Patents

Literature

540 results about "Core drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A core drill is a drill specifically designed to remove a cylinder of material, much like a hole saw. The material left inside the drill bit is referred to as the core. Core drills used in metal are called annular cutters. Core drills used for concrete are generally called Diamond Core Drills and are water cooled. For drilling masonry, carbide core drills can be used.

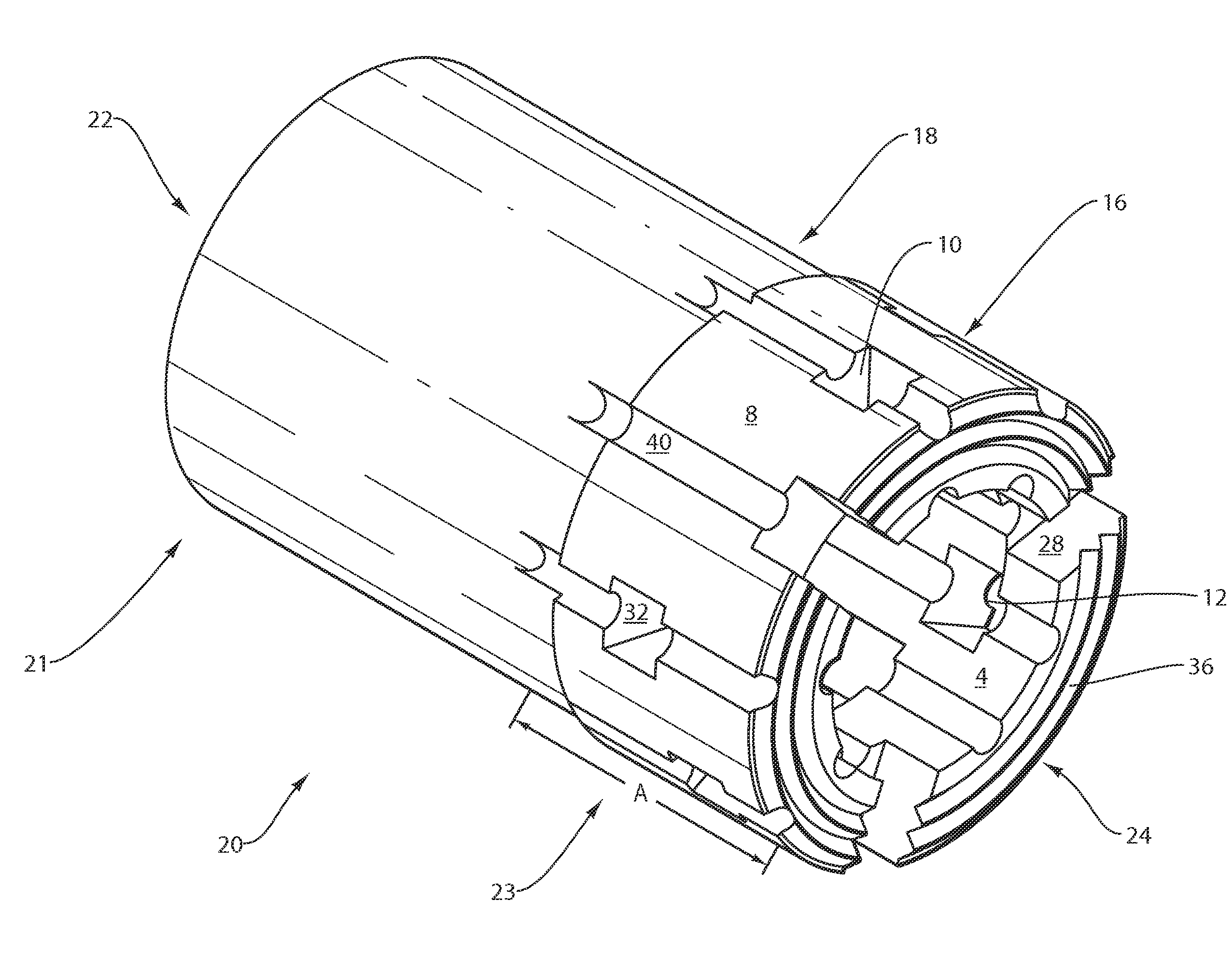

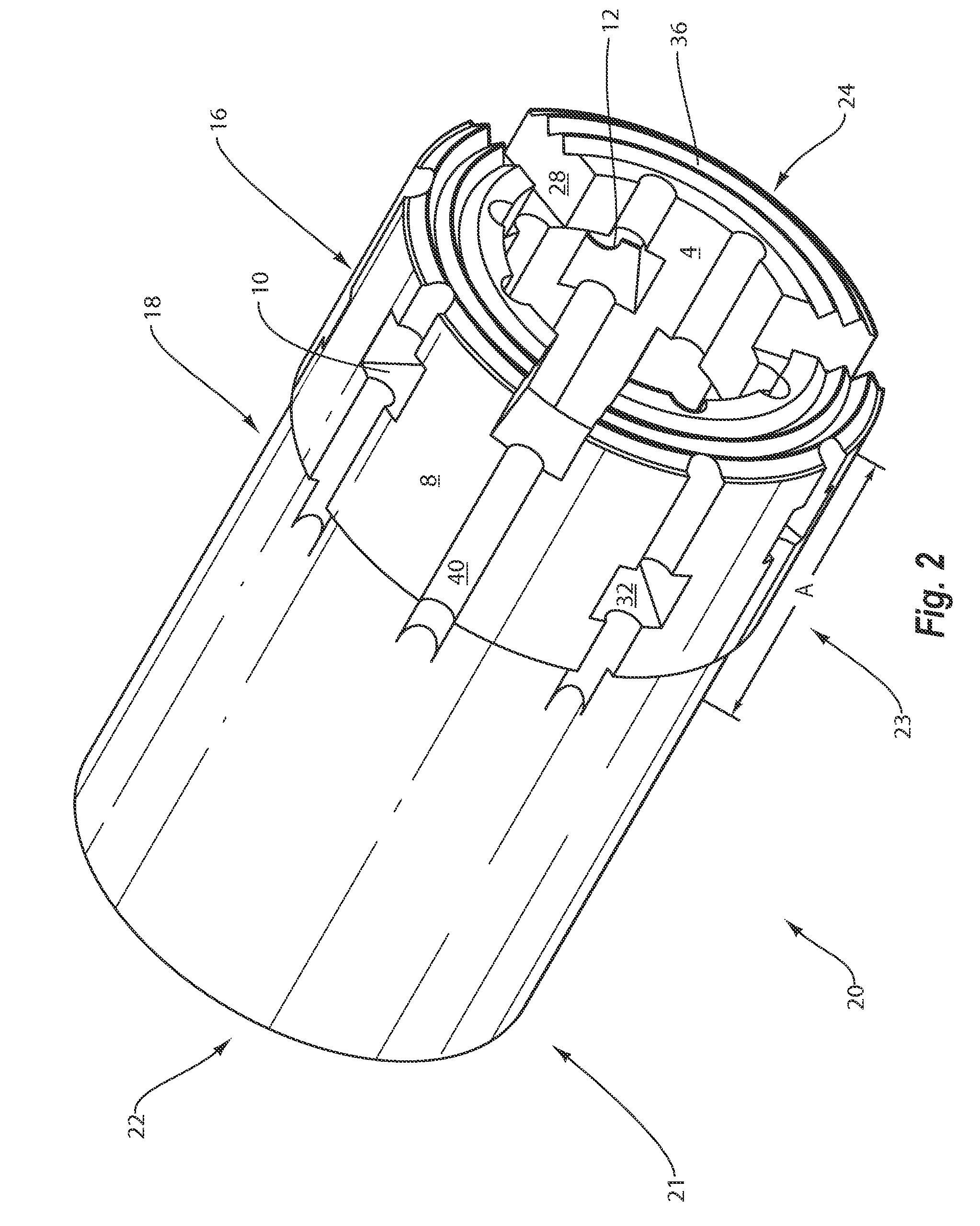

Drill bits with enclosed fluid slots

InactiveUS20100012385A1Reduced structureLess trippingDrill bitsMetal-working drilling toolsMechanical engineeringCrowning tooth

Core drill bits with long crown heights are described herein. The core drill bits have a series of slots or openings that are not located at the tip of the crown and are therefore enclosed in the body of the crown. The slots may be staggered and / or stepped throughout the crown. As the cutting portion of the drill bit erodes through normal use, the fluid / debris notches at the tip of the bit are eliminated. As the erosion progresses, the slots become exposed and then they function as fluid / debris ways. This configuration allows the crown height to be extended and lengthened without substantially reducing the structural integrity of the drill bit.

Owner:BOART LONGYEAR

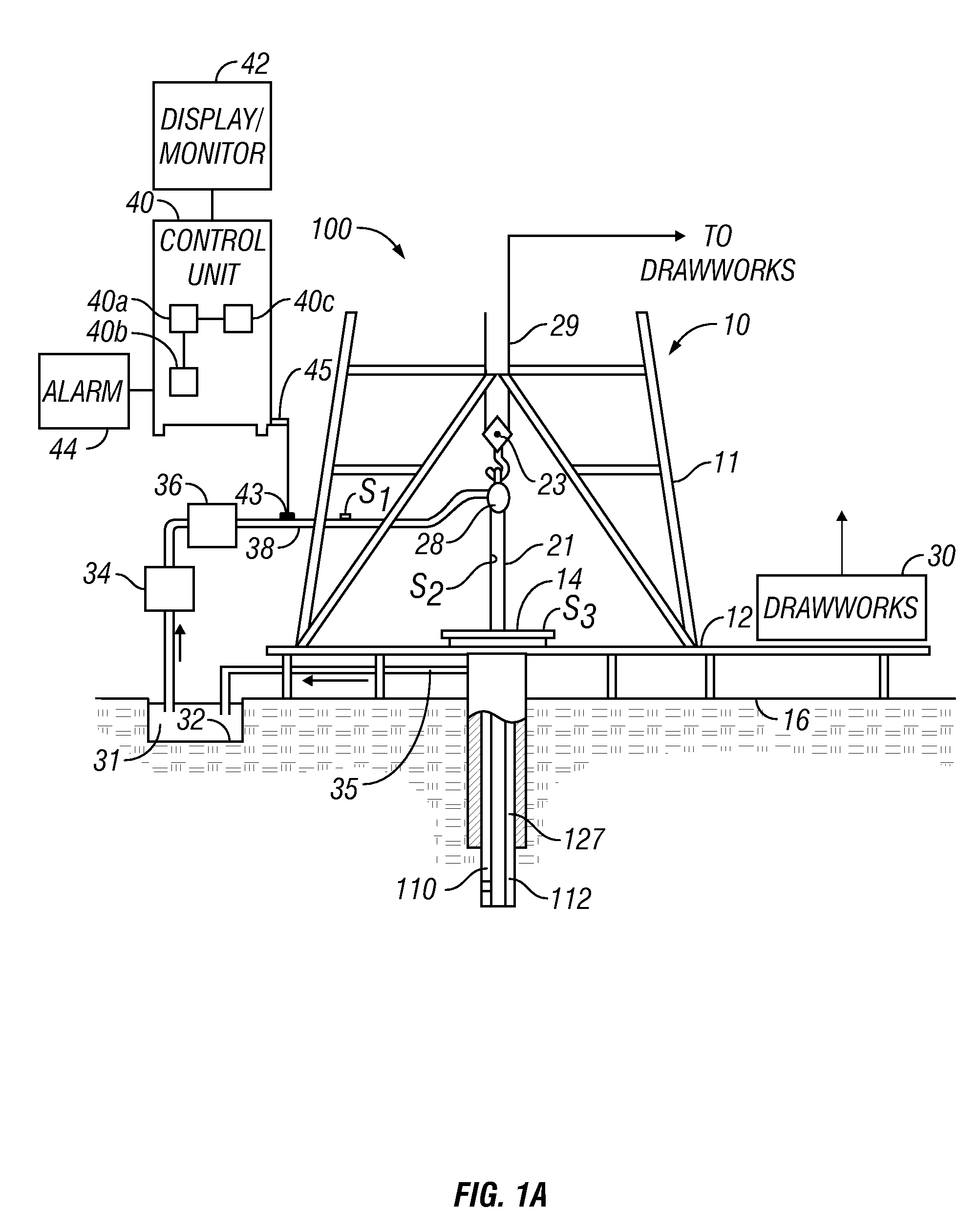

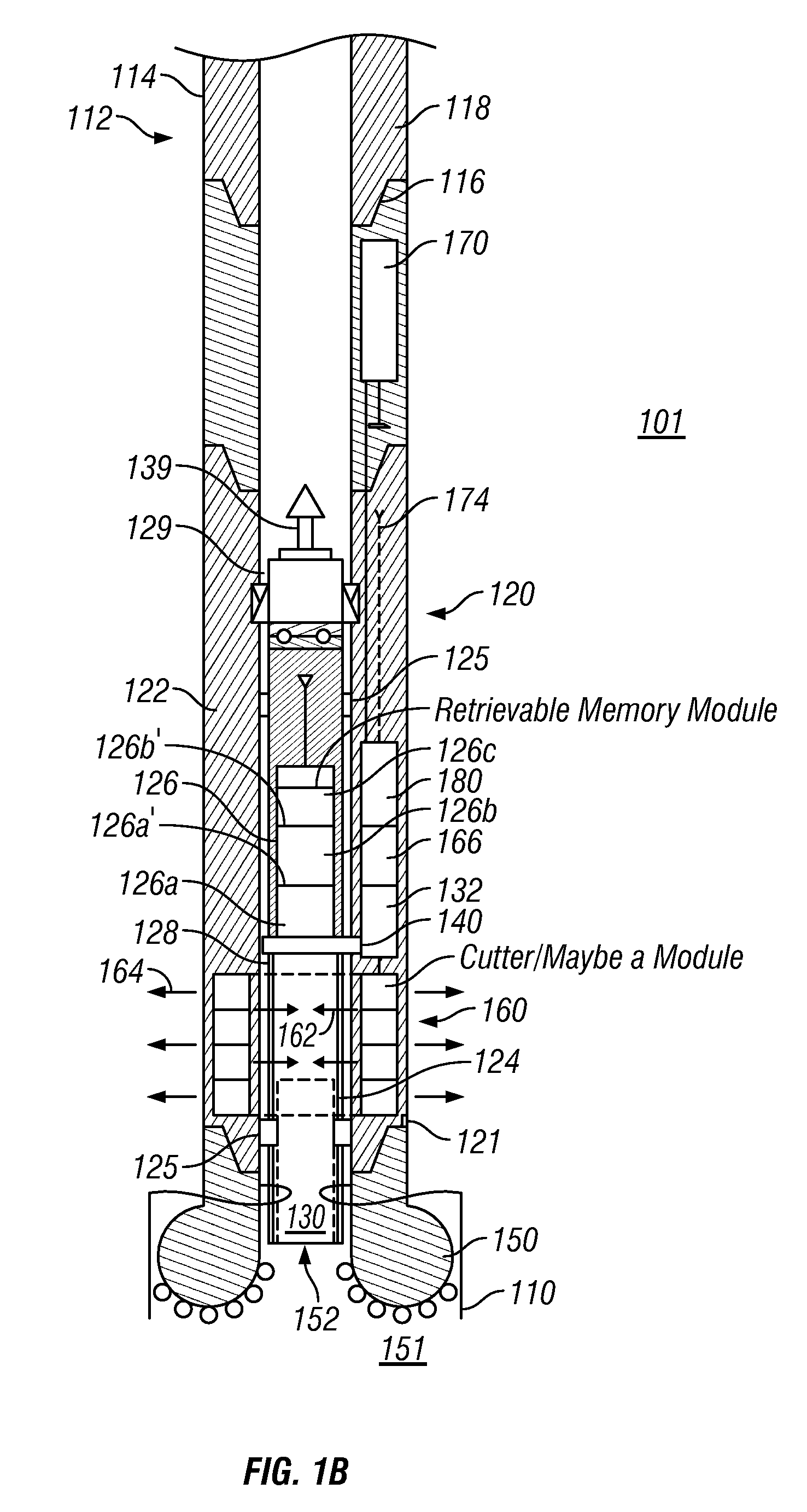

Apparatus and Methods for Continuous Tomography of Cores

Owner:BAKER HUGHES HLDG LLC

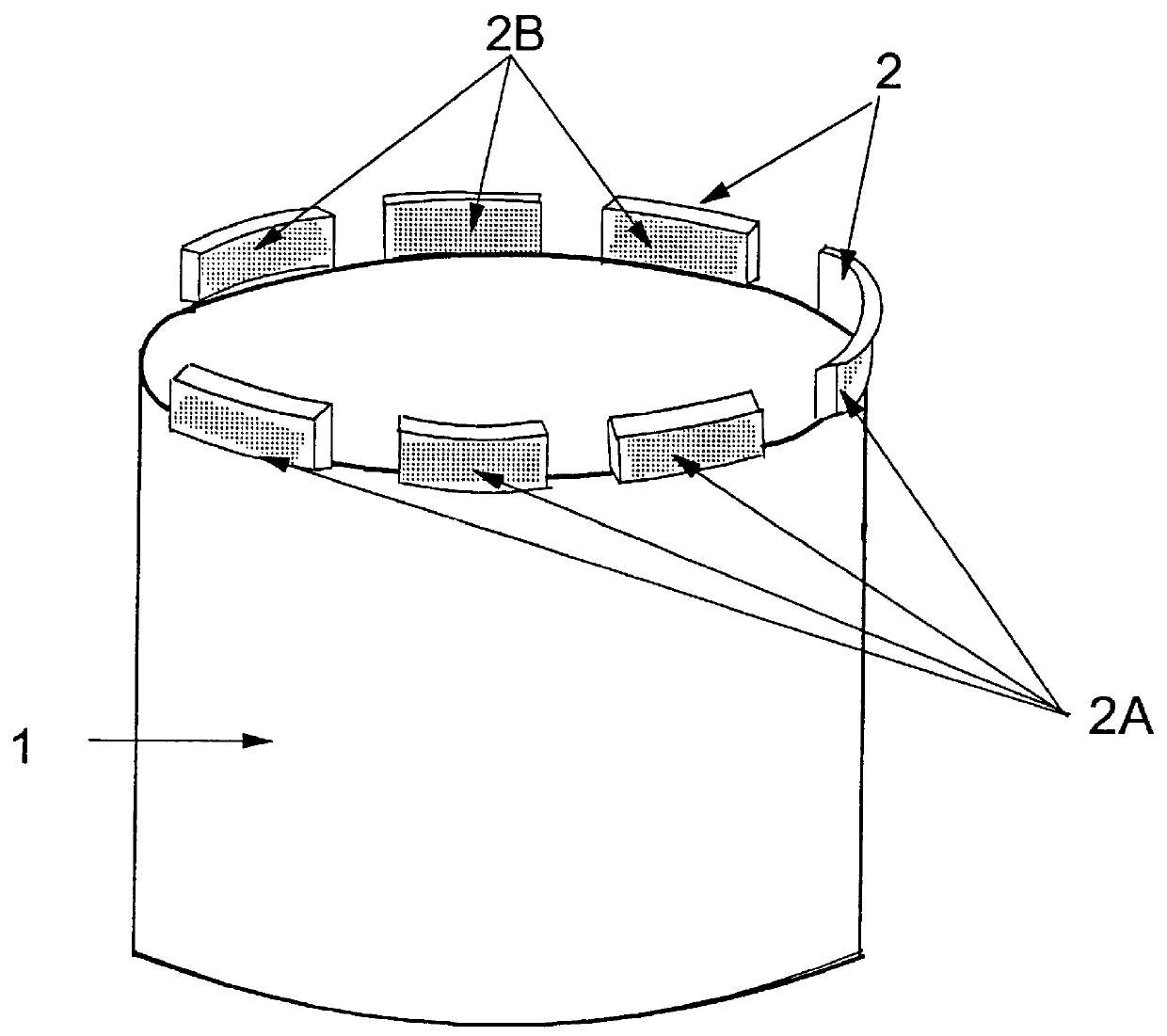

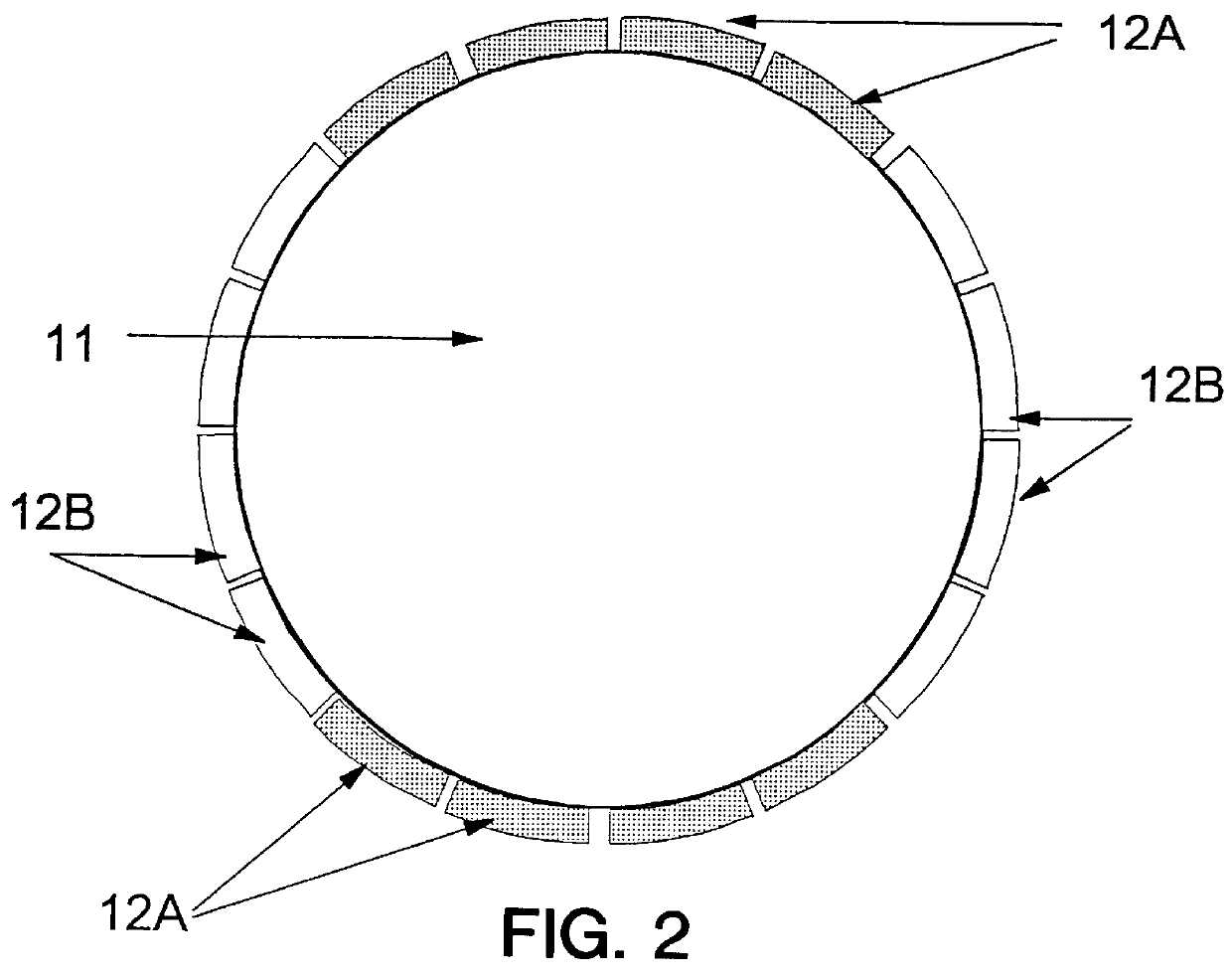

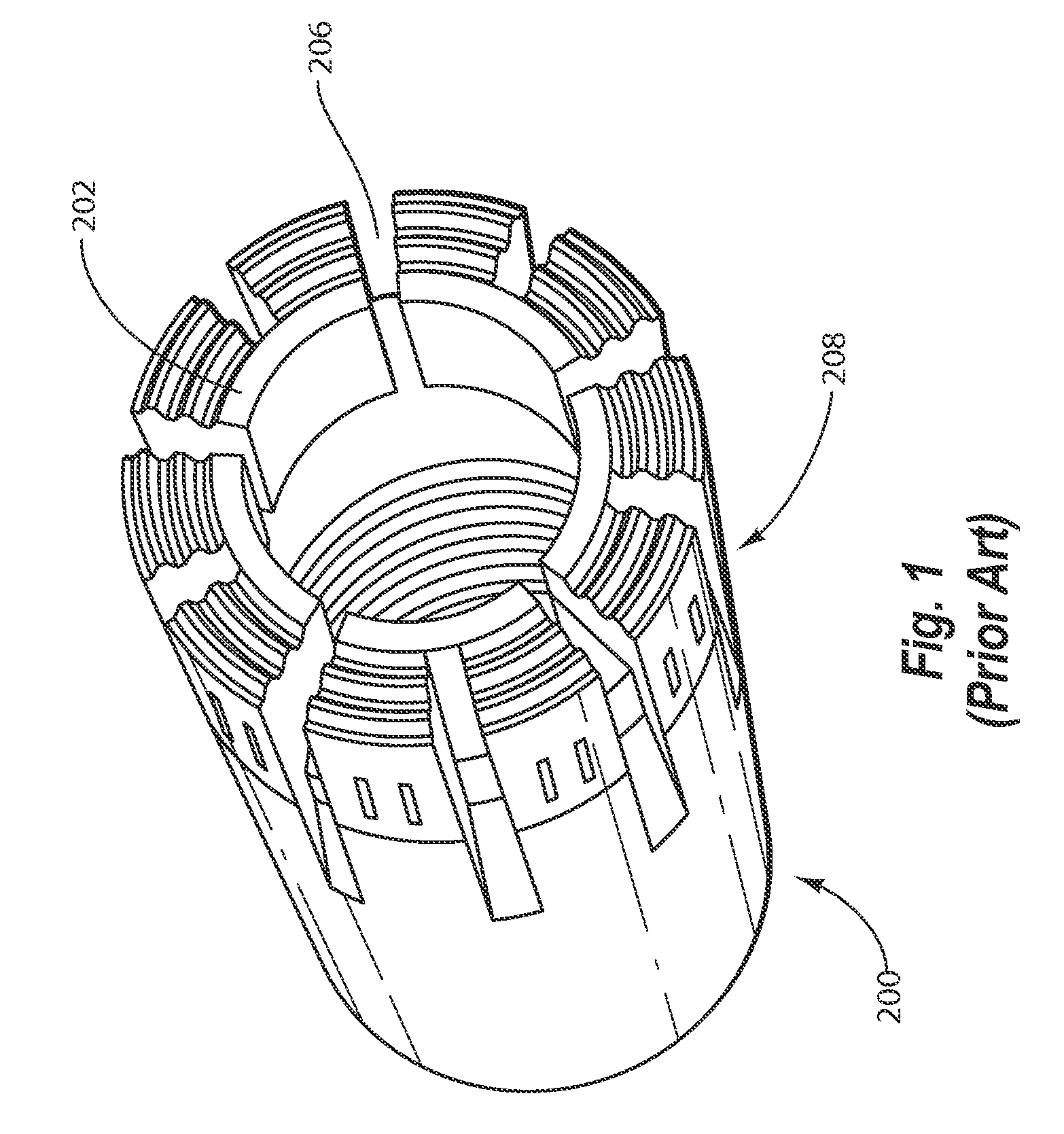

Segmented cutting tools

Segmented cutting tools such core drill bits and diamond saw blades can be made more efficient by hardening a portion of the sides of each of the segments.

