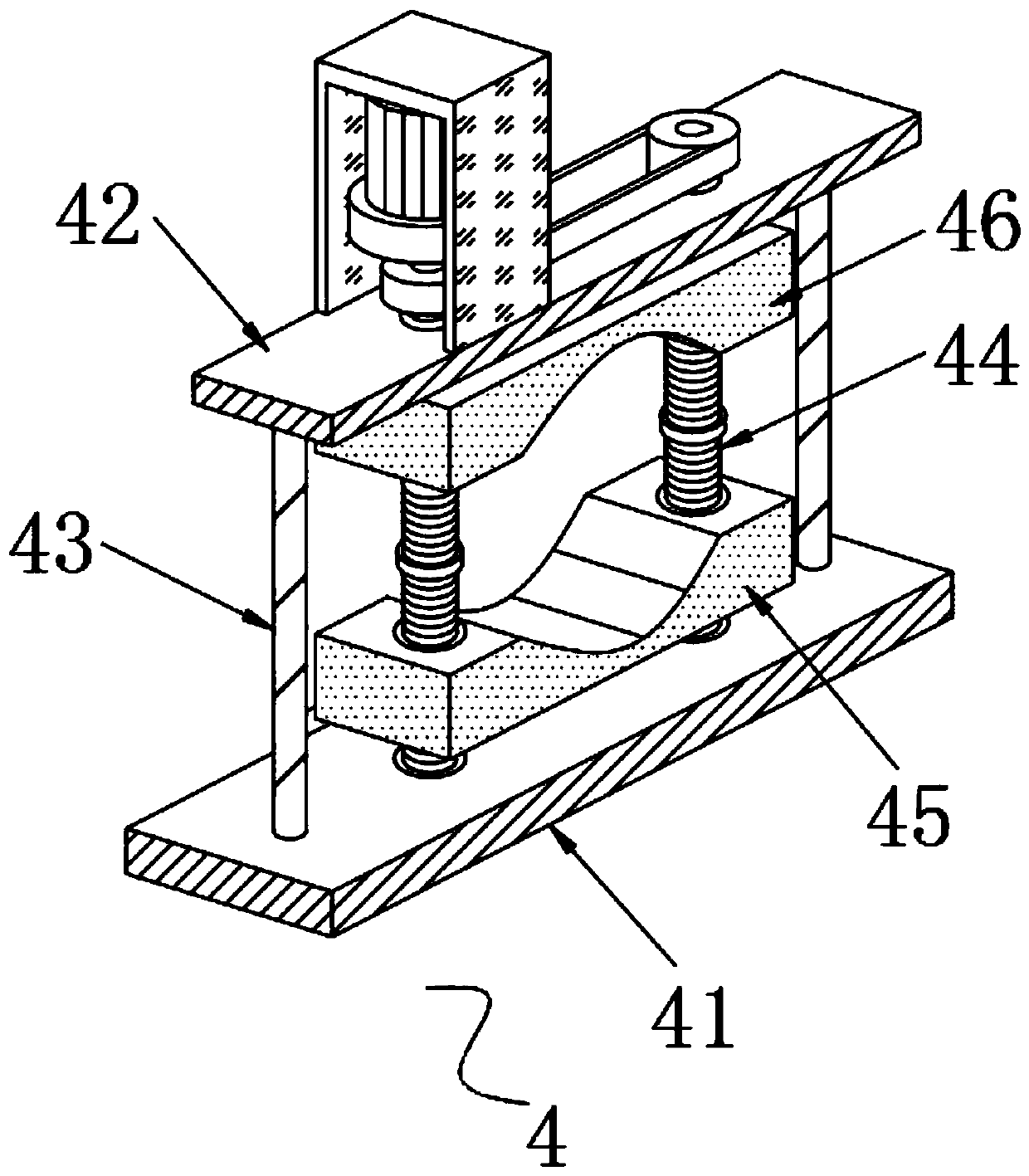

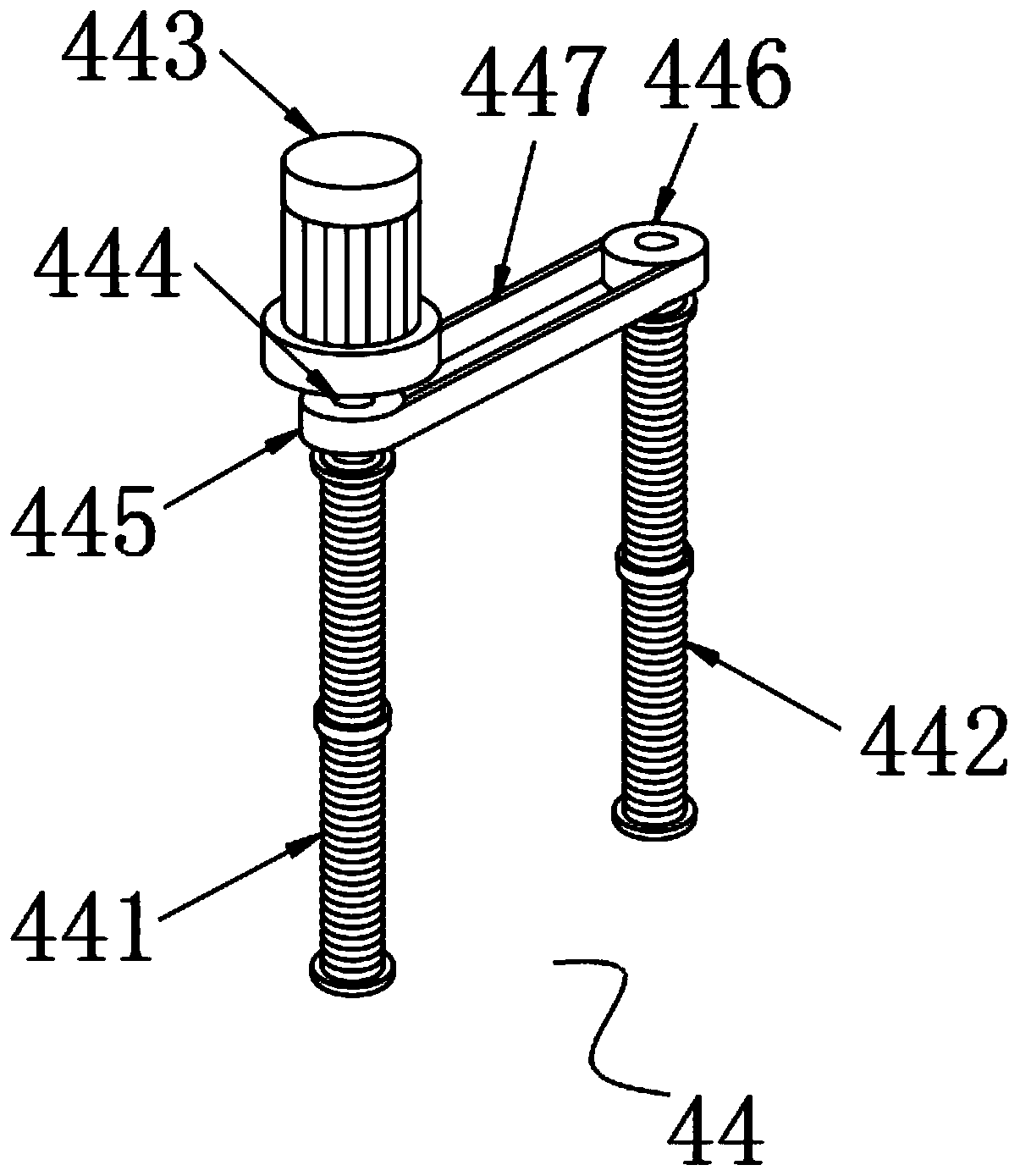

Box filling frame assembly of box discharge mechanism

ActiveCN106043813AMeet the requirements for storing trays of different sizesAccurate separationPackagingEngineeringMechanical engineering

The invention relates to the field of machining box filling, in particular to a box filling frame assembly of a box discharge mechanism. The box filling frame assembly comprises an adjustable box filling frame and a lifting suction part located below the adjustable box filling frame. The adjustable box filling frame comprises an installation left plate, an installation right plate, an installation front plate and an installation rear plate. The left-right interval can be adjusted through the installation left plate and the installation right plate. The front-back interval can be adjusted through the installation front plate and the installation rear plate. The installation left plate, the installation right plate, the installation front plate and the installation rear plate are each vertically provided with a protection plate for limiting supporting boxes. A supporting box storage space for containing the supporting boxes is defined by the protection plates. For the situation that the supporting boxes are closely stacked or horizontal edges of the supporting boxes are not obvious, the supporting boxes which are closely stacked can be accurately separated. The left-right interval and the front-back interval can be adjusted through the adjustable box filling frame, and therefore the left-right size and the front-back size of the supporting box storage space are adjusted in a driving manner, and the box filling frame assembly can adapt to box discharge processing conducted on the supporting boxes of different sizes.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

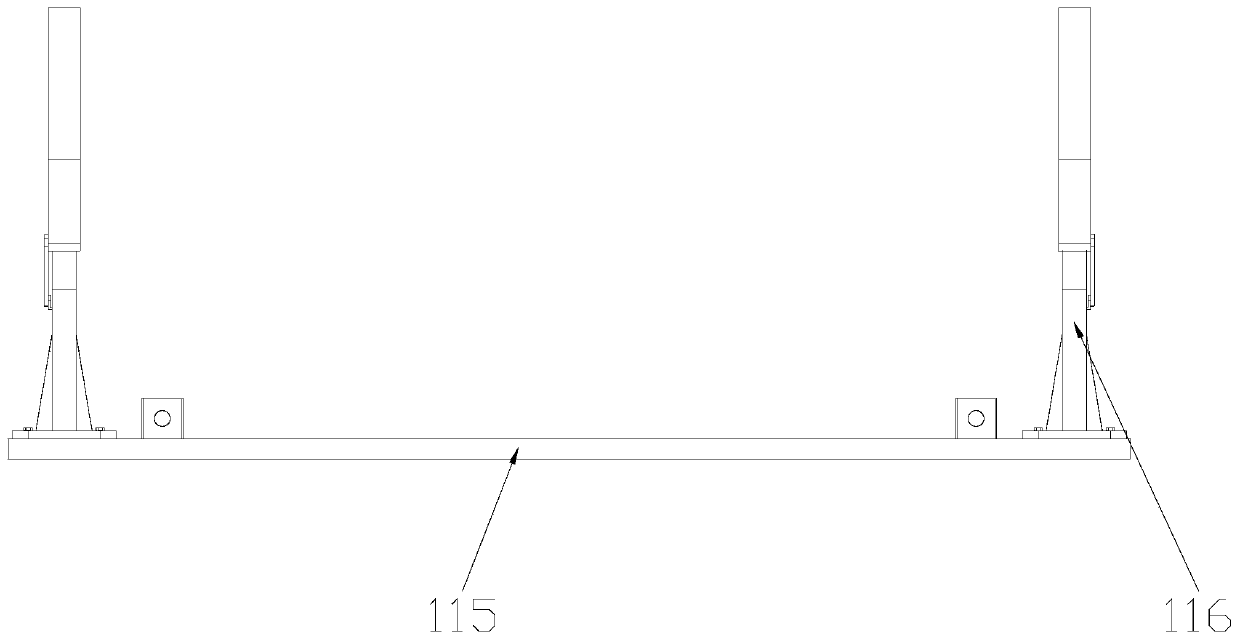

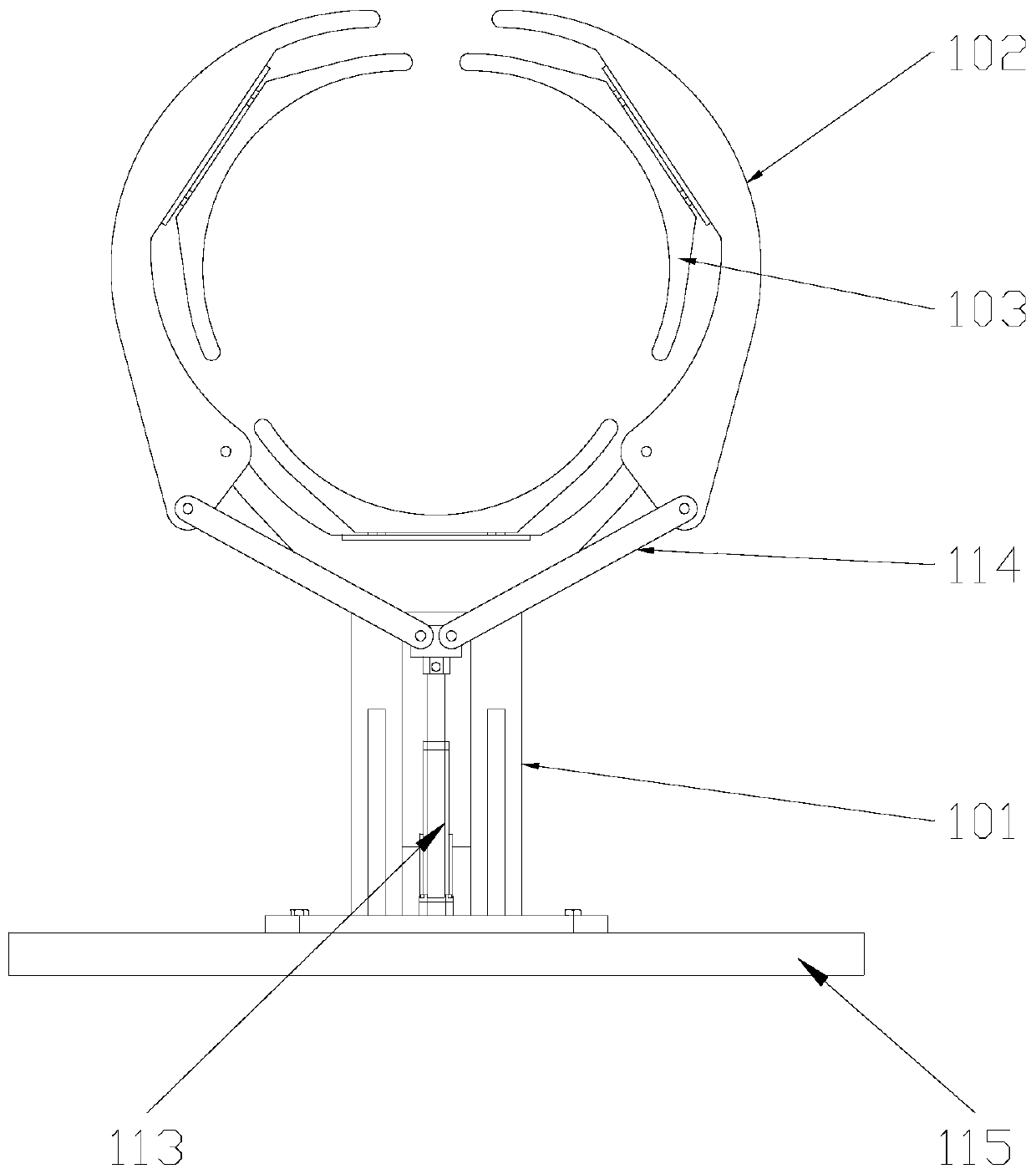

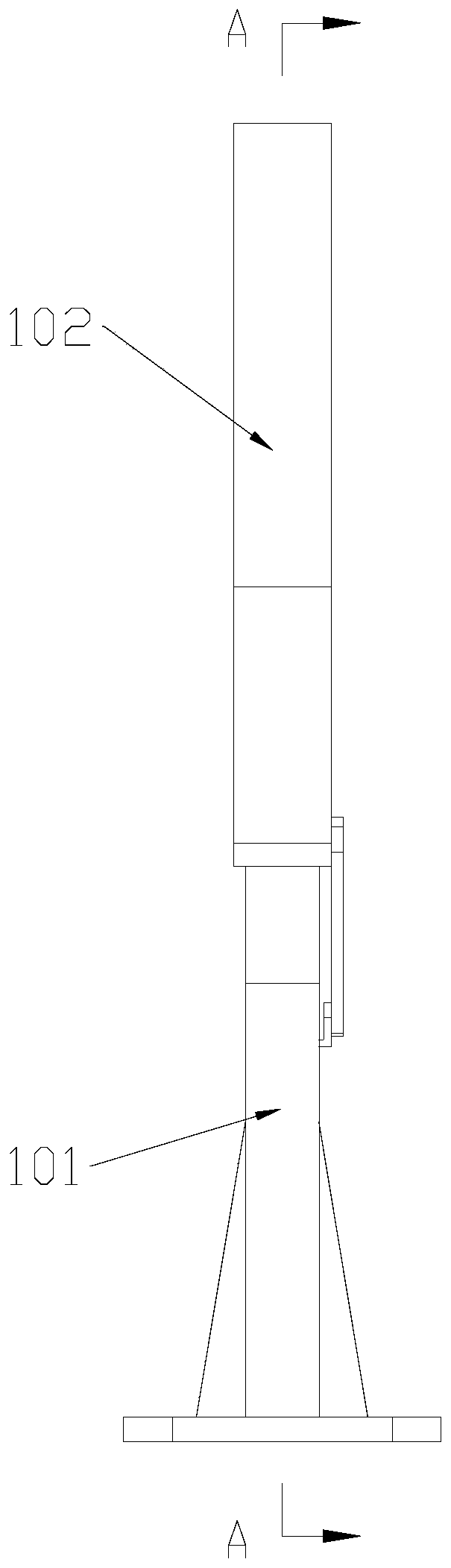

Intelligent automatic branches pruning device

InactiveCN107926332AImprove pruning efficiencyImprove versatilityCuttersMotor driven pruning sawsAgricultural engineeringPruning

The invention discloses an intelligent automatic branch pruning device, which is composed of a climbing mechanism, a pruning mechanism and a pressing mechanism, and is characterized in that a pruning mechanism is installed on the climbing mechanism, and a pressing mechanism is installed on the climbing mechanism . The advantage is that the intelligent automatic branch pruning device can replace manual branch pruning, which improves the efficiency of branch pruning and reduces the labor intensity of garden workers. Moreover, the device can realize the pruning of tree branches of different thicknesses. Different, the intelligent automatic branch pruning device can automatically adjust the internal spacing to meet the pruning work for trees of different thicknesses, avoiding the difficulty that the same branch pruning device cannot complete the job due to different tree thicknesses, improving the versatility of the branch pruning device, reducing pruning costs.

