Follower fixture for shaft products, and fixture unit thereof

A fixture and product technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of circumferential rotation error, difficulty in realizing circumferential clamping and positioning, and different positioning references, so as to prevent circumferential rotation, Effects of preventing damage and improving efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

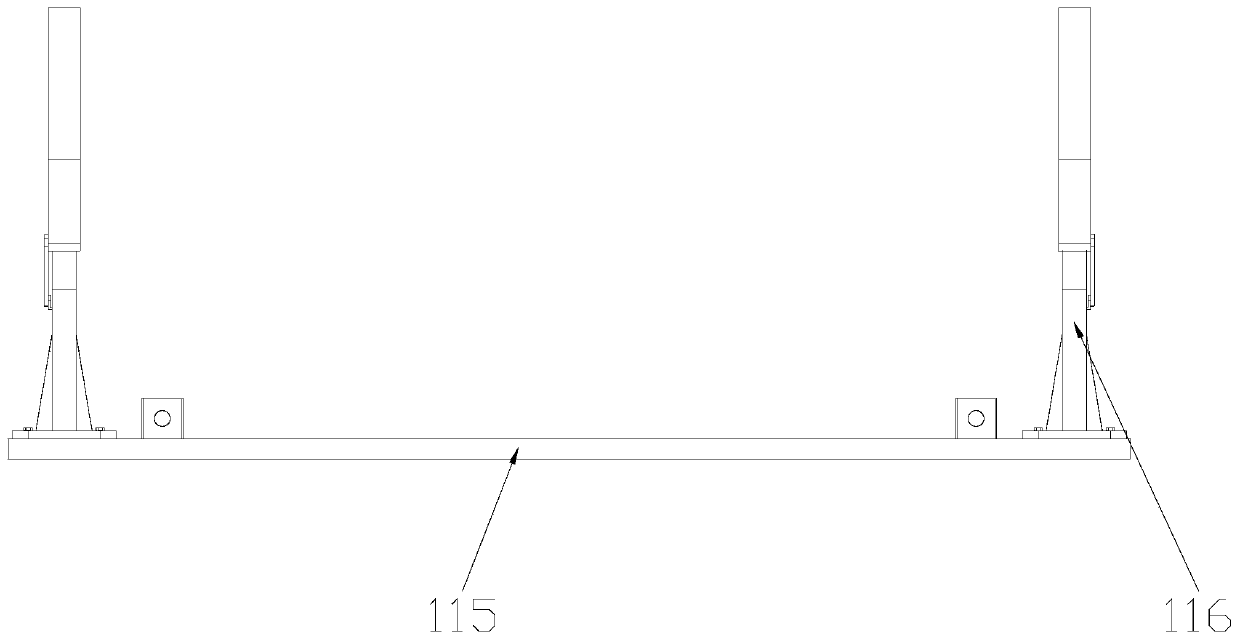

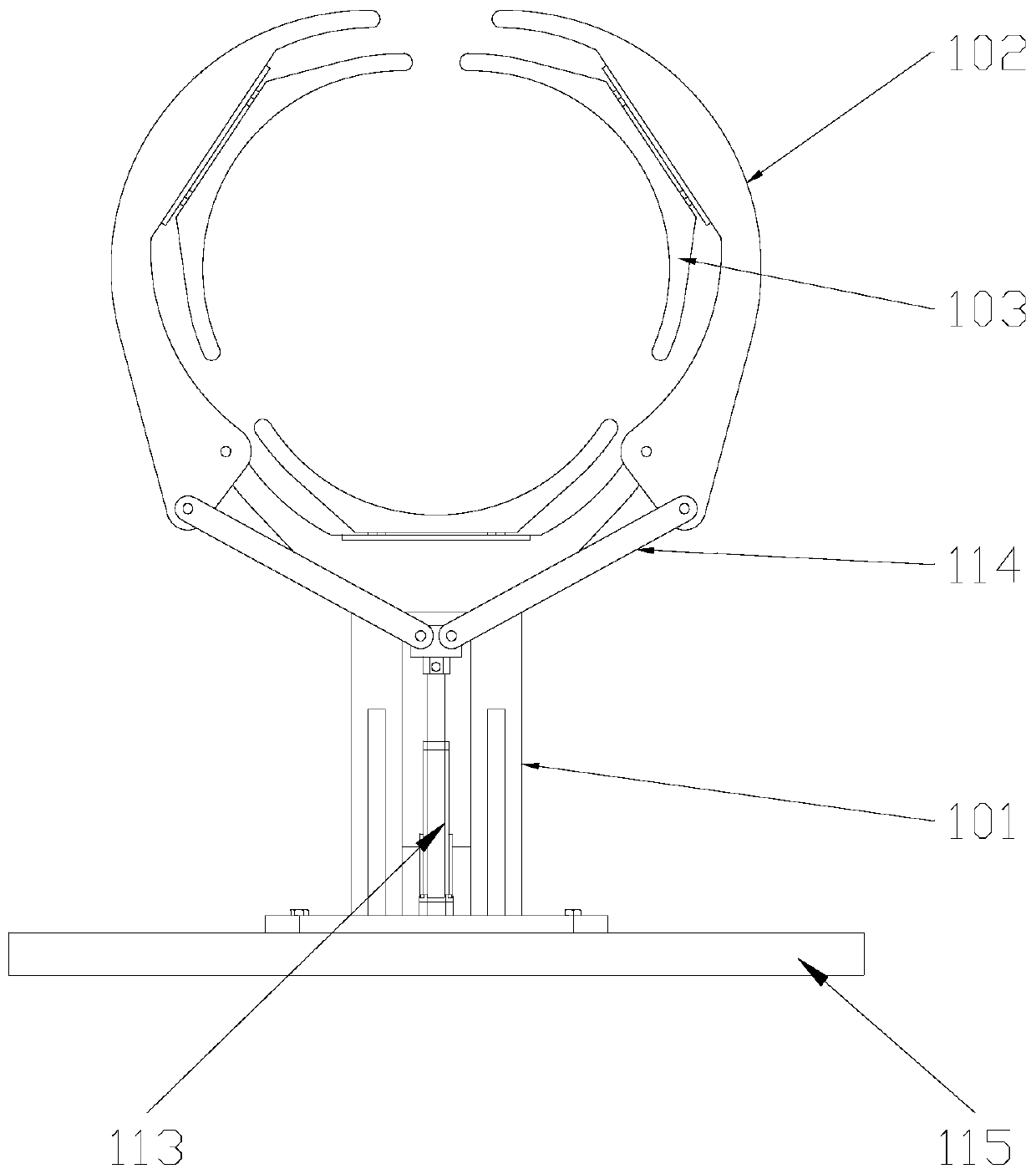

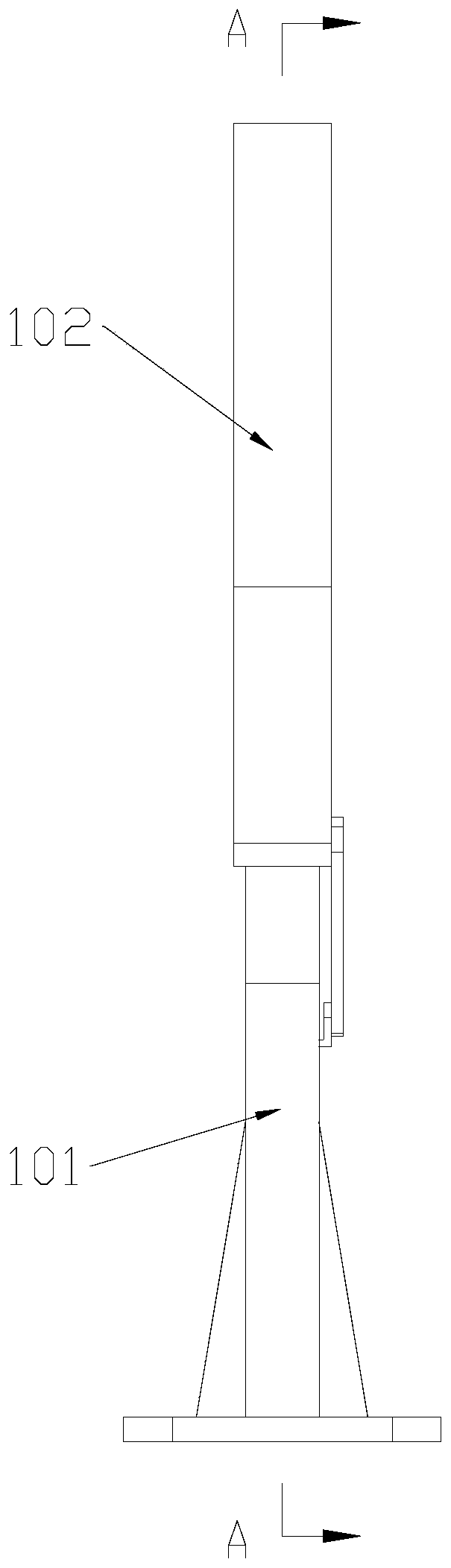

[0046] Such as figure 1 As shown, it is a schematic structural diagram of Embodiment 1 of the traveling clamp for shaft products of the present invention. The traveling clamp for shaft products of this embodiment includes a traveling base 115; the traveling base 115 is provided with at least two clamp units 116 whose axes are located on the same straight line and are used to hold the shaft products.

[0047] The clamp unit of this embodiment includes a holding device base 101. Both ends of the holding device base 101 are respectively provided with holding arms 102 that are rotatably matched with the holding device base 101, and the holding device base 101 is provided with a holding arm 102 for driving the holding arms 102 to rotate and hold tightly. A flexible drive mechanism for shaft products or loose shaft products; the holding device base 101 and the holding arm 102 are respectively provided with arc-shaped grooves or V-shaped grooves that match the shaft products. Specifical...

Embodiment 2

[0055] This embodiment also proposes a traveling clamp for shaft products, which includes a traveling base 115. At least three clamp units 116 for holding shaft products are spaced apart on the traveling base 115.

[0056] Among all the clamp units 116, the two clamp units 116 located at both ends are end clamp units, and the clamp unit 116 located between the two end clamp units is an intermediate clamp unit. The axes of the two end clamp units are always on the same straight line; among all the middle clamp units, the axis of at least one middle clamp unit and the axes of the two end clamp units are not collinear.

[0057] Specifically, the clamp unit 116 can be installed on the accompanying base 115 in various ways, such as:

[0058] All the clamp units 116 are fixedly installed on the traveling base 115; or,

[0059] The accompany base 115 is provided with a longitudinal slide rail parallel to a straight line, and among all the gripper units 116 whose axis is collinear with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com