Owner:MORTON CO

Core orientation

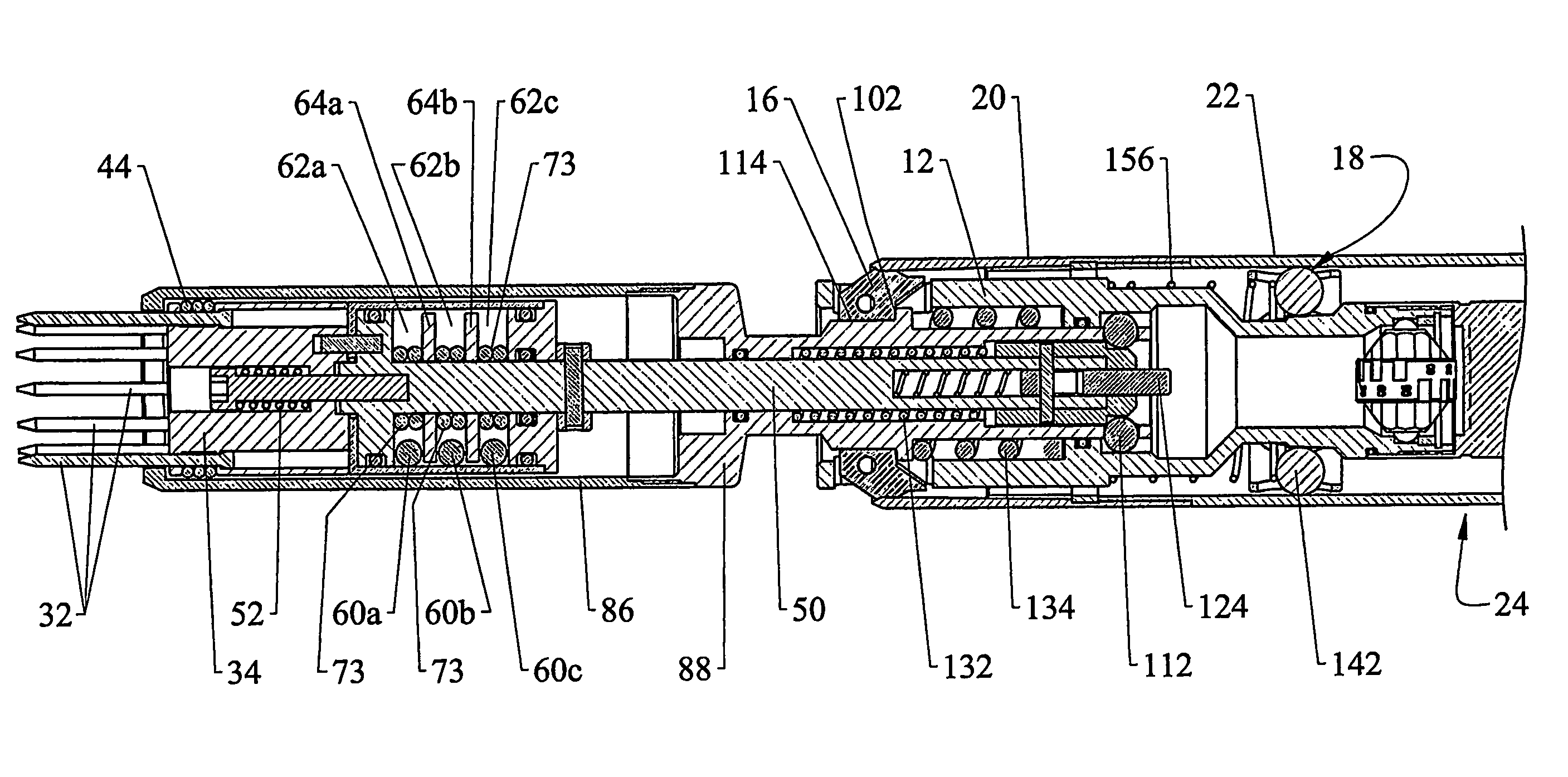

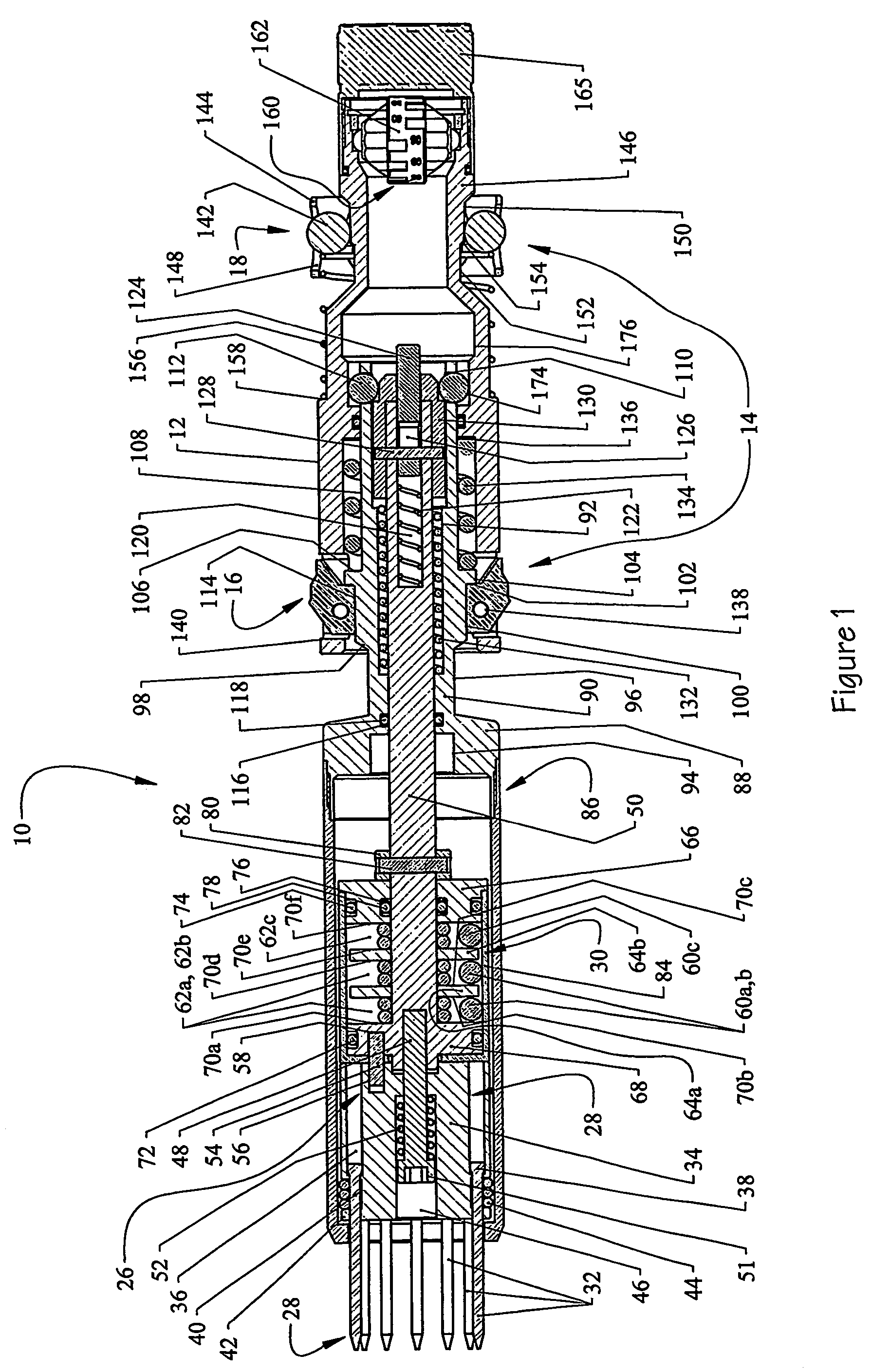

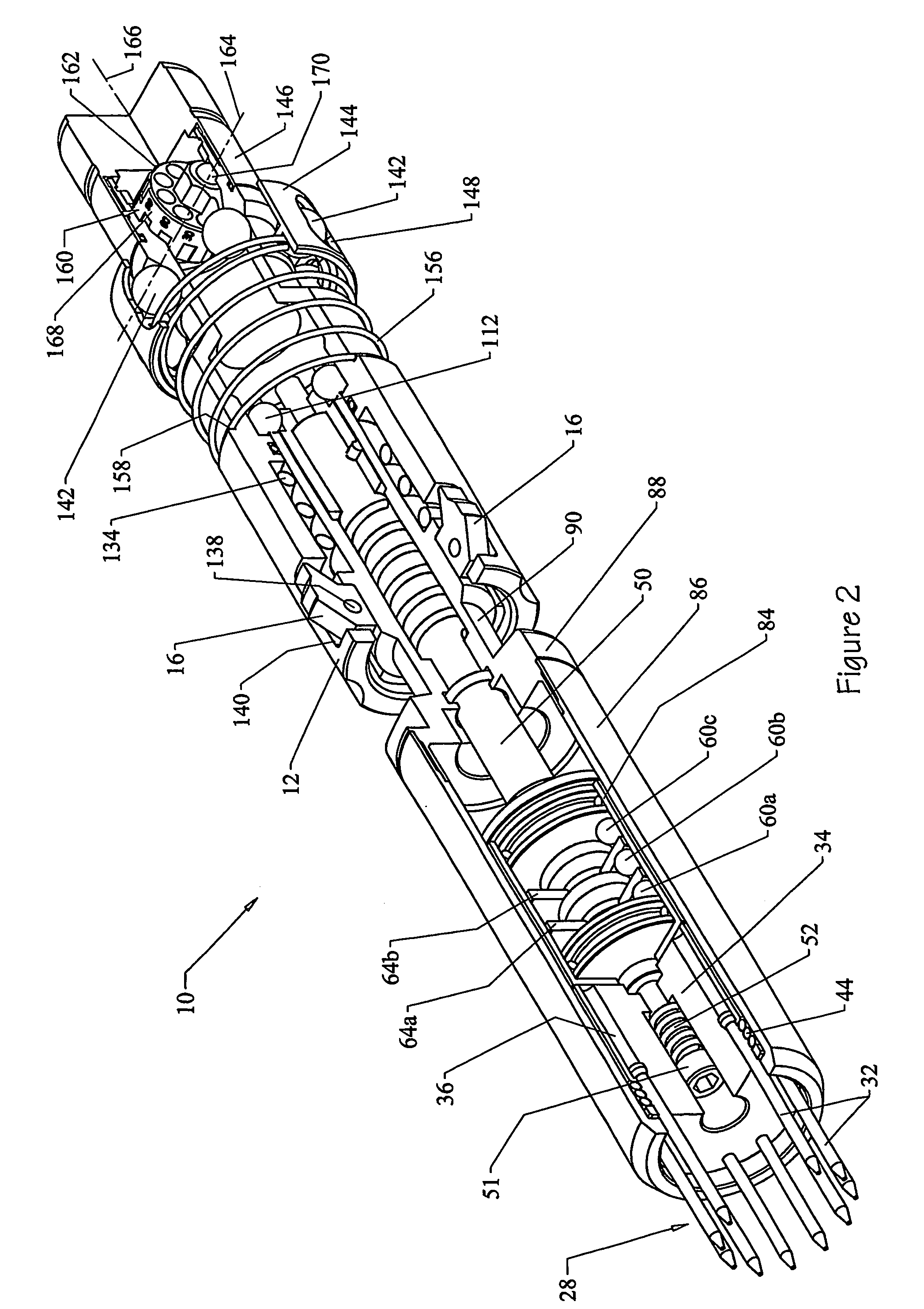

Core orientator for a core drill includes a face orientator and a bottom orientator supported by a shaft which extends into a shroud. A tubular extension is coupled to the shroud and is slidably coupled to a main body. The main body includes first and second latches. The first latches releasably lock the device to a core lifter case assembly disposed within the core drill, to selectively prevent the device from advancing in an uphole direction within the core drill. The latching system operates to prevent the device from falling out of the core drill. Face orientator includes a plurality of pins which can move axially to provide a plurality of profile reference points to a facing surface of a hole to be drilled. The bottom orientator includes a plurality of balls disposed within respective braces.

Owner:IMDEX TECH AUSTRALIA PTY LTD

Orientation device for a core sample

Core orientator for a core drill includes a face orientator and a bottom orientator supported by a shaft which extends into a shroud. A tubular extension is coupled to the shroud and is slidably coupled to a main body. The main body includes first and second latches. The first latches releasably lock the device to a core lifter case assembly disposed within the core drill, to selectively prevent the device from advancing in an uphole direction within the core drill. The latching system operates to prevent the device from falling out of the core drill. Face orientator includes a plurality of pins which can move axially to provide a plurality of profile reference points to a facing surface of a hole to be drilled. The bottom orientator includes a plurality of balls disposed within respective braces.

Owner:IMDEX TECH AUSTRALIA PTY LTD

Hole bottom freezing cord coring drill and coring method thereof

Owner:JILIN UNIV

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

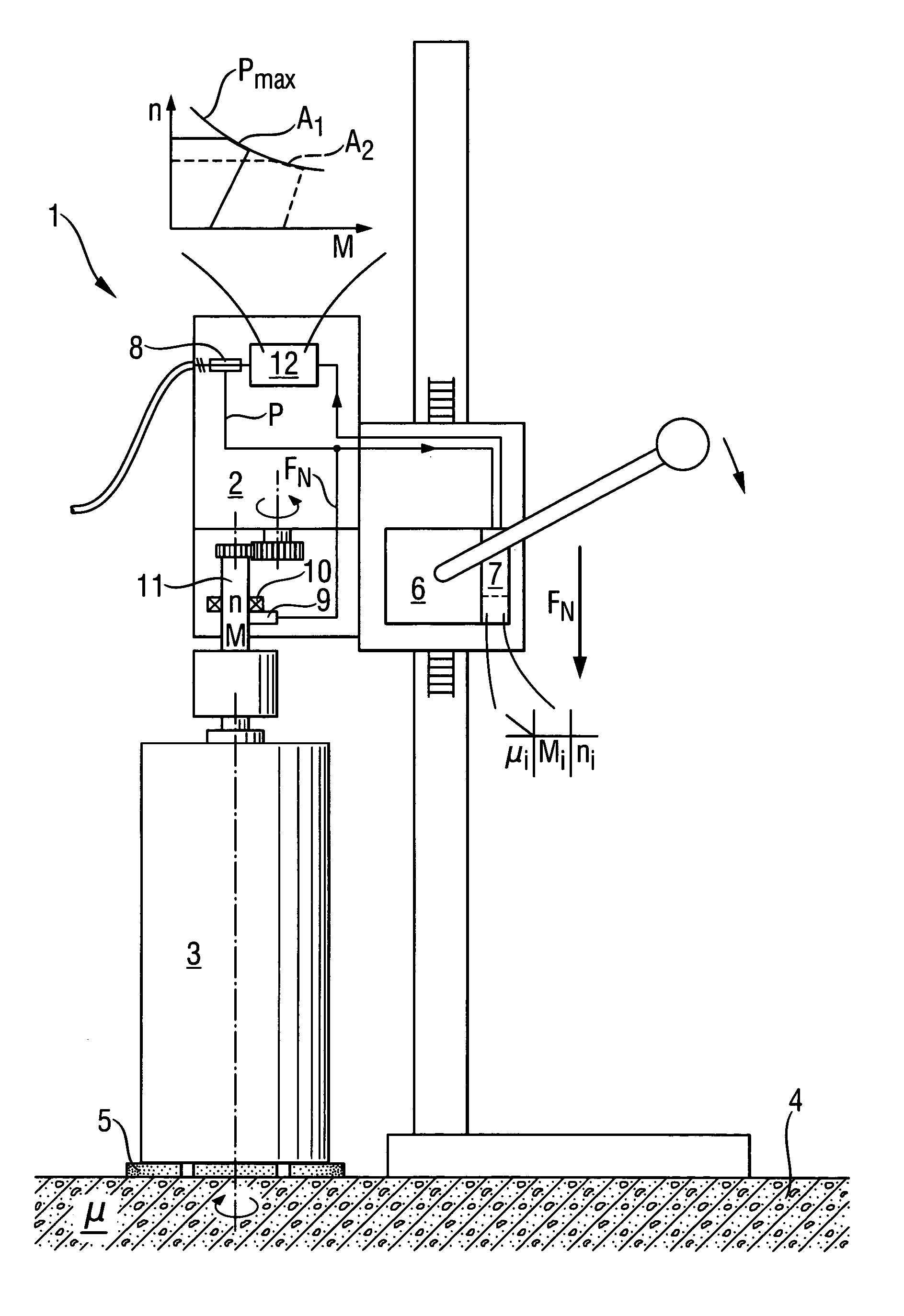

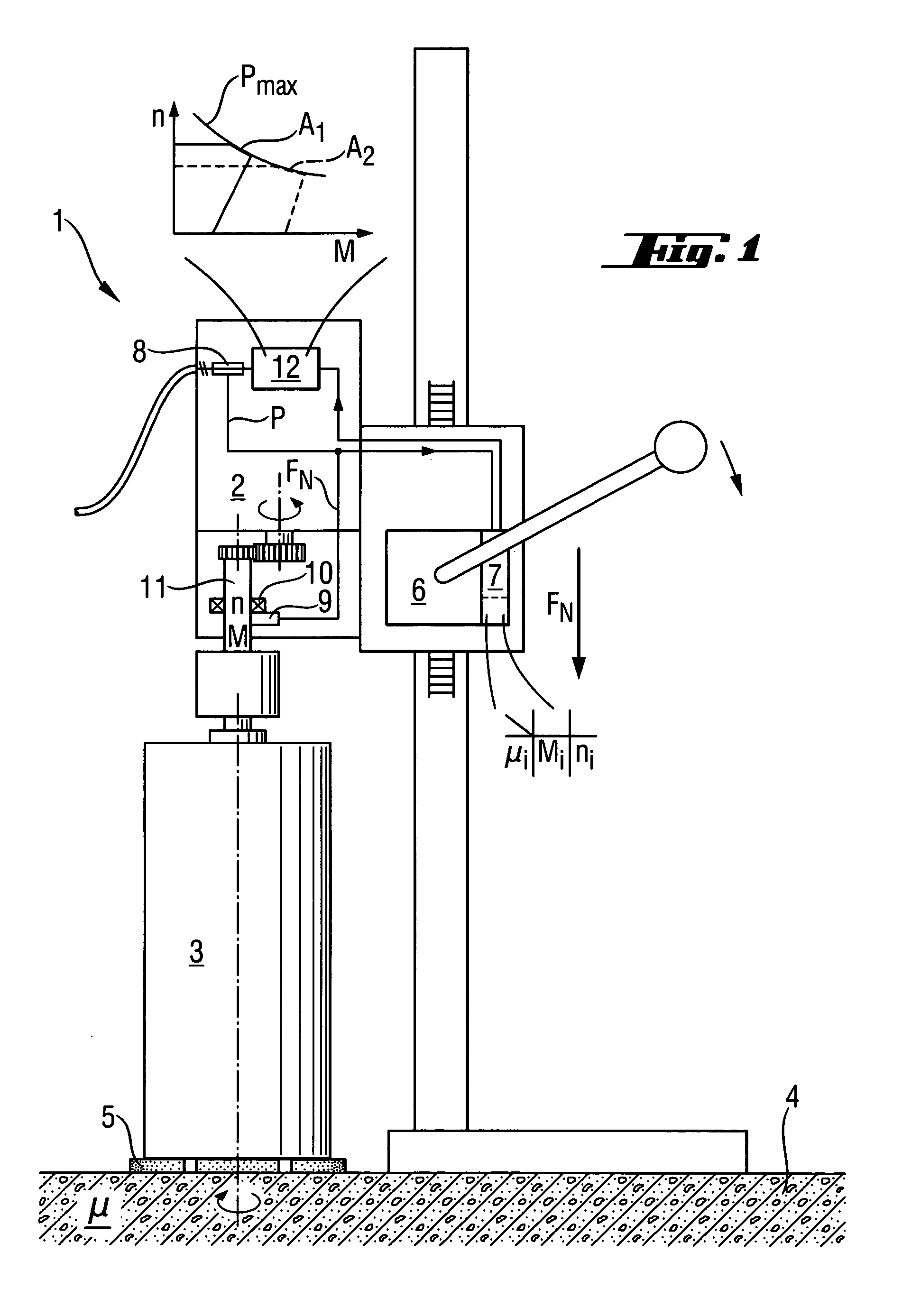

Feed adaptation core drill

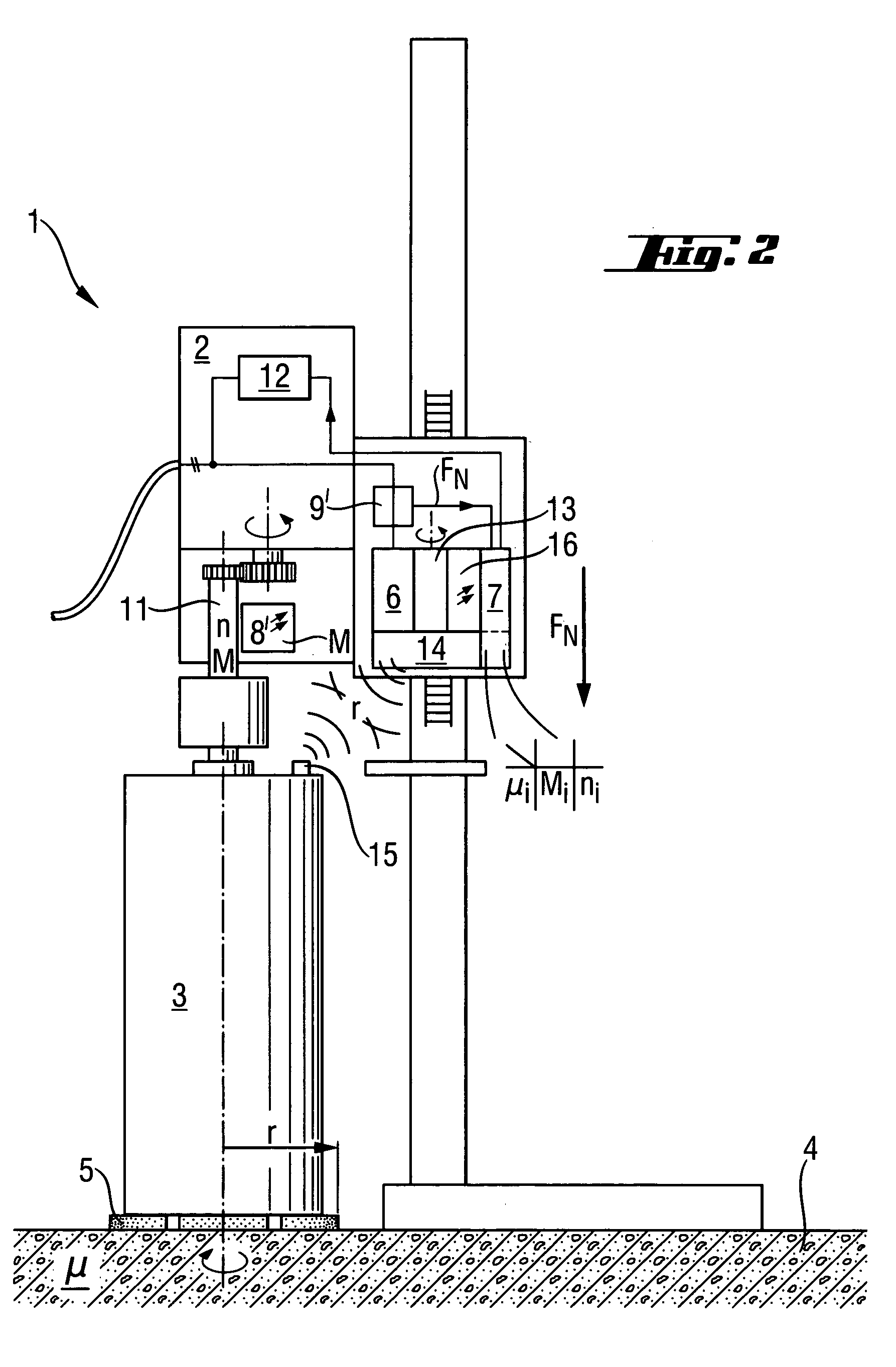

A process for controlling and a core drilling machine (1) having an electrical motor (2) for rotational drive of a core drill bit (3) having cutting edges (5) oriented axial to a work piece (4), a feeding means (6) for generating the feed of the core drill bit (3) against the work piece (4) and having a controller (7) for controlling, relative to a first one-to-one control parameter, detected by a sensor (8, 8′) for electrical power consumption (P) or torque (M). A force sensor (9, 9′) is connected to the controller (7) for detecting the contact pressing force (FN) of the core drill bit (3) as the second control parameter.

Owner:HILTI AG

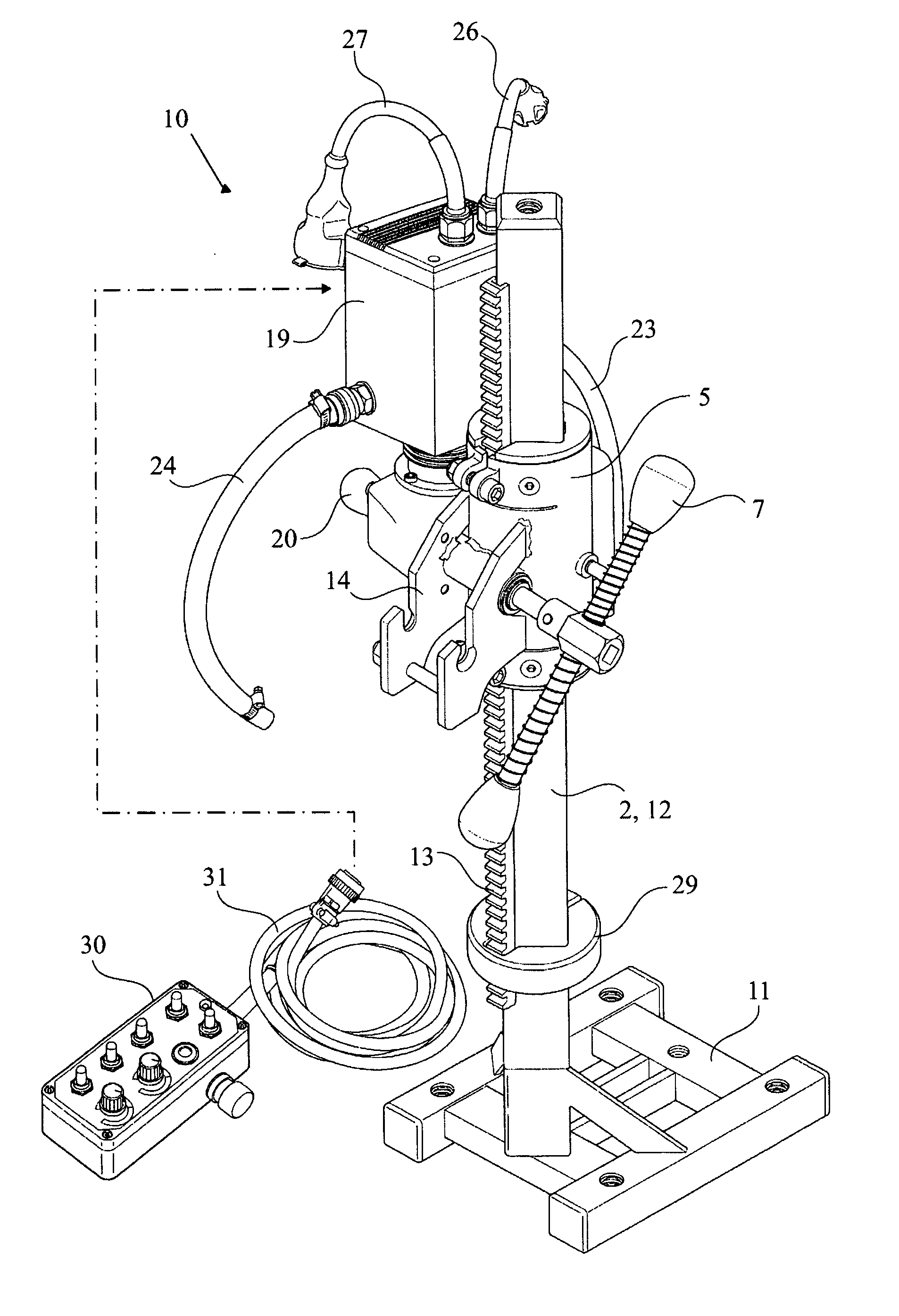

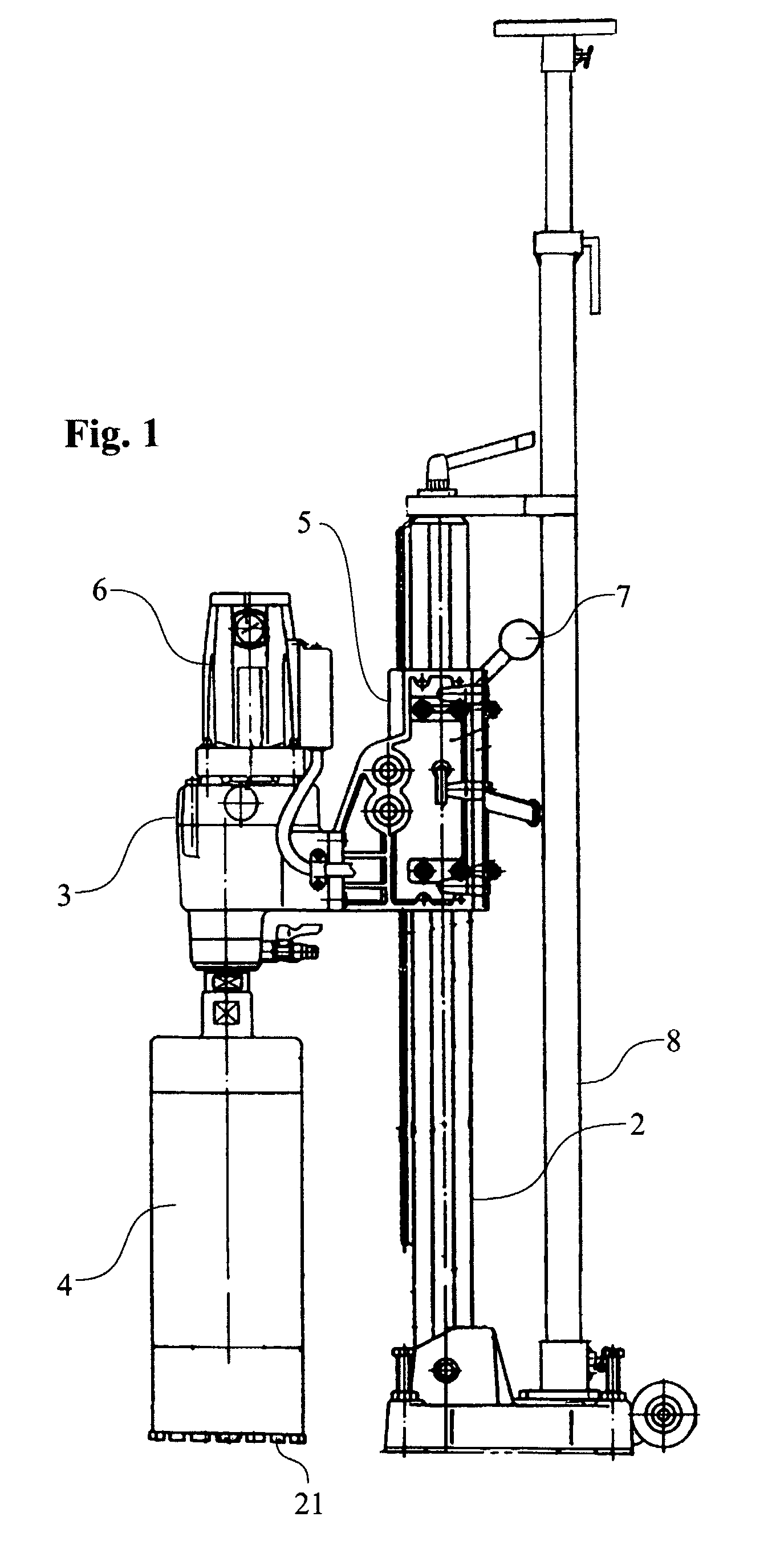

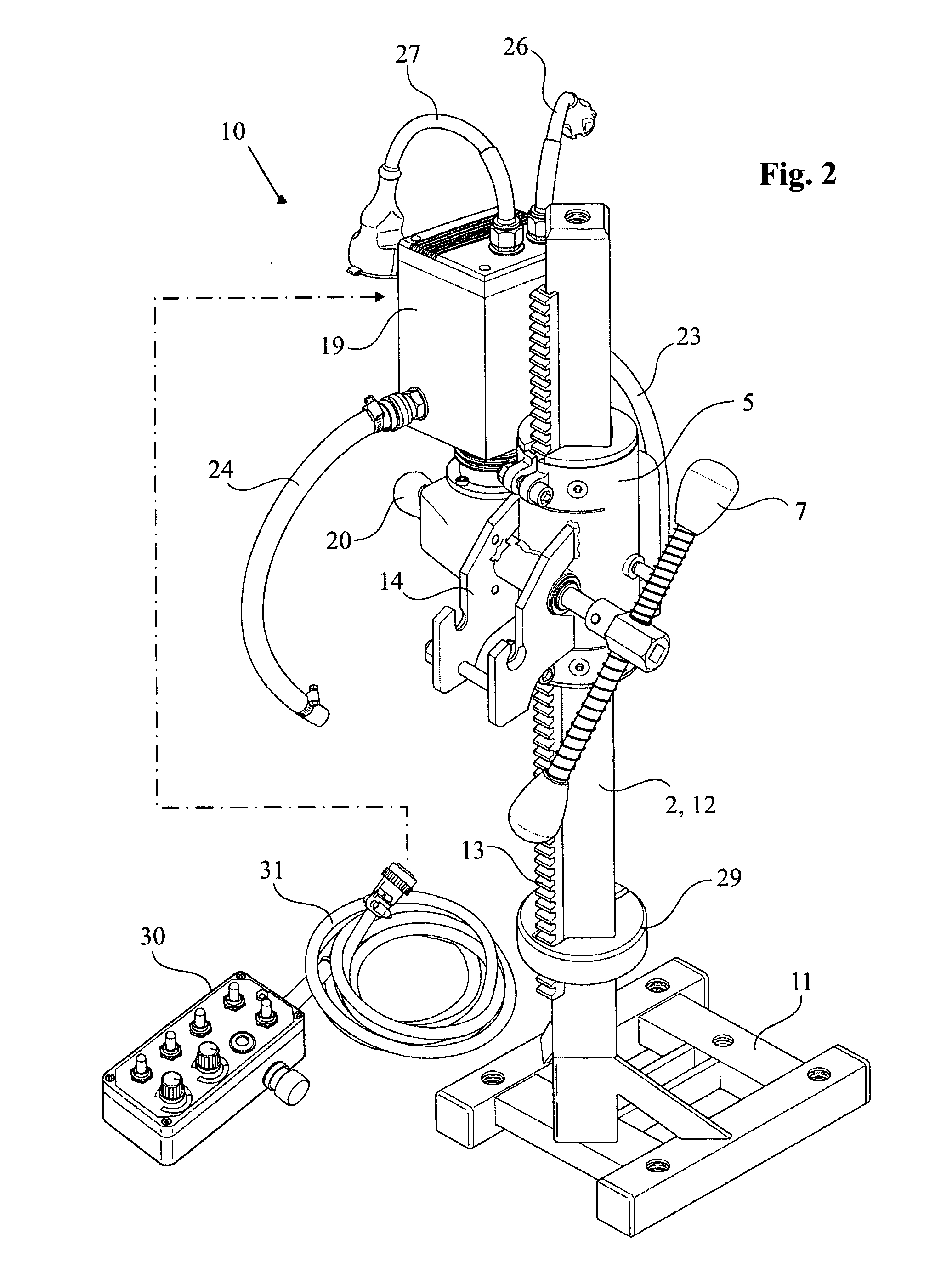

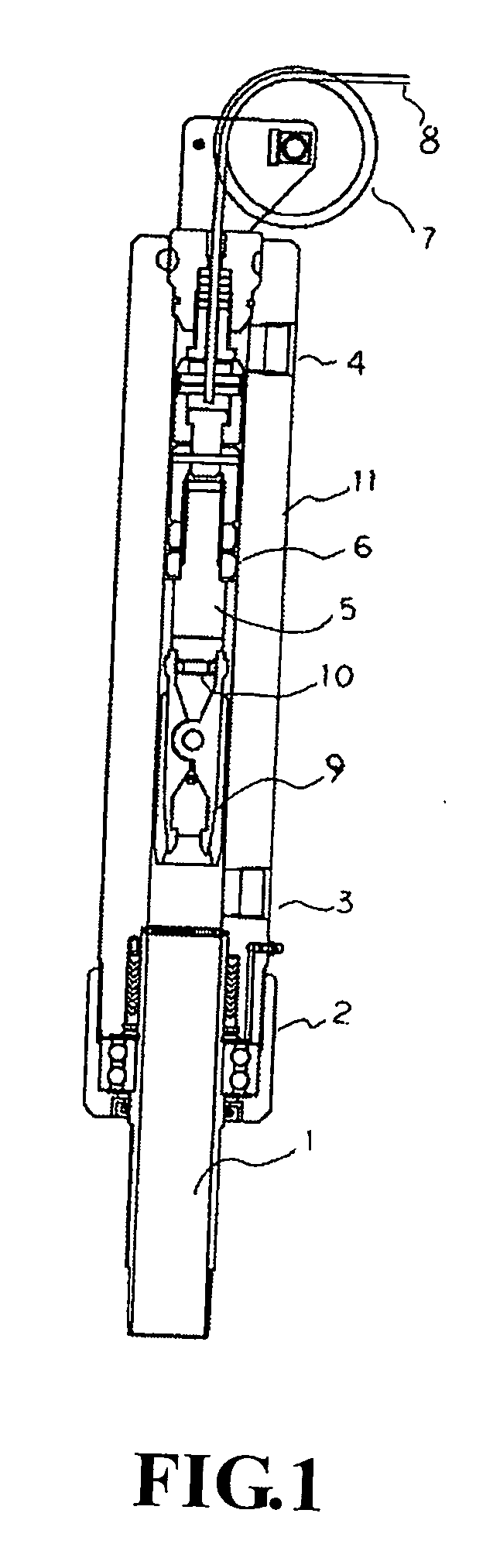

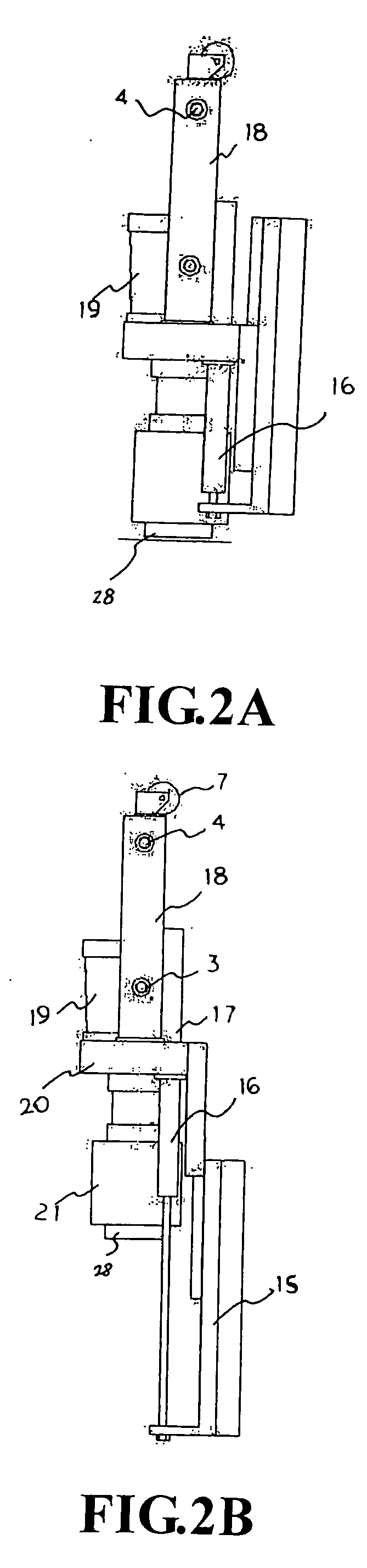

Core Drilling Device With Electrical Feeding That Is Manually Controlled

InactiveUS20070217879A1Thread cutting auxillary apparatusWorking accessoriesElectricityFeeding force

A core-drilling device (10) comprising a drilling machine (3) with a core drill (4), a drill stand (2), a feeding housing suspending the drilling machine and which is movable along the stand, an electric drilling motor for rotation of the core drill in the drilling machine and a feeding unit (19) with an electric feeding motor (17) for the feeding of the feeding housing along the stand. A control unit (30), which is electrically connected to the feeding unit, comprises at least a first control (33) for manual influence of the feeding motor's (17) feeding force.