Owner:李洪龙

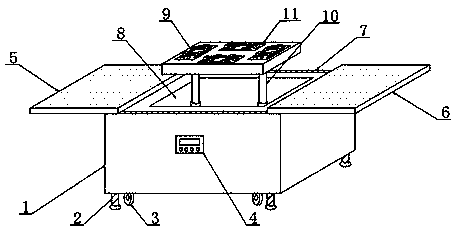

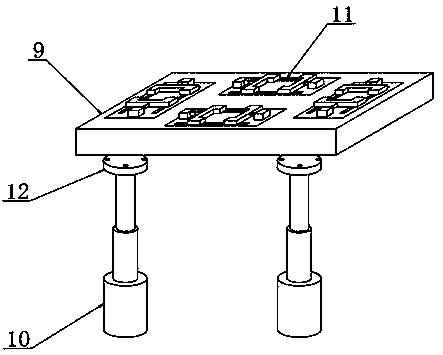

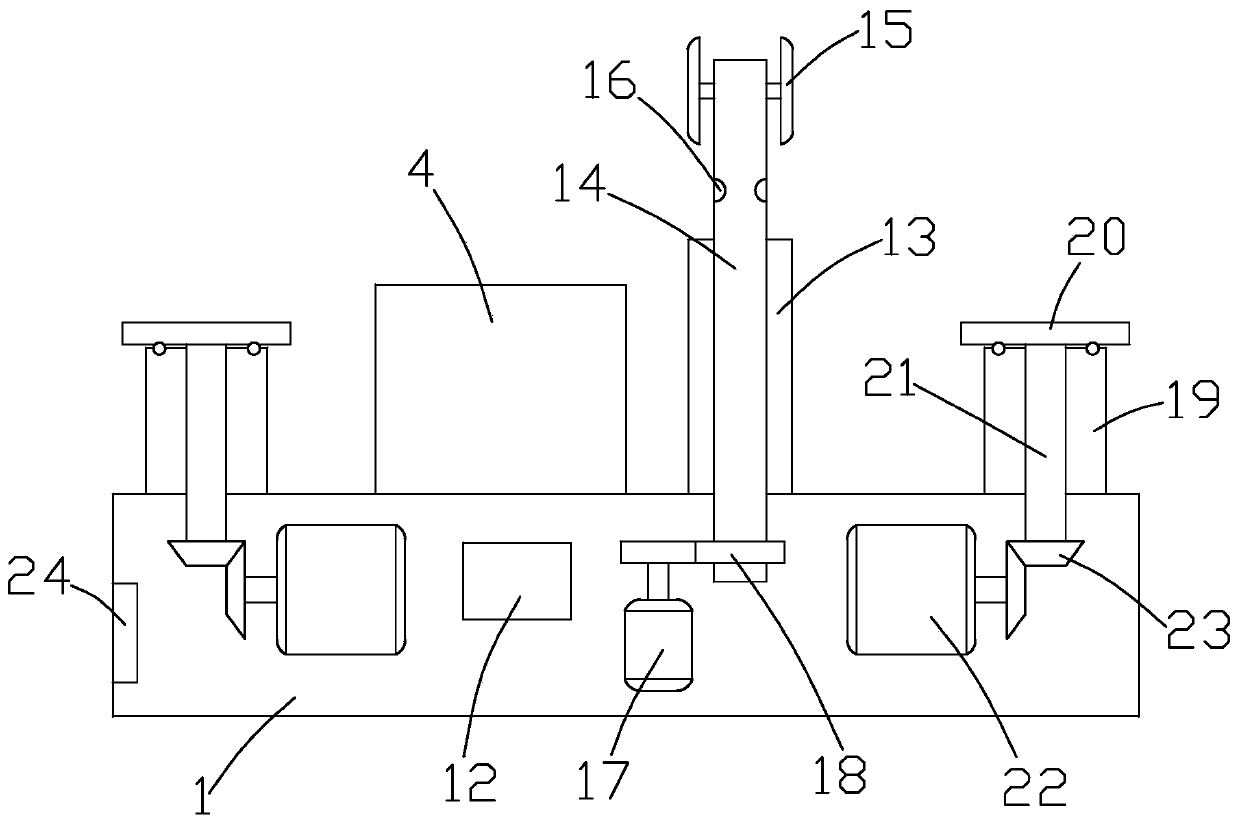

Multi-station machining device for pressure sensor manufacturing

The invention discloses a multi-station machining device for pressure sensor manufacturing. The multi-station machining device comprises a rack. Adjusting supporting legs are fixedly installed at thebottom end of the rack, and universal wheels are arranged at the positions, located on one sides of the adjusting supporting legs, of the rack. A control panel is arranged on the front side of the rack in an embedded manner, a first panel is arranged on one side of the top of the rack, and a second panel is installed on the other side of the top of the rack. The multi-station machining device is scientific and reasonable in structure and convenient to operate, due to the fact that electric telescopic rods are arranged, height adjustment of a machining table can be achieved, and corresponding adjustment is conducted according to the height of an actual user; due to the fact that sliding rails are arranged, sliding of the first panel and the second panel can be achieved, and a certain protection effect is achieved on the machining table; and due to the fact that a first adjusting air cylinder and a second adjusting air cylinder are arranged to act, a first clamp and a second clamp can bedriven to slide to work on a first sliding groove and a second sliding groove, and the multi-station machining device can be suitable for various sizes of pressure sensors.

Owner:芜湖凯兴汽车电子有限公司

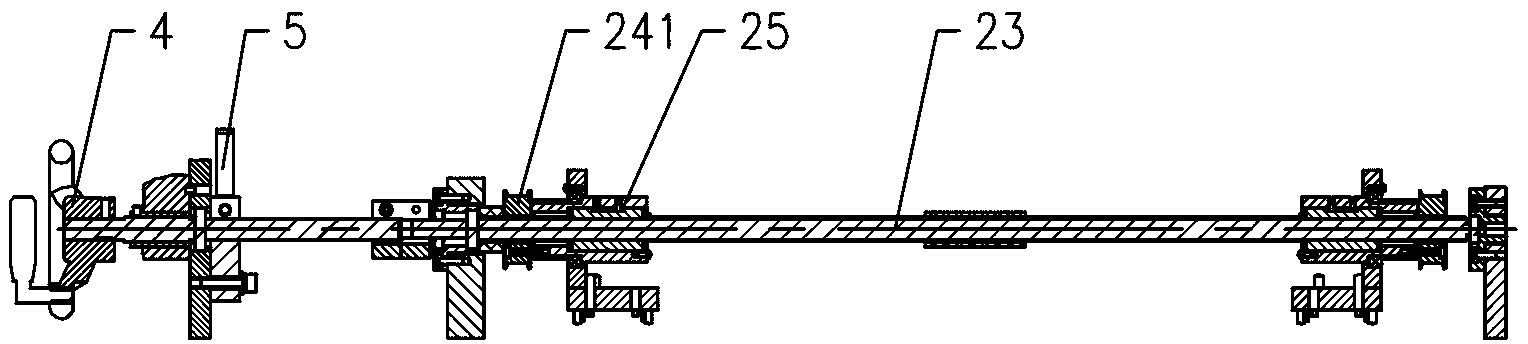

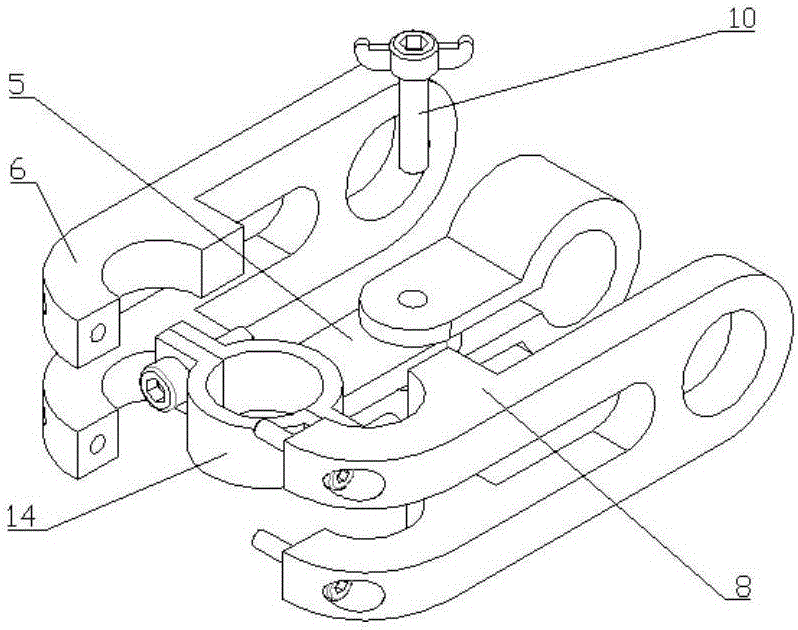

Universal type transportation table supporting arm mechanism for engine cover

ActiveCN106628591AEasy accessPrevent overturningPackaging vehiclesContainers for machinesSpare partEngineering

The invention relates to a universal transportation table supporting arm mechanism for an engine cover. The universal transportation table supporting arm mechanism comprises installation frames, a supporting shaft, limiting block installation seats and limiting blocks. The supporting shaft is installed between the symmetric installation frames. The multiple limiting block installation seats are arranged on the supporting shaft from the part taking end to the part storing end, and the limiting blocks are installed in the limiting block installation seats one by one. The limiting block installation seats are arranged on the supporting shaft in an overturning type sliding and sleeving manner. Multiple pin holes are formed in the part taking end of the supporting shaft. A pin hole is formed in the limiting block installation seat at the part taking end. The limiting block installation seat at the part taking end and the part taking end of the supporting shaft are positioned through a lock pin. The universal transportation table supporting arm mechanism for the engine cover is scientific and reasonable in structural design, adjustability of limiting grooves can be achieved, meanwhile, due to the sequentially positioning type storing and taking operation of side limiting mechanisms, the storing and taking convenience of automobile accessories is greatly improved, universality is high, the use frequency of devices is improved, possible waste losses are reduced, the spare part circulation efficiency is improved, and spare part packaging, logistic cost and the like are optimized.

Owner:CHINA PACKAGING RES & TEST CENT

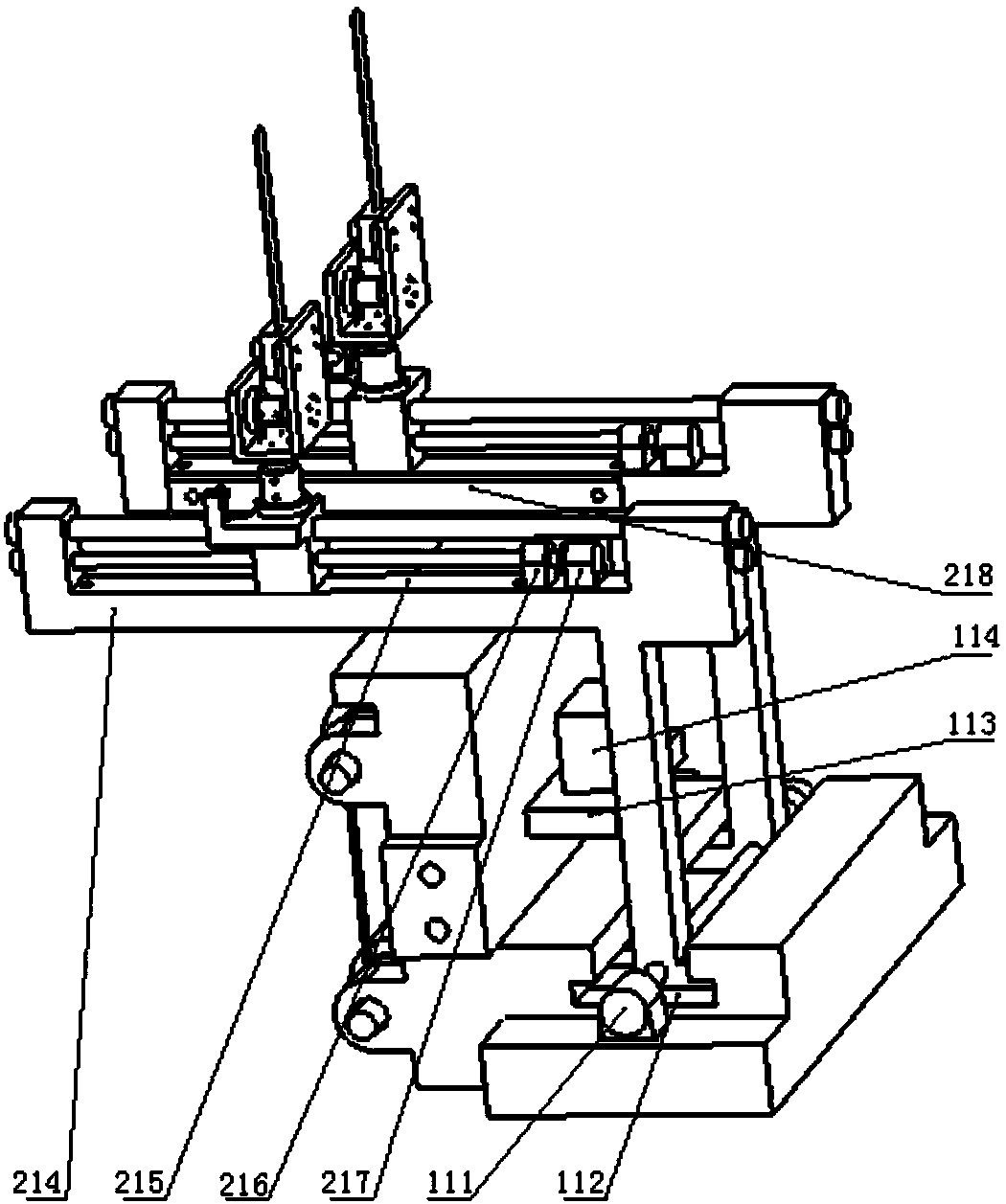

Device and method for automatically detecting flatness of surfaces of circuit boards

PendingCN111495793AEasy accessShorten the timeMeasurement devicesSortingStructural engineeringElectrical and Electronics engineering

Owner:浙江新连宇电子有限公司

Intelligent welding tool for metal pipe fitting in workshop

InactiveCN110280965ARealize clamping workQuick fixWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses an intelligent welding tool for a metal pipe fitting in a workshop, and relates to the technical field of metal pipe fittings. The intelligent welding tool for the metal pipe fitting in the workshop comprises a machine frame. A control panel is fixedly arranged on the front side of the machine frame. A containing cavity is formed in one side of the upper surface of the machine frame. A first fixing mechanism is fixedly installed at the position, located on one side of the containing cavity, of the upper surface of the machine frame. A sliding mechanism is embedded in the containing cavity. The intelligent welding tool is reasonable in structure and simple to operate. The fixation of the metal pipe fitting can be rapidly and automatically realized through an arranged driving mechanism. The automation degree and intelligence degree of the welding tool are improved. The overall use value is high. The intelligent welding tool is suitable for wide popularization. Through the sliding mechanism, the distance between the first fixing mechanism and a second fixing mechanism can be adjusted, so that the welding tool can be suitable for metal pipe fittings with different lengths, the application range of the welding tool is expanded, and the practicability of the welding tool is improved.

