Double-cylinder loose blade clamping and taking type self-locking cutting tooth core drill cylinder

A loose leaf card and core drilling technology, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., can solve the problems of unfavorable construction efficiency, increased drilling resistance, and failure to extract rock mass, so as to improve drilling work High efficiency, low drilling resistance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

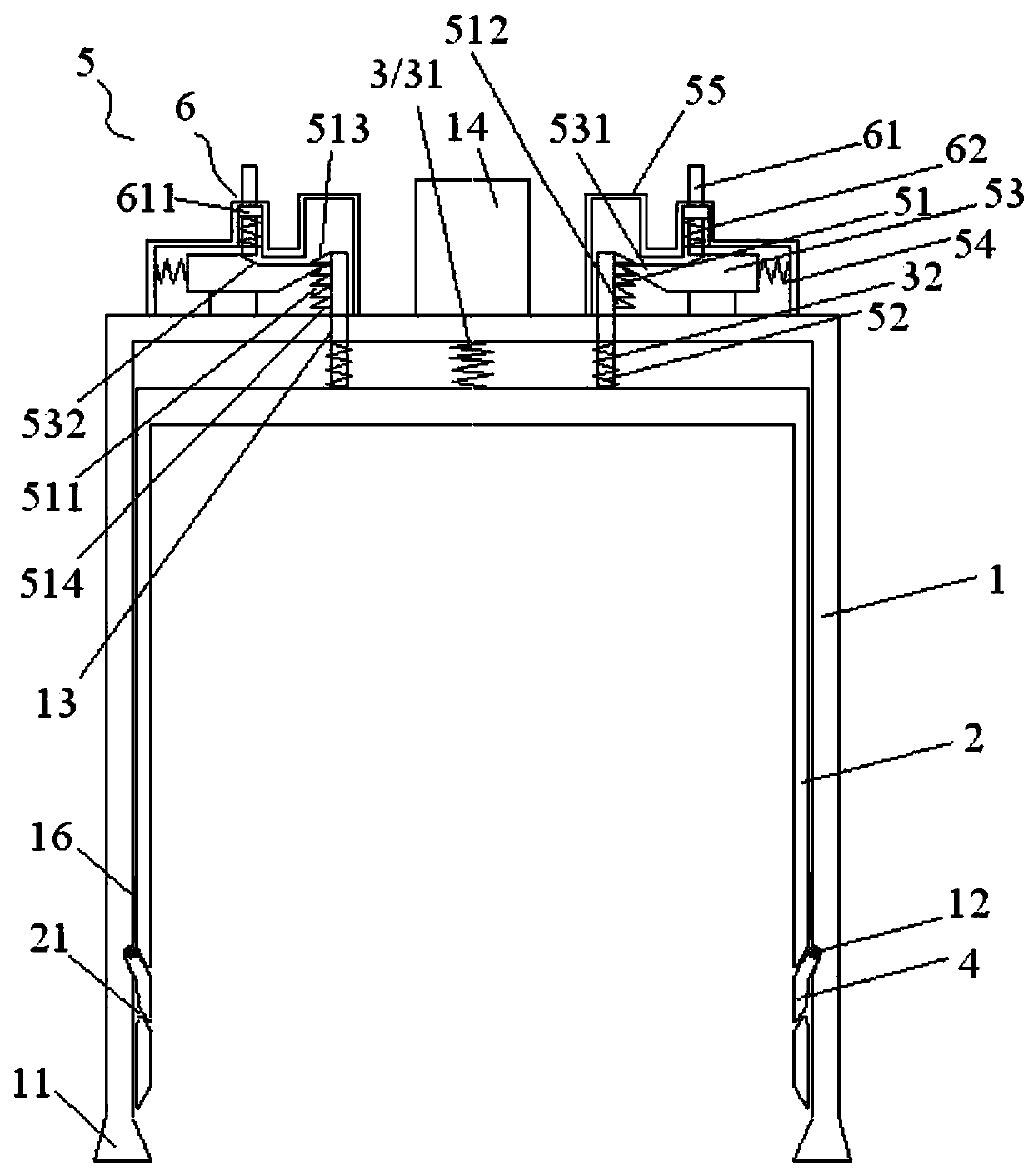

[0034] see Figure 1 ~ Figure 4 A double-barrel leaf card is taken from a lock-type pick core drill barrel, including an outer cylinder 1, an inner cylinder 2, a first return spring 3, several rotating leaflets 4, several sets of self-locking mechanisms 5 and each One set of unlocking device 6 corresponding to the self-locking mechanism:

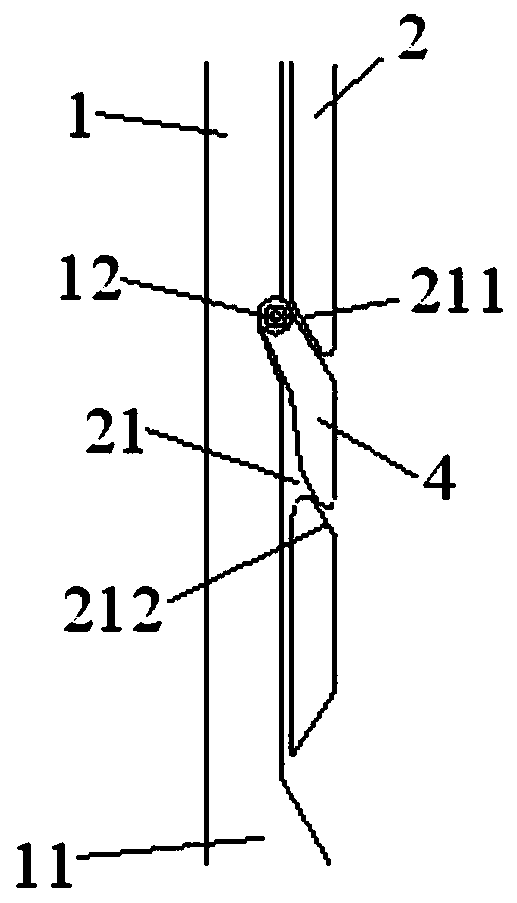

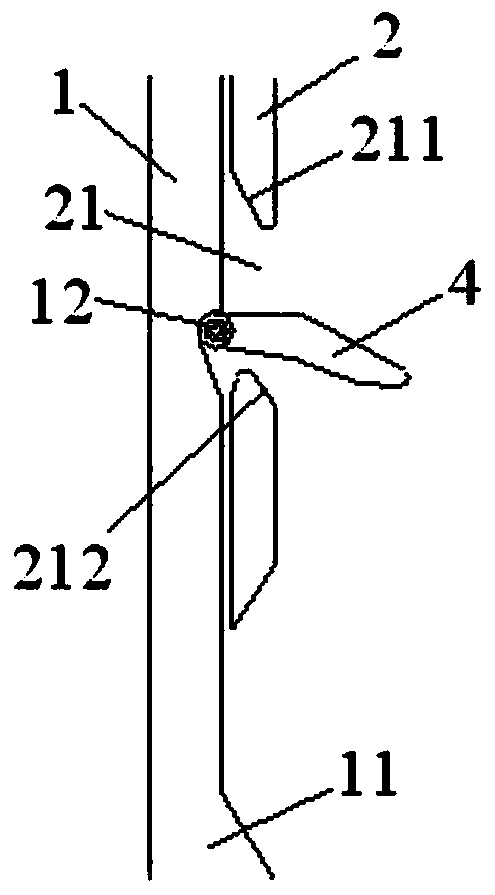

[0035] The bottom of the outer cylinder is provided with a pick 11 for cutting the rock mass, the inner cylinder is arranged on the radial inner side of the outer cylinder, the inner space of the inner cylinder is used to accommodate the rock mass, and the inner cylinder can move up and down along the axial direction of the outer cylinder;

[0036] In this embodiment, one end of the rotating flap is rotatably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com