Owner:HUSQVARNA AB

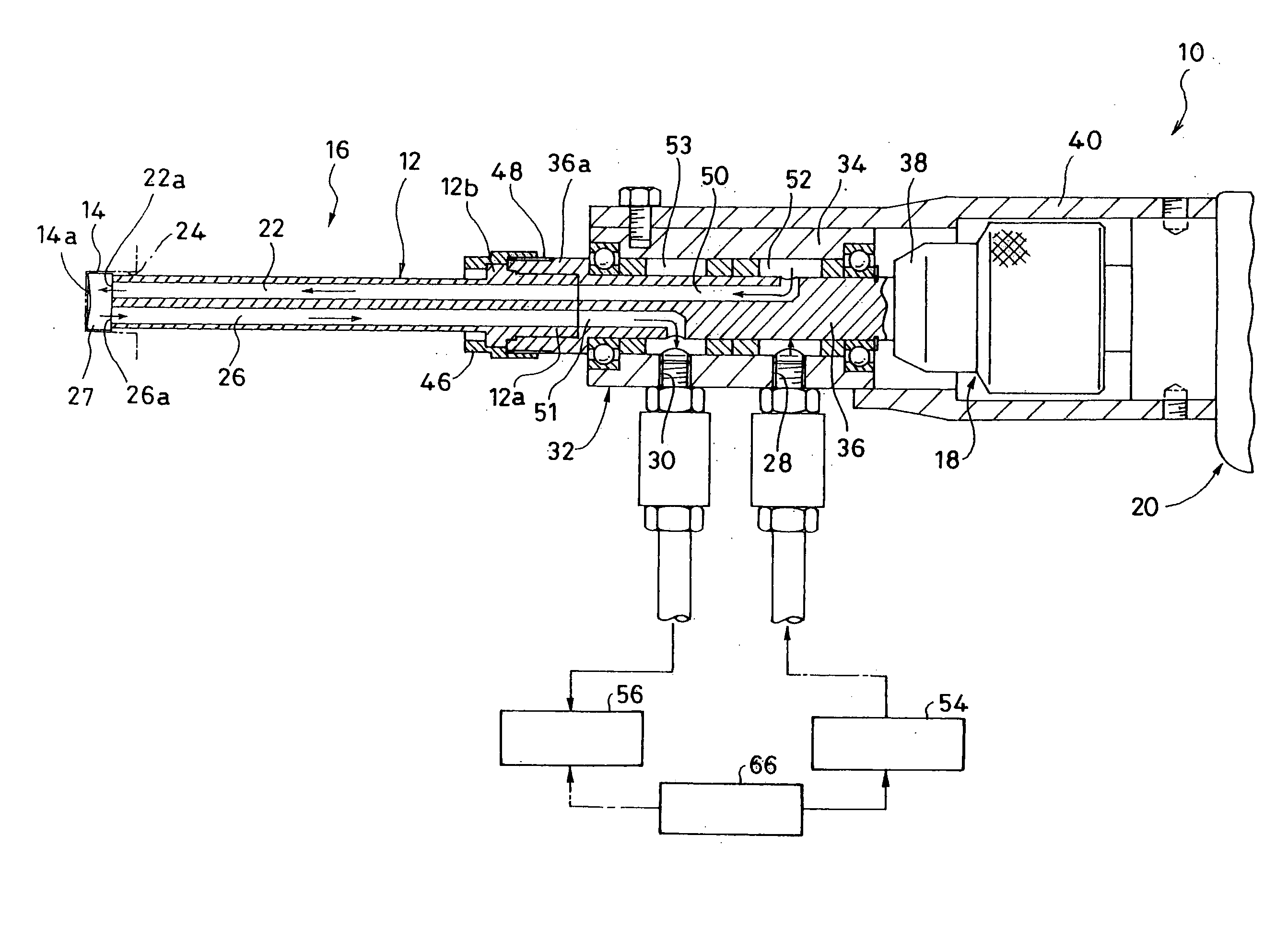

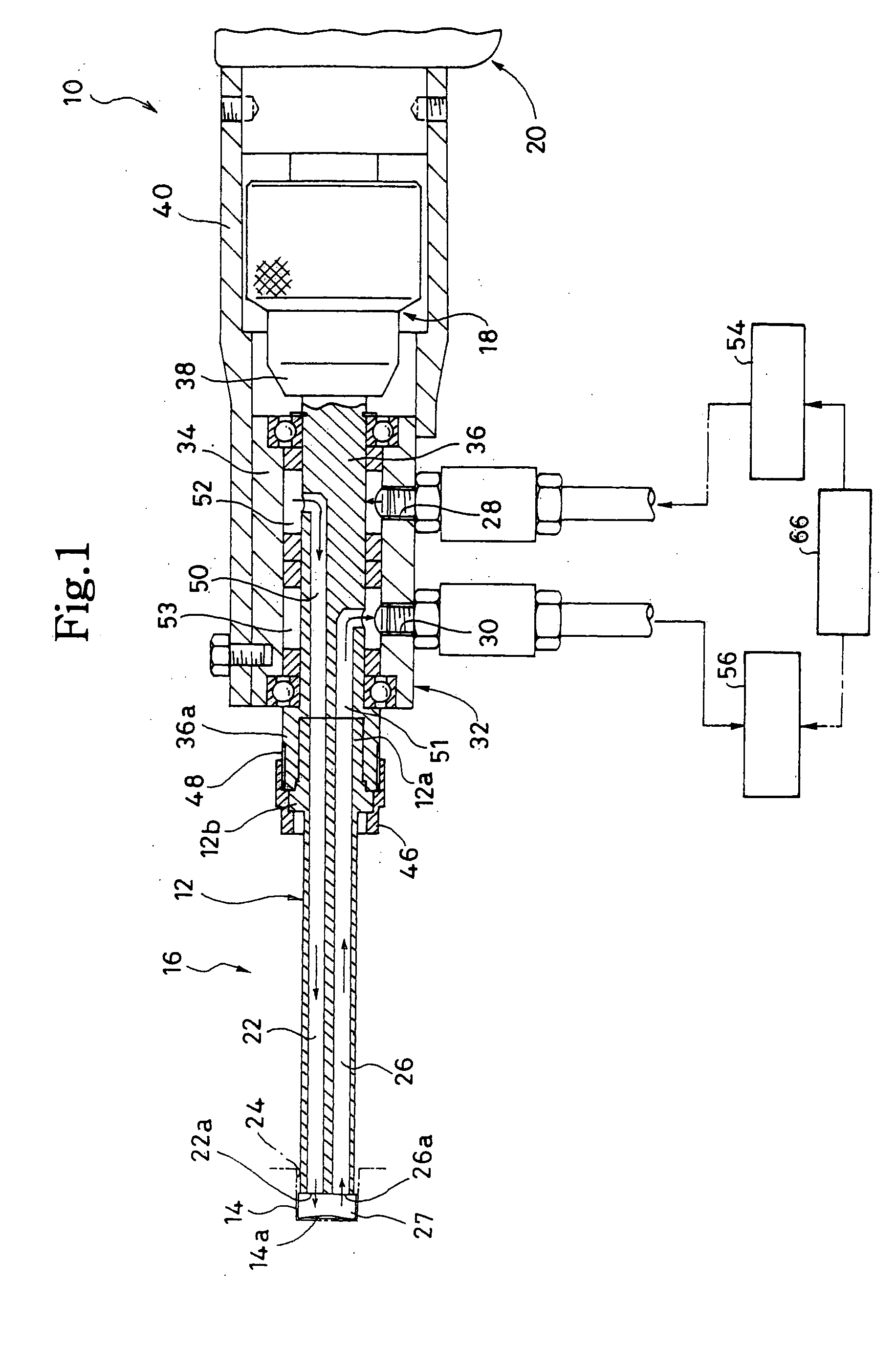

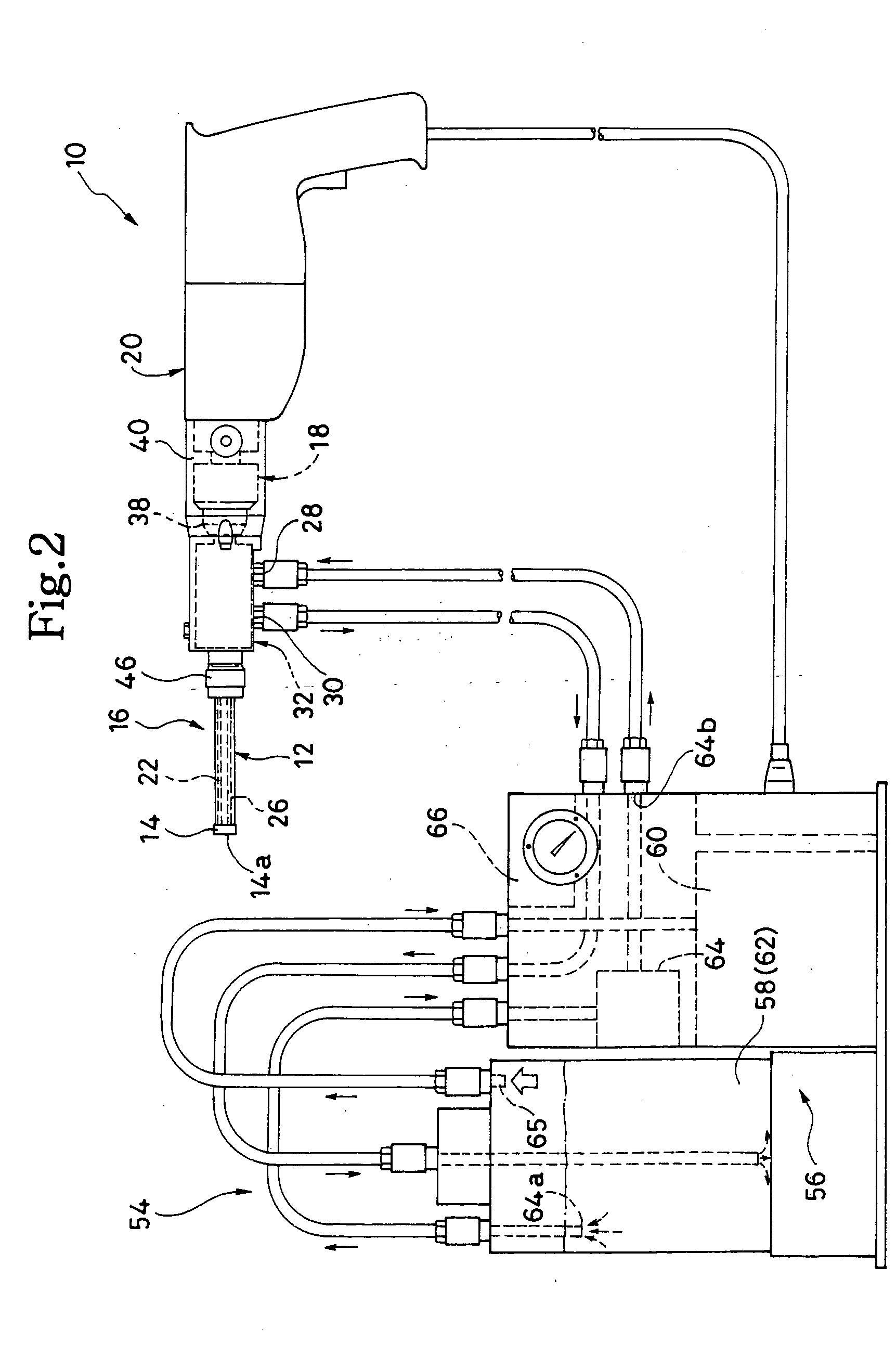

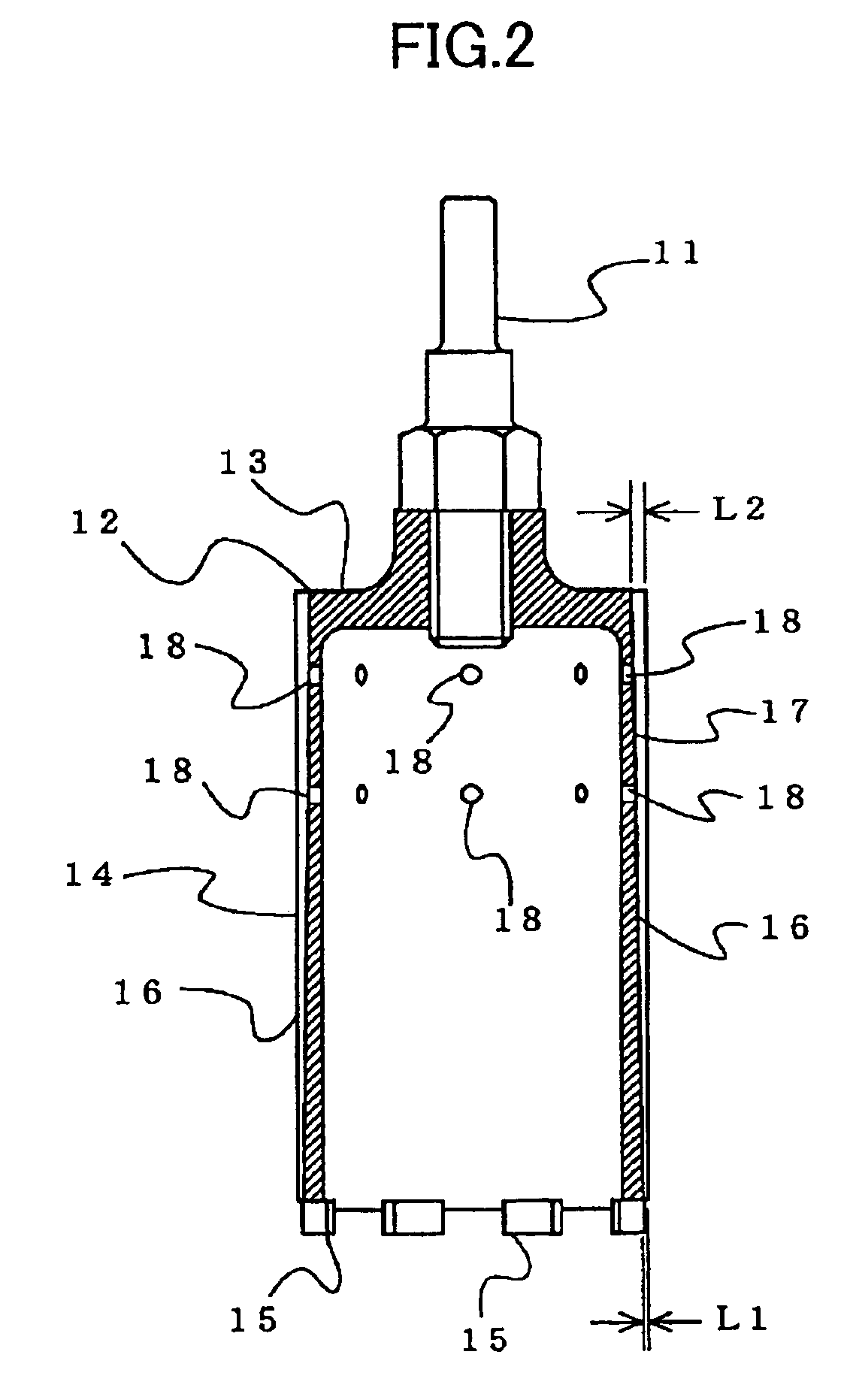

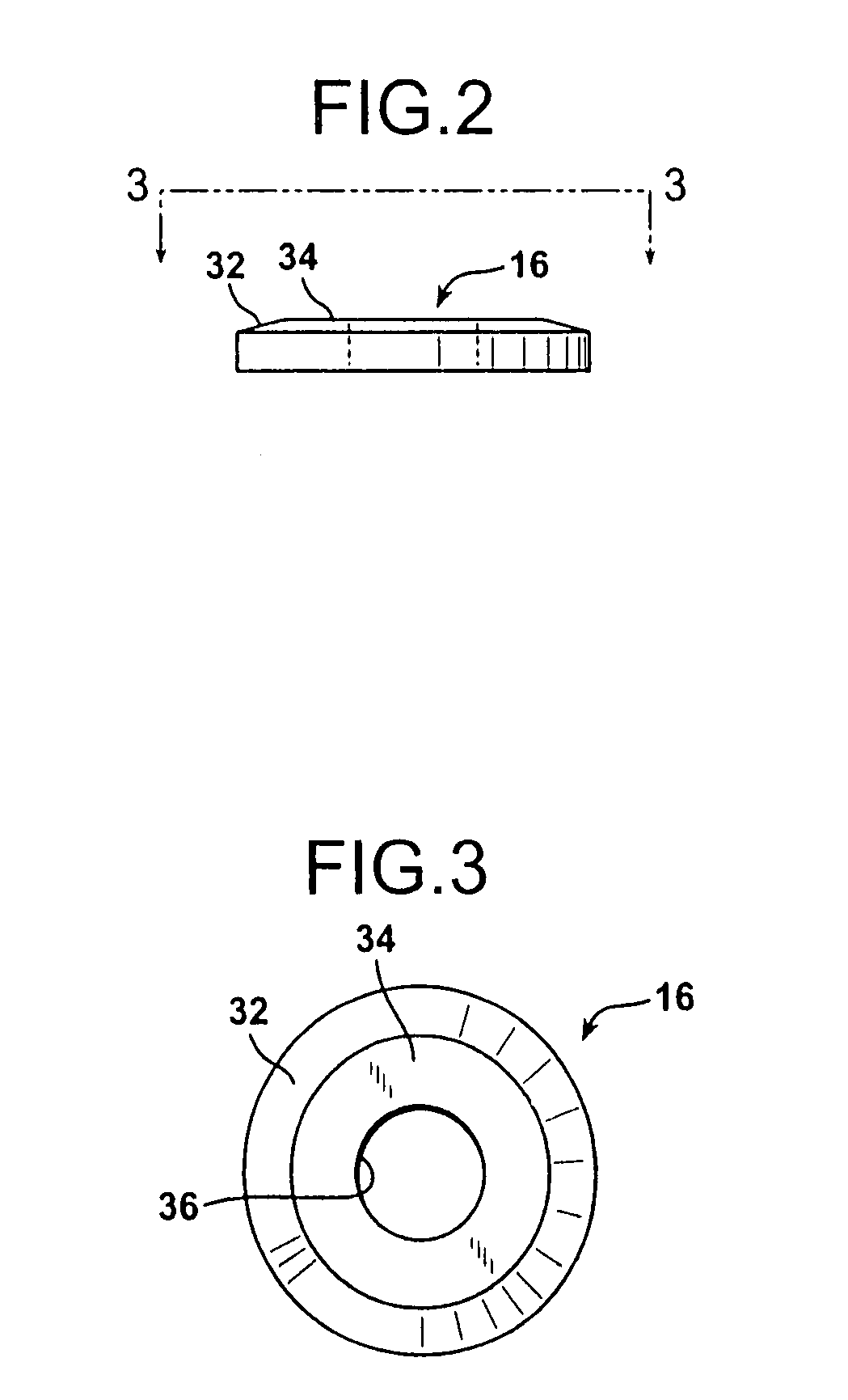

Non-core type bit, non-core drill apparatus, and method of supplying cooling water thereto

InactiveUS20050105977A1Absolute reductionConvenient for boringTransportation and packagingMulti-purpose machinesSuction forceWater source

A cutting tip 14 is secured to the distal end of the shank 12 of a non-core type bit 16 that is designed to bore holes. The shank 12 has a water-supplying passage 22 and a water-discharging passage 26. The water-supplying passage 22 is configured to supply cooling water to the tip 14. The water-discharging passage 26 is configured to discharge the cooling water from a hole 24 being bored by the tip 14. A swivel 32 has a water-supplying port 28 that is connected to a cooling-water source 54. The cooling water flows from the cooling-water source 54 to the bit 14 through the water-supplying passage 22. A suction force applied by a cooling-water discharging means 56 compels the cooling water out of the hole 24. The cooling water is thereby discharged through the water-discharging passage 26.

Owner:ISHIHARA KIKAI INDS

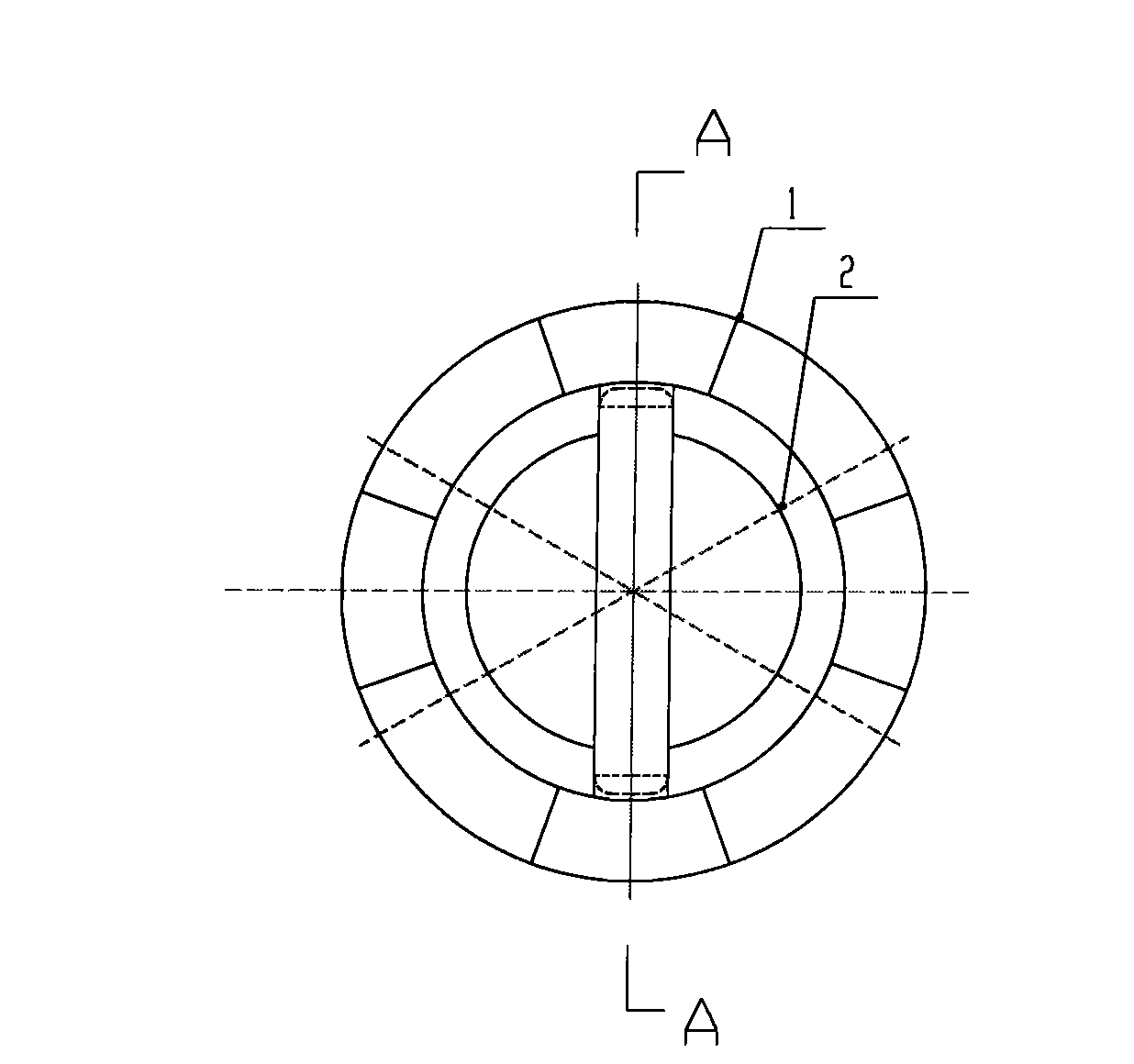

Core drill

A plurality of chip evacuating grooves (16, 26, 36, 46a, 46b) in a vertical direction in parallel with a rotational axis of a core main body (14) are formed at an outer peripheral face of the core main body (14) in a circumferential direction from a lower end portion to an upper end portion of the core main body (14) in a cylindrical shape provided with a drilling blade (15) at a lower end edge thereof. Further, a sectional area of the chip evacuating groove (16) is formed to gradually increase from a lower end to an upper end of the core main body (14). Further, a number of projections (52, 62, 70, 72) are formed at the outer peripheral face of the core main body (14) between the chip evacuating grooves.