Owner:NANJING YUSHENG ROBOT CO LTD

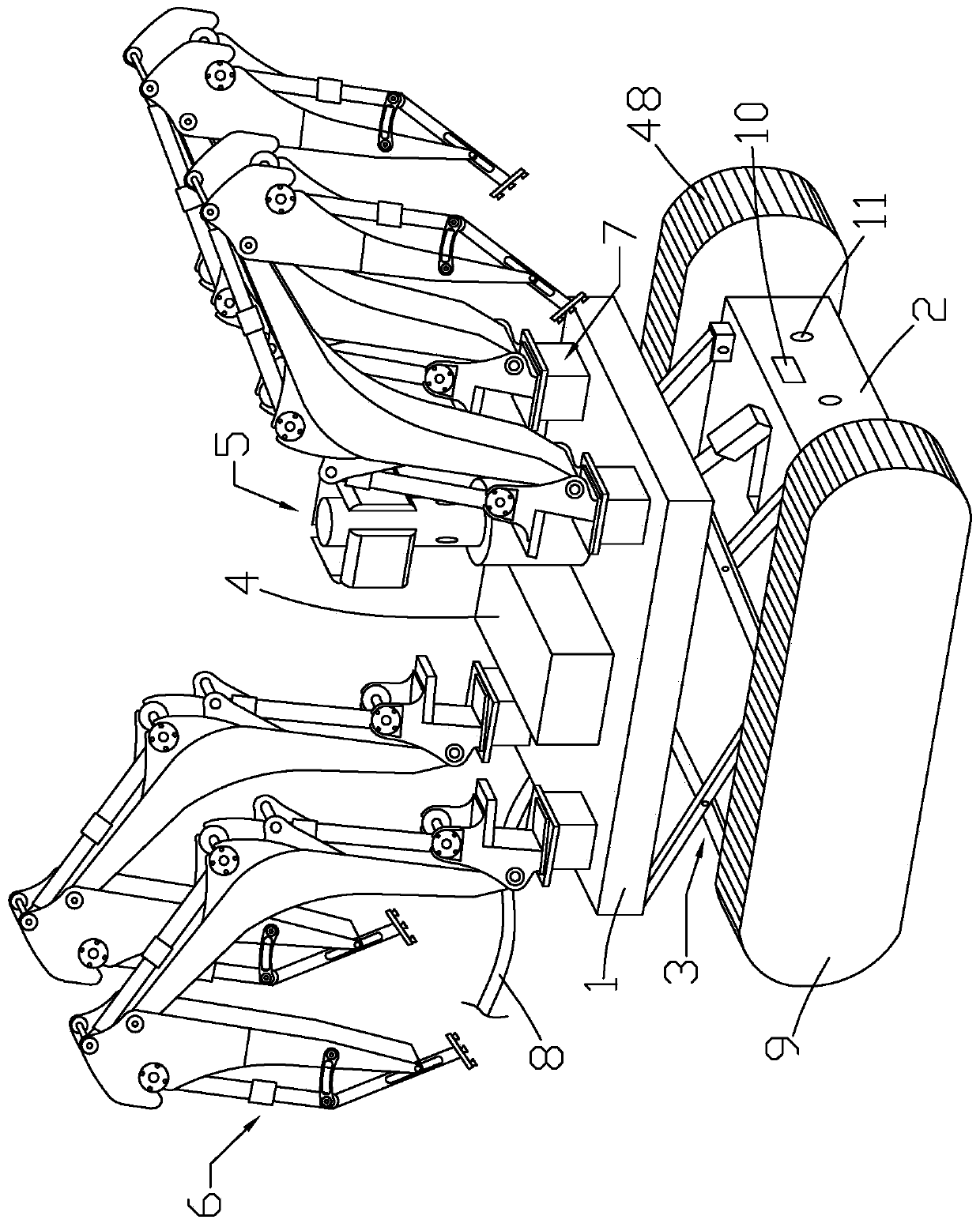

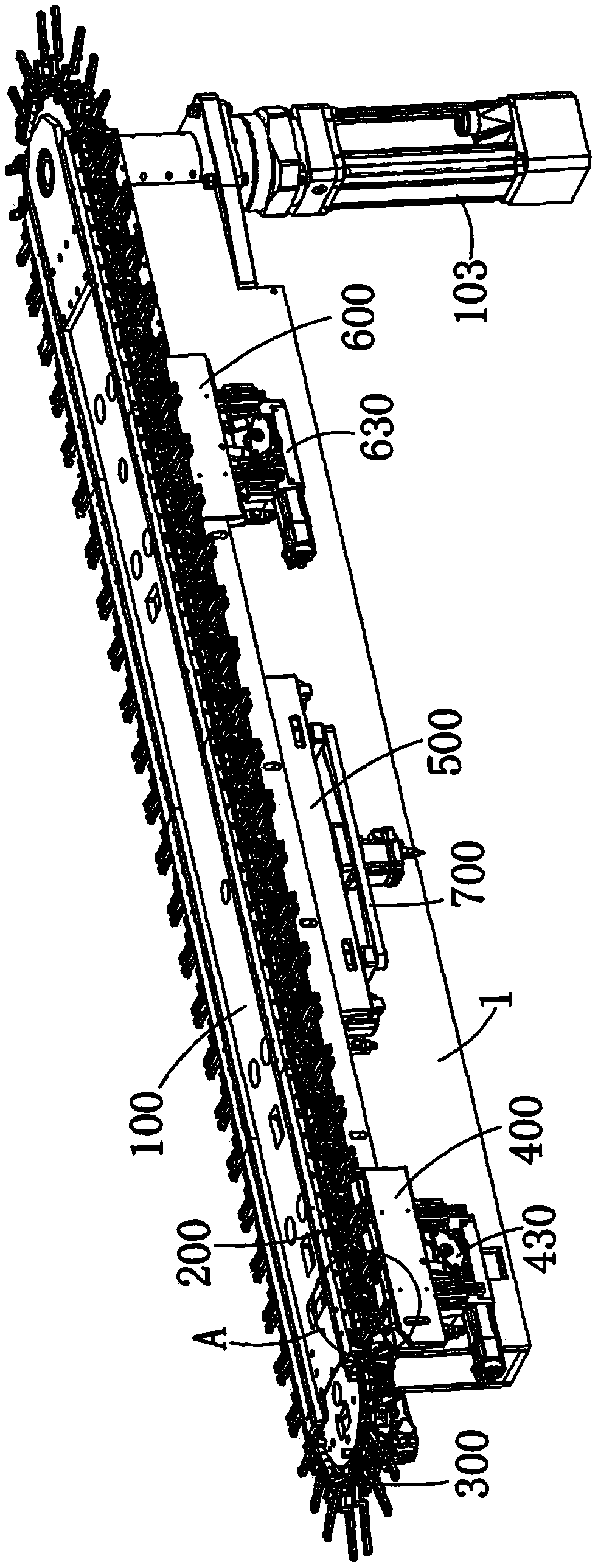

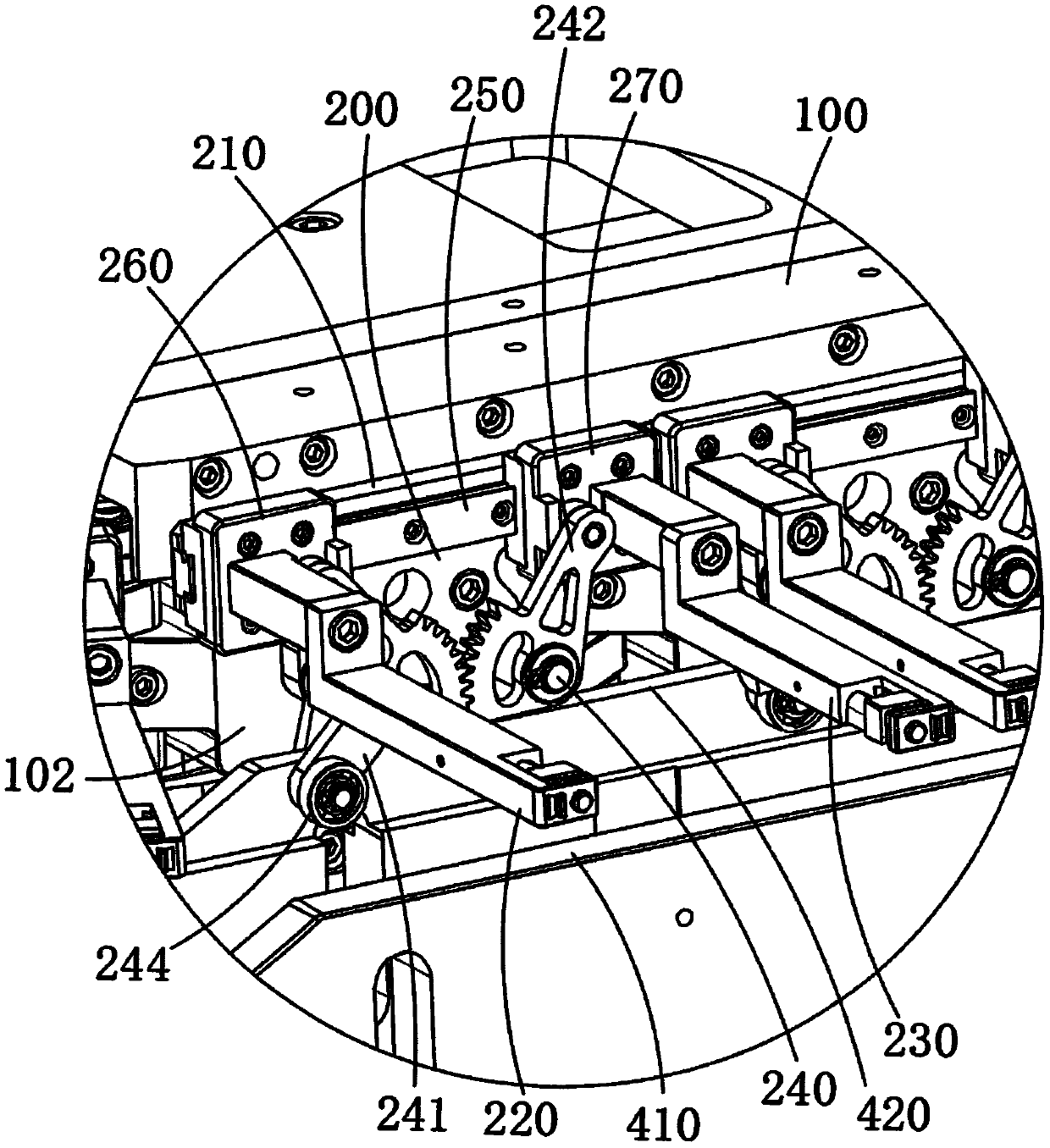

Multi- foot crawler belt float valve type crawler and crawling method thereof

ActiveCN111532349AImprove stabilityImprove reliabilityAmphibious vehiclesLighting support devicesMarine engineeringStructural engineering

The invention discloses a multi-foot crawler belt float valve type crawler and a crawling method thereof. The crawler comprises a base plate, a main float valve box, auxiliary float valve boxes, crawler belts and crawling feet. A first detection mechanism, a hydraulic oil tank and a steering platform are arranged on a top surface of the base plate, a hydraulic oil pump is arranged in the hydraulicoil tank, the four steering platforms are evenly arranged on a periphery of a top surface of the base plate, the crawling feet are connected to the steering platforms, the main float valve box is connected to a lower portion of the base plate through a lifting mechanism, the auxiliary float valve boxes are symmetrically arranged on the two sides of the main float valve box, and the crawler beltsare arranged on the auxiliary float valve boxes. The method comprises the steps of base plate machining, crawling foot installation, main float valve box and auxiliary float valve box machining, lifting mechanism installation and crawl operation of a crawl device. Crawler belt type float valve crawling driving advancing or multi-foot crawling driving advancing can be adopted, the crawling method of the crawler is simple in step, an equipment detection range is enlarged, and use and operation are flexible and convenient.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

