Variable-distance straw cutting-off device

A technology of cutting device and straw, which is applied in cutting equipment, agricultural machinery and implements, etc. It can solve the problems of low cutting efficiency, poor cutting effect, and different product specifications, so as to save labor costs, reduce dust emission, and protect The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

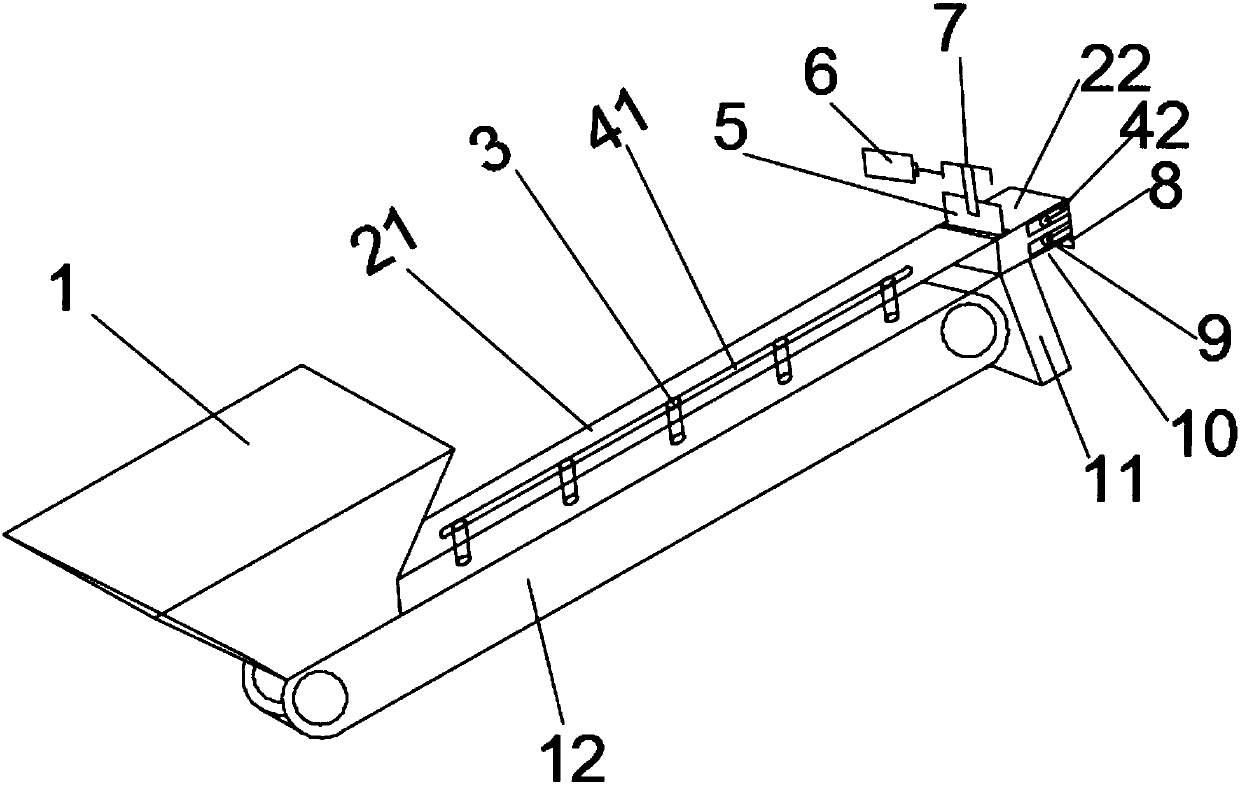

[0021] Such as figure 1 As shown, the present embodiment provides a variable-pitch straw cutting device, including a feed port 1, a guillotine 5, and a discharge port 10. The straw cutting device also includes a conveyor belt 12, a top cover, a crank linkage mechanism 7, and a motor 6. , a baffle plate 8 and a cutting table 11, the top cover includes a first top cover 21 and a second top cover 22, the feed inlet 1 is located above one end of the conveyor belt 12, and the top of the conveyor belt 12 is provided with a first top cover Cover 21, the top of the first top cover 21 is provided with a first slide rail 41, the first slide rail 41 is provided with a plurality of carding columns 3 pointing to the conveyor belt 12, and the first top cover 21 is far away from the feed inlet 1 is provided with a guillotine 5 and a cutting table 11 arranged up and down, the first top cover 21 and the second top cover 22 are respectively arranged on both sides of the guillotine 5, and the en...

Embodiment 2

[0023] Such as figure 1 As shown, the present embodiment provides a variable-pitch straw cutting device, including a feed port 1, a guillotine 5, and a discharge port 10. The straw cutting device also includes a conveyor belt 12, a top cover, a crank linkage mechanism 7, and a motor 6. , a baffle plate 8 and a cutting table 11, the top cover includes a first top cover 21 and a second top cover 22, the feed inlet 1 is located above one end of the conveyor belt 12, and the top of the conveyor belt 12 is provided with a first top cover Cover 21, the top of the first top cover 21 is provided with a first slide rail 41, the first slide rail 41 is provided with a plurality of carding columns 3 pointing to the conveyor belt 12, and the first top cover 21 is far away from the feed inlet 1 is provided with a guillotine 5 and a cutting table 11 arranged up and down, the first top cover 21 and the second top cover 22 are respectively arranged on both sides of the guillotine 5, and the en...

Embodiment 3

[0027] Such as figure 1 As shown, the present embodiment provides a variable-pitch straw cutting device, including a feed port 1, a guillotine 5, and a discharge port 10. The straw cutting device also includes a conveyor belt 12, a top cover, a crank linkage mechanism 7, and a motor 6. , a baffle plate 8 and a cutting table 11, the top cover includes a first top cover 21 and a second top cover 22, the feed inlet 1 is located above one end of the conveyor belt 12, and the top of the conveyor belt 12 is provided with a first top cover Cover 21, the top of the first top cover 21 is provided with a first slide rail 41, the first slide rail 41 is provided with a plurality of carding columns 3 pointing to the conveyor belt 12, and the first top cover 21 is far away from the feed inlet 1 is provided with a guillotine 5 and a cutting table 11 arranged up and down, the first top cover 21 and the second top cover 22 are respectively arranged on both sides of the guillotine 5, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com