Owner:MAX CO LTD

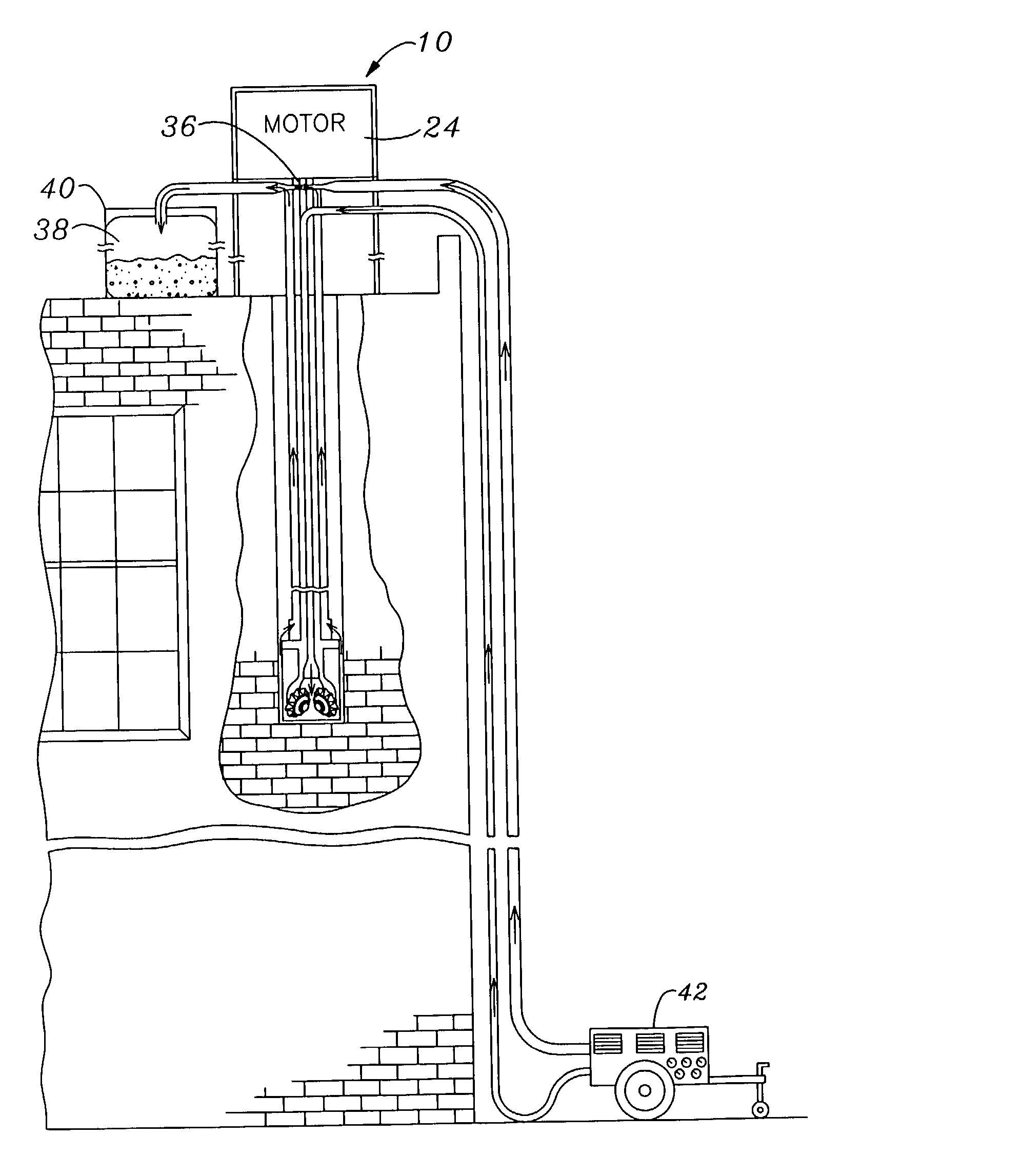

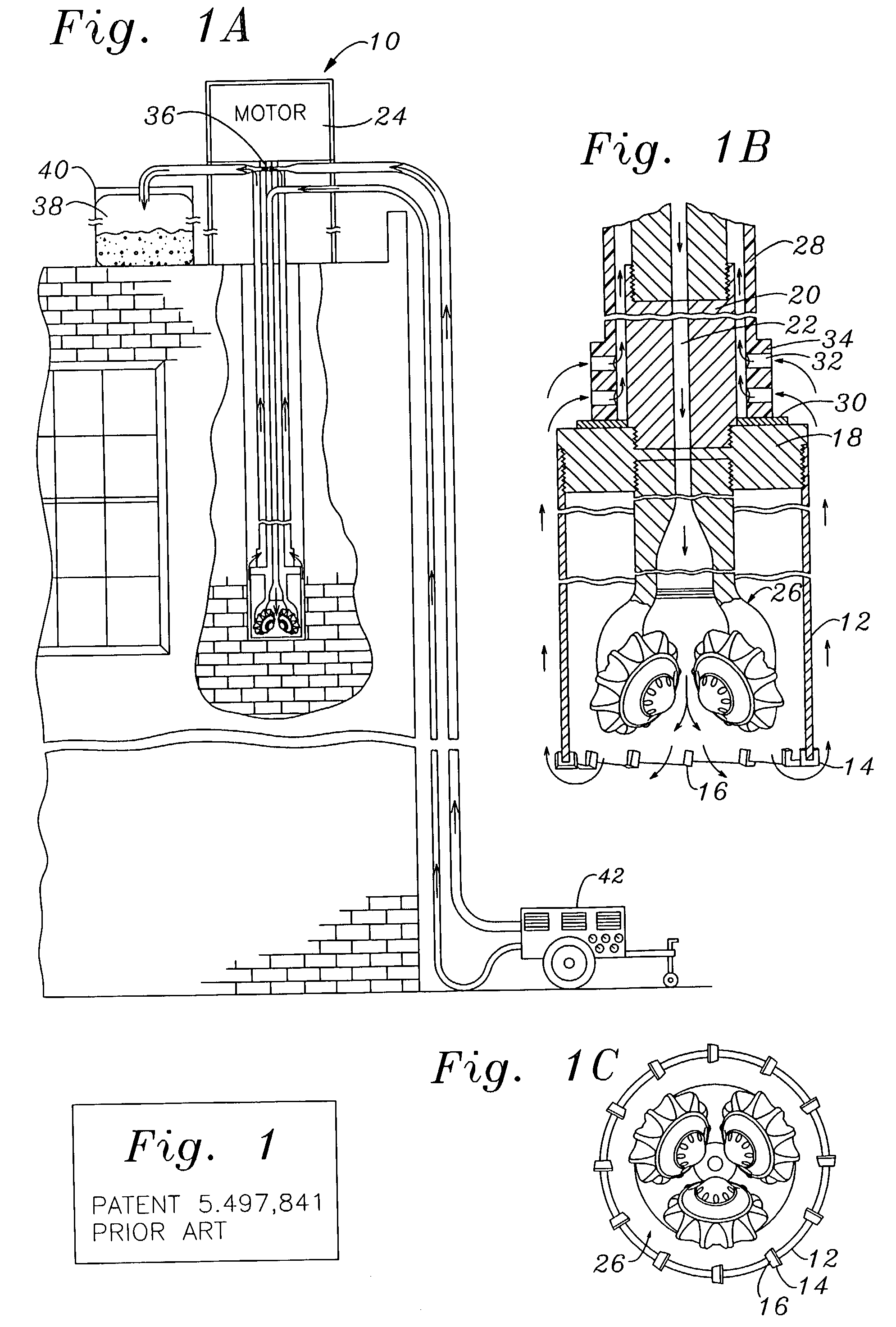

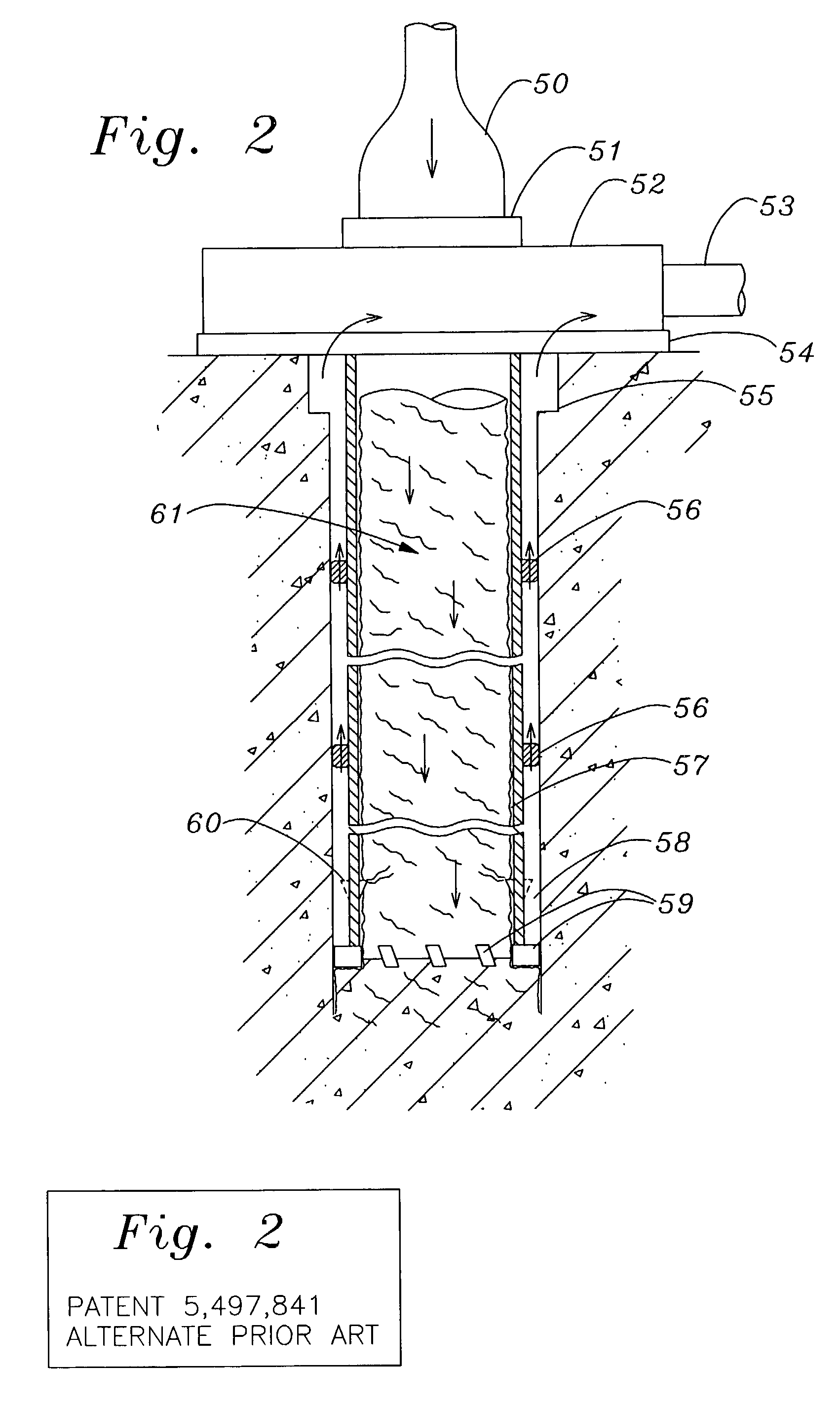

Advanced processes for coring and grouting masonry

Advanced masonry coring systems for coring and grouting masonry walls are disclosed in this patent. The systems include rotating machinery and a drill column in the form of a cylindrical double-piped string of pipe sections, rotating a cylindrical drill body. The drill body mounts cutting end faces having alternative means of employing carbide or diamond cutting and / or pulverizing elements. The double drill pipe weight is made workable through new aerospace composite fabrication. The double pipe permits more efficient routing of air and removal of drill cuttings. Advancement in various system components and means of placing reinforcement into walls is disclosed. Further disclosure is included of advanced means of optimizing resin grouting materials and procedures to fill the wall cavities created by the core drill, integrating the reinforcement into the walls.

Owner:MOHLENHOFF WILLIAM

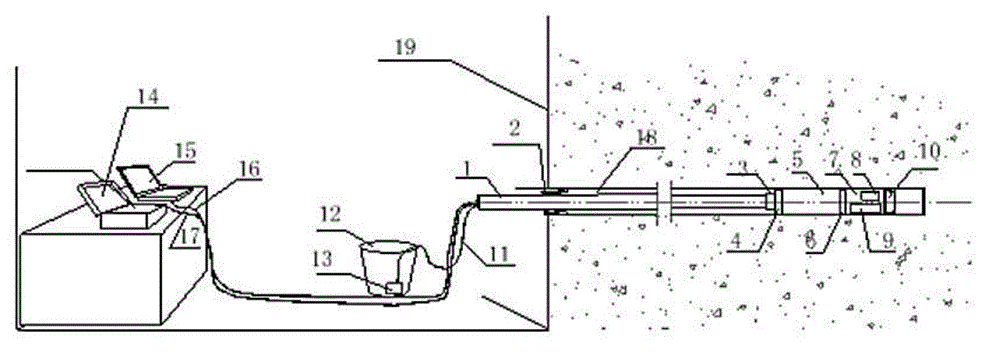

Horizontal hole ground stress measurement device based on BWSRM (Borehole Wall Stress Relief Method) principle

InactiveCN102979520ASmall sizeReduce broken coreConstructionsBorehole/well accessoriesStress measurementMeasuring instrument

The invention relates to a horizontal hole ground stress measurement device based on a BWSRM (Borehole Wall Stress Relief Method) principle, which is used for the technical field of measurement of stress of rocks in an underground cavity or a mine opening. The horizontal hole ground stress measurement device comprises a sealed cable joint, a stress measurement main working part, a multiway stress measuring instrument, a measurement control unit and a detection part, wherein the sealed cable joint is connected with the front end of the stress measurement main working part to be used as an output port for a power cable and a communication cable of the integral device; the stress measurement main working part is sequentially connected with the multiway stress measuring instrument, the measurement control unit and the detection part; the multiway stress measuring instrument is used for recording variation of stress on a working surface in the process that a thin-walled diamond core drill implements ring-shaped cutting on surrounding rocks of the hole wall of a borehole; and the detection part is used for observing and recording the quality condition of the hole wall of the borehole in the process of propelling integral equipment into the horizontal borehole to a working hole depth and providing reference basis for a local hole section which is selected to be subjected to stress relief. According to the invention, the integral measuring process is controlled sufficiently by an electromechanical integration technology through adopting a main control module; and test reliability and measurement accuracy can be greatly improved. The horizontal hole ground stress measurement device is convenient to carry and apply in the field and easy to operate in the field and can carry out three-dimensional ground stress actual measurement easily.

Owner:SHANGHAI JIAO TONG UNIV

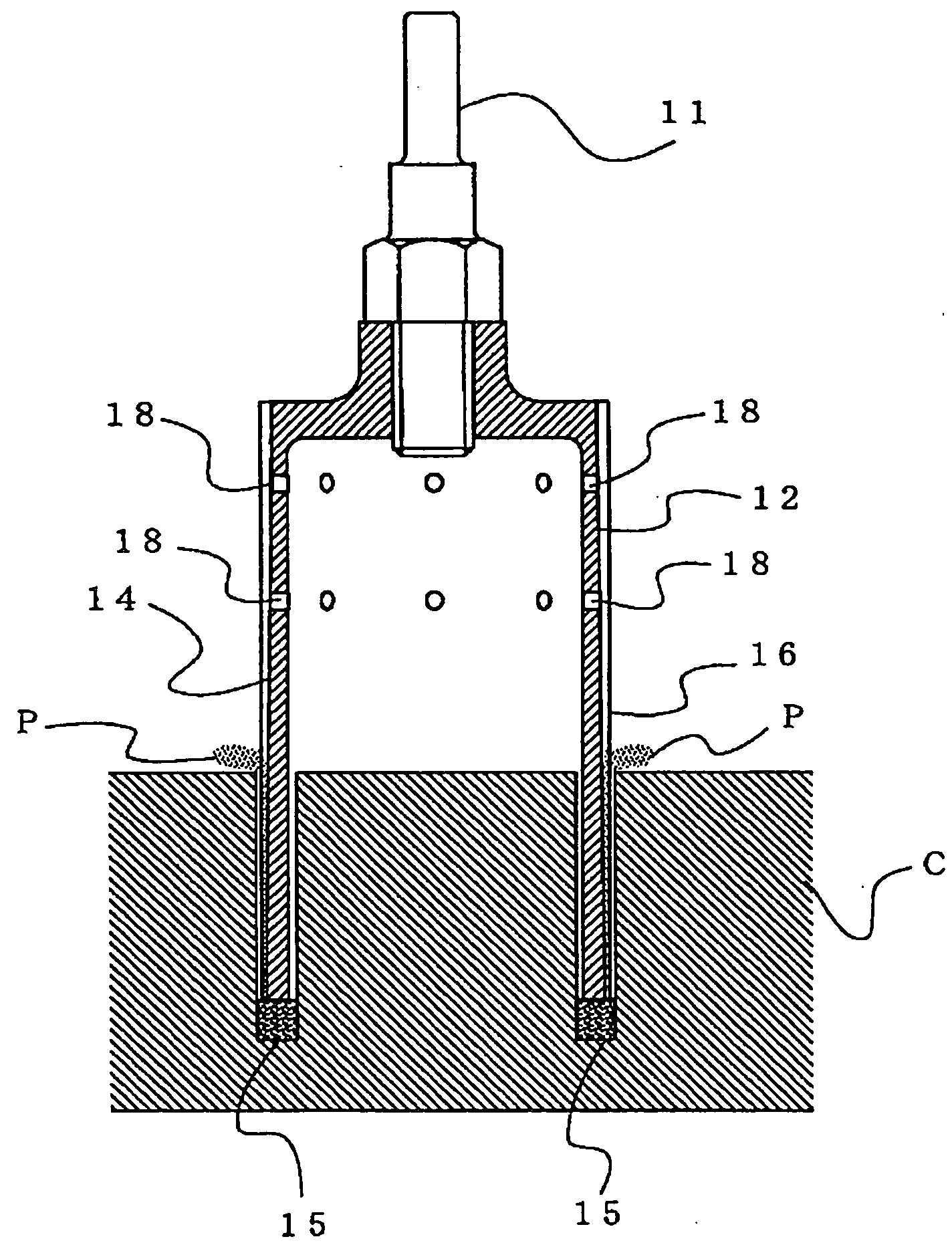

Hole coring system with lever arm

A hole coring system is provided that greatly stabilizes a tubular core drill bit for drilling into concrete or other materials enabling large diameter holes to be drilled with a handheld tool. The drill bit is guided by a mandrel which is attached to the concrete. The mandrel serves as a central guidepost that ensures that a relatively large diameter, tubular core drill bit remains precisely centered relative to the guide mandrel. This enables the operator to use a commonly available tool to rotate the drill and apply drill pressure only. The motor may rotate the drill bit via a gear box. The gear box may have a lever arm which may be used to resist any torquing action of the gear box due to the friction between the drill bit and the concrete. Additionally, in the event the motor's housing is not fixed to the gearbox and allowed to rotate, a brace may be attached to the lever arm which may be used to resist any torquing action of the motor's housing due to the friction between the drill bit and the concrete.

Owner:DUNCAN

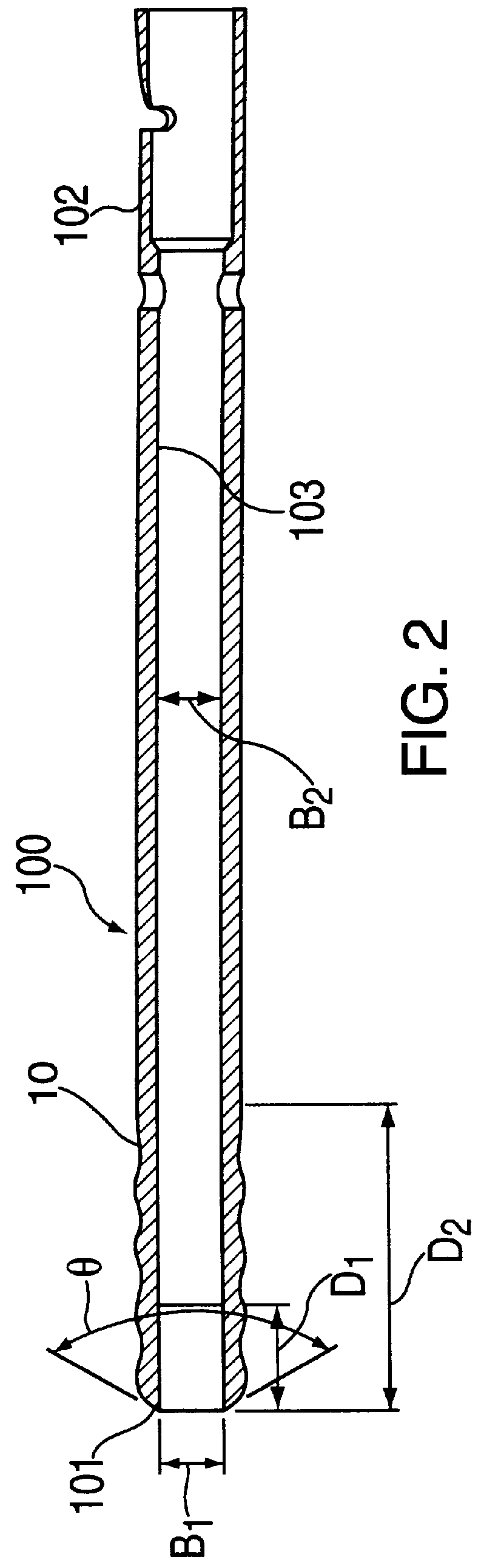

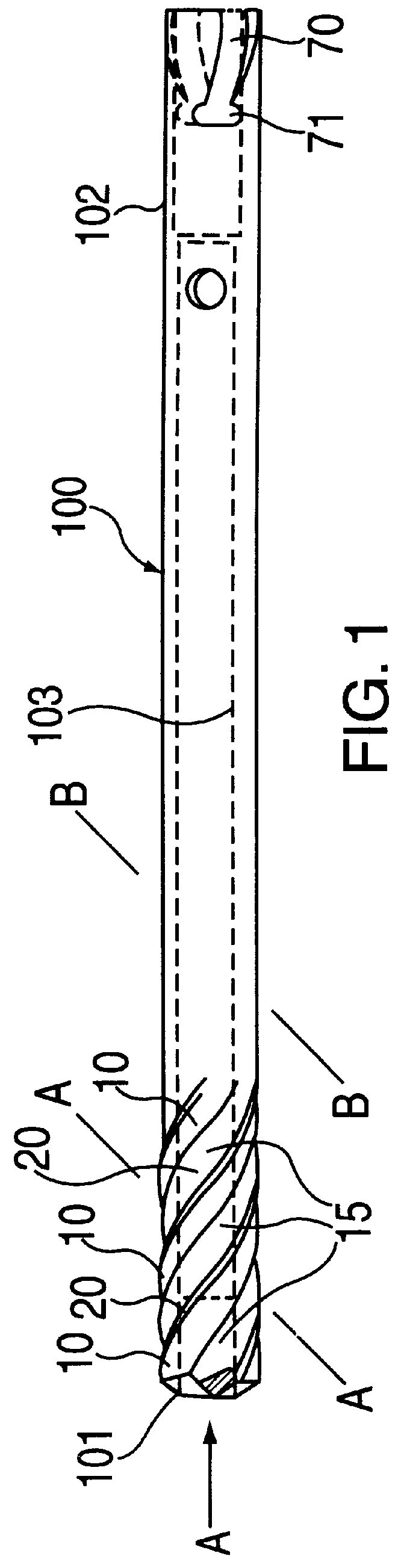

Wood corer device

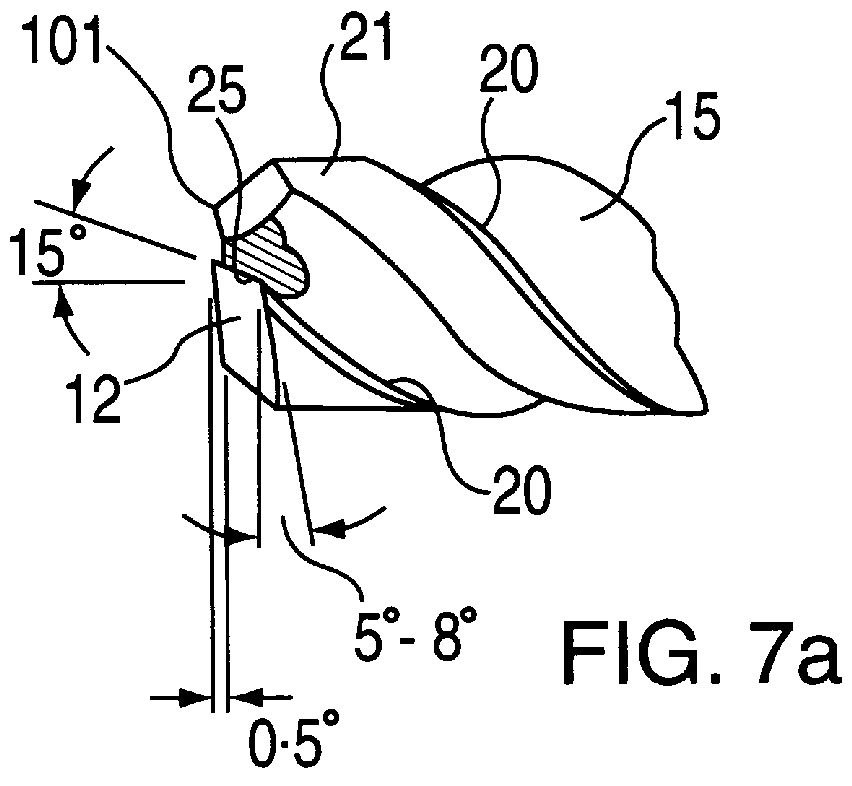

PCT No. PCT / AU96 / 00587 Sec. 371 Date Sep. 1, 1998 Sec. 102(e) Date Sep. 1, 1998 PCT Filed Sep. 19, 1996 PCT Pub. No. WO97 / 11346 PCT Pub. Date Mar. 27, 1997A wood coring drill bit comprising a hollow tube having an internal bore (103) and an exterior (100) with equally spaced bodies (10) of substantially uniform width extending in a helical manner from a cutting end (10) of said drill bit, said bodies (10) defining equally spaced flutes (15) between the edges of adjacent bodies (10), each body (10) comprising a land (20) upstanding from a relief (21) at the leading edge of the body (10), a respective cutting face (12) and associated lip (25) being formed at the end of each body (10) at said cutting end. The wood coring drill bit is characterized by having three equally spaced bodies (10) and flutes (15) said cutting face (12) has an included angle which is preferably 125 DEG for hardwood and drywood and 112 DEG for softwood. The lip (25) has a lip clearance angle that is about 6 DEG + / -1 DEG , the lands (20) on the bodies (10) extend for an axial distance of about 65 mm+ / -5 mm from said cutting end (101) and the internal bore (103) of the hollow tube is tapered outwardly from or adjacent the cutting end (101).

Owner:COMMONWEALTH SCI & IND RES ORG

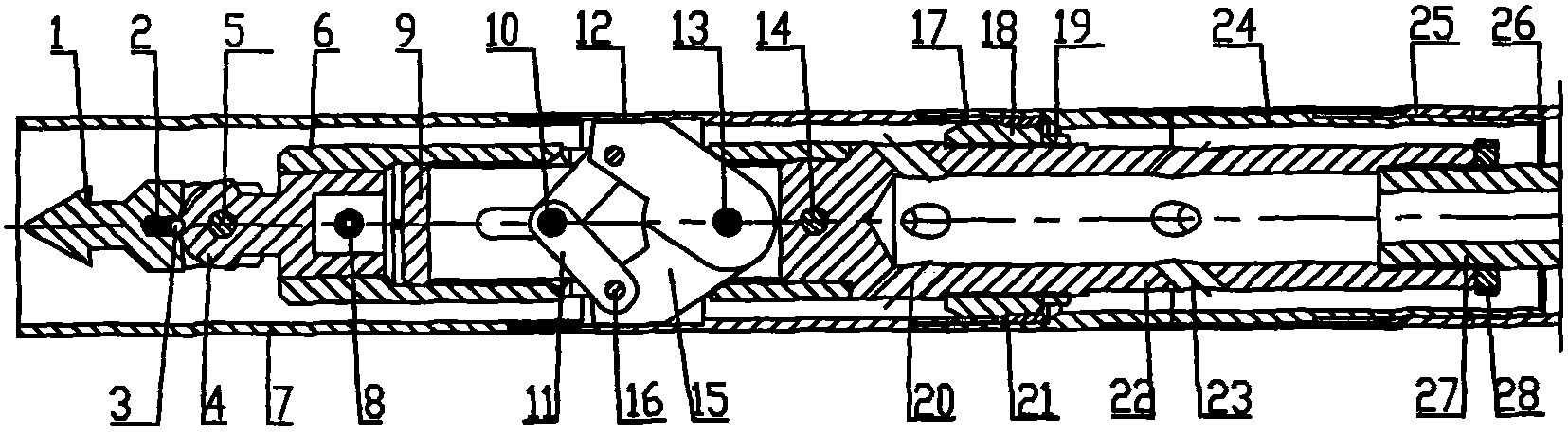

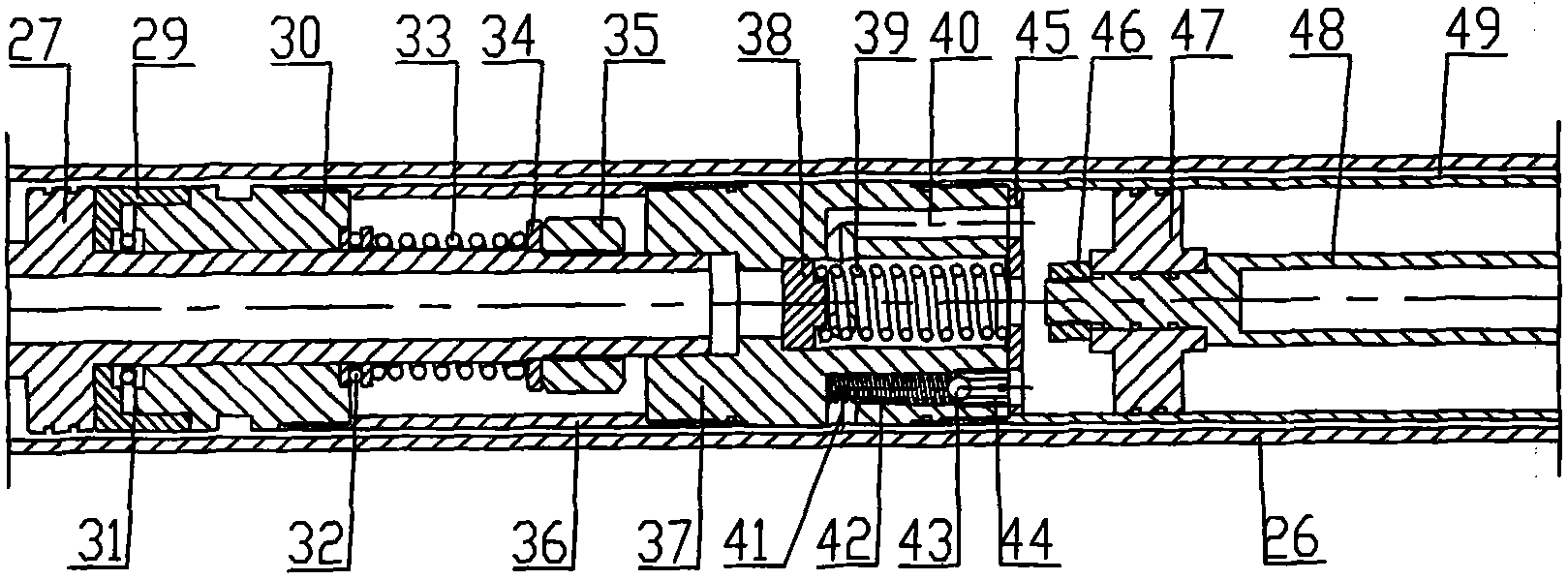

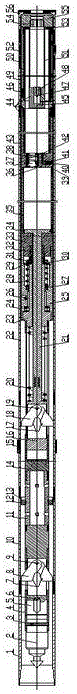

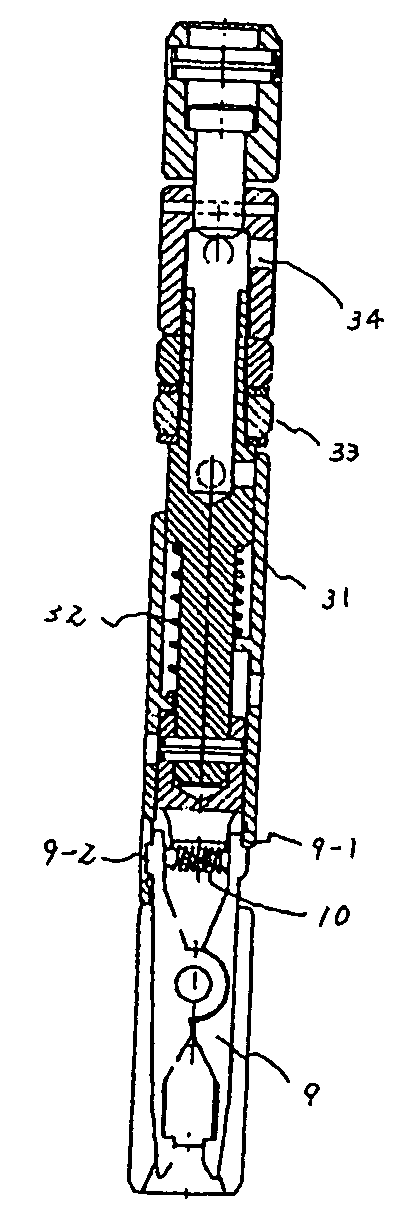

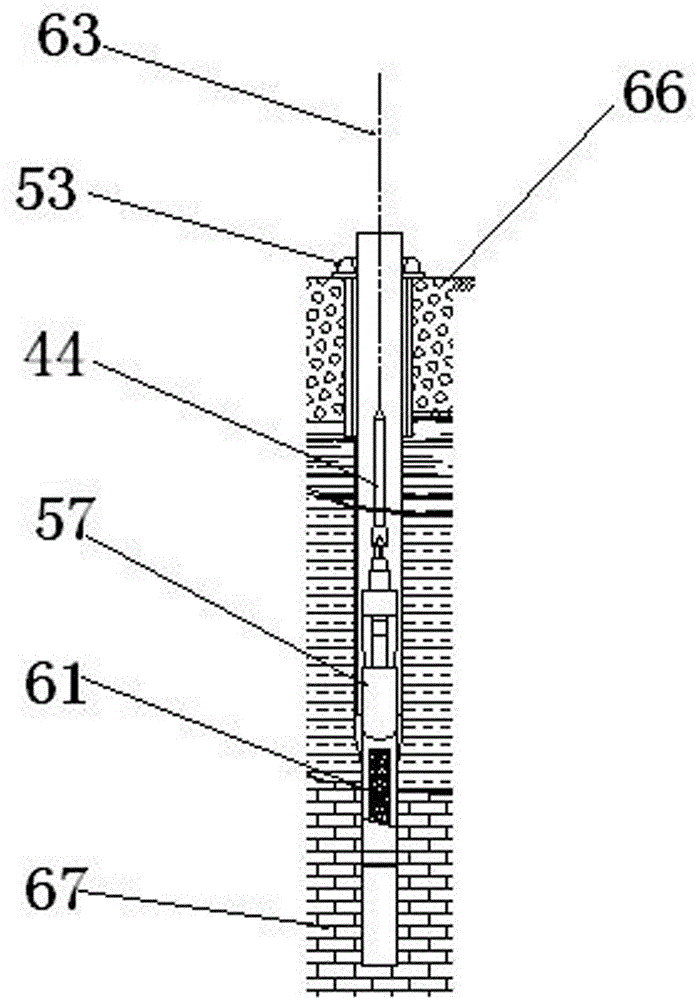

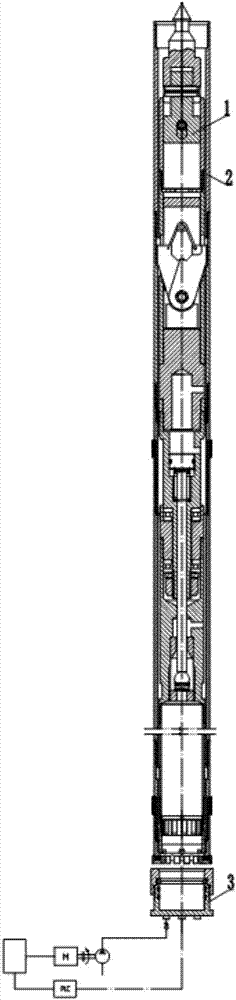

Hydraulic control natural gas hydrate hole bottom frozen rope core drill and coring method

The invention discloses a hydraulic control natural gas hydrate hole bottom frozen rope core drill and a coring method, which are particularly suitable for drilling and coring of natural gas hydrates of deep sea and permafrost lands. The hydraulic control natural gas hydrate hole bottom frozen rope core drill uses dry ice as a cold source, uses ethyl alcohol as cooling catalyst and secondary refrigerant, and can achieve rapid freezing of natural gas hydrate rock cores. The hydraulic control natural gas hydrate hole bottom frozen rope core drill achieves to rapidly core without lifting a drill by combining rope coring and hole bottom freezing. The hydraulic control natural gas hydrate hole bottom frozen rope core drill drives a control valve machine to achieve the process that the cold source is injected into a refrigeration mechanism by adopting drilling fluid column pressure, and has high feasibility. An inner pipe assembly does not rotate when drilling, prevents hydrate rock cores from being damaged because of mechanical force which is produced by a drill in a large extent, thereby more effectively improving recovery rate of rock cores, integrity and representative, and can rapidly obtain the rock cores on the ground by adopting a split core barrel mode to rapidly sample on the ground.