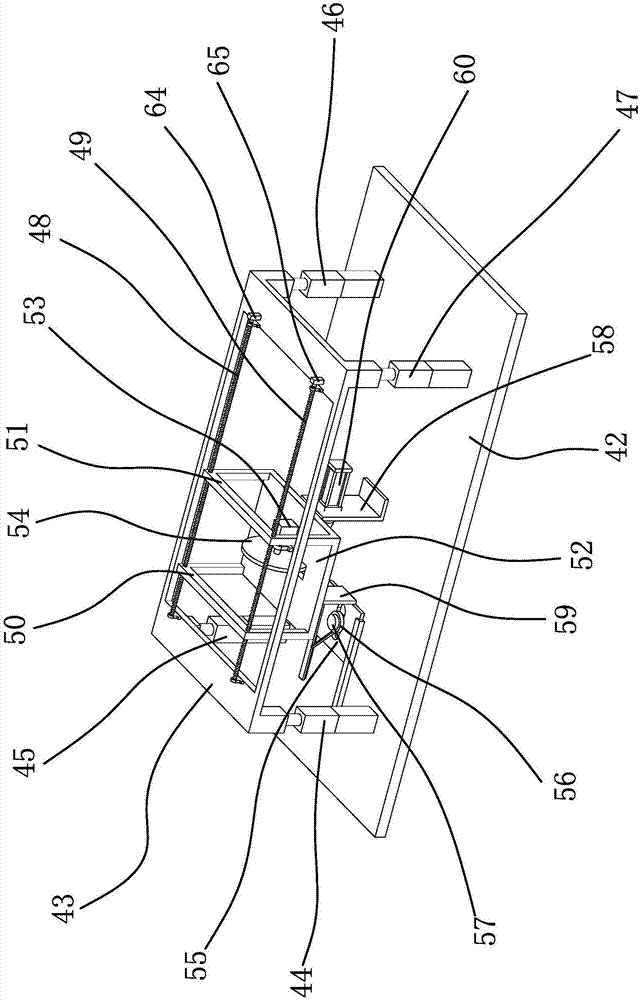

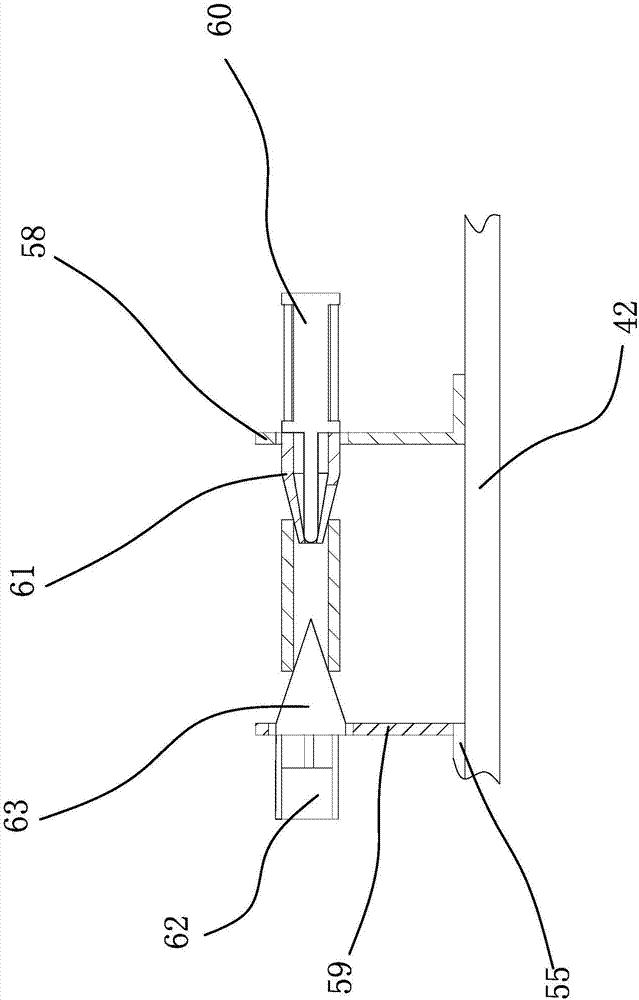

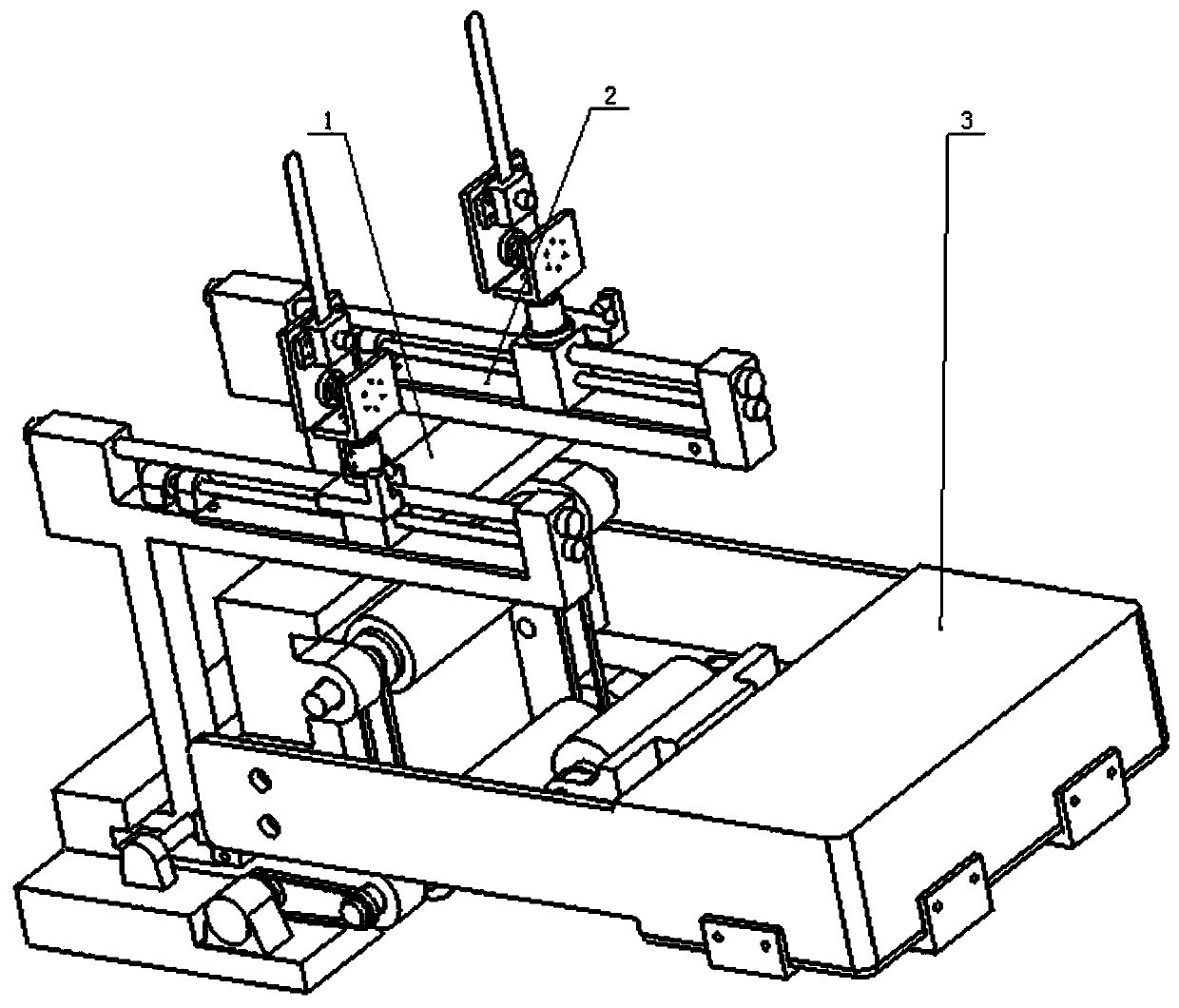

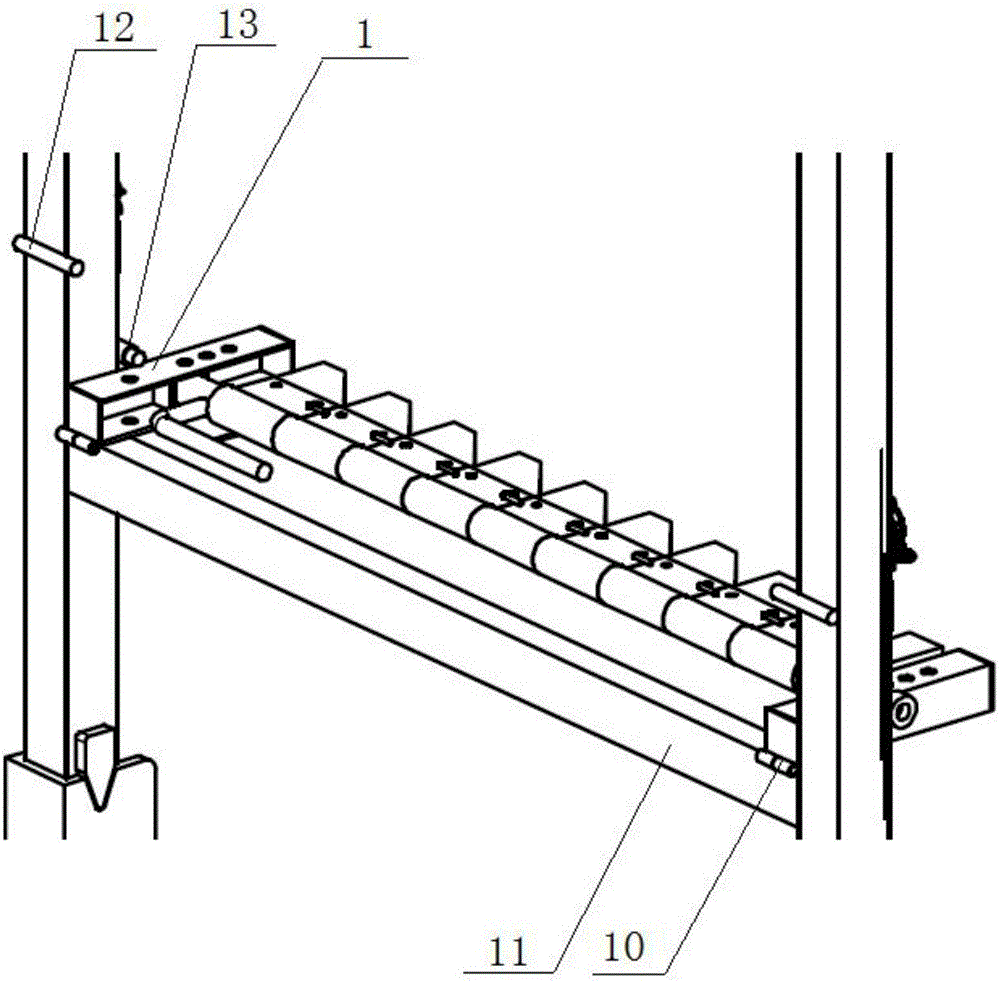

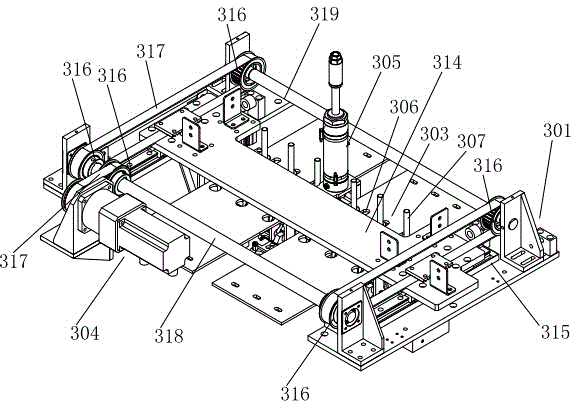

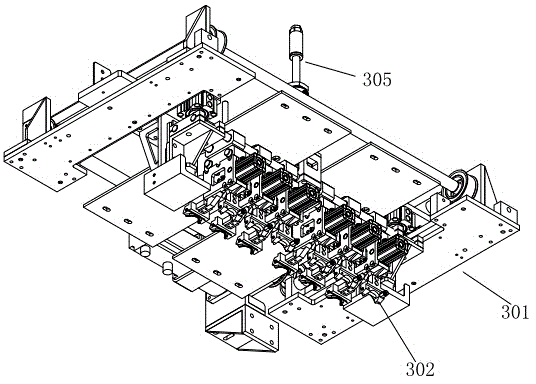

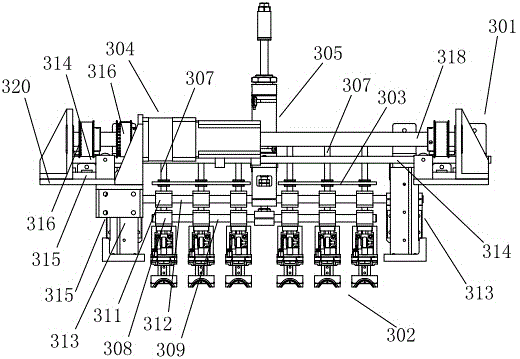

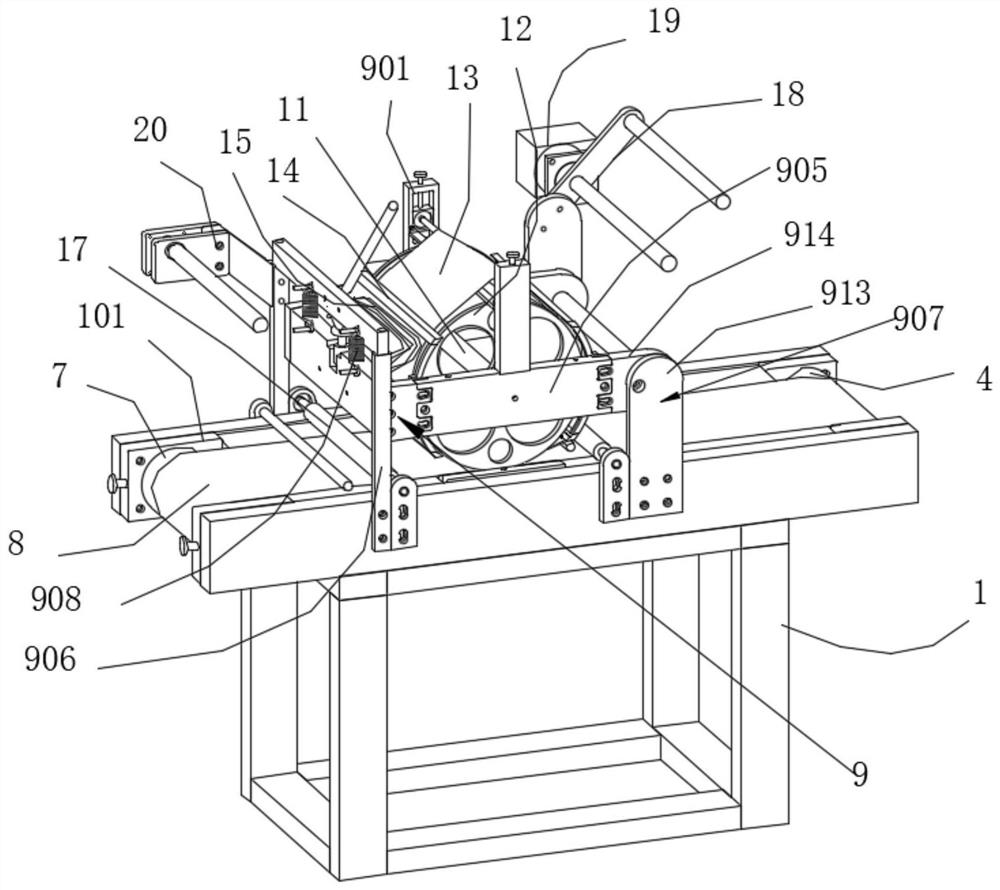

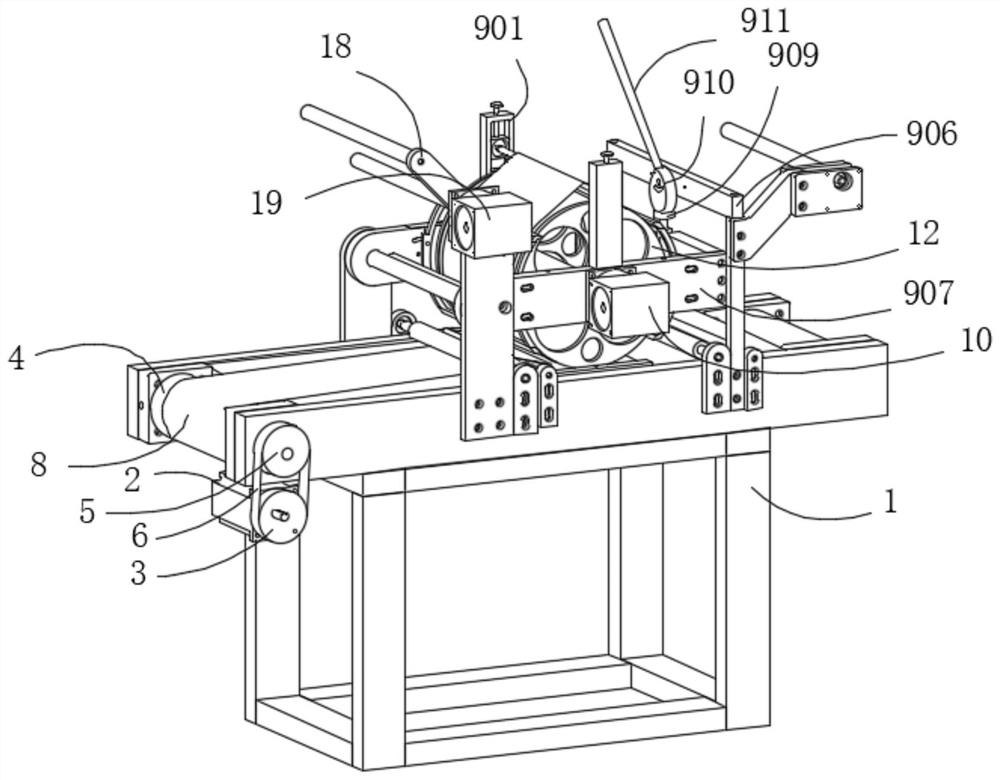

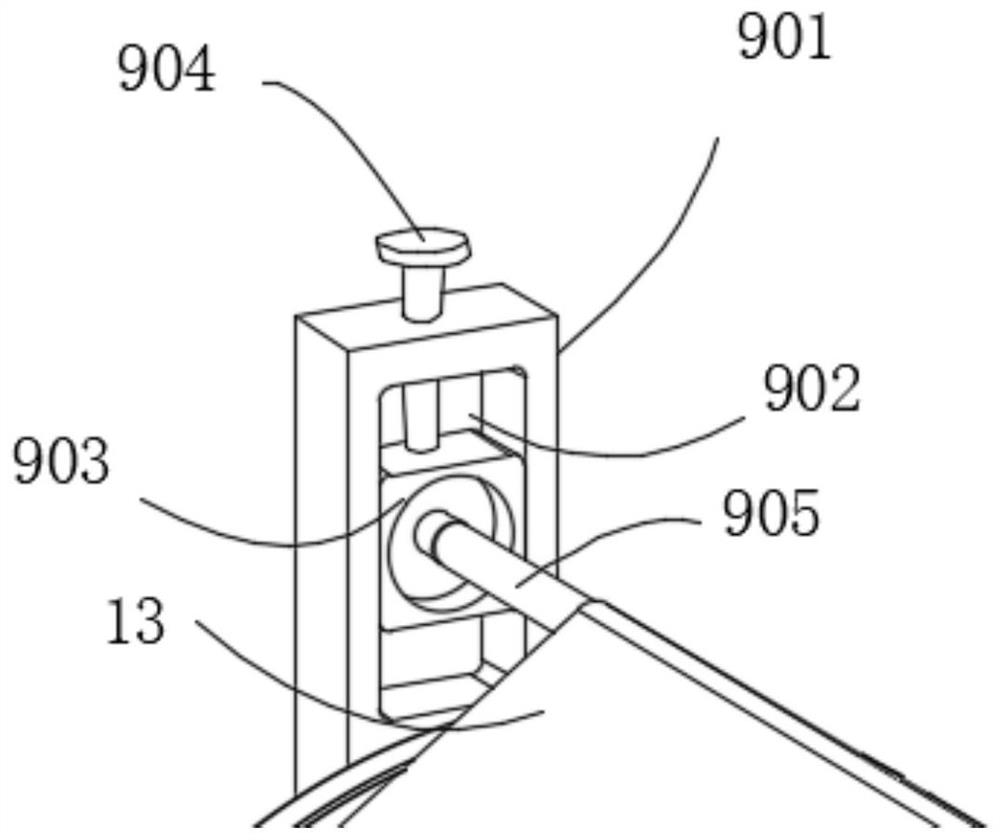

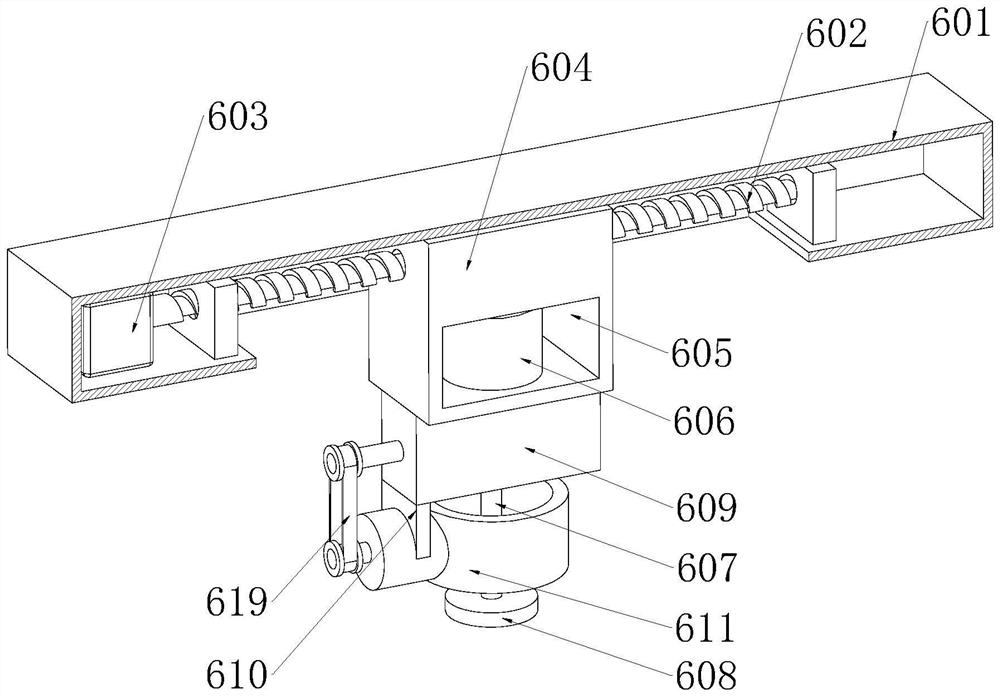

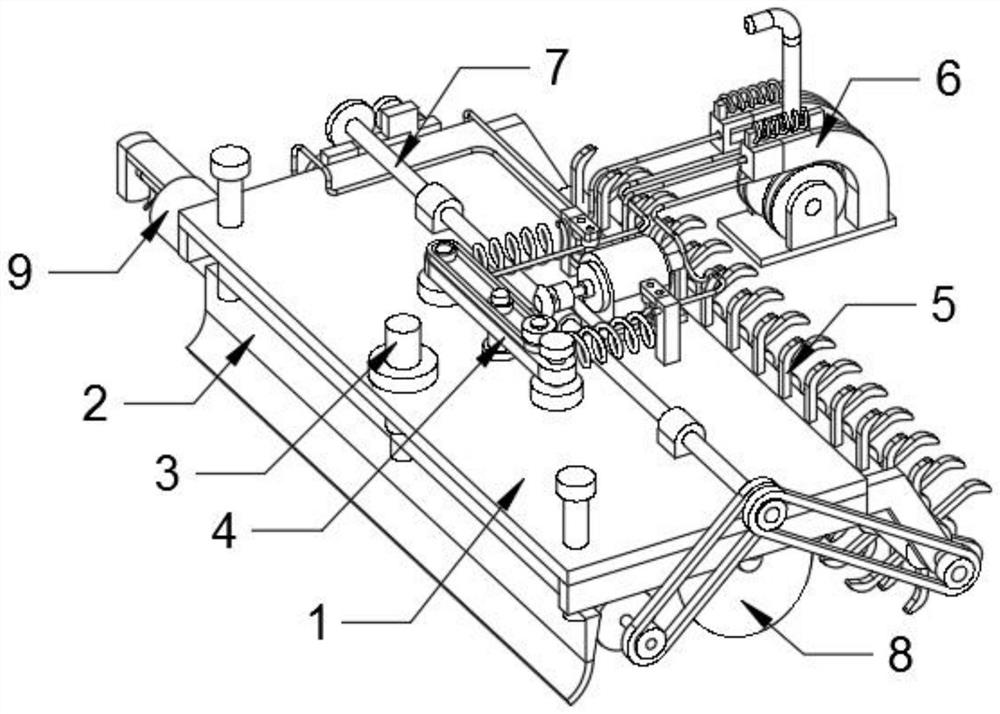

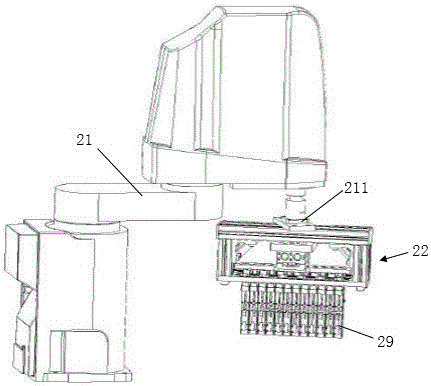

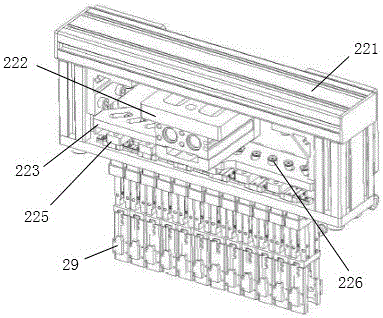

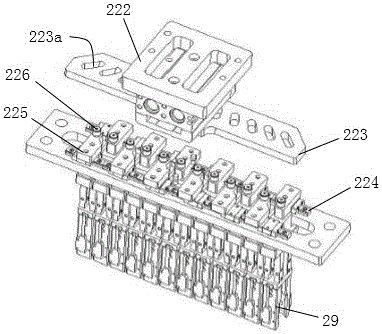

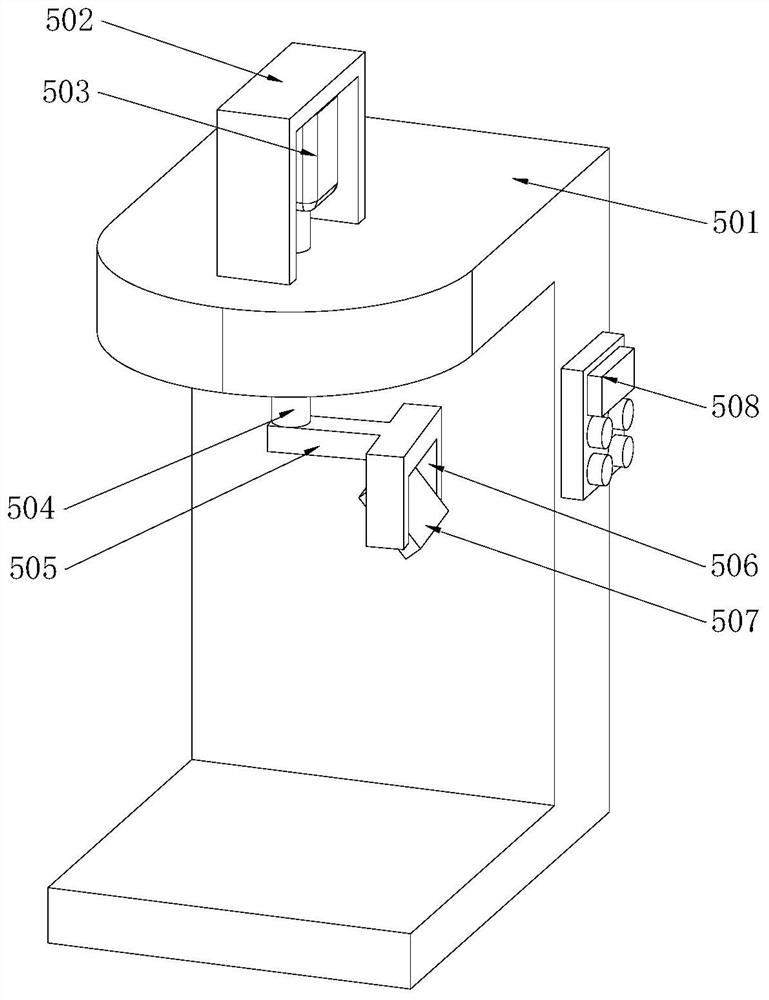

Clamping mechanism of food boxing machine

ActiveCN104816850ARealize spacing adjustmentExclude human interventionIndividual articlesMechanical equipmentEngineering

The invention relates to the field of food processing mechanical equipment, in particular to a clamping mechanism of a food boxing machine. The clamping mechanism comprises a mounting frame on which a plurality of mechanical clamping jaws are arranged, the mechanical clamping jaws are provided with a guide device used for adjusting a distance between every two mechanical clamping jaws, the mechanical clamping jaws are connected with a horizontal driving mechanism which drives the mechanical clamping jaws to move horizontally and is further connected with a vertical driving mechanism which drives the mechanical clamping jaws to realize up-and-down vertical motion. According to the clamping mechanism provided by the invention, the motions of the mechanical clamping jaws in three directions can be realized by a guiding device, a horizontal driving mechanism and a vertical driving mechanism, and the full-automatic regulation can be realized, therefore the mechanical clamping jaws can realize spacing adjustment without manual force, the clamping mechanism can be applicable to support boxes of applicable sizes by changing a rail plate, the manual intervention can be eliminated, the production efficiency can be improved, and the degree of automation can be enhanced.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Electromagnetic rolling number plate continuous hot-stamping method and number plate hot-stamping machine

ActiveCN111806071AImprove work efficiencyHot stamping effect is goodTransfer printingInk transfer from master sheetStamping processHot stamping

The invention discloses an electromagnetic rolling number plate continuous hot-stamping method. Number plates needing to be hot-stamped are heated and hot-stamped through electromagnetically-heated rollers, and therefore the number plates are hot-stamped. A number plate hot-stamping machine comprises a body seat, a motor is arranged on one side of the body seat, a first belt wheel is arranged at the stretching-out end of the motor, the driving roller is arranged on the body seat, a second belt wheel is arranged at one end of the driving roller, a belt is wound around the first belt wheel and the second belt wheel jointly, the driven roller is arranged at one end of the body seat, and a conveying belt is wound around the driven roller and the driving roller. By means of an electromagnetic heating rolling hot-stamping manner, the electromagnetic rolling number plate continuous hot stamping method has the beneficial effects that the heating time is short; temperature replenishing is rapidin the hot-stamping process, and the production efficiency is greatly improved; and the number plates are heated uniformly, the percent of pass of hot-stamping is high, the cost depletions are greatly reduced, and the safety is improved.

