Double-wall spindle power head for core drill

A technology of core drilling rig and power head, which is applied in the direction of rotary drilling rig, earthwork drilling, drilling equipment, etc. It can solve the problems of poor waterproof and sealing performance, low degree of automation, and long auxiliary working time, so as to improve reliability and maintainability, simple and compact structure, and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

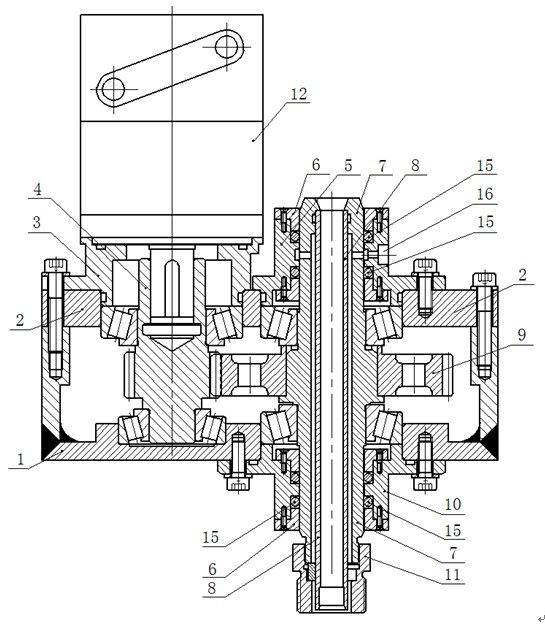

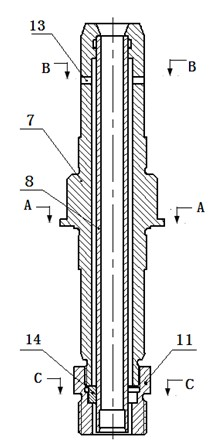

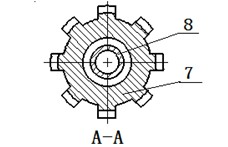

[0029] Embodiment 1: a kind of double-wall mandrel core drilling rig power head of the present invention is used for underwater core drilling rig drilling, and its structure is as follows figure 1 As shown, it includes an outer box body, a power mechanism, a transmission system, a spindle and a sealing unit, and the power mechanism uses a waterproof motor 12; the outer box body is composed of a box assembly 1 and an upper box cover 2, The box assembly is welded by plates, figure 1 The black part in the middle box assembly is a welding symbol. The box assembly and the upper box cover are positioned by positioning pins and connected with screws; the transmission system is composed of the driving gear shaft 4 and the driven gear 9; the mandrel is double-walled The mandrel is composed of the mandrel outer tube 7 and the mandrel inner tube 8. The faucet joint 16 is welded together with the mandrel outer tube 7. The flushing liquid passes through the annular space between the double...

Embodiment 2

[0033] Embodiment 2: A power head of a double-wall mandrel core drilling rig of the present invention is used for land core drilling. The power mechanism of the power head adopts a hydraulic motor 12, and other structures are the same as in Embodiment 1. The working state of the power head is as follows: Figure 6 and Figure 7 shown. see Figure 6 , the power head 17 feeds along the tower 21 during the drilling process, and its own mandrel has a rotary motion at the same time. During this process, the drill pipe 20 is connected to the power head 17 for rotary drilling, and the wireline coring sampler 18 is suspended by a steel cable and stored in the mandrel inner tube 8 of the power head 17 . exist Figure 7 In the process, the power head 17 stops rotating, and the rope coring sampler 18 is lowered into the orifice 19 for rope coring. In traditional wireline coring, it is necessary to remove the power head 17 in most cases so that the wireline coring sampler 18 can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com