Owner:JILIN UNIV

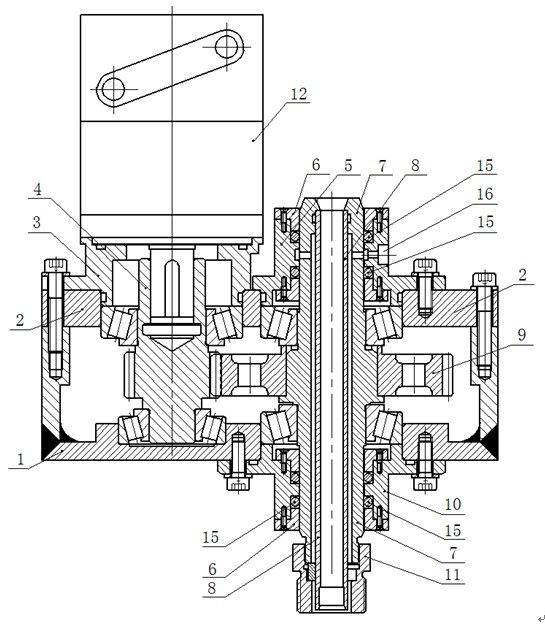

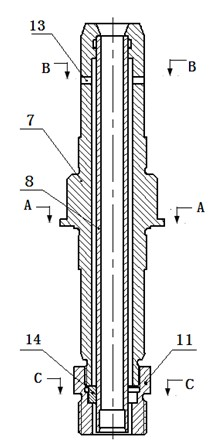

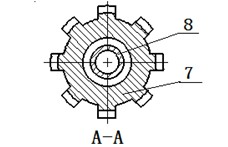

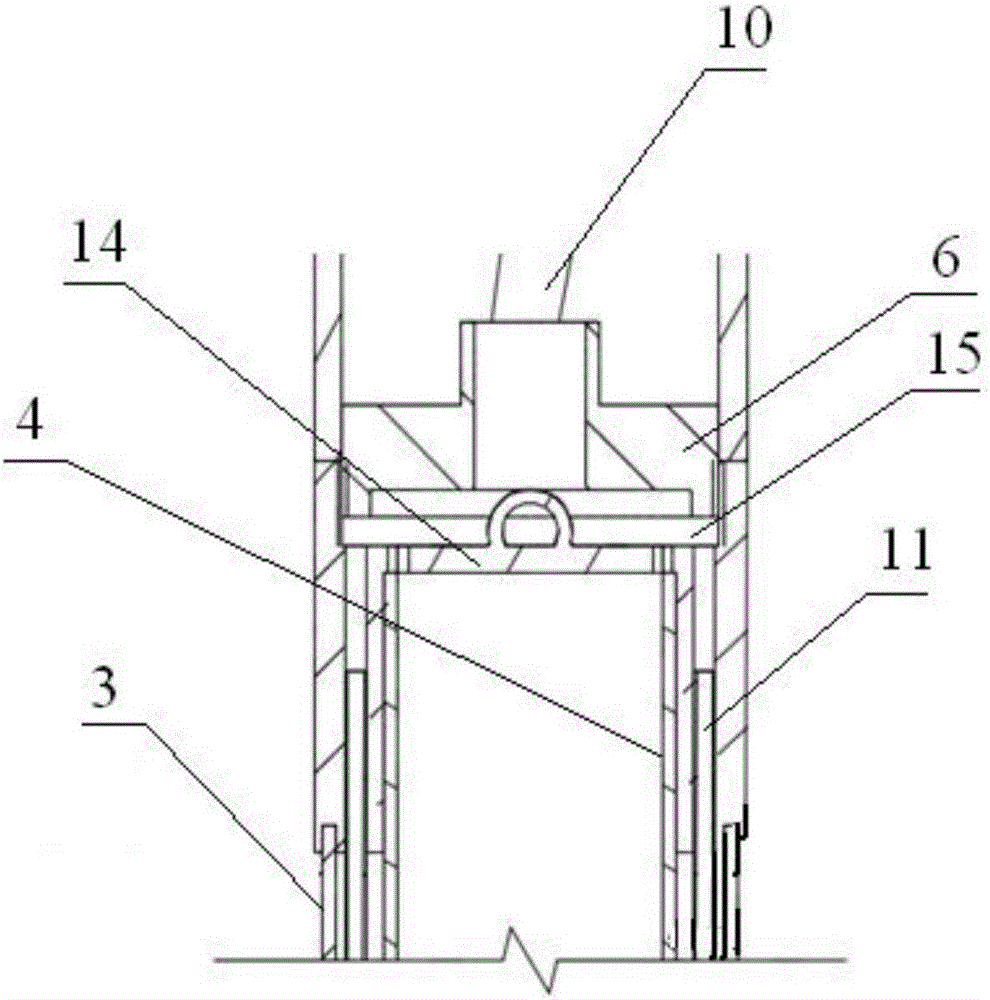

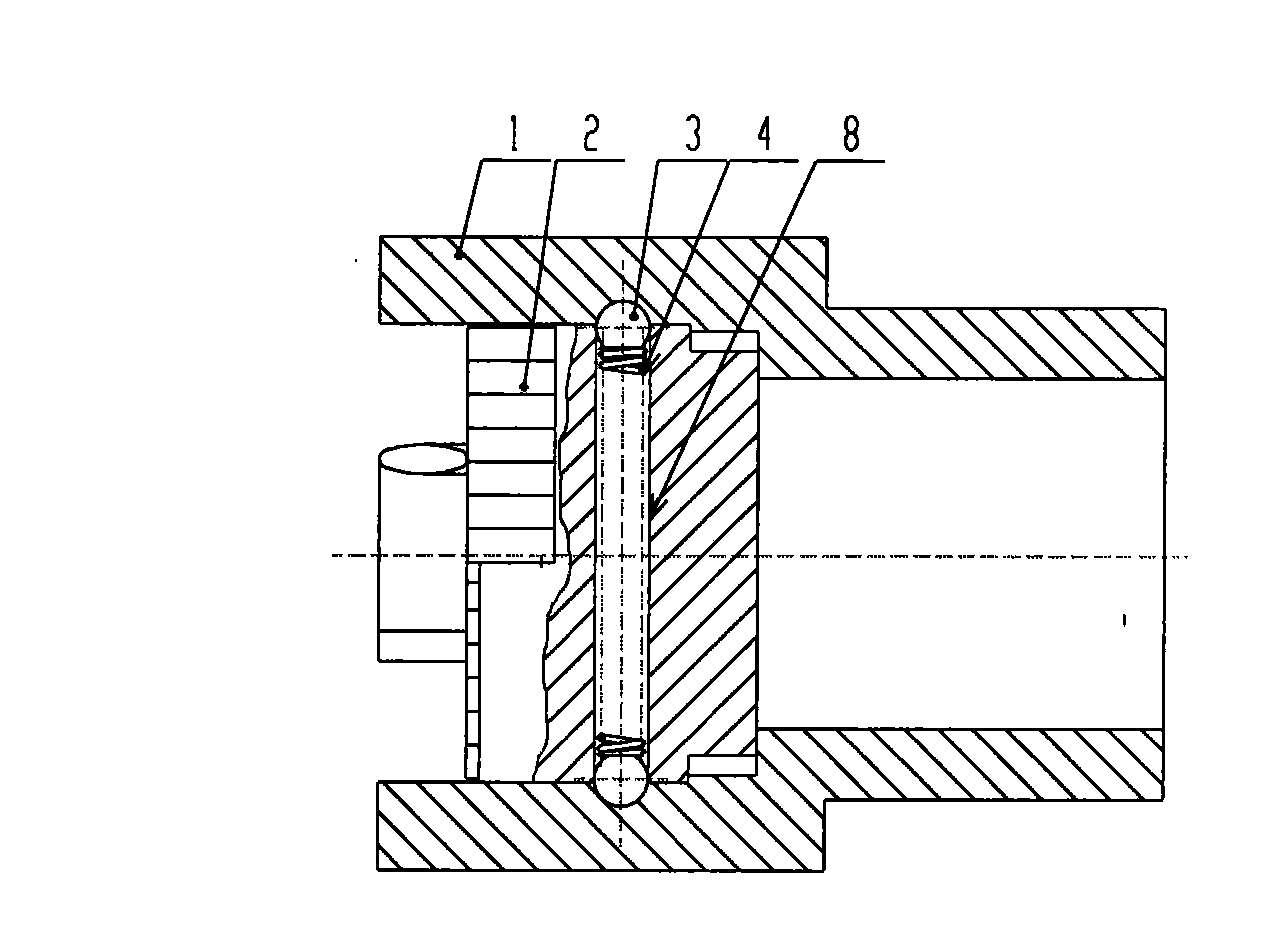

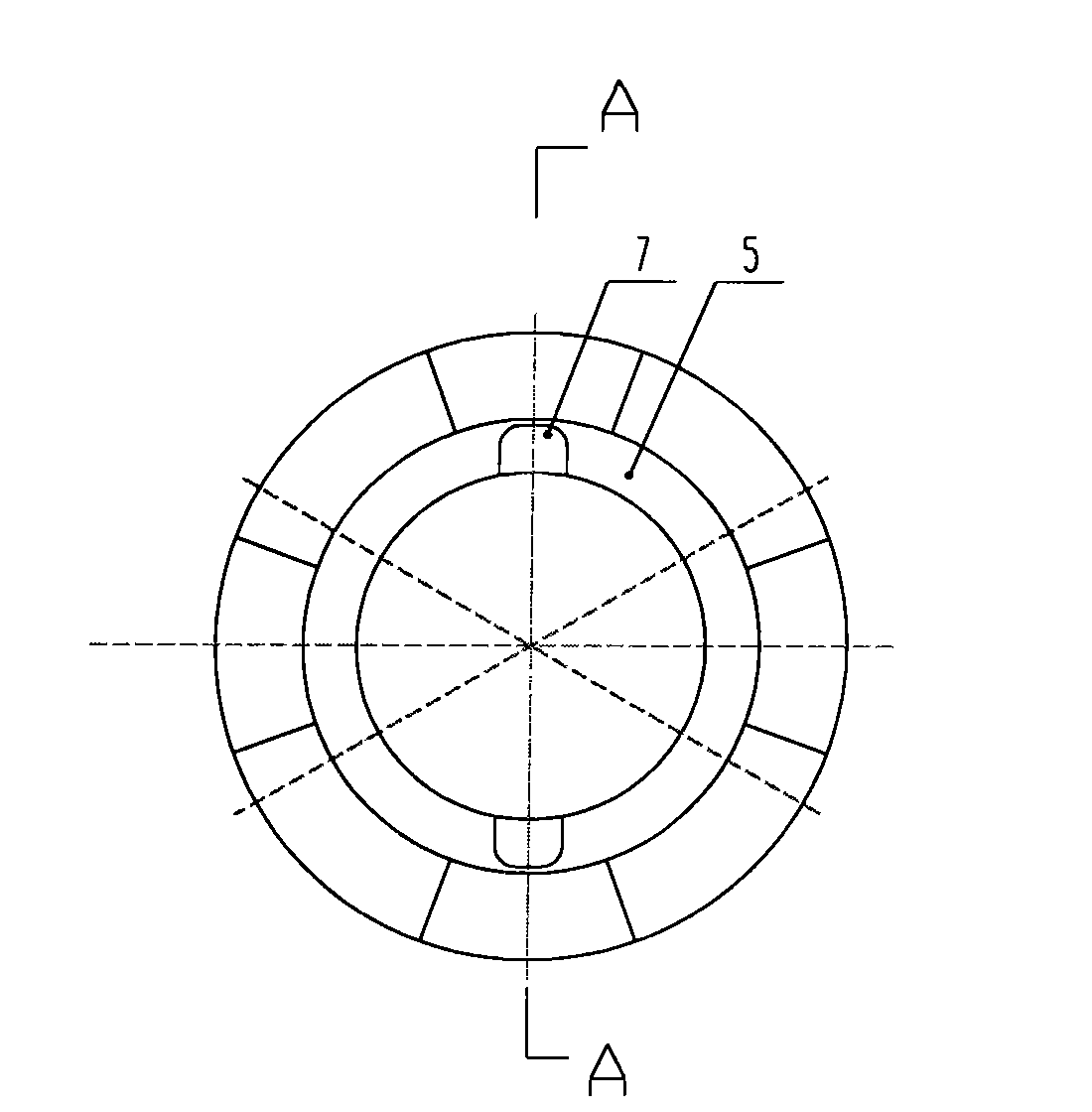

Double-wall spindle power head for core drill

InactiveCN102134964ASuitable for workCompact structureConstructionsFlushingHydraulic motorDouble wall

The invention relates to a double-wall spindle power head for a core drill. The power head comprises an outer box body, a power mechanism, a transmission system, a spindle and a sealing unit, wherein the outer box body consists of a box body assembly and an upper box cover which are positioned by a positioning pin and connected by a screw; the power mechanism is a hydraulic motor or a motor; the transmission system consists of a driving gear shaft and a driven gear; the double-wall spindle consists of a spindle outer tube and a spindle inner tube; the spindle outer tube is connected with the driven gear through a spline; the driving gear shaft and the spindle outer tube, and the box body assembly and the upper box cover are connected through a rolling bearing respectively; a shaft hole and a key groove are reserved on the driving gear shaft and used for connecting the power mechanism; the spindle outer tube is provided with a through hole for washing solution to pass through; a sampler can be stored in a cavity of the spindle inner tube; and the sealing unit comprises a dynamic seal and a static seal. The power head has a compact structure and high sealing property, provides rotary motion, rotary torque and washing solution for the drilling of the drill, and is suitable for underwater and land core drilling; and an orifice is not required to be avoided and a water tap is not required to be disassembled when a core is taken.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

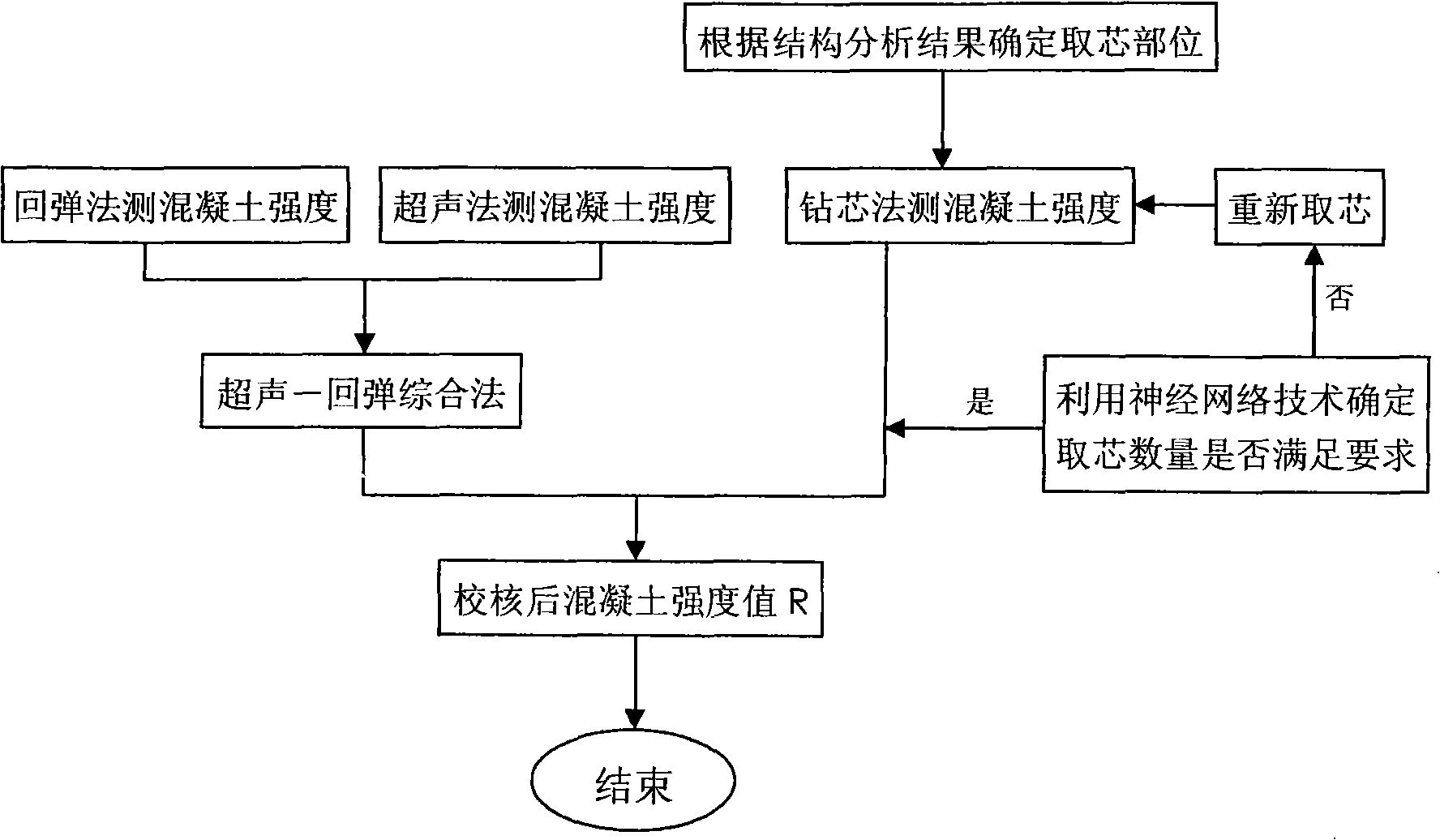

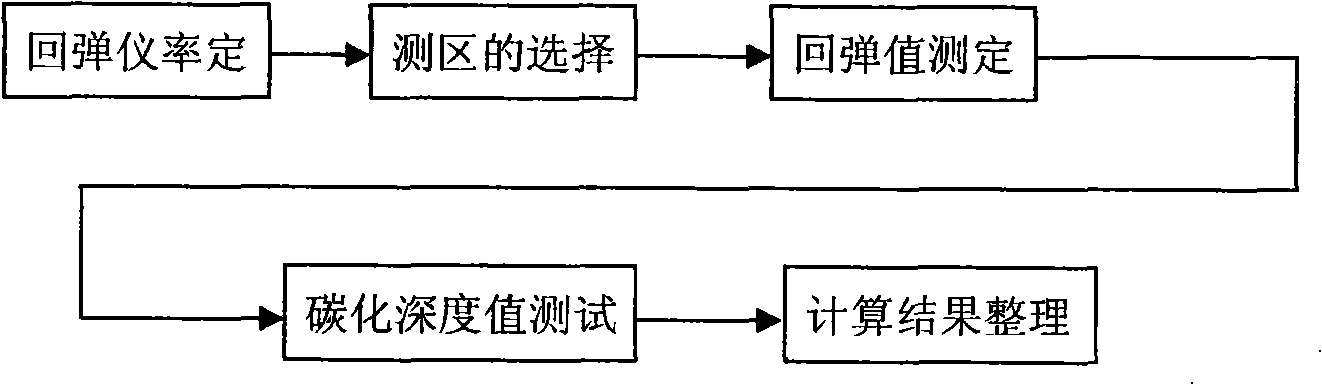

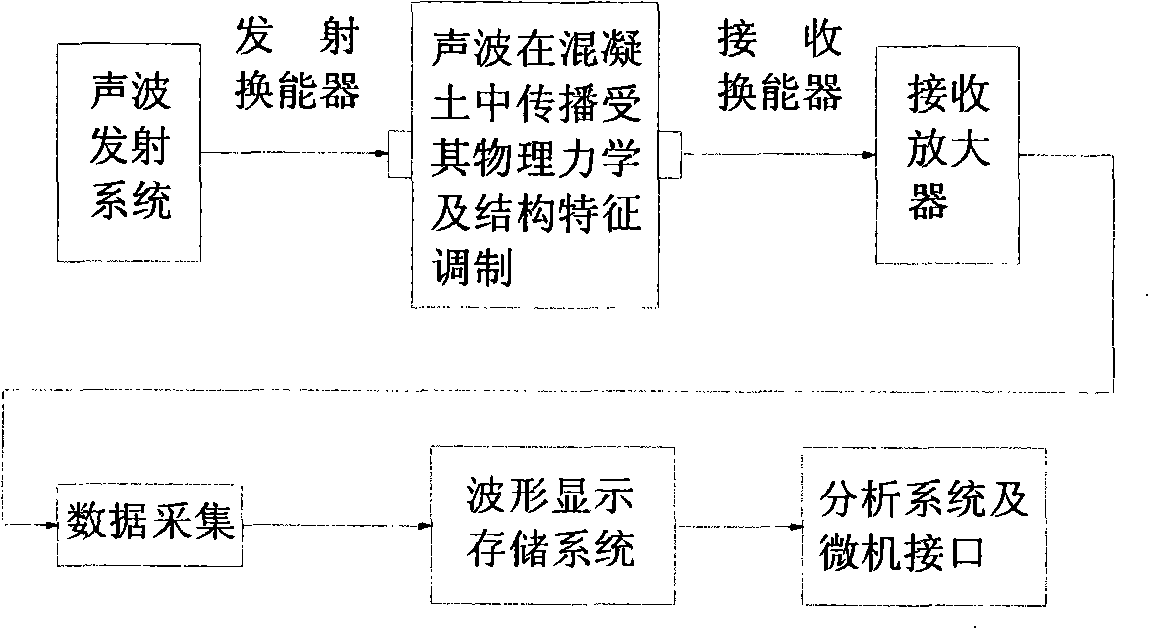

Integrated strength testing method based on neural network technology

InactiveCN101303329AAvoid damageReliable test resultsAnalysing solids using sonic/ultrasonic/infrasonic wavesInvestigating material hardnessOperabilityEngineering structures

The invention relates to a comprehensive strength testing method of the neural network technique, which combines the advantages of three strength testing methods: supersonic, rebounding and core drilling, thus solving various disadvantages of the existing single strength testing technique. The basic principle of the comprehensive strength testing method includes that: firstly, the strength of structural concrete is tested in full dimensions with the supersonic-rebounding comprehensive method, and then the R-N-C benchmark curve is properly corrected by the core drilling method, wherein, the determination of the optimum drilling core number is solved by the neural network technique. Concrete materials are degraded to different extends as large quantity of engineering structures are being influenced by such factors as environmental corrosion and temperature change, and the method of the invention can, on the basis of ensuring accurate and reliable test results, greatly reduce the structural damages caused by the core drilling strength testing method, improve the analysis efficiency and operability of the supersonic-rebounding-core drilling comprehensive strength testing method, so the method of the invention has wide application prospects in the strength testing of various concrete works .

Owner:SOUTHEAST UNIV

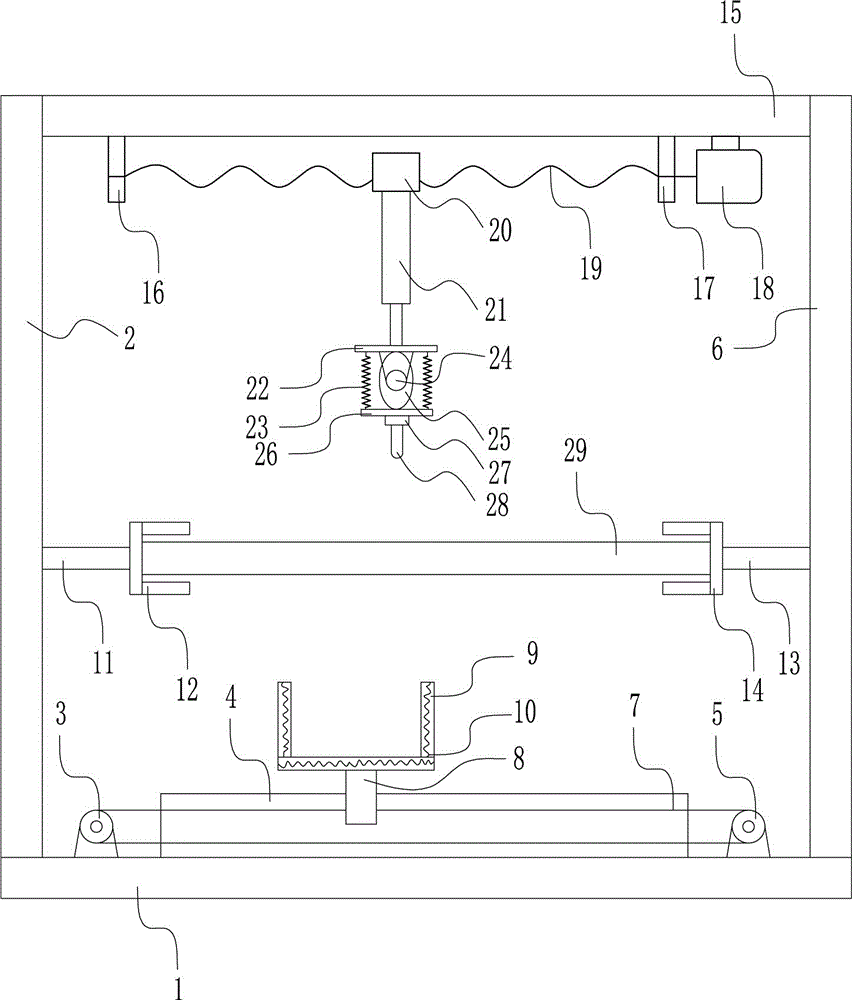

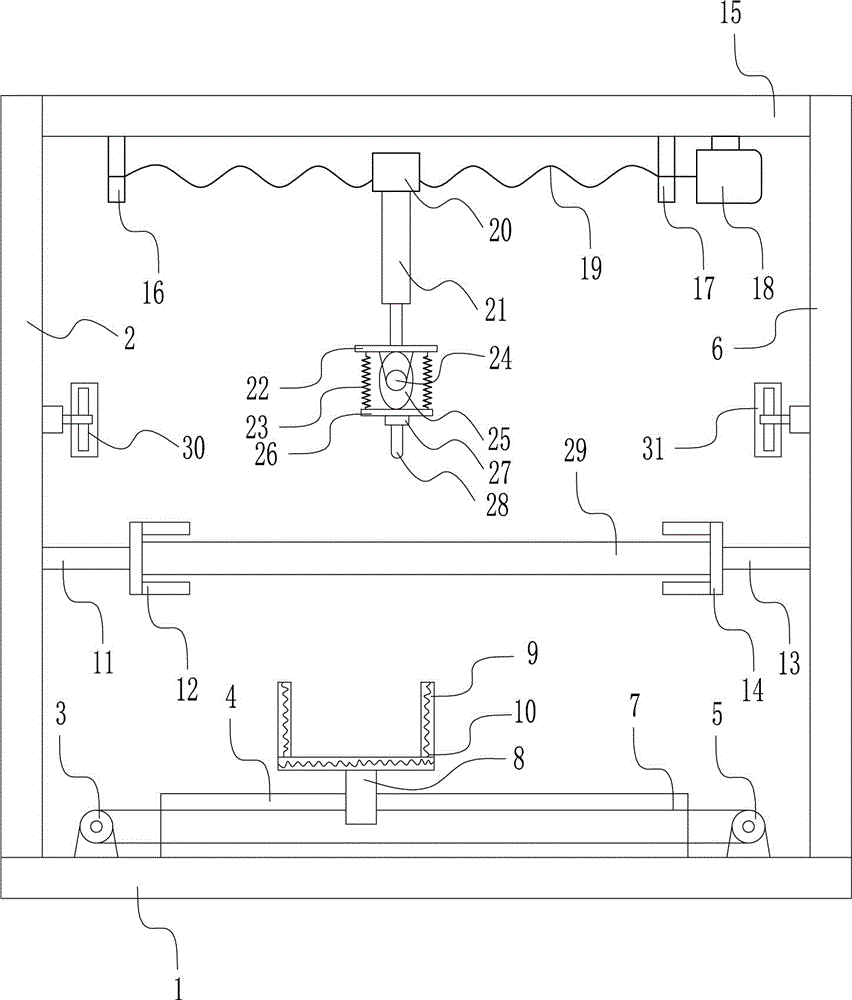

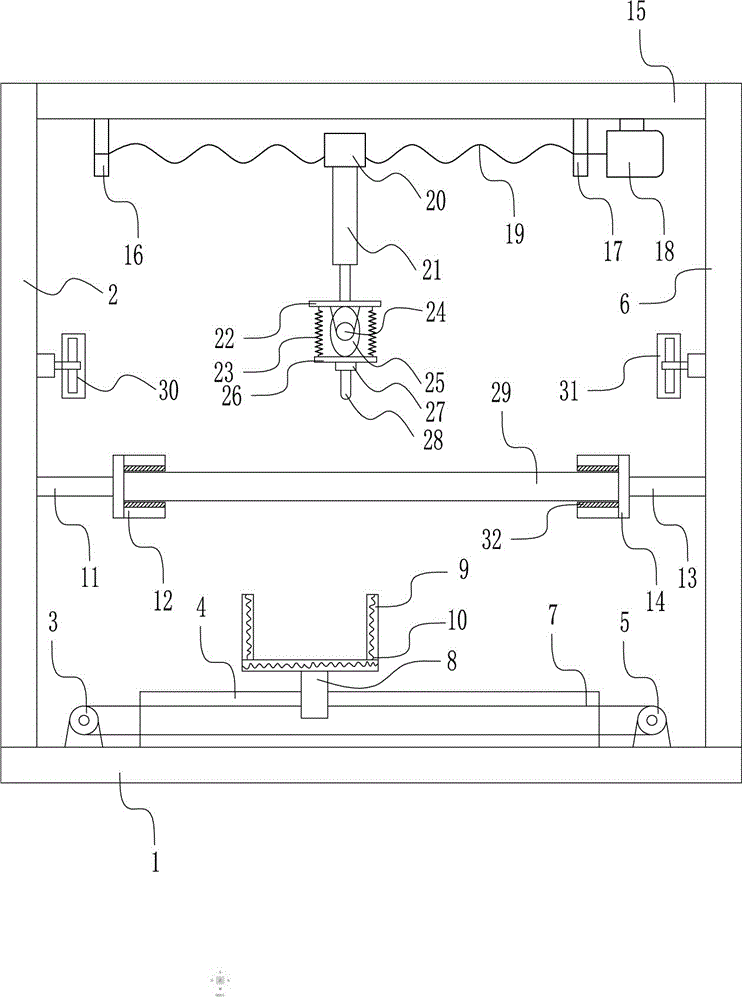

Plastic pipe punching energy-saving device

The invention relates to an energy-saving device, in particular to a plastic pipe punching energy-saving device. The plastic pipe punching energy-saving device can reuse waste plastic blocks, saves resources and is easy to operate. The plastic pipe punching energy-saving device comprises a bottom plate, a left supporting rod, an electric wheel, a sliding rail, a driven wheel, a right supporting rod, a pull wire, a slider, a collection box, an electric heating wire, a connection rod I, a thumb cylinder I, a connection rod II, a thumb cylinder II, a top plate I, a left bearing block, a right bearing block, a motor I, a lead screw, a nut, an electric push rod, a top plate II, springs, a motor II, a cam, a push plate, a motor III and a hollow drill bit. The left supporting rod, the electric wheel, the sliding rail, the driven wheel and the right supporting rod are sequentially arranged on the top of the bottom plate from left to right. The device has the effects that waste plastic blocks can be reused, resources are saved and operation is easy.