Owner:浙江智博交通科技有限公司

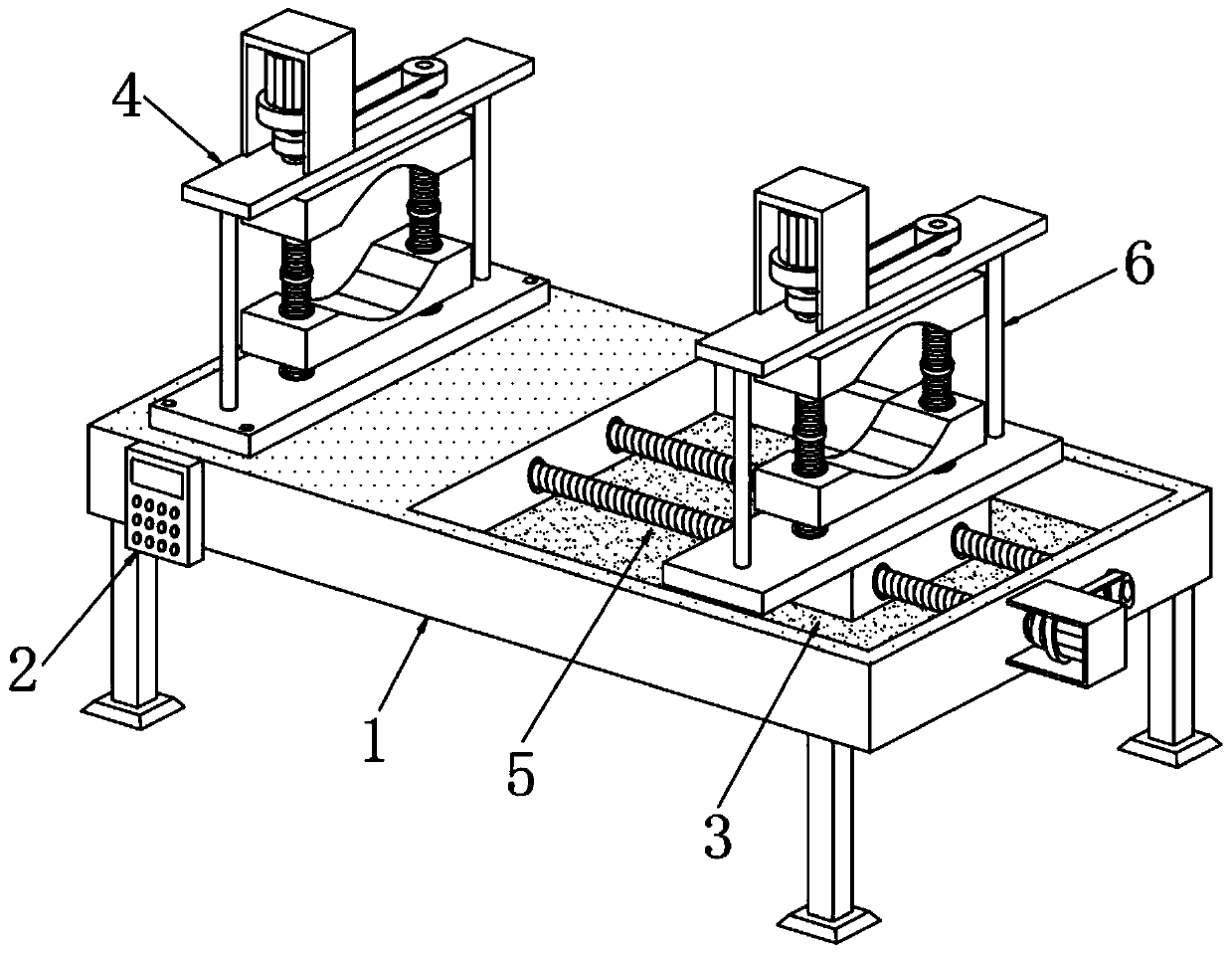

Polishing device for waterproof and anti-corrosion plate of environmental protection engineering

ActiveCN114378658AAchieve grindingRealize heat dissipationGrinding work supportsPlane surface grinding machinesElectric machineryStructural engineering

The polishing device comprises a fixing plate, fixing frames are arranged on the two sides of the top end of the fixing plate, first threaded rods are arranged in the fixing frames, one ends of the first threaded rods penetrate through the side walls of one ends of the fixing frames and are provided with first motors, and stand columns are arranged in the fixing frames; a first threaded groove matched with the first threaded rod is formed in the bottom end of the stand column, and a grinding mechanism is arranged at the top end of the stand column. A lifting mechanism is arranged in the middle of the top end of the fixing plate, a placing table is arranged above the lifting mechanism, a clamping mechanism is arranged in the placing table, dust falling boxes are arranged on the two sides of the bottom end of the placing table, and dust suction boxes are arranged on the two sides of the end, away from the first motor, of the top end of the fixing plate. The plate polishing device is reasonable and reliable in structure, simple and convenient to operate and capable of polishing plates comprehensively and stably, so that the product quality of the polished plates is guaranteed, the production cost is reduced, and the productivity is improved.

Owner:上海豫宏建设集团有限公司

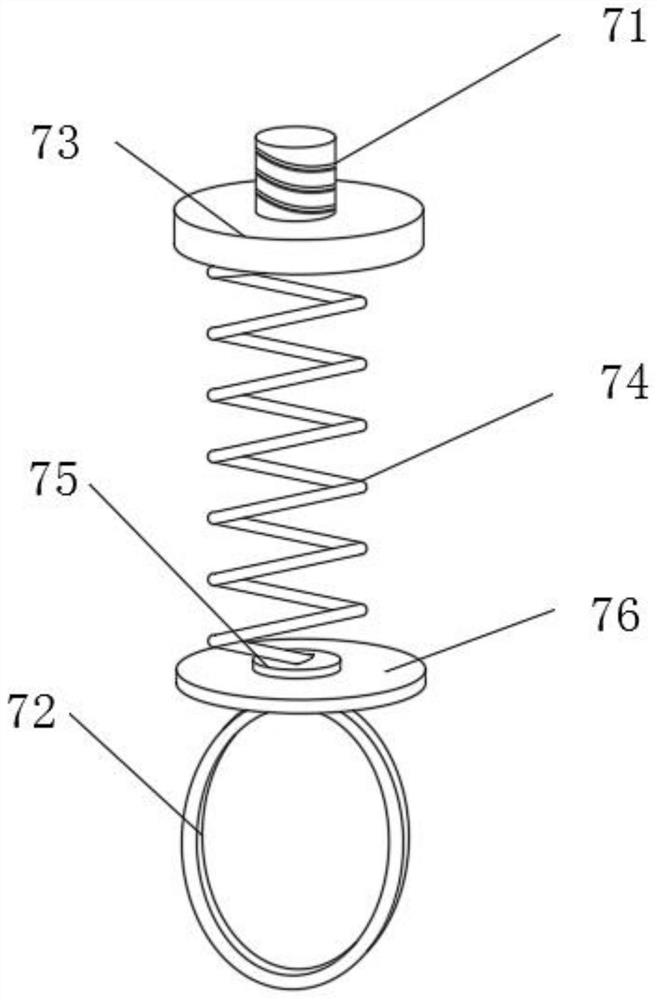

Patient rehabilitation training device for burn department

InactiveCN111760242ASpeed up recoveryTargetedMovement coordination devicesMuscle exercising devicesCushionEngineering

The invention discloses a patient rehabilitation training device for the burn department. The device comprises a bottom plate, a slideway is formed in the left part of the upper end of the bottom plate; a sliding piece is mounted in the slideway in a sliding manner; a seat is fixedly mounted in the middle of the upper end of the sliding piece; a soft cushion is laid on the seat; massage cushions are fixedly mounted in the middle of the soft cushion and at the upper end of the seat; a supporting rod, a supporting device and two lower limb training devices are fixedly installed on the right portion of the upper end of the bottom plate, the upper end of the supporting device is movably sleeved with two lantern rings, the lower ends of the two lantern rings are in threaded connection with armtraining devices, and a console is fixedly installed at the upper end of the supporting rod. According to the patient rehabilitation training device for the burn department, a patient is scientifically trained through a display screen and a voice prompter, and the maintenance efficiency can be improved by disassembling and assembling a first spring and a second spring; a third fastening knob and the sliding piece are used for achieving interval adjustment, and therefore, the application range is wide; and a safety belt and spring pieces can improve the safety performance of the training device.

Owner:深圳市龙华区中心医院

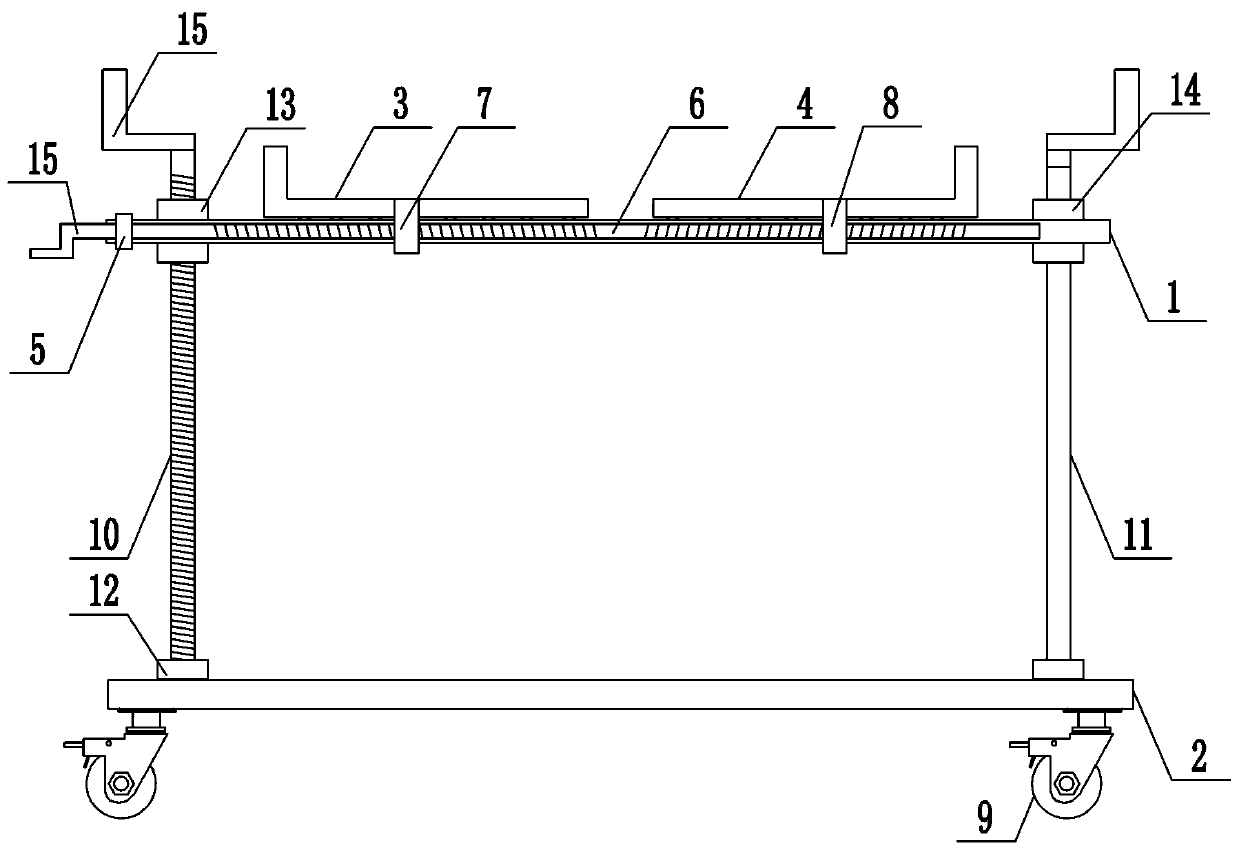

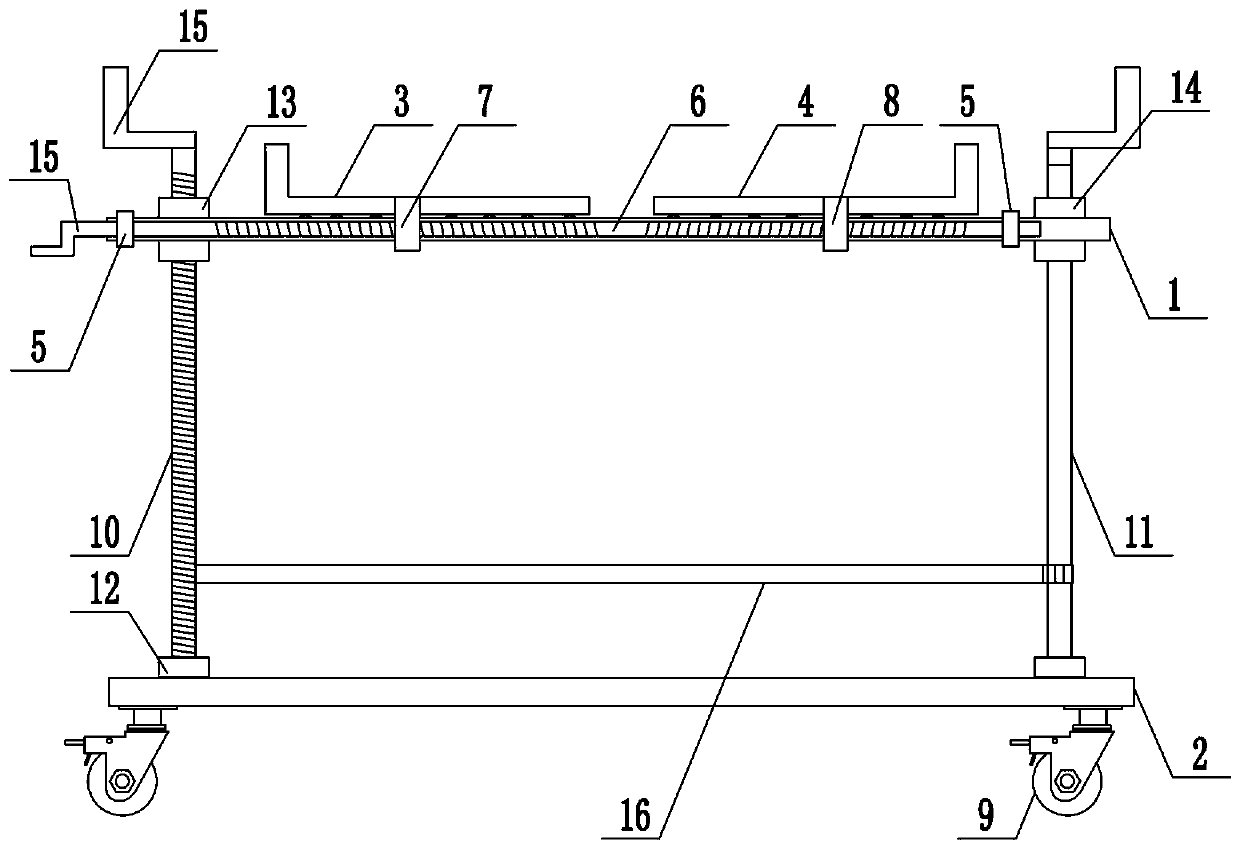

Multifunctional overhauling platform

InactiveCN109599774AAvoid instabilityImprove securitySwitchgearArchitectural engineeringScrew thread

Owner:漯河市高级中学 +1

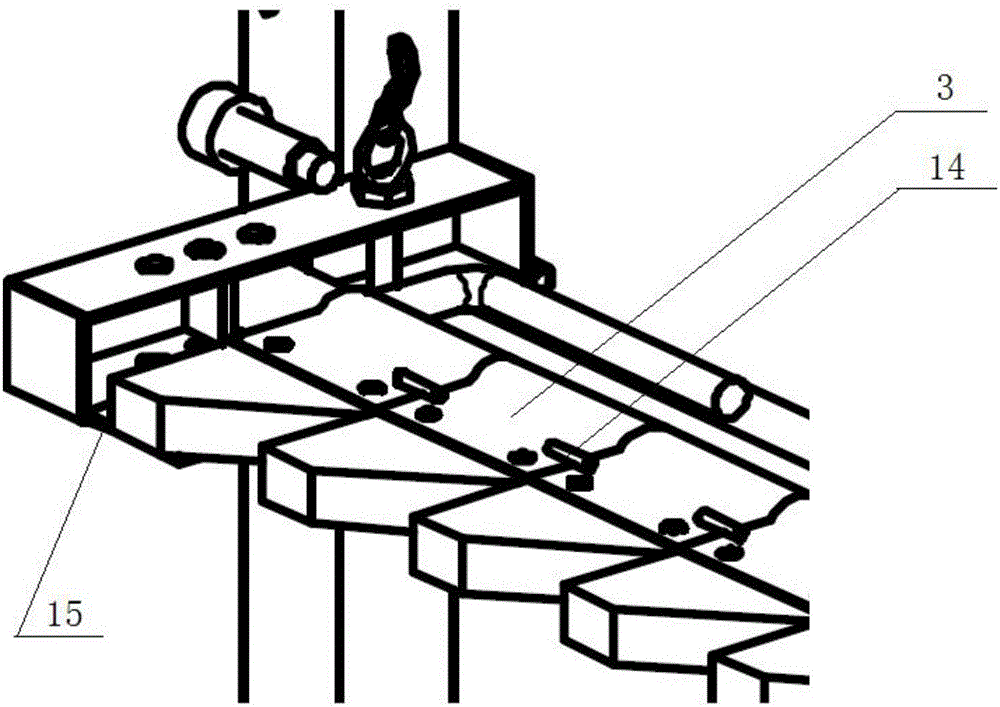

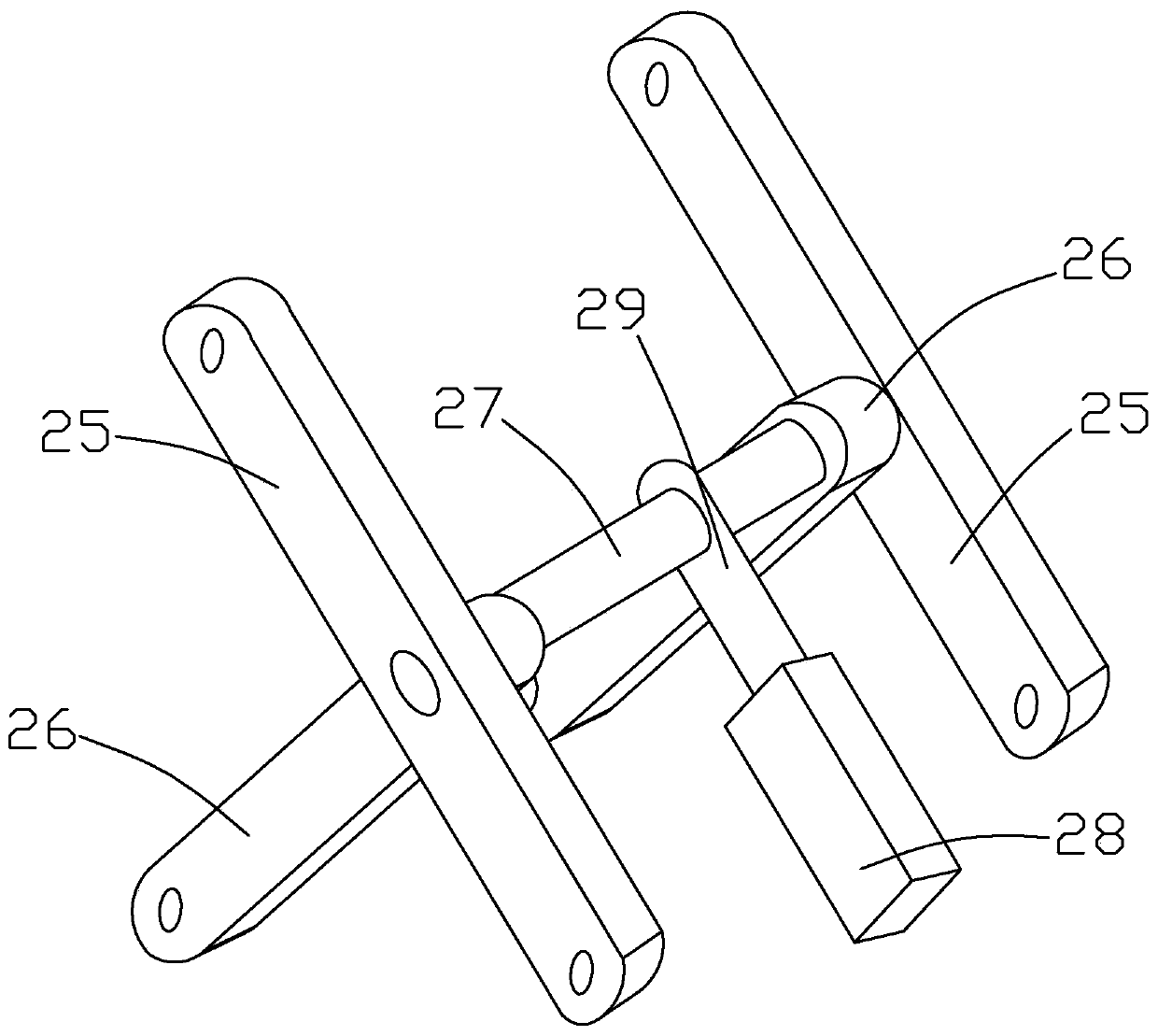

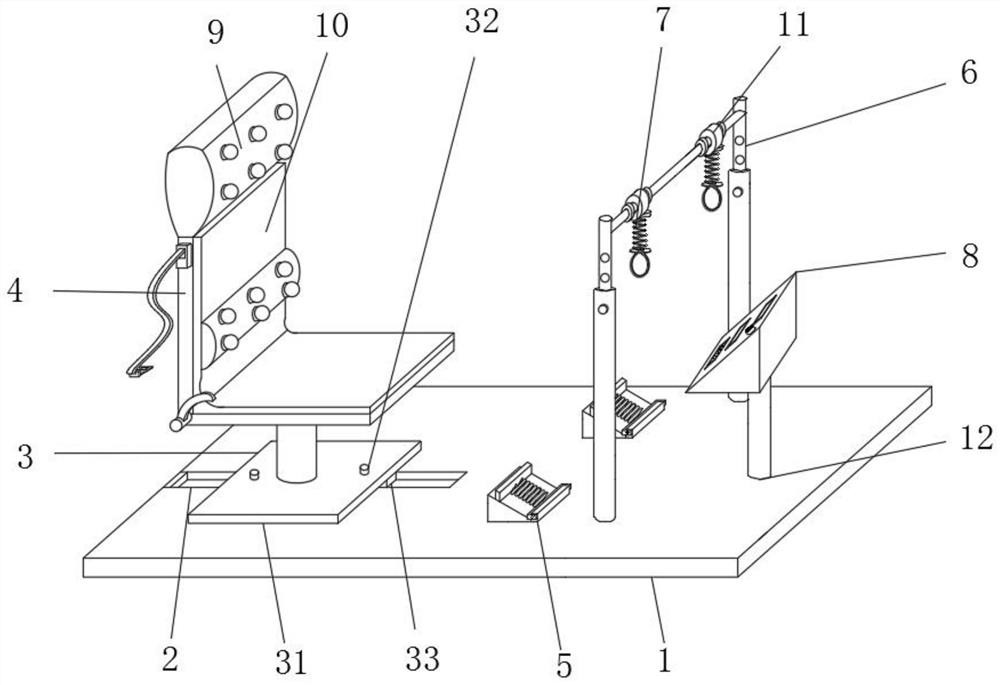

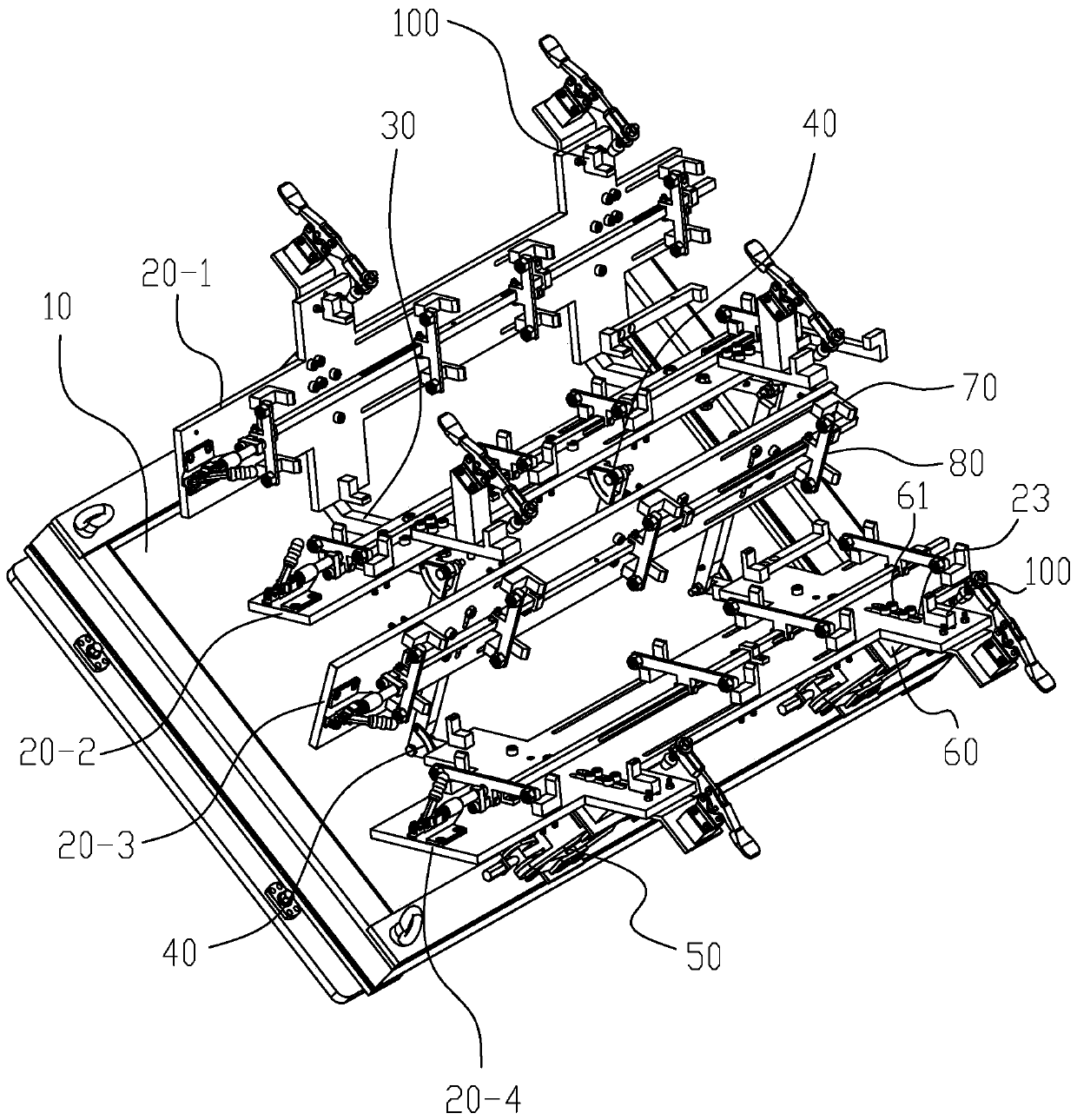

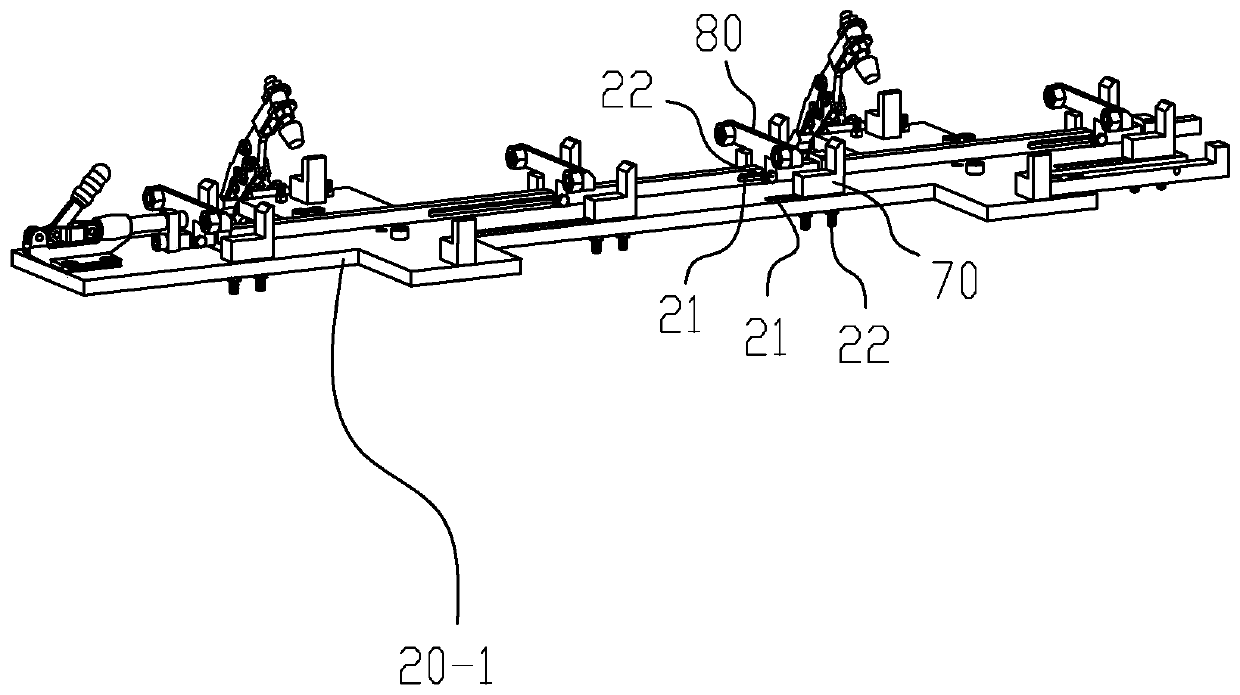

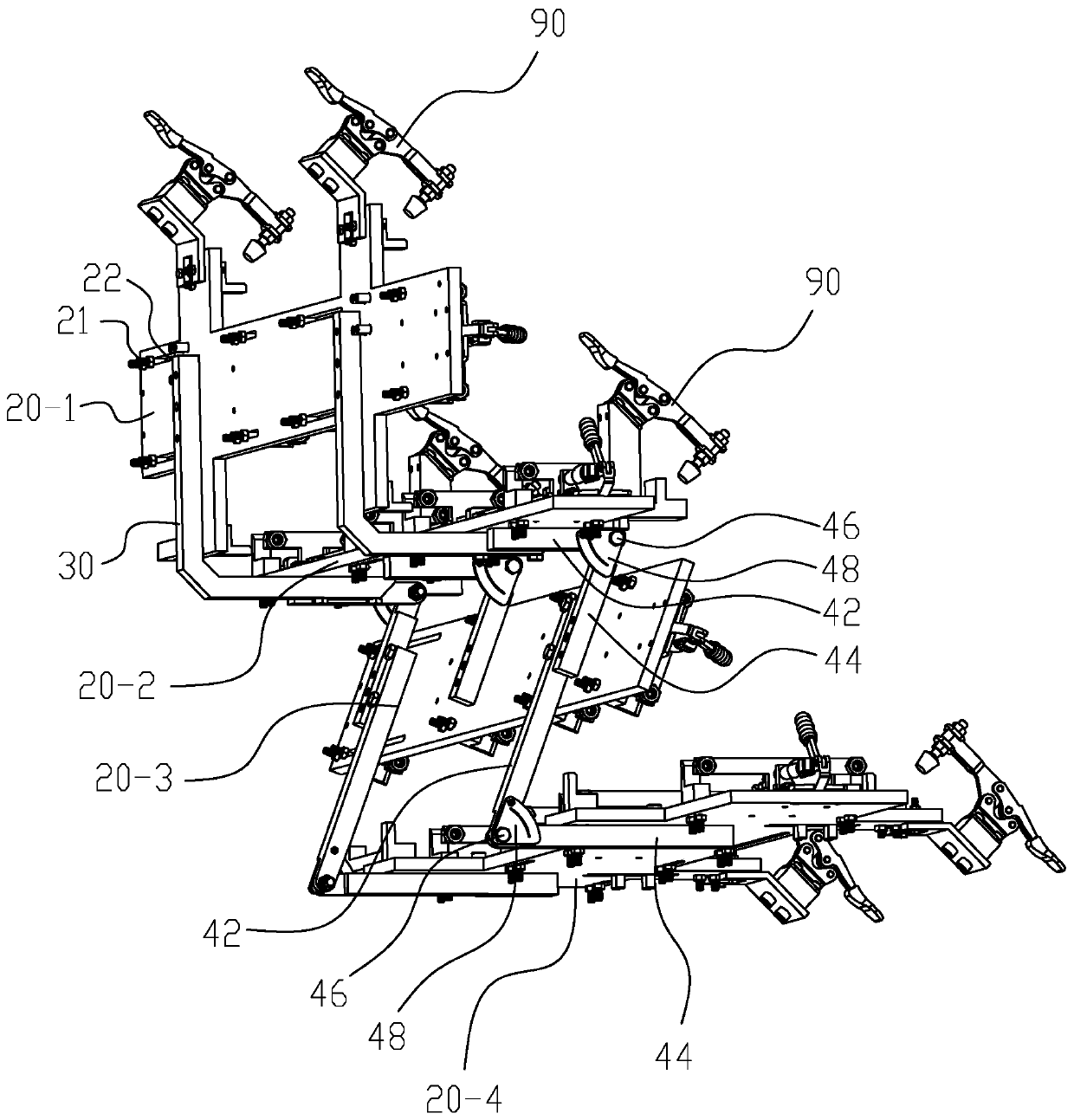

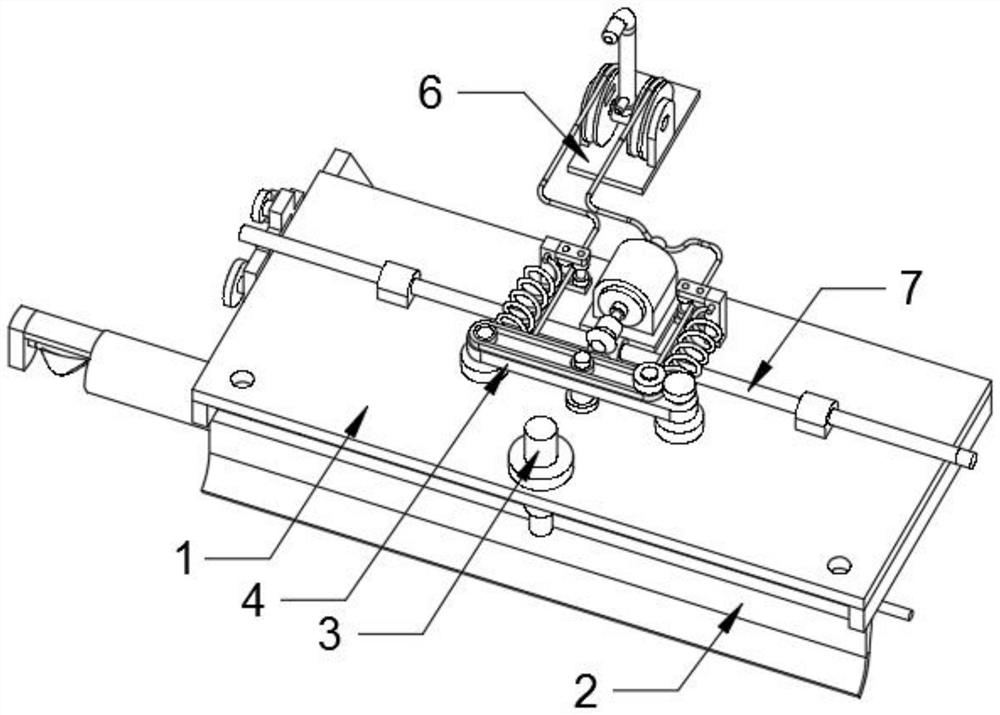

Flexible clamp for passenger car pedal skeleton welding

PendingCN110052770AImprove the range of use and flexibilityLow manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesStructural differenceEngineering

The invention discloses a flexible clamp for passenger car pedal skeleton welding. The flexible clamp comprises a base and four limiting plates longitudinally arranged above the base, wherein the limiting plates are connected by a hinge mechanism; a positioning block and a clamping block which can transversely slide are arranged on the top surface of each limiting plate, and sliding grooves corresponding to the positioning block and the clamping block are respectively formed in each limiting plate; the positioning block and the clamping block are locked on the corresponding limiting plate respectively through bolt components; and the positioning block and the clamping block are mutually matched to clamp a longitudinal rod of a skeleton. According to a series of structural differences of the passenger car pedal skeleton, the welding clamp is regulated to a designated position precisely and quickly to carry out corresponding clamping and fixation, thus the adjustment of several degrees of freedom in a plane and space is realized, the application scope and flexibility of the fixture tool are improved, the manufacturing cost is reduced, and the manufacturing time is shortened. The clamping block and the positioning block are fixed through the bolt components, so that the rigid positioning is ensured, and the positioning precision and the clamping function can also be ensured.