Owner:王勇

Self-connecting type and high-strength seamless steel tube for rope coring drill rod, as well as manufacturing method thereof

InactiveCN103276297AIntrinsic Quality GuaranteeReduce surface cracksDrilling rodsMetallic material coating processesCoringSteel tube

The invention relates to a self-connecting type and high-strength seamless steel tube for a rope coring drill rod. The seamless steel tube is characterized by comprising components in percentage by weight as follows: 0.38%-0.43% of C, 0.17%-0.35% of Si, 0.70%-0.90% of Mn, P smaller than or equal to 0.015%, S smaller than or equal to 0.010%, 090%-1.10% of Cr, 0.15%-0.25% of Mo. Cu smaller than or equal to 0.10%. Ni smaller than or equal to 0.10%, AS smaller than or equal to 0.015%, Sn smaller than or equal to 0.015%, Sb smaller than or equal to 0.010%, Pb smaller than or equal to 0.008%, Bi smaller than or equal to 0.010%, and the balance of Fe. The seamless steel tube has high strength. The invention further relates to a manufacturing method of the seamless steel tube.

Owner:浙江新纪元管业科技有限公司

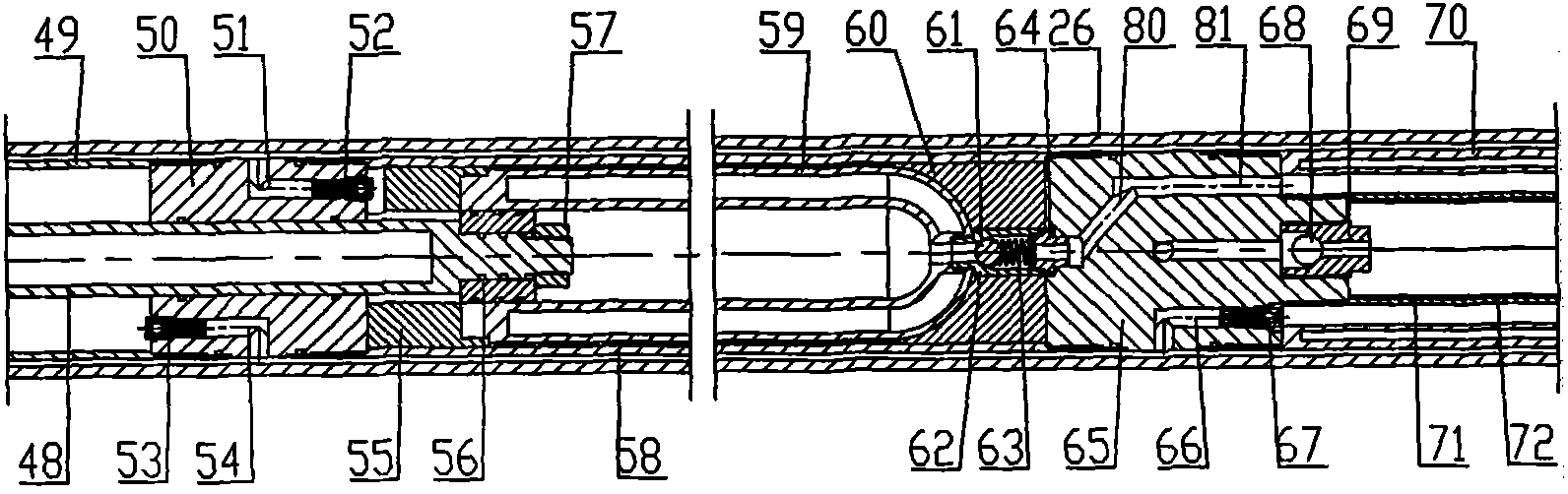

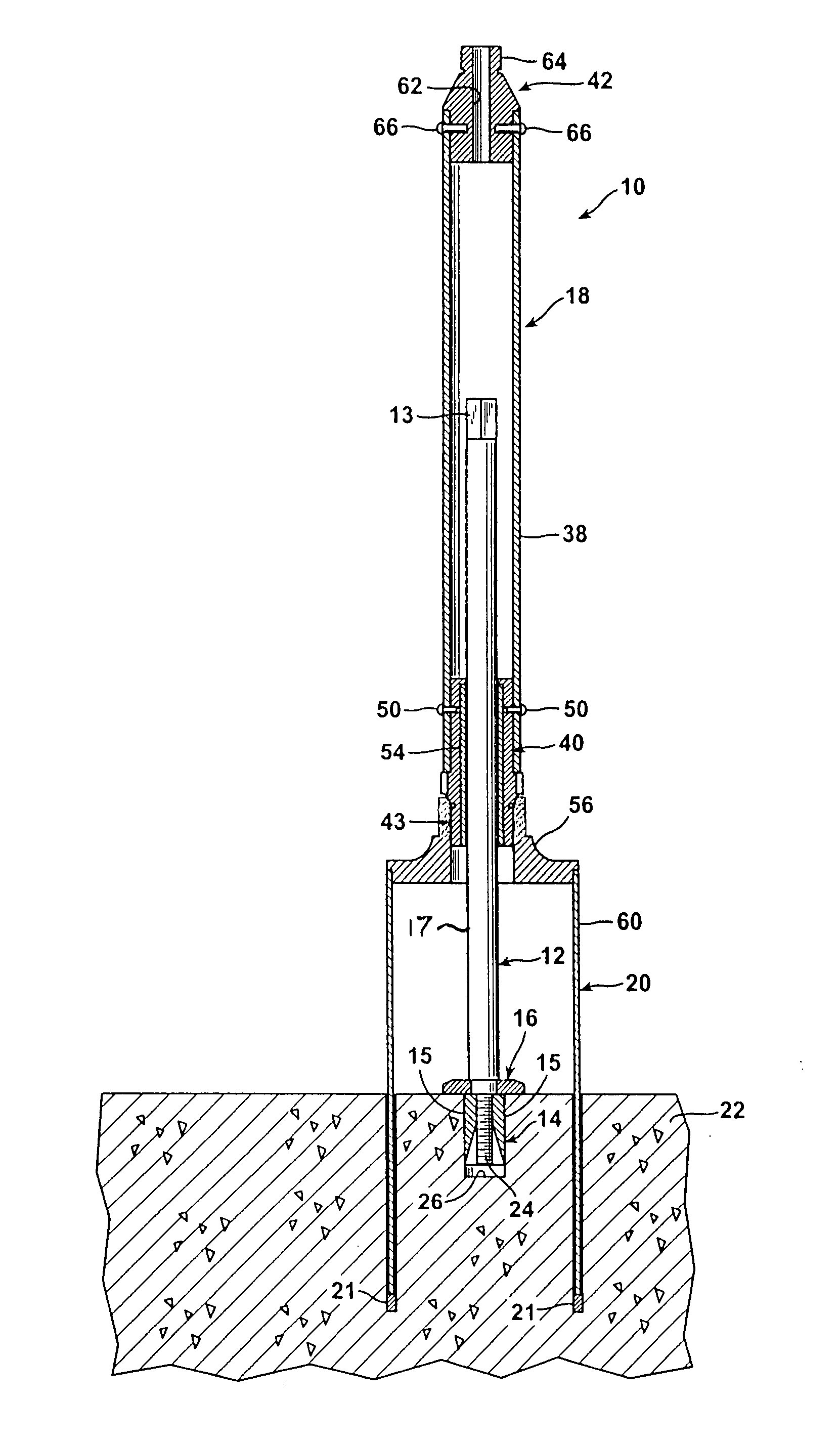

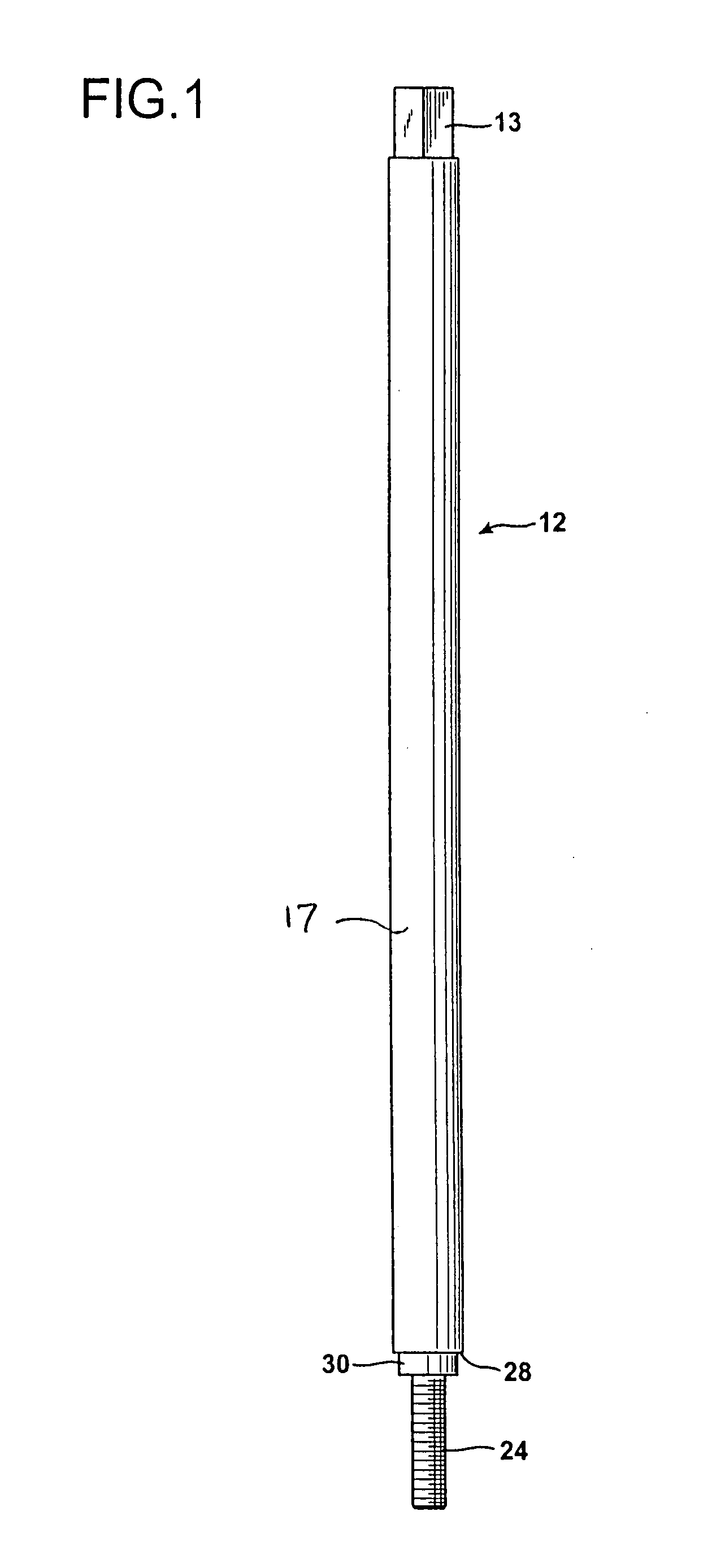

Remote operation wire line core sampling device

InactiveUS20060169493A1Easy to operateImprove sampling qualityEarth drilling toolsDrill bitsEngineeringSea bottom

A remote operation wire line core sampling device capable of increasing the efficiency of working and maintaining the wall of a hole by using a stabilized sea-bottom core drill at a sea-bottom and adopting a wire line system, comprising a drill rod held by the chuck of the sea-bottom core drill, a wire line core barrel having, at the tip thereof, a bit for annularly drilling a ground, an inner tube assembly detachably incorporated in the wire line core barrel, and an over-shot assembly (5) having a function for the engagement thereof with a spear head part at the top end of the inner tube assembly. The device also comprises a water swivel (18) in which water supply ports (3) and (4) are formed at the upper and lower parts thereof and a modified built-in type over-shot assembly (4) are formed at the upper and lower parts thereof and a modified built-in type over-shot assembly (5) is incorporated therein so as to reside at the intermediate part thereof.

Owner:MITSUI ENG & SHIPBUILD CO LTD +2

Hot water core drill used at glacier

The invention discloses a hot water core drill used at a glacier. The hot water core drill comprises a plunger pump, a two-way pipe, a heat insulation pipe, an ice core pipe, a drill bit and a flower divider, wherein the plunger pump is arranged in a pump storage pipe, the upper end of the plunger pump is connected with a water outlet pipe, the lower end of the plunger pump is connected with a water absorption pipe, the two-way pipe is connected to the lower end of the pump storage pipe, the lower end of the two-way pipe is connected with the heat insulation pipe, the ice core pipe is inserted in the heat insulation pipe, the drill bit is arranged below the heat insulation pipe and the ice core pipe, the flow divider is arranged on the lower portion of the two-way pipe and at the top end of the ice core pipe, the top end of the flow divider is connected with a hot water injection pipe, the lower portion of the flow divider is connected with a plurality of drainage pipes which are arranged in a gap between the heat insulation pipe and the ice core pipe, and hot water injected by the hot water injection pipe at the top end of the flow divider is injected into the drainage pipes through the flow divider. The hot water core drill has the advantages that due to the fact that the hot-melting drill bit is adopted for tapping and drilling of the hot water drill, and molten water is extracted to serve as a raw material of the hot water drill, cost is reduced, and the energy utilization rate is increased.

Owner:JILIN UNIV

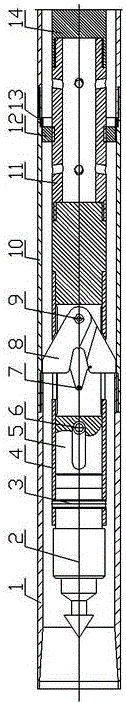

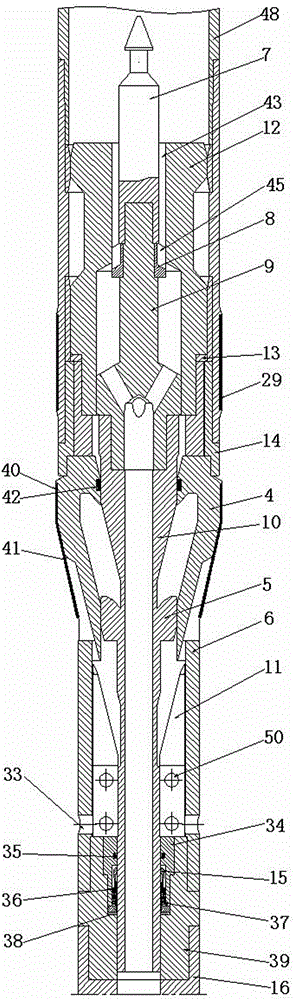

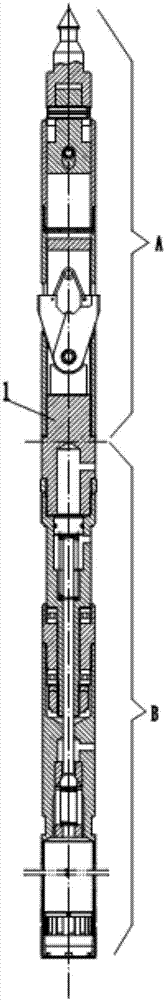

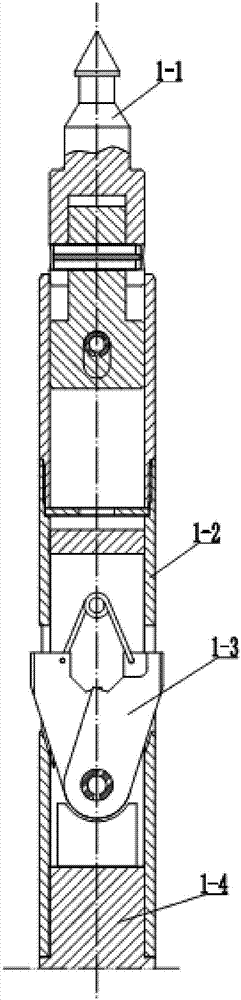

Casing coring drill and casing coring drilling method

InactiveCN103603625AImplementation checkAchieve replacementDrill bitsCore removalGeological explorationCoring

The invention discloses a casing coring drill applied to a core drilling project in geological exploration, and a casing coring drilling method. The casing coring drill is a hole bottom drilling device for carrying out coring drilling without lifting the drill to replace a drilling bit, and is mainly composed of an inner pipe drill capable of feeding and fishing and an outer pipe drill connected with a casing. The casing coring drilling method is characterized by comprising the following main process flows: replacing an inner hole drill stem with the casing; drilling for coring; fishing with a core; inspecting or replacing the drilling bit; feeding a coring drill; and lifting an inner pipe drill so as to finish the casing drilling operation. The casing coring drilling method disclosed by the invention adopts the casing instead of the drill stem to transfer drilling loads. The coring drilling without lifting the drill to replace the drilling bit is carried out by the casing coring drill, and running casing along with the drill is achieved; drilling is quickly and effectively achieved, and reaches the expected hole depth as a complex formation or the casing is isolated. Thus, the technical problems including but not limited to coring drilling of the complex formation are solved.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

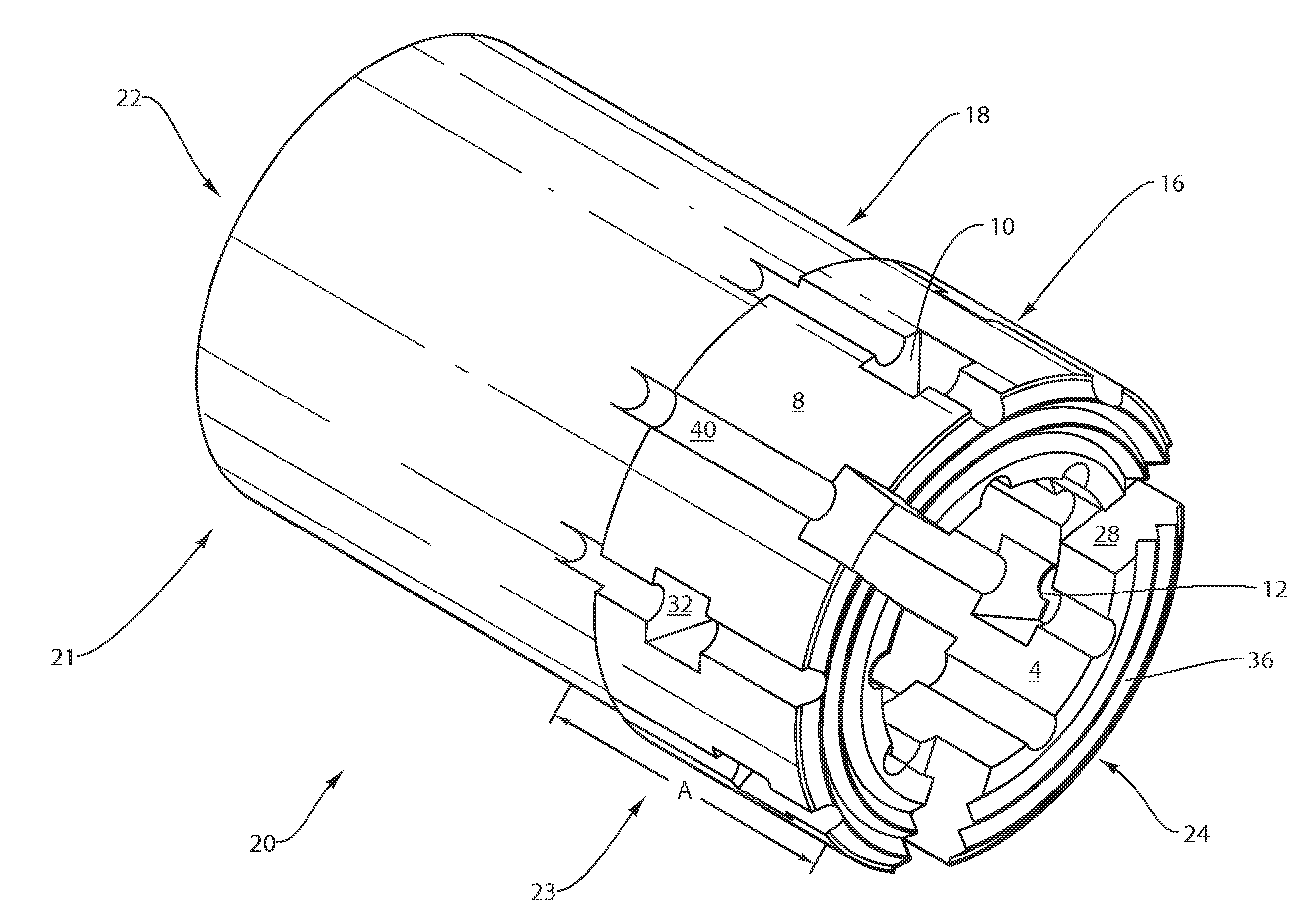

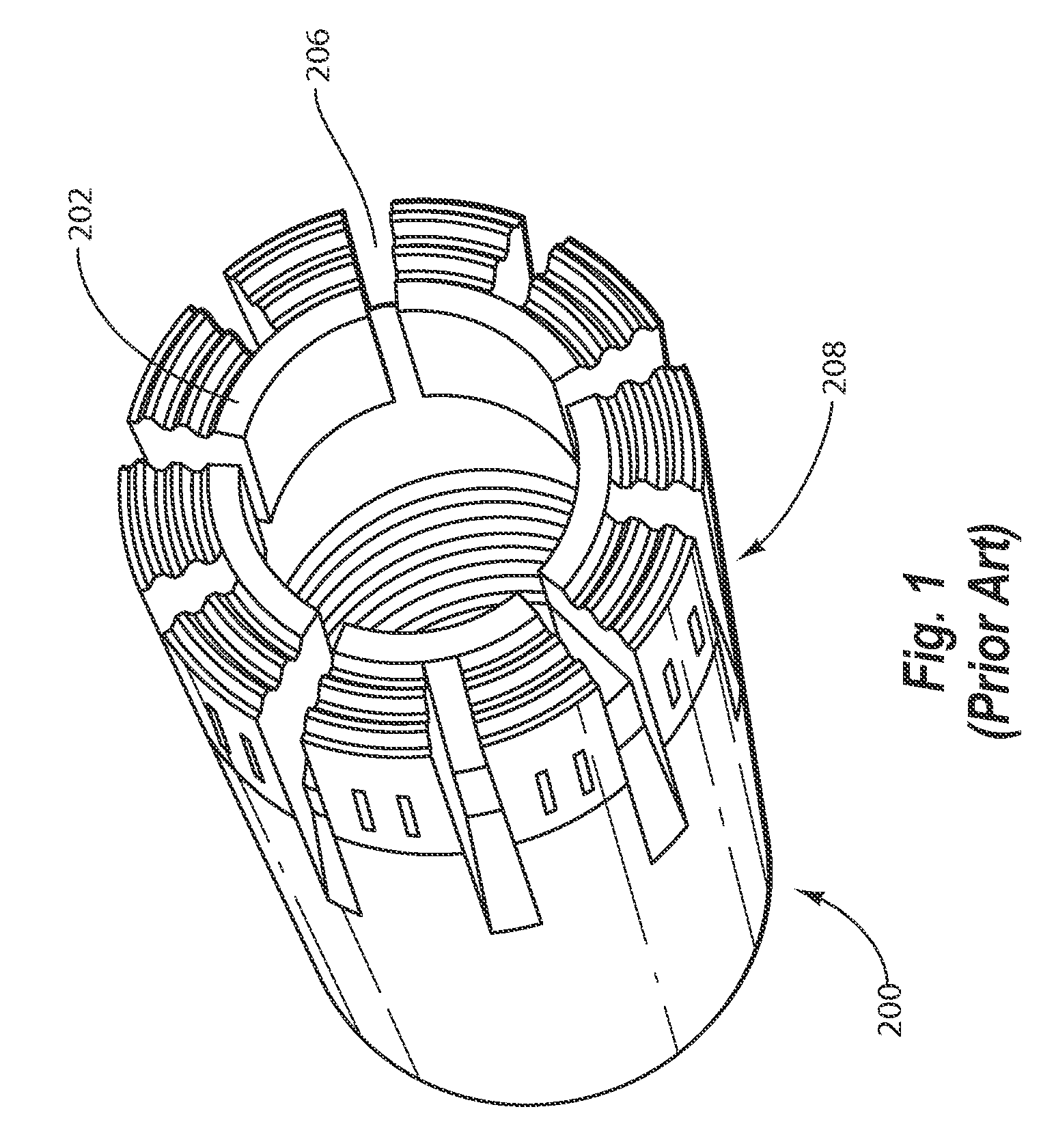

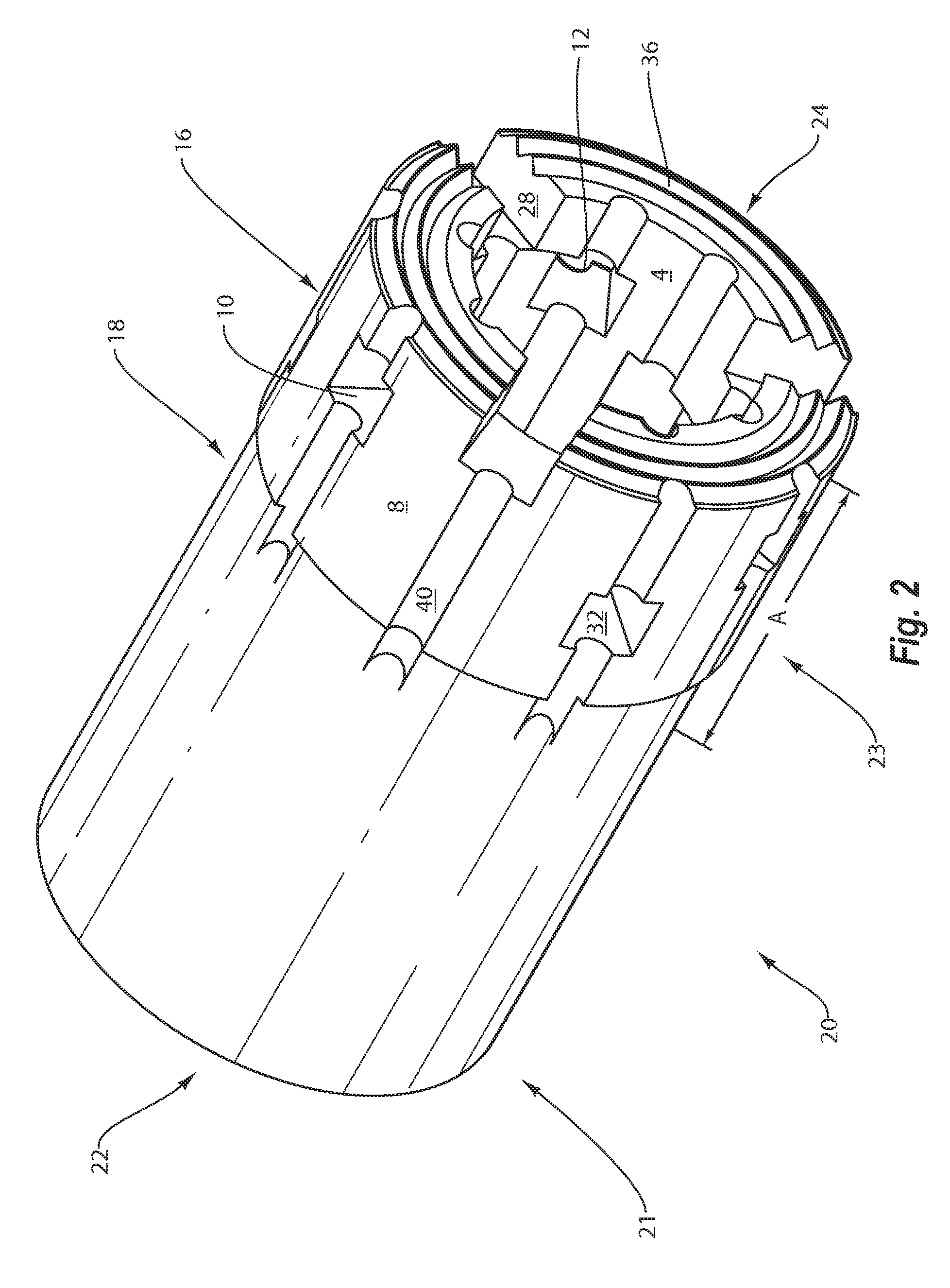

Drill bits with enclosed fluid slots and internal flutes

ActiveUS20100006344A1Reduce their structural integrityLess trippingDrill bitsCutting machinesFluteEngineering

Core drill bits with long crown heights are described herein. The core drill bits have a series of slots or openings that are not located at the tip of the crown and are therefore enclosed in the body of the crown. The slots may be staggered and / or stepped throughout the crown. As the cutting portion of the drill bit erodes through normal use, the fluid / debris notches at the tip of the bit are eliminated. As the erosion progresses, the slots become exposed and then they function as fluid / debris ways. This configuration allows the crown height to be extended and lengthened without substantially reducing the structural integrity of the drill bit.

Owner:LONGYEAR TM

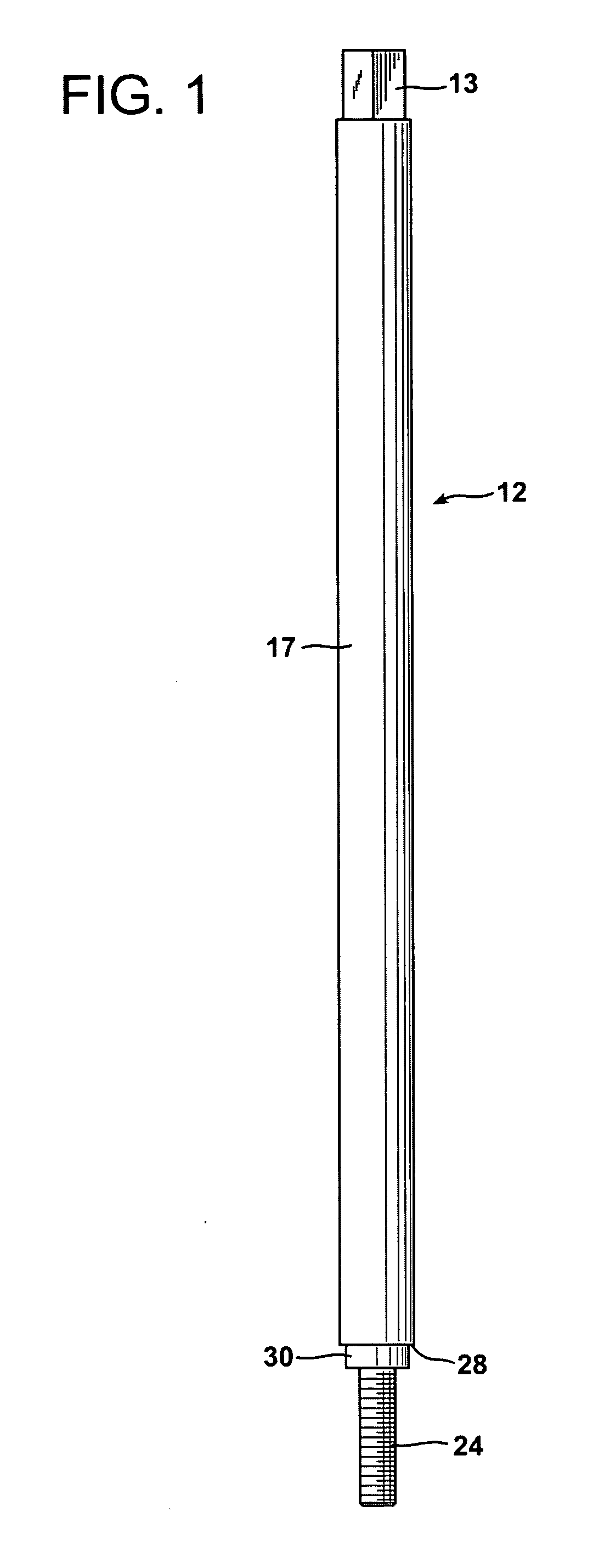

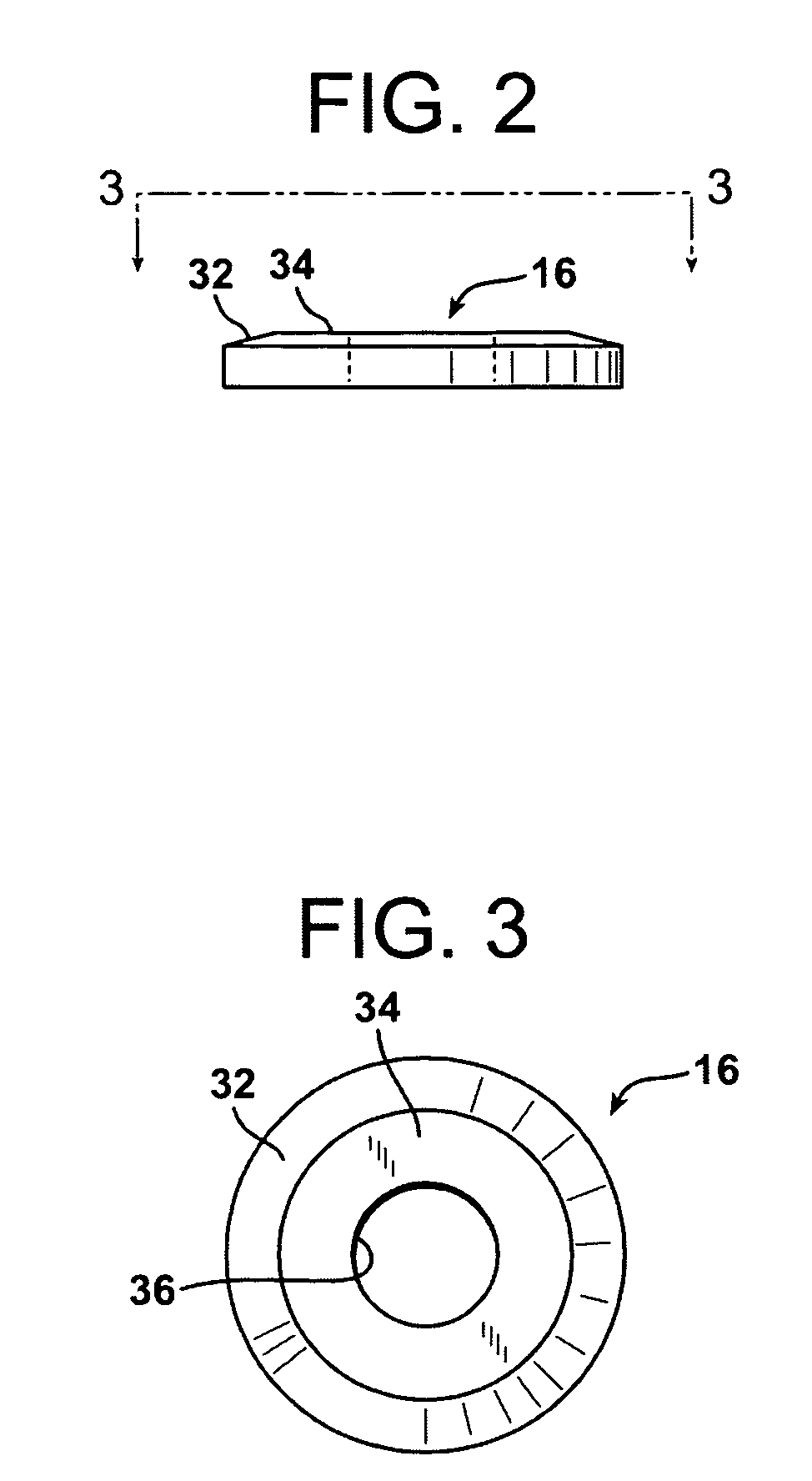

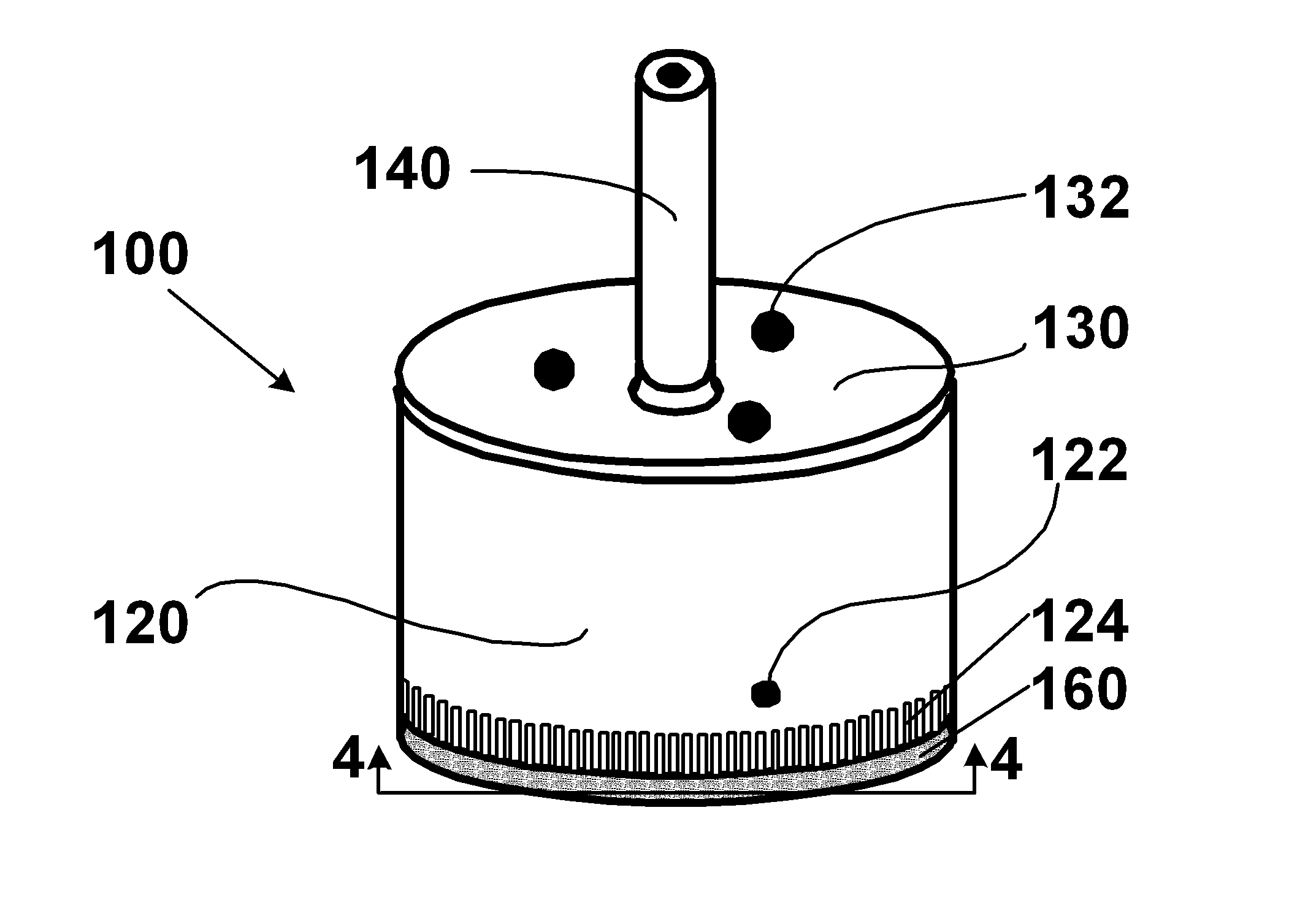

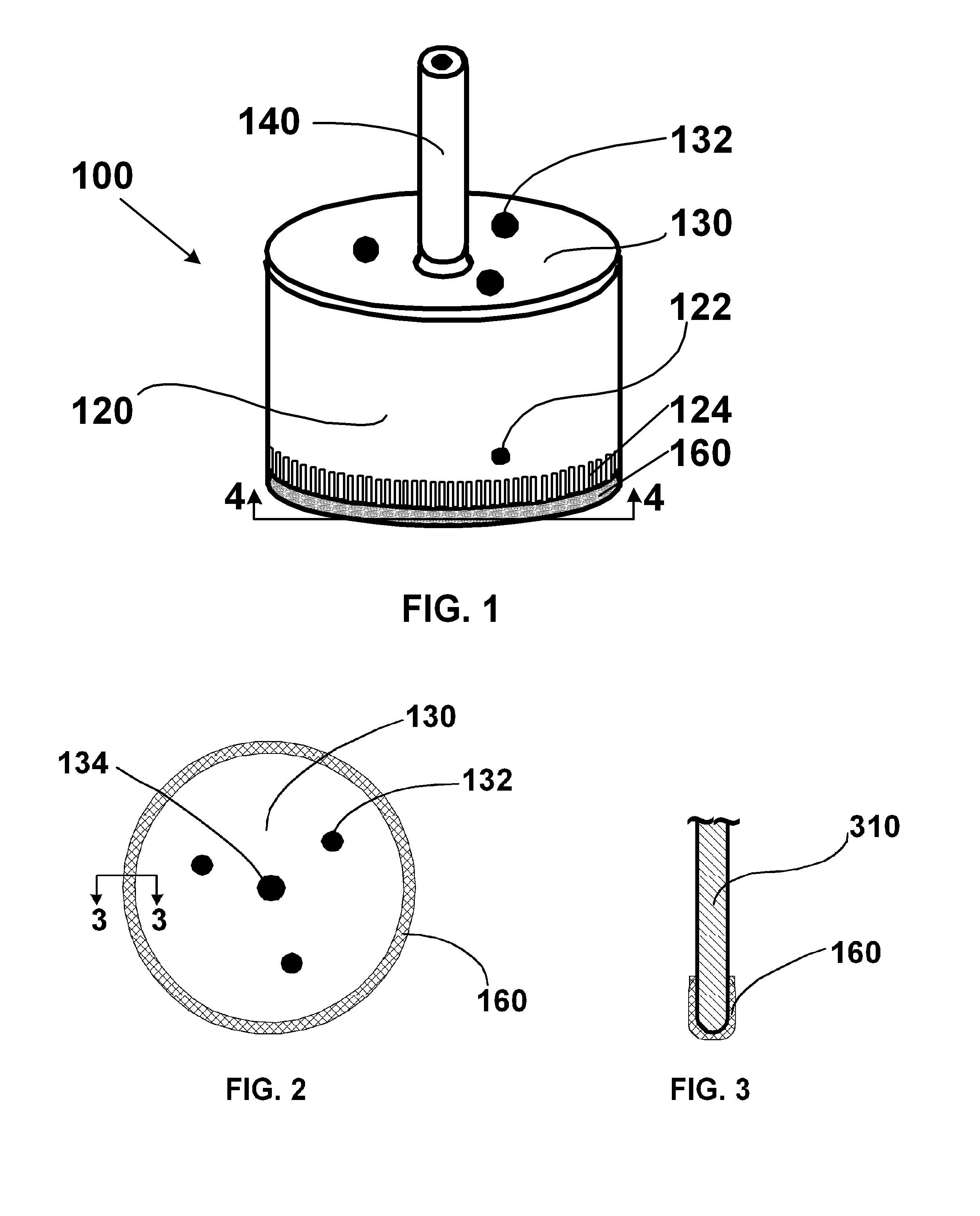

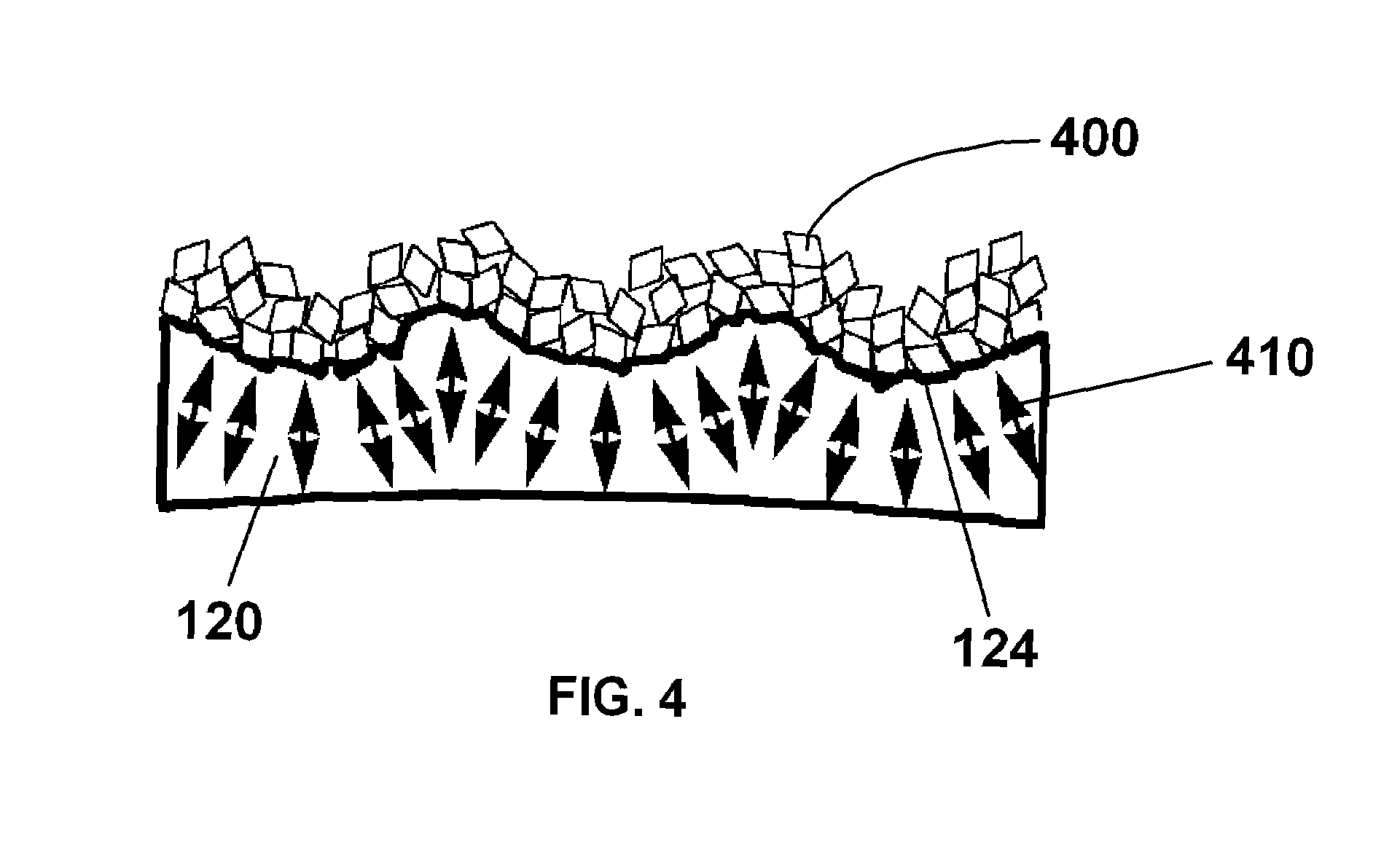

Diamond core drill bit

ActiveUS7204244B1Improve drilling efficiencyReduce wasteRevolution surface grinding machinesHoning machinesDrive shaftLubrication

A diamond core drill bit (100) is disclosed. The drill bit has a right-circular cylindrical body (120) with at least one side lubrication hole (122) toward the bottom of the body and a plurality of parallel grooves (124) oriented in an axial direction at the bottom circumferential sidewall of the body. A cap (130) at the top of the cylindrical body (120) closes one end of the body. The cap has a central lubrication hole (134) and alternative embodiments have at least one core extraction hole (132). These holes extend through the cap to the interior of the body. A hollow drive shaft (140) is mated to the cap (130) over the central lubrication hole (134), such that a lubricant can flow through the hollow shaft and into the internal volume of the body and out a side lubrication hole (122). Diamond grit (160) is bonded around the bottom edge on a portion of the internal and external sidewall surfaces at the bottom circumferential edge of the body (120) in such a way that the diamond grit (160) is bonded over a portion of the axial height of the grooves (124).

Owner:LUMINARE SUPPLY CORP

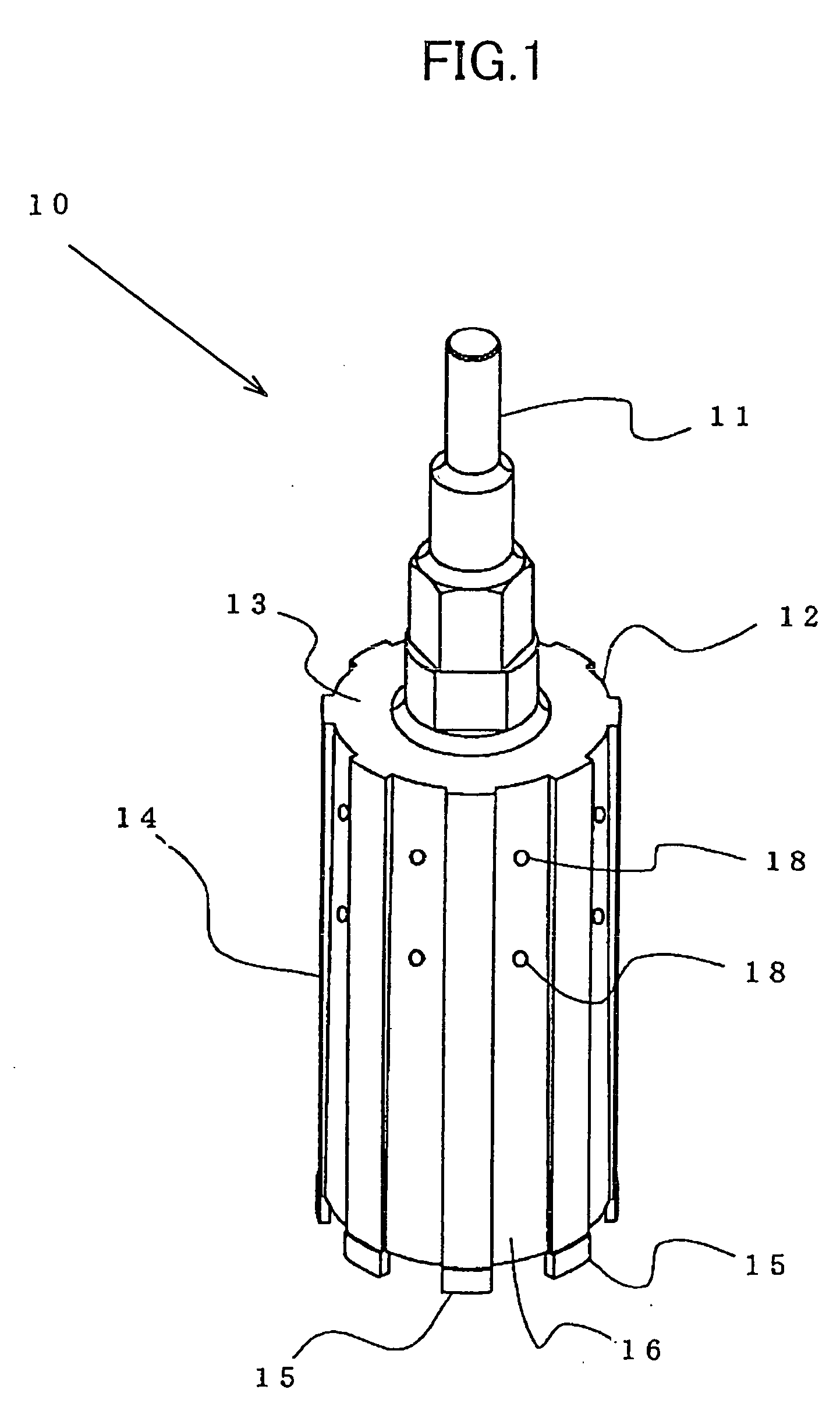

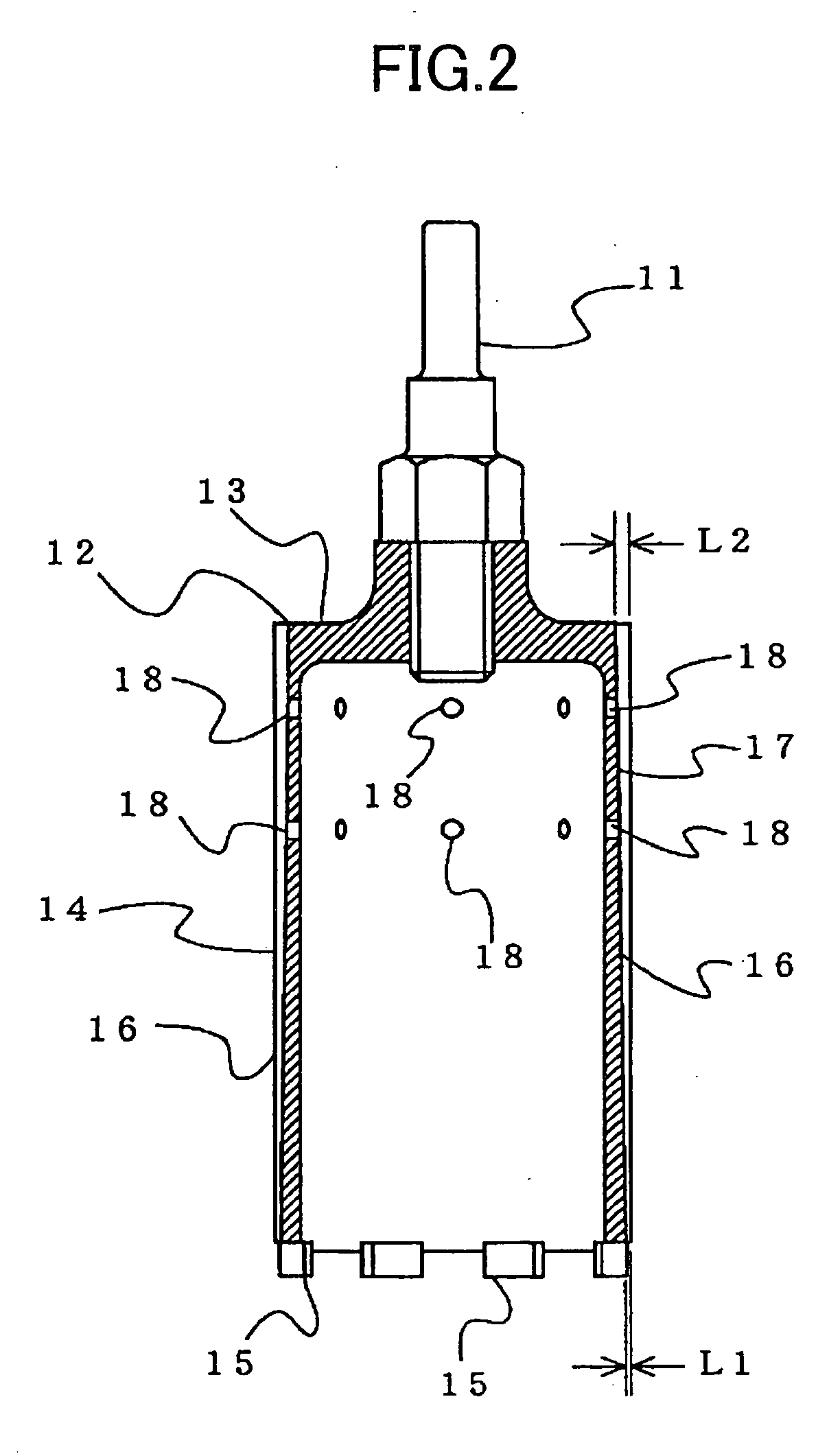

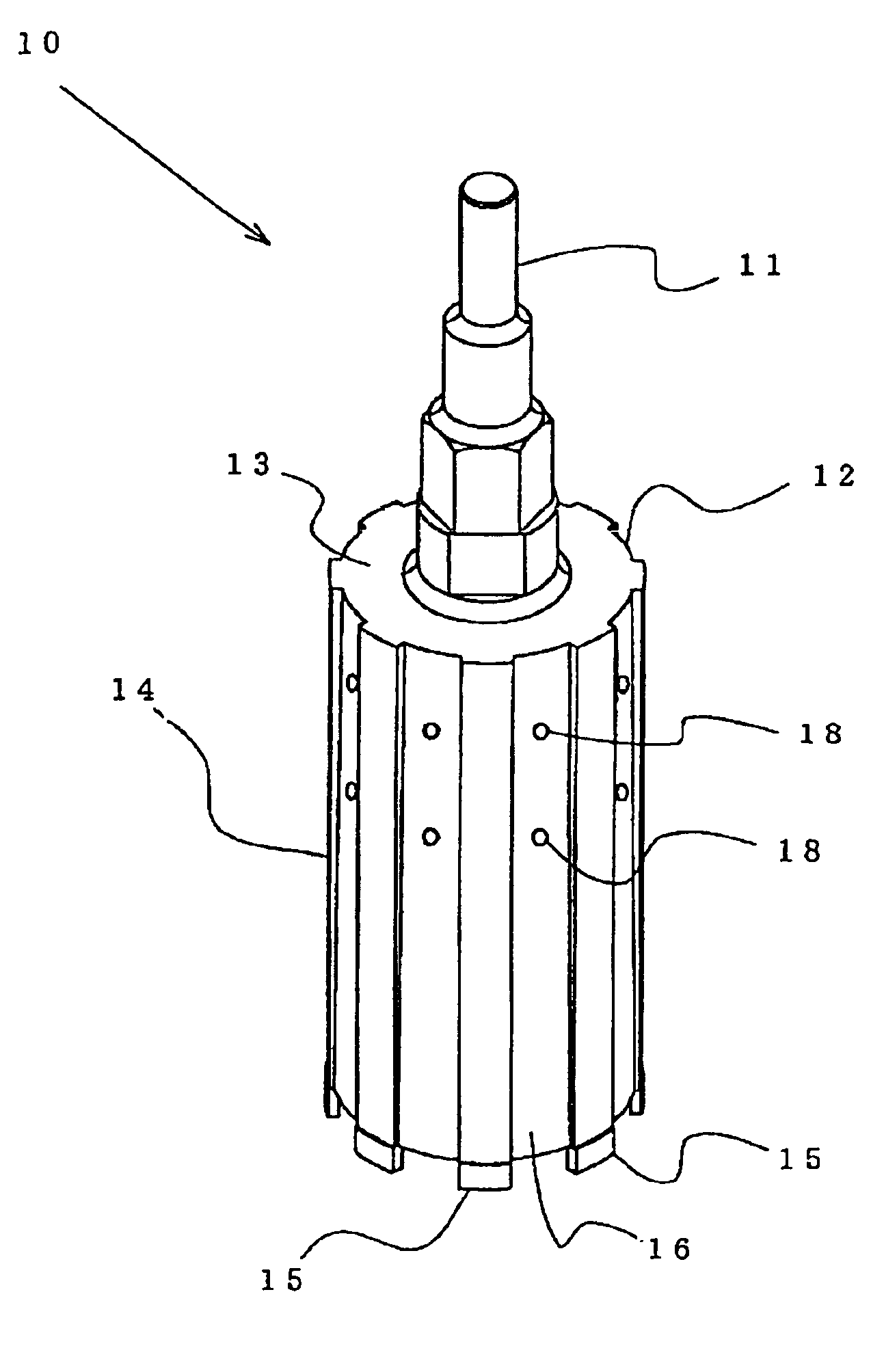

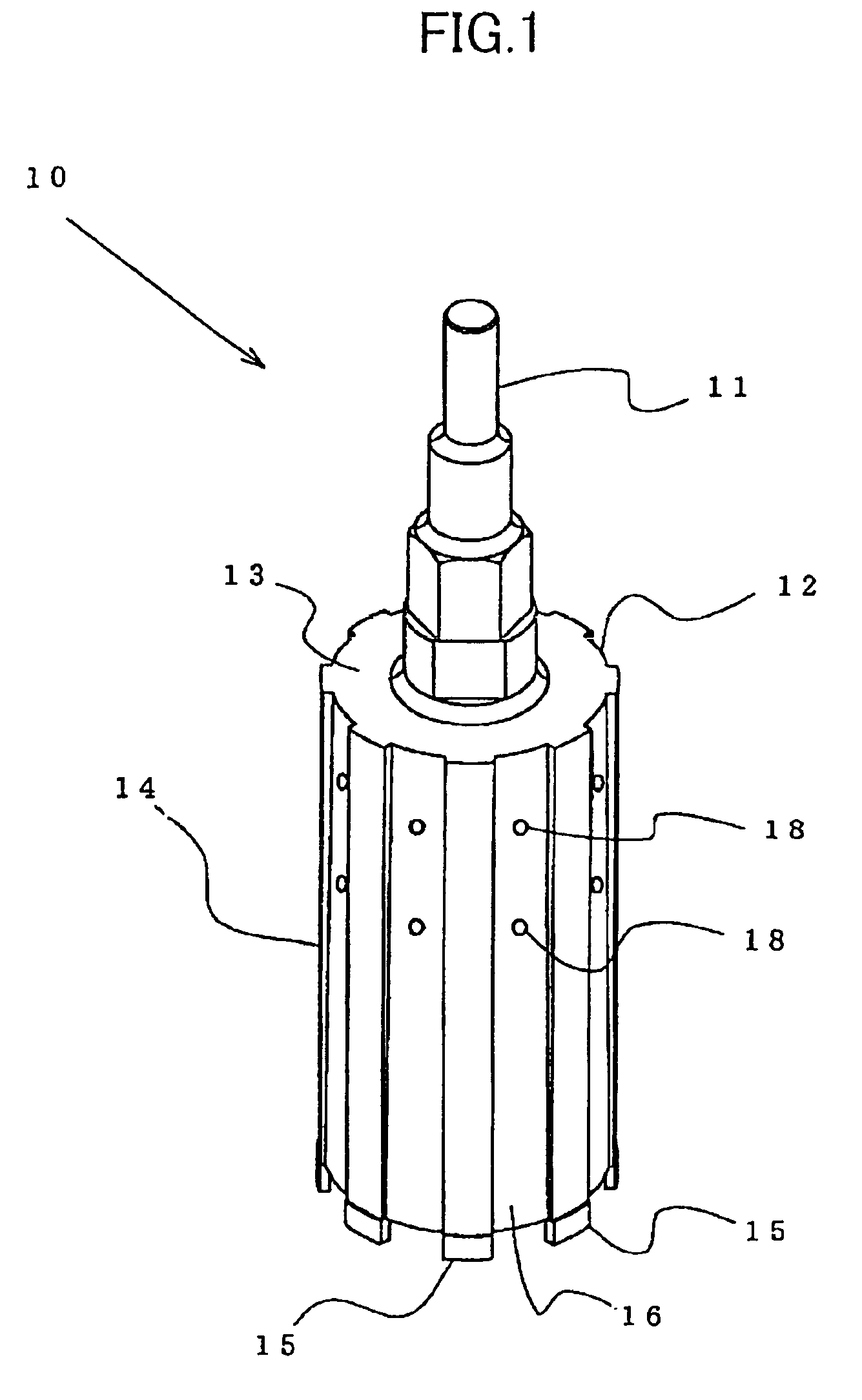

Core drill

InactiveUS6945339B2Reduce frictional resistanceLow costDrill bitsDrilling rodsRotational axisEngineering

A plurality of chip evacuating grooves (16, 26, 36, 46a, 46b) in a vertical direction in parallel with a rotational axis of a core main body (14) are formed at an outer peripheral face of the core main body (14) in a circumferential direction from a lower end portion to an upper end portion of the core main body (14) in a cylindrical shape provided with a drilling blade (15) at a lower end edge thereof. Further, a sectional area of the chip evacuating groove (16) is formed to gradually increase from a lower end to an upper end of the core main body (14). Further, a number of projections (52, 62, 70, 72) are formed at the outer peripheral face of the core main body (14) between the chip evacuating grooves.

Owner:MAX CO LTD

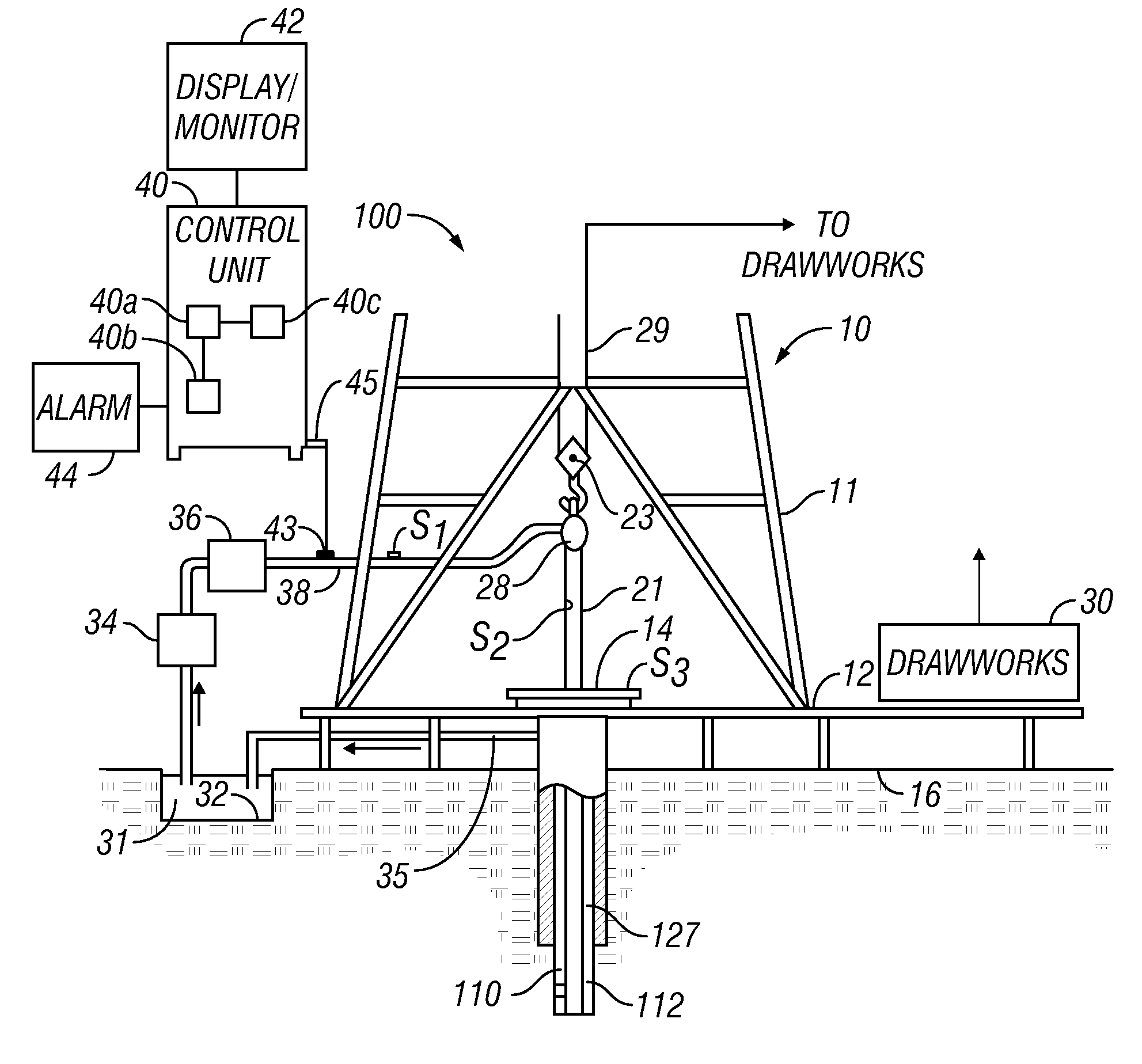

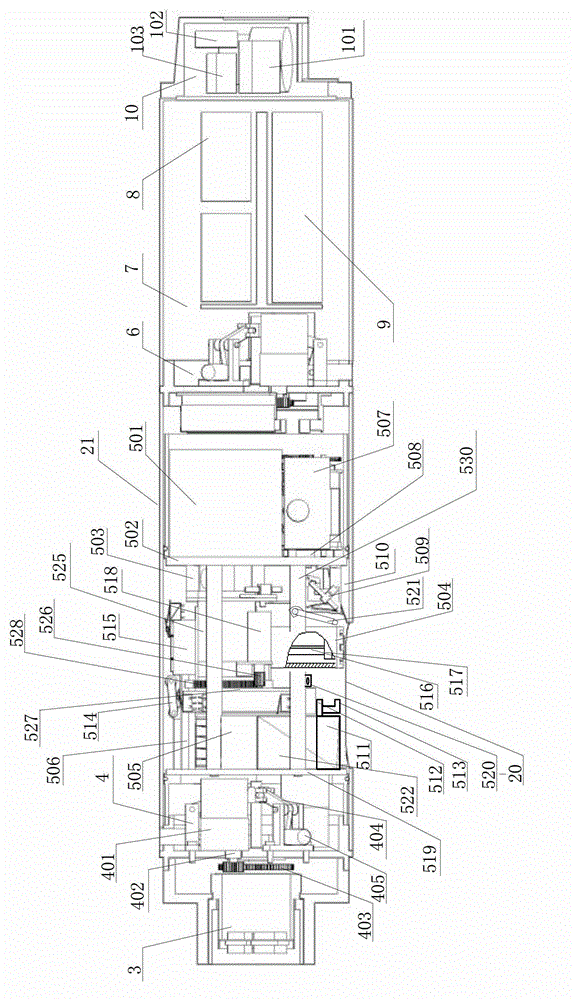

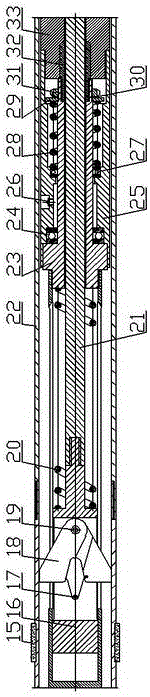

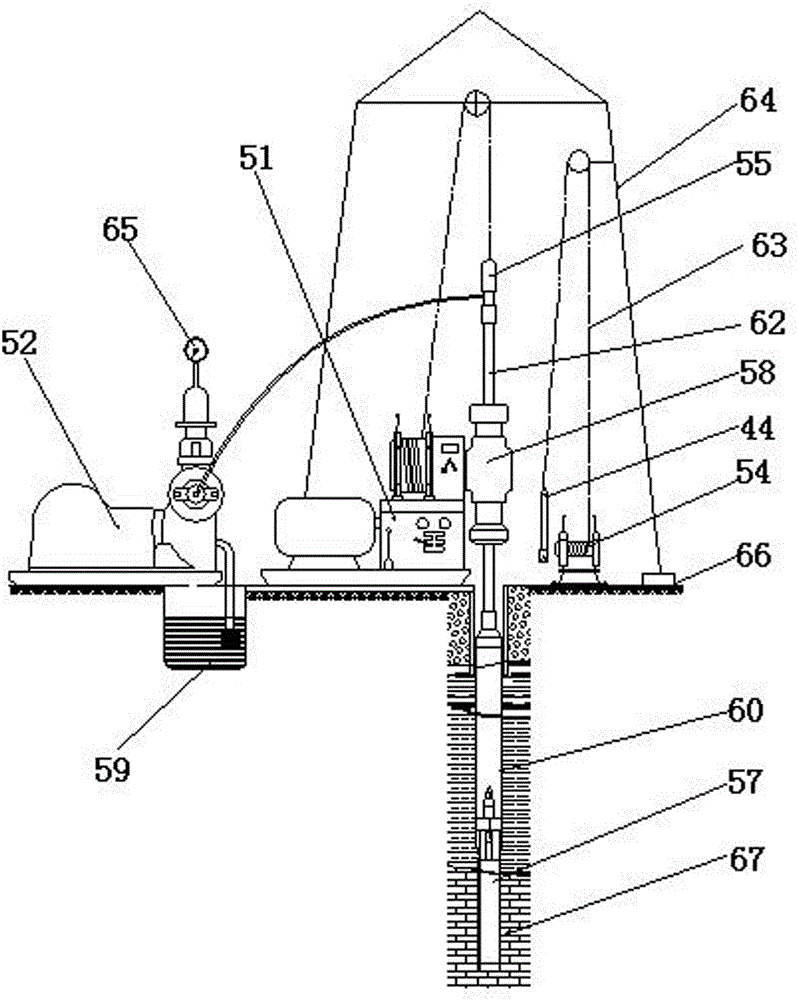

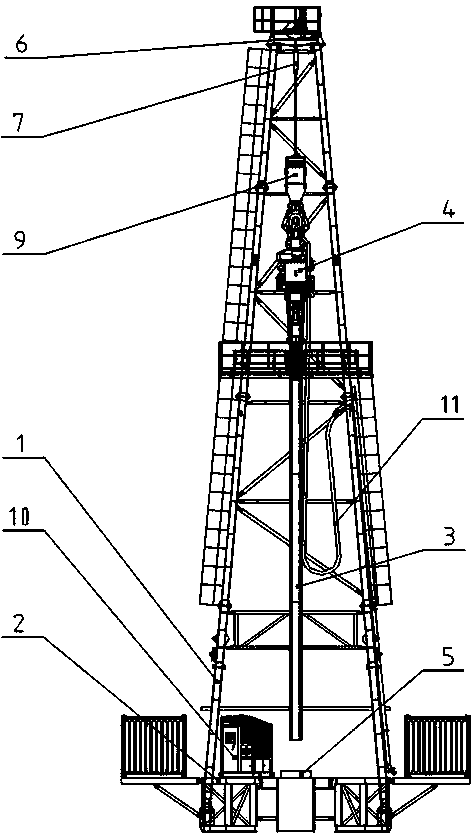

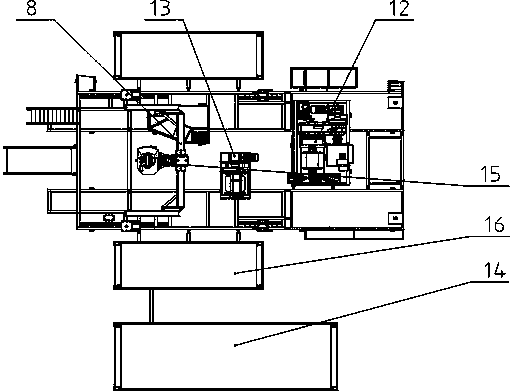

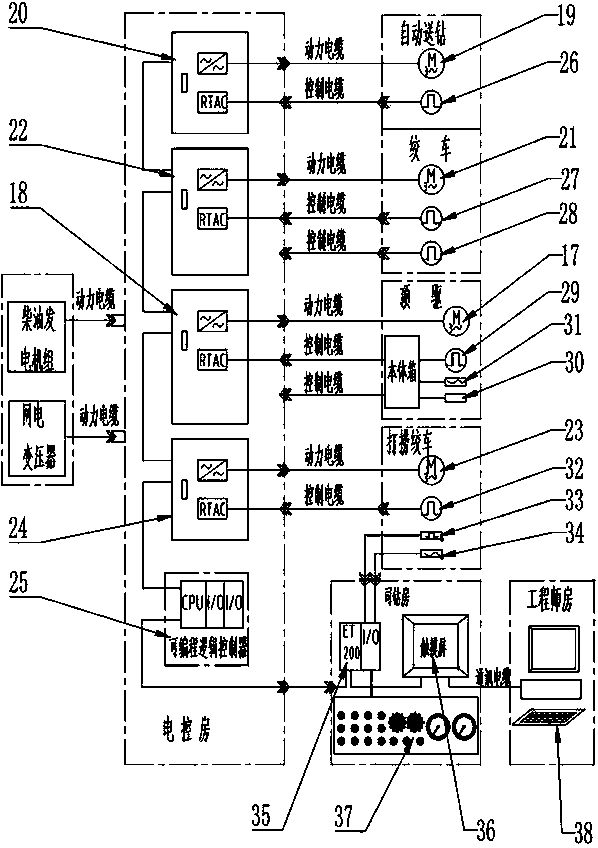

Variable-frequency electrically-driven top drive type core drill used for geological coring exploration

InactiveCN103711431ARealize stepless flexible controlTension real-time monitoringConstructionsRotary drillingFrequency changerTop drive

The invention discloses a variable-frequency electrically-driven top drive type core drill used for geological coring exploration. The drill comprises a platform and a vertical derrick arranged on the platform, wherein an electrically-driven winch and a salvage winch are arranged on the platform and are used for reeling and unreeling a rope, an electrically-driven turn plate is further arranged on the platform and located at the lower end of the derrick, a guide rail parallel to the derrick is arranged on the derrick and is connected with a top driver through a bracket pulley, the top driver is directly connected with a drill rod through a connecting shaft by means of a variable-frequency motor, a motor of the top driver, a motor of the electrically-driven winch, a motor of the salvage winch and a motor of the electrically-driven turn plate are driven by a frequency converter in an electric control room, the frequency converter controls the motors to work in the electric control room, the drill is further provided with an engineer room used for monitoring the work of the drill, and a rope tension and rope speed detection device is further arranged at the top end of the derrick. According to the variable-frequency electrically-driven top drive type core drill used for geological coring exploration, the drill is driven by an alternating-current variable-frequency motor to achieve rotating, rising, feeding, salvaging and the like, the long-stroke guide rail is provided, the rope speed and tension detection function is achieved, and high efficiency and low energy consumption drilling operation is achieved under the control of the frequency converter.

Owner:中核大地勘察设计有限公司 +2

Drill bit with removable inner core for drilling

The invention relates to a drill bit with a removable inner core for drilling. In the prior art, the drill bit has an integral type structure, and cannot directly convey articles to a drilling hole of a collapsed stratum through a through hole in a drilling rod; if the integral type drill bit is completely abandoned at the hole bottom, and the articles are conveyed to the drilling hole through the through hole in the drilling rod, the cost is too high, and subsequent construction can be affected; and after the drill bit and the drilling rod are taken out, the drilling hole is easy to collapse, the success ratio is low, and the operation is troublesome. The drill bit with the removable inner core for drilling consists of an outer drill bit, an inner core drill bit, a steel ball and a spring, and after being stressed by certain pushing force, the inner core drill bit can be separated from the outer drill bit. Therefore, the drill bit with the removable inner core for drilling has the characteristics of simple structure, less abandoned parts, low cost, high reliability, convenient operation, and the like.

Owner:煤炭科学研究总院有限公司西安研究院

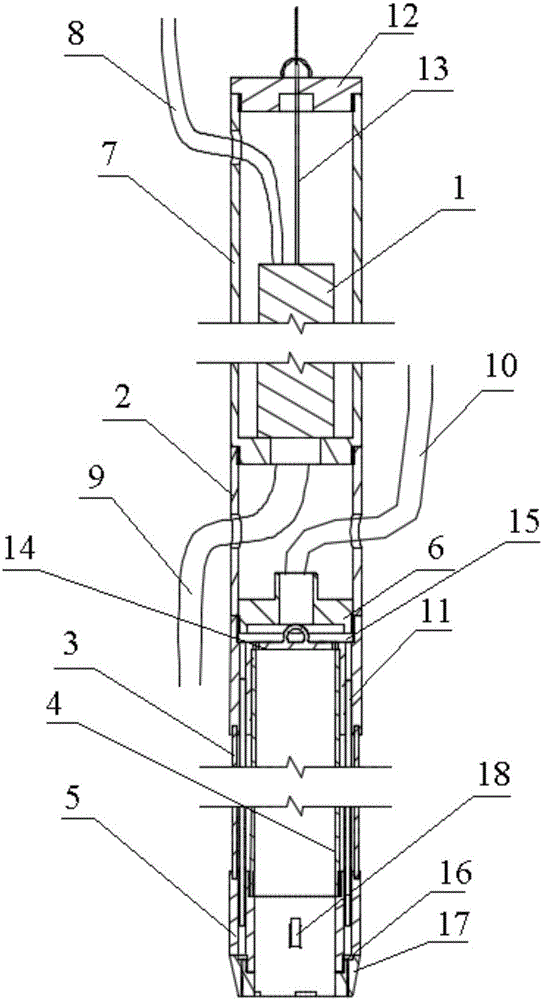

Core pressure-maintaining coring drill tool for submarine natural gas hydrate

The invention discloses a core pressure-maintaining coring drill tool for a submarine natural gas hydrate and belongs to the technical field of well drilling equipment. The core pressure-maintaining coring drill tool is matched with a rope fishing coring-drilling technique and comprises an inner pipe assembly and an outer pipe assembly. The outer pipe assembly is of the structure of a vertically-through cavity, the upper end of the outer pipe assembly is connected with a drill rod, and a drill bit is arranged at the lower end of the outer pipe assembly. The inner pipe assembly is placed in the cavity of the outer pipe assembly. A core pipe is arranged at the lower end of the inner pipe assembly, and a clamp spring and a clamp spring seat are arranged at the lower end of the core pipe. The core pressure-maintaining coring drill tool is characterized by further comprising a pressure compensation system; the pressure compensation system is provided with a pressure-maintaining cap assembly; the pressure-maintaining cap assembly is matched with the clamp spring seat in the inner pipe assembly; and when a core of the natural gas hydrate is transferred onto the submarine drilling machine from the bottom of a hole, the pressure-maintaining cap assembly is in inserted connection with the clamp spring seat so as to seal the lower end of the core pipe. The occurrence condition of submarine minerals can be restored to the largest extent through a core sample obtained by the core pressure-maintaining coring drill tool, and the basis is provided for improving the mining technology of the natural gas hydrate.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI

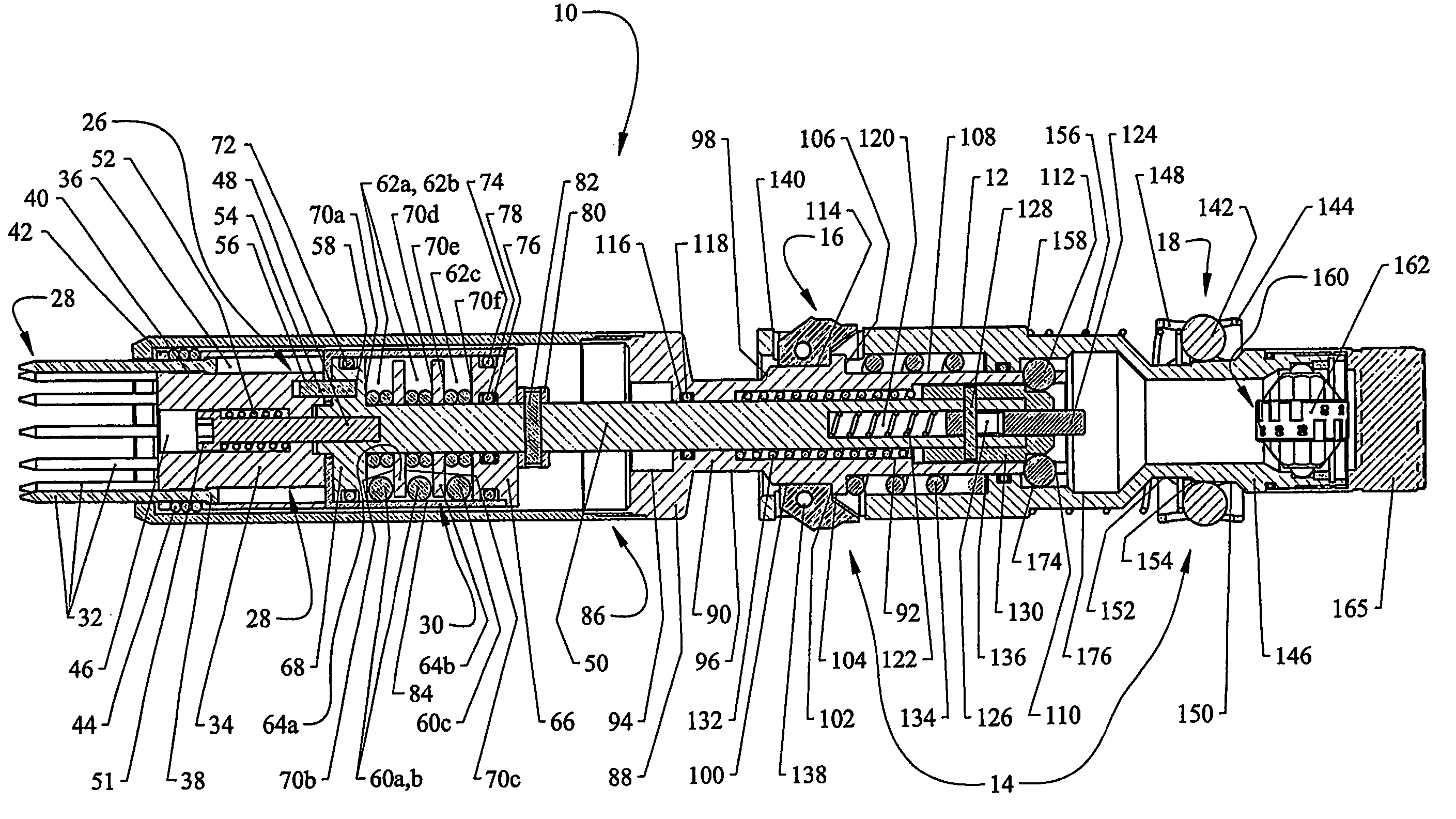

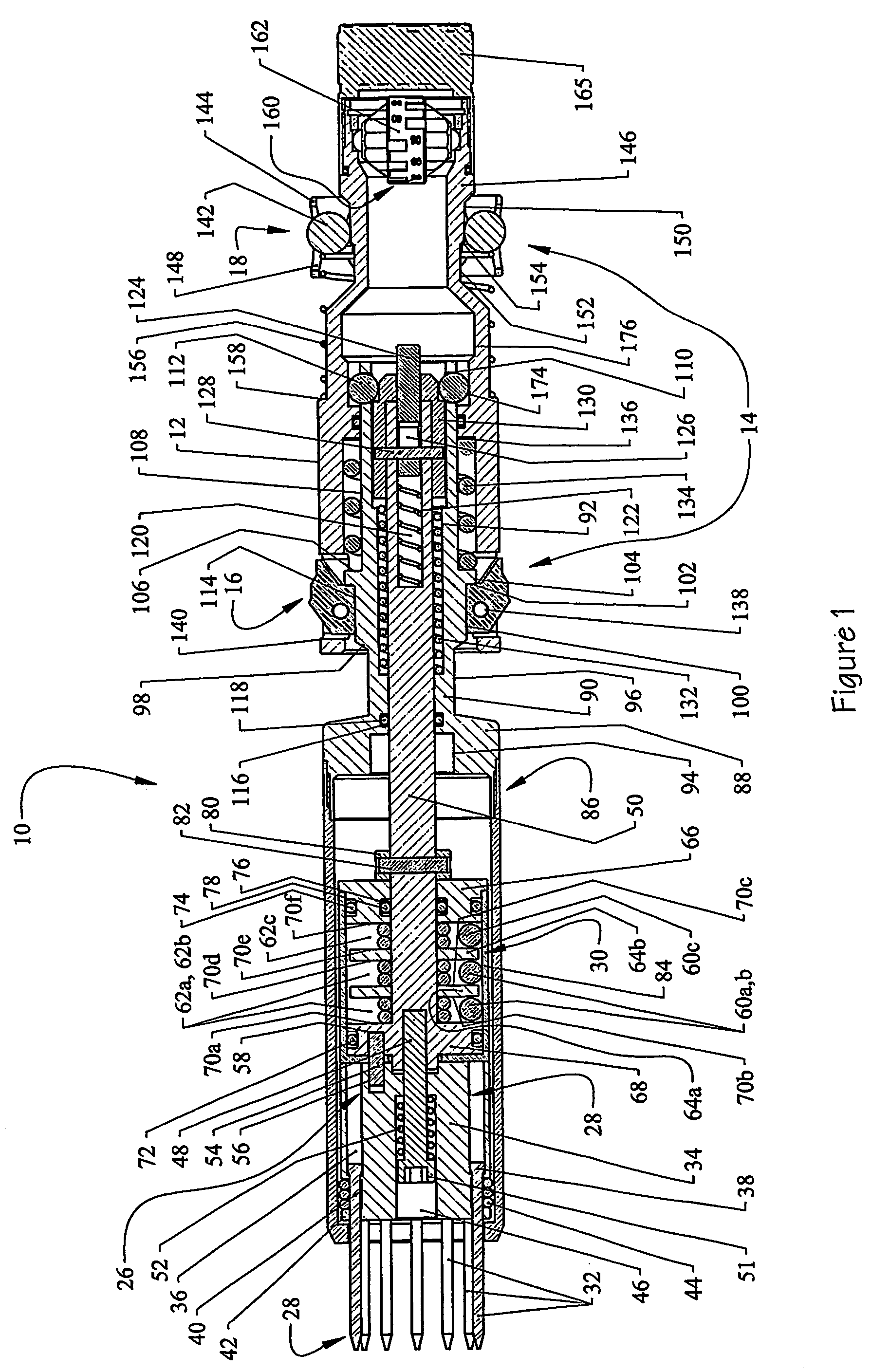

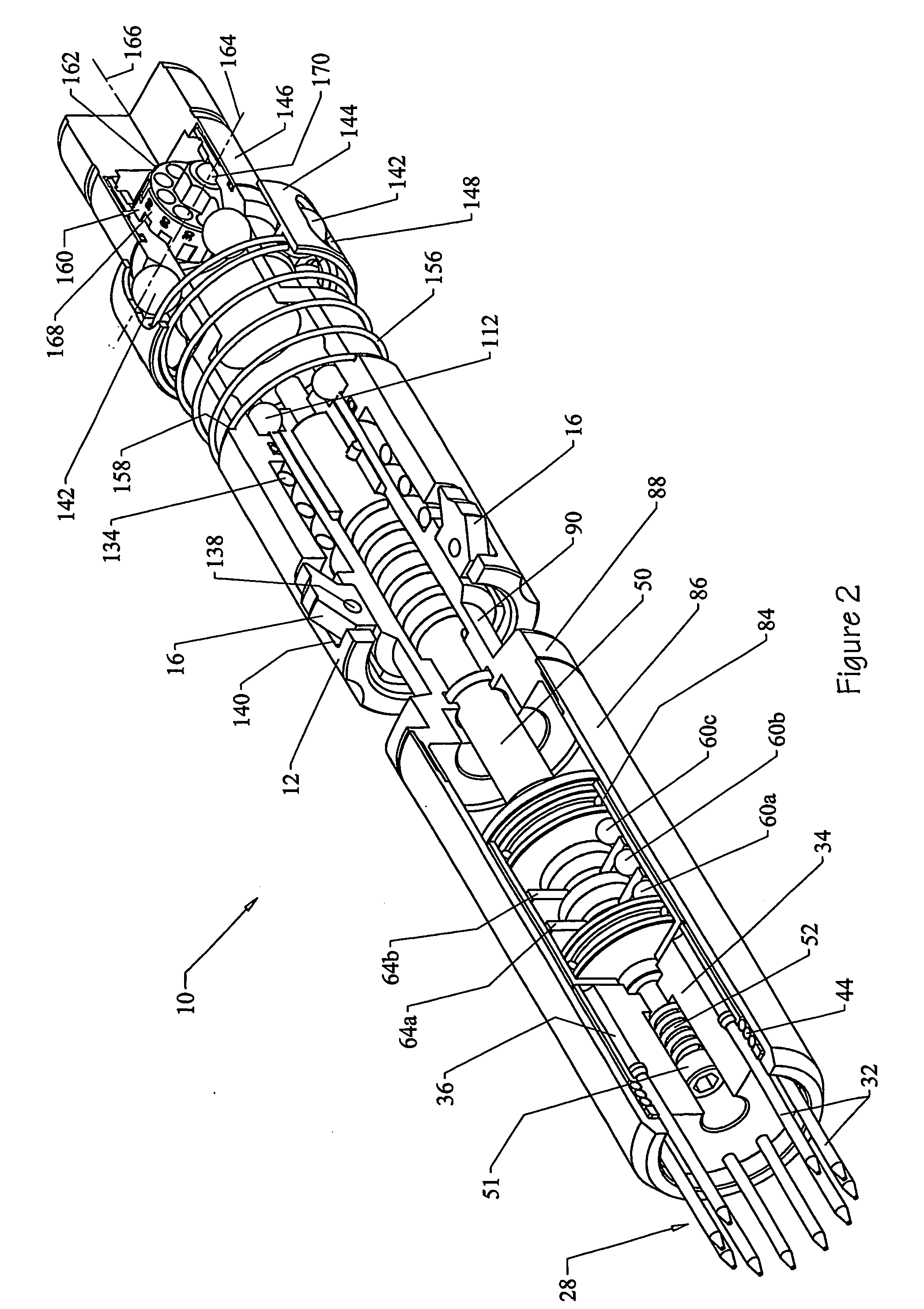

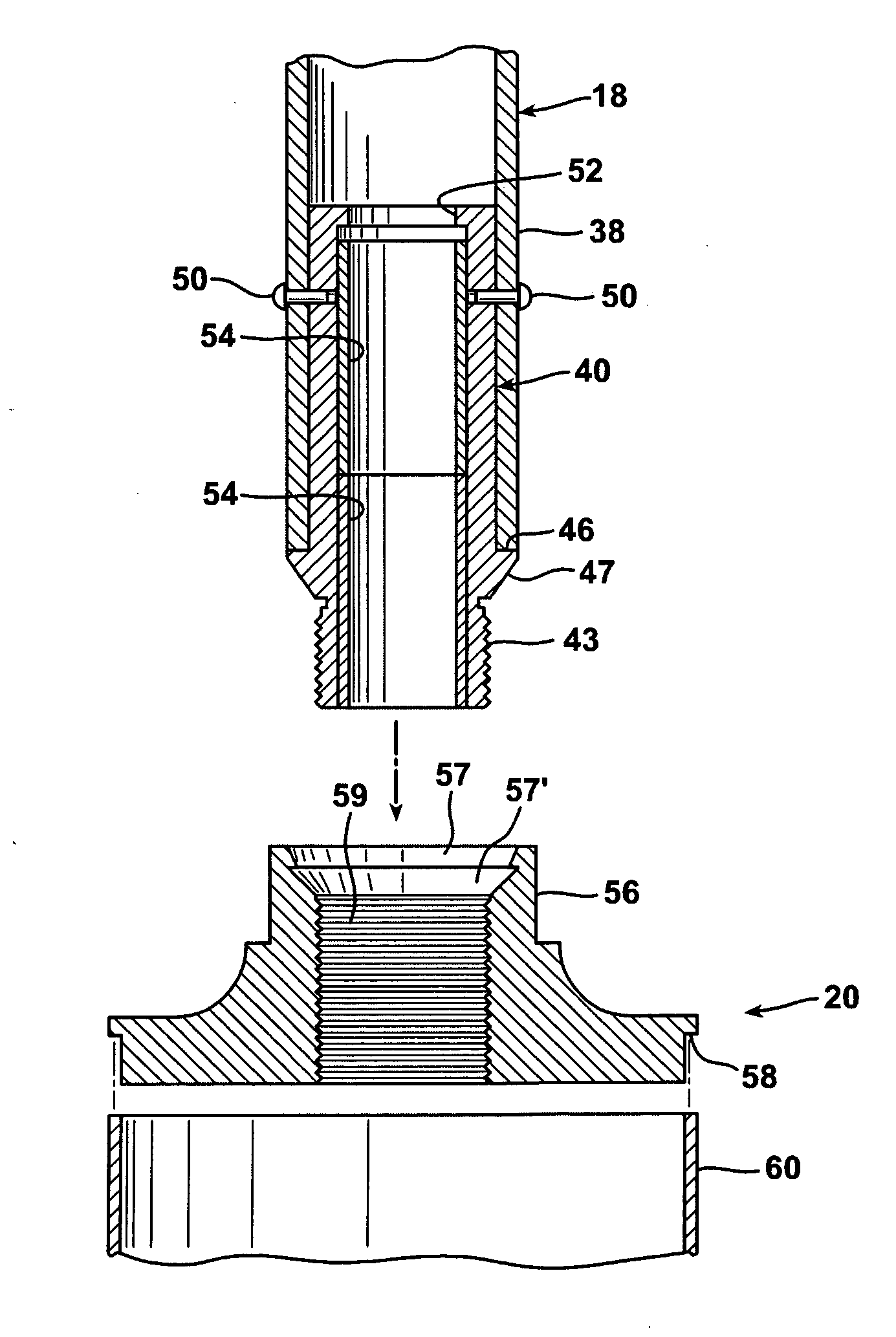

Hole coring system

A hole coring system is provided that greatly stabilizes a tubular core drill bit for drilling into concrete or other materials enabling large diameter holes to be drilled with a handheld tool. The hole coring assembly includes a hollow drive shaft assembly that fits over a stationary mandrel that is initially installed and anchored in a pilot hole in the concrete or other material. Once the mandrel has been firmly installed as a guidepost extending rigidly out from the concrete surface, the hollow drive shaft assembly is lowered onto the mandrel. The drive shaft assembly is stabilized relative to the mandrel by means of elongated, cylindrical bearing sleeves, which may be formed of self-lubricated or fluid lubricated bearing materials. The mandrel serves as a central guidepost that ensures that a relatively large diameter, tubular core drill bit remains precisely centered relative to the guide mandrel. This enables the operator to use a commonly available tool to rotate the drill and apply drill pressure only. Preferably a releaseable latch and catch mechanism is provided to releaseably couple the drive shaft assembly to said mandrel.

Owner:U S SAWS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com