Owner:XIAMEN UNIV

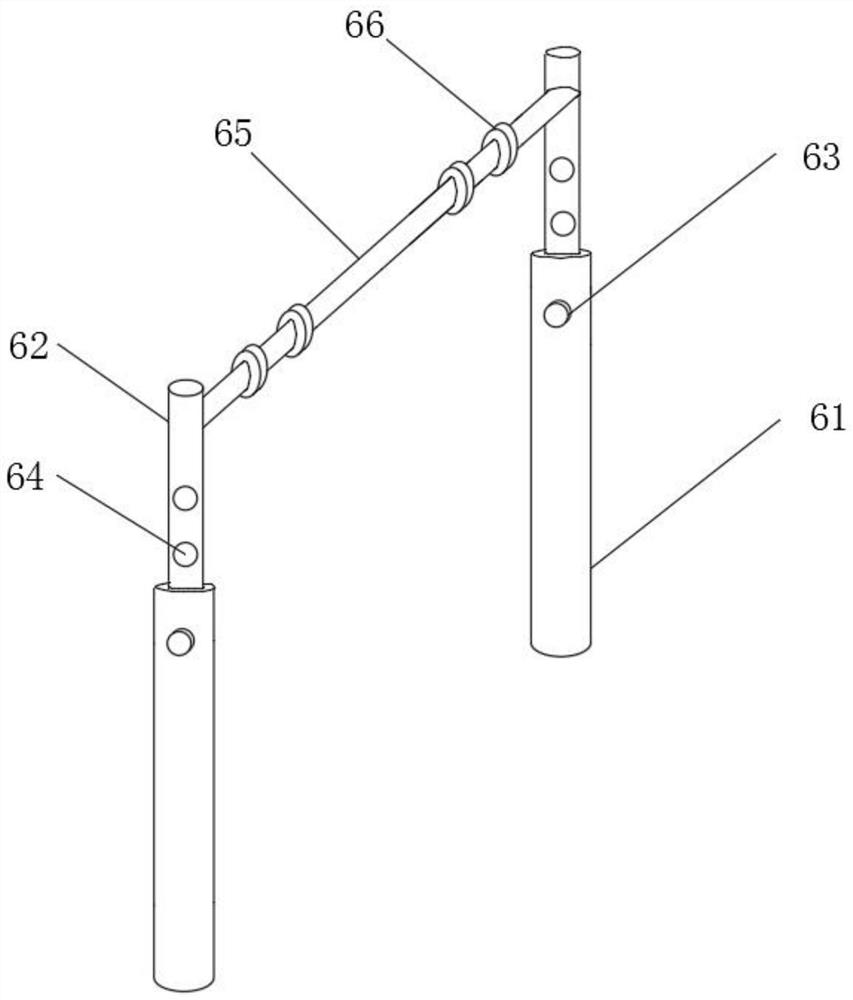

Electrostatic spraying device of plant protection unmanned aerial vehicle

ActiveCN106583075ASolve the problem of live electricityImprove uniformityAircraft componentsLiquid spraying plantsAviationDiaphragm pump

The invention relates to an aviation electrostatic spraying device. The device mainly comprises two parts of a spraying rod adjusting device and an electrostatic atomization system. The spraying rod adjusting device mainly consists of such several parts as a rotating block, a fixed piece, a spraying rod and a fastening screw; the electrostatic atomization system includes an atomization system and an electrostatic generation device; the atomization system mainly consists of a medicine box, a diaphragm pump, a pipeline, a three-way valve, a nozzle and the like; and the electrostatic generation device mainly consists of a direct-current power supply, a high-voltage generator and an electrode. In the aviation electrostatic spraying device, the spraying rod can rotate and extend trough the rotating block to adapt to different spraying width requirements. The whole atomization system is insulated in liquid loop. The electrostatic spraying can improve the aviation spraying uniformity and reduce drifting. The aviation electrostatic spraying device realizes the nozzle gap adjusting problem in the aviation electrostatic spraying, improves the aviation spraying operation efficiency, improves the adaptability of aviation spraying to different plant protections, and reduces the operation time and the material cost.

Owner:JIANGSU UNIV

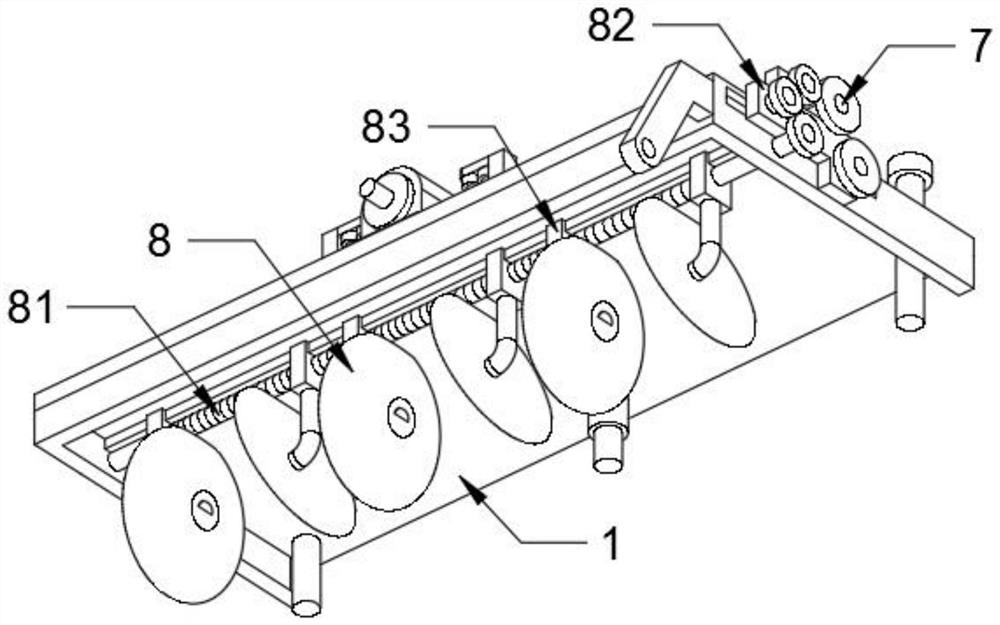

Ridging machine with adjustable ridge height and ridging method

The invention relates to the field of ridging machines, in particular to a ridging machine with adjustable ridge height and a ridging method.The ridging machine comprises a plate frame, a scraper is arranged at the end of the plate frame, a screw barrel is rotationally installed on the surface of the plate frame, a gear is connected to the surface of the screw barrel in a sleeving mode, and a stud fixed to the scraper is in threaded connection with the bottom of the screw barrel; a swing part is installed on the top face of the plate frame and connected with an adjuster through two sets of steel wires, the adjuster pulls the swing part to rotate leftwards or rightwards through the steel wires, and the left end or the right end of the swing part makes contact with a gear on the surface of the screw barrel. According to the invention, the regulator is used as a control part to directly regulate the swing of the swing part in the running process of the agricultural machine, and is used for driving the screw cylinder to rotate forwards or backwards, so that the height of the scraper is regulated, the regulation difficulty is greatly reduced, and the regulation is conveniently carried out in real time according to the ridging condition.

Owner:民勤县忠圣机械制造有限公司

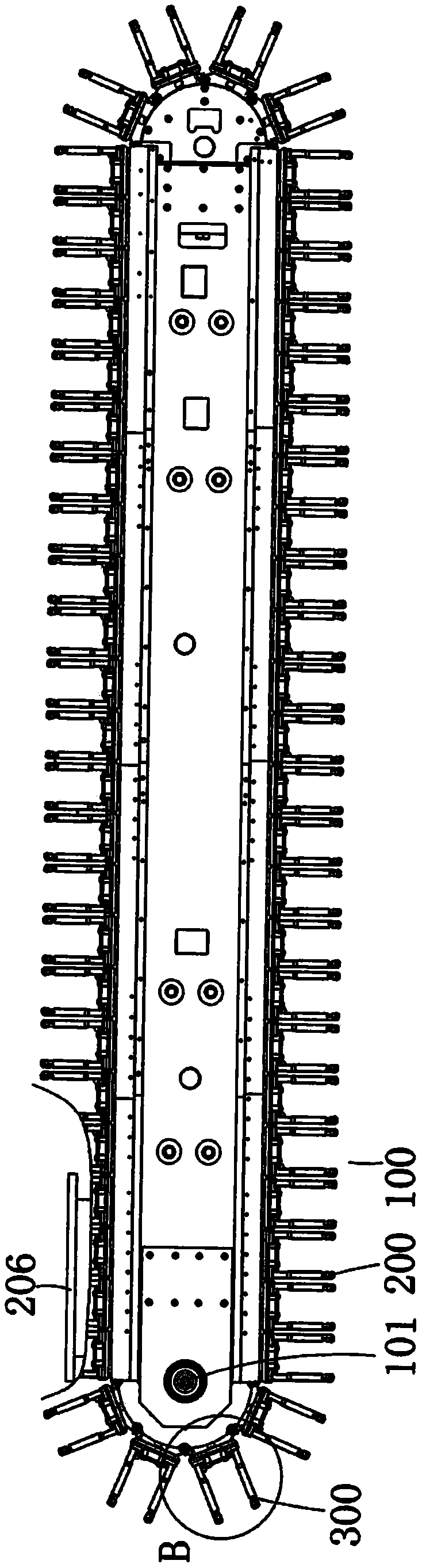

Bag clamping conveying mechanism and bag clamping conveying method

The invention discloses a bag clamping conveying mechanism and a bag clamping conveying method. The bag clamping conveying mechanism comprises a rack, a conveying mechanism and clamping hand assemblies arranged on the conveying mechanism and used for conveying bags, wherein the conveying mechanism comprises a chain wheel, a chain and a chain wheel driving motor used for driving the chain wheel to rotate, the clamping hand assemblies comprise the A-type clamping hand assemblies and the B-type clamping hand assemblies, one or more A-type clamping hand assemblies form a group, one or more B-type clamping hand assemblies form a group, the number of the A-type clamping hand assemblies in each group is the same as the number of the B-type clamping hand assemblies in each group, and with the group as a unit, the A-type clamping hand assemblies and the B-type clamping hand assemblies are arranged at intervals. According to the bag clamping conveying mechanism and the bag clamping conveying method, packaging bags can be continuously and quickly conveyed, so that a packaging machine can achieve a faster working speed, and the working efficiency is greatly improved; and the distance between clamping hands of the hand clamping assemblies is adjusted through the control of a guide rail mechanism, actions such as bag opening and bag closing are completed, and the overall structure is compact.

Owner:LANGRUI PACKAGING TECH CANGZHOU CO LTD

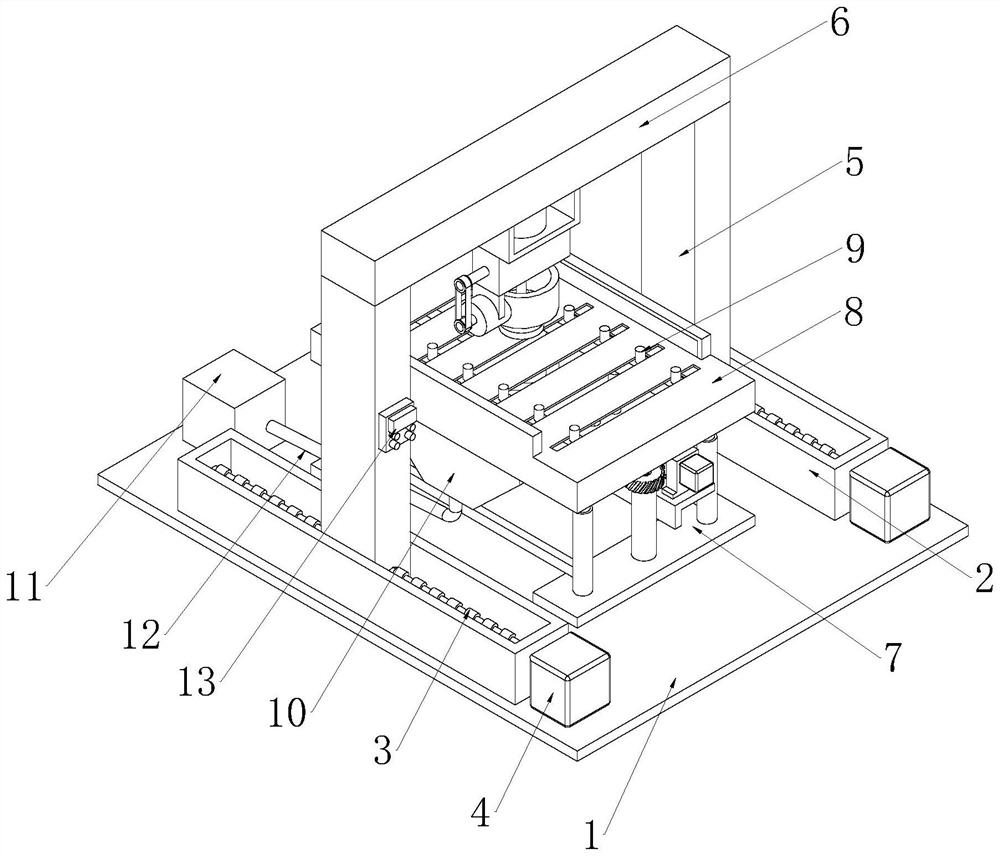

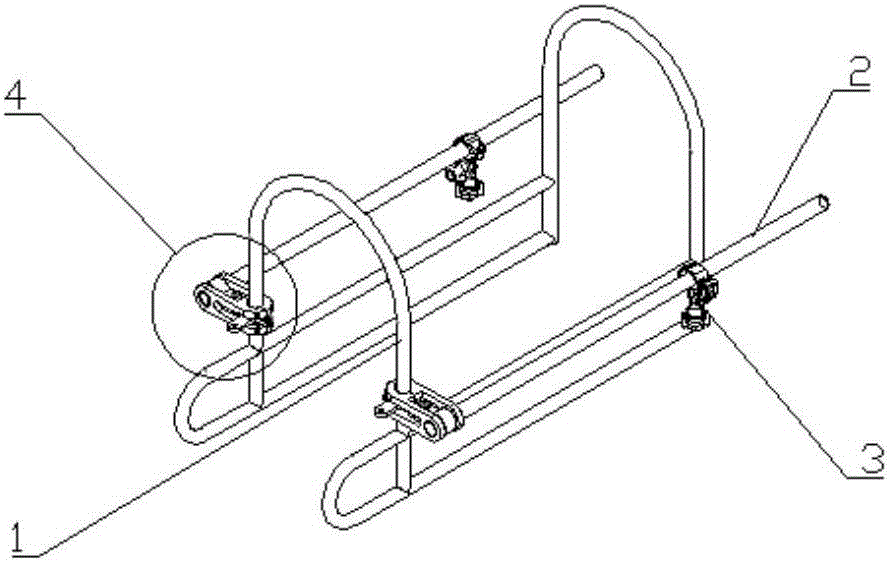

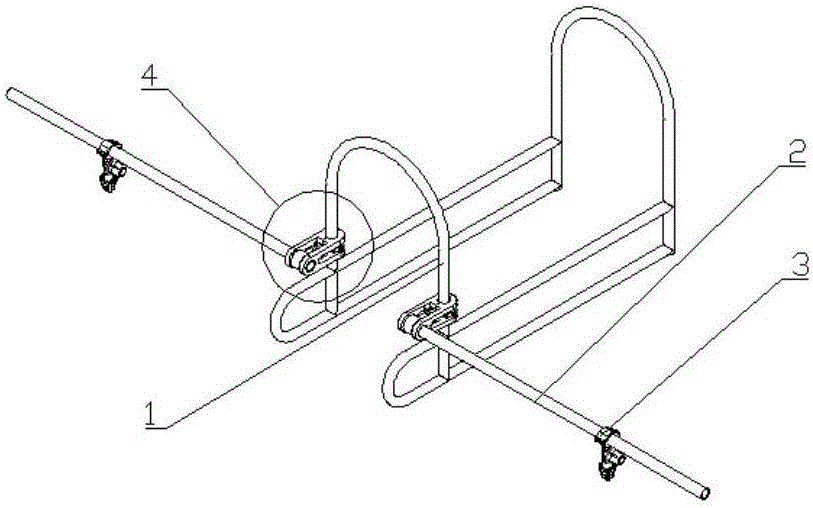

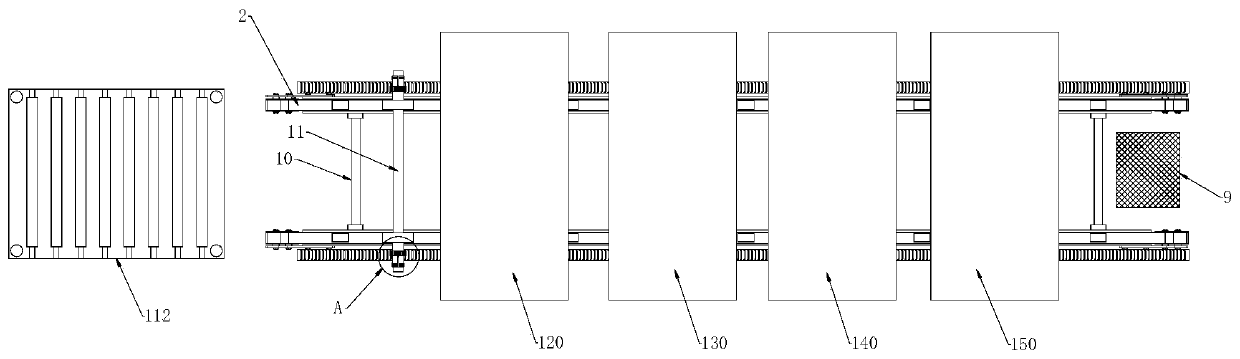

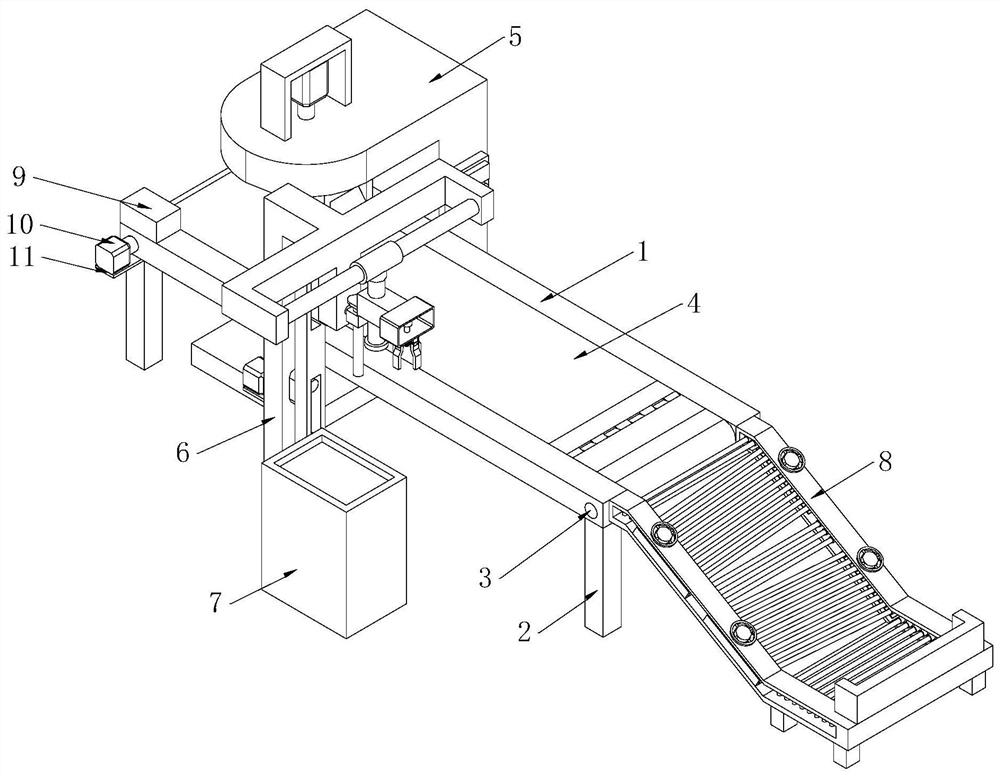

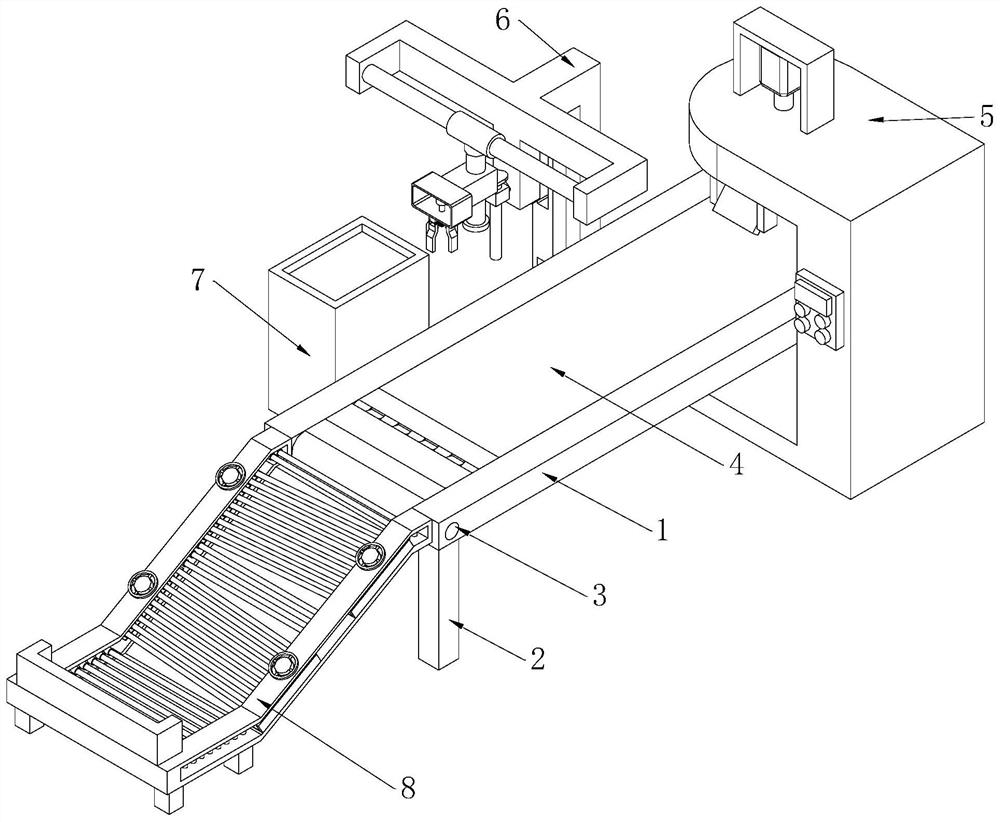

Greenhouse support pipe production line

InactiveCN110815882AAvoid duplicationAvoid disassemblyConveyorsTubular articlesPlastic packagingGreenhouse

The invention discloses a greenhouse support pipe production line, belongs to the technical field of greenhouse support pipe production, and solves the problems that raw material pipes need to be transferred to different devices in the processing process, the transfer is complex, the clamping is repeated, the process is complex and the working efficiency is low. Continuous operation production isrealized, and the production efficiency is improved. The greenhouse support pipe production line comprises a feeding frame, a polishing machine, a medium-frequency heating machine, a plastic packagingmachine and a cooling system which are sequentially arranged side by side, wherein a conveying device is arranged below the polishing machine, the medium-frequency heating machine, the plastic packaging machine and the cooling system; fixed seats of which every two fall into one group are arranged at the upper end of the conveying device side by side, the upper ends of one group of fixed seats are correspondingly provided with installing seats of which every two fall into one group, the installing seats are provided with through holes allowing the pipes to penetrate through, the pipes are rotationally connected with the installing seats, and fastening units used for driving the pipes to rotate are arranged on the outer sides of the installing seats.

Owner:于树来

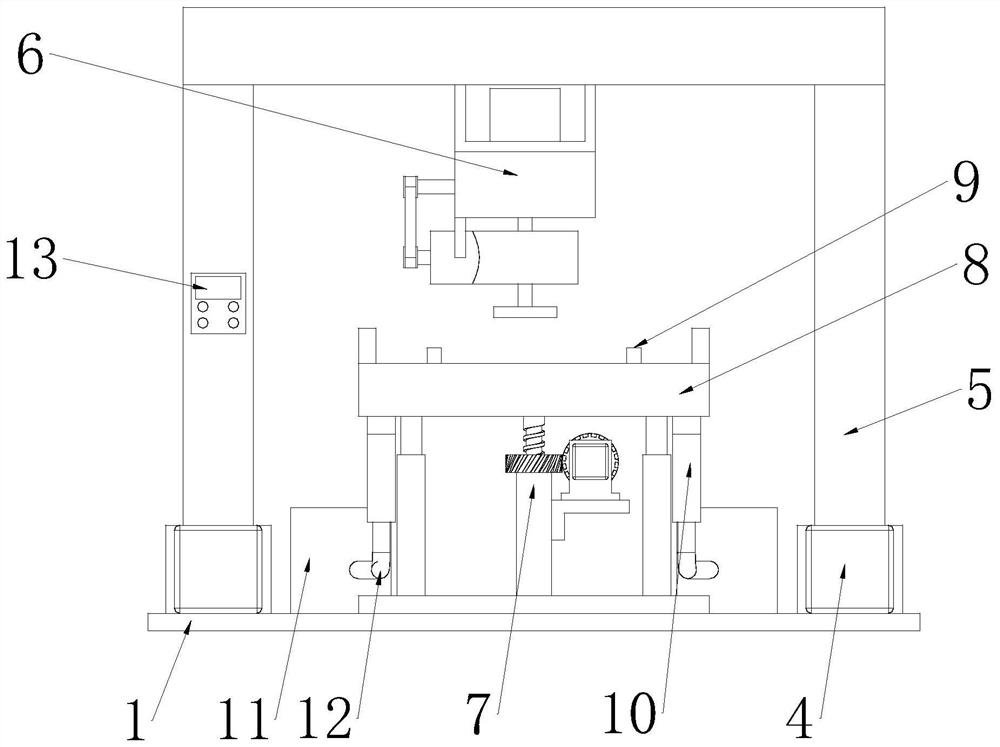

Dust removal air pipe outer wall polishing machine

PendingCN107263297AAchieve circumferential polishingAchieve clampingPolishing machinesGrinding/polishing safety devicesCircular discBall screw

The invention provides a dust removal air pipe outer wall polishing machine, and belongs to the technical field of machines. The dust removal air pipe outer wall polishing machine comprises a frame body and a polishing disc, the frame body comprises a lower platform and an upper platform, a first lifting air cylinder, a second lifting air cylinder, a third lifting air cylinder and a fourth lifting air cylinder are vertically arranged on the upper surface of the lower platform, a first ball screw and a second ball screw are rotatably arranged on the upper platform, a square through hole is formed in the upper platform, a first U-shaped frame, a second U-shaped frame and a mounting plate are arranged in the square through hole, a first servo motor is fixed to the mounting plate, the polishing disc is fixed to an output shaft of the first servo motor, and a clamping mechanism capable of clamping a dust removal air pipe is arranged on the lower platform. According to the polishing machine, a dust removal air pipe can be more stably fixed, and the beneficial effect that the outer wall of the dust removal air pipe can be polished is effectively achieved.

Owner:ZHEJIANG JIEYU ENVIRONMENTAL PROTECTION EQUIPCO

Variable-distance straw cutting-off device

The invention discloses a variable-distance straw cutting-off device, relates to the field of environmental-friendly mechanical equipment, and is used for solving the problem that lengths of straws cut off by an existing straw cutting-off device are uncontrollable. The variable-distance straw cutting-off device comprises a feed inlet, a straw chopper and a discharge port, and further comprises a conveying belt, a top cover, a crank connecting rod mechanism, a motor, a baffle and a cutting-off table; the top cover comprises a first top cover and a second top cover; the feed inlet is formed above one end part of the conveying belt; the first top cover is arranged at the upper part of the conveying belt; a first sliding rail is arranged at the top of the first top cover; a plurality of combing pillars pointing to the conveying belt are arranged on the first sliding rail; an end part, which is far away from the feed inlet, of the first top cover is provided with the straw chopper and the cutting-off table arranged up and down; the first top cover and the second top cover are respectively arranged at both sides of the straw chopper; the baffle is arranged at an end part of the second top cover; a second sliding rail and a pulley are arranged on the side wall of the second top cover; the pulley is fixedly connected with the baffle. The variable-distance straw cutting-off device has the advantages that the structure is simple; the variable-distance straw cutting-off device is applicable to various straw cutting-off; the cutting-off length is accurate and controllable.

Owner:四川点草成金科技有限责任公司

Distance adjusting device

InactiveCN105775711ARealize spacing adjustmentMeet the needs of adjusting spacingConveyorsFinal product manufactureFixed SlideEngineering

Owner:WUXI AOTEWEI INTELLIGENT EQUIP CO LTD

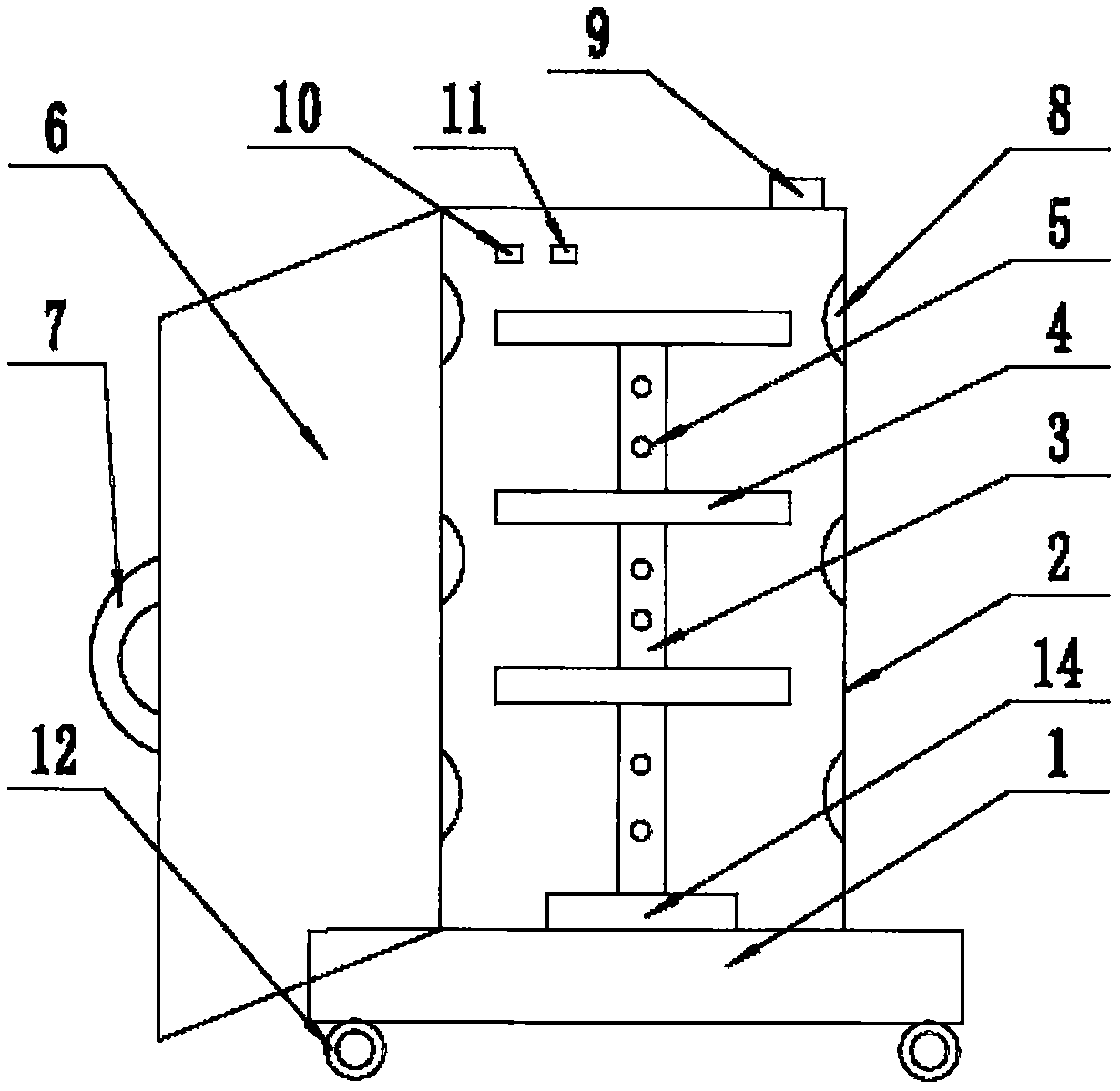

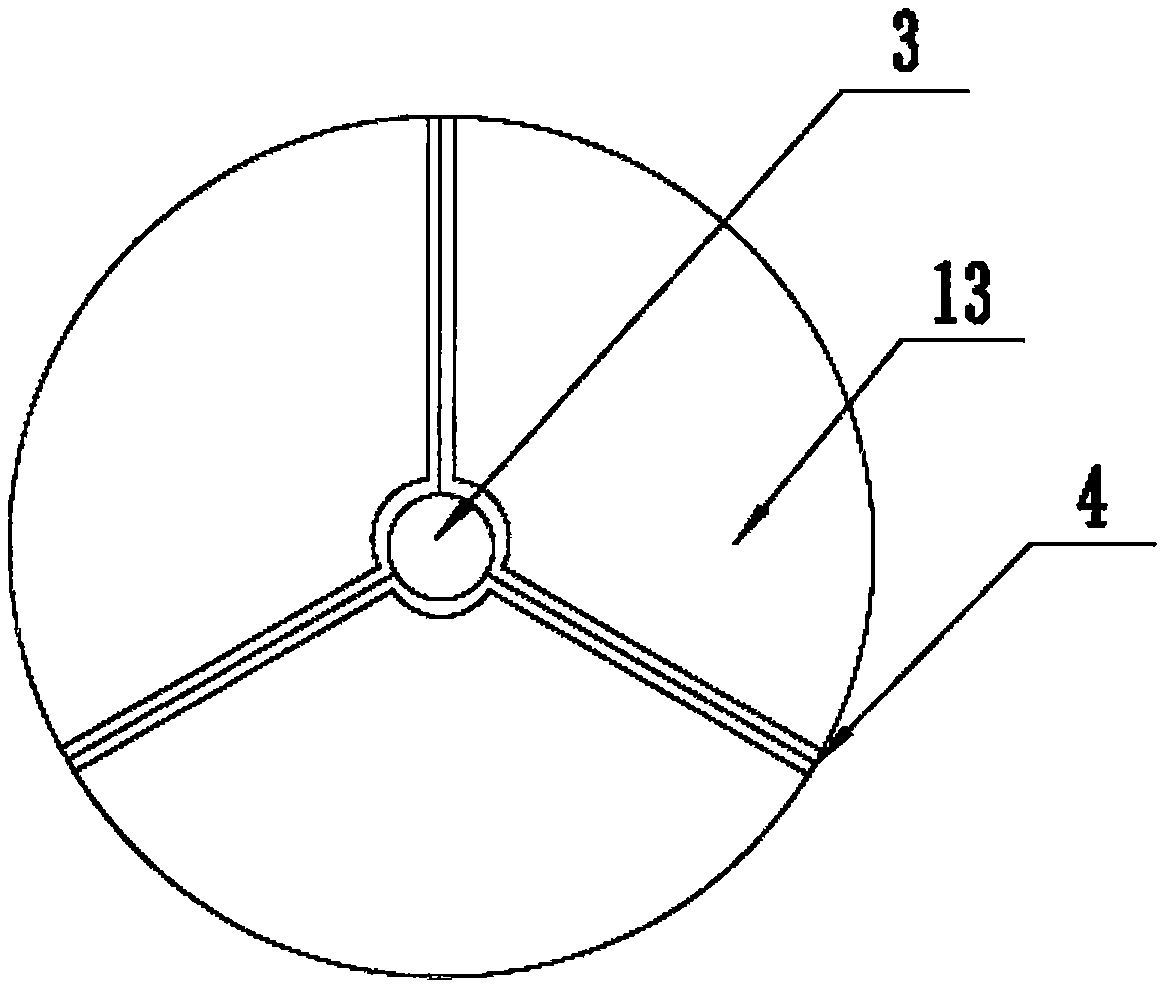

Illumination culture device

InactiveCN109329065AEasy to adjustRealize spacing adjustmentPlant tissue cultureHorticulture methodsPlant tissueCulture vessel

The invention discloses an illumination culture device which comprises a base, a culture box body, a culture platform and an illumination device; the culture platform comprises a turntable, a rotatingshaft and a plurality of laminates, wherein the turntable drives the laminates to rotate through the rotating shaft; the laminates are used for holding culture vessels holding to-be-cultured tissues;the laminates are fixed on the rotating shaft through shaft sleeves. The illumination culture device disclosed by the invention has the benefits that as the turntable drives the laminates to rotate through the rotating shaft, plant tissues in the culture vessels on the laminates can be uniformly illuminated; by fixing the shaft sleeves on first bolt holes of different heights on the rotating shaft, the height regulation of each of the laminates is realized, and further the spacing between the every two laminates can be regulated. Therefore, the illumination culture device is adapted to the culture of a variety of different plant tissues.

Owner:HUBEI UNIV FOR NATITIES

Industrial robot for automatic quality inspection operation and control method

ActiveCN113546863AGuaranteed stabilityImprove work efficiencyMeasurement devicesSortingElectric machineryIndustrial robotics

The invention discloses an industrial robot for automatic quality inspection operation and a control method. The industrial robot for automatic quality inspection operation comprises two supporting rods, supporting bases are arranged at the two ends of each supporting rod, roll shafts are arranged at the two ends between the two supporting rods, the outer sides of the two roll shafts are sleeved with belts, a detection mechanism is arranged on one side of one end of one supporting rod, a grabbing mechanism is arranged on one side of the middle of the other supporting rod, a placing table is arranged on one side of the grabbing mechanism, and an object falling mechanism is arranged at the ends, away from the detection mechanism, of the two supporting rods; and an infrared sensor is arranged at the top of one end of each supporting rod, a first motor is arranged on the side, close to one side of the detection mechanism, of each roll shaft, and a first bottom plate fixedly connected with the corresponding supporting base is arranged at the bottom end of each first motor. The industrial robot has the beneficial effects that appearance detection of injection molding products is achieved, and classified collection of qualified products and unqualified products after detection is achieved; and the detection efficiency of the injection molding products is further improved.

Owner:深圳市